Infrared Thermography for Weld Inspection: Feasibility and Application

Abstract

1. Introduction and Background

- Applicable to all common geometries

- Suitable for all material thicknesses

- Capable of rapid inspection without need for cool down

- Objective results independent of inspector interpretation

2. Materials and Methods

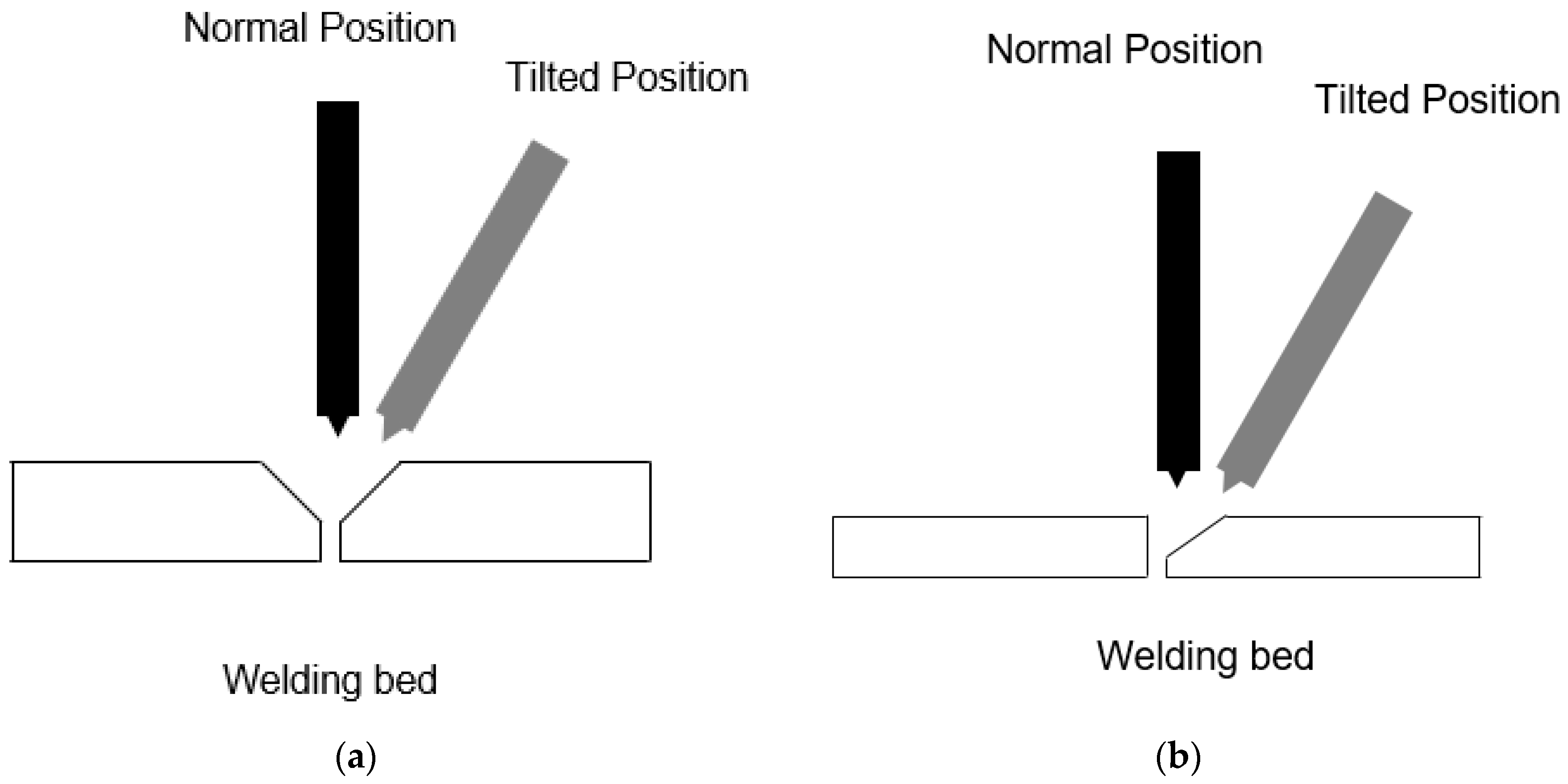

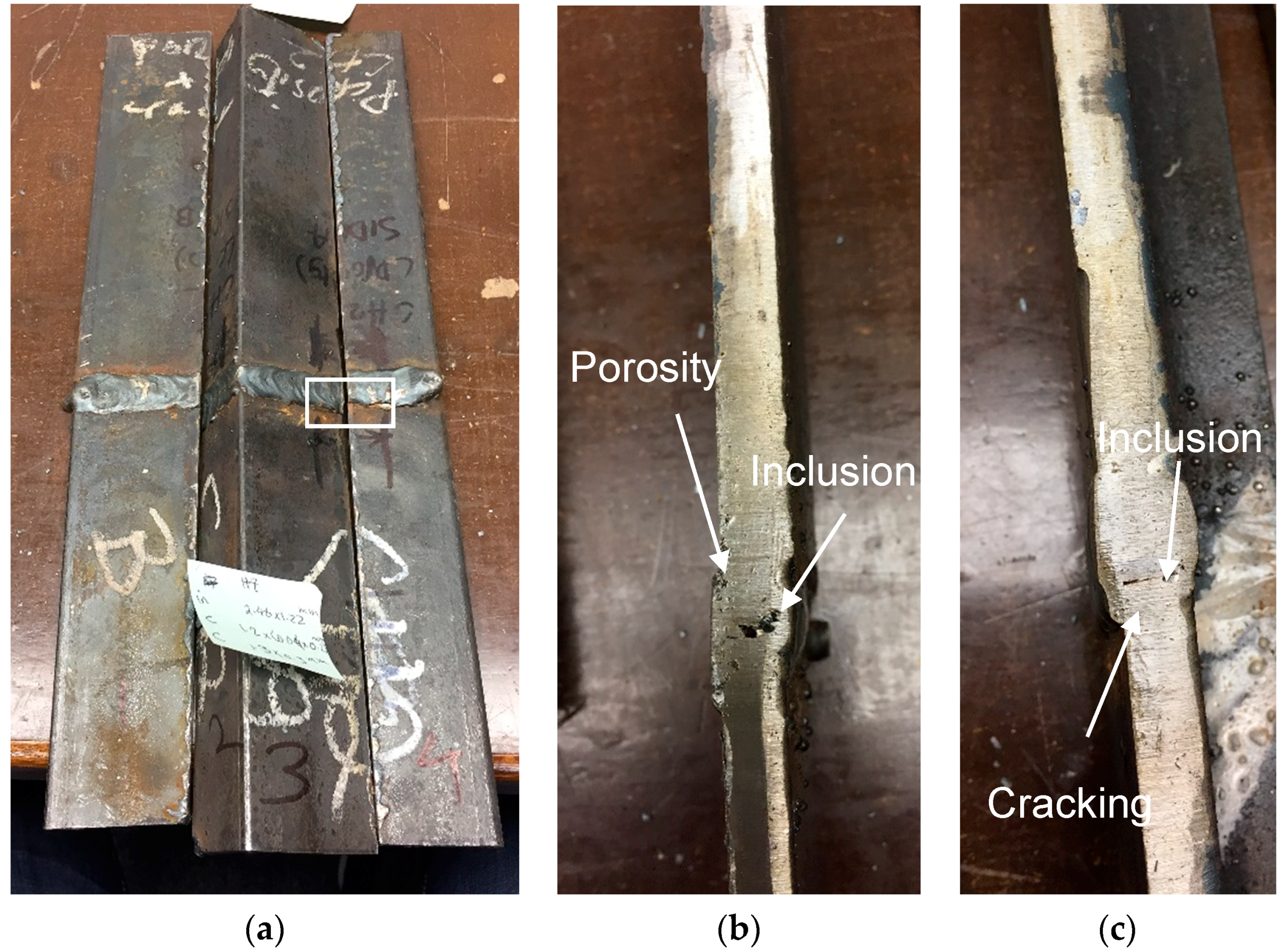

2.1. Defect Manufacturing

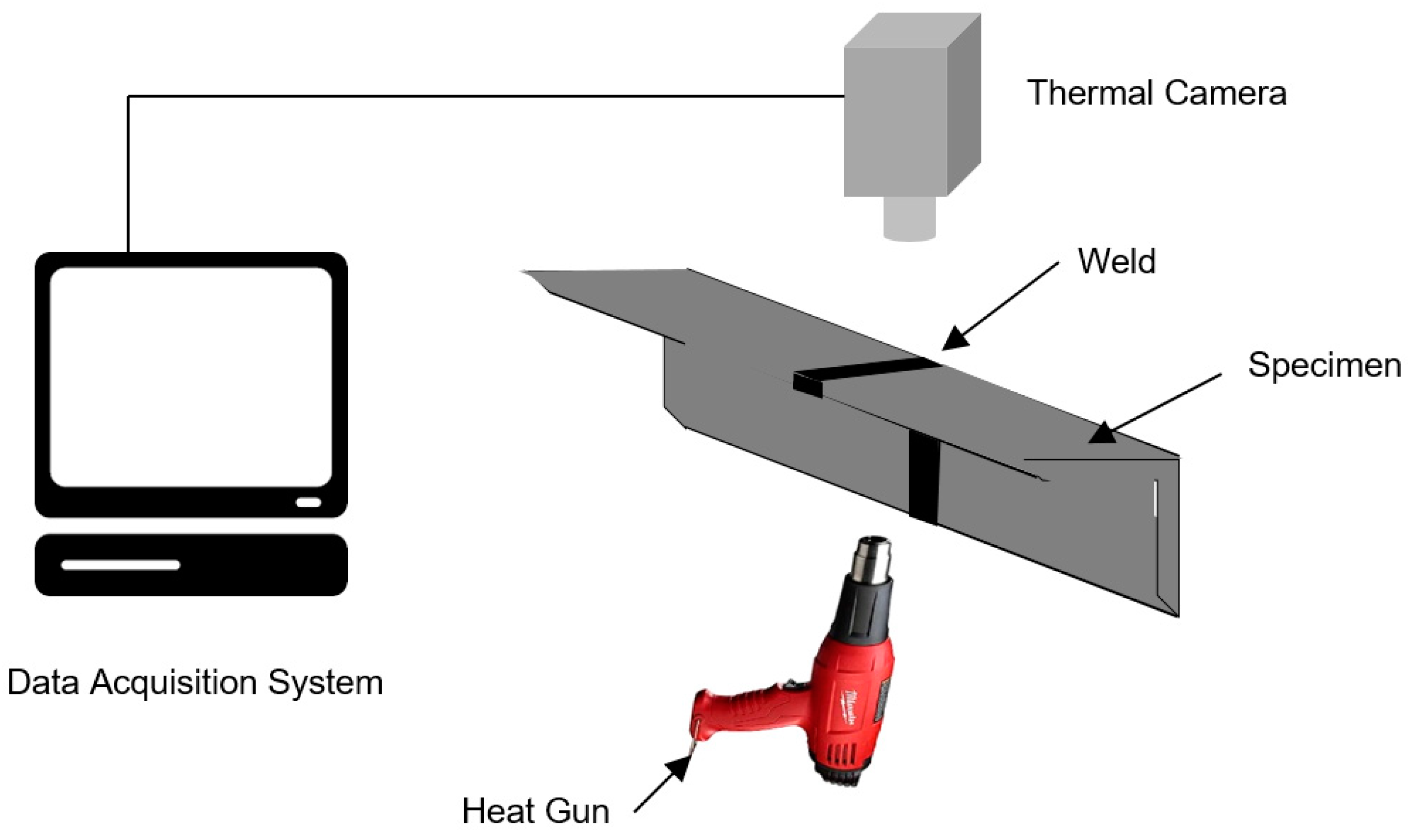

2.2. IRT Method

2.3. Experimental Program

3. Results and Discussion

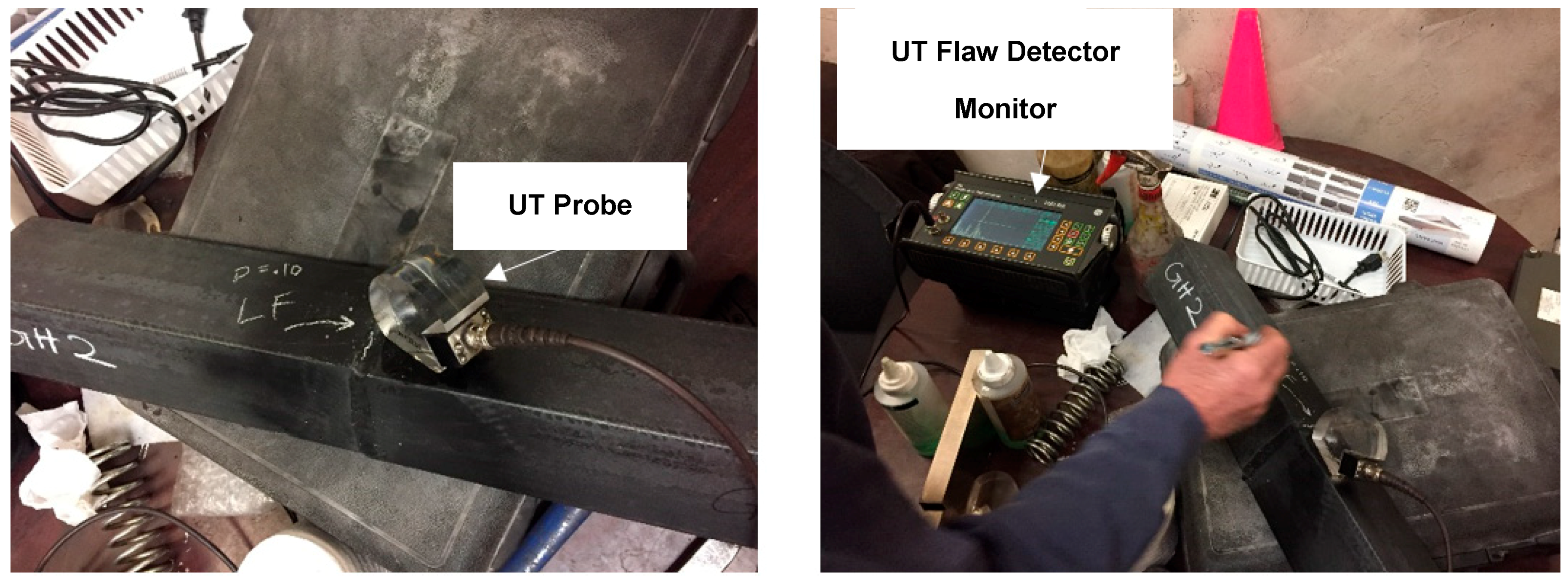

3.1. Results of the UT Inspections

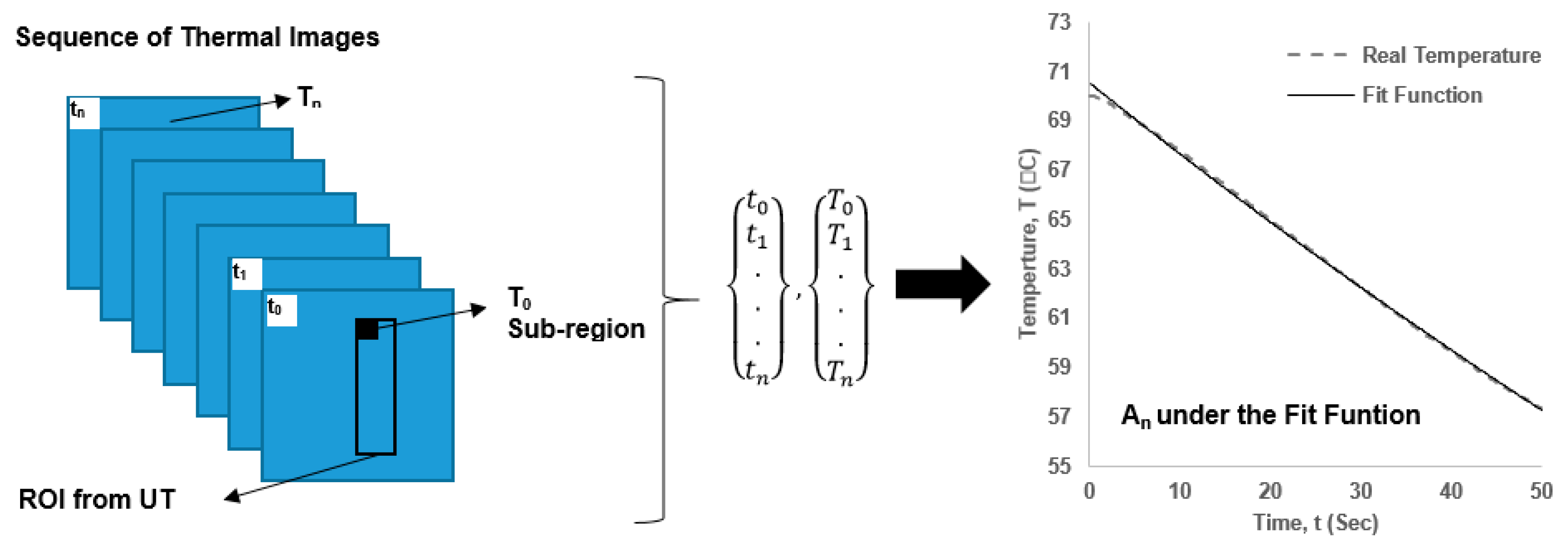

3.2. Results of the Proposed IRT Inspections

3.3. Using the Proposed IRT Method for the 3 mm Specimens

3.4. Destructive Testing

3.5. Challenges to Implementation

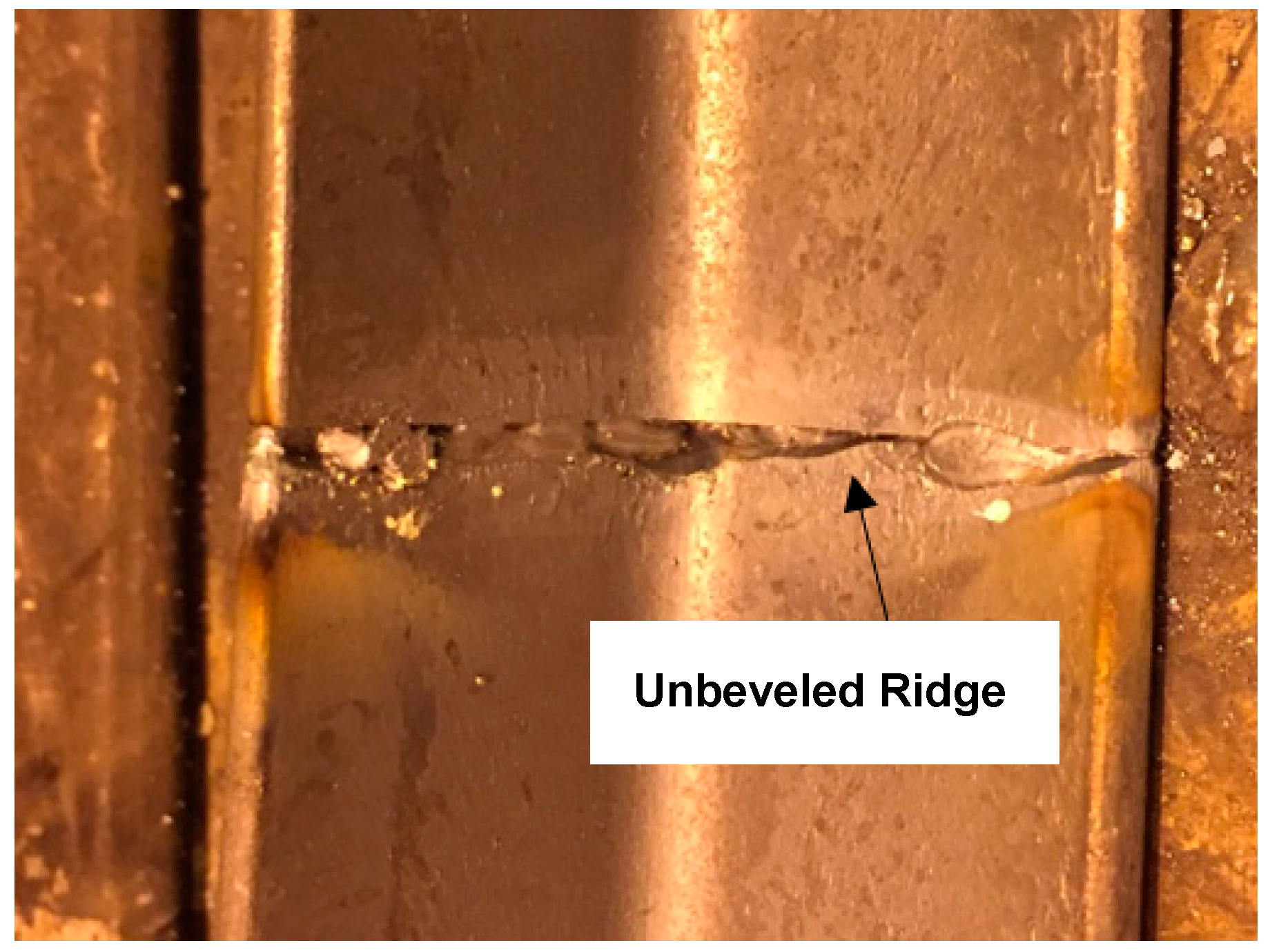

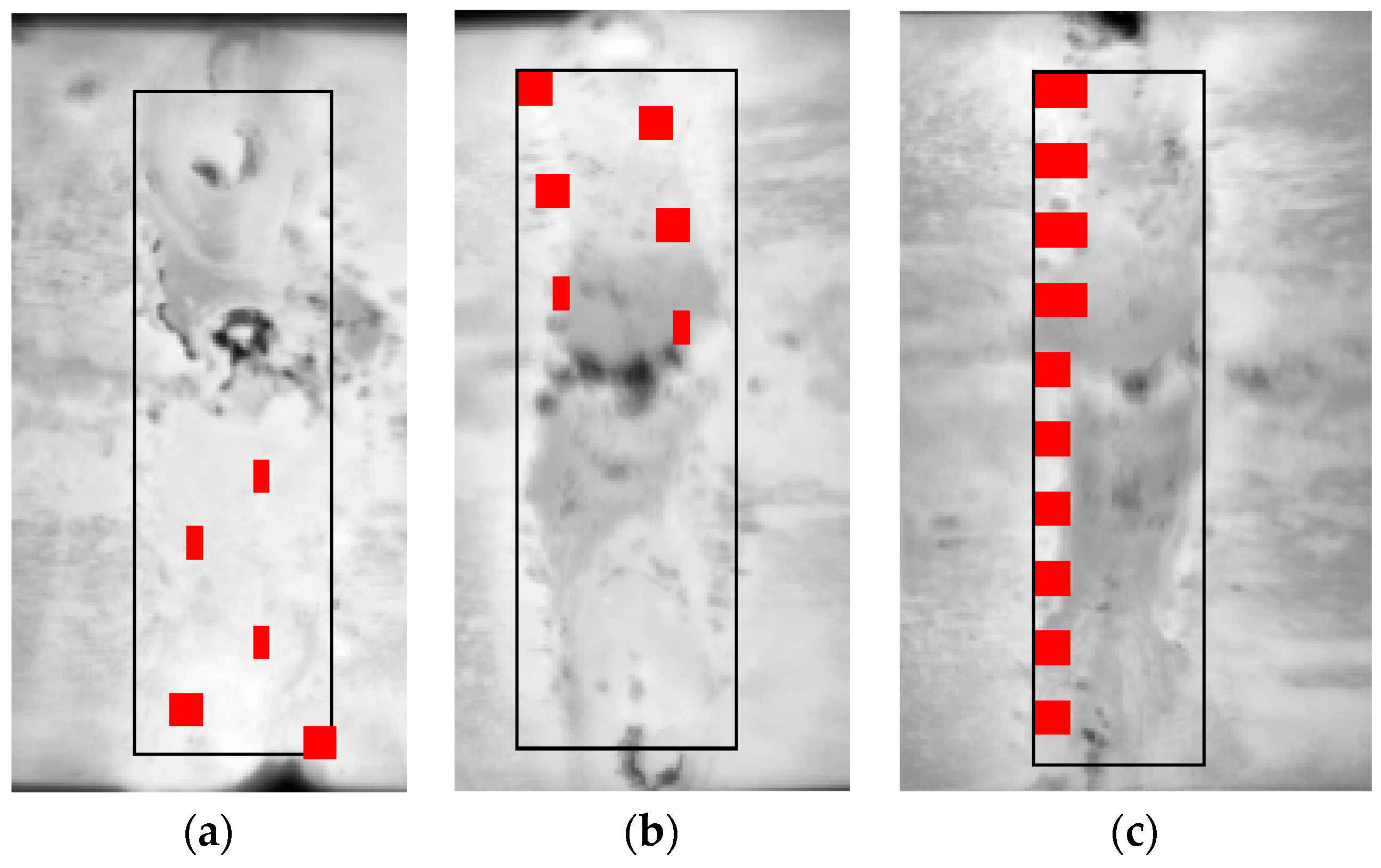

3.5.1. Weld Surface

3.5.2. Emissivity Control

3.5.3. Camera

3.5.4. Uncontrolled and Uneven Heating

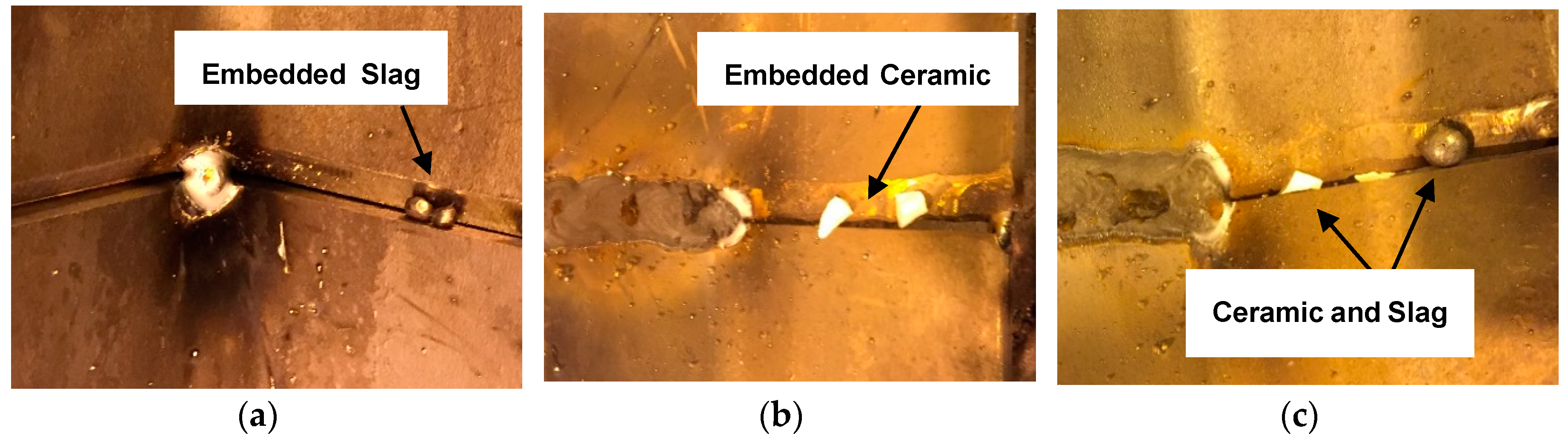

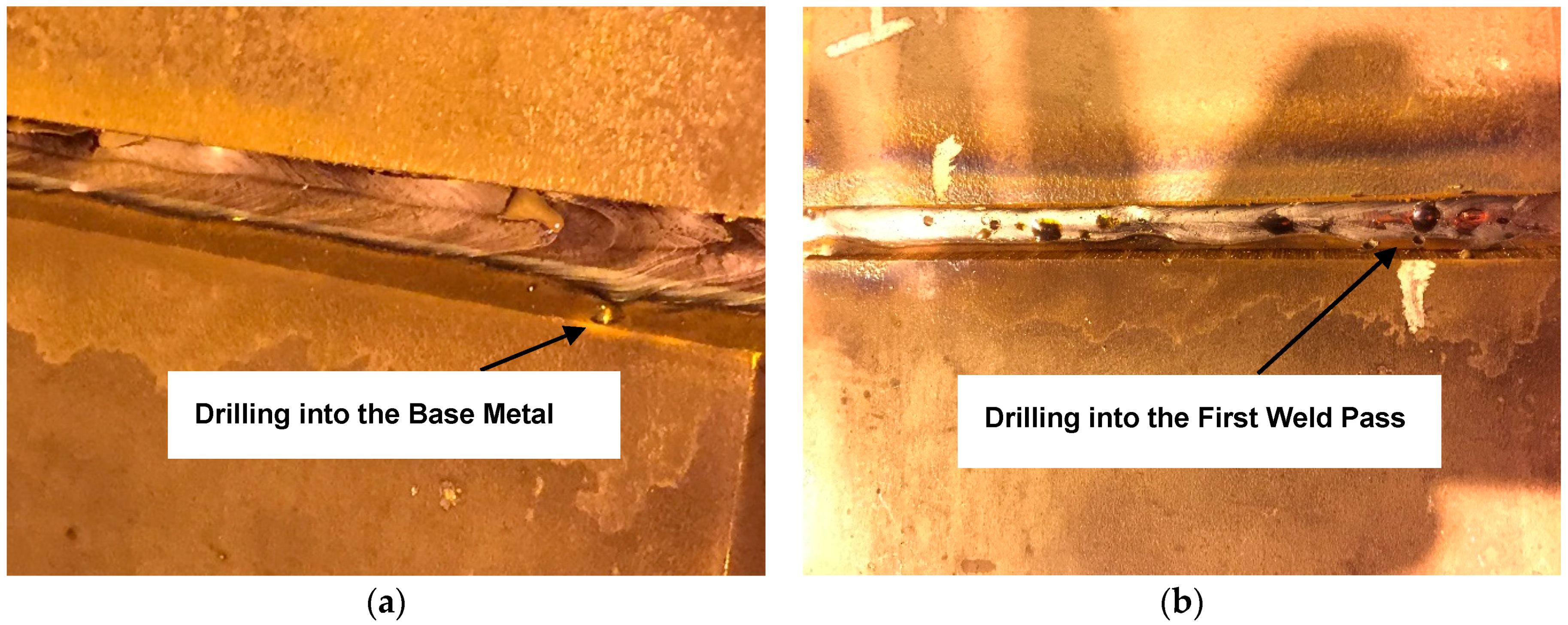

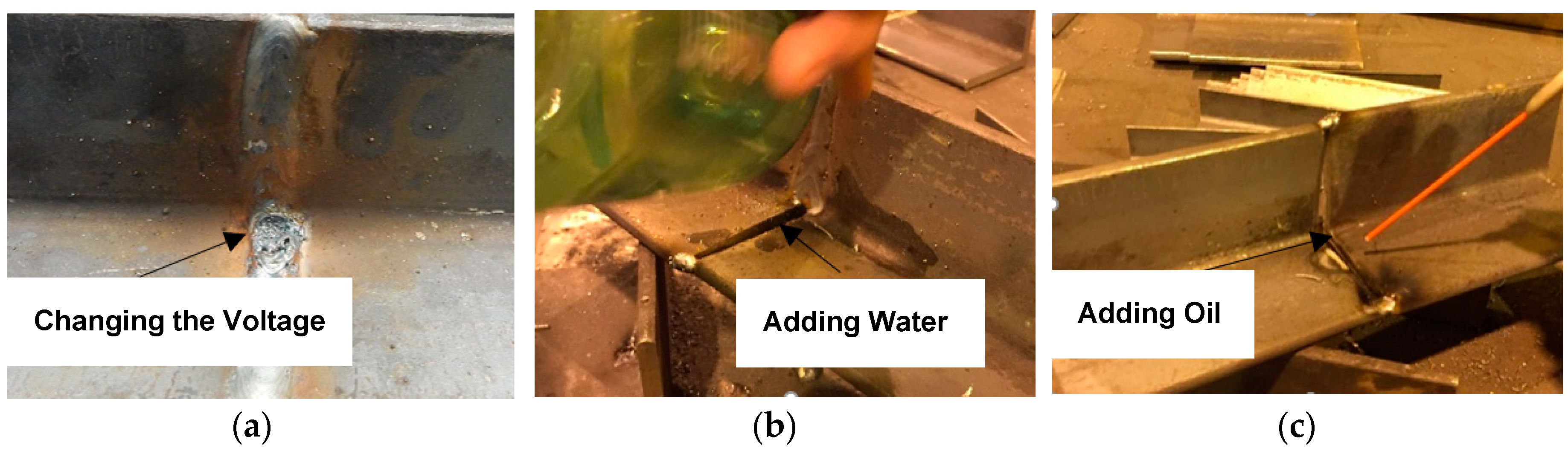

3.5.5. Defect Manufacturing

3.5.6. Welding Process

4. Conclusions

- Surface clutter and the uneven surface created during welding were not related to the presence of defects in the welds, but they can be misleading in the captured thermal images. Having this clutter changes the surface emissivity of the material and can cause inaccuracy in the camera readings, especially in low-emissivity materials.

- The camera used for this study, FLIR SC 640, only measures temperature in the range of −40 to 80 °C, which limits the application for in-line weld inspections.

- Using the fit function of the temperature decay for a five by five sub-region instead of using actual temperatures presented in each pixel alleviated the effects of un-even heating and surface clutters to some extent, but did not completely resolve them. This condition is also similar to the conditions that would exist during in-line inspections using only the heat generated by the welding process.

- Despite using standard methods to fabricate defects, some were hard to create, including cracks and inclusions. The manufactured porosities were mostly on the material surface instead of sub-surface. Lack of fusion was manifested in welds when it was not supposed to; either they were built to have a different defect or no defects at all.

- Using high temperature range cameras coupled with a data acquisition system and software.

- Continue to develop methods for reliable and quantifiable defect fabrication.

- Examine the applicability of IRT weld inspection to other weld processes, including both automatic and semi-automatic processes.

- Using controlled heat sources to excite the specimens, such as high power halogen or UV lamps.

- Using the inherent heat from the welding process for a real-world study of in-line weld inspection.

Author Contributions

Funding

Conflicts of Interest

References

- Liao, T.W.; Li, Y. An automated radiographic NDT system for weld inspection: Part II-Flaw Detection. NDT E Int. 1998, 31, 183–192. [Google Scholar] [CrossRef]

- Wang, G.; Liao, T.W. Automatic identification of different types of welding defects in radiographic images. NDT E Int. 2002, 35, 519–528. [Google Scholar] [CrossRef]

- Yusa, N.; Janousek, L.; Rebican, M.; Chen, Z.; Miya, K.; Chigusa, N.; Ito, H. Detection of embedded fatigue cracks in Inconel weld overlay and the evaluation of the minimum thickness of the weld overlay using eddy current testing. Nuclear Eng. Des. 2006, 236, 1852–1859. [Google Scholar] [CrossRef]

- Smid, R.; Docekal, A.; Kreidl, M. Automated classification of eddy current signatures during manual inspection. NDT E Int. 2005, 38, 462–470. [Google Scholar] [CrossRef]

- Jiles, D.C. Review of magnetic methods for nondestructive evaluation (Part 2). NDT Int. 1990, 23, 83–92. [Google Scholar] [CrossRef]

- Ditchburn, R.J.; Burke, S.K.; Scala, C.M. NDT of welds: State of the art. NDT E Int. 1996, 29, 111–117. [Google Scholar] [CrossRef]

- Buttram, J. Ultrasonic Method for the Accurate Measurement of Crack Height in Dissimilar Metal Welds Using Phased Array. U.S. Patent Application 11/030,365, 4 January 2007. [Google Scholar]

- Latimer, P.J.; MacLauchlan, D.T. EMAT Probe and Technique for Weld Inspection. U.S. Patent 5,760,307, 2 June 1998. [Google Scholar]

- Petcher, P.A.; Dixon, S. Weld defect detection using PPM EMAT generated shear horizontal ultrasound. NDT E Int. 2015, 74, 58–65. [Google Scholar] [CrossRef]

- Rasooli, B. Inspection-for-Industry.com. Available online: https://www.inspection-for-industry.com/radiographic-testing.html (accessed on 17 August 2018).

- Hayes, C. The ABC’s of nondestructive weld examination. Weld. J. 1997, 76, 45–51. [Google Scholar]

- Lhémery, A.; Calmon, P.; Lecœur-Taıbi, I.; Raillon, R.; Paradis, L. Modeling tools for ultrasonic inspection of welds. NDT E Int. 2000, 33, 499–513. [Google Scholar] [CrossRef]

- Kim, K.; Kang, S.; Kim, W.; Cho, H.; Park, J. Improvement of radiographic visibility using an image restoration method based on a simple radiographic scattering model for x-ray nondestructive testing. NDT E Int. 2018, 98, 117–122. [Google Scholar] [CrossRef]

- Rao, B.P.; Raj, B.; Jayakumar, T.; Kalyanasundaram, P. An artificial neural network for eddy current testing of austenitic stainless steel welds. NDT E Int. 2002, 35, 393–398. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Elert, G. The Physics Factbooks. 2003. Available online: https://hypertextbook.com/facts/2003/EstherDorzin.shtml (accessed on 26 August 2018).

- ASTM International. Standard Practice for Contact Ultrasonic Testing of Weldments; ASTM E164-13; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Broberg, P. Surface crack detection in welds using thermography. NDT E Int. 2013, 57, 69–73. [Google Scholar] [CrossRef]

- Li, T.; Almond, D.P.; Rees, D.A.S. Crack imaging by scanning pulsed laser spot thermography. NDT E Int. 2011, 44, 216–225. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.M.; Squillace, A.; Giorleo, G. The use of infrared thermography for nondestructive evaluation of joints. Infrared Phys. Technol. 2004, 46, 93–99. [Google Scholar] [CrossRef]

- Schlichting, J.; Brauser, S.; Pepke, L.A.; Maierhofer, C.; Rethmeier, M.; Kreutzbruck, M. Thermographic testing of spot welds. NDT E Int. 2012, 48, 23–29. [Google Scholar] [CrossRef]

- Rodríguez-Martín, M.; Lagüela, S.; González-Aguilera, D.; Arias, P. Cooling analysis of welded materials for crack detection using infrared thermography. Infrared Phys. Technol. 2014, 67, 547–554. [Google Scholar] [CrossRef]

- Tang, Q.; Liu, J.; Wang, Y.; Liu, H. Subsurface interfacial defects of metal materials testing using ultrasound infrared lock-in thermography. Procedia Eng. 2011, 16, 499–505. [Google Scholar] [CrossRef]

- Lee, S.; Nam, J.; Hwang, W.; Kim, J.; Lee, B. A study on integrity assessment of the resistance spot weld by Infrared Thermography. Procedia Eng. 2011, 10, 1748–1753. [Google Scholar] [CrossRef]

- Plum, R.; Ummenhofer, T. Ultrasound excited thermography of thickwalled steel load bearing members. Quant. Infrared Thermogr. J. 2009, 6, 79–100. [Google Scholar] [CrossRef]

- Renshaw, J.B.; Glass, S.W., III; Thigpen, B.A.; Taglione, M. Vibrothermographic Weld Inspections. U.S. Patent 9,146,205, 29 September 2015. [Google Scholar]

- Plum, R.; Ummenhofer, T. Use of ultrasound excited thermography applied to massive steel components: Emerging crack detection methodology. J. Bridge Eng. 2011, 18, 455–463. [Google Scholar] [CrossRef]

- Garrido, I.; Laguela, S.; Arias, P. Infrared Thermography’s Application to Infrastructure Inspections. Infrastructures 2018, 3, 35. [Google Scholar] [CrossRef]

- Maldague, X.; Galmiche, F.; Ziadi, A. Advances in pulsed phase thermography. Infrared Phys. Technol. 2002, 43, 175–181. [Google Scholar] [CrossRef]

- Schönberger, A.; Virtanen, S.; Giese, V.; Schröttner, H.; Spießberger, C. Non-destructive detection of corrosion applied to steel and galvanized steel coated with organic paints by the pulsed phase thermography. Mater. Corros. 2012, 63, 195–199. [Google Scholar] [CrossRef]

- Roche, J.M.; Leroy, F.H.; Balageas, D.L. Images of thermographic signal reconstruction coefficients: A simple way for rapid and efficient detection of discontinuities. Mater. Eval. 2014, 72, 73–82. [Google Scholar]

- Maldague, X.P. Introduction to NDT by active infrared thermography. Mater. Eval. 2002, 60, 1060–1073. [Google Scholar]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared thermography for temperature measurement and non-destructive testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef] [PubMed]

- Runnemalm, A.; Ahlberg, J.; Appelgren, A.; Sjökvist, S. Automatic inspection of spot welds by thermography. J. Nondestruct. Eval. 2014, 33, 398–406. [Google Scholar] [CrossRef]

- Rajic, N. Principal component thermography for flaw contrast enhancement and flaw depth characterisation in composite structures. Compos. Struct. 2002, 58, 521–528. [Google Scholar] [CrossRef]

- Manuel, M.V.; Washer, G. Use of Infrared Thermography for the Inspection of Welds in the Shop and Field; No. FDOT BDV31-977-64; Transportation Research Board: Washington, DC, USA, 2017. [Google Scholar]

- Sakagami, T.; Izumi, Y.; Kobayashi, Y.; Mizokami, Y.; Kawabata, S. Applications of Infrared Thermography for Nondestructive Testing of Fatigue Cracks in Steel Bridges. In Proceedings of the Thermosense: Thermal Infrared Applications XXXVI, Bellingham, WA, USA, 21 May 2014. [Google Scholar]

- Consonni, M.; Wee, C.F.; Schneider, C. Manufacturing of welded joints with realistic defects. Insight Non Destr. Test. Cond. Monit. 2012, 54, 76–81. [Google Scholar] [CrossRef]

- Kemppainen, M.; Virkkunen, I.; Pitkanen, J.; Paussu, R.; Hanninen, H. Realistic Cracks for In-Service Inspection Qualification Mock-Ups. J. Nondestruct. Test. 2003, 8, 1–8. [Google Scholar]

- Sadiq, H.; Wong, M.B.; Tashan, J.; Al-Mahaidi, R.; Zhao, X.L. Determination of steel emissivity for the temperature prediction of structural steel members in fire. J. Mater. Civ. Eng. 2012, 25, 167–173. [Google Scholar] [CrossRef]

- Vollmer, M.; Möllmann, K.P. Infrared Thermal Imaging: Fundamentals, Research and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Jonietz, F.; Myrach, P.; Suwala, H.; Ziegler, M. Examination of spot welded joints with active thermography. J. Nondestruct. Eval. 2016, 35. [Google Scholar] [CrossRef]

- Leike, A. Demonstration of the exponential decay law using beer froth. Eur. J. Phys. 2001, 23, 21–26. [Google Scholar] [CrossRef]

| Specimen Number | Specimen Thickness (mm) | Detected Defect |

|---|---|---|

| 1 | 13 | Inclusion (I) |

| 2 | Lack of Fusion (LoF) | |

| 3 | 8 | Inclusion (I) |

| 4–15 | Porosity (P) | |

| 16–17 | Cracking (C) | |

| 18–28 | Lack of Fusion (LoF) | |

| 29–30 | Overpass (OP) |

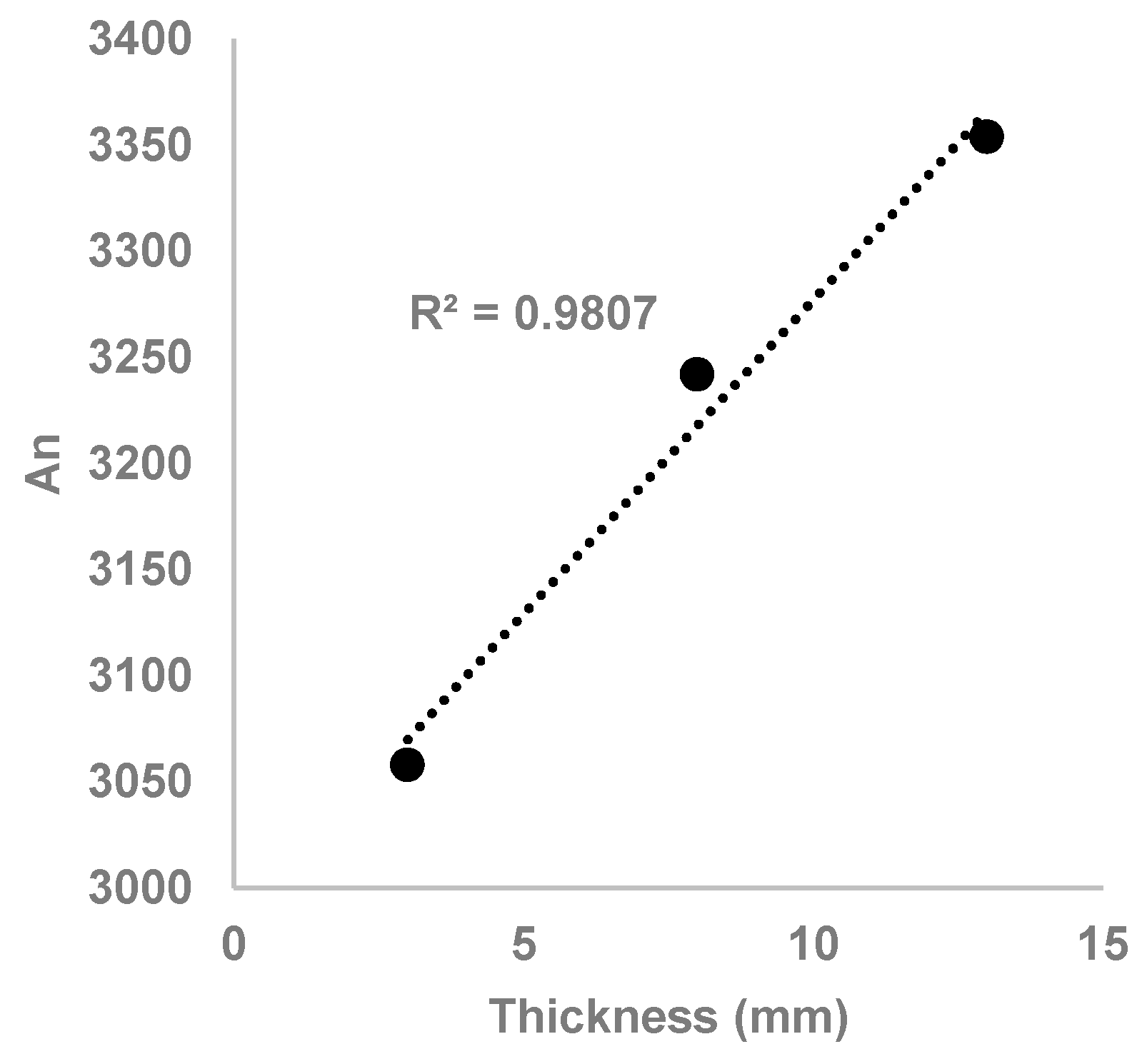

| Specimen Thickness (mm) | Defect (ID) | (Avg.) | (COV%) |

|---|---|---|---|

| 13 | Sound (S) | 3354 | NA |

| Inclusion (I) | 3130 | 3.2 | |

| 8 | Lack of fusion (LoF) | 3341 | NA |

| Sound (S) | 3242 | NA | |

| Inclusion (I) | 3102 | NA | |

| Porosity (P) | 3047 | 3.9 | |

| Cracking (C) | 3122 | 1.0 | |

| Lack of fusion (LoF) | 2939 | 2.7 | |

| Overpass (OP) | 3138 | 2.3 |

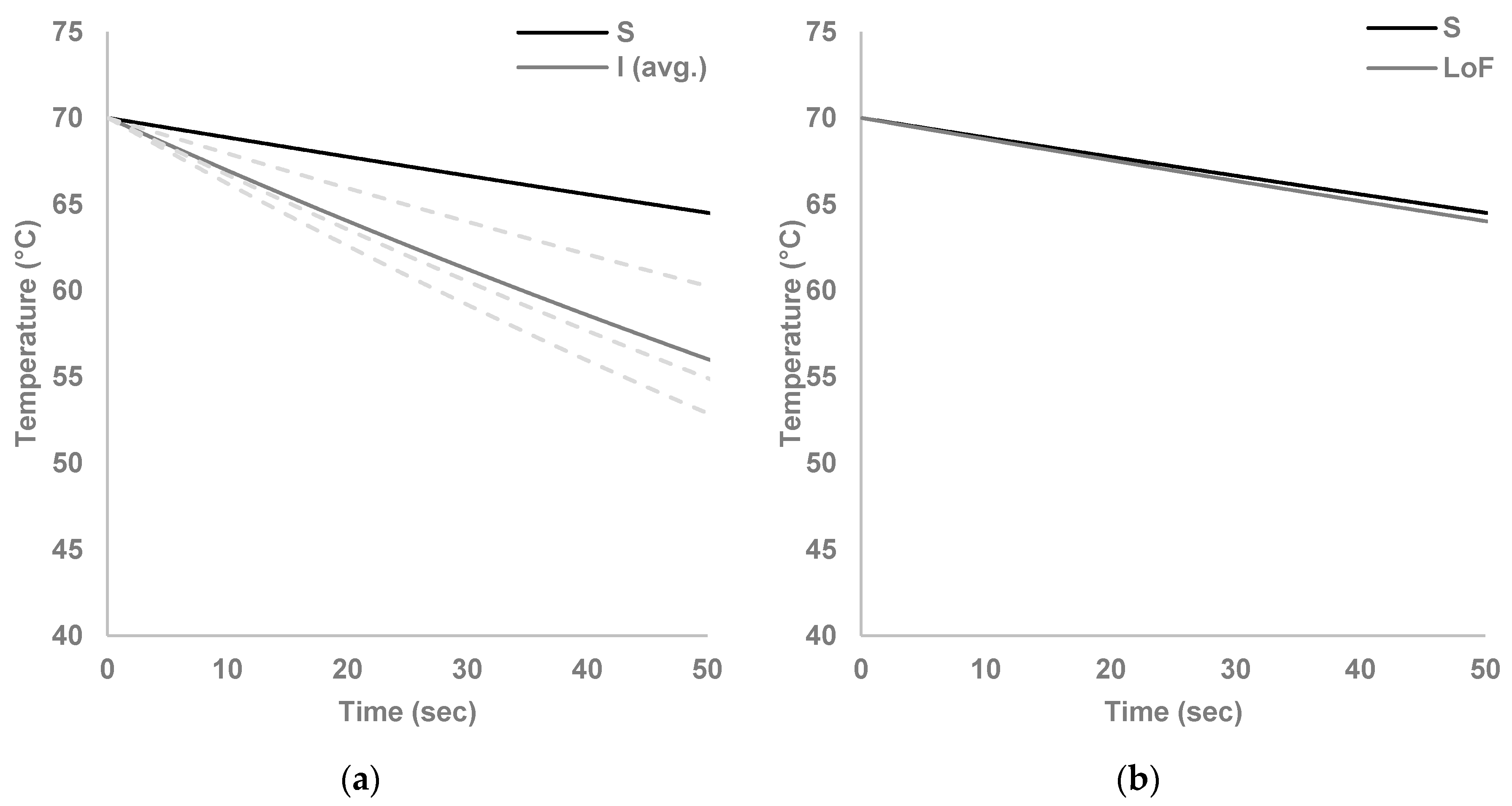

| Value | Sound | Inclusion | Lack of Fusion |

|---|---|---|---|

| R2 (avg.) | 0.96 * | 0.97 | 0.98 * |

| a (avg.) | 70 * | 70.1 | 70 * |

| a (COV%) | NA * | 0.013 | NA * |

| b (avg.) | 0.00196 * | 0.00410 | 0.00202 * |

| b (COV%) | NA * | 32.72 | NA * |

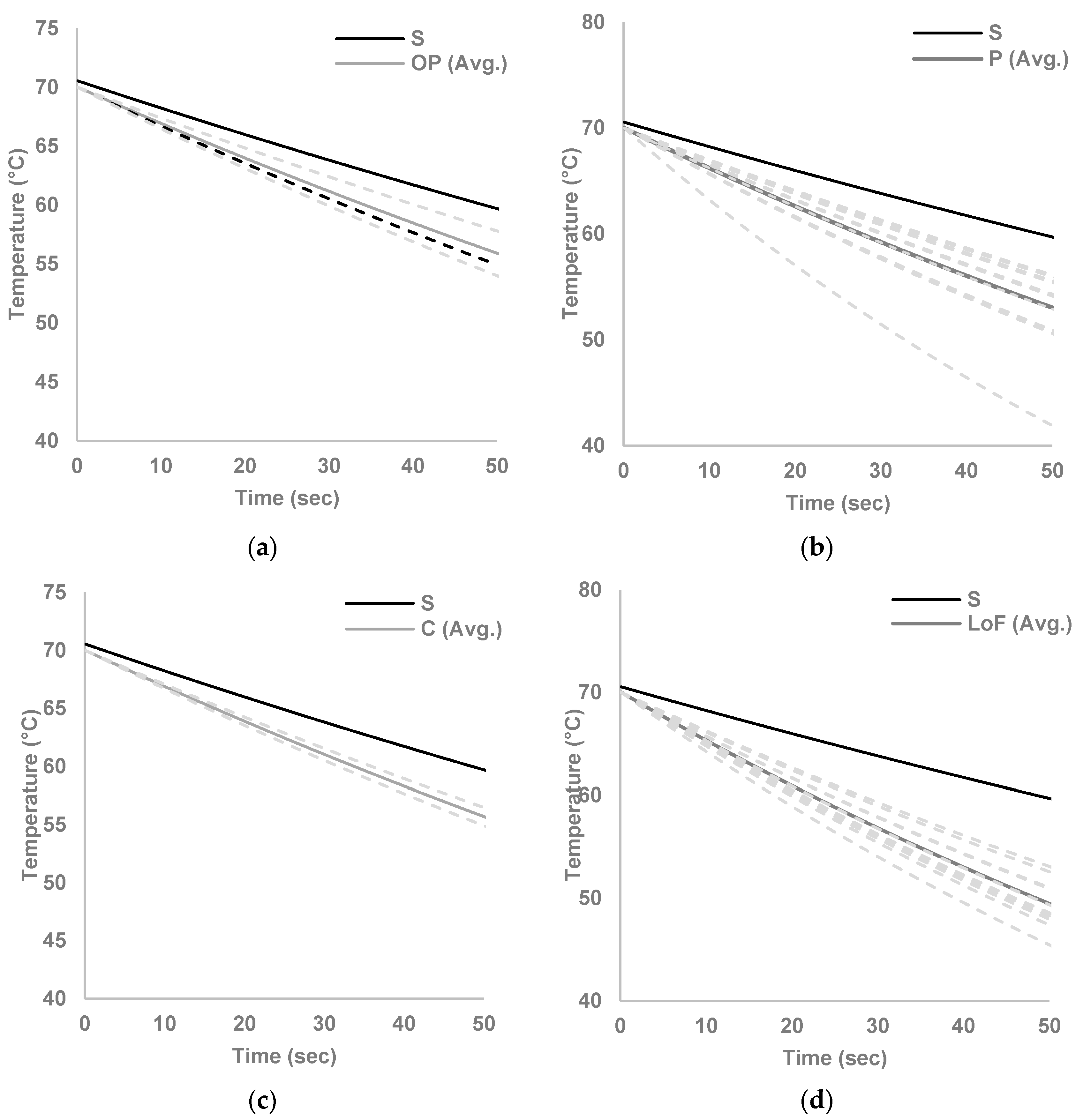

| Value | Sound | Inclusion | Overpass | Porosity | Cracking | Lack of Fusion |

|---|---|---|---|---|---|---|

| R2 (avg.) | 0.94 * | 0.96 * | 0.93 | 0.93 | 0.97 | 0.96 |

| a (avg.) | 70 * | 70 * | 70 | 70 | 70 | 70 |

| a (COV%) | NA * | NA * | 0.01 | 0.005 | 0.02 | 0.01 |

| b (avg.) | 0.00377 * | 0.00510 * | 0.00521 | 0.00614 | 0.00519 | 0.00825 |

| b (COV%) | NA * | NA * | 21.32 | 25.33 | 24.22 | 13.52 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dorafshan, S.; Maguire, M.; Collins, W. Infrared Thermography for Weld Inspection: Feasibility and Application. Infrastructures 2018, 3, 45. https://doi.org/10.3390/infrastructures3040045

Dorafshan S, Maguire M, Collins W. Infrared Thermography for Weld Inspection: Feasibility and Application. Infrastructures. 2018; 3(4):45. https://doi.org/10.3390/infrastructures3040045

Chicago/Turabian StyleDorafshan, Sattar, Marc Maguire, and William Collins. 2018. "Infrared Thermography for Weld Inspection: Feasibility and Application" Infrastructures 3, no. 4: 45. https://doi.org/10.3390/infrastructures3040045

APA StyleDorafshan, S., Maguire, M., & Collins, W. (2018). Infrared Thermography for Weld Inspection: Feasibility and Application. Infrastructures, 3(4), 45. https://doi.org/10.3390/infrastructures3040045