Composites for Timber-Replacement Bearers in Railway Switches and Crossings

Abstract

:1. Introduction

2. Materials and Methods

- Extra length of timber bearers in comparison with standard sleepers;

- Centrifugal forces through curved pairs of rails;

- Forces and bending moments induced from points, motors, and other signaling equipment;

- Impact forces induced by wheel-rail interaction;

- Mechanical rail joints (maximum spacing of bearers is 600 mm);

- P0 = Vehicle static wheel load (kN)

- Mu = Vehicle unstrung mass per wheel (kg)

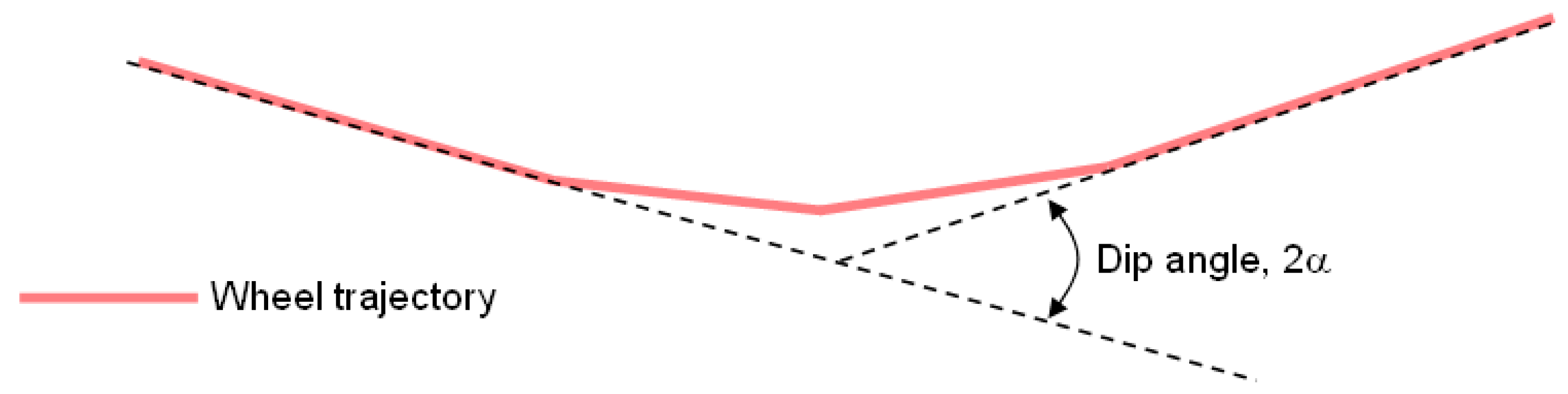

- 2α = Total joint angle or equivalent dip angle (rad)

- v = Vehicle velocity (m/s)

- Kt = Equivalent track stiffness (MN/m)

- Ct = Equivalent track damping (kNs/m)

- Mt = Equivalent track mass (kg)

3. Materials Sensitivity

3.1. Timber

3.2. Concrete

3.3. Steel

3.4. Plastic, Polymer, and Composites

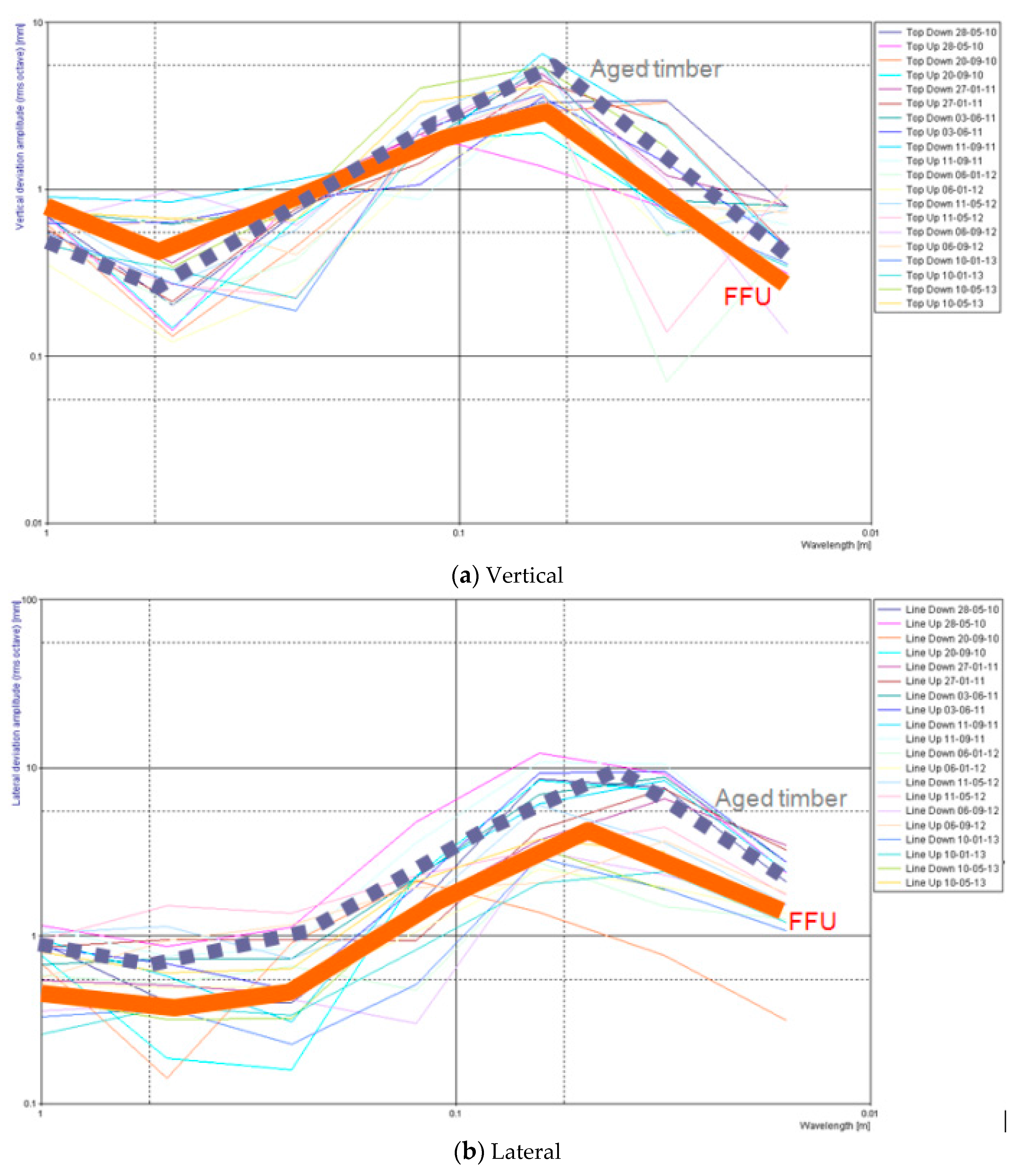

4. Review of a Practical Case Study

5. Carbon Footprint

6. Georisk

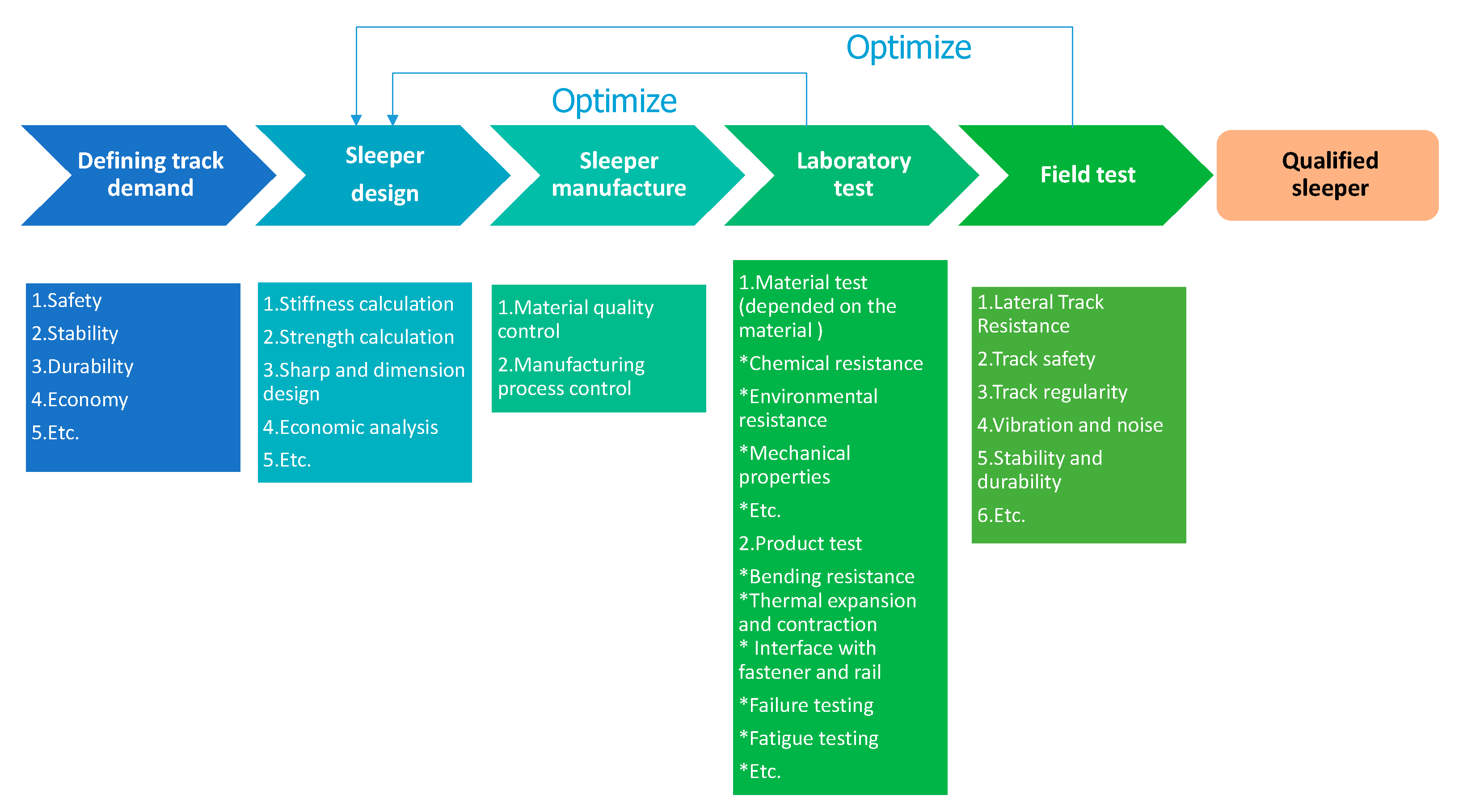

7. Systems Requirements

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kaewunruen, S. Acoustic and dynamic characteristics of a complex urban turnout using fibre-reinforced foamed urethane (FFU) bearers. In Proceedings of the 2013 International Workshop on Railway Noise, Uddevalla, Sweden, 9–13 September 2013. [Google Scholar]

- Kaewunruen, S. Monitoring in-service performance of fibre-reinforced foamed urethane material as timber-replacement sleepers/bearers in railway urban turnout systems. Struct. Monit. Maint. 2014, 1, 131–157. [Google Scholar]

- Kaewunruen, S. In situ performance of a complex urban turnout grillage system using fibre-reinforced foamed urethane (FFU) bearers. In Proceedings of the 10th World Congress on Rail Research, Sydney, Australia, 25–28 November 2013. [Google Scholar]

- Kaewunruen, S. Monitoring structural deterioration of railway turnout systems via dynamic wheel/rail interaction. Case Stud. Nondestr. Test. Eval. 2014, 1, 19–24. [Google Scholar] [CrossRef]

- Indraratna, B.; Salim, W.; Rujikiatkamjorn, C. Advanced Rail Geotechnology—Ballasted Track; CRC Press/Balkema: Leiden, The Netherlands, 2011. [Google Scholar]

- Remennikov, A.M.; Kaewunruen, S. A review of loading conditions for railway track structures due to train and track vertical interaction. Struct. Control Health Monit. 2007, 15, 207–234. [Google Scholar] [CrossRef]

- Standards Australia. Australian Standards: AS3818.2 Timber; Standards Australia: Sydney, Australia, 2001. [Google Scholar]

- RailCorp. Timber Sleepers & Bearers; Engineering Specification SPC 231; RailCorp: Sydney, Australia, 2012. [Google Scholar]

- Kaewunruen, S.; Remennikov, A.M. Dynamic flexural influence on a railway concrete sleeper in track system due to a single wheel impact. Eng. Fail. Anal. 2009, 16, 705–712. [Google Scholar] [CrossRef]

- Sekisui Co. Engineering Properties of FFU Materials; Sekisui Co.: Tokyo, Japan, 2012. [Google Scholar]

- Kaewunruen, S. Review of Alternative Fibre-Reinforced Foamed Urethane (FFU) Material for Timber-Replacement Turnout Bearers; Technical Report TR162; RailCorp: Sydney Australia, 2011. [Google Scholar]

- Kaewunruen, S. In-Situ Performance of Alternative Fibre-Reinforced Foamed Urethane (FFU) Material for Timber-Replacement Turnout Bearers; Technical Report TR188; RailCorp: Sydney Australia, 2011. [Google Scholar]

- Kaewunruen, S. Vertical and Lateral Stability Performance of Alternative Fibre-Reinforced Foamed Urethane (FFU) Material for Timber-Replacement Turnout Bearers; Technical Report TR197; RailCorp: Sydney Australia, 2012. [Google Scholar]

- Jenkins, H.H.; Stephenson, J.E.; Clayton, G.A.; Morland, J.W.; Lyon, D. The effect of track and vehicle parameters on wheel/rail vertical dynamic forces. Railw. Eng. J. 1974, 3, 2–16. [Google Scholar]

- CarbonLoc Pty Ltd. Comparison of Engineering Properties of Composite Materials for Sleepers; CarbonLoc Pty Ltd.: Toowoomba, Australia, 2014. [Google Scholar]

- Kreso, S.; Mirza, O.; He, Y.; Makin, P.; Kaewunruen, S. Field investigation and parametric study of greenhouse gas emissions from railway plain-line renewals. Transp. Res. D Transp. Environ. 2016, 42, 77–90. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Remennikov, A.M. Current state of practice in railway track vibration isolation: An Australian overview. Aust. J. Civ. Eng. 2016, 14, 63–71. [Google Scholar] [CrossRef]

- Dindar, S.; Kaewunruen, S.; An, M. Identification of Appropriate Risk Analysis Techniques for Railway Turnout Systems. J. Risk Res. 2016. [Google Scholar] [CrossRef]

- Pen, L.L. Track Behaviour: The Importance of the Sleeper to the Ballast Interface. Ph.D. Thesis, University of Southampton, Southampton, UK, 2008. [Google Scholar]

- Esveld, C. Modern Railway Track; MRT-Productions: Zaltbommel, The Netherlands, 2001. [Google Scholar]

- Chandra, S.; Agarwal, M. Railway Engineering; Oxford University Press: Oxford, UK, 2007. [Google Scholar]

- Xiao, S.; Lin, H.; Shi, S.; Cai, L. Optimum processing parameters for wood-bamboo hybrid composite sleepers. J. Reinf. Plast. Compos. 2014, 33, 2010–2018. [Google Scholar] [CrossRef]

- Sadeghi, J.; Barati, P. Comparisons of the mechanical properties of timber, steel and concrete sleepers. Struct. Infrastruct. Eng. 2010, 8, 1–9. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Lewandrowski, T.; Chamniprasart, K. Dynamic responses of interspersed railway tracks to moving train loads. Int. J. Struct. Stab. Dyn. 2017. [Google Scholar] [CrossRef]

- Manalo, A. Behaviour of Fibre Composite Sandwich Structures: A Case Study on Railway Sleeper Application. Ph.D. Thesis, Centre of Excellence in Engineered Fibre Composites Faculty of Engineering and Surveying University of Southern Queensland Toowoomba, Queensland, Australia, 2011. [Google Scholar]

- Li, D.; Selig, E. Evaluation of railway subgrade problems. Transp. Res. Rec. 1995, 1489, 17. [Google Scholar]

- Tata Steel. Steel Sleepers, 1st ed.; Tata Steel Europe Ltd.: Brockhurst Cres, Walsall, UK, 2014; Available online: http://www.tatasteeleurope.com/file_source/StaticFiles/Business_Units/Rail/Steel%20sleepers.pdf (accessed on 9 August 2016).

- Health and Safety Executive. Rail Track and Associated Equipment for Use Underground in Mines. 2007. Available online: http://www.hse.gov.uk/pubns/mines06.pdf (accessed on 5 August 2016).

- European Federation of Railway Trackworks Contractors. Newsletters EFRTC. 2007. Available online: http://www.efrtc.org/htdocs/newsite/newsletters.htm (accessed on 24 July 2016).

- Van Erp, G.; McKay, M. Recent Australian Developments in Fibre Composite Railway Sleepers. Electron. J. Struct. Eng. 2013, 13, 62–66. [Google Scholar]

- Bastos, P. Análise Experimental de Dormentes de Concreto Protendido Reforçados com Fibras de aço; Doutor em Engenharia de Estruturas, Universidade de São Paulo: São Paulo, Brazil, 1999. [Google Scholar]

- Griffin, D.W.P.; Mirza, O.; Kwok, K.; Kaewunruen, S. Finite element modelling of modular precast composites for railway track support structure: A battle to save Sydney Harbour Bridge. Aust. J. Struct. Eng. 2015, 16, 150–168. [Google Scholar] [CrossRef]

- Lampo, R. Recycled Plastic Composite Railroad Crossties; Construction Innovation Forum US Army ERDC-CERL: Champaign, IL, USA, 2002. [Google Scholar]

- Griffin, D.; Mirza, O.; Kwok, K.; Kaewunruen, S. Composite slabs for railway construction and maintenance: A mechanistic review. IES J. A Civ. Struct. Eng. 2014, 7, 243–262. [Google Scholar]

- Bilec, M.; Ries, R.; Matthews, H.; Sharrard, A. Example of a Hybrid Life-Cycle Assessment of Construction Processes. J. Infrastruct. Syst. 2006, 12, 207–215. [Google Scholar] [CrossRef]

- Crawford, R. Greenhouse Gas Emissions Embodied in Reinforced Concrete and Timber Railway Sleepers. Environ. Sci. Technol. 2009, 43, 3885–3890. [Google Scholar] [CrossRef] [PubMed]

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Kaewunruen, S.; Paes Cortes Lopes, L.M.; Papaelias, M.P. Influences of sleeper/crosstie material choices on Georisks in railway systems under climate uncertainties. In Proceedings of the CESARE17 Coordinating Engineering For Sustainability and Resilience, Jordan University of Science and Technology, Dead Sea, Amman, Jordan, 3–8 May 2017. [Google Scholar]

- Zhao, J.; Chan, A.H.C.; Burrow, M.P.N. Reliability analysis and maintenance decision for railway sleepers using track condition information. J. Oper. Res. Soc. 2007, 58, 1047–1055. [Google Scholar] [CrossRef]

- Kaewunruen, S. Experimental and Numerical Studies for Evaluating Dynamic Behaviour of Prestressed Concrete Sleepers Subject to Severe Impact Loading. Ph.D. Thesis, University of Wollongong, Wollongong, Australia, 2007. [Google Scholar]

- European Committee for Standardization (CEN). Railway Applications. Track. Concrete Sleepers and Bearers. Part 1: General Requirements; European Standard EN 13230–1; CEN: Brussels, Belgium, 2016. [Google Scholar]

- European Committee for Standardization (CEN). Railway Applications. Track. Concrete Sleepers and Bearers. Part 2: Prestressed Monoblock Sleepers; European Standard EN 13230–2; CEN: Brussels, Belgium, 2016. [Google Scholar]

- European Committee for Standardization (CEN). Railway Applications. Track. Concrete Sleepers and Bearers with under Sleeper Pads; European Standard EN 16730; CEN: Brussels, Belgium, 2016. [Google Scholar]

- Ferdous, W.; Manalo, A.; Aravinthan, T.; Van Erp, G. Composite railway sleepers: New developments and opportunities. In Proceedings of the 11th International Heavy Haul Association Conference: Operational Excellence (IHHA 2015), Perth, Australia, 21–24 June 2015. [Google Scholar]

- Ferdous, W.; Manalo, A.; Van Erp, G.; Aravinthan, T.; Kaewunruen, S.; Remennikov, A.M. Composite railway sleepers—Recent developments, challenges and future prospects. Compos. Struct. 2015, 134, 158–168. [Google Scholar] [CrossRef]

- You, R.; Silva, E.A.; Kaewunruen, S. Methodologies for designing railway plastic and composite sleepers. Chin. J. Railw. Eng. 2017, in press. [Google Scholar]

- Vu, M.; Kaewunruen, S.; Attard, M. Nonlinear 3D finite element modeling for structural failure analysis of concrete sleepers/bearers at an urban turnout diamond. In Handbook of Materials Failure Analysis with Case Studies from the Chemicals, Concrete and Power Industries; Butterworth-Heinemann: Oxford, UK, 2016; Chapter 6; pp. 123–160. ISBN 97-0-08-100116-5. [Google Scholar]

- Gamage, E.K.; Kaewunruen, S.; Remennikov, A.M.; Ishida, T. Toughness of Railroad Concrete Crossties with Holes and Web Openings. Infrastructures 2017, 2, 3. [Google Scholar] [CrossRef]

- Gamage, E.K.; Kaewunruen, S.; Remennikov, A.M.; Ishida, T. Reply to Giannakos, K. Comment on: Toughness of Railroad Concrete Crossties with Holes and Web Openings. Infrastructures 2017, 2, 5. [Google Scholar] [CrossRef]

- Silva, E.A.; Pokropski, D.; You, R.; Kaewunruen, S. Comparison of structural design methods for railway composites and plastic sleepers and bearers. Aust. J. Struct. Eng. 2017. accepted. [Google Scholar]

- Nagafuji, T.; Abe, N. Fifteen Years’ Experience with Synthetic Sleeper. RTRI Rep. 1997, 11, 43–48. (In Japanese) [Google Scholar]

- Oikawa, Y. Evaluation of FFU Sleeper installed in Track for 30 years. J. Jpn. Railw. Civ. Eng. Assoc. 2012, 50–58, 41–44. (In Japanese) [Google Scholar]

- You, R.; Li, D.; Ngamkhanong, C.; Janeliukstis, J.; Kaewunruen, S. Fatigue life assessment methods for railway prestressed concrete sleepers. Front. Built Environ. 2017. accepted. [Google Scholar]

- Kaewunruen, S.; Sussman, J.M.; Matsumoto, A. Grand Challenges in Transportation and Transit Systems. Front. Built Environ. 2016, 2, 4. [Google Scholar] [CrossRef]

| Group | Common Name | Scientific Name |

|---|---|---|

| Group 1 | Ironbark Grey | E. Siderophloia |

| Ironbark Grey | E Paniculata | |

| Ironbark Grey | E Drepanophylla | |

| Ironbark Red (broad leaved) | E Fibrosa | |

| Ironbark Red (narrow leaved) | E Creba | |

| Ironbark Red | E Sideroxylon | |

| Gum Slaty or Box Slaty | E Dawsonil | |

| Box White | E Albens | |

| Group 2 | Box Grey | E Microcarpa |

| Box Grey | E Moluccana | |

| Tallow wood | E Microcorys | |

| Gum Grey | E Punctata | |

| Gum Grey | E Propinqua | |

| Gum Forest Red | E Tereticornis | |

| Mahogany White | E Acmeniodies |

| Cross Section (mm) | Application | Standard Timber Lengths Supporting Turnouts and Crossovers (m) |

|---|---|---|

| 250 × 180 * | General | 2.8, 3.0, 3.2, 3.4, 3.6, 3.8, 4.0, 4.2, 4.4, 4.6, 4.8, 5.0, 5.2, 5.4, 5.8, 6.0, 6.2, 6.4 |

| 250 × 200 * | Points (motor) | 2.8, 3.0, 3.2, 3.4, 3.6, 3.8, 4.0, 4.2, 4.8, 5.0, 5.2 |

| Properties [24] | Australian Hardwood Bearers 1 | Birch (Softwood) Bearers 2 | FFU Bearers [3] | |||

|---|---|---|---|---|---|---|

| New | After 10 Years | After 15 Years | After 30 Years | |||

| Service life (years) | 5–10 | 5–10 | 50 | 40 | 35 | 20 |

| Density (kg/m3) | 1050–1120 | 750 | 740 | 740 | 740 | 740 |

| Bending strength (MPa) > 70 | 65 | 80 | 142 | 125 | 131 | 116 |

| Vertical compression strength (MPa) > 40 | 60 | 40 | 58 | 66 | 63 | 55 |

| Shear strength (MPa) > 7 | 6.1 | 12 | 10 | 9.5 | 9.6 | 7 |

| Elastic modulus (MPa) > 6000 | 16,000 | 7100 | 8100 | 8044 | 8788 | 8414 |

| Fatigue flexural strength | 50,000 cycles at 40 MPa | 50,000 cycles at 40 MPa | 1 million cycles at 94 MPa | |||

| Hardness (MPa) | 10 | 17 | 28 | 25 | 17 | |

| Water absorption (mg/cm2) < 10 | 137 | 137 | 3.3 | 3.3 | 3.3 | 3.3 |

| Impact bending strength (MPa) | ||||||

| @ 20 °C | - | 20 | 41 | - | - | - |

| @ −20 °C | - | 8 | 41 | - | - | - |

| Destructive voltage (kV) | ||||||

| - dry (>20,000) | 8 | 8 | >25 | >25 | >25 | >25 |

| - wet (>20,000) | <1 | <1 | 22 | 24 | 23 | 25 |

| Insulation resistance (Ω) | ||||||

| - dry (>1.0 × 104) | 6.6 × 107 | 6.6 × 107 | 1.6 × 1013 | 2.1 × 1012 | 3.6 × 1012 | 8.2 × 1011 |

| - wet (>1.0 × 104) | 5.9 × 104 | 5.9 × 104 | 1.4 × 108 | 5.9 × 1010 | 1.9 × 109 | - |

| Dog spike pull-out strength (kN) > 15 | 25 | 25 | 28 | 28 | 23 | 22 |

| Screw spike pull-out strength (kN) > 30 | 40 | 43 | 65 | 39 | 44 | 33 |

| Properties | Axion | Carbonloc |

|---|---|---|

| Flexural Strength | 20.6 MPa | 70 MPa |

| Modulus of Elasticity | 1724 MPa | 5000 MPa |

| Shear Strength | 7.5 MPa | 15 MPa |

| Compression perpendicular to grain | 8.2 MPa | 50 MPa |

| Average Flame Spread Index | 147.43 | 0 |

| Smoke Density Dmax | 16.9 | 1 |

| Material | Service Life (Years) | Material | Service Life (Years) |

|---|---|---|---|

| Timber | 15–25 [17] | Steel | 20–30 [17] |

| Concrete | 50 [17] | Plastic/Polymer | over 50 [14] |

| Climate Impact Group | Risks | Safety Impact | Performance Impact | Likely Negative Impact from Climate Change | Long or Short Term | Influence of Sleepers |

|---|---|---|---|---|---|---|

| Sea Level Rise | Increased flooding generally | High | High | High | Long | ● Regarding the design of the track bed, the load distribution pattern at the sleeper/ballast interface is a parameter of critical importance since it is a major function of the sleeper smoothly distributes the loads imposed on it by rails to the subsequent layers. ● The formation is often damaged by excessive moisture content especially when flooding occurs after rains. Concrete sleepers tend to cause formation failure quicker than other sleepers because they are often used in a heavier operation, resulting in a higher bearing pressure. Therefore, if formation is undermined by water, it is highly likely that such track will fail even though it looks perfect from the top view. ● Reconstruction of track formation and foundation is required if damage occurs. ● Ballast-sleeper interaction will be negatively affected by incompressible fluid stagnant on tracks. For timber sleepers softened by moisture content, the ballast can further damage the soffit of the sleepers and the ballast-sleeper interlocking can be impaired. ● For steel sleepers, supporting ballast can be easily washed away from the climate effect (due to relatively less lateral friction between ballast and steel sleepers). |

| Increased Rainfall | Settlement | Medium | High | Low | Long | Need to monitor the ground movement and the relationship with rainfall intensity. Settlement under heavy haul track is usually accelerating higher. However, deteriorated timber sleepers by moisture content can lose the vertical stiffness and yield excessive deformation and higher total settlement. Ballast voids and pockets could be expected under timber and steel sleepers. Due to their relatively lightweight, the dancing and hanging sleepers can further impose detrimental impact loading conditions on ballast and formation. |

| Increased Rainfall | Stability | High | High | High | Long | Embankment, rock cutting, earth cuttings and culverts are at risk of being instable, disregarding of any type of sleepers. |

| Heat | Track buckling | High | High | High | Long | ● Sleepers have the major role of providing satisfactory lateral resistance to avoid lateral movements of rails. If the lateral forces overcome the lateral resistance of sleepers, rail buckling may occur. In fact, timber and steel sleepers perform poorly laterally under elevated temperature. ● The elevated temperature can increase ballast dilation and curve pull-out on curved track. Tracks with steel and timber sleepers are prone to buckling and large lateral movement. With large sideway movement, the timber and steel sleepers tend to hang on the rail without support from ballast. The hanging sleepers will aggravate sleeper-ballast interaction and impose aggressive impact loading on railway tracks, failing track components and formation. |

| Increased Rainfall | Geotechnical Failure | Medium | High | High | Long | ● Cyclic stresses are a major concern for the stability of the subgrade. Repeated traffic overloads are related with many subgrade problems, being the progressive shear failure and excessive plastic deformation some of the causes of formation failure most commonly found in railways around the world. The differential local track stiffness would aggravate the impact loading at sleeper-ballast interface and further damage the tracks. Furthermore, the overstress can wear the superficial soil of the subgrade that combined with water form mud. More than the weakening of the soil, this mud under repeated loads can pumps into the ballast and damage the drainage of the track (using any type of sleepers). Fine-grained soils, as clays, are usually more susceptible to these failures modes. ● Timber sleepers are often decayed with high moisture content. ● Steel sleepers can be oxidized at higher level. Steel sleepers can aggravate the ballast conditions and incur ballast dilations induced by fluid flow. |

| Cold Snap | Damage | Medium | High | Medium | Short | ● Steel, plastic and resin in composite sleepers become very brittle in very low temperature. These sleepers could be damaged by ice-stiffened tracks, resulting in excessive groundborne noise and vibration. ● Freeze-thaw effects can cause concrete sleeper damage. ● Ice-stiffening can cause ballast dilation, cracking subballast, cracking formation, and frozen rail joints. ● Icing can also cause frozen rubber/under sleeper pad/under ballast mat. ● Due to their lightweights, timber and steel sleepers could not sufficiently restore lateral track stiffness in cold temperature and could result in the curve pull-in. Then, the hanging timber and steel sleepers can increase dynamic effects on sleeper-ballast-formation interaction, and could lead to excessive ballast dilation, poor track geometry and unbalanced track loading (causing low rail to damage formation further). |

| Track Category | Common Usage | Typical Axle Load | Typical Maximum Speed | Typical Rail Section |

|---|---|---|---|---|

| TC1 | Urban light rail and some Industrial track | Between 100 kN and 130 kN | 100 km/h | 49E1 |

| TC2 | Urban light rail and some Industrial track | 160 kN | 140 km/h | 54E1 |

| TC3 | Conventional main line railways | 225 kN | 200 km/h | 60E1 |

| High speed railways | 200 kN | 320 km/h | 60E1 | |

| TC4 | Mixed traffic line | 300 kN | 200 km/h | 60E1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaewunruen, S.; You, R.; Ishida, M. Composites for Timber-Replacement Bearers in Railway Switches and Crossings. Infrastructures 2017, 2, 13. https://doi.org/10.3390/infrastructures2040013

Kaewunruen S, You R, Ishida M. Composites for Timber-Replacement Bearers in Railway Switches and Crossings. Infrastructures. 2017; 2(4):13. https://doi.org/10.3390/infrastructures2040013

Chicago/Turabian StyleKaewunruen, Sakdirat, Ruilin You, and Makoto Ishida. 2017. "Composites for Timber-Replacement Bearers in Railway Switches and Crossings" Infrastructures 2, no. 4: 13. https://doi.org/10.3390/infrastructures2040013

APA StyleKaewunruen, S., You, R., & Ishida, M. (2017). Composites for Timber-Replacement Bearers in Railway Switches and Crossings. Infrastructures, 2(4), 13. https://doi.org/10.3390/infrastructures2040013