Abstract

Phosphogypsum, a by-product of phosphate fertilizer production, was predominantly used as a supplementary additive in recycled construction materials. However, there are few detailed studies on utilizing phosphogypsum as the primary component in inorganic cementing materials while achieving cost-effective detoxification. This study aimed to develop a harmless phosphogypsum-based inorganic cementing material (PICM) mainly based on phosphogypsum, in which cement, quicklime, and a stabilizer were used as additives. Harmful ions and acidity were first detected through X-ray fluorescence and ion chromatography and then harmlessly treated with quicklime. Compaction parameters, mechanical performance, X-ray diffraction analysis, moisture, and freezing resistance were characterized successively. The results illustrated that fluoride and phosphate ions were the primary soluble contaminants, whose leaching solution concentration can be reduced to 15.31 mg/L and undetectable with 2% quicklime through the mass proportion of phosphogypsum added and mixed. Meanwhile, the corresponding pH value was also raised to over 8. Cement content and quicklime were positively correlated with PICM’s maximum dry density. PICM with 25% cement and 2.5% stabilizer presented the highest unconfined compression strength, and flexural strength did not show significant regularity. PICM was mainly composed of quartz, gypsum, ettringite, and calcite, whose content decreased as cement content and quicklime content increased. Stabilizer, quicklime and cement content were positively correlated with PICM’s freezing and moisture resistance.

1. Introduction

The utilization of solid waste as a substitute for natural mineral material in construction has advantages, such as environmental friendliness, energy efficiency, and greater cost-effectiveness. This issue is becoming increasingly urgent, with continuous mining of natural aggregates and the increasing accumulation of solid waste. Bulk solid waste produced as a result of industrial production has been maturely applied in engineering, such as fly ash [1], steel slag [2] and blast furnace slag, which are usually used as building materials. They are mainly used as modifiers [3], stabilizers [4], fillers [5], and cementitious materials [6], which can be used in roads [7], backfill [8,9], tunnels [10,11], and buildings. However, certain solid wastes may present environmental risks through the potential leaching of hazardous substances. Therefore, the harmless assessment and treatment of toxic substances in solid waste before they are recycled have been important procedures in the context of sustainable development. For instance, steel slag, blast furnace slag, and coal gangue [12], which can be employed to fabricate rejuvenated concrete, sinter brick, and cementing material, may release some heavy metal ions [13], such as Cr, Pb, Mn, etc. These solid wastes are predominantly employed as additives or partial replacements in construction materials in small amounts, owing to concerns about their performance defects and environmental hazards. Expanding their use as primary components in building materials through addressing their toxic and property issues could significantly accelerate waste recycling efforts. The recycling of solid wastes could be accelerated if they are used as the main component in building materials.

Phosphogypsum [14,15] refers to the powdery substance generated in the wet processes of the phosphoric acid industry. The main component of phosphogypsum is CaSO4·2H2O, while the remaining few substances are generally fluorides, soluble phosphides, heavy metal ions and other minerals [16] that are toxic to the natural environment and humans. Therefore, addressing the pollution risk of phosphogypsum has been regarded as a prerequisite for large-scale application. The conventional method for eliminating harmful impurities is calcination [17,18]. Cao [19] discussed the effect of the calcination temperature on the recycling of phosphogypsum. The results suggested that calcination at high temperatures converted harmful impurities into inert insoluble calcium pyrophosphate, calcium metaphosphate, calcium fluoride, and sodium sulfate. However, the high-temperature calcination process resulted in a sharp increase in costs; thus, adopting a more low-carbon and economical approach is the key issue for phosphogypsum application in actual construction. Wu [20] reported that toxic substances of phosphogypsum are generally phosphate, fluoride, and heavy metals. A harmless treatment technology through the addition of calcium carbide slag, polymeric ferric sulfate or polymeric aluminum chloride presented an adequate purification effect. Shu [21] developed an environmentally safe treatment for removing Mn2+, NH4+ , F−, and PO43− pollutants in phosphogypsum leachate wastewater through the combined use of iron-rich electrolytic manganese residue and an electric field. These results suggested that it is feasible to suppress harmful substances in the absence of high-temperature treatment. Therefore, achieving the large-scale application of phosphogypsum while ensuring economic and environmentally friendly development is of great significance for the sustainable development of the building materials industry.

The recycling of phosphogypsum as a raw material instead of natural mineral resources in construction is an effective way to reduce pollution and energy consumption [22]. Large quantities of phosphogypsum can be effectively consumed when it is incorporated into concrete, cementitious, and stabilized materials. Kumar [23] reported the suitability of a fly ash–lime–phosphogypsum-based composite material, which presented adequate unconfined compressive strength, split tensile strength, and slake durability as a base/subbase course material in road pavement in America. Min [24] developed Ca(OH)2-pretreated phosphogypsum as an aggregate applied in underground mining backfill construction. It proved that phosphogypsum can be used as the main component of construction materials after adequate treatment. Ou [25] and Dong [26] investigated the possibility of replacing mineral powder with treated phosphogypsum as a filler in asphalt mixtures. The results implied that asphalt mastic can be physically hardened using phosphogypsum as a filler. Fu proposed a phosphogypsum-based composite cementitious material whose unconfined compression strength reached 35 MPa after 180 days of curing [27]. On the other hand, phosphogypsum whiskers were also employed as a modifier of asphalt [28], which was found to improve the rigidity, uniformity, viscosity, and high-temperature performance of asphalt binder. However, these applications exhibit limited demand for phosphogypsum, leading to low consumption efficiency.

This study aimed to develop a cementitious material with phosphogypsum as the primary component, contrasting with existing materials that generally utilize it as a minor additive. The detection and inhibition of the harmful soluble ions as well as the acidity of phosphogypsum were first examined and discussed. Phosphogypsum-based cementitious materials consisted of phosphogypsum, P.O 42.5 cement, quicklime and stabilizer, designed and prepared after a harmless treatment. The mechanical performance and composition variation of the material were eventually characterized, indicating the influence of material composition on its properties.

2. Materials and Methodology

2.1. Materials

2.1.1. Phosphogypsum

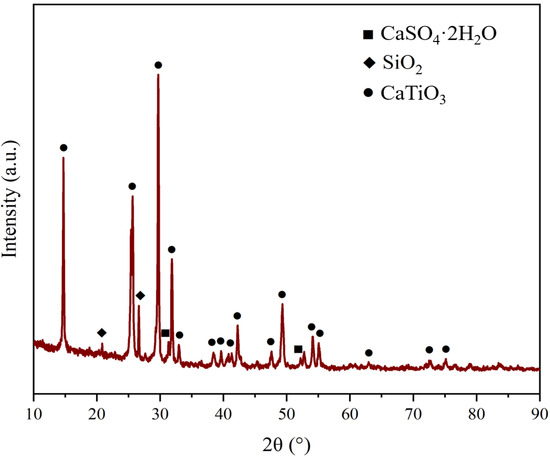

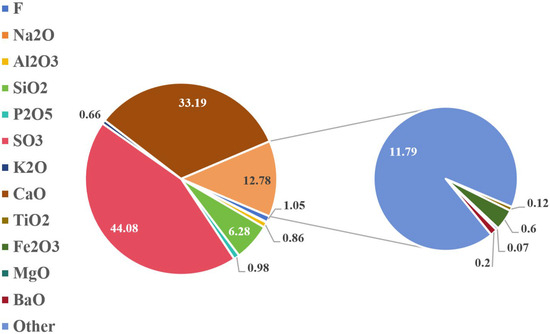

Phosphogypsum used in this study came from Xiaogan City, Hubei Province, China, with an exposure time in natural environment of over 24 months. Phosphogypsum in natural environments often appears as a gray powder, as presented in Figure 1. Figure 2 shows X-ray diffraction (XRD) spectrogram of phosphogypsum. It indicates that calcium sulfate dihydrate (CaSO4 • 2H2O) is the main component of phosphogypsum, accounting for over 90%, while the other typical crystal composition is SiO2 and CaTiO3. Figure 3 illustrates element composition of phosphogypsum introduced in this study by their common forms of oxides. We stored phosphogypsum in a dry environment with a moisture content of 6.5%. Particle size distribution and screening results of phosphogypsum are shown in Table 1, in which 98.1% particle diameter was less than 0.075 mm via mechanical screening of powders according to “Test Methods of Aggregate for High way Engineering (JTG E42-2005)” [29].

Figure 1.

Appearance of phosphogypsum.

Figure 2.

XRD spectrogram of phosphogypsum.

Figure 3.

Element composition of phosphogypsum.

Table 1.

Particle size distribution and screening results of phosphogypsum.

2.1.2. Cement

This study used commercial-grade P.O 42.5 cement produced in Wuhan city, China, as a raw material. It was used as a vital composition of phosphogypsum-based cementitious materials and graded crushed stone. Its performance is shown in Table 2, suggesting it can meet the requirements of specifications (GB175-2023, standard for common portland cement) [30].

Table 2.

Performance of 42.5-grade cement.

2.1.3. Quicklime

Quicklime produced in Wuhan city, China, also known as calcined lime, was mainly composed of CaO and generally obtained by calcining natural calcium carbonate. It was used as an acidic neutralizing agent for phosphogypsum and attempted to dissolve harmful substances in phosphogypsum [31], due to its potential modification and inhibition effects on acidity and harmful ions. Its quantity in phosphogypsum was set from 0% to 2% considering its effect on neutralizing and suppression on harmful ion overflow. Then, it was set as 2% to 5% when preparing the inorganic cementing material. Properties of quicklime are shown in Table 3, which proved that it meets specification of JC/T 479-2013 (standard for building quicklime) [32].

Table 3.

Properties of quicklime.

2.1.4. Stabilizer

This study used a soil stabilizer produced from a factory in Henan province, China, as an additive for cementitious material to enhance early strength. It is a water-based liquid state material that is suitable for being used as a binder or auxiliary material in soil and powder solidification engineering. Table 4 showed properties of stabilizer, which can meet the reference value provided by factory.

Table 4.

Properties of stabilizer.

2.2. Experimental Method

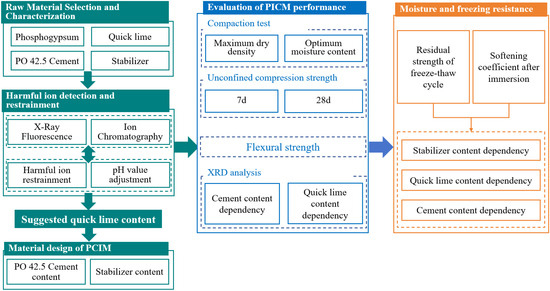

This study can be divided into three parts that are described in Figure 4. Raw materials, like phosphogypsum, quicklime, cement, and stabilizer, were first selected and characterized. X-ray fluorescence and ion chromatography were used to establish harmful substances in phosphogypsum and characterize overflow concentration of harmful ions, respectively. A pH meter was also used to detect pH value of phosphogypsum’s leachate. Harmless treatment was also achieved, in which the optimum content of quicklime was determined according to “Solid waste-extraction procedure for leaching toxicity-horizontal vibration method (HJ 557-2010)” [33]. Phosphogypsum-based inorganic cementing material (PICM) was then designed and prepared based on cement and stabilizer content dependency, in which maximum dry density and optimum moisture content of PICM were tested.

Figure 4.

Outline of this study.

Unconfined compression strength after maintenance time of 7 days and 28 days was characterized, while corresponding flexural strength after 7-day curing was evaluated as well. X-ray powder diffractometer (XRD, Wuhan, China) was used to examine effect of different cement contents and quicklime content on composition of PICM. At last, how contents of stabilizer, quicklime, and cement affect PICM’s moisture durability regarding residual strength of freeze–thaw cycle and softening coefficient after immersion were systemically investigated.

2.2.1. Harmful Ion Concentration and pH Value Characterization

Harmful ion concentration characterization was used to investigate inhibition effect of harmful ions in phosphogypsum so that environmental friendliness of PICM can be guaranteed. Harmful ion concentration characterization was conducted in reference to solid waste determination of fluoride-ion selective electrode method (GB/T 15555.11-1995) [34]. A 25 g sample (phosphogypsum or corresponding mixture of quicklime and phosphogypsum) was put in a volumetric flask containing 250 mL deionized water. Samples should be immersed in deionized water for 12 h to achieve complete soaking. Afterwards, volumetric flasks were put in a box-type constant temperature oscillator for 8 h oscillation, in which oscillation frequency was about 110 times per minute and amplitude was 40 mm. Leaching solution was, thus, obtained, whose solid suspension was then filtered through a vacuum filter. Finally, ion chromatography was used to detect ion concentration of the leaching solution.

Additionally, this study finally selected quicklime, whose mass proportion of CaO was over 90%, to reduce harmful ions and acidity of phosphogypsum. Quicklime was first mixed with phosphogypsum mechanically to prepare the mixture of quicklime and phosphogypsum (Q-P mixture). Leaching solution of Q-P mixture was also prepared to establish effect of quicklime content on inhibition of harmful ion overflow and pH value.

2.2.2. Design and Preparation of PICM

PICM consists of phosphogypsum, cement content, stabilizer, and quicklime (performed as activator), designed and prepared after overflow level of harmful ions was adequately controlled. Table 5 illustrates the designed composition of PICM throughout this study, in which 15 groups of PICM samples were fabricated. Cement, stabilizer, and quicklime were added to phosphogypsum based on their mass proportion to that of phosphogypsum itself. Thereby, cement’s mass proportion of phosphogypsum was 15%, 20%, 25%, while that of stabilizer was 1%, 1.5%, 2%, and 2.5% after trial and error, respectively. For instance, experimental group of 15-1 meant adding 15% cement, 2% quicklime, and 1% stabilizer in phosphogypsum, whose mass proportion was 100%. Experimental group labels from 1 to 12 only indicated cement and stabilizer content since their quicklime contents were 2%. Additionally, groups of 13, 14, and 15, such as 20-1-3, meaning quicklime content was increased to 3%, were labelled with specific quicklime content.

Table 5.

Designed composition of PICM.

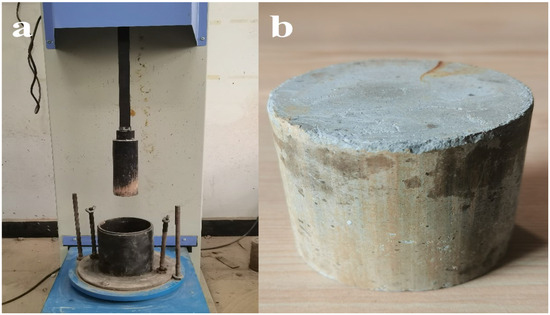

Phosphogypsum, cement, stabilizer, quicklime, and water were manually added and mixed in a specific mold after corresponding optimum moisture contents were determined. Then, the mold with PICM material was set in electric compaction device, presented in Figure 5a. PICM material’s compaction times by driving hammer were set as 27 [35] according to “Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering (JTG E51-2009)” [36], which should be taken out from mold after 24 h when compaction is finished, as Figure 5b shows. The materials, including phosphogypsum, cement, stabilizer, and quicklime, were first mixed in dry state, which were then mixed with water of optimum content for soaking for 6~8 h. After that, a pressure machine was used to statically compact and produce PICM samples, which were a cylinder of Φ50 mm × 50 mm, Φ150 mm × 150 mm and beam sample of 50 mm × 50 mm × 200 mm.

Figure 5.

Electric compaction device (a) and PICM sample (b).

2.2.3. Compaction Parameter Characterization

Compaction parameters refer to optimum moisture and maximum dry density after compaction. Maximum dry density refers to the maximum mass per unit volume of material at optimum moisture content state. Optimum moisture content of PICM as well as common cementitious material should be carefully investigated according to JTG E51-2009 [36] so that the optimal compactness of PICM can be achieved. During the experiment, pretreated PICM samples were mixed with water at different estimated water contents; then, they were layered into compaction molds. PICM samples were then compacted using a compaction device with a specified compacting time to simulate compaction process in actual construction. Dry density at different water contents was calculated by measuring the mass and volume of compacted PICM samples, and a relationship curve between dry density and water content was plotted. Peak point on curve represents the maximum dry density of PICM sample and its corresponding optimal water content.

2.2.4. Mechanical Performance Characterization

Mechanical performance, including unconfined compression strength and flexural strength [35], reflected PICM’s resistance to external loading based on the cylinder sample of Φ50 mm × 50 mm and beam specimen of 50 mm × 50 mm × 200 mm, respectively. An electronic universal testing machine was used to provide corresponding loading on PICM sample according to JTG E51-2009. Curing period for unconfined compression strength was set as 7 d and 28 d, and curing temperature was 20 °C ± 2 °C. Meanwhile, curing time for flexural strength was set as 7 d. On the last day of curing, if the specimens showed no wearing and chipping, specimens should be soaked in water of 20 °C ± 2 °C for 24 h.

2.2.5. Moisture and Freezing Resistance Characterization

Softening coefficient test and residual strength of freeze–thaw of PICM were used to assess the moisture and freezing resistance. Immersion group should be put in a water bath with constant temperature at 20 °C for 24 h, so that samples can reach state of saturation. Finally, both unconfined compression strengths of absolute dry and saturated samples were tested. Softening coefficient of PICM was equal to the ratio of unconfined compression strength of absolute dry samples to saturated samples.

In addition, cylindrical samples of Φ150 mm × 150 mm were prepared and divided into frost group and control group. Unconfined compression strengths of PICM samples of control group (Sc) should be tested when their 28-day maintenance is finished, during which the samples should be saturated for at least 24 h. Frost group was placed in a low-temperature chamber for freezing treatment, which was usually frozen for 16 h. Then, the samples were removed and put into a water bath box at 20 °C for melting treatment, whose time was set as 8 h. Then, freeze–thawing process should be repeated and stopped when average mass loss rate of frost group exceeds 5% of their mass. Afterwards, unconfined compression strengths of frost group (Sft) were tested. Ratio of unconfined compression strength of frost group to that of control group (Rfc) was calculated using Equation (1):

where,

- = Ratio of unconfined compression strength of frost group to that of control group, %;

- Unconfined compression strength of control group, MPa;

- = Unconfined compression strength of frost group, MPa.

3. Results and Discussion

3.1. Harmful Ion Detection and Inhibition

3.1.1. Detection of Harmful Ions in Phosphogypsum

Figure 3 indicated that Ca and S were the dominant elements, constituting CaSO4 that was found to be the main crystalline substance in phosphogypsum. In addition, fluorine and phosphorus elements were also found. Soluble fluoride or phosphate ions in phosphogypsum were thought to be an environmentally harmful substance. Therefore, how to reduce their overflow ion concentration when exposed in the natural environment should be carefully treated to guarantee the harmless treatment of phosphogypsum-based material.

On the other hand, phosphogypsum was generally acidic since it was a kind of by-product of the phosphoric acid production industry. The acidity of phosphogypsum negatively affected the hydration reaction of cement [37], including reducing the hydration rate and hydration product amount, which thereby damaged PICM’s strength. To conclude, it suggested that transforming phosphogypsum into alkaline should be finished before preparing PICM.

3.1.2. Inhibition of Harmful Ion Overflow in Phosphogypsum

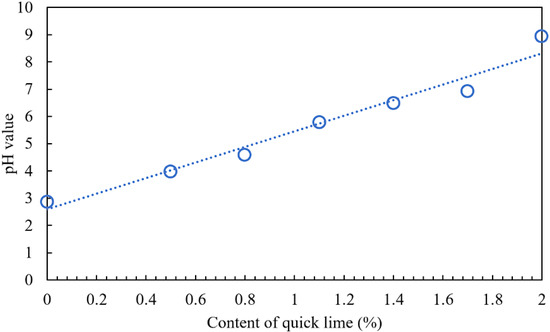

Figure 6 presents the results for the pH value of the leaching solution of the Q-P mixture with different quicklime contents. It is implied that the pH value of the Q-P mixture showed an increasing tendency as the quicklime content rose, while the original pH value of phosphogypsum was 2.60. We found an approximate linear relationship between the quicklime content and pH value. The fitted equation was (pH value) = 2.8627 × (quicklime content, %) + 2.5971, and its coefficient of determination was over 0.96, suggesting its fitting degree was reliable. The corresponding pH value was about 9 when 2% quicklime was introduced, when the Q-P mixture was alkaline and positive for the production of ettringite, which may result in higher density and strength of PICM. Therefore, 2% quicklime was highly recommended considering its high cost and benefits for the production of ettringite by creating an alkaline environment. Table 6 illustrates the concentration of soluble ions in the leaching solution of original and treated phosphogypsum. The concentration of fluoride ions and phosphate ions should not exceed 20 mg/L and 1 mg/L, respectively, according to the comprehensive wastewater discharge standard (GB8978-2002) [38]. Therefore, fluoride ion and phosphate ion concentrations in the leaching solution from the original phosphogypsum failed to meet GB8978-2002, which were 100.45 mg/L and 139.21 mg/L. Nevertheless, the leaching solution of phosphogypsum with 2% quicklime presented fluoride ions of 15.31 mg/L, while phosphate ions were not detected, which can meet the requirement of GB8978-2002. Fluoride ions were eliminated through the chemical reaction of “Ca(OH)2 + 2F− = CaF2↓ + 2OH−”, in which Ca(OH)2 was generated from CaO in quicklime. In addition, phosphate ions were also supposed to be purged due to the reaction of “2PO43− + 3Ca2+ = Ca3(PO4)2↓”. This suggests that the harmless treatment introduced in this study through the addition of 2% quicklime was achieved.

Figure 6.

pH value of Q-P mixture with different quicklime contents.

Table 6.

Concentration of soluble ions in the leaching solution of original and treated phosphogypsum.

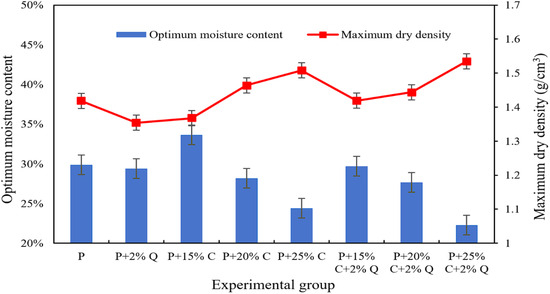

3.2. Compaction Parameter for PICM Preparation

Compaction parameters, including the optimum moisture content and maximum dry density, were systemically characterized. Figure 7 presented the results of the optimum moisture content and maximum dry density of PICM across different experimental groups. Experimental group abbreviations were used, such as “P + 15%C + 2%Q,” which referred to the experimental group of PICM of phosphogypsum, with 15% cement and 2% quicklime, and so forth, while “P” meant original phosphogypsum. It was found that the sample with 2% quicklime showed lower optimum moisture content than that of the sample without quicklime, independent of the cement content. Furthermore, the cement content was positively correlated with PICM samples’ maximum dry density, regardless of the quicklime content. On the contrary, the optimum moisture content illustrated a decreasing tendency as the cement content rose. Higher cement content was proved to develop PICM’s maximum dry density and lower corresponding optimum moisture content. The maximum dry density of P + 25%C + 2%Q was about 0.1 g/cm3 higher than that of P + 20%C + 2%Q, considering that the theoretical density increase, namely before the chemical reaction, was only 0.06 g/cm3 when 5% more cement was added. This suggested that a higher cement content would result in a lower porosity of PICM. Similarly, 2% quicklime was detected to increase the maximum dry density but reduce the optimum moisture content of PICM with cement. The alkalinity enhancement presented in Figure 6 promoted the production of ettringite, which contributed to the higher compactness of PICM.

Figure 7.

Optimum moisture content and maximum dry density of PICM.

3.3. Mechanical Performance

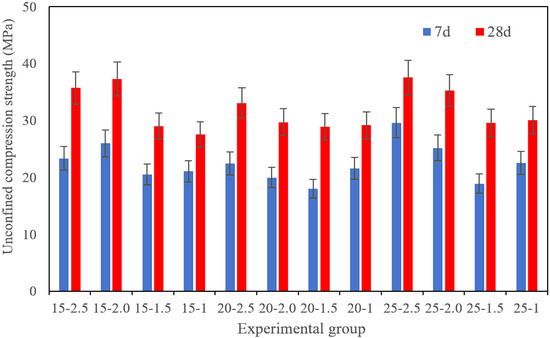

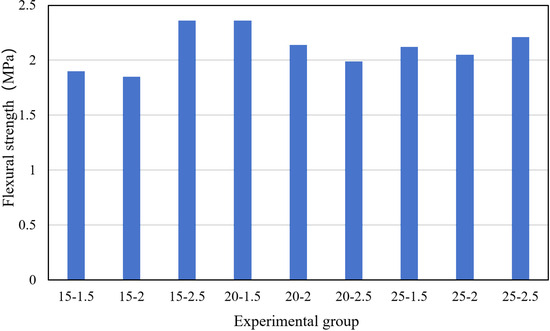

PICM samples were kept in a standard maintainer for cement concrete for 7 and 28 days after their compaction finished. The unconfined compression strength of PICM with different maintenance times is shown in Figure 8. The standard deviation of each result with the same testing parameters was found to range from 0.53 to 2.25, showing adequate statistical significance. Experimental groups were abbreviated, like “15-2.5”, which meant the corresponding PICM composition was 100% phosphogypsum, with 15% cement and 2.5% stabilizer, and so on. It should be emphasized that the quicklime content was 2% for each PICM sample. PICM’s 28 d compression strength was generally over 30 MPa, which can meet the specification limit for the material of affiliated facility of highway according to “Technical Specifications for Construction of Traffic Engineering and Affiliated Facility of Highway Tunnel JTG/T 3661-2025”. It might also be used as a material for temporary or access roads in site and low-grade pavement. Meanwhile, the unconfined compression strength of other phosphogypsum-based cementitious materials, like Shen [39] and Dutta [23] reported, was found to be 8 MPa and 2.2 MPa, respectively. This suggested that the PICM introduced in this study showed much higher strength than typical phosphogypsum-based material. Samples with 25% cement showed higher unconfined compression strength. Higher maximum dry density, as shown in Figure 8, may lead to higher strength. It was obvious that a longer maintenance time would result in higher compression strength, of which PICM with 25% cement and 2.5% stabilizer presented the highest unconfined compression strength, regardless of the maintenance time. It proved that extra stabilizers, which perform as a binder, can further enhance PICM’s strength. The flexural strength results of PICM were also obtained after 7 d maintenance, as implied in Figure 9, and the corresponding standard deviation ranged from 1.92 to 5.32. However, its results did not show significant regularity. To conclude, PICM can be used as a subgrade material or temporary facility material such as access road and auxiliary facility materials in road engineering owing to its adequate strength.

Figure 8.

Unconfined compression strength of PICM at 7 d and 28 d.

Figure 9.

Flexural strength of PICM.

3.4. XRD Analysis

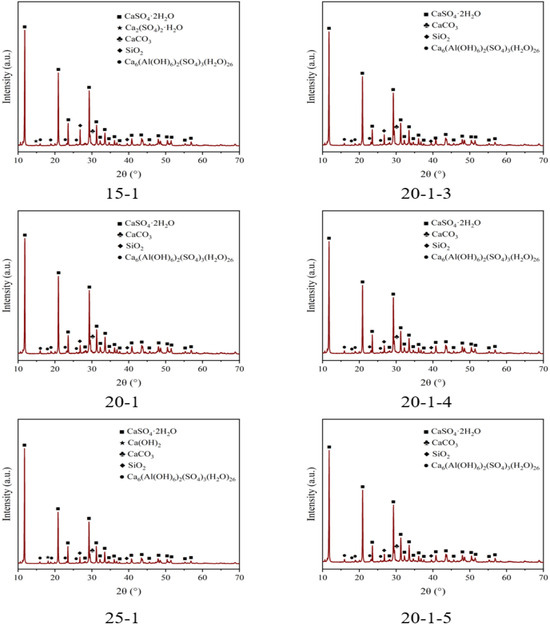

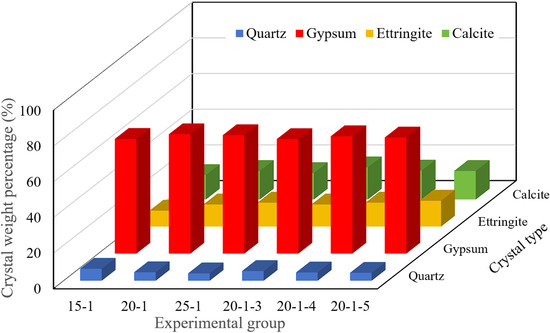

Figure 10 illustrates the X-ray diffraction spectrum of PICM with different compositions after 7-day maintenance. It can be seen from the spectrum that the main composition of PICM was SiO2, CaSO4·2H2O, Ca6(Al(OH)6)2(SO4)3(H2O)26, and CaCO3, namely quartz, gypsum, ettringite, and calcite, respectively. In addition, the 15-2 sample contained 6.4% bassanite (Ca2(SO4)2(H2O)), which was transferred from gypsum and with higher strength. Compared with the 20-2 sample, the 25-2 sample was found to have an extra 1.3% portlandite (Ca(OH)2). Figure 11 presented the composition analyzed from the XRD spectrum. The quartz content illustrated a decreasing tendency as the cement content and quicklime content rose. On the contrary, the ettringite content presented a rising trend when the cement and quicklime content increased. More cement and quicklime created an environment with higher alkalinity, contributing to higher ettringite production, which is usually generated in an alkaline environment. Therefore, PICM’s strength might be enhanced by a greater addition of quicklime since ettringite was of relatively high stiffness. In addition, the quicklime content had a negative effect on the calcite content.

Figure 10.

X-ray diffraction spectrum of PICM.

Figure 11.

PICM composition analyzed via XRD spectrum.

3.5. Moisture and Freezing Resistance

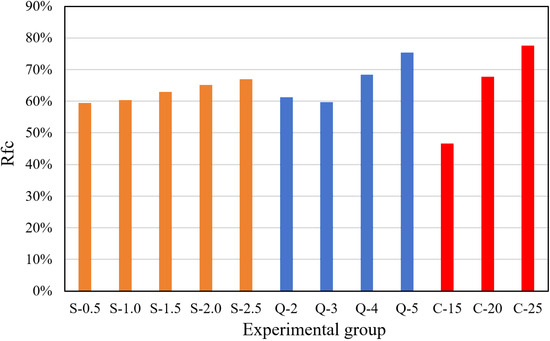

The freezing resistance of PICM in terms of its residual strength after the freeze–thaw process is shown in Figure 12. For instance, S-0.5, Q-2, and C-15 referred to the sample with 0.5% stabilizer, 2% quicklime, and 15% cement, respectively. , the ratio of the unconfined compression strength of the frost group to that of the control group, was used as an indicator to imply the PICM sample’s ability against freezing. PICM’s cement and stabilizer content was 20% and 1% by quicklime and stabilizer content dependency, in which the ratio of residual strength was found to generally increase as the quicklime content rose from 2% to 5%. It was laterally analyzed that a greater addition of quicklime might further fill the void in PICM due to the higher production of ettringite, which resulted in better freezing resistance. Similarly, the stabilizer and cement content also showed a positive relationship with PICM’s when their other material composition was constant. Therefore, a higher content of stabilizer, quicklime and cement can enhance PICM’s freezing resistance.

Figure 12.

result by quicklime, stabilizer and cement content dependency.

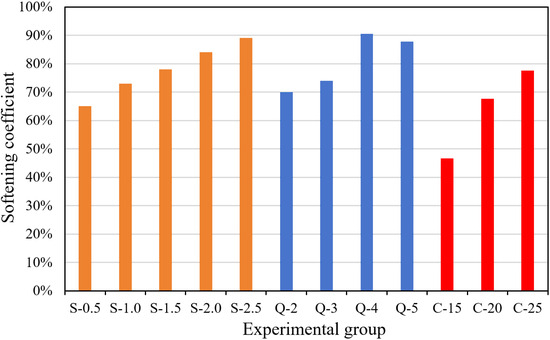

On the other hand, the softening coefficient that reflected PICM’s resistance to moisture, which was vital for its actual application, was investigated. Figure 13 presents the softening coefficient results of PICM by stabilizer, quicklime and cement content dependency, respectively. It can be seen in Figure 13 that an increment in the stabilizer and cement content was able to increase the softening coefficient so that the moisture damage degree was reduced. In addition, the softening coefficient showed a first increasing but then decreasing tendency along with increasing quicklime content, during which it reached the highest value when the quicklime content was 4%. Developing cement content will help to increase the production of ettringite, making PICM denser. A higher content of stabilizer may also fill the void of PICM since it is a good binder with adequate liquidity. However, PICM’s resistance to moisture and freezing investigated in this study was merely examined on samples after 7-day curing. How the curing time affects its resistance as a newly introduced material was not systemically studied, which will be examined in a further study.

Figure 13.

Softening coefficient result by quicklime, stabilizer and cement content dependency.

4. Conclusions

This study developed a phosphogypsum-based inorganic cementing material composed primarily of phosphogypsum, after corresponding harmful substances and acidity were detected and treated. The optimum moisture content, maximum dry density, unconfined compression strength, flexural strength, X-ray diffraction analysis, as well as moisture and freezing resistance, were successively characterized and discussed. Based on the above results, the following conclusions can be drawn.

- 1.

- Fluoride and phosphate ions were found to be potential harmful soluble substances in phosphogypsum, with concentrations in its leachate of 100.45 mg/L and 139.21 mg/L, respectively. These results were over the environmental safety upper limit of the harmful ion concentration in the phosphogypsum overflow solution, suggesting corresponding harmless treatment was required that was thought to be an essential stage before preparing PICM. In addition, the original pH value of the phosphogypsum leaching solution was 2.60. The concentration of fluoride and phosphate ions was found to be 15.31 mg/L and undetectable when 2% quicklime by mass proportion of phosphogypsum was added and mixed as a harmless treatment; meanwhile, the pH value was also raised to 9. Environmental safety through suppressing the leaching of harmful ions from the phosphogypsum-based material was, thus, achieved by adding quicklime. It also provided an alkaline environment that was positive for higher ettringite production during the curing of PICM that might lead to higher stiffness.

- 2.

- The cement content and quicklime dosage were positively correlated with PICM’s maximum dry density and negatively affected the corresponding optimum moisture content. A longer curing time would result in higher compression strength, of which PICM with 25% cement and 2.5% stabilizer presented the highest unconfined compression strength. PICM’s 28 d unconfined compression strength was generally over 30 MPa, which can meet the requirement of materials used in the affiliated facility of the highway. The corresponding flexural strength results exhibited no clear trend.

- 3.

- The main composition of PICM was quartz, gypsum, ettringite, and calcite according to XRD characterization. The quartz content decreased as the cement content and quicklime content rose. The ettringite content presented a reducing trend when the cement and quicklime content increased. The quicklime content had a negative effect on the calcite content. Developing the content of stabilizer, quicklime, and cement can enhance PICM’s freezing and moisture resistance, owing to the denser microstructure of PICM. PICM was thought to be used as material for temporary or access roads, affiliated facility and replacement of cement concrete for rural or low-grade pavement due to its adequate strength and reliable environmental innocuity.

Author Contributions

Conceptualization, H.X. B.G. and Z.F.; methodology, C.D.; software, H.X.; validation, C.D., X.H. and Z.F.; formal analysis, C.D.; investigation, H.X., H.W. B.G. and Y.M.; resources, H.G.; data curation, H.X.; writing—review and editing, H.X. and Z.F.; visualization, C.D.; supervision, X.H. B.G. and Z.F.; project administration, H.X., H.W. and J.W.; funding acquisition, J.W. and H.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Project of China State Construction Railway Investment and Engineering Group Co., Ltd. (No. CSCECZJTT-2022-09).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors are grateful for the financial support from the Science and Technology Project of China State Construction Railway Investment and Engineering Group Co., Ltd. (No.CSCECZJTT-2022-09), National Natural Science Foundation of China (No. 52108414), Science and Technology Project of Hubei Provincial Department of Transportation (No. 2023-121-1-6), and the Scientific Research Starting Foundation of Wuhan Institute of Technology (No. K202021).

Conflicts of Interest

H.H., C.D. H.W., B.G., Y.M., and H.G. are affiliated with China State Construction Railway Investment and Engineering Group Co., Ltd., and China Construction Third Engineering Bureau Group Co., Ltd. All authors confirm that there is no conflict of interest to declare.

References

- Chen, K.; Dai, S.; Li, J.; Lin, L.; Qin, W.; Gao, Y.; Hu, E.; Jiang, J. Towards circular economy: Sustainable valorization of municipal solid waste incineration fly ash for recovery of high-purity chlorides and calcium, and separation of heavy metals. Environ. Res. 2025, 277, 121536. [Google Scholar] [CrossRef]

- Gu, J.; Wei, C.; Wu, P.; Cao, Z.; Shao, Y.; Liu, X.; Zhang, Z. Application and mechanism analysis of steel slag in resource recovery and environmental remediation: A review. Miner. Eng. 2025, 227, 109268. [Google Scholar] [CrossRef]

- Murali, G.; Azab, M. Recent research in utilization of phosphogypsum as building materials: Review. J. Mater. Res. Technol. 2023, 25, 960–987. [Google Scholar] [CrossRef]

- Yue, H.; Fang, A.; Hua, S.; Gu, Z.; Jia, Y.; Yang, C. Development and Field Application of Phosphogypsum-Based Soil Subgrade Stabilizers. J. Renew. Mater. 2022, 10, 2247–2261. [Google Scholar] [CrossRef]

- Bakker, E.; Soen, H.; van Kempen, M.; van Leest, A.; van der Wegen, G.; Dehaudt, S.; Cheeseman, C. Industrial trials using the mineral fraction of municipal solid waste incinerator bottom ash as a filler in unreinforced concrete products. Prog. Eng. Sci. 2025, 2, 100055. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, W.; Li, X.; Zhu, Z.; Yang, Y.; Sui, Y.; Xu, G. Utilization of oil shale residue from Alberta Taciuk process in phosphogypsum slag cement: Compressive strength, hydration behavior, and microstructural characteristics. J. Build. Eng. 2025, 107, 112771. [Google Scholar] [CrossRef]

- Hyks, J.; Šyc, M.; Korotenko, E.; Cajthaml, T.; Semerád, J.; Hjelmar, O. Leaching of per- and polyfluoroalkyl substances (PFAS) from municipal solid waste incineration bottom ash intended for utilization as secondary aggregates in road subbase. J. Hazard. Mater. 2025, 483, 136635. [Google Scholar] [CrossRef]

- Osemudiamhen, A.E.; Ma, L.; Ngo, I.; Cao, G. Machine learning-driven strength prediction for solid waste-based backfill materials using infrared radiation indices. Infrared Phys. Technol. 2025, 149, 105898. [Google Scholar] [CrossRef]

- Xu, J.; Luo, Q.; Tang, Y.; Zeng, Z.; Liao, J. Experimental Study and Application of Controlled Low-Strength Materials in Trench Backfilling in Suqian City, China. Materials 2024, 17, 775. [Google Scholar] [CrossRef]

- Song, W.; Zha, F.; Zhu, Z.; Xu, L.; Kang, B.; Yang, J.; Pu, S. Freeze-thaw resistance and deterioration mechanism of alkali-activated filling grouts prepared from full industrial solid wastes for tunnels. Mater. Today Commun. 2024, 41, 111009. [Google Scholar] [CrossRef]

- Xu, J.; Wu, X.; Huang, H.; Mao, Y. Experimental study of the pore pressure variation during EPB shield tunnelling in the saturated sand. Tunn. Undergr. Space Technol. 2025, 161, 106576. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Su, L.; Geng, J. Study on the influence of composite modified coal gangue coarse aggregate on the mechanical properties of concrete and mesoscopic simulation. J. Build. Eng. 2025, 106, 112549. [Google Scholar] [CrossRef]

- Zhao, C.; Liang, S.; Wu, Z.; Huang, Y.; Peng, D.; Huang, T. Mechanically activated steel slag induces Ca-P crystallization to recover phosphates from phosphogypsum leachate: Adsorption and crystallization coupled processes. Colloids Surf. A Physicochem. Eng. Asp. 2025, 713, 136535. [Google Scholar] [CrossRef]

- DeWindt, M.A.; Weiksnar, K.D.; Laux, S.J.; Ferraro, C.C.; Townsend, T.G. A review of the suitability and performance of phosphogypsum as a material for road base and subbase construction. Resour. Conserv. Recycl. 2025, 215, 108120. [Google Scholar] [CrossRef]

- Men, J.; Li, Y.; Cheng, P.; Zhang, Z. Recycling phosphogypsum in road construction materials and associated environmental considerations: A review. Heliyon 2022, 8, e11518. [Google Scholar] [CrossRef]

- Millán-Becerro, R.; Pérez-López, R.; Cánovas, C.R.; Macías, F.; León, R. Phosphogypsum weathering and implications for pollutant discharge into an estuary. J. Hydrol. 2023, 617, 128943. [Google Scholar] [CrossRef]

- Geraldo, R.H.; Costa, A.R.D.; Kanai, J.; Silva, J.S.; Souza, J.D.; Andrade, H.M.C.; Gonçalves, J.P.; Fontanini, P.S.P.; Camarini, G. Calcination parameters on phosphogypsum waste recycling. Constr. Build. Mater. 2020, 256, 119406. [Google Scholar] [CrossRef]

- Qu, F.; Zhang, Y.; Li, M.; Dong, W.; Li, W.; Tsang, D.C.W. Resource recycling of industrial waste phosphogypsum in cementitious materials: Pretreatment, properties, and applications. J. Environ. Manag. 2025, 376, 124291. [Google Scholar] [CrossRef]

- Cao, W.; Yi, W.; Peng, J.; Li, J.; Yin, S. Recycling of phosphogypsum to prepare gypsum plaster: Effect of calcination temperature. J. Build. Eng. 2022, 45, 103511. [Google Scholar] [CrossRef]

- Wu, F.; Chen, B.; Qu, G.; Liu, S.; Zhao, C.; Ren, Y.; Liu, X. Harmless treatment technology of phosphogypsum: Directional stabilization of toxic and harmful substances. J. Environ. Manag. 2022, 311, 114827. [Google Scholar] [CrossRef]

- Shu, J.; Zhao, J.; Wei, X.; Chen, M.; Li, B.; Gao, Y.; Yang, Y.; Deng, Z. Synergistic harmless treatment of phosphogypsum leachate wastewater with iron-rich electrolytic manganese residue and electric field. Miner. Eng. 2023, 204, 108399. [Google Scholar] [CrossRef]

- Shi, X.; Zeng, A.; Duan, H.; Zhang, H.; Yang, J. Status and development trends of phosphogypsum utilization in China. Circ. Econ. 2024, 3, 100116. [Google Scholar] [CrossRef]

- Dutta, R.K.; Kumar, V. Suitability of Flyash-Lime-Phosphogypsum Composite in Road Pavements. Period. Polytech.-Civ. Eng. 2016, 60, 455–469. [Google Scholar] [CrossRef]

- Min, C.D.; Shi, Y.; Lu, X.Y.; Liu, Z.X.; Zhou, Y.A. Cemented backfill using Ca(OH)2-pretreated phosphogypsum as aggregate: Hydration characteristics, structural features and strength development. Constr. Build. Mater. 2023, 402, 133011. [Google Scholar] [CrossRef]

- Ou, L.; Li, R.; Zhu, H.; Zhao, H.; Chen, R. Upcycling waste phosphogypsum as an alternative filler for asphalt pavement. J. Clean. Prod. 2023, 420, 138332. [Google Scholar] [CrossRef]

- Dong, C.Y.; Xiang, H.; Hu, X.D.; Wu, H.; Gao, B.; Wan, J.M.; Rao, Z.M.Y.; Fan, Z.W.; Ma, Y. Evaluation of the Influence of Phosphogypsum-Based Composite Filler on Performance of the SMA-13 Asphalt Mixture and Its Harmless Treatment. Sustainability 2024, 16, 6613. [Google Scholar] [CrossRef]

- Fu, R.; Lu, Y.; Wang, L.; An, H.; Chen, S.; Kong, D. The effects of admixtures on the durability properties of phosphogypsum-based cementitious materials. Constr. Build. Mater. 2024, 411, 134379. [Google Scholar] [CrossRef]

- Meng, Y.; Pan, Z.; Luo, X.; Zhao, J.; Lu, T.; He, G.; Huang, J. Study on the high-temperature performance of phenol-amine co-deposited phosphogypsum whisker/SBS composite modified asphalt. Constr. Build. Mater. 2025, 464, 140076. [Google Scholar] [CrossRef]

- JTG E42-2005; Test Methods of Aggregate for High Way Engineering. Highway Research Institute of the Ministry of Transport: Beijing, China, 2005.

- GB 175-2023; Common Portland Cement. National Standardization Administration of China: Beijing, China, 2023.

- Zhou, Z.; Liu, J.; Luo, K.; Wu, A.; Wang, H. Study on Performance Regulation and Mechanism of Quicklime and Biopolymer on Hemihydrate Phosphogypsum. J. Renew. Mater. 2021, 10, 373–384. [Google Scholar] [CrossRef]

- JC/T 479-2013; Building Quicklime. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2013.

- HJ 557-2010; Solid Waste-Extraction Procedure for Leaching Toxicity-Horizontal Vibration Method. Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2010.

- GB/T 15555. 11-1995; Solid Waste—Determination Offluoride—Ion Selective Electrode Method. National Environmental Protection Administration, National Technical Supervision Administration: Beijing, China, 1995.

- Toualbia, Y.; Sari-Ahmed, B.; La Porta, G.; Makhlouf, A.; Ghrici, M.; Pirulli, M. Unconfined compressive strength prediction of lime-stabilised clayey soils under freeze-thaw conditions. Environ. Geotech. 2025. [Google Scholar] [CrossRef]

- JTG E51-2009; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2009.

- Ciaccio, J.A.; Scaramella, L.Y. Establishing the Regioselectivity of a Small-Scale Alkene Hydration Reaction Using TLC Co-spotting. J. Chem. Educ. 2024, 101, 3993–3997. [Google Scholar] [CrossRef]

- GB8978-1996; Integrated Wastewater Discharge Standard. State Bureau of Environment Protection: Beijing, China, 1996.

- Shen, W.; Zhou, M.; Ma, W.; Hu, J.; Cai, Z. Investigation on the application of steel slag–fly ash–phosphogypsum solidified material as road base material. J. Hazard. Mater. 2009, 164, 99–104. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).