Strength Enhancement of Interlocking Hollow Brick Masonry Walls with Low-Cost Mortar and Wire Mesh

Abstract

:1. Introduction

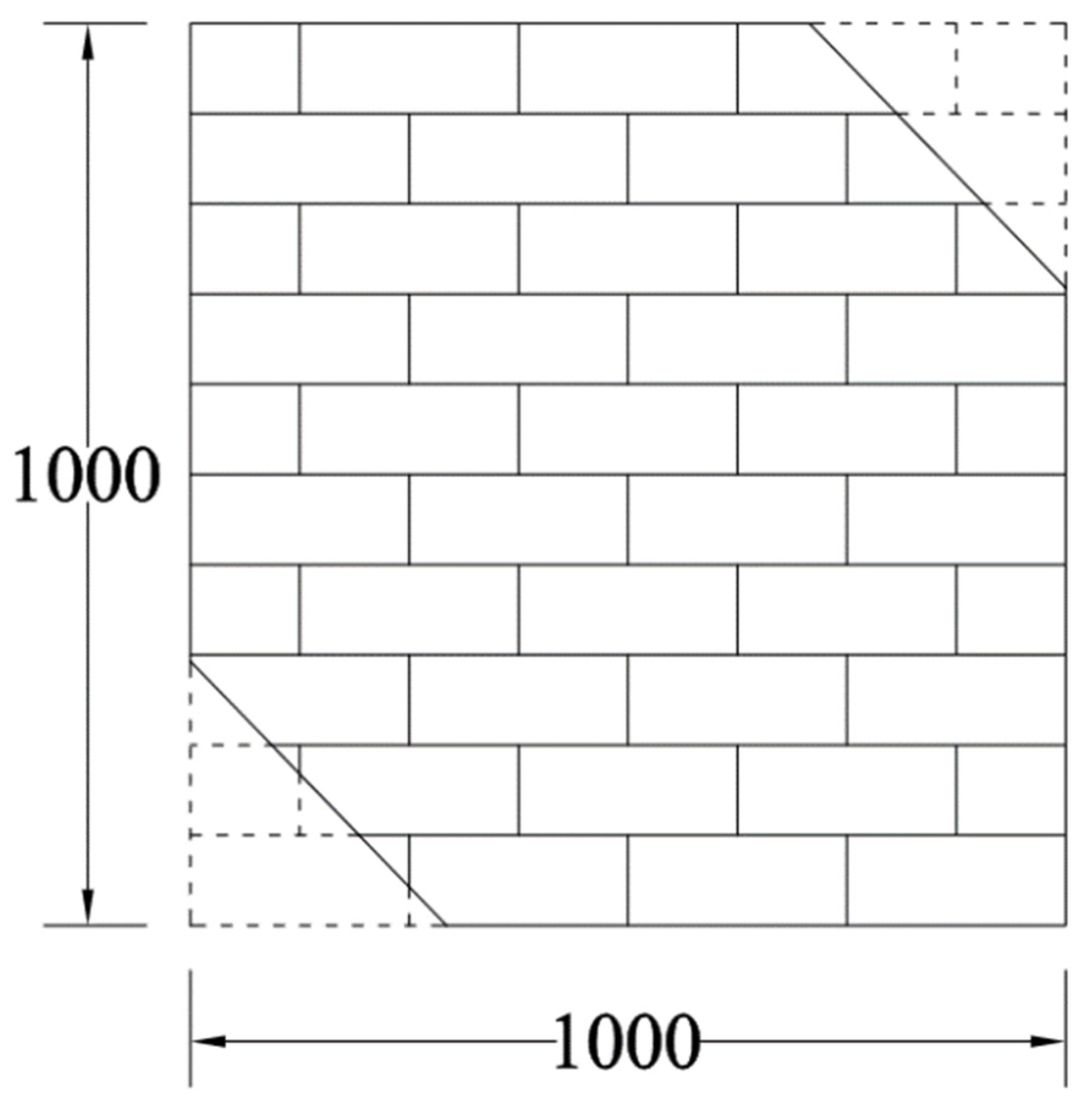

2. Details of Experimental Program

3. Dimensional Details of Masonry Walls

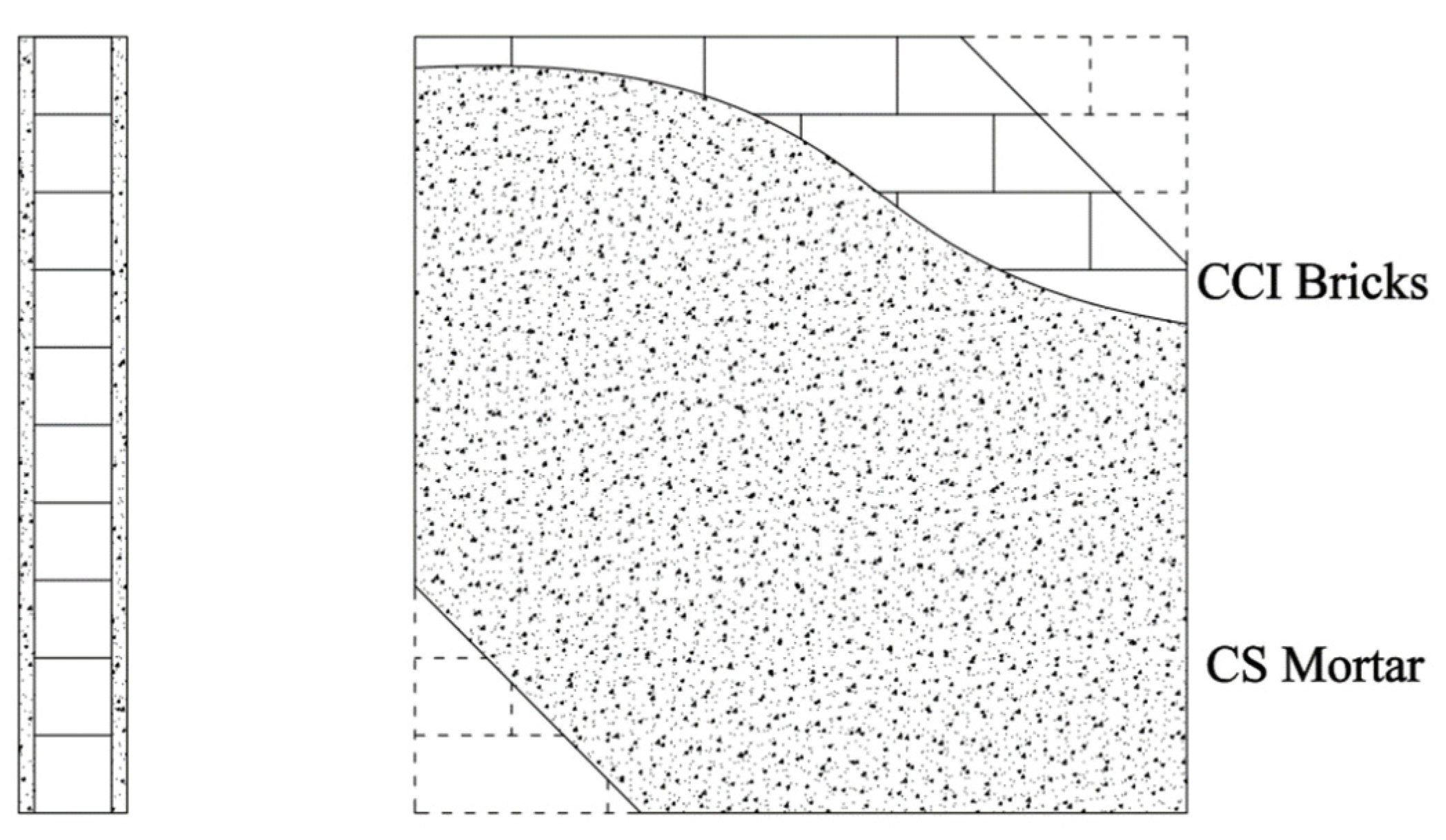

4. Materials

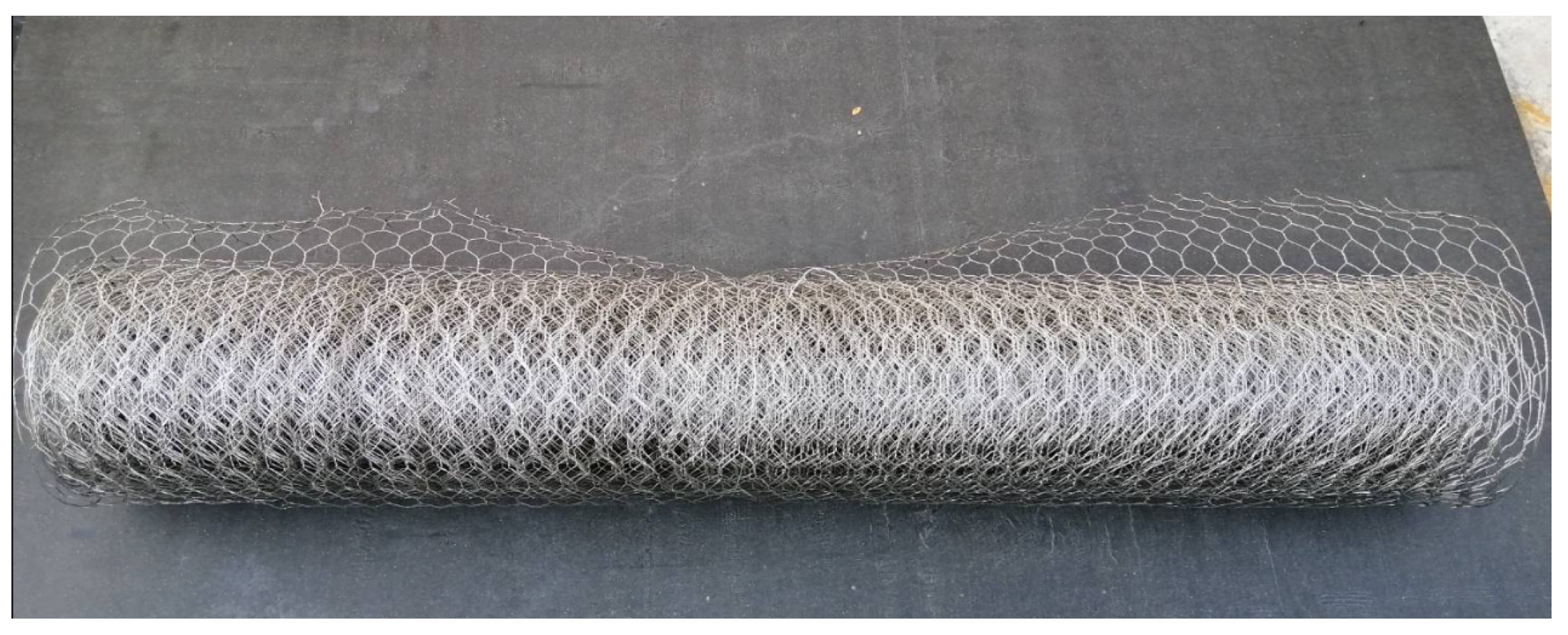

5. Strengthening of CCIHBM Walls

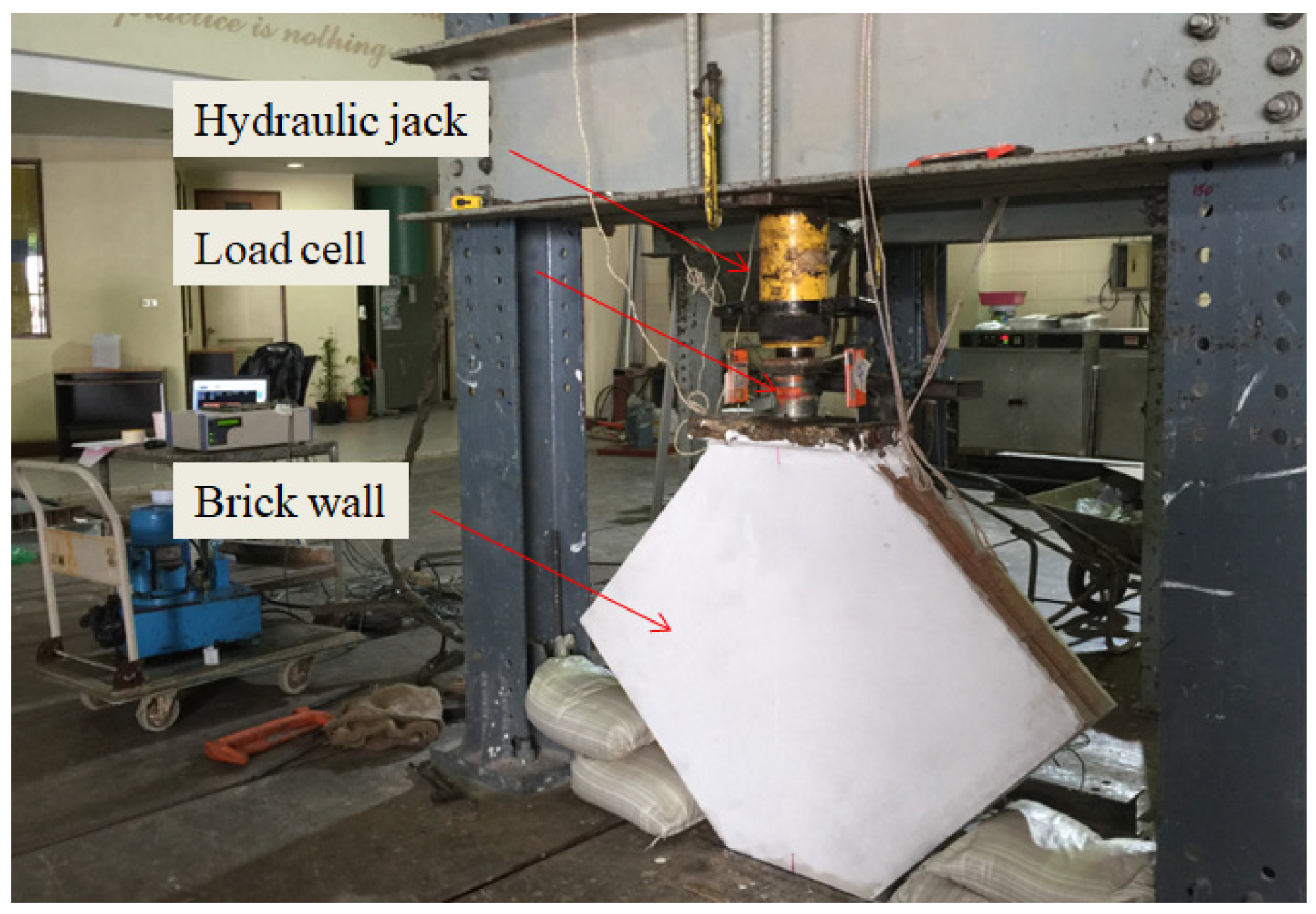

6. Load and Instrumentation

7. Results and Discussion

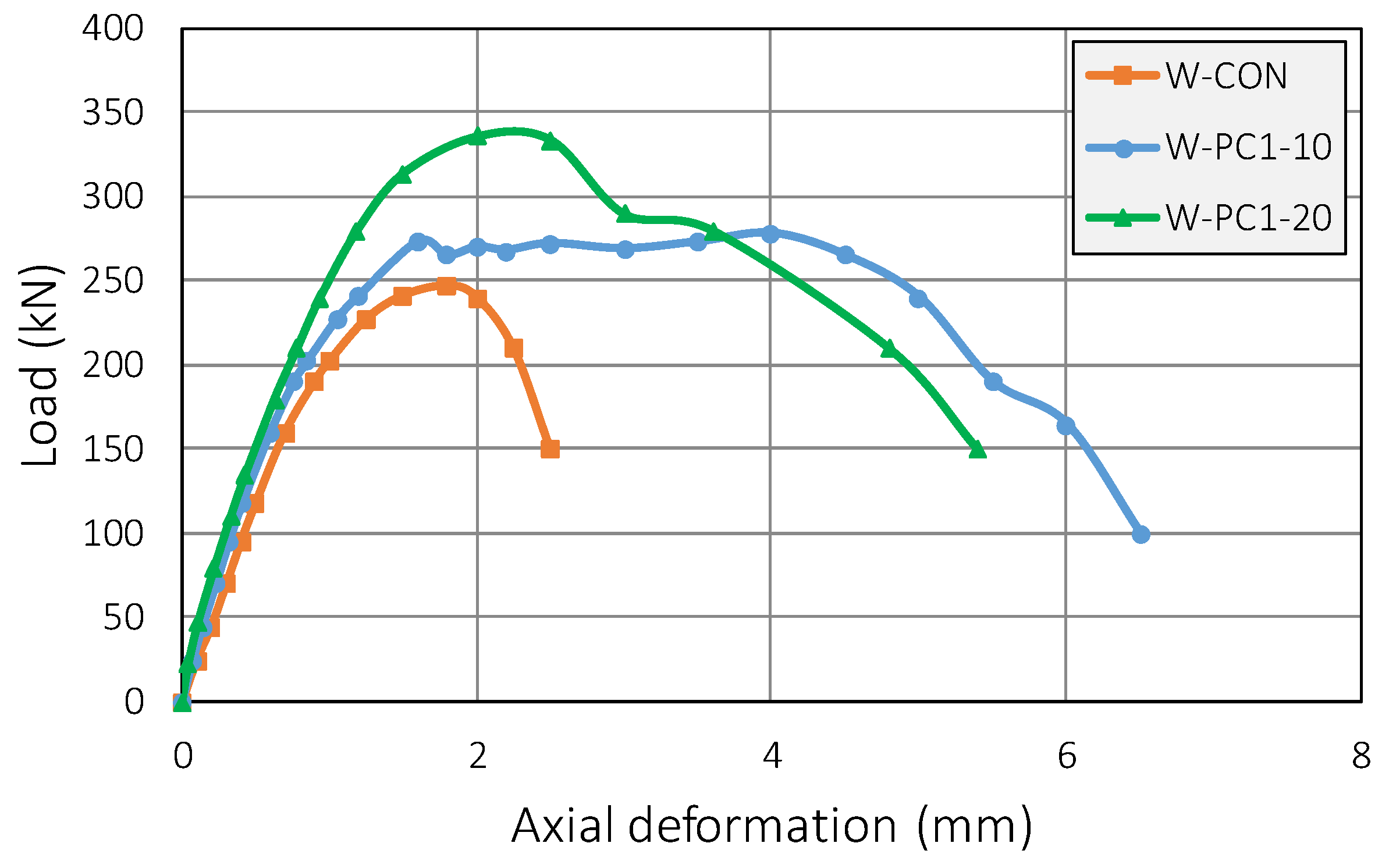

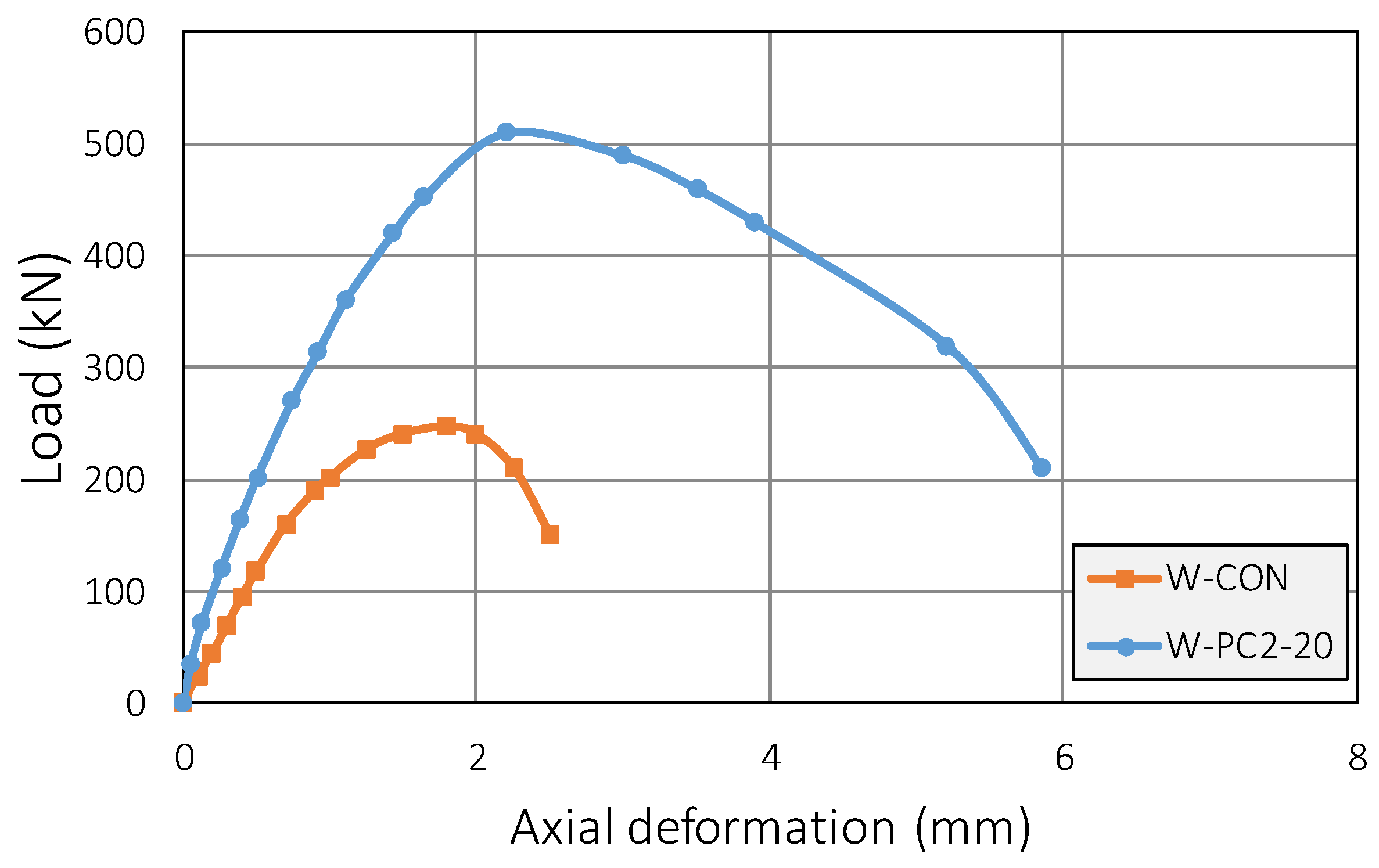

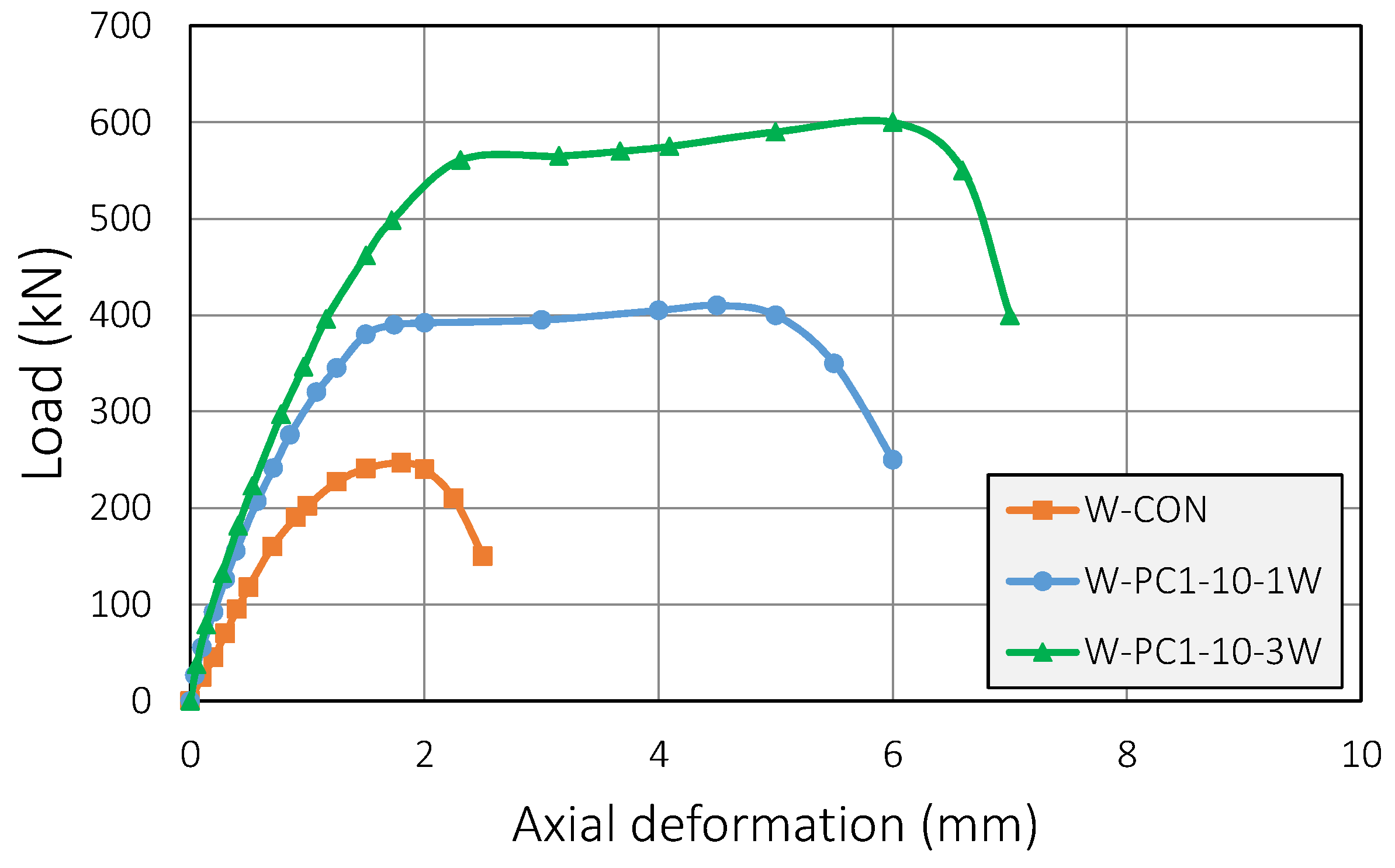

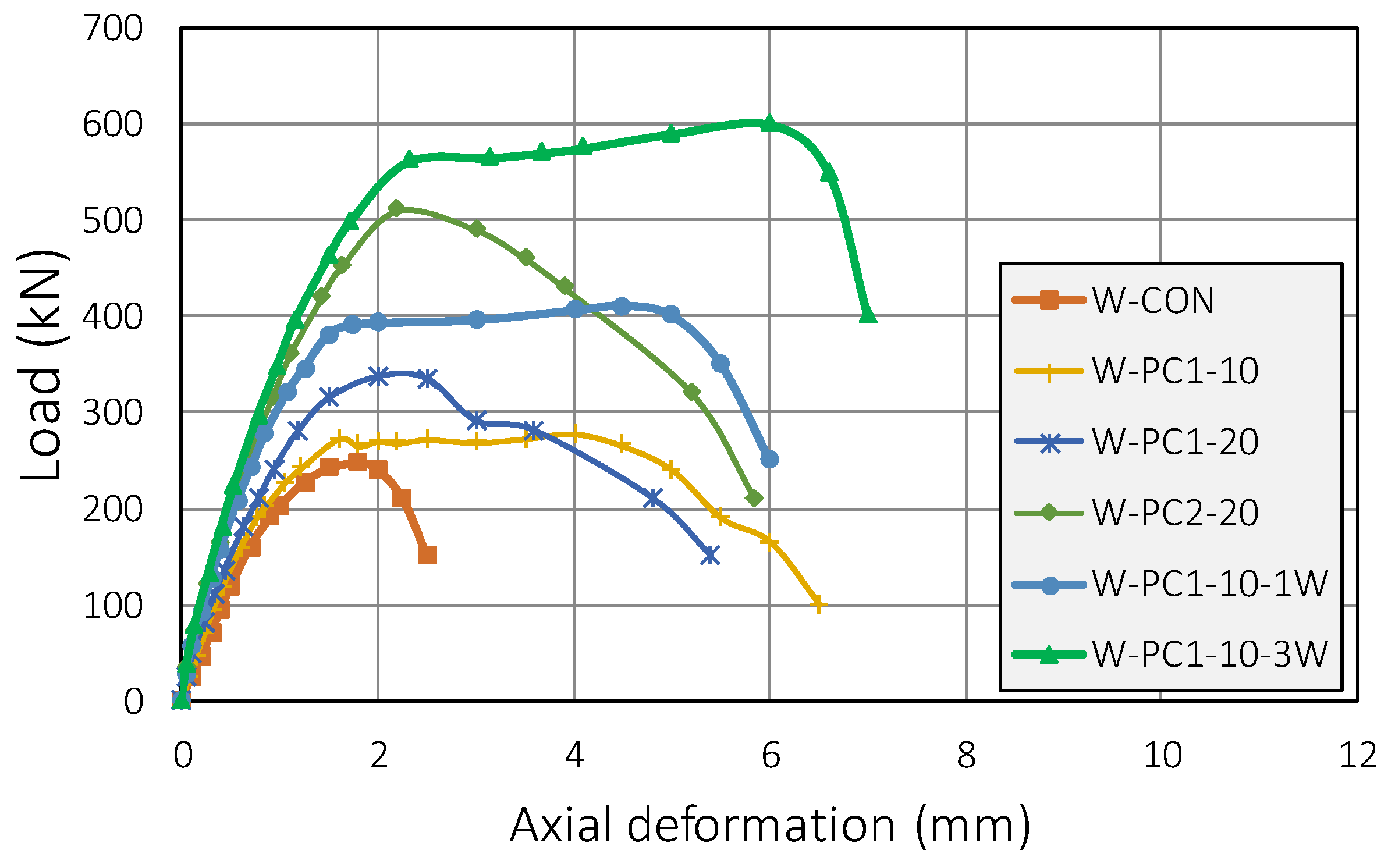

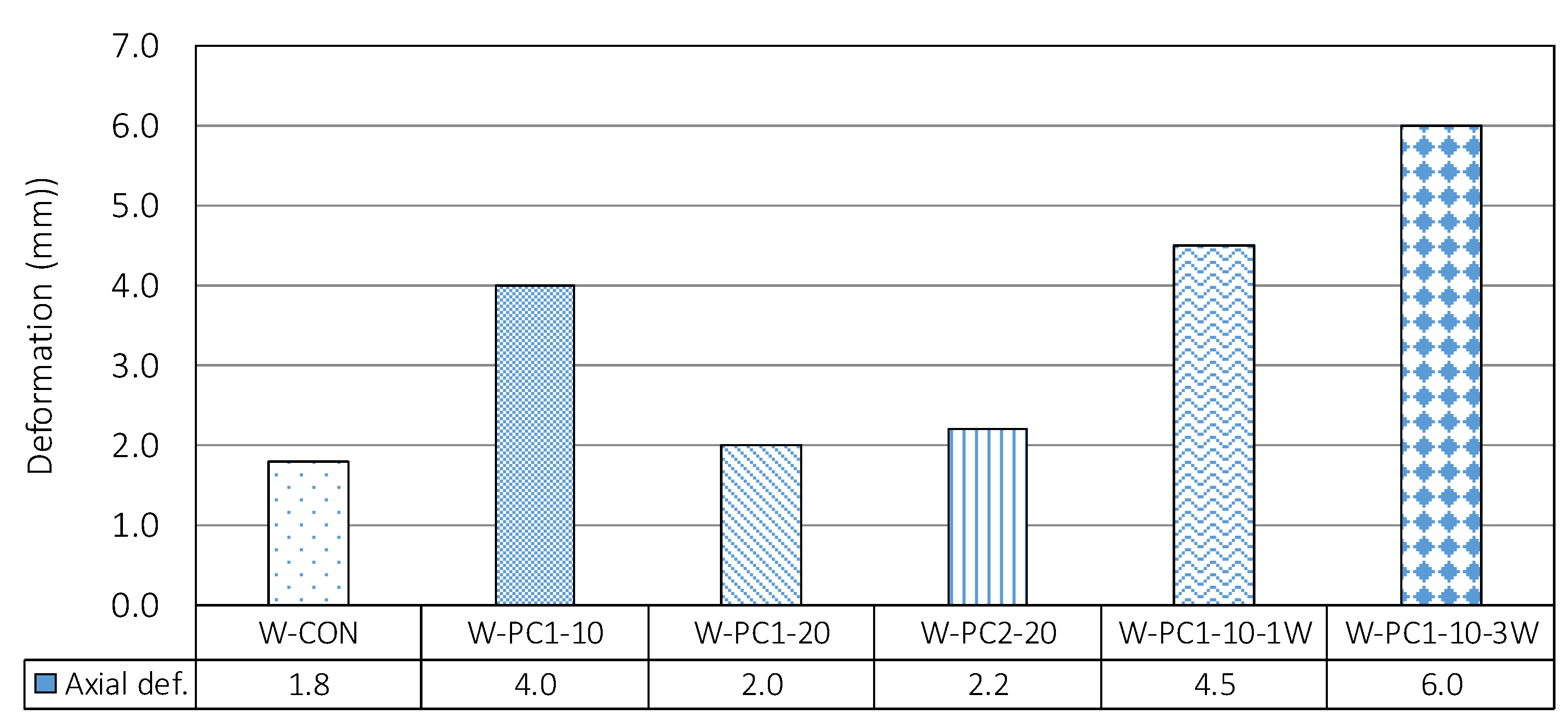

7.1. Axial Load versus Deformation Responses

7.2. Load Behavior of CCIHBM Walls

7.3. Ductility of the CCIHBM Walls

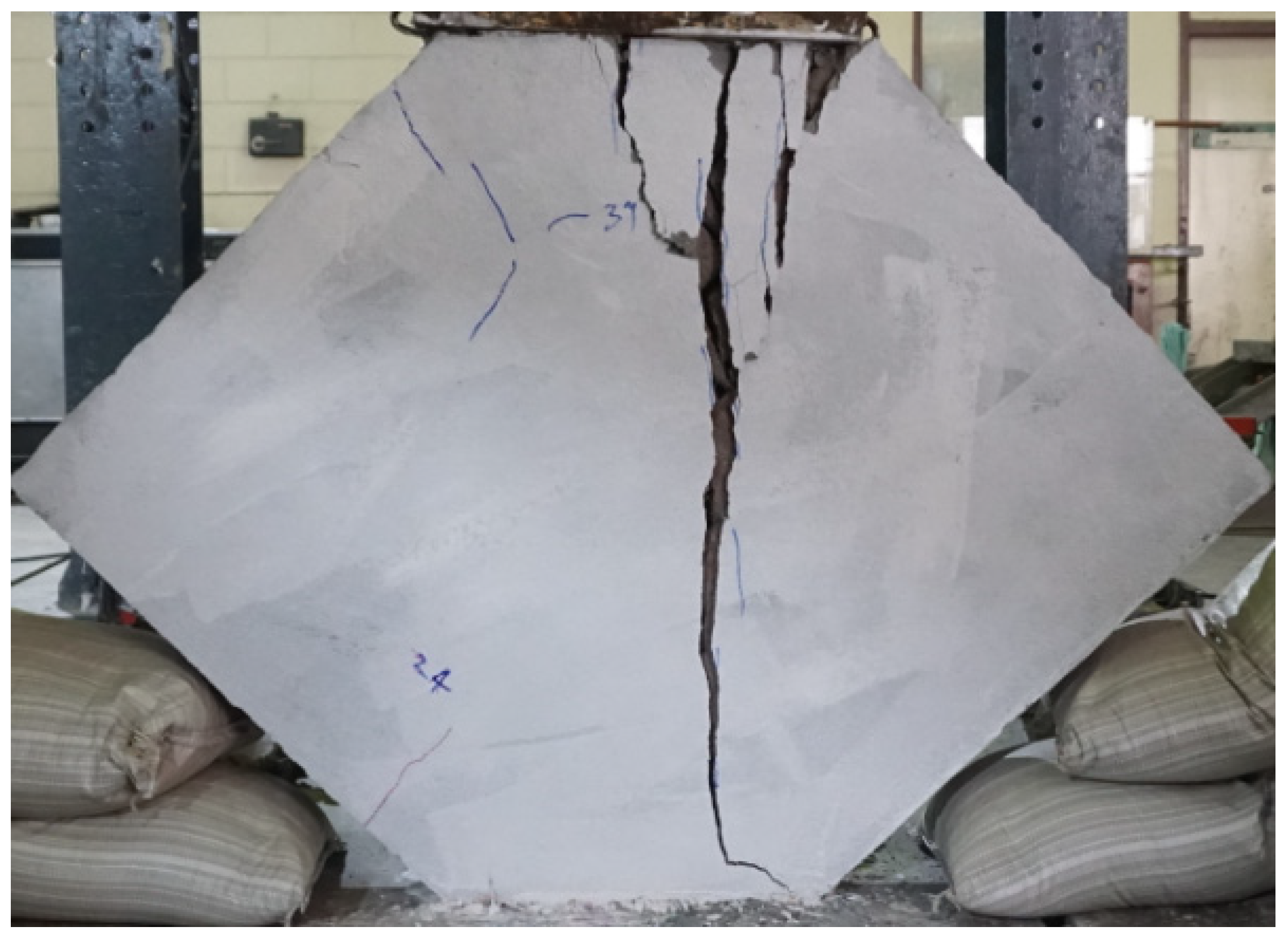

7.4. Failures of CCIHBM Walls

8. Conclusions

- The ultimate failure of control masonry wall was very brittle and sudden. The control CCIHBM wall, i.e., W-CON, failed at an ultimate load of 247 kN, and the corresponding deflection was 1.8 mm.

- The ultimate failure modes of the CEMENT mortar with wire mesh strengthened CCIHBM walls were found to be ductile.

- For the cement mortar and wire-mesh-strengthened walls, i.e., W-PC1-10-1W and W-PC1-10-3W, the ultimate axial deformation was increased by 150% and 233%, respectively, as compared to the control wall, i.e., W-CON.

- The ultimate load carrying capacity of CCIHBM walls W-PC1-10-1W and W-PC1-10-3W was increased by 66% and 143%, respectively, as compared to the control wall, i.e., W-CON.

- Based on experimental results, it can be concluded that the use of CEMENT mortar and wire-mesh is practical. However, there is need to evaluate and compare the performance of this method with other techniques.

- Future studies also required to develop constitutive material models for CCIHBM walls strengthened with cement mortar and wire mesh using finite element analysis and analytical studies.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| CCIHBM | Clay Interlocking Hollow Brick Masonry |

| CCIHB | Clay Interlocking Hollow Brick |

| OPC | Ordinary Portland Cement |

| FRP | Fibre Reinforced Polymers |

References

- Senaldi, I.; Magenes, G.; Ingham, J.M. Damage assessment of unreinforced stone masonry buildings after the 2010–2011 Canterbury earthquakes. Int. J. Archit. Herit. 2015, 9, 605–627. [Google Scholar] [CrossRef]

- Sorrentino, L.; Cattari, S.; Da Porto, F.; Magenes, G.; Penna, A. Seismic behaviour of ordinary masonry buildings during the 2016 central Italy earthquakes. Bull. Earthq. Eng. 2019, 17, 5583–5607. [Google Scholar] [CrossRef] [Green Version]

- Ravindra, R.; Anand, K.B.G.; Santhosh, N. Behavior of Concrete Masonry Blocks with Ceramic Waste. Recent Trends Civ. Eng. Technol. 2015, 5, 35–40. [Google Scholar]

- Riaz, M.H.; Khitab, A.; Ahmad, S.; Anwar, W.; Arshad, M.T. Use of ceramic waste powder for manufacturing durable and eco-friendly bricks. Asian J. Civ. Eng. 2020, 21, 243–252. [Google Scholar] [CrossRef]

- Khitab, A.; Riaz, M.S.; Jalil, A.; Khan, R.B.N.; Anwar, W.; Khan, R.A.; Tayyab, S. Manufacturing of Clayey Bricks by Synergistic Use of Waste Brick and Ceramic Powders as Partial Replacement of Clay. Sustainability 2021, 13, 10214. [Google Scholar] [CrossRef]

- Moon, L.M.; Griffith, M.C.; Dizhur, D.; Ingham, J.M. Performance of unreinforced masonry structures in the 2010/2011 Canterbury earthquake sequence. In Proceedings of the 15th World Conference on Earthquake Engineering (15WCEE), Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Ruangrassamee, A.; Ornthammarath, T.; Lukkunaprasit, P. Damage due to 24 March 2011 M6. 8 Tarlay earthquake in Northern Thailand. In Proceedings of the 15th World Conference on Earthquake Engineering (15WCEE), Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Ruangrassamee, A.; Yanagisawa, H.; Foytong, P.; Lukkunaprasit, P.; Koshimura, S.; Imamura, F. Investigation of tsunami-induced damage and fragility of buildings in Thailand after the December 2004 Indian Ocean tsunami. Earthq. Spectra 2019, 22, 377–401. [Google Scholar] [CrossRef]

- Farzampour, A. Compressive behavior of concrete under environmental effects. In Compressive Strength of Concrete; IntechOpen: Rijeka, Croatia, 2019. [Google Scholar]

- Farzampour, A. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659. [Google Scholar]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano silica and metakaolin effects on the behavior of concrete containing rubber crumbs. CivilEng 2020, 1, 264–274. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental Investigation of Sound Transmission Loss in Concrete Containing Recycled Rubber Crumbs. 2021. Available online: http://hdl.handle.net/10919/103191 (accessed on 22 November 2021).

- Mansouri, I.; Shahheidari, F.S.; Hashemi, S.M.A.; Farzampour, A. Investigation of steel fiber effects on concrete abrasion resistance. Adv. Concr. Constr. 2020, 9, 367–374. [Google Scholar]

- Hendry, E.A. Masonry walls: Materials and construction. Constr. Build. Mater. 2001, 15, 323–330. [Google Scholar] [CrossRef]

- Hendry, A.W.; Khalaf, F.M. Masonry Wall Construction; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Shakir, A.A.; Mohammed, A.A. Durability property of clay ash, quarry dust and billet scale bricks. J. Eng. Sci. Technol. 2015, 10, 591–605. [Google Scholar]

- Deboucha, W.; Alachek, I.; Plassiard, J.P.; Plé, O. New Composite Material for Masonry Repair: Mortar Formulations and Experimental Studies. Materials 2021, 14, 912. [Google Scholar] [CrossRef] [PubMed]

- Valluzzi, M.R.; Tinazzi, D.; Modena, C. Shear behavior of masonry panels strengthened by FRP laminates. Constr. Build. Mater. 2002, 16, 409–416. [Google Scholar] [CrossRef]

- Turco, V.; Secondin, S.; Morbin, A.; Valluzzi, M.R.; Modena, C. Flexural and shear strengthening of un-reinforced masonry with FRP bars. Compos. Sci. Technol. 2006, 66, 289–296. [Google Scholar] [CrossRef]

- Wahab, N.; Srinophakun, P.; Hussain, Q.; Chaimahawan, P. Performance of concrete confined with a jute–polyester hybrid Fiber reinforced polymer composite: A novel strengthening technique. Fibers 2019, 7, 72. [Google Scholar] [CrossRef] [Green Version]

- Joyklad, P.; Suparp, S.; Hussain, Q. Flexural response of JFRP and BFRP strengthened RC beams. Int. J. Eng. Technol. 2019, 11, 3. [Google Scholar] [CrossRef] [Green Version]

- Chaiyasarn, K.; Hussain, Q.; Joyklad, P.; Rodsin, K. New hybrid basalt/E-glass FRP jacketing for enhanced confinement of recycled aggregate concrete with clay brick aggregate. Case Stud. Constr. Mater. 2021, 14, e00507. [Google Scholar] [CrossRef]

- Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P.; Wijeyewickrema, A.C. Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii. Buildings 2021, 11, 355. [Google Scholar] [CrossRef]

- Tumialan, J.G.; Morbin, A.; Nanni, A.; Modena, C. Shear Strengthening of Masonry Walls with FRP Composites. In Proceedings of the COMPOSITES 2001 Convention and Trade Show, Composites Fabricators Association, Tampa, FL, USA, 3–6 October 2001; p. 6. [Google Scholar]

- Iii, H.R.H.; Dolan, C.W. Flexural capacity of glass FRP strengthened concrete masonry walls. J. Compos. Constr. 2001, 5, 170–178. [Google Scholar]

- Bui, T.L.; Larbi, A.S.; Reboul, N.; Ferrier, E. Shear behaviour of masonry walls strengthened by external bonded FRP and TRC. Compos. Struct. 2015, 132, 923–932. [Google Scholar] [CrossRef]

- Corradi, M.; Castori, G.; Sisti, R.; Borri, A.; Pesce, G.L. Repair of block masonry panels with cfrp sheets. Materials 2019, 12, 2363. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hernoune, H.; Benabed, B.; Kanellopoulos, A.; Al-Zuhairi, A.H.; Guettala, A. Experimental and numerical study of behaviour of reinforced masonry walls with NSM CFRP strips subjected to combined loads. Buildings 2020, 10, 103. [Google Scholar] [CrossRef]

- Hamoush, S.A.; McGinley, M.W.; Mlakar, P.; Scott, D.; Murray, K. Out-of-plane strengthening of masonry walls with reinforced compo-sites. J. Compos. Constr. 2001, 5, 139–145. [Google Scholar] [CrossRef]

- Bousias, S.; Spathis, A.L.; Fardis, M.N. Seismic retrofitting of columns with lap spliced smooth bars through FRP or concrete jackets. J. Earthq. Eng. 2007, 11, 653–674. [Google Scholar] [CrossRef]

- Joyklad, P.; Nawaz, A.; Hussain, Q. Effect of fired clay brick aggregates on mechanical properties of concrete. Suranaree J. Sci. Technol. 2018, 25, 349–362. [Google Scholar]

- Joyklad, P.; Hussain, Q.; Ali, N. Mechanical properties of cement-clay interlocking (CCI) hollow bricks. Eng. J. 2020, 24, 89–106. [Google Scholar] [CrossRef]

- Joyklad, P.; Hussain, Q. Experimental study on axial and diagonal compressive behavior of brick masonry walls. Kasem Bundit Eng. J. 2018, 8, 2561. [Google Scholar]

- Joyklad, P.; Hussain, Q. Axial compressive response of grouted cement–clay interlocking hollow brick walls. Asian J. Civ. Eng. 2019, 20, 733–744. [Google Scholar] [CrossRef]

- Joyklad, P.; Hussain, Q. Performance of cement clay interlocking hollow brick masonry walls subjected to diagonal compres-sion. J. Eng. Sci. Technol. 2019, 14, 2152–2170. [Google Scholar]

- Joyklad, P.; Hussain, Q. Lateral response of cement clay interlocking brick masonry walls subjected to earthquake loads. J. Eng. Sci. Technol. 2020, 15, 4320–4338. [Google Scholar]

- Yardim, Y.; Lalaj, O. Shear strengthening of unreinforced masonry wall with different fiber reinforced mortar jacketing. Constr. Build. Mater. 2016, 102, 149–154. [Google Scholar] [CrossRef]

| Wall Specimen | Strengthening Material | Thickness (mm) | Type of Cement |

|---|---|---|---|

| W-CON | - | - | - |

| W-PC1-10 | Cement mortar | 10 | OPC Type 1 |

| W-PC1-20 | Cement mortar | 20 | OPC Type 1 |

| W-PC2-20 | Cement mortar | 20 | OPC Type 2 |

| W-PC1-10-1W | Cement mortar + Wire Mesh | 10 | OPC Type 1 |

| W-PC1-10-3W | Cement mortar + Wire Mesh | 20 | OPC Type 1 |

| Test Walls | Load (kN) | Deflection (mm) | Initial Stiffness (kN/mm) |

|---|---|---|---|

| W-CON | 247 | 1.8 | 235 |

| W-PC1-10 | 278 | 4.0 | 295 |

| W-PC1-20 | 336 | 2.0 | 414 |

| W-PC2-20 | 510 | 2.2 | 500 |

| W-PC1-10-1W | 410 | 4.5 | 498 |

| W-PC1-10-3W | 600 | 6.0 | 524 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joyklad, P.; Ali, N.; Rashid, M.U.; Hussain, Q.; Magbool, H.M.; Elnemr, A.; Chaiyasarn, K. Strength Enhancement of Interlocking Hollow Brick Masonry Walls with Low-Cost Mortar and Wire Mesh. Infrastructures 2021, 6, 166. https://doi.org/10.3390/infrastructures6120166

Joyklad P, Ali N, Rashid MU, Hussain Q, Magbool HM, Elnemr A, Chaiyasarn K. Strength Enhancement of Interlocking Hollow Brick Masonry Walls with Low-Cost Mortar and Wire Mesh. Infrastructures. 2021; 6(12):166. https://doi.org/10.3390/infrastructures6120166

Chicago/Turabian StyleJoyklad, Panuwat, Nazam Ali, Muhammad Usman Rashid, Qudeer Hussain, Hassan M. Magbool, Amr Elnemr, and Krisada Chaiyasarn. 2021. "Strength Enhancement of Interlocking Hollow Brick Masonry Walls with Low-Cost Mortar and Wire Mesh" Infrastructures 6, no. 12: 166. https://doi.org/10.3390/infrastructures6120166

APA StyleJoyklad, P., Ali, N., Rashid, M. U., Hussain, Q., Magbool, H. M., Elnemr, A., & Chaiyasarn, K. (2021). Strength Enhancement of Interlocking Hollow Brick Masonry Walls with Low-Cost Mortar and Wire Mesh. Infrastructures, 6(12), 166. https://doi.org/10.3390/infrastructures6120166