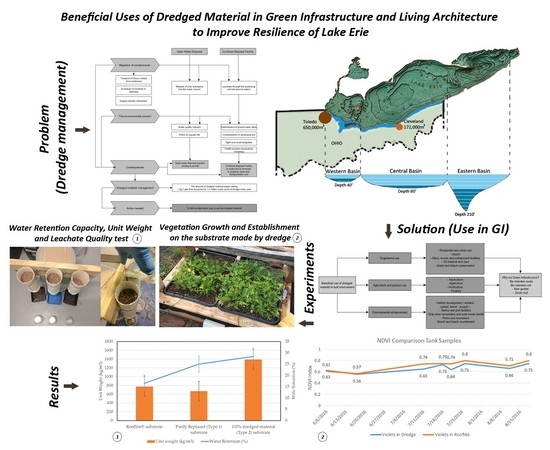

Beneficial Uses of Dredged Material in Green Infrastructure and Living Architecture to Improve Resilience of Lake Erie

Abstract

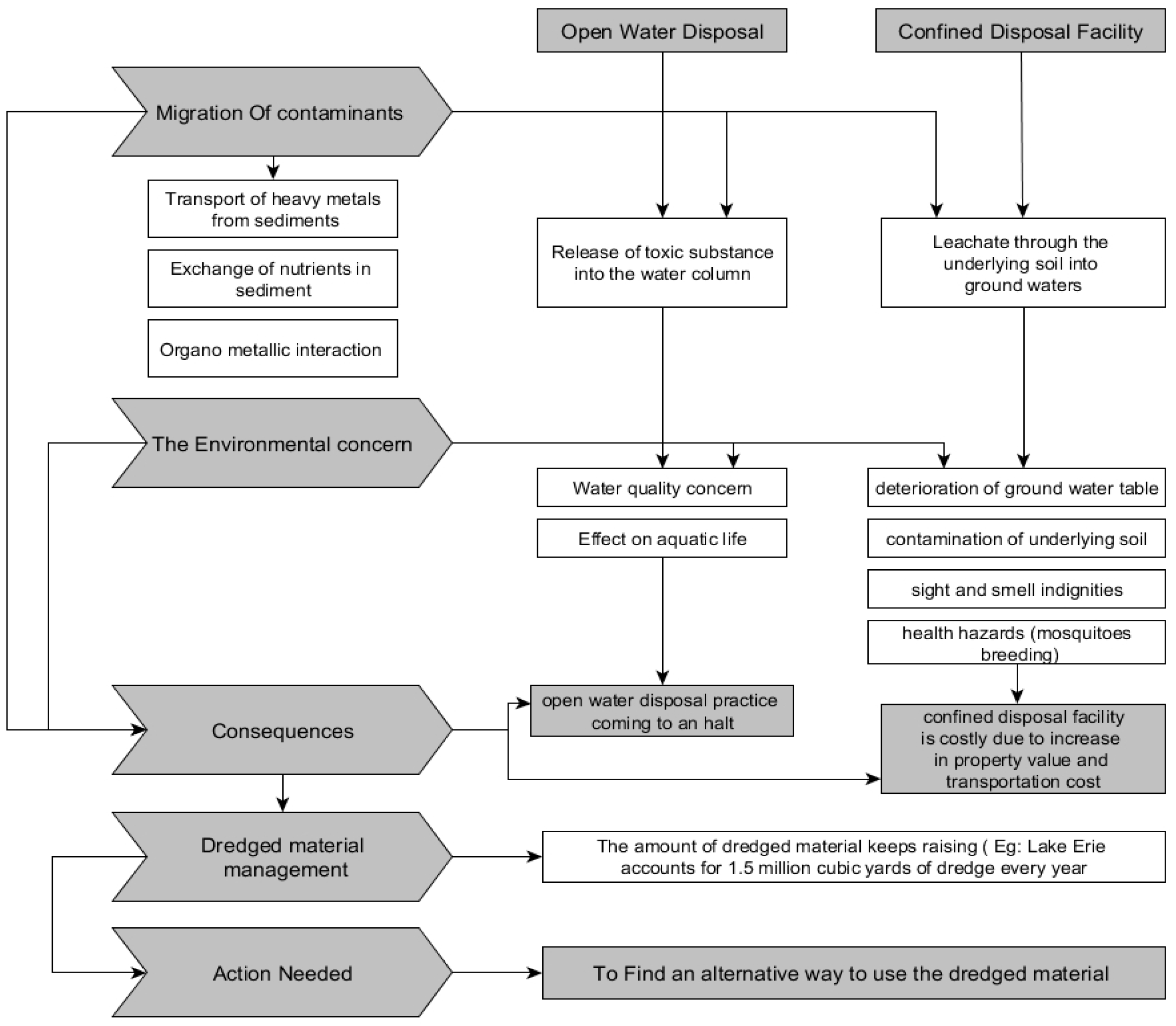

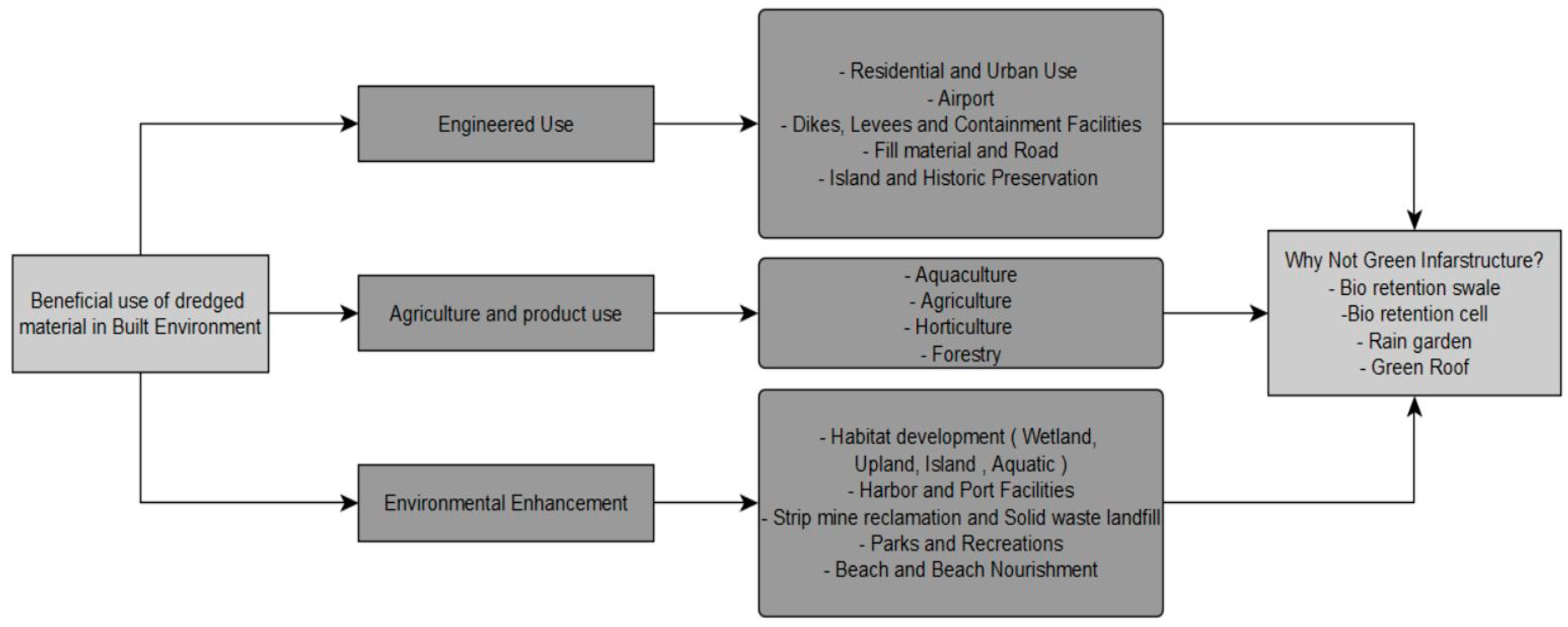

1. Introduction

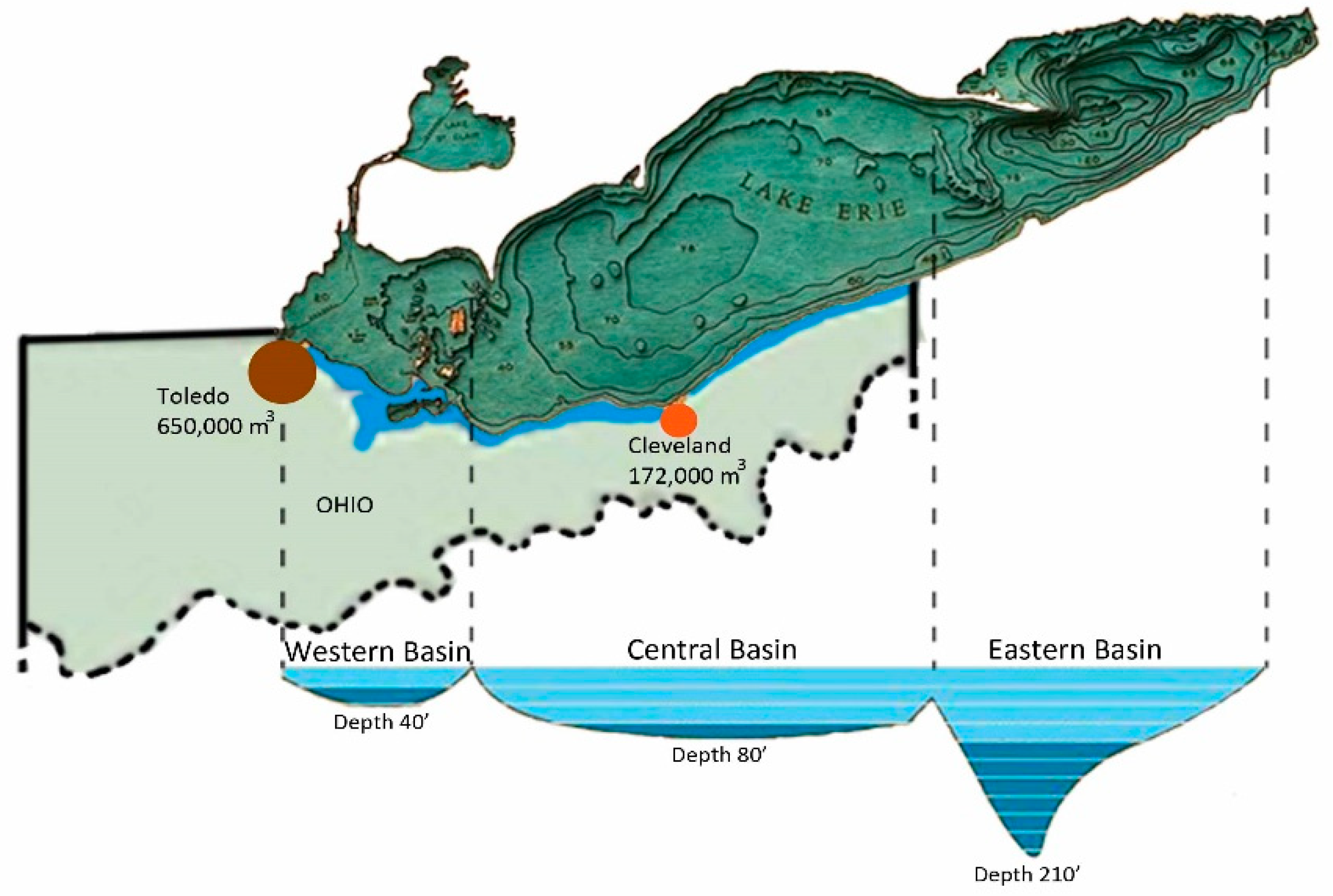

2. Site Description

3. Materials and Methods

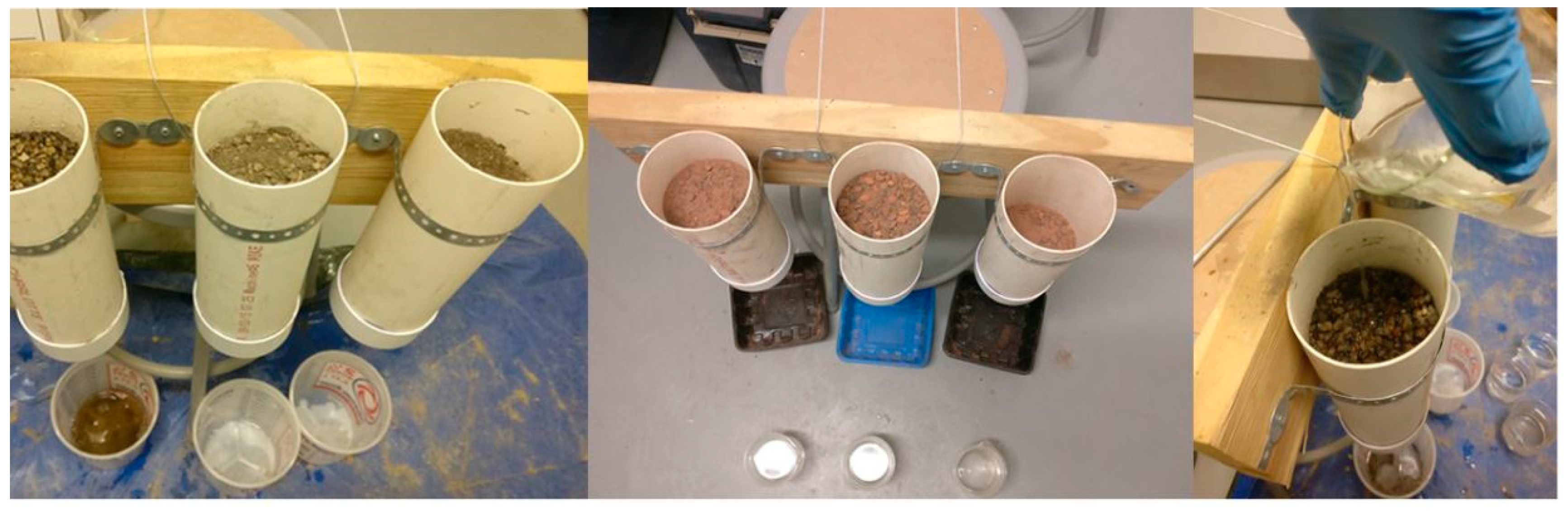

3.1. Experimental Design

3.2. Water Retention Capacity, Unit Weight and Leachate Quality

3.3. Vegetation Growth and Establishment on the Growth Media Made by Dredge Material

4. Results

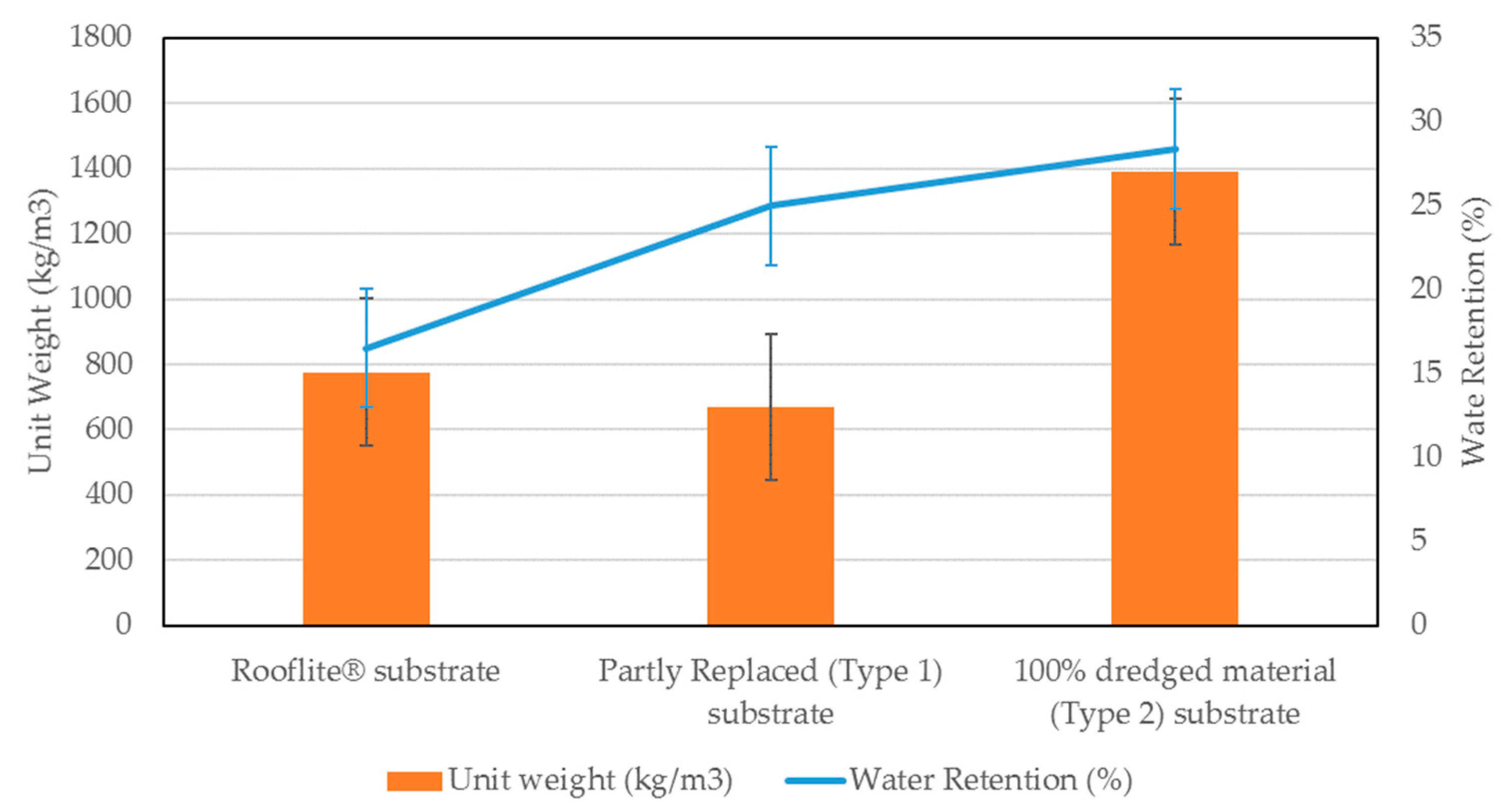

4.1. Water Retention Capacity, unit weight and Leachate Quality

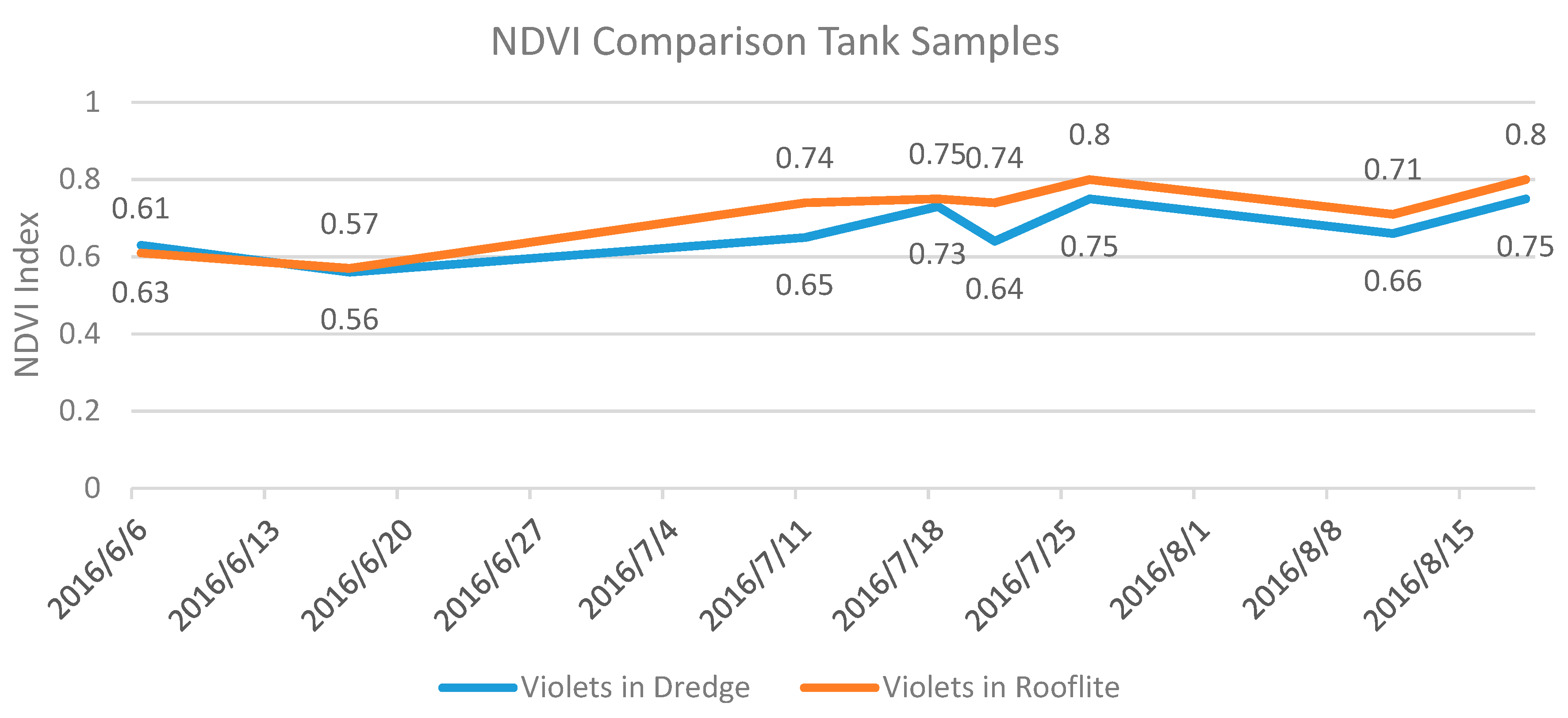

4.2. Vegetation Growth and Establishment on the Growth Media Made by Dredge Material

4.3. Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- U.S. Army Corps of Engineers. Beneficial Uses of Dredged Material. USACE Engineer Manual No. 1110-2-5026. 1987, p. 284. Available online: https://www.publications.usace.army.mil/portals/76/publications/engineermanuals/em_1110-2-5025.pdf (accessed on 22 June 2018).

- Walling, D.E.; Webb, B.W. Erosion and Sediment Yield: Global and Regional Perspectives: Proceedings of an International Symposium Held at Exeter, UK, from 15 to 19 July 1996; IAHS Press, Institute of Hydrology: Wallingford, UK, 1996; pp. 3–19. ISBN 0-947571-89-2. [Google Scholar]

- Chen, K.Y.; Eichenberger, B.; Mang, J.L.; Hoeppel, R.E. Confined Disposal Area Effluent and Leachate Control (Laboratory and Field Investigations); University of Southern California: Los Angeles, CA, USA, 1978; Available online: https://emrrp.el.erdc.dren.mil/elpubs/pdf/trd78-43.pdf (accessed on 15 May 2017).

- Truitt, C.L. Dredge Material Behavior During Open Water Disposal. J. Coast. Res. 1988, 4, 489–497. [Google Scholar]

- Brandon, D.L.; Price, R.A. Summary of Available Guidance and Best Practices for Determining Suitability of Dredged Material for Beneficial Uses. Engineer Research and Development Center Vicksburg Ms Environmental Lab, 2007. Available online: http://www.dtic.mil/dtic/tr/fulltext/u2/a474463.pdf (accessed on 19 August 2017).

- Liu, R.; Coffman, R. Lightweight Aggregate Made from Dredged Material in Green Roof Construction for Stormwater Management. Materials 2016, 9, 611. [Google Scholar] [CrossRef] [PubMed]

- Francingues, N.R.; Thompson, D.W.; Hamons, F.L. Exploring Innovative Reuse of Dredged Material from Baltimore Harbor. In Proceeding of the 2011 WEDA Technical Conference and Texas A&M Dredging Seminar, Nashville, TN, USA, 5–8 June 2011; pp. 271–280. [Google Scholar]

- Kreitinger, J.P.; Price, R.; Borrowman, T.D.; Kennedy, A.J.; Brandon, D.L.; Bourne, M. Evaluation of Beneficial Use Suitability for Cleveland Harbor Dredged Material: Interim Capacity Management and Long-Term Planning; ERDC/EL Project Report; US Army Corps of Engineers: Washington, DC, USA, 2011; Available online: http://www.lrb.usace.army.mil/Portals/45/docs/Cleveland/Army_ERDC_Cleveland_BU_Final_Report.pdf (accessed on 24 September 2018).

- Hamer, K.; Karius, V. Brick production with dredged harbour sediments. An industrial-scale experiment. Waste Manag. 2002, 22, 521–530. [Google Scholar] [CrossRef]

- Hula, R.C. Reclaiming Brownfields: A Comparative Analysis of Adaptive Reuse of Contaminated Properties; Routledge: Abingdon, UK, 2016; p. 263. [Google Scholar]

- Maher, A.W.; Douglas, S.; Jafari, F.; Pecchioli, J. The Processing and Beneficial Use of Fine-Grained Dredged Material, A Manual for Engineers. Centre for Advance Infrastructure and Transportation, 2013. Available online: http://www.state.nj.us/transportation/airwater/maritime/documents/PDM_FINAL_4.24.13-cs.pdf (accessed on 21 June 2016).

- Rulkens, W. Introduction to the Treatment of Polluted Sediments. Rev. Environ. Sci. Biotechnol. 2005, 4, 213–221. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Contaminated Sediment Remediation Guidance for Hazardous Waste Sites. Office of Solid Waste and Emergency Response, 2005; p. 236. Available online: https://nepis.epa.gov/Exe/ZyNET.exe/P1000R7F.TXT?ZyActionD=ZyDocument&Client=EPA&Index=2000+Thru+2005&Docs=&Query=&Time=&EndTime=&SearchMethod=1&TocRestrict=n&Toc=&TocEntry=&QField=&QFieldYear=&QFieldMonth=&QFieldDay=&IntQFieldOp=0&ExtQFieldOp=0&XmlQuery=&File=D%3A%5Czyfiles%5CIndex%20Data%5C00thru05%5CTxt%5C00000015%5CP1000R7F.txt&User=ANONYMOUS&Password=anonymous&SortMethod=h%7C-&MaximumDocuments=1&FuzzyDegree=0&ImageQuality=r75g8/r75g8/x150y150g16/i425&Display=hpfr&DefSeekPage=x&SearchBack=ZyActionL&Back=ZyActionS&BackDesc=Results%20page&MaximumPages=1&ZyEntry=1&SeekPage=x&ZyPURL (accessed on 30 July 2016).

- U.S. Army Corps of Engineers. Army Low Impact Development Technical User Guide. January 2013. Available online: https://www.usace.army.mil/Portals/2/docs/Sustainability/Hydrology_LID/Army_LID_Technical_User_Guide_January2013.pdf (accessed on 15 May 2017).

- Maes, J.; Liquete, C.; Teller, A.; Erhard, M.; Paracchini, M.L.; Barredo, J.I.; Grizzetti, B.; Cardoso, A.; Somma, F.; Petersen, J.E.; et al. An indicator framework for assessing ecosystem services in support of the EU Biodiversity Strategy to 2020. Ecosyst. Serv. 2016, 17, 14–23. [Google Scholar] [CrossRef]

- Fletcher, T.D.; Shuster, W.; Hunt, W.F.; Ashley, R.; Butler, D.; Arthur, S.; Trowsdale, S.; Barraud, S.; Semadeni-Davies, A.; Bertrand-Krajewski, J.L.; et al. SUDS, LID, BMPs, WSUD and more—The evolution and application of terminology surrounding urban drainage. Urban Water J. 2015, 12, 525–542. [Google Scholar] [CrossRef]

- Bolund, P.; Hunhammar, S. Ecosystem Services in Urban Areas. Ecol. Econ. 1999, 29, 293–301. [Google Scholar] [CrossRef]

- Villarreal, E.L.; Bengtsson, L. Response of a Sedum Green roof to Individual Rain Events. Ecol. Eng. 2005, 25, 1–7. [Google Scholar] [CrossRef]

- Pataki, D.E.; Carreiro, M.M.; Cherrier, J.; Grulke, N.E.; Jennings, V.; Pincetl, S.; Pouyat, R.V.; Whitlow, T.H.; Zipperer, W.C. Coupling Biogeochemical Cycles in Urban Environments: Ecosystem Services, Green Solutions, and Misconceptions. Front. Ecol. Environ. 2011, 9, 27–36. [Google Scholar] [CrossRef]

- Oberndorfer, E.; Lundholm, J.; Bass, B.; Coffman, R.R.; Doshi, H.; Dunnett, N.; Gaffin, S.; Köhler, M.; Liu, K.K.; Rowe, B. Green Roofs as Urban Ecosystems: Ecological Structures, Functions, and Services. Bioscience 2007, 57, 823–833. [Google Scholar] [CrossRef]

- Moreno-Garcia, M.C. Intensity and Form of the Urban Heat Island in Barcelona. Int. J. Climatol. 1994, 14, 705–710. [Google Scholar] [CrossRef]

- Hardin, P.J.; Jensen, R.R. The Effect of Urban Leaf Area on Summertime Urban Surface Kinetic Temperatures: A Terre Haute Case Study. Urban For. Urban Green. 2007, 6, 63–72. [Google Scholar] [CrossRef]

- Nowak, D.J.; Crane, D.E. The Urban Forest Effects (UFORE) Model: Quantifying Urban Forest Structure and Functions. In Integrated Tools for Natural Resources Inventories in the 21st Century; General Technical Report NC-212; Hansen, M., Burk, T., Eds.; U.S. Department of Agriculture, Forest Service, North Central Forest Experiment Station: St. Paul, MN, USA, 2000; pp. 714–720. [Google Scholar]

- McPhearson, T. Toward a Sustainable New York City: Greening through Urban Forest Restoration. In Sustainability in America’s Cities: Creating the Green Metropolis; Slavin, E., Ed.; Island Press: Washington, DC, USA, 2011; pp. 181–204. [Google Scholar]

- Farber, S. The Value of Coastal Wetlands for Protection of Property against Hurricane Wind Damage. J. Environ. Econ. Manag. 1987, 14, 143–151. [Google Scholar] [CrossRef]

- Danielsen, F.; Sørensen, M.K.; Olwig, M.F.; Selvam, V.; Parish, F.; Burgess, N.D.; Hiraishi, T.; Karunagaran, V.M.; Rasmussen, M.S.; Hansen, L.B.; et al. The Asian Tsunami: A Protective Role for Coastal Vegetation. Science 2005, 310, 643. [Google Scholar] [CrossRef] [PubMed]

- Depietri, Y.; Renaud, F.G.; Kallis, G. Heat Waves and Floods in Urban Areas: A Policy Oriented Review of Ecosystem Services. Sustain. Sci. 2012, 7, 95–107. [Google Scholar] [CrossRef]

- Kerr, A.M.; Baird, A.H. Natural Barriers to Natural Disasters. BioScience 2007, 57, 102–103. [Google Scholar] [CrossRef]

- McPherson, G.E.; Nowak, D.J.; Rowntree, R.A. Chicago’s Urban Forest Ecosystem: Results of the Chicago Urban Forest Climate Project; Gen. Tech. Rep. NE-186; US Department of Agriculture, Forest Service, Northeastern Forest Experiment Station: Radnor, PA, USA, 1994.

- Nowak, D.J. Notes: Estimating Leaf Area and Leaf Biomass of Open-grown Deciduous Urban Trees. For. Sci. 1996, 42, 504–507. [Google Scholar]

- Dzierzanowski, K.; Popek, R.; Gawrońska, H.; Sæbø, A.; Gawroński, S.W. Deposition of Particulate Matter of Different Size Fractions on Leaf Surfaces and in Waxes of Urban Forest Species. Int. J. Phytoremed. 2011, 13, 1037–1046. [Google Scholar] [CrossRef] [PubMed]

- Aylor, D. Noise Reduction by Vegetation and Ground. J. Acoust. Soc. Am. 1972, 51, 197–205. [Google Scholar] [CrossRef]

- Kragh, J. Road Traffic Noise Attenuation by Belts of Trees. J. Sound Vib. 1981, 74, 235–241. [Google Scholar] [CrossRef]

- Fang, C.; Ling, D. Investigation of the Noise Reduction Provided by Tree Belts. Landsc. Urban Plan. 2003, 63, 187–195. [Google Scholar] [CrossRef]

- Ishii, M. Measurement of Road Traffic Noise Reduced by the Employment of Low Physical Barriers and Potted Vegetation. Inter-Noise 1994, 29–31, 595–597. [Google Scholar]

- Pathak, V.; Tripathi, B.D.; Mishra, V.K. Dynamics of Traffic Noise in A Tropical City Varanasi and Its Abatement through Vegetation. Environ. Monit. Assess. 2007, 146, 67–75. [Google Scholar] [CrossRef] [PubMed]

- Clausen, J.C. Jordan Cove Watershed Project, Final Report; Department of Natural Resource Management and Engineering, University of Connecticut: Hartford, CT, USA, 2007. [Google Scholar]

- Shuster, W.; Morrison, M.; Webb, R. Front-loading Urban Stormwater Management for success: A Perspective Incorporating Current Studies on the Implementation of Retrofit Low Impact Development. Cities Environ. (CATE) 2008, 1, 8. [Google Scholar]

- Kadas, G. Rare invertebrates colonizing green roofs in London. Urban Habitats 2006, 4, 66–86. [Google Scholar]

- Coffman, R. Elevating Habitat:Creating biodiversity through quasi-traditional green roof design. Landsc. Archit. Mag. 2009, 99, 72–77. [Google Scholar]

- Hopkins, G.; Goodwin, C. Living Architecture: Green Roofs and Walls; Csiro Publishing: Clayton, Australia, 2011. [Google Scholar]

- Peck, S.W. The Rise of Living Architecture; Green Roofs for Healthy Cities: Toronto, ON, Canada, 2012; ISBN 0988051702, 9780988051706. Available online: https://books.google.com/books?hl=en&lr=&id=DbjmOWakmYYC&oi=fnd&pg=PA32&dq=The+Rise+of+Living+Architecture&ots=TiG1AXdpss&sig=iP-KrV37UnPEXqeR19H12fjeAt0#v=onepage&q=The%20Rise%20of%20Living%20Architecture&f=false (accessed on 24 September 2018).

- Loder, A. ‘There’s a meadow outside my workplace’: A phenomenological exploration of aesthetics and green roofs in Chicago and Toronto. Landsc. Urban Plan. 2014, 126, 94–106. [Google Scholar] [CrossRef]

- Graceson, A.; Adams, H. Characterising the components of green roof growing media. In Proceedings of the 1st National Green Roof Student Conference, London, UK, 16–17 May 2011; pp. 15–16. [Google Scholar]

- Eksi, M.; Rowe, D.B. Green roof substrates: Effect of recycled crushed porcelain and foamed glass on plant growth and water retention. Urban For. Urban Green. 2016, 20, 81–88. [Google Scholar] [CrossRef]

- Virginia Approved Stormwater BMP Standards and Specifications. Available online: https://www.vwrrc.vt.edu/swc/StandardsSpecs.html (accessed on 15 January 2018).

- Prince George’s County. Bioretention Manual; Programs & Planning Division Department of Environmental Resources: Landover, MD, USA, 2002.

- Hinman, C. Bioretention Soil Mix Review and Recommendations for Western Washington. 2009. Available online: http://citeseerx.ist.psu.edu/viewdoc/download;jsessionid=9D3D66D721A26FBCE87DAEFDD17C8020?doi=10.1.1.431.4124&rep=rep1&type=pdf (accessed on 30 January 2018).

- Santa Clara Valley. Urban Runoff Pollution Prevention Program. Available online: http://scvurppp-w2k.com/ (accessed on 15 January 2018).

- Biohabits. Bioretention Guidance. Lake County, Ohio. 2005. Available online: http://www.lakecountyohio.gov/portals/21/Final%20Report%203-17-06.pdf (accessed on 15 January 2018).

- Anderson, S.; Piza, H. Ultra Urban Green Infrastructure Guidelines. Available online: https://www.denvergov.org/content/dam/denvergov/Portals/705/documents/ultra-urban-green-infrastructure-guidelines.pdf (accessed on 12 March 2018).

- Ampim, P.; Sloan, J.J.; Cabrera, R.I.; Jaber, F. Green Roof Growing Substrates: Types, Ingredients, Composition and Properties. J. Environ. Hortic. 2010, 28, 244–252. [Google Scholar]

- Ohio EPA, Lake Erie Dredged Material Program. Available online: http://epa.ohio.gov/dir/dredgehttp://epa.ohio.gov/dir/dredge (accessed on 12 March 2018).

- Wright, J.G. Risks and Rewards of Brownfield Redevelopment; Lincoln Institute of Land Policy: Cambridge, MA, USA, 1996. [Google Scholar]

- Arnold, C.L., Jr.; Gibbons, C.J. Impervious surface coverage: The Emergence of a key Environmental Indicator. J. Am. Plan. Assoc. 1996, 62, 243–258. [Google Scholar] [CrossRef]

- Korhonen, J.; Leskinen, P.; Matthies, B.D.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2017, 135, 246–264. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2017, 135, 190–201. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Liew, O.W.; Chong, P.C.; Li, B.; Asundi, A.K. Signature optical cues: Emerging technologies for monitoring plant health. Sensors 2008, 8, 3205–3239. [Google Scholar] [CrossRef] [PubMed]

- Jackson, R.D.; Huete, A.R. Interpreting vegetation indices. Prev. Vet. Med. 1991, 11, 185–200. [Google Scholar] [CrossRef]

- Govaerts, B.; Verhulst, N. The Normalized Difference Vegetation Index (NDVI) Greenseeker (TM) Handheld Sensor: Toward the Integrated Evaluation of Crop Management Part A: Concepts and Case Studies; CIMMYT: Mexico, 2010. [Google Scholar]

| Analysis | Appropriate Tests | Standards | Application |

|---|---|---|---|

| Physical Analysis | Grain Size—Standard Sieve test and Hydrometer test | ASTM D422 | Structural and Non-structural applications |

| Particle Shape/Texture | ASTM D2488 | ||

| Water Content/% Moisture | ASTM D2216 | ||

| Permeability | ASTM D2434, ASTM D5084 | ||

| Atterberg Limit | ASTM D4318 | ||

| Organic content/organic matter | ASTM D2487 | ||

| Unit weight | ASTM D29, ASTM D854, ASTM D1556, ASTM D2922 | ||

| Engineering properties | Compaction Tests Standard Compaction Test Modified Compaction Test 15 Blow Compaction Test | ASTM D698 ASTM D1557 ASTM D5080 | Structural application |

| Consolidation tests | ASTM D2435 | ||

| Bearing capacity | ASTM D1883 | ||

| Shear Strength | ASTM D2850, ASTM D3080, ASTM D4767 | ||

| Compressive Strength | ASTM D2166, ASTM D4219 | ||

| Chemical properties | pH | ASA 1996: Ch 16 | Structural and Non-structural applications |

| Calcium Carbonate Equivalent | ASA 1996: Ch 16 | ||

| Cation Exchange Capacity | ASA 1996: Ch 40 | ||

| Salinity | ASA 1996: Ch 14 | ||

| Sodium | ASA 1996: Ch 19 | ||

| Chloride | ASA 1996: Ch 31 | ||

| Electrical Conductivity | ASA 1996: Ch 14 | ||

| Total Organic Carbon | ASTM D2974; D2974-87; ASA 1982: 29-4.2 | ||

| Ammonium Nitrogen | EPA-CRL-324 | ||

| Nitrate-nitrogen; Nitrite-nitrogen | EPA-SW846-9200 | ||

| Total Phosphorus | EPA-CRL-435 | ||

| Ortho-phosphorus | EPA-CRL-435 | ||

| Potassium | ASA 1996: Ch 19 | ||

| Total Metals | EPA-SW846-200.9; ASA 1996: Ch 18-30 | ||

| Pesticides (chlorinated) | EPA-SW846-8080 | ||

| Polynuclear Aromatic Hydrocarbons (PAHs) | EPA-SW846-8270 | ||

| Dioxins | EPA-SW846-8290 and 1630 | ||

| Biological Properties | Animal Bioassay | ASTM 1998 | Structural and Non-structural applications |

| Elutriate Bioassay | EPA 1991 (Method 11.14) |

| Specimens | Dry Material wt. (kg) | Water Adsorbed (mL) | Wet wt. of Sample (kg) | Water Retention (%) | Wet Unit Weight (kg/m3) |

|---|---|---|---|---|---|

| Rooflite® substrate | |||||

| Column1 | 1.3 | 276.69 | 1.58 | 21.18 | 786.5 |

| Column2 | 1.33 | 181.46 | 1.51 | 13.65 | 751.2 |

| Column3 | 1.38 | 204.11 | 1.58 | 14.7 | 789.55 |

| Average | 1.33 | 220.75 | 1.56 | 16.51 | 775.77 |

| Standard Deviation | 0.04 | 49.75 | 0.04 | 4.08 | 21.32 |

| Partly Replaced (Type 1) substrate | |||||

| Column1 | 1.03 | 270 | 1.3 | 25.04 | 650 |

| Column2 | 1.08 | 280 | 1.36 | 25.52 | 676.7 |

| Column3 | 1.09 | 270 | 1.36 | 24.38 | 679 |

| Average | 1.07 | 273.33 | 1.34 | 24.98 | 668.45 |

| Standard Deviation | 0.03 | 5.77 | 0.03 | 0.57 | 16.12 |

| 100% dredged material (Type 2) substrate | |||||

| Column1 | 2.22 | 598.74 | 2.82 | 26.9 | 1403.2 |

| Column2 | 2.13 | 557.91 | 2.69 | 26.17 | 1337.8 |

| Column3 | 1.31 | 421.84 | 1.74 | 32.06 | 1425.6 |

| Average | 2.13 | 526.16 | 2.42 | 28.38 | 1389.2 |

| Standard Deviation | 0.50 | 92.62 | 0.59 | 3.21 | 45.62 |

| Quality | Distilled Water | Rooflite® | Type 1 Substrate | Type 2 Substrate |

|---|---|---|---|---|

| pH | 8.5 | 8.5 | 8.5 | 8.5 |

| Total Alkalinity (mg/L) | 500 | 180 | 240 | 240 |

| Total Chlorine (mg/L) | 0.2 | 0 | 0 | 0 |

| Total Hardness (mg/L) | 50 | 425 | 425 | 425 |

| Nitrate Nitrogen (mg/L) | 0 | 50 | 50 | 50 |

| Nitrite Nitrogen (mg/L) | 0 | 0.3 | 0.3 | 0.3 |

| Sample No. | Plant Cover Area (cm2) Dredged Material | Plant Cover Area (cm2) Rooflite® Material |

|---|---|---|

| 1 | 253.8 | 348.232 |

| 2 | 168.613 | 322.59 |

| 3 | 415.631 | 255.38 |

| 4 | 215.126 | 334.13 |

| 5 | 302.2 | 514.31 |

| 6 | 450.426 | 558.38 |

| 7 | 511.941 | 407.85 |

| 8 | 244.844 | 239.5 |

| Total (sq.cm) | 2562.581 | 2980.372 |

| Average (cm2) | 320.323 | 372.547 |

| Standard Deviation (cm2) | 123.786 | 114.561 |

| Probability (t-test) | 0.198 > 0.05 (Statistically insignificant) | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhairappanavar, S.; Liu, R.; Coffman, R. Beneficial Uses of Dredged Material in Green Infrastructure and Living Architecture to Improve Resilience of Lake Erie. Infrastructures 2018, 3, 42. https://doi.org/10.3390/infrastructures3040042

Bhairappanavar S, Liu R, Coffman R. Beneficial Uses of Dredged Material in Green Infrastructure and Living Architecture to Improve Resilience of Lake Erie. Infrastructures. 2018; 3(4):42. https://doi.org/10.3390/infrastructures3040042

Chicago/Turabian StyleBhairappanavar, Shruti, Rui Liu, and Reid Coffman. 2018. "Beneficial Uses of Dredged Material in Green Infrastructure and Living Architecture to Improve Resilience of Lake Erie" Infrastructures 3, no. 4: 42. https://doi.org/10.3390/infrastructures3040042

APA StyleBhairappanavar, S., Liu, R., & Coffman, R. (2018). Beneficial Uses of Dredged Material in Green Infrastructure and Living Architecture to Improve Resilience of Lake Erie. Infrastructures, 3(4), 42. https://doi.org/10.3390/infrastructures3040042