Effects of Crumb Rubber-Modified Asphalt as a Pavement Layer in Railways: A Scoping Review

Abstract

1. Introduction

2. Materials and Methods

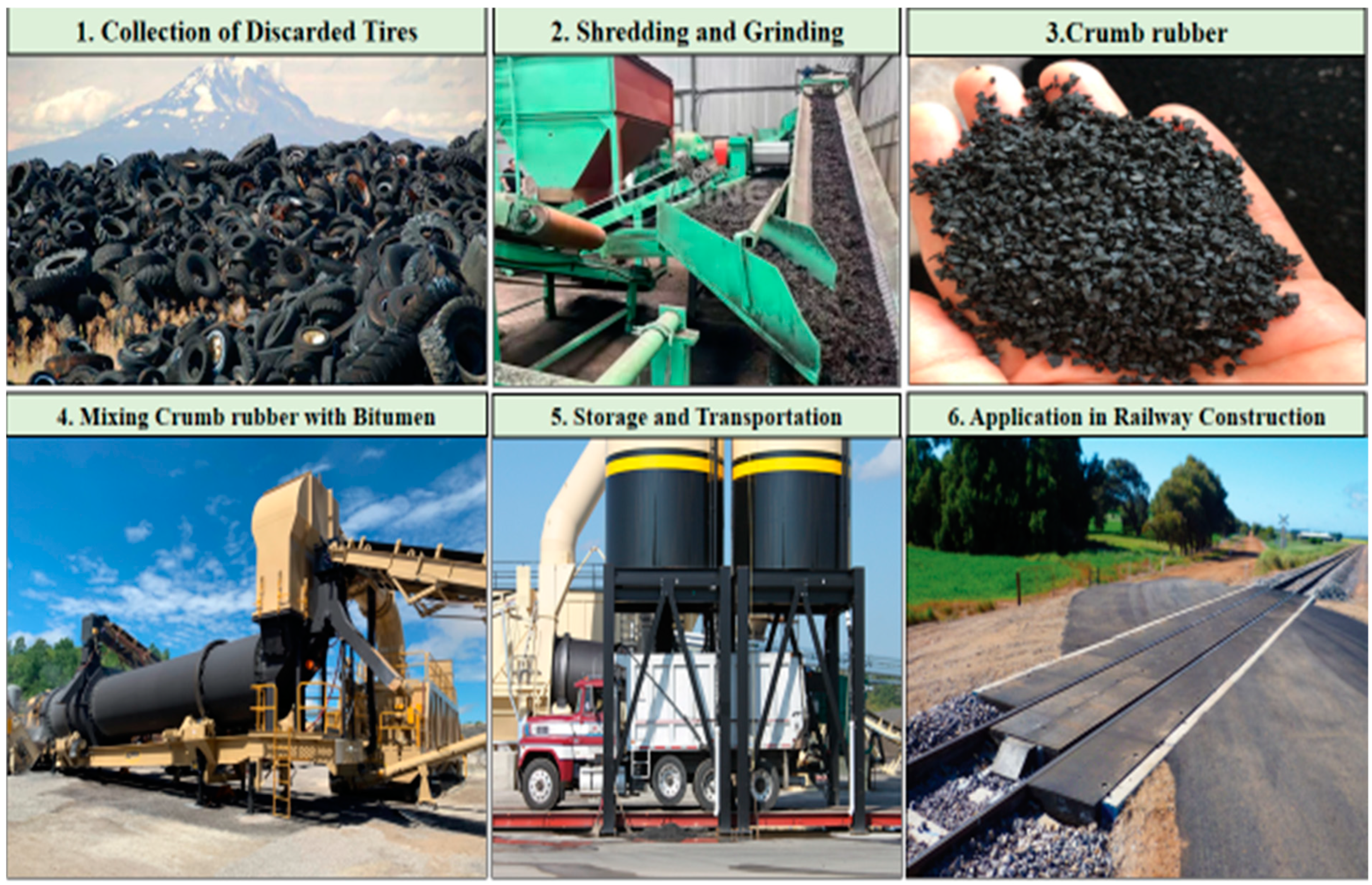

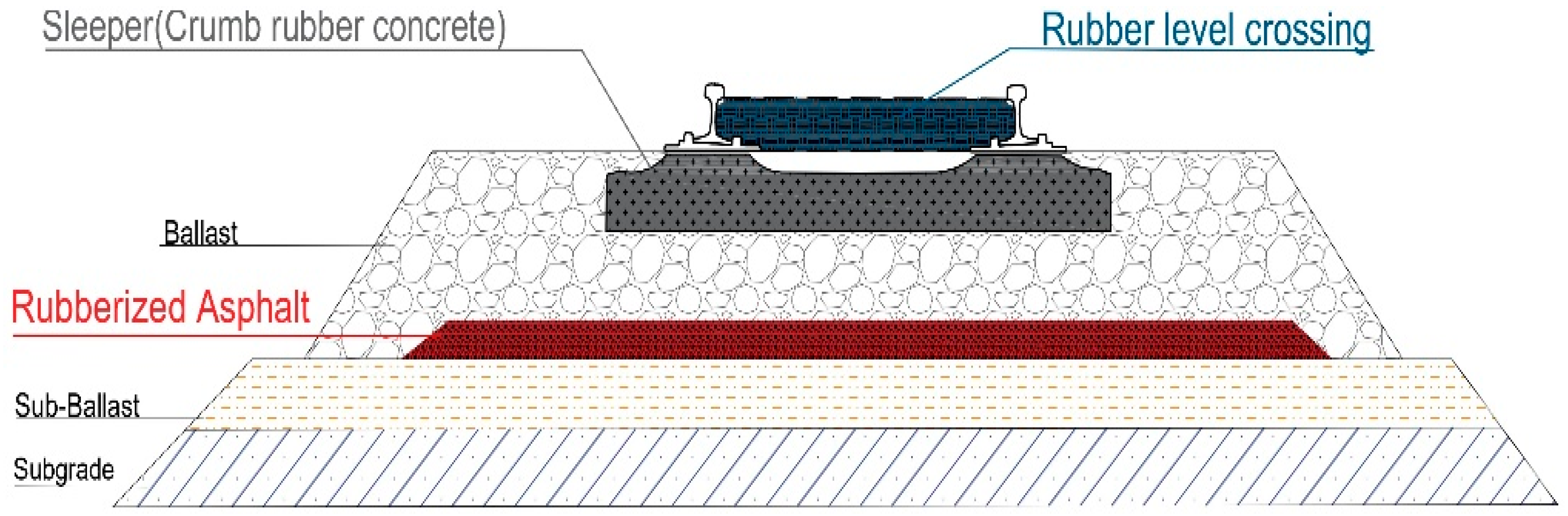

2.1. Background

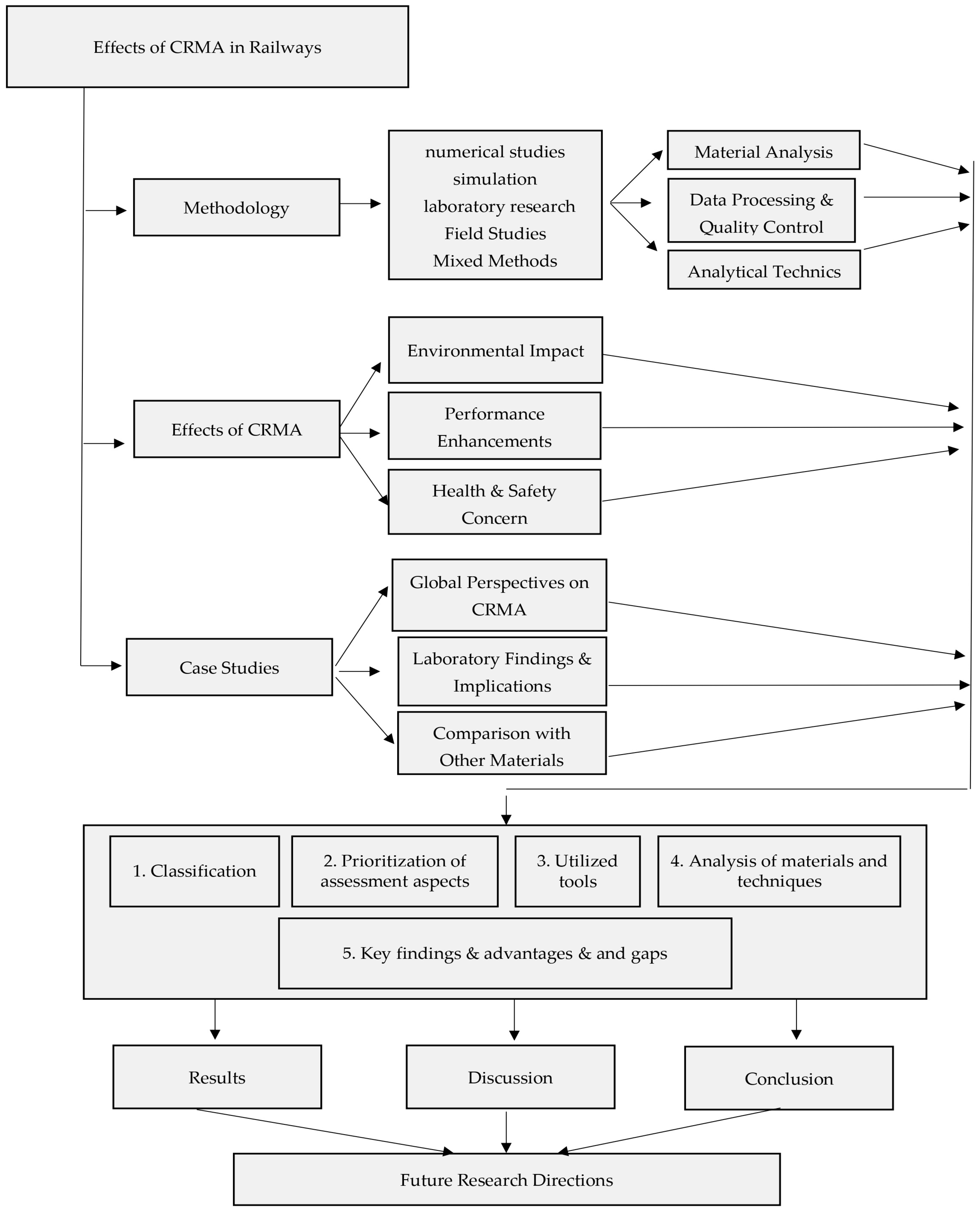

2.2. Methodology

2.2.1. Research Method of This Review

2.2.2. Review of Common Methods

2.3. Material Analysis

2.4. Data Processing and Quality Control

2.5. Analytical Techniques

3. Results

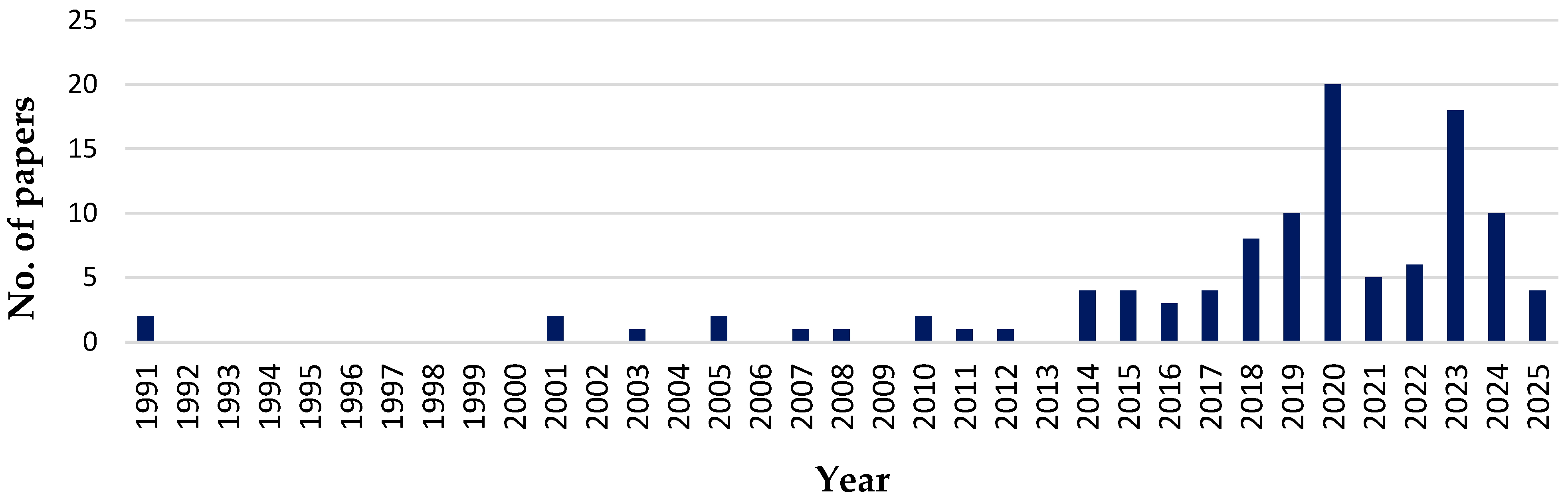

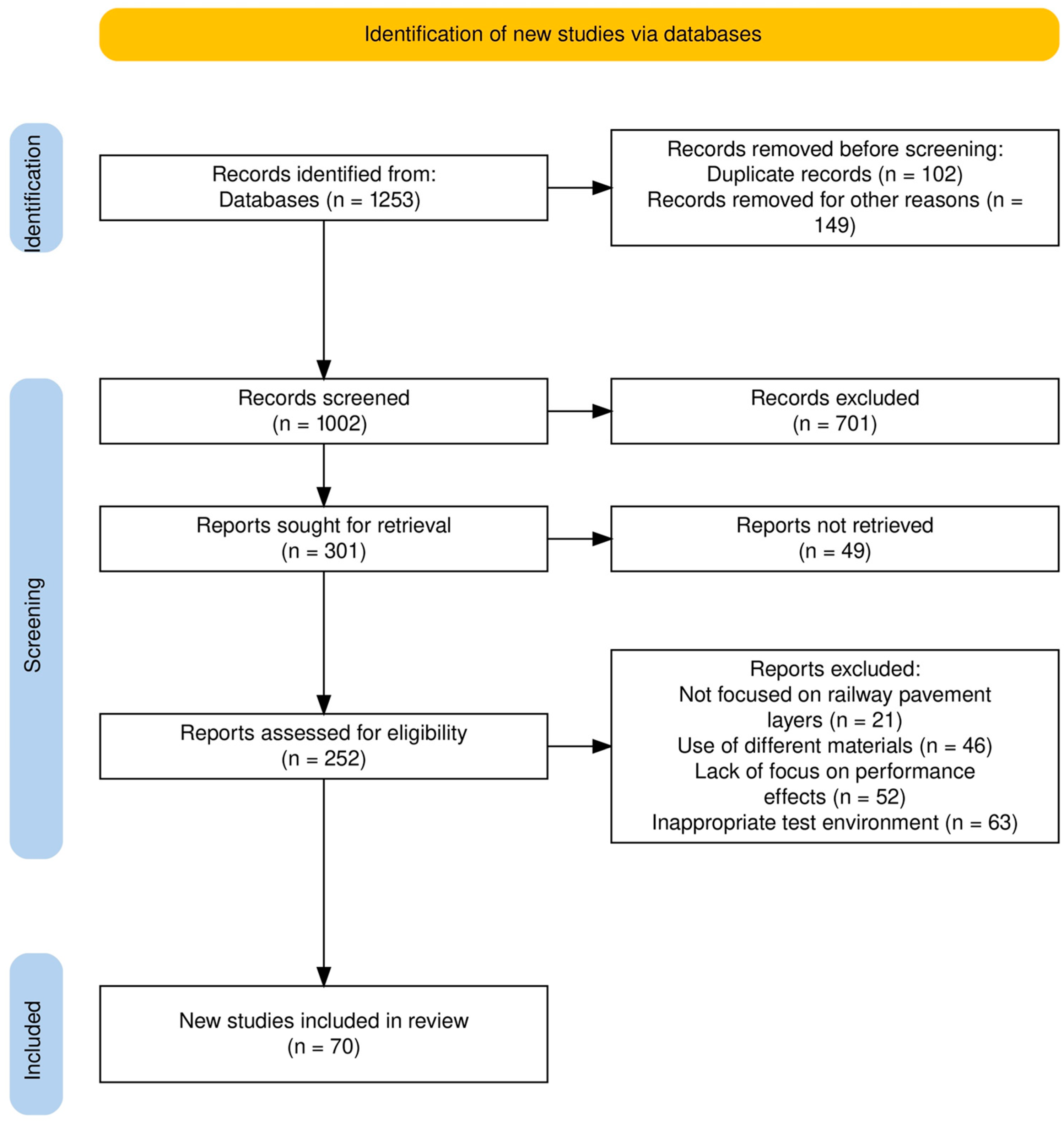

3.1. Study Selection

3.2. Effects of Crumb Rubber-Modified Asphalt

3.2.1. Environmental Impact

3.2.2. Performance Enhancements

3.2.3. Health and Safety Concerns

3.3. Case Studies

3.4. Global Perspectives on CRMA

3.5. Laboratory Findings and Implications

3.6. Comparison with Other Materials

- DRA (desulfurized rubber asphalt) provides better low-temperature flexibility but has lower rutting resistance compared to CRMA [34].

- PMA (polymer-modified asphalt) exhibits high rutting resistance but is significantly more expensive than CRMA [34].

- In hot climates, CR-modified asphalt has effectively reduced rutting while maintaining lower costs than PMA, making it a more sustainable option [45].

4. Discussion

5. Conclusions

- Implementation of non-destructive testing (NDT) and AI-driven simulations and optimizations: develop advanced non-destructive testing (NDT) techniques and AI-powered predictive models (e.g., FEM, DEM) [112,113] to evaluate material performance, optimize mix designs, and assess long-term structural integrity;

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABM | asphalt-based materials |

| AASHTO | American Association of State Highway and Transportation Officials |

| ASB | asphalt stabilized ballast |

| ASTB | asphalt slab track bed |

| AUL | asphalt underlayment |

| BBR | bending beam rheometer |

| CR | crumb rubber |

| CRMA | crumb rubber-modified asphalt |

| CRMB | crumb rubber-modified bitumen |

| DARC | dry asphalt rubber concrete |

| DEM | discrete element method or discrete element modeling |

| DRA | desulfurized rubber asphalt |

| DSR | dynamic shear rheometer |

| EPS | expanded polystyrene |

| FAM | fine aggregate matrix |

| FEM | finite element modeling |

| GHG | greenhouse gas |

| HMA-RFI | hot mix asphalt based on Italian standard (Rete Ferroviaria Italiana) |

| ITS | indirect tensile strength |

| LCA | life cycle assessment |

| LCCA | life cycle cost analysis |

| LVDT | linear variable differential transformer |

| MSCR | multiple stress creep recovery |

| NDT | non-destructive testing |

| PMA | polymer-modified asphalt |

| RMA | rubber-modified asphalt |

| SEM | scanning electron microscopy |

| SGC | superpave gyratory compactor |

| TDA | tire-derived aggregate |

| TPU/WRP | thermoplastic polyurethane/waste rubber powder |

| UBM | under-ballast mat |

| USP | under-sleeper pad |

| VECD | viscoelastic continuum damage |

| VOCs | volatile organic compounds |

| WTR | waste tire rubber |

References

- Zeng, X. Rubber-modified asphalt concrete for high-speed railway roadbeds. High-Speed Rail IDEA Program Final. Rep. 2005, 1, 1–120. Available online: https://onlinepubs.trb.org/onlinepubs/archive/studies/idea/finalreports/highspeedrail/hsr-40final_report.pdf (accessed on 29 March 2025).

- Zalacko, R.; Zöldy, M.; Simongáti, G. Comparative study of two simple marine engine BSFC estimation methods. Brodo-Gradnja 2020, 71, 13–25. [Google Scholar] [CrossRef]

- Zöldy, M.; Baranyi, P.; Török, Á. Trends in cognitive mobility in 2022. Acta Polytech. Hung. 2024, 21, 189–202. [Google Scholar] [CrossRef]

- Zöldy, M.; Zsombók, I. Influence of external environmental factors on range estimation of autonomous hybrid vehicles. Syst. Saf. Hum.-Tech. Facil.-Environ. 2019, 1, 472–480. [Google Scholar] [CrossRef]

- Ézsiás, L.; Tompa, R.; Fischer, S. Investigation of the possible correlations between specific characteristics of crushed stone aggregates. Spectr. Mech. Eng. Oper. Res. 2024, 1, 10–26. [Google Scholar] [CrossRef]

- Rose, J.G. Asphalt Underlayment Railway Trackbeds: Designs, Applications, and Long-Term Performance Evaluations; NURail Center, University of Kentucky: Lexington, KY, USA, 2017. [Google Scholar]

- Fischer, S.; Kocsis Szürke, S. Detection process of energy loss in electric railway vehicles. Facta Univ. Ser. Mech. Eng. 2023, 21, 81–99. [Google Scholar] [CrossRef]

- Fischer, S.; Hermán, B.; Sysyn, M.; Kurhan, D.; Kocsis Szürke, S. Quantitative analysis and optimization of energy efficiency in electric multiple units. Facta Univ. Ser. Mech. Eng. 2025, 23, 13299. [Google Scholar] [CrossRef]

- Kocsis Szürke, S.; Kovács, G.; Sysyn, M.; Liu, J.; Fischer, S. Numerical optimization of battery heat management of electric vehicles. J. Appl. Comput. Mech. 2023, 9, 1076–1092. [Google Scholar] [CrossRef]

- Jovanović, V.; Marinković, D.; Janošević, D.; Petrović, N. Influential factors in the loading of the axial bearing of the slewing platform drive in hydraulic excavators. Teh. Vjesn. 2023, 30, 158–168. [Google Scholar] [CrossRef]

- Asgharzadeh, S.M.; Sadeghi, J.; Peivast, P.; Pedram, M. Fatigue properties of crumb rubber asphalt mixtures used in railways. Constr. Build. Mater. 2018, 184, 248–257. [Google Scholar] [CrossRef]

- Kuchak, A.T.J.; Marinkovic, D.; Zehn, M. Parametric investigation of a rail damper design based on a lab-scaled model. J. Vib. Eng. Technol. 2021, 9, 51–60. [Google Scholar] [CrossRef]

- Kuchak, A.T.J.; Marinkovic, D.; Zehn, M. Finite element model updating—Case study of a rail damper. Struct. Eng. Mech. 2020, 73, 27–35. [Google Scholar] [CrossRef]

- Volkov, V.; Taran, I.; Volkova, T.; Pavlenko, O.; Berezhnaja, N. Determining the efficient management system for a specialized transport enterprise. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2020, 2020, 185–191. [Google Scholar] [CrossRef]

- Fischer, S. Investigation of the settlement behavior of ballasted railway tracks due to dynamic loading. Spectr. Mech. Eng. Oper. Res. 2025, 2, 24–46. [Google Scholar] [CrossRef]

- Xiao, X.; Cai, D.; Lou, L.; Shi, Y.; Xiao, F. Application of asphalt-based materials in railway systems: A review. Constr. Build. Mater. 2021, 304, 124630. [Google Scholar] [CrossRef]

- Fischer, S. Evaluation of inner shear resistance of layers from mineral granular materials. Facta Univ. Ser. Mech. Eng. 2023, 1, 41–50. [Google Scholar] [CrossRef]

- Eller, B.; Fischer, S. Application of Concrete Canvas for enhancing railway substructure performance under static and dynamic loads. Facta Univ. Ser. Mech. Eng. 2025. [Google Scholar] [CrossRef]

- Liu, J.; Sysyn, M.; Liu, Z.; Kou, L.; Wang, P. Studying the Strengthening Effect of Railway Ballast in the Direct Shear Test due to Insertion of Middle-size Ballast Particles. J. Appl. Comput. Mech. 2022, 8, 1387–1397. [Google Scholar] [CrossRef]

- Zeng, X.; Rose, J.G.; Rice, J.S. Stiffness and damping ratio of rubber-modified asphalt mixes: Potential vibration attenuation for high-speed railway trackbeds. J. Vib. Control 2001, 7, 527–538. [Google Scholar] [CrossRef]

- Itoh, K.; Zeng, X.; Murata, O.; Kusakabe, O. Centrifugal simulation of vibration reduction generated by high-speed trains using rubber-modified asphalt foundation and EPS barrier. Int. J. Phys. Model. Geotech. 2003, 2, 1–10. [Google Scholar] [CrossRef]

- Kou, L.; Sysyn, M.; Liu, J. Influence of crossing wear on rolling contact fatigue damage of frog rail. Facta Univ. Ser. Mech. Eng. 2024, 22, 25–44. [Google Scholar] [CrossRef]

- Brautigam, A.; Szalai, S.; Fischer, S. Investigation of the application of austenitic filler metals in paved tracks for the repair of the running surface defects of rails considering field tests. Facta Univ. Ser. Mech. Eng. 2023; accepted manuscript in Online first. [Google Scholar] [CrossRef]

- Fischer, S.; Harangozó, D.; Németh, D.; Kocsis, B.; Sysyn, M.; Kurhan, D.; Brautigam, A. Investigation of heat-affected zones of thermite rail welding. Facta Univ. Ser. Mech. Eng. 2024, 22, 689–710. [Google Scholar] [CrossRef]

- Kampczyk, A. Technical specifications for interoperability and the provisions of Polish design geometry of the railway line. Bauingenieur 2015, 90, 229–234. [Google Scholar] [CrossRef]

- Kampczyk, A.; Rombalska, K. Configuration of the geometric state of railway tracks in the sustainability development of electrified traction systems. Sensors 2023, 23, 2817. [Google Scholar] [CrossRef]

- Indraratna, B.; Qi, Y.; Malisetty, R.S.; Navaratnarajah, S.K.; Mehmood, F.; Tawk, M. Recycled materials in railroad substructure: An energy perspective. Railw. Eng. Sci. 2022, 30, 304–322. [Google Scholar] [CrossRef]

- Soto, F.M.; Di Mino, G. Procedure for a temperature-traffic model on rubberized asphalt layers for roads and railways. J. Traffic Transp. Eng. 2017, 5, 171–202. [Google Scholar] [CrossRef][Green Version]

- Pavelčík, V.; Dižo, J.; Blatnický, M.; Ishchuk, V.; Molnár, D. Analysis of the Test Bench Design Influence on the Cooling Performance of a Rail Vehicle Brake Disc. Communications 2023, 25, 194–200. [Google Scholar] [CrossRef]

- Szalai, S.; Szívós, B.F.; Kocsis, D.; Sysyn, M.; Liu, J.; Fischer, S. The Application of DIC in Criminology Analysis Procedures to Measure Skin Deformation. J. Appl. Comput. Mech. 2024, 10, 817–829. [Google Scholar] [CrossRef]

- Lovska, A.; Gerlici, J.; Dižo, J.; Ishchuk, V. The strength of rail vehicles transported by a ferry considering the influence of sea waves on its hull. Sensors 2023, 24, 183. [Google Scholar] [CrossRef]

- Yang, E.; Wang, K.C.; Luo, Q.; Qiu, Y. Asphalt concrete layer to support track slab of high-speed railway. Transp. Res. Rec. 2015, 2505, 6–14. [Google Scholar] [CrossRef]

- Xu, L.; Ni, H.; Zhang, Y.; Sun, D.; Zheng, Y.; Hu, M. Porous asphalt mixture use asphalt rubber binders: Preparation and noise reduction evaluation. J. Clean. Prod. 2022, 376, 134119. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Z.; Li, Z. Performance evaluation of desulfurized rubber asphalt based on rheological and environmental effects. J. Mater. Civ. Eng. 2020, 32, 04019330. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Moreno-Navarro, F.; Saiz, L.; Rubio-Gámez, M.C. Recycling waste rubber particles for the maintenance of different states of railway tracks through a two-step stoneblowing process. J. Clean. Prod. 2020, 244, 118570. [Google Scholar] [CrossRef]

- Dižo, J.; Blatnický, M.; Droździel, P.; Melnik, R.; Caban, J.; Kafrik, A. Investigation of driving stability of a vehicle–trailer combination depending on the load’s position within the trailer. Acta Mech. Autom. 2023, 17, 60–67. [Google Scholar] [CrossRef]

- Németh, A.; Fischer, S. Investigation of the glued insulated rail joints applied to CWR tracks. Facta Univ. Ser. Mech. Eng. 2021, 19, 681–704. [Google Scholar] [CrossRef]

- Zöldy, M.; Baranyi, P. The Cognitive Mobility Concept. Infocommun. J. 2023, (SP), 35–40. [Google Scholar] [CrossRef]

- Di Mino, G.; Di Liberto, C.M. Experimental survey on dry asphalt rubber concrete for sub-ballast layers. J. Civ. Eng. Archit. 2012, 6, 1615–1626. Available online: https://iris.unipa.it/retrieve/handle/10447/78990/75856/2.%20Journal%20of%20Civil%20Engineering%20and%20Architecture.pdf (accessed on 29 March 2025).

- Zu-yuan, L.; Hou-zhi, W.; Chen-guang, S.; Xing, C.; Jun, Y.; Yun-hong, Y. Evaluation of the fractures of asphalt concrete added with rubber particles based on the fine aggregate mixtures. Constr. Build. Mater. 2022, 332, 127365. [Google Scholar] [CrossRef]

- Soto, F.M.; Di Mino, G. Improvements in the mix-design, performance features and rational methodology of rubber modified binders for the thermal evaluation of the railway sub-ballast. Int. J. Res. Sci. Manag. 2018, 5, 90–108. Available online: https://ijrsm.com/index.php/journal-ijrsm/article/view/279 (accessed on 29 March 2025).

- Albalat, S.A.; Domingo, L.M.; Sanchis, I.V.; Herráiz, J.I.R.; Segarra, A.V. Crumb Rubber Modified Bitumen for sub-ballast layer. In 9th World Congress on Railway Research; UIC: Paris, France, 2011; Available online: https://www.researchgate.net/profile/Ignacio-Villalba/publication/265301366_An_environmentely_friendly_railway_Crumb_Rubber_Modified_Bitumen_for_sub-ballast_layer/links/54084b4f0cf23d9765afe272/An-environmentely-friendly-railway-Crumb-Rubber-Modified-Bitumen-for-sub-ballast-layer.pdf (accessed on 29 March 2025).

- Xiao, X.; Wang, J.; Cai, D.; Lou, L.; Xiao, F. A novel application of thermoplastic polyurethane/waste rubber powder blend for waterproof seal layer in high-speed railway. Transp. Geotech. 2021, 27, 100503. [Google Scholar] [CrossRef]

- Qiang, W.; Jing, G.; Connolly, D.P.; Aela, P. The use of recycled rubber in ballasted railway tracks: A review. J. Clean. Prod. 2023, 420, 138339. [Google Scholar] [CrossRef]

- Apeh, S.A.; Adeyeri, J.B.; Amu, O.O. Experimental study on the influence of crumb rubber on temperature susceptibility of asphalt for railway application in the tropics. Am. J. Traffic Transp. Eng. 2024, 9, 98–104. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Li, D.; Chen, Y.; Xiang, Z. Enhancement of dynamic damping in eco-friendly railway concrete sleepers using waste-tyre crumb rubber. Materials 2018, 11, 1169. [Google Scholar] [CrossRef]

- Roy, A.; Rajkumar, K.; Kapgate, B. Crumb Rubber Modified Asphalt: Fundamentals to Recent Developments; IntechOpen: London, UK, 2024. [Google Scholar] [CrossRef]

- Bressi, S.; Santos, J.; Giunta, M.; Pistonesi, L.; Presti, D.L. A comparative life-cycle assessment of asphalt mixtures for railway sub-ballast containing alternative materials. Resour. Conserv. Recycl. 2018, 137, 76–88. [Google Scholar] [CrossRef]

- Halsband, C.; Sørensen, L.; Booth, A.M.; Herzke, D. Car tire crumb rubber: Does leaching produce a toxic chemical cocktail in coastal marine systems? Front. Environ. Sci. 2020, 8, 557495. [Google Scholar] [CrossRef]

- Jovanović, V.; Janošević, D.; Marinković, D.; Petrović, N.; Pavlović, J. Railway load analysis during the operation of an excavator resting on the railway track. Acta Polytech. Hung. 2023, 20, 79–93. [Google Scholar] [CrossRef]

- Kovalchuk, V.; Sysyn, M.; Gerber, U.; Nabochenko, O.; Zarour, J.; Dehne, S. Experimental investigation of the influence of train velocity and travel direction on the dynamic behavior of stiff common crossings. Facta Univ. Ser. Mech. Eng. 2019, 17, 345–356. [Google Scholar] [CrossRef]

- Kurhan, D.; Fischer, S. Modeling of the dynamic rail deflection using elastic wave propagation. J. Appl. Comput. Mech. 2022, 8, 379–387. [Google Scholar] [CrossRef]

- Semenov, S.; Mikhailov, E.; Kovtanets, M.; Sergienko, O.; Dižo, J.; Blatnický, M.; Gerlici, J.; Kostrzewski, M. Kinematic running resistance of an urban rail vehicle undercarriage: A study of the impact of wheel design. Sci. Rep. 2023, 13, 10856. [Google Scholar] [CrossRef]

- Ficzere, P. The role of artificial intelligence in the development of rail transport. Cogn. Sustain. 2023, 2, 81. [Google Scholar] [CrossRef]

- Melnik, R.; Koziak, S.; Dižo, J.; Kuźmierowski, T.; Piotrowska, E. Feasibility study of a rail vehicle damper fault detection by artificial neural networks. Eksploat. I Niezawodn. 2023, 25, 5. [Google Scholar] [CrossRef]

- Saukenova, I.; Oliskevych, M.; Taran, I.; Toktamyssova, A.; Aliakbarkyzy, D.; Pelo, R. Optimization of schedules for early garbage collection and disposal in the megapolis. East.-Eur. J. Enterp. Technol. 2022, 1, 13–23. [Google Scholar] [CrossRef]

- Zeng, Z.; Shuaibu, A.A.; Liu, F.; Ye, M.; Wang, W. Experimental study on the vibration reduction characteristics of the ballasted track with rubber composite sleepers. Constr. Build. Mater. 2020, 262, 120766. [Google Scholar] [CrossRef]

- Vitković, N.; Marinković, D.; Stan, S.-D.; Simonović, M.; Miltenović, A.; Tomić, M.; Barać, M. Decision support system for managing marshalling yard deviations. Acta Polytech. Hung. 2024, 21, 121–134. [Google Scholar] [CrossRef]

- Bouraima, M.B.; Qiu, Y.; Stević, Ž.; Marinković, D.; Deveci, M. Integrated intelligent decision support model for ranking regional transport infrastructure programmes based on performance assessment. Expert Syst. Appl. 2023, 222, 119852. [Google Scholar] [CrossRef]

- Rose, J.G.; Teixeira, P.F.; Ridgway, N.E. Utilization of asphalt/bituminous layers and coatings in railway trackbeds: A compendium of international applications. Jt. Rail Conf. 2010, 49064, 239–255. [Google Scholar] [CrossRef]

- Soto, F.M.; Di Mino, G. Optimization of the Mix-Design System for the Sub-Ballast Railroad. J. Traffic Transp. Eng. 2017, 5, 246–259. [Google Scholar] [CrossRef]

- Peng, J.; Deng, D.; Liu, Z.; Yuan, Q.; Ye, T. Rheological models for fresh cement asphalt paste. Constr. Build. Mater. 2014, 71, 254–262. [Google Scholar] [CrossRef]

- Ouyang, J.; Tan, Y.; Corr, D.J.; Shah, S.P. The thixotropic behavior of fresh cement asphalt emulsion paste. Constr. Build. Mater. 2016, 114, 906–912. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Z.; Wang, T.; Hu, S. A novel method to evaluate the setting process of cement and asphalt emulsion in CA mortar. Mater. Struct. 2008, 41, 643–647. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Z.; Hu, S. Early age volume change of cement asphalt mortar in the presence of aluminum powder. Mater. Struct. 2010, 43, 493–498. [Google Scholar] [CrossRef]

- Li, X.; Lin, D.; Lu, K.; Chen, X.; Yin, S.; Li, Y.; Chen, G. Graphene oxide orientated by a magnetic field and application in sensitive detection of chemical oxygen demand. Anal. Chim. Acta 2020, 1122, 31–38. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Moreno-Navarro, F.; Tauste-Martínez, R.; Saiz, L.; Rubio-Gámez, M.C. Recycling Tire-Derived Aggregate as elastic particles under railway sleepers: Impact on track lateral resistance and durability. J. Clean. Prod. 2020, 277, 123322. [Google Scholar] [CrossRef]

- Rutherford, T.; Wang, Z.; Shu, X.; Huang, B.; Clarke, D. Laboratory investigation into mechanical properties of cement emulsified asphalt mortar. Constr. Build. Mater. 2014, 65, 76–83. [Google Scholar] [CrossRef]

- Zeng, X.; Li, Y.; Ran, Y.; Yang, K.; Qu, F.; Wang, P. Deterioration mechanism of CA mortar due to simulated acid rain. Constr. Build. Mater. 2018, 168, 1008–1015. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Zhong, G.Y.; Zhang, P.Z. Chemical constituents isolated from Clematis akebioides (Maximowicz) Veitch. Biochem. Syst. Ecol. 2019, 83, 13–16. [Google Scholar] [CrossRef]

- Peng, H.; Peters, S.; Vaughan, J. Leaching kinetics of thermally-activated, high silica bauxite. In Light Met; Springer: New York, NY, USA; International Publishing: New York, NY, USA, 2019; pp. 11–17. [Google Scholar] [CrossRef]

- Li, Y.C.; Shen, J.D.; Lu, S.F.; Zhu, L.L.; Wang, B.Y.; Bai, M.; Xu, E.P. Transcriptomic analysis reveals the mechanism of sulfasalazine-induced liver injury in mice. Toxicol. Lett. 2020, 321, 12–20. [Google Scholar] [CrossRef]

- Wang, B.; Lu, S.; Zhang, C.; Zhu, L.; Li, Y.; Bai, M.; Xu, E. Quantitative proteomic analysis of the liver reveals antidepressant potential protein targets of Sinisan in a mouse CUMS model of depression. Biomed. Pharmacother. 2020, 130, 110565. [Google Scholar] [CrossRef]

- Feng, Q.; Sun, K.; Chen, H.; Lei, X.; Wang, W. Lifetime performance assessment of railway ballastless track systems affected by a mortar interface defect. J. Aerosp. Eng. 2019, 32, 04019037. [Google Scholar] [CrossRef]

- Shi, H.; Yu, Z.; Shi, H.; Zhu, L. Recognition algorithm for the disengagement of cement asphalt mortar based on dynamic responses of vehicles. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 270–282. [Google Scholar] [CrossRef]

- Li, Y.; Chen, J.; Wang, J.; Shi, X.; Chen, L. Study on the interface damage of CRTS II slab track under temperature load. Structures 2020, 26, 224–236. [Google Scholar] [CrossRef]

- Ren, J.; Chen, Z.; Sun, M.; Sun, Q. Design and implementation of the PI-type active disturbance rejection generalized predictive control. In Proceedings of the 2020 IEEE 9th Data Driven Control and Learning Systems Conference (DDCLS), Liuzhou, China, 19–21 June 2020; pp. 12–17. [Google Scholar] [CrossRef]

- Xu, H.; Lin, H.S.; Wang, P.; Yan, H. The influence of water immersion on the mechanical property of cement asphalt mortar and its implications on the slab track. J. Vibroeng. 2017, 19, 477–486. [Google Scholar] [CrossRef]

- Liu, S.; Chen, X.; Ma, Y.; Yang, J.; Cai, D.; Yang, G. Modelling and in-situ measurement of dynamic behavior of asphalt supporting layer in slab track system. Constr. Build. Mater. 2019, 228, 116776. [Google Scholar] [CrossRef]

- Fang, M.; Cerdas, S.F. Theoretical analysis on ground vibration attenuation using sub-track asphalt layer in high-speed rails. J. Mod. Transp. 2015, 23, 214–219. [Google Scholar] [CrossRef]

- Fu, X.; Huang, Z.J.; Li, Q.; Kirillova, K. Dissecting Chinese adolescents’ overseas educational travel experiences: Movements, representations and practices. In Current Issues in Asian Tourism; Routledge: Oxfordshire, UK, 2020; pp. 14–35. [Google Scholar] [CrossRef]

- Ye, Y.; Xu, G.; Lou, L.; Chen, X.; Cai, D.; Shi, Y. Evolution of rheological behaviors of styrene-butadiene-styrene/crumb rubber composite modified bitumen after different long-term aging processes. Materials 2019, 12, 2345. [Google Scholar] [CrossRef]

- Yusupov, B.; Qiu, Y.; Sharipov, G.; Wu, C. Characterization of vertical response of asphalt trackbed concrete in railway substructure to external loads. Adv. Mater. Sci. Eng. 2020, 2020, 3578281. [Google Scholar] [CrossRef]

- Yang, E.; Wang, K.C.; Qiu, Y.; Luo, Q. Asphalt concrete for high-speed railway infrastructure and performance comparisons. J. Mater. Civ. Eng. 2016, 28, 04015202. [Google Scholar] [CrossRef]

- Li, T.F.; Cai, D.G.; Yan, H.Y.; Bao, L.M.; Zhang, X.G.; Lyu, S. Temperature effect of whole section asphalt concrete waterproof sealing structure for high speed railway subgrade in severe cold regions. Railw. Eng 2018, 58, 63–68. [Google Scholar]

- Chen, X.; Wang, F.; Cao, P.; Ma, X.; Yuan, L.; Zhang, Y.; Nie, D.; Chen, J.; Zhou, X.; Liu, M.; et al. Fusion Gene Map of Acute Lymphoblastic Leukemia Revealed By Transcriptome Sequencing of a Consecutive Cohort of 350 Cases in a Single Center. Blood 2020, 136, 16–17. [Google Scholar] [CrossRef]

- Lv, S. Research on Performance and Cracking Mechanism of Asphalt Concrete Layer Under the Ballastless Track of High Speed Railway. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2019. (In Chinese). [Google Scholar]

- Shi, Y.; Lou, L.; Cai, D.; Lv, S.; Cai, Y.; Zhang, Z. Evaluation on Fatigue Characteristics of Railway Asphalt Concrete Subballast Layer Based on KENTRACK Software. Railw. Eng. 2020, 60, 145–149. Available online: https://jglobal.jst.go.jp/en/detail?JGLOBAL_ID=202002219884981912 (accessed on 29 March 2025).

- Ramirez, D.; Jamel, B.; Sofia, C.D.A.; Nicolas, C.; Alain, R.; Di, B.H.; Cedric, S. High-Speed Ballasted Track Behavior with Sub-Ballast Bituminous Layer. Georail. 2014. Available online: https://www.researchgate.net/publication/280730520_High-speed_ballasted_track_behaviour_with_sub-ballast_bituminous_layer#:~:text=In%20this%20paper,%20two%20aspects%20are%20analysed%20from,track%E2%80%99s%20behaviour.%20Three%20different%20track%20configurations%20are%20studied (accessed on 29 March 2025).

- Li, J.; He, L. Modification and aging mechanism of crumb rubber modified asphalt based on molecular dynamics simulation. Materials 2025, 18, 197. [Google Scholar] [CrossRef]

- Arachchige, C.M.K.; Indraratna, B.; Rujikiakamjorn, C.; Qi, Y.; Siddiqui, A.R. Use of waste rubber inclusions for ballasted railway construction—A real-life case study. In Smart Geotechnics for Smart Societies; CRC Press: Boca Raton, FL, USA, 2023; pp. 2567–2570. [Google Scholar] [CrossRef]

- Li, D.; Rose, J.; LoPresti, J. Test of Hot-Mix Asphalt Trackbed over Soft Subgrade Under Heavy Axle Loads. Technology Digest-01-009, Assoc. of American Railroads, April 2001, 4. Available online: https://www.researchgate.net/profile/Dingqing-Li/publication/265083775_Test_of_Hot-Mix_Asphalt_Trackbed_over_Soft_Subgrade_under_Heavy_Axle_Loads/links/5686e39f08aebccc4e13cc0f/Test-of-Hot-Mix-Asphalt-Trackbed-over-Soft-Subgrade-under-Heavy-Axle-Loads.pdf (accessed on 29 March 2025).

- Rose, J.G.; Hensley, M.J. Performance of hot-mix-asphalt railway trackbeds. Transp. Res. Rec. 1991, 1300. Available online: https://onlinepubs.trb.org/Onlinepubs/trr/1991/1300/1300-005.pdf (accessed on 29 March 2025).

- Khairallah, D.; Blanc, J.; Cottineau, L.M.; Hornych, P.; Piau, J.M.; Pouget, S.; Hosseingholian, M.; Ducreau, A.; Savin, F. Monitoring of railway structures of the high-speed line BPL with bituminous and granular sublayers. Constr. Build. Mater. 2019, 211, 337–348. [Google Scholar] [CrossRef]

- Apeh, A.S.; Adeyeri, J.B.; Amu, O.O. Study on the performance of crumb rubber modified asphalt concrete mixtures for railway application in the tropics. Nnamdi Azikiwe Univ. J. Civ. Eng. (NAUJCVE) 2024, 2, 50–60. Available online: https://naujcve.com/index.php/NAUJCVE/article/view/128 (accessed on 29 March 2025).

- Momoya, Y.; Sekine, E. Performance-based design method for railway asphalt roadbed. Doboku Gakkai Ronbunshuu E 2007, 63, 608–619. Available online: https://www.ntnu.no/ojs/index.php/BCRRA/article/download/3178/3063/ (accessed on 29 March 2025).

- Yoshitsugu, M.; Etsuo, S.; Fumio, T. Deformation characteristics of railway roadbed and subgrade under moving-wheel load. Soils Found. 2005, 45, 99–118. [Google Scholar] [CrossRef]

- Xiao, F.; Wang, T.; Hou, X.; Yuan, J.; Jiang, C.; Luo, Y. Waterproof and antiscour properties of asphalt-based composite seals for airfield base layer. J. Mater. Civ. Eng. 2020, 32, 04019328. [Google Scholar] [CrossRef]

- Barbieri, M.; Mambelli, F.; Lucchi, J.; Diversi, R.; Tilli, A.; Sartini, M. Condition monitoring of a paper feeding mechanism using model-of-signals as machine learning features. PHM Soc. Eur. Conf. 2020, 5, 1–10. Available online: https://www.researchgate.net/profile/Matteo-Barbieri-2/publication/345321472_Condition_Monitoring_of_a_Paper_Feeding_Mechanism_Using_Model-of-Signals_as_Machine_Learning_Features/links/5fa3ce42458515157bec0a5a/Condition-Monitoring-of-a-Paper-Feeding-Mechanism-Using-Model-of-Signals-as-Machine-Learning-Features.pdf (accessed on 29 March 2025). [CrossRef]

- Setiawan, D.M. Worldwide hot mix asphalt layer application and scrap rubber and bitumen emulsion studies on railway track-bed. Semesta Tek. 2018, 21, 166–177. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Jia, M.; Du, Q. Emission risk and inhibition technology of asphalt fume from crumb rubber modified asphalt. Sustainability 2024, 16, 8840. [Google Scholar] [CrossRef]

- Le, T.H.M.; Park, D.W.; Seo, J.W.; Phan, T.M. Anti-chemical resistance and mock-up test performance of cement asphalt mortar modified with polymer for ballast stabilizing. Constr. Build. Mater. 2020, 232, 117260. [Google Scholar] [CrossRef]

- Huang, C.S.; Sun, Z.Z. Railway application and development of asphalt track bed. J. Railw. Eng. Soc 1991, 132–140. [Google Scholar]

- Cheng, H.; Liu, J.; Sun, L.; Liu, L.; Zhang, Y. Fatigue behaviours of asphalt mixture at different temperatures in four-point bending and indirect tensile fatigue tests. Constr. Build. Mater. 2021, 273, 121675. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Tire Crumb Questions and Answers. U.S. Environmental Protection Agency. Available online: https://www.epa.gov/chemical-research/tire-crumb-questions-and-answers (accessed on 9 March 2025).

- Foscari, A.; Schmidt, N.; Seiwert, B.; Herzke, D.; Sempéré, R.; Reemtsma, T. Leaching of chemicals and DOC from tire particles under simulated marine conditions. Front. Environ. Sci. 2023, 11, 1206449. [Google Scholar] [CrossRef]

- Pavilonis, B.T.; Weisel, C.P.; Buckley, B.; Lioy, P.J. Bioaccessibility and risk of exposure to metals and SVOCs in artificial turf field fill materials and fibers. Risk Anal. 2014, 34, 44–55. [Google Scholar] [CrossRef]

- Dižo, J.; Blatnický, M.; Semenov, S.; Mikhailov, E.; Kostrzewski, M.; Droździel, P.; Šťastniak, P. Electric and plug-in hybrid vehicles and their infrastructure in a particular European region. Transp. Res. Procedia 2021, 55, 629–636. [Google Scholar] [CrossRef]

- Blatnický, M.; Dižo, J.; Kravchenko, A.; Steišūnas, S. Optimization of a Trestle Weight of an Operating Hydraulic Jack Used During Wagons Repairing. In International Conference TRANSBALTICA: Transportation Science and Technology; Springer International Publishing: Cham, Switzerland, 2021; pp. 48–57. [Google Scholar] [CrossRef]

- Blatnický, M.; Dižo, J.; Bruna, M.; Sága, M. Applied research of high-strength steel utilization for a track of demining machine in terms of mechanical properties. Int. J. Adv. Manuf. Technol. 2023, 127, 5879–5896. [Google Scholar] [CrossRef]

- Blatnický, M.; Dižo, J.; Saga, M.; Kopas, P. Applied Research of Applicability of High-Strength Steel for a Track of a Demining Machine in Term of Its Tribological Properties. Metals 2021, 11, 505. [Google Scholar] [CrossRef]

- Zamfirache, I.A.; Precup, R.E.; Petriu, E.M. Q-Learning, Policy Iteration and Actor-Critic Reinforcement Learning Combined with Metaheuristic Algorithms in Servo System Control. Facta Univ. Ser. Mech. Eng. 2023, 21, 615–630. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Aglikov, A.S. Triboinformatics: Machine Learning Methods for Frictional Instabilities. Facta Univ. Ser. Mech. Eng. 2024, 22, 423–433. [Google Scholar] [CrossRef]

- Taran, I.; Karsybayeva, A.; Naumov, V.; Murzabekova, K.; Chazhabayeva, M. Fuzzy-Logic Approach to Estimating the Fleet Efficiency of a Road Transport Company: A Case Study of Agricultural Products Deliveries in Kazakhstan. Sustainability 2023, 15, 4179. [Google Scholar] [CrossRef]

- Oliskevych, M.; Taran, I.; Volkova, T.; Klymenko, I. Simulation of cargo delivery by road carrier: Case study of the transportation company. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2022, 2022, 118–123. [Google Scholar] [CrossRef]

- Novytskyi, O.; Taran, I.; Zhanbirov, Z. Increasing mine train mass by means of improved efficiency of service braking. E3S Web Conf. 2019, 123, 01034. [Google Scholar] [CrossRef]

- Udvardy, K.; Görbe, P.; Bódis, T.; Botzheim, J. Conceptual Framework for Adaptive Bacterial Memetic Algorithm Parameterization in Storage Location Assignment Problem. Mathematics 2024, 12, 3688. [Google Scholar] [CrossRef]

- Görbe, P.; Bódis, T. Generalized objective function to ensure robust evaluation for evolutionary storage location assignment algorithms. In International Conference on Computational Collective Intelligence; Springer Nature: Cham, Switzerland, 2023; pp. 546–559. [Google Scholar] [CrossRef]

- Jóvér, M.; Major, Z.; Németh, A.; Sysyn, M.; Kurhan, D.; Fischer, S. Investigation of the Geometrical Deterioration Process of Tramway Superstructure Systems—A Case Study. Acta Polytech. Hung. 2025. Paper 7157, accepted manuscript. Available online: https://www.researchgate.net/publication/388847188_Investigation_of_the_geometrical_deterioration_process_of_tramway_superstructure_systems_-_A_case_study (accessed on 29 March 2025).

- Saleh, A.; Gáspár, L. Optimizing Foamed Bitumen Bound Asphalt Mixture Design Using Neural Network. Period. Polytech. Civ. Eng. 2024, 68, 1040–1051. [Google Scholar] [CrossRef]

- Saleh, A.; Gáspár, L. Optimizing asphalt foaming using neural network. Pollack Period. 2024, 19, 130–136. [Google Scholar] [CrossRef]

- Merrill, D.; Van Dommelen, A.; Gáspár, L. A review of practical experience throughout Europe on deterioration in fully-flexible and semi-rigid long-life pavements. Int. J. Pavement Eng. 2006, 7, 101–109. [Google Scholar] [CrossRef]

- Horváth, E.; Harsányi, G.; Henap, G.; Török, Á. Mechanical modelling and life cycle optimisation of screen printing. J. Theor. Appl. Mech. 2012, 50, 1025–1036. [Google Scholar]

- Dizo, J.; Blatnicky, M. Evaluation of vibrational properties of a three-wheeled vehicle in terms of comfort. Manuf. Technol 2019, 19, 197–203. [Google Scholar] [CrossRef]

- Dižo, J.; Steišunas, S.; Blatnický, M. Vibration analysis of a coach with the wheel-flat due to suspension parameters changes. Procedia Eng. 2017, 192, 107–112. [Google Scholar] [CrossRef]

- Safaei, B.; Onyibo, E.C.; Goren, M.; Kotrasova, K.; Yang, Z.; Arman, S.; Asmael, M. Free vibration investigation on RVE of proposed honeycomb sandwich beam and material selection optimization. Facta Univ. Ser. Mech. Eng. 2023, 21, 31–50. [Google Scholar] [CrossRef]

- Rayapureddy, S.M.; Maknickas, A.; Matijošius, J.; Vainorius, D.; Kilikevičius, A. Computational study of frequency impact onto the particle parameters and change in acoustic agglomeration time with the number of particles. Facta Univ. Ser. Mech. Eng. 2024, 22, 741–757. [Google Scholar] [CrossRef]

- Maghrour Zefreh, M.; Török, Á.; Zitricky, V. Theoretical Comparison of the Effects of Different Traffic Conditions on Urban Road Traffic Noise. J. Adv. Transp. 2018, 2018, 7949574. [Google Scholar] [CrossRef]

| Category of Methodology | Objective/Description | Techniques/Tools Used |

|---|---|---|

| Laboratory Dynamic Tests | Evaluate the dynamic properties of CRMA under varying temperature and pressure conditions and assess vibration reduction in the railway track. | Laboratory tests, numerical simulations, dynamic modulus tests, fatigue tests [1,6]. |

| Fatigue Evaluation and VECD Modeling | Investigate the fatigue properties of CRMA using viscoelastic continuum damage (VECD) theory with creep, monotonic loading, and cyclic fatigue tests to enhance fatigue life. | Creep tests, monotonic loading, cyclic fatigue tests, VECD modeling [11]. |

| Performance Evaluation of ABM in Railways | Assess the overall performance of ABM systems through a combination of laboratory tests, field evaluations, and numerical simulations. | Dynamic modulus tests, fatigue tests, large-scale tests, finite element analysis (FEM) [16]. |

| Resonant Column Tests for RMA | Measure the stiffness and damping ratio of RMA to determine its vibrational performance and resistance to dynamic loads. | Resonant column tests [20]. |

| Centrifuge Model Tests for Vibration | Simulate the effects of CRMA and EPS barriers on reducing ground vibrations caused by high-speed trains using frequency analysis. | Centrifuge model tests, multiple ball-dropping system, FFT analysis [21]. |

| Integration of Sustainable Materials (TDA) | Evaluate the use of tire-derived aggregate (TDA) as a sustainable substitute in railway substructures by investigating enhanced durability, reduced ballast degradation, and optimized lateral resistance. | Controlled dosage determination of TDA, laboratory evaluations [67]. |

| Vibration Tests for Rubber Composite Sleepers | Investigate the vibration reduction characteristics of rubber composite sleepers compared to conventional concrete sleepers. | Full-scale laboratory model, drop hammer testing, time and frequency domain analysis [57]. |

| Energy Assessment and Analysis of Recycled Materials | Conduct a comprehensive assessment of the physical, mechanical, and chemical properties of recycled materials and evaluate energy consumption from extraction to installation. | Laboratory tests, energy modeling, life cycle energy assessment (LCEA) framework, statistical analysis [27]. |

| Characterization of Rubberized Asphalt | Evaluate the mechanical and microstructural performance of rubberized asphalt using Marshall tests, indirect tensile strength tests, dynamic modulus, fatigue tests, and microscopic analysis. | Marshall tests, indirect tensile strength tests, dynamic modulus tests, fatigue tests, SEM, spectroscopy, LCEA framework [28]. |

| Evaluation of Asphalt Support Layer for Rail | Assess the asphalt layer as a rail support in terms of stiffness, dynamic modulus, and damping characteristics under dynamic loading. | Static and dynamic load tests, fatigue and impact tests, finite element modeling (FEM) [32]. |

| Testing of Porous Asphalt Mixtures | Evaluate the mechanical properties, durability, and noise reduction performance of porous asphalt mixtures containing crumb rubber. | Porosity tests, permeability tests, sound absorption tests using standard methods [33]. |

| Full-Scale Laboratory Simulation of Ballasted Railway Sections | Simulate the performance of ballasted railway sections with varying settlement levels and evaluate stiffness, rail oscillations, and settlement recovery. | Construction of a full-scale laboratory section, application of dynamic loads (5 Hz), and measurements using LVDTs [35]. |

| Full-Scale Laboratory Simulation of Sub-Ballast Sections | Simulate sub-ballast and ballast layers using Marshall mix design, four-point bending tests, and 2D lumped mass modeling to assess sub-ballast performance. | Four-point bending tests (4PB-PR), 2D lumped mass modeling, dynamic testing protocol [39]. |

| Numerical Modeling for CRMB Sub-Ballast | Assess the structural behavior of CRMB sub-ballast—including load distribution, settlement, fatigue life, and thermal effects under varying conditions. | Finite element modeling in ANSYS, (Ansys Inc., Canonsburg, Pennsylvania, United States of America; ANSYS 13.0) application of the dynamic axle load criterion from the Eisenmann model [42]. |

| Mechanical Evaluation of TPU/WRP | Evaluate the mechanical performance and water resistance of the TPU/WRP composite as a waterproof and load-distributing layer in the railway substructure. | Compressive tests, permeability tests, FEM modeling (3D and 2D), dynamic elastic modulus tests [43]. |

| Laboratory/ Standard Tests for Asphalt Properties | Determine the physical properties of asphalt—including hardness, softening point, flash point, ductility, viscosity, and specific gravity—to evaluate changes from crumb rubber addition. | Utilization of standard ASTM tests (D5, D36, D92, D113, D4402, D70) [45]. |

| Component | Analysis/Methodology | Key Details |

|---|---|---|

| Crumb Rubber Granules (CRG) | Comprehensive GC-MS analysis using three approaches. | Non-target full-scan for all GC-amenable additives; SIM for PAHs; SIM for benzothiazole compounds; equipment: Agilent 7890A with Agilent 5975C MSD (Agilent Technologies, Inc., Santa Clara, California, United States of America), EI source; detailed conditions in Supplementary Info [49]. |

| Sleepers | Material characterization of railway sleepers. | Standard Concrete Sleeper Type II (for freight/passenger, 25-ton axle load, 120 km/h) and Rubber Composite Sleeper Type I (made from recycled plastic, bitumen, fillers; low maintenance, sustainable) [57]. |

| Asphalt Binder and Rubber Powders | Binder formulation and rubber powder production. | Uses Dongming 70# base asphalt with two rubber powders (desulfurized and conventional); twin-screw shearing desulfurization method ensuring simpler production, lower cost, and minimal environmental impact [34]. |

| Asphalt Concrete Mixtures | Preparation of asphalt concrete with rubber particles as a substitute for polyurethane-based trackbeds. | Two binders used: epoxy-modified and rubber-modified; recycled tire rubber particles sized 2.36–4.75 mm; four FAM mixtures with varied rubber contents (9% and 11% for epoxy–FAM, 3% and 6% for rubber–FAM) [40]. |

| Aggregate Gradations | Evaluation of different aggregate gradations in asphalt mixtures. | Comparison of dense-graded asphalt concrete (max 22.4 mm) vs. gap-graded stone mastic asphalt (max 31.5 mm); rubber content of 1.5–3% by weight (particle sizes 0.2–4 mm); binder per Superpave PG criteria [41]. |

| Sub-Ballast Comparison | Comparative analysis of conventional vs. CRMB (crumb rubber-modified bitumen) sub-ballast. | Conventional sub-ballast: crushed gravel and well-graded sand; CRMB: standard bitumen modified with finely ground recycled tire rubber to ensure compatibility with railway trackbed requirements [42]. |

| TPU/WRP Composite | Composite formulation and characterization. | Consists of a TPU matrix (from polyol and diisocyanate), waste rubber powder (0.16 mm from end-of-life tires), and a PU defoaming agent; formulation optimized by varying PU-to-rubber ratio (25–35% WRP) [43]. |

| Waste Tire Rubber (WTR) Categorization | Classification based on particle size. | Categorized into shreds (50–300 mm), chips (10–50 mm), crumb rubber (0.425–12 mm), and powder (<1 mm); selection depends on the application (e.g., under-ballast mats, rail pads, rubberized sleepers) [44]. |

| Bitumen Modification with Crumb Rubber | Testing the effects of adding crumb rubber to bitumen. | Uses 60/70 penetration-grade bitumen modified with 1–4% crumb rubber (particle size: 0.3 mm) to assess impacts on asphalt’s physical properties [45]. |

| Crumb Rubber as Fine Aggregate Replacement | Partial replacement of fine aggregates with crumb rubber and silica fume addition. | Uses crumb rubber particles sized 75 µm, 180 µm, and 400 µm; silica fume added (0%, 5%, and 10%) to compensate for strength loss; various mix designs evaluated [46]. |

| Aspect | Method/Technique and Tests | Key Details |

|---|---|---|

| Chromatogram Data Processing | Deconvolution algorithms; compound identification via matching with the NIST 2017 library. | Peaks are filtered to include compounds present in at least 3 of 6 replicates with >90% match; biogenic compounds are excluded to refine the dataset [49]. |

| Standardized Laboratory Testing Protocols | Basic pavement performance tests (penetration, softening point, ductility, viscosity); rheological tests (dynamic shear, bending beam); aging and storage stability tests; gas emissions measurement. | Comprehensive testing to determine the mechanical and thermal behavior of DRA using viscosity-temperature curve analysis, MSCR tests, and performance grading (PG) classification [34]. |

| Mix Design and Field Simulation | Use of superpave gyratory compactor (SGC) for mix design; evaluation via Marshall stability and flow tests, indirect tensile strength (ITS), thermal conductivity, and fatigue tests; FEM modeling for thermal performance. | Target air void content is set at 3% for optimal performance; a finite element model developed to predict the thermal behavior of sub-ballast layers under varying environmental conditions [41]. |

| Performance Assessment of WTR-Modified Components | Laboratory and field tests; finite element method (FEM) and discrete element method (DEM) simulations. | Assess mechanical performance, vibration damping, and environmental durability; simulations used to predict load distribution, stress transfer, and settlement behavior [44]. |

| Analytical Technique | Method/Tools Used | Key Details |

|---|---|---|

| Chemical Quantification and ICP-MS Analysis | Six-level calibration curve normalized to internal standards; ICP-MS for metal content in leachates. | Comprehensive assessment of chemical characteristics of crumb rubber via deconvolution of chromatogram peaks and stringent filtering criteria [49]. |

| Quality Control Framework in Chemical Analysis | Systematic approach addressing data gaps with rigorous quality control measures. | Establishes a robust framework for analyzing chemical properties of crumb rubber in modified asphalt, ensuring reliable and accurate results [47]. |

| Vibration Performance Analysis | Time-domain analysis (peak acceleration, vibrational energy, RMS); frequency-domain analysis using Fourier Transform to obtain power spectral density (PSD); transfer loss calculation. | Evaluates dynamic responses of track components (e.g., sleepers) to assess vibration reduction in sleepers, ballast, and ground through both time and frequency domain analyses [57]. |

| Rheological and Environmental Impact Assessment | Dynamic shear rheometry (DSR), bending beam. Rheometry (BBR), gas chromatography, multiple stress creep recovery (MSCR) test. | Measures rutting resistance and assesses rheological behavior of DRA; advanced analytical tools provide precise evaluation of mechanical and environmental performance characteristics [34]. |

| Fracture Behavior and Crack Propagation Analysis | Specimen preparation (controlled mixing, cylindrical and semi-circular test pieces); semi-circular bending (SCB) test at multiple temperatures; acoustic emission (AE) analysis; X-ray CT scanning. | Investigates fracture mechanics by recording crack initiation and propagation; AE sensors coupled with CT scanning offer insights into internal crack development and controlled crack propagation mechanisms [40]. |

| Mechanical Performance and Numerical Modeling | Triaxial compression tests; resilient modulus testing; railway ballast box tests; finite element method (FEM) and discrete element method (DEM) simulations. | Assesses shear strength, deformation characteristics, and real-world loading conditions for WTR-modified components; numerical models (FEM/DEM) simulate load distribution, stress transfer, and settlement behavior under load [44]. |

| Aspect | Key Findings and Benefits | Implications for Railway Infrastructure |

|---|---|---|

| Mechanical Performance and Durability | CRMA exhibits improved resistance to cracking, temperature fluctuations, and fatigue. Studies report enhanced flexibility, increased fatigue life, reduced cracking, and lower maintenance needs. | Leads to longer service life, improved structural integrity, and reduced frequency of track repairs and maintenance [16,27,28]. |

| Environmental Sustainability | The incorporation of recycled tire rubber reduces the demand for virgin materials, lowers embodied energy and greenhouse gas emissions, and contributes to waste reduction and a circular economy. | Enhances the sustainability of railway substructures by lowering the environmental footprint and reducing life cycle costs associated with material production and maintenance [27,28,67]. |

| Vibration Damping and Load Distribution | Incorporating asphalt layers (including DARC) improves load distribution and vibration damping. Although DARC shows a lower stiffness modulus (about half that of conventional mixtures), it achieves significantly higher damping ratios, reducing dynamic stresses and rail oscillations. | Results in better track geometry maintenance, improved ride quality, and extended service life, particularly important for high-speed rail operations [32,35,39]. |

| Noise Reduction | Adding crumb rubber to porous asphalt mixtures significantly improves sound absorption due to increased porosity and elasticity, thereby enhancing the damping of traffic-induced vibrations. | Contributes to a quieter rail environment and improved quality of life in urban areas by reducing noise pollution from rail operations [33]. |

| Additional Infrastructure Benefits | Asphalt trackbeds offer improved load distribution, moisture protection, and drainage while reducing maintenance frequency and associated costs. | Provides enhanced protection of the subgrade, ensures optimal moisture conditions, and reduces overall maintenance expenditures [60]. |

| Potential Challenges | Some challenges include the potential release of volatile organic compounds (VOCs) and long-term bonding issues associated with CRMA, which require further investigation and optimization. | Highlights the need for ongoing research and mitigation strategies to ensure health, environmental safety, and long-term performance reliability in railway applications [16]. |

| Environmental Aspect | Key Findings and Benefits | Implications for Railway Infrastructure |

|---|---|---|

| Waste Tire Recycling | CRMA repurposes non-biodegradable waste, reducing landfill accumulation and pollution. Over 1.5 billion tires are generated annually, making recycling crucial for sustainability. | Reduces environmental hazards from tire stockpiling and burning, contributing to a circular economy [1,45,62,91]. |

| Carbon Footprint Reduction | Using CRMA lowers CO2 emissions by reducing the demand for virgin materials and requiring less energy in production. | Leads to lower embodied energy in railway substructures and a reduced overall carbon footprint [6,20,44,48]. |

| Noise and Vibration Reduction | Rubberized track components, including CRMA, lower noise pollution by 1–2 dB and mitigate ground vibration transmission. | Enhances the quality of life in urban areas and reduces environmental disturbances caused by railway operations [21,44,57]. |

| Reduced Harmful Emissions | CRMA produces fewer volatile organic compounds (VOCs) and gas emissions than traditional rubberized asphalt (RRA). | Minimizes air pollution during material production and extends sustainability benefits of railway infrastructure [34]. |

| Resource Efficiency and Circular Economy | The use of recycled rubber in CRMA and rubber composite sleepers reduces reliance on virgin materials, lowering the environmental footprint of railway infrastructure. | Supports circular economy initiatives by promoting waste reduction, resource efficiency, and sustainable construction practices [40,43,57,67]. |

| Energy Savings | CRMA production requires lower mixing temperatures, reducing energy consumption compared to conventional asphalt. | Leads to lower energy demand in railway material production and maintenance [27,45]. |

| Climate Adaptability | CRMA enhances asphalt durability in extreme climates, making it suitable for high-temperature and cold-weather railway operations. | Provides long-term resilience in railway tracks, reducing maintenance needs in harsh environmental conditions [45]. |

| Aspect | Key Findings and Benefits | Implications for Railway Infrastructure |

|---|---|---|

| Mechanical Performance and Durability | Enhanced resistance to cracking, rutting, thermal cracking, and fatigue deformations. | Extended service life and reduced maintenance frequency. Improved structural integrity and durability of trackbeds and sleepers. [1,6,11,20,41,42,46,95]. |

| Increased adhesion with aggregates and higher binder viscosity. | ||

| Optimized CRMA mixtures (e.g., 2% air void content) yield up to 18.2× higher fatigue life. | ||

| Superior load distribution in CRMB sub-ballast; improved bearing capacity and stress distribution. | ||

| Vibration Attenuation and Damping | High damping ratio and stiffness effectively reduce vibrations from high-speed trains. | Improved ride quality and track stability. Lower dynamic stresses lead to reduced track degradation and maintenance needs. [1,6,20,21,39,46,57]. |

| Laboratory tests report up to 61.8% reduction in peak vibration amplitude and 55% lower sleeper vibration velocity. | ||

| Enhanced energy dissipation minimizes dynamic stresses on the track system. | ||

| Thermal and Temperature Performance | Increased resistance to temperature fluctuations extends the viscoelastic range of asphalt. | Enhanced performance in extreme climates. Better long-term durability under varying temperature conditions. [34,41,45,47,95]. |

| Higher softening point and stiffness indicate superior high-temperature performance. | ||

| Lower thermal conductivity and enhanced low-temperature cracking resistance (as seen in DRA) mitigate thermal stresses. | ||

| Load Distribution and Structural Integrity | Improved stress distribution reduces vertical stresses in ballast by up to 30%. | More resilient track structure with lower settlement and deformation. Extended lifespan of ballast and subgrade components. [42,43,44,67,91]. |

| Increased lateral resistance and optimized load distribution reduce ballast degradation and track misalignment. | ||

| TPU/WRP composites offer even load distribution and flexible stress management. | ||

| Workability and Additional Benefits | Improved storage stability and lower mixing temperatures (by ~30 °C) enhance workability and reduce energy consumption. | Simplified construction processes and improved long-term performance. Reduced overall maintenance and improved safety of railway infrastructure components. [34,40,45,46,60,100]. |

| Enhanced energy absorption and crack mitigation in rubberized concrete. | ||

| Additional benefits include improved electrical resistivity, fire safety, and moisture retention. |

| Concern | Key Findings and Risks | Mitigation Strategies/Recommendations |

|---|---|---|

| VOC Emissions | Higher rubber content in CRMA can lead to increased emissions of harmful VOCs (e.g., p-xylene, toluene, benzene), especially at elevated temperatures, posing health risks to workers and nearby communities. | Incorporate inhibitors (e.g., kaolin, expanded graphite) to control VOC, NO, and H2S release; conduct comprehensive risk assessments [1,6,11,20,21,101]. |

| Excessive Rubber Content | Excessive rubber (>3–4% in asphalt mixtures; >35% in TPU/WRP) may reduce material stiffness, potentially leading to premature deformation and compromised track stability, which can affect overall safety. | Optimize rubber content to balance flexibility and structural integrity; adjust mix design to ensure adequate stiffness and durability [40,41,42,43,45]. |

| Rubber Migration and Moisture Sensitivity | Loose rubber particles in ballast layers can migrate, interfering with track stability. Additionally, variable permeability of waste tire rubber (WTR) may lead to moisture accumulation and instability under extreme conditions. | Optimize mix designs to prevent rubber migration; evaluate permeability and modify formulations to ensure consistent performance under varying temperatures [44]. |

| Aging and Long-Term Durability | Aging of CRMA mixtures may reduce fatigue life and affect long-term performance, potentially compromising safety over extended service periods. | Further research into modification strategies is needed to enhance aging resistance and maintain mechanical performance over time [11,34]. |

| Case Study/Region | Application/Technique | Key Findings and Benefits |

|---|---|---|

| Bridge Approaches and Tunnel Floors | Asphalt underlayment in high-stress areas. | Improved track performance and reduced maintenance costs through enhanced vibration damping [6]. |

| High-Speed Rail in Europe | Use of asphalt underlayment (AUL) and cement asphalt mortar (CAM). | Significant improvements in load distribution, subgrade protection, and noise reduction [16]. |

| Global Integration of Recycled Materials | Incorporation of recycled aggregates and CRMA in substructures. | Achieves energy savings, maintains structural integrity under diverse conditions, and offers competitive performance compared to traditional methods [27]. |

| Laboratory vs. Field Comparative Analysis | Rubberized asphalt testing under simulated railway loads. | Modified mixes demonstrate superior stiffness and durability; laboratory results align with field data [28]. |

| High-Speed Railway Systems | Asphalt concrete support layers. | Reduced track degradation, improved load distribution, and lower dynamic stresses leading to enhanced ride quality and prolonged service life [32]. |

| Porous Asphalt for Noise Reduction | CR-modified porous asphalt mixtures. | Enhanced sound absorption and noise reduction, though mechanical properties must be balanced to ensure long-term durability [33]. |

| Ballasted Tracks—Two-Step Stoneblowing Process | Addition of recycled rubber over stone layers. | Optimizes elastic distribution; reduces rail deflection fluctuations and ballast stress; offers significant environmental and economic benefits (e.g., recycling ~300 tire tread layers/km) [35]. |

| Laboratory Simulation of Sub-Ballast | DARC-based sub-ballast under dynamic load simulation. | Provides better damping and reduced stress concentrations compared to conventional HMA-RFI (hot mix asphalt based on Italian standard), with dynamic deflections maintained due to viscous properties [39]. |

| International Applications—CRMB | Use of CRMB sub-ballast in high-speed rail projects. | Demonstrates long-term stability, effective waterproofing, and reduced track degradation in projects from Italy, Japan, Germany, and the United States [42]. |

| International Applications—WTR Usage | Application of waste tire rubber in rail dampers and under-ballast mats. | Enhances noise and vibration control, improves waterproofing, and reduces maintenance cycles, promoting overall sustainability [44]. |

| Global Asphalt Trackbed Implementations | Asphalt trackbeds for rehabilitation and new construction. | Offers improved track stability, effective load distribution and drainage, and reduced maintenance costs; widely applied in the United States, Japan, Italy, Germany, France, Spain, and Austria [11,60]. |

| Norway—Environ- mental Compatibility | Use of CRG in artificial turf and CRMA in railway applications. | CRG shows acceptable environmental compatibility with contaminants below regulatory limits; CRMA effectively reduces ground vibrations, making it viable for harsh coastal climates in Norway [1,20]. |

| Aspect | Key Findings and Benefits | Implications for Global Applications |

|---|---|---|

| Standardization and Climatic Influence | Global survey reveals challenges in establishing unified mixing and compaction standards for CRMA, with workability significantly affected by regional climatic conditions. | Highlights the need for standardized application methods to optimize performance and ensure safety across diverse climatic regions [47]. |

| Cross-Industry Real-World Applications | Successful integration of waste rubber in railway track structures demonstrates improved performance and longevity. | Provides evidence of CRMA’s feasibility and potential for knowledge transfer to road construction, supporting the adoption of sustainable materials across transportation sectors [91]. |

| Field and Laboratory Validation | Controlled integration of tire-derived aggregate (TDA) under railway sleepers shows enhanced track resilience and reduced lateral deformations under simulated traffic conditions. | Confirms the adaptability of recycled rubber in both railway and road infrastructure, validating its effectiveness under varied climates and traffic conditions worldwide [67]. |

| Rubber Composite Sleepers Evaluation | Full-scale laboratory tests of rubber composite sleepers indicate significant reductions in ground vibrations (up to 76%), improved track elasticity, and long-term durability compared to conventional options. | Demonstrates the global applicability of rubber-modified infrastructure materials and supports the cross-industry adoption of recycled rubber, reinforcing its benefits in enhancing both railway and highway engineering [57]. |

| Aspect | Key Findings and Benefits | Implications for Railway Infrastructure |

|---|---|---|

| Fatigue Life and Durability | CRMA exhibits significantly higher fatigue life compared to conventional asphalt. | Longer pavement lifespan and reduced maintenance requirements for railway tracks [11,105]. |

| Reducing air void content from 4% to 2% can increase fatigue life by up to 18.2×. | ||

| Vibration Attenuation and Damping | CRMA and RMA show higher stiffness and damping ratios, especially at low temperatures. | Improved track stability and ride quality; effective attenuation of vibrations from high-speed trains [1,20,21]. |

| Centrifuge tests indicate that CRMA with 1/5 scale aggregates can reduce ground vibrations by up to 30%. | ||

| Enhanced damping improves energy absorption. | ||

| Rheological and Thermal Performance | DRA exhibits superior viscosity-temperature behavior, allowing easier mixing and compaction. | Enhanced mix workability, reduced risk of thermal cracking, and consistent performance under fluctuating climatic conditions [34,41,45]. |

| Optimal rubber content (≈2% by weight) balances durability and workability. | ||

| Better insulation and reduced thermal-induced cracking observed. | ||

| CRM increases stiffness and improves heat resistance, maintaining stability across temperature variations. | ||

| Crack Propagation and Fracture Behavior | Acoustic Emission (AE) analysis shows that epoxy–FAM experiences more stable crack propagation than rubber–FAM. | Better understanding of fracture mechanisms leading to optimized mix designs for improved crack resistance [40]. |

| CT scanning confirms crack initiation at pre-cut slits with gradual microcrack expansion. | ||

| Clustering analysis differentiates between tensile and shear cracking modes. | ||

| Track Settlement and Structural Stability | CRMB sub-ballast reduces seasonal vertical displacements by up to 50%. | Reduced settlement and enhanced structural performance of track systems, leading to longer service life and lower maintenance costs [42]. |

| FEM simulations indicate that CRMB withstands over 100 million load cycles. | ||

| Thickness optimization shows that 9–14 cm of CRMB can replace 30 cm of conventional granular sub-ballast, yielding material and cost savings. | ||

| Composite Material Performance | TPU/WRP composites demonstrate reduced water permeability, effective absorption of train-induced vibrations, and structural stability under repeated loading. | Improved waterproofing and stress distribution, resulting in enhanced long-term track stability and reduced subgrade deformation [44]. |

| WTR-modified ballast reduces track settlement by up to 50% and improves damping, with stiffness varying with temperature. | ||

| Additional Enhancements and Mix Optimization | Incorporation of crumb rubber reduces the density of sleepers, making them lighter and easier to transport. | Lighter, more durable sleepers with enhanced impact resistance and energy dissipation, contributing to overall railway infrastructure efficiency and safety [46]. |

| An optimal mix (10% silica fume + 5% CR) maintains sufficient strength while maximizing damping efficiency. |

| Research Area | Key Topics/Focus | Implications/Goals |

|---|---|---|

| Long-Term Field Performance Monitoring | Evaluate the durability, aging, and mechanical degradation of CRMA under real-world traffic and climatic conditions. | Validate laboratory findings, optimize maintenance, and ensure long-term performance [1,11,32,35,39,40,41,42,43,44,45,46,47,57,67,91]. |

| Optimization of Material Composition and Mix Design | Optimize composition, dimensions, and rubber content in CRMA, RMA, DRA, CRMB, TPU/WRP, and rubberized sleepers. | Enhance durability, workability, and cost efficiency while balancing flexibility and stiffness [11,20,21,40,41,42,43,45,46]. |

| Noise Reduction and Vibration Attenuation | Assess and improve noise reduction capabilities and vibration attenuation through field tests and laboratory evaluations. | Achieve better ride quality and reduced environmental noise; further mitigate vibrations in high-speed rail systems [1,21,47,57]. |

| Hybrid Material Innovations and Integration | Explore hybrid modifications by integrating recycled rubber with polymers, nano-additives, fibers, or other sustainable additives. | Develop next-generation, high-performance materials with superior mechanical and environmental properties [27,28,34,40,41,42,43,44,45,46,67,91]. |

| Advanced Testing and Simulation Techniques | Develop non-destructive testing methods and advanced simulation models (FEM, DEM) to predict long-term behavior and optimize material formulations. | Enhance prediction accuracy and streamline material development processes [16,32,44,67,91]. |

| Economic Feasibility and Life Cycle Assessments | Conduct comprehensive life cycle assessment (LCA) and life cycle cost analysis (LCCA) studies to quantify environmental and economic benefits. | Provide quantifiable evidence for sustainable adoption and support policy decisions in railway infrastructure [27,33,34,41,42,43,44,45,46,57,67,91]. |

| Adhesion and Environmental Impact Studies | Investigate innovative methods to enhance the adhesion properties of crumb rubber in asphalt mixtures; assess long-term environmental and health impacts. | Improve pavement performance while mitigating potential health and environmental risks [21,47]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazemian, M.; Raeisi, E.H.; Ghezelhesar, A.D.; Hajimirzajan, A.; Fischer, S. Effects of Crumb Rubber-Modified Asphalt as a Pavement Layer in Railways: A Scoping Review. Infrastructures 2025, 10, 84. https://doi.org/10.3390/infrastructures10040084

Kazemian M, Raeisi EH, Ghezelhesar AD, Hajimirzajan A, Fischer S. Effects of Crumb Rubber-Modified Asphalt as a Pavement Layer in Railways: A Scoping Review. Infrastructures. 2025; 10(4):84. https://doi.org/10.3390/infrastructures10040084

Chicago/Turabian StyleKazemian, Milad, Ebrahim Hadizadeh Raeisi, Ahmad Davari Ghezelhesar, Amir Hajimirzajan, and Szabolcs Fischer. 2025. "Effects of Crumb Rubber-Modified Asphalt as a Pavement Layer in Railways: A Scoping Review" Infrastructures 10, no. 4: 84. https://doi.org/10.3390/infrastructures10040084

APA StyleKazemian, M., Raeisi, E. H., Ghezelhesar, A. D., Hajimirzajan, A., & Fischer, S. (2025). Effects of Crumb Rubber-Modified Asphalt as a Pavement Layer in Railways: A Scoping Review. Infrastructures, 10(4), 84. https://doi.org/10.3390/infrastructures10040084