Quantitative Evaluation of Sustainable Construction and Demolition Waste Management System Performance in South Africa

Abstract

1. Introduction

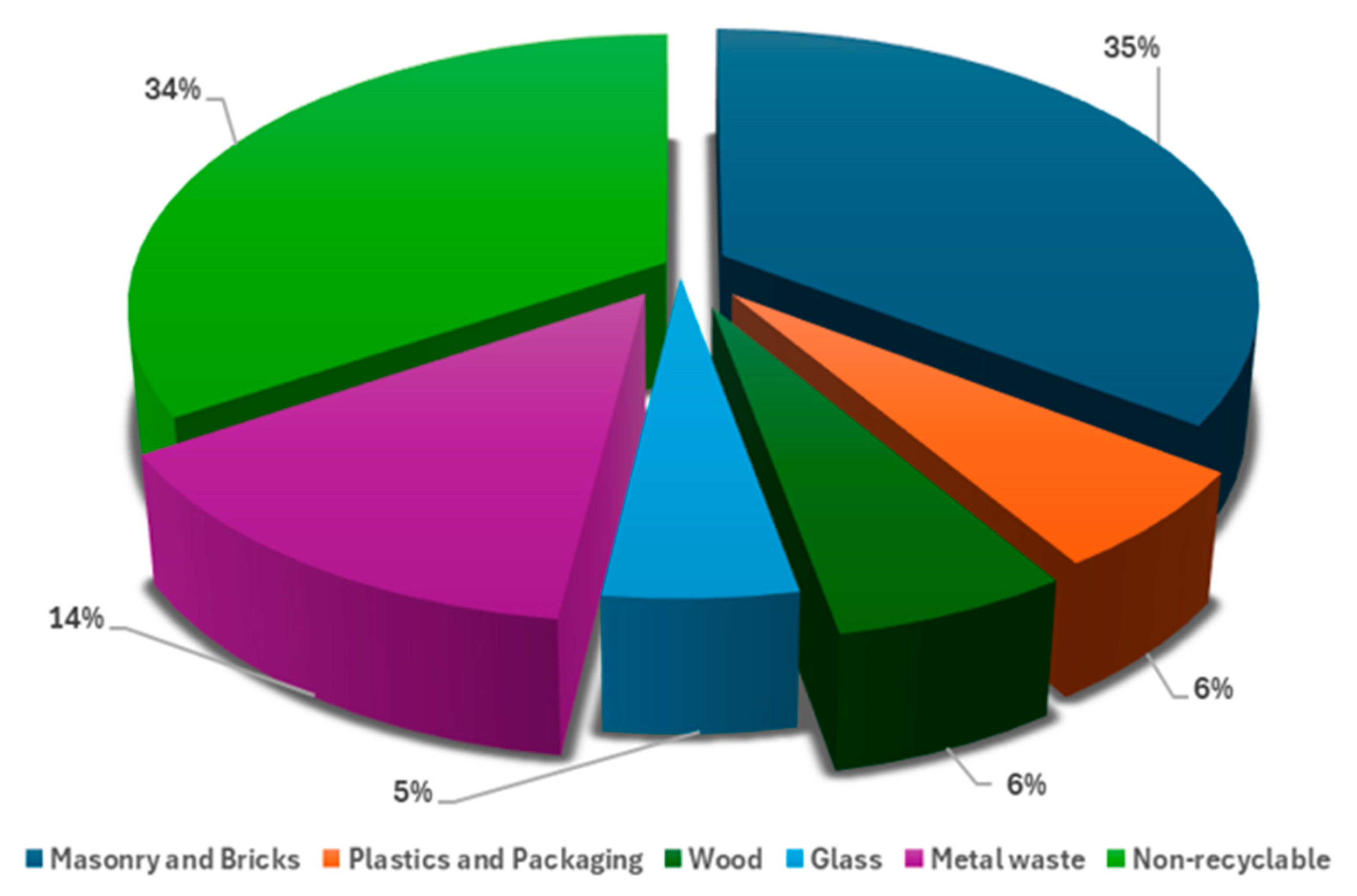

1.1. Overview of South Africa Waste Sector

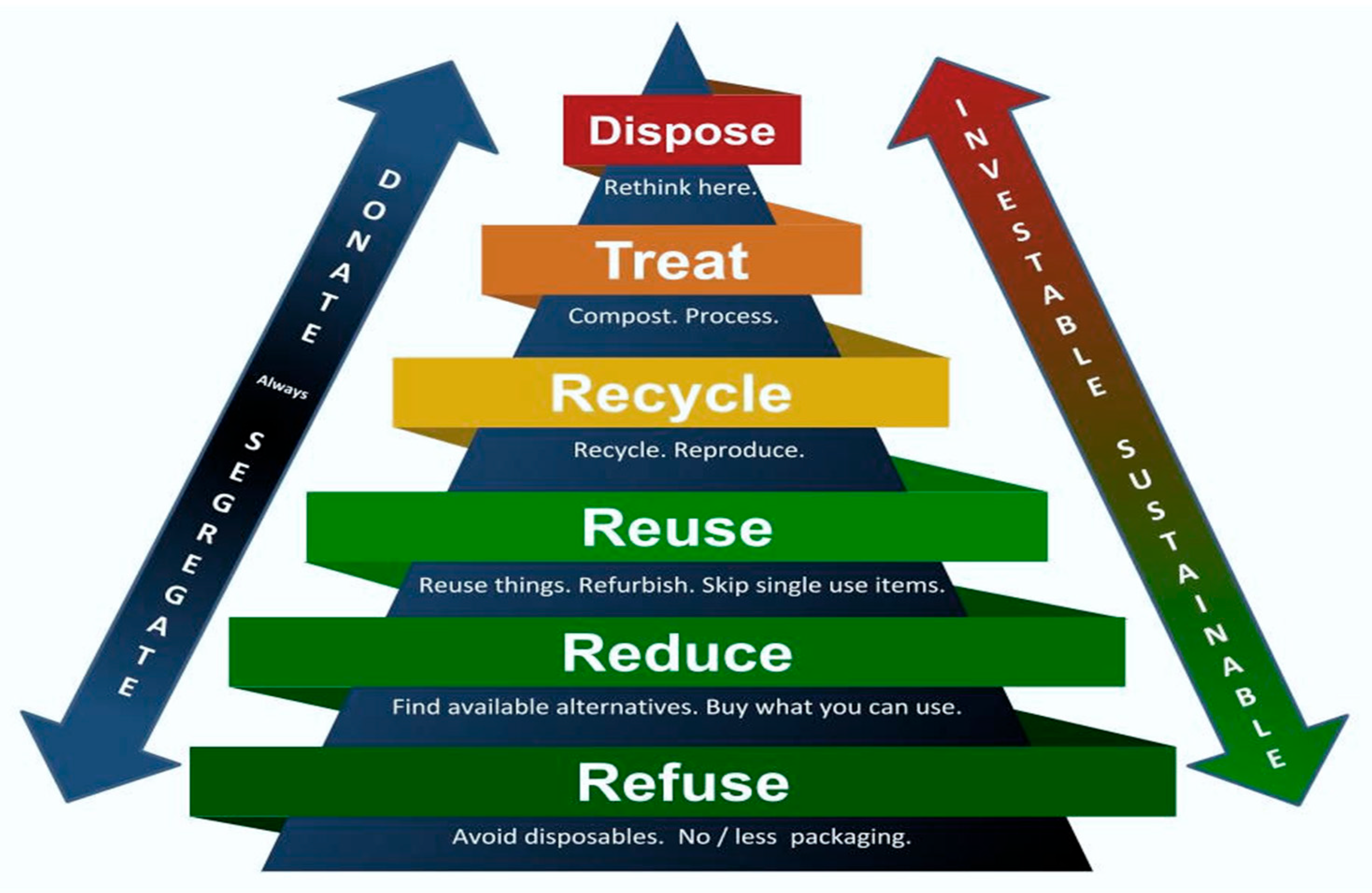

1.2. Utilization of Zero-Waste Management Approach

1.3. The South Africa Waste Management Policy and Framework

1.4. Requirement for Waste Management Performance Evaluation in South Africa

2. Methodology and Design

2.1. Study Region

2.2. Research Design and Approach

2.3. Sample Size and Sampling Method

2.4. Ethical Considerations

2.5. Data Analysis

3. Results and Discussion

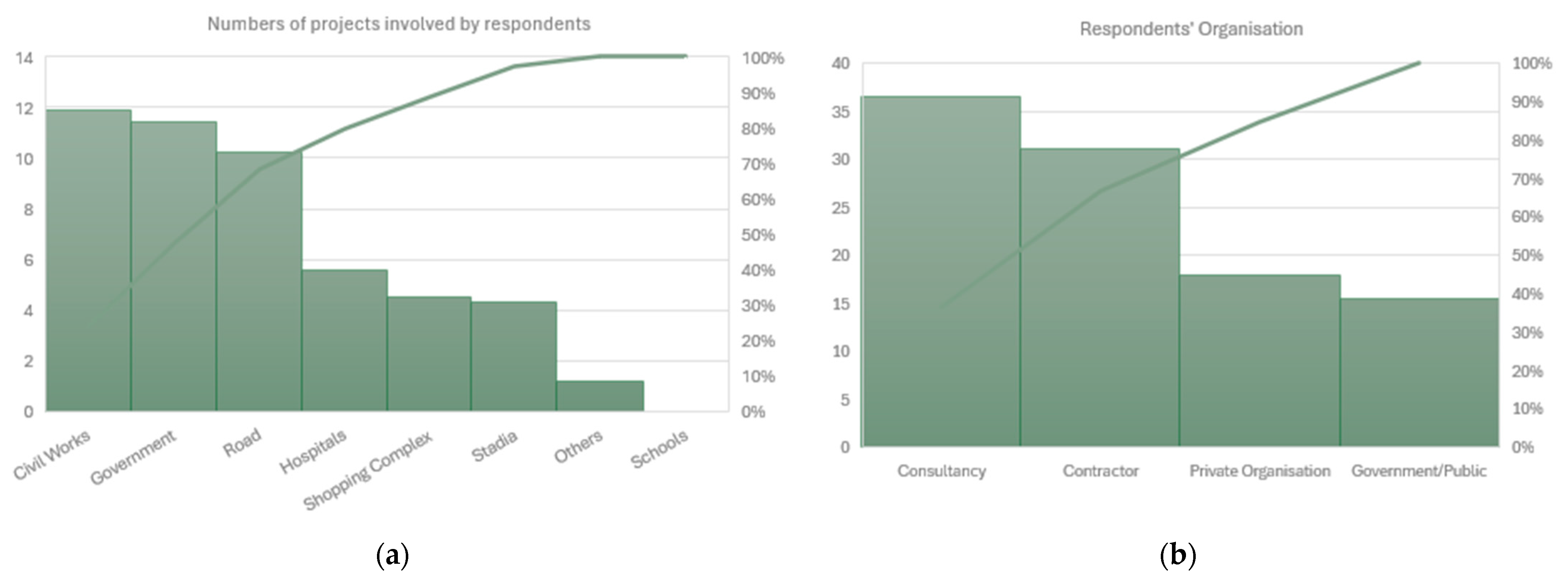

3.1. Descriptive Results

3.2. Cluster Descriptions and Analysis

3.3. Data Reliability and Validity Test

3.4. Implication of Findings

4. Conclusions and Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BREEAM | Building Research Establishment Environmental Assessment Method |

| BIM | Building Information Modeling |

| C&DW | Construction and Demolition Waste |

| COE | Construction and Execution |

| GDP | Gross Domestic Product |

| IFT | Initiation and Feasibility Testing |

| ISO | International Organization for Standardization |

| IWMP | Integrated Waste Management Plans |

| LCA | Life-Cycle Assessment |

| LCI | Life-Cycle Analysis |

| MWSP | Municipal Waste Sector Plan |

| MSA | Municipal Systems Act |

| NEMA | National Environmental Management Agency |

| PAD | Planning and Design |

| PCC | Procurement |

| PEM | Performance and Monitoring |

| POC | Post Construction |

| REN | Renovation |

| SAWA | South African Waste Act |

| SPI | Sustainability Performance Index |

| SPSS | Statistical Package for Social Sciences |

| WRAP | Waste and Resources Action Programme |

References

- Al-Ansary, M.S.; El-Haggar, S.M.; Taha, M.A. Proposed Guidelines for Construction Waste Management in Egypt for Sustainability of Construction Industry. In Proceedings of the International Conference on Sustainable Construction Waste Management, Singapore, 10–12 June 2004; p. 221, in press. [Google Scholar]

- Aboginije, A.J. An Assessment of Construction and Demolition Waste Management Systems in the Nigerian Construction Industry. Master’s Dissertation, University of Johannesburg, Johannesburg, South Africa, 2020. [Google Scholar]

- Abarca-Guerrero, L.; Maas, G.; Hogland, W. Solid waste management challenges for cities in developing countries. J. Waste Manag. 2013, 33, 220–232. [Google Scholar] [CrossRef]

- Abdelhamid, M.S. Assessment of different construction and demolition waste management approaches. HBRC J. 2014, 10, 317–326. [Google Scholar] [CrossRef]

- Almorza, D.; Brebbia, C. Waste Management and Environment; Boston Participation in Domestic Waste; WIT Press: Ashurst, UK, 2000. [Google Scholar]

- Abidin, N.Z. Investigating the awareness and application of sustainable construction concept by Malaysian developers. Habitat Int. 2010, 34, 421–426. [Google Scholar] [CrossRef]

- Abioye, A.; Rao, B. Sustainable Approach to Managing Construction and Demolition Waste: An Opportunity or a New Challenge? J. Innov. Res. Sci. Eng. Technol. 2015, 4, 10368–10378. [Google Scholar]

- Ginindza, B.; Muzenda, E. Community Perception on Waste Management and Minimization: A Case Study for Mogale City and Westonaria Municipalities. In Proceedings of the International Conference on Integrated Waste Management and Green Energy Engineering—‘ICIWMGEE’, Johannesburg, South Africa, 15–16 April 2013. [Google Scholar]

- Lee, S.; Chang, H.; Lee, J. Construction and demolition waste management and its impacts on the environment and human health: Moving forward sustainability enhancement. Sustain. Cities Soc. 2024, 115, 105855. [Google Scholar] [CrossRef]

- Aboginije, A.; Aigbavboa, C.; Thwala, W.; Samuel, S. Determining the Impact of Construction and Demolition Waste Reduction practices on Green Building Projects in Gauteng Province, South Africa. In Proceedings of the 10th Annual International Conference of Industrial Engineering and Operational Management, Dubai, United Arab Emirate, 10–12 March 2020; pp. 2428–2437. [Google Scholar]

- Aboginije, A.; Aigbavboa, C.; Thwala, W. Modeling and usage of a sustainametric technique for measuring the life-cycle performance of a waste management system: A case study of South Africa. Front. Sustain. 2023, 3, 943635. [Google Scholar] [CrossRef]

- South African Government News Agency. Government Committed to Creating Jobs. Available online: https://www.sanews.gov.za/south-africa/government-committed-creating-jobs (accessed on 12 July 2024).

- Macozoma, D.S. Developing a Self-Sustaining Secondary Construction Materials Market in South Africa. Master’s Dissertation, Faculty of Engineering and the Built Environment, University of the Witwatersrand, Johannesburg, South Africa, 2006. [Google Scholar]

- Simelane, T.; Mohee, R. Future Directions of Municipal Solid Waste Management in Africa; Africa Institute of South Africa: Johannesburg, South Africa, 2012; Policy Briefing: No. 81. [Google Scholar]

- Mosidi, M. Key Areas in Waste Management: A South African Perspective, Integrated Waste Management; IntechOpen: London, UK, 2010; Volume II. [Google Scholar]

- Berge, S.; von Blottnitz, H. An estimate of construction and demolition waste quantities and composition expected in South Africa. S. Afr. J. Sci. 2022, 1–5. [Google Scholar] [CrossRef]

- Nkosi, N.; Muzenda, E.; Zvimba, J.; Pilusa, J. The Current Waste Generation and Management Trends in South Africa: A Review. In Proceedings of the International Conference of Integrated Waste management and Green Energy Engineering, Johannesburg, South Africa, 15–16 April 2013; pp. 303–308. [Google Scholar]

- South African Department of Environmental Affairs (DEA). South Africa State of Waste Report; DEA: Pretoria, South Africa, 2018. Available online: http://sawic.environment.gov.za/?menu=346 (accessed on 12 July 2024).

- Muzenda, E.; Ntuli, F.; Pilusa, T.J. Waste management, strategies, and the situation in South Africa. In Proceedings of the International Conference on Chemical Engineering and Technology, Oslo, Norway, 13–14 August 2012; World Academy of Science, Engineering and Technology: New York, NY, USA, 2012; Volume 68, pp. 309–312. [Google Scholar]

- Nkosi, N.; Muzenda, M. Waste Management Participants: A South African Perspective. In Proceedings of the 3rd International Conference on Medical Sciences and Chemical Engineering—ICMSCE, Bangkok, Thailand, 25–26 December 2013. [Google Scholar]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.O.; Alaka, H.A. Ineffectiveness of construction waste management strategies: Knowledge gap analysis. In Proceedings of the First International Conference of the CIB Middle East and North Africa Research Network (CIB-MENA 2014), Abu Dhabi, United Arab Emirate, 14–16 December 2014; pp. 261–280. [Google Scholar]

- DST (Department of Science and Technology). A National Waste R&D and Innovation Roadmap for South Africa: Phase 1 Status Quo Assessment. In Current and Required Institutional Mechanisms to Support Waste Innovation; Department of Science and Technology: Pretoria, South Africa, 2012; Available online: http://wasteroadmap.co.za/download/report_support_waste_innovation.pdf (accessed on 22 January 2025).

- Serge, K.N. The role of community participation in solid waste management in Sub-Saharan Africa: A study of Orlando East, Johannesburg, South Africa. S. Afr. Geogr. J. 2020, 103, 223–236. [Google Scholar] [CrossRef]

- Ragossnig, A.M. Construction and demolition waste—Major challenges ahead! Waste Manag. Res. 2020, 38, 345–346. [Google Scholar] [CrossRef]

- Aboginije, A.; Aigbavboa, C.; Thwala, W. A Holistic Assessment of Construction and Demolition Waste Management in the Nigerian Construction Projects. Sustainability 2021, 13, 6241. [Google Scholar] [CrossRef]

- Chen, Z.; Feng, Q.; Yue, R.; Chen, Z.; Moselhi, O.; Soliman, A.; Hammad, A.; An, C. Construction, renovation, and demolition waste in landfill: A review of waste characteristics, environmental impacts, and mitigation measures. Environ. Sci. Pollut. Res. 2022, 29, 46509–46526. [Google Scholar] [CrossRef] [PubMed]

- Arslan, H.; Cosgun, N.; Salgin, B. Chapter 14: Construction and Demolition Waste Management in Turkey. In Waste Management—An Integrated Vision; InTech Open: London, UK, 2016; pp. 312–332. [Google Scholar]

- Dlamini, B.R.; Rampedi, I.T.; Ifegbesan, A.P. Community resident’s opinions and perceptions on the effectiveness of waste management and recycling potential in the Umkhanyakude and Zululand District Municipalities in the KwaZulu-Natal Province of South Africa. J. Sustain. 2017, 9, 1835. [Google Scholar] [CrossRef]

- Baumgartner, R.J.; Ebner, D. Corporate sustainability strategies: Sustainability profiles and maturity levels. Sustain. Dev. 2010, 18, 76–89. [Google Scholar] [CrossRef]

- Lehmann, S. Urban Metabolism and the Zero Waste City: Transforming Cities through Sustainable Design and Behaviour Change. In Green Cities for Asia and the Pacific; Lindfield, M., Steinberg, F., Eds.; ADB Publication Unit: Manila, Philippines, 2012; Available online: http://www.adb.org/publications/greencities (accessed on 2 December 2024).

- Awasthi, A.K.; Cheela, V.S.; D’Adamo, I.; Iacovidou, E.; Islam, M.R.; Johnson, M.; Miller, T.R.; Parajuly, K.; Parchomenko, A.; Radhakrishan, L.; et al. Zero waste approach towards a sustainable waste management. Resour. Environ. Sustain. 2021, 3, 100014. [Google Scholar] [CrossRef]

- Song, Q.; Li, J.; Zeng, X. Minimizing the increasing solid waste through zero waste strategy. J. Clean. Prod. 2015, 104, 199–210. [Google Scholar] [CrossRef]

- Bojan, R.; Neven, V.; Branka, I. Concept of sustainable waste management in the city of Zagreb: Towards the implementation of circular economy approaches. J. Air Waste Manag. Assoc. 2016, 67, 241–259. [Google Scholar] [CrossRef]

- Khurshid, Z.; Zubair, M.O.; Humaira, A. Comprehensive Review on the Development of Zero Waste Management. In Zero Waste Management Technologies; Bhat, R.A., Dar, G.H., Hajam, Y.A., Eds.; Springer: Cham, Switzerland, 2024; pp. 1–22. [Google Scholar]

- Zaman, A.; Ahsan, T. Zero-Waste: Reconsidering Waste Management for the Future; Routledge: New York, NY, USA, 2019; pp. 1–24. [Google Scholar]

- Begum, R.A.; Satari, S.K.; Pereira, J.J. Waste Generation and Recycling: Comparison of Conventional and Industrialized Building Systems. Am. J. Environ. Sci. 2010, 6, 383–388. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Giacchetta, G. Development of a sustainable product life cycle in manufacturing firms: A case study. Int. J. Prod. Res. 2007, 45, 4073–4098. [Google Scholar] [CrossRef]

- Bourne, M.; Neely, A.; Platts, K.; Mills, J. The success and failure of performance measurement initiatives: Perceptions of participating managers. Int. J. Oper. Prod. Manag. 2002, 22, 1288–1310. [Google Scholar] [CrossRef]

- Kubanza, N.S.; Simatele, M.D. Sustainable solid waste management in developing countries: A study of institutional strengthening for solid waste management in Johannesburg, South Africa. J. Environ. Plan. Manag. 2019, 14, 28–34. [Google Scholar] [CrossRef]

- CSIR. The Situation of Waste Management and Pollution Control in South Africa; Prepared for the Department of Environment Affairs; CSIR: Pretoria, South Africa, 1999. [Google Scholar]

- DEAT—Department of Environmental Affairs and Tourism. White Paper on Integrated Pollution and Waste Management for South Africa; A Policy on Pollution Prevention, Waste Minimization, Impact Management, and Remediation. Government Gazette No. 20978, Notice No. 227; DEAT: Pretoria, South Africa, 2001.

- Godfrey, L.; Strydom, W.; Muswema, A.; Oelofse, S.; Roman, H.; Mange, M. The state of innovation in the South African Waste Sector. In Proceedings of the Solid Waste World Congress, ISWA 2014, Sao Paulo, Brazil, 8–10 September 2014; pp. 1–14. [Google Scholar]

- DEA. National Waste Management Strategy Report; Department of Environmental Affairs: Pretoria, South Africa, 2011.

- DEA. National Waste Information Baseline Report; Department of Environmental Affairs: Pretoria, South Africa, 2012.

- Sentime, K. The impact of legislative framework governing waste management and collection in South Africa. Afr. Geogr. Rev. 2014, 33, 81–93. [Google Scholar] [CrossRef]

- Godfrey, L.; Oelofse, S. Historical review of waste management and recycling in South Africa. Resources 2017, 6, 57. [Google Scholar] [CrossRef]

- Buchheim, R.K. Developing performance metrics for a design engineering department. IEEE Trans. Eng. Manag. 2000, 47, 309–320. [Google Scholar] [CrossRef]

- Cheng, J.C.; Ma, L.Y. A BIM-based system for demolition and renovation waste estimation and planning. J. Waste Manag. 2013, 33, 1539–1551. [Google Scholar] [CrossRef] [PubMed]

- Holden, E.; Linnerud, K.; Banister, D. The Imperatives of Sustainable Development. Sustain. Dev. 2017, 25, 213–226. [Google Scholar] [CrossRef]

- Hirai, T. A balancing act between economic growth and sustainable development: Historical trajectory through the lens of development indicators. Sustain. Dev. 2022, 30, 1900–1910. [Google Scholar] [CrossRef]

- Demirbas, A. Waste management, waste resource facilities, and waste conversion processes. Energy Convers. Manag. J. 2011, 52, 1280–1287. [Google Scholar] [CrossRef]

- Faniran, O.O.; Caban, G. Minimizing Waste on Construction Project Sites. J. Eng. Constr. Archit. Manag. 1998, 5, 182–188. [Google Scholar] [CrossRef]

- Department of Sustainability, Environment, Water, Population and Communities, Australian Government. Construction and Demolition Waste Guide-Recycling and Re-Use Across the Supply Chain; DSEWPaC: Canberra, Australia, 1997.

- Godfrey, L.; Nahman, A. Are Developing Countries Ready for First World Waste Policy Instruments? In Proceedings of the Sardinia Conference, Eleventh International Waste Management and Landfill Symposium, Cagliari, Italy, 1–5 October 2007; Available online: http://researchspace.csir.co.za/dspace/handle/10204/846 (accessed on 22 December 2024).

- Nappi, V.; Rozenfeld, H. Sustainability performance indicators for product life-cycle management. In Proceedings of the 22nd International Congress of Mechanical Engineering (COBEM), Ribeirão Preto, Brazil, 3–7 November 2013; ABCM: Riberia/Porto, Portugal, 2013; p. 4071. [Google Scholar]

- Veleva, V.; Ellenbecker, M. Indicators of sustainable production: Framework and methodology. J. Clean. Prod. 2001, 9, 519–549. [Google Scholar] [CrossRef]

- Hawkins, R.G.; Shaw, H.S. The Practical Guide to Waste Management Law: With a List of Abbreviations; Thomas Telford Publishing: London, UK, 2004. [Google Scholar]

- Jeffrey, C. Construction and Demolition Waste Recycling—A Literature Review; Inhabitant 2011; Dalhousie University’s Office of Sustainability: Halifax, NS, Canada, 2011. [Google Scholar]

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; The World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Kazerooni, M.A.; Abdullah, A.; Navazandeh, M.S.; Kamal, M.B.; Torshizi, F.; Taherkhani, R. Reduce, Reuse, Recycle and Recovery in Sustainable Waste Management. J. Adv. Mater. Res. 2012, 446–449, 937–944. [Google Scholar] [CrossRef]

- Keeble, J.J.; Topiol, S.; Berkeley, S. Using indicators to measure sustainability performance at a corporate and project level. J. Bus. Ethics 2003, 44, 149–158. [Google Scholar] [CrossRef]

- Kumar, S.; Smith, S.R.; Fowler, G.; Velis, C.; Kumar, S.J.; Arya, S.R.; Kumar, R.; Cheeseman, C. Challenges and opportunities associated with waste management in India. R. Soc. Open Sci. 2017, 4, 160764. [Google Scholar] [CrossRef]

- McCool, S.F.; Stankey, G.H. Indicators of sustainability: Challenges and opportunities at the interface of science and policy. Environ. Manag. 2004, 33, 294–305. [Google Scholar] [CrossRef]

- Nagapan, I.S.; Abul-Rahman, I.A.; Aziz, A.A. Construction Waste Management: Malaysian Perspective. Int. Conf. Civ. Environ. Eng. Sustain. 2012, 2, 299–309. [Google Scholar]

- Nahman, A.; Godfrey, L. Economic Instrument for Solid Waste Management in South Africa: Opportunities and Constraints. J. Resour. Conserv. Recycl. 2010, 54, 521–531. [Google Scholar] [CrossRef]

- Nyika, J.M.; Onyari, E.K.; Mishra, S.; Dinka, M.O. Waste Management in South Africa. In Sustainable Waste Management Challenges in Developing Countries; Pariatamby, A., Hamid, F.S., Bhatti, M., Eds.; IGI Global Scientific Publishing: Hershey, PA, USA, 2020; pp. 327–351. [Google Scholar] [CrossRef]

- Republic of South Africa. National Environmental Management: Waste Amendment Act 26 of 2014; Government Gazette No. 36784, Notice No. 449; Republic of South Africa: Pretoria, South Africa, 2014.

- Marais, L.; Twala, C. Bloemfontein: The rise and fall of South Africa’s judicial capital. Afr. Geogr. Rev. 2020, 40, 49–62. [Google Scholar] [CrossRef]

- Wanda, E.M.M.; Nyoni, H.; Mamba, B.B.; Msagati, T.A.M. Occurrence of Emerging Micropollutants in Water Systems in Gauteng, Mpumalanga, and Northwest Provinces, South Africa. Int. J. Environ. Res. Public Health 2017, 14, 79. [Google Scholar] [CrossRef] [PubMed]

- Widmer, R.; Lombard, R. E-Waste Assessment in South Africa: A Case Study of the Gauteng Province; EMPA Material Science and Technology: Dübendorf, Switzerland, 2005. [Google Scholar]

- Creswell, J.W. Educational Research: Planning, Conducting, and Evaluating Quantitative and Qualitative Research, 3rd ed.; Pearson: Upper Saddle River, NJ, USA, 2008. [Google Scholar]

- Creswell, J.W.; Creswell, J.D. Research Design: Qualitative, Quantitative, and Mixed Methods Approach; Sage Publications: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Boru, T. Chapter Five: Research Design and Methodology. Ph.D. Thesis, University of South Africa, Pretoria, South Africa, 2018; p. 41. [Google Scholar] [CrossRef]

- Gray, D.E. Doing Research in Real World, 3rd ed.; Sage Publications: Thousand Oaks, CA, USA, 2014; pp. 1–896. ISBN 152976551X/9781529765519. [Google Scholar]

- Robson, C. Real World Research: A Resource for Social Scientists and Practitioner-Researchers; Blackwell: Oxford, UK, 2002. [Google Scholar]

- Fox, W.; Bayat, M.S. A Guide to Managing Research; Juta Publications: Cape Town City, South Africa, 2007; p. 45. [Google Scholar]

- Srivastava, S.; Chini, A. Construction Materials and C&D Waste in India. In CIB W11 Construction—Material Stewardship; International Council of Building Research Studies and Documentation: Delft, The Netherlands, 2009; pp. 72–76. [Google Scholar]

- Udawatta, N.; Zuo, J.; Chiveralls, K.; Zillante, G. Improving waste management in construction projects: An Australian study. Resour. Conserv. Recycling 2015, 101, 73–83. [Google Scholar] [CrossRef]

- Formoso, C.T.; Soibelman, L.; De Cesare, C.; Isatto, E.L. Material Waste in Building Industry: Main Causes and Prevention. J. Constr. Eng. Manag. 2002, 128, 316–325. [Google Scholar] [CrossRef]

- Omotayo, O.O.; Akingbonmire, S.L.; Ikumapayi, S.M. Sustainable Application of Construction and Demolition Waste: A Review; Federal University of Tech: Akure, Nigeria, 2017. [Google Scholar]

- Waste Resources Action Plan. Achieving Good Practice Waste Minimization and Management: Guidance for Construction Clients, Design Teams, and Contractors. 2007. Available online: www.wrap.org.uk/construction (accessed on 3 October 2024).

- World Bank Group. Trends in Solid Waste Management. 2018. Available online: https://datatopics.worldbank.org/what-a-waste/trends_in_solid_waste_management.html (accessed on 3 October 2024).

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A life-cycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- Zorpas, A.A.; Lasaridi, K. Measuring waste prevention. J. Waste Manag. 2013, 33, 1047–1056. [Google Scholar] [CrossRef] [PubMed]

- World Economic Outlook Database, April 2024 Edition. (South Africa); International Monetary Fund: Washington, DC, USA, 2024; Archived from the original on 16 April 2024. Retrieved 17 April 2024; Available online: www.imf.org (accessed on 7 December 2024).

- South Africa Fast Facts. SouthAfrica.info. April 2007. Archived from the Original on 19 July 2008. Retrieved 14 January 2025. Available online: http://southafrica.info/ (accessed on 7 December 2024).

- Olubambi, A.; Aigbavboa, C.; Ikotun, B. Conceptualizing a dynamic BIM-based waste management system in enabling net-zero cities. ICE-Waste Resour. Manag. 2025, 1–13. [Google Scholar] [CrossRef]

| Sustainability Performance Indicators (SPIs) | Triple Bottom Line Dimension | Construction Lifecycle Phases | Source | ||||||

|---|---|---|---|---|---|---|---|---|---|

| IFT | PAD | PCC | COE | PEM | REN | POC | |||

| Waste avoidance where possible | Environmental, Economic | ✓ | ✓ | [2,10,21,65] | |||||

| Recovery of resources and energy if possible | Environmental | ✓ | ✓ | [11,23,78] | |||||

| Imposing landfill levy | Economic, Social | ✓ | ✓ | [67,79] | |||||

| Material reuse as backfills | Environmental, Economic | ✓ | ✓ | ✓ | [5,6,26,79] | ||||

| Encouragement of resources conservation | Environmental, Economic | ✓ | ✓ | ✓ | ✓ | [31,34,36] | |||

| Awareness among clients and contractors | Social | ✓ | ✓ | [4,12,21] | |||||

| Institutionalizing laws against incineration | Economic, Social | ✓ | ✓ | [26,52,79] | |||||

| Waste-to-energy initiatives | Environmental, Economic | ✓ | ✓ | [11,23,38] | |||||

| Implementation of BIM | Environmental, Economic | ✓ | ✓ | ✓ | [4,49] | ||||

| Design and purchase of recyclable materials | Economic, Social | ✓ | ✓ | ✓ | [8,39,61] | ||||

| Conservation of landfill sites | Environmental, Economic | ✓ | ✓ | ✓ | ✓ | [17,67] | |||

| Selection of materials that maximize reusability | Economic | ✓ | ✓ | [6,11,48] | |||||

| Maximizing recycled materials | Economic | ✓ | ✓ | ✓ | [10,17,25] | ||||

| Reduction in price of recycled materials | Economic | ✓ | ✓ | [66,69] | |||||

| Sustainable contractual agreement | Economic | ✓ | ✓ | [13,35,36] | |||||

| Application of IWS systems | Environmental, Economic | ✓ | ✓ | [29,32,64] | |||||

| Avoidance of complex design and detailing | Environmental, Economic | ✓ | ✓ | ✓ | [38,53,56] | ||||

| Sustainable procurement methods | Economic, Social | ✓ | ✓ | [10,35,36] | |||||

| Functional legal framework | Economic, Social | ✓ | ✓ | [50,52,53] | |||||

| Waste-expertise involvement on sites | Social | [2,4,28] | |||||||

| WRAP implementation | Environmental, Economic | ✓ | ✓ | [41,43,56] | |||||

| Development of resilient secondary materials market | Economic | ✓ | [5,17,35,36] | ||||||

| Sustainability Performance Indicators | Mean Score (MS) | Standard Deviation (SD) | Rankings |

|---|---|---|---|

| Reduction in price of recycled materials | 3.94 | 0.830 | 1 |

| Sustainable procurement methods | 3.91 | 0.800 | 2 |

| Waste-expertise involvement on sites | 3.87 | 0.810 | 3 |

| Material reuse as backfills | 3.76 | 0.760 | 4 |

| Development of resilient secondary material market | 3.66 | 0.755 | 5 |

| Conservation of landfill sites | 3.65 | 0.800 | 6 |

| Institutionalizing laws against incineration | 3.62 | 0.756 | 7 |

| Waste-to-energy initiatives | 3.60 3.59 | 0.870 | 8 |

| WRAP implementation | 3.57 | 0.740 | 9 |

| Design and purchase of recyclable materials | 3.55 | 0.750 | 10 |

| Awareness among clients and contractors | 3.54 | 0.730 | 11 |

| Selection of materials that maximize reusability | 3.52 | 0.770 | 12 |

| Maximizing recycled materials | 3.51 | 0.810 | 13 |

| Waste avoidance where possible | 3.50 | 0.820 | 14 |

| Encouragement of resource conservation | 3.49 | 0.790 | 15 |

| Application of IWS systems | 3.48 | 0.840 | 16 |

| Avoidance of complex design and detailing | 3.47 | 0.780 | 17 |

| Recovery of resources and energy, if possible | 3.45 | 0.870 | 18 |

| Functional legal framework | 3.44 | 0.780 | 19 |

| Implementation of BIM | 3.42 | 0.720 | 20 |

| Imposing landfill levy | 3.41 | 0.710 | 21 |

| Sustainable contractual agreement | 3.40 | 0.702 | 22 |

| Factors | Initial Eigenvalues | Extraction Sums of Squared Loadings | ||||

|---|---|---|---|---|---|---|

| Total | % Variance | Cumulative % | Total | % Variance | Cumulative % | |

| 1 | 6.364 | 28.928 | 28.928 | 6.016 | 27.343 | 27.343 |

| 2 | 2.599 | 11.814 | 40.742 | 2.310 | 10.500 | 37.843 |

| 3 | 2.008 | 9.126 | 49.868 | 1.709 | 7.768 | 45.611 |

| 4 | 1.692 | 7.691 | 57.559 | 1.348 | 6.129 | 51.740 |

| 5 | 1.584 | 7.199 | 64.758 | 1.229 | 5.844 | 57.324 |

| 6 | 1.105 | 5.023 | 69.780 | 0.853 | 3.877 | 61.201 |

| 7 | 1.029 | 4.679 | 74.460 | 0.692 | 3.145 | 64.346 |

| Kaiser–Meyer–Olkin measure of sampling adequacy | 0.786 | |

| Approx. Chi-Square | 1554.928 | |

| Bartlett’s test of sphericity | Df. | 324 |

| Sig. | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olubambi, A.; Akinradewo, O.; Aigbavboa, C.; Ikotun, B. Quantitative Evaluation of Sustainable Construction and Demolition Waste Management System Performance in South Africa. Infrastructures 2025, 10, 150. https://doi.org/10.3390/infrastructures10060150

Olubambi A, Akinradewo O, Aigbavboa C, Ikotun B. Quantitative Evaluation of Sustainable Construction and Demolition Waste Management System Performance in South Africa. Infrastructures. 2025; 10(6):150. https://doi.org/10.3390/infrastructures10060150

Chicago/Turabian StyleOlubambi, Ademilade, Opeoluwa Akinradewo, Clinton Aigbavboa, and Bolanle Ikotun. 2025. "Quantitative Evaluation of Sustainable Construction and Demolition Waste Management System Performance in South Africa" Infrastructures 10, no. 6: 150. https://doi.org/10.3390/infrastructures10060150

APA StyleOlubambi, A., Akinradewo, O., Aigbavboa, C., & Ikotun, B. (2025). Quantitative Evaluation of Sustainable Construction and Demolition Waste Management System Performance in South Africa. Infrastructures, 10(6), 150. https://doi.org/10.3390/infrastructures10060150