Flexural and Shear Strengthening of High-Strength Concrete Beams Using near Surface Basalt Fiber Bars

Abstract

1. Introduction

2. Experimental Program

2.1. Material

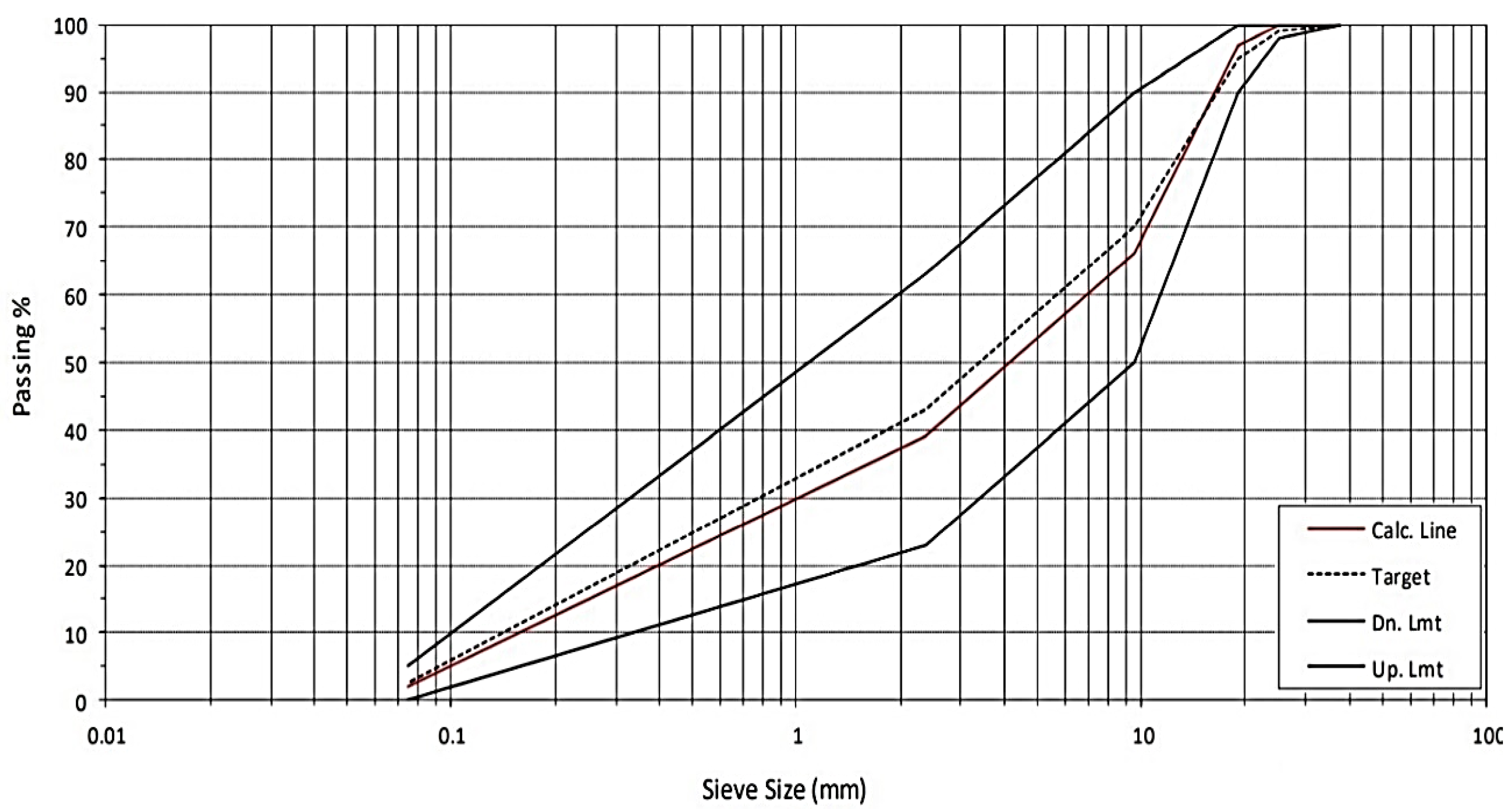

2.1.1. Concrete

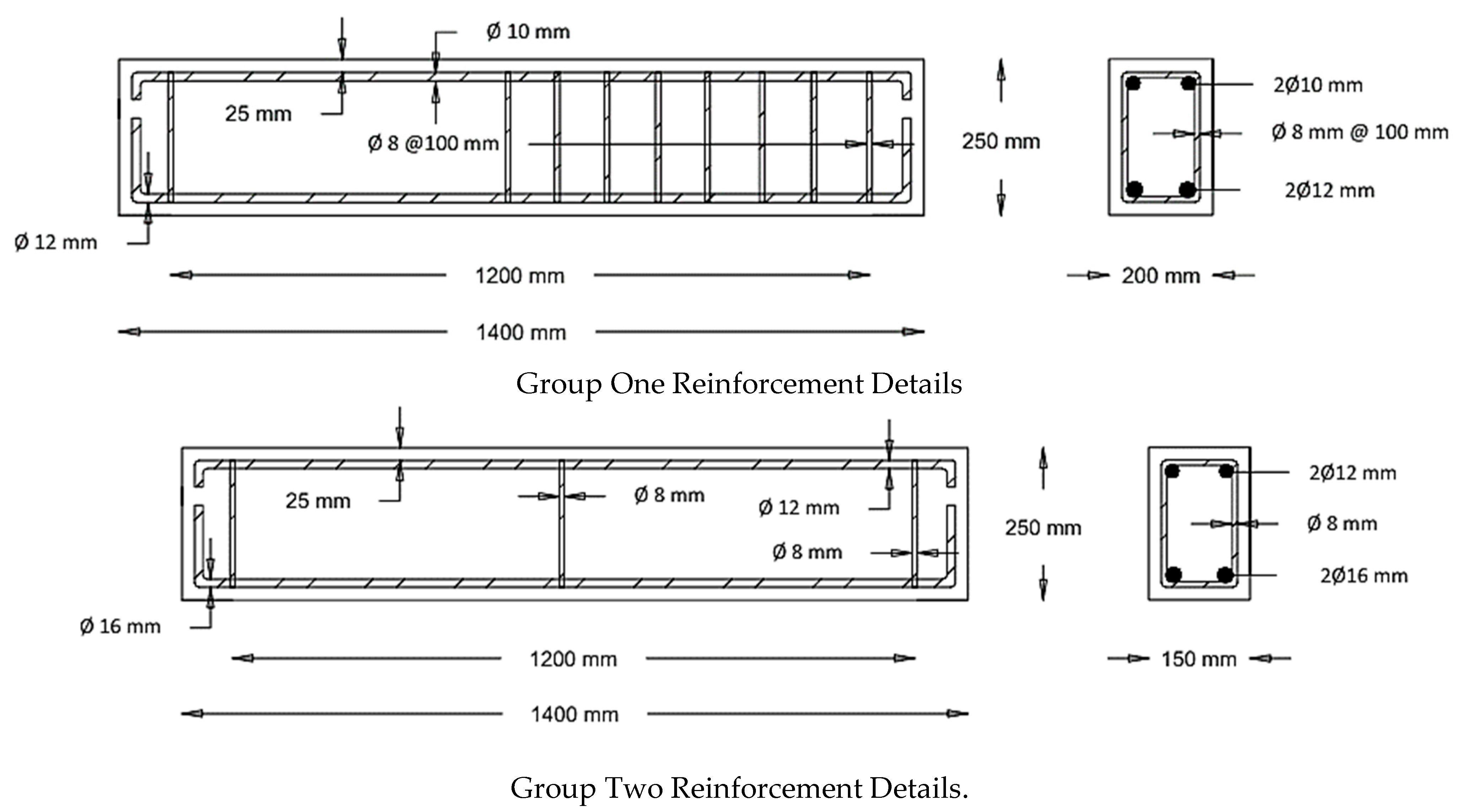

2.1.2. Steel Reinforcement

2.1.3. BFRP and Adhesives

2.2. Beam Specimens

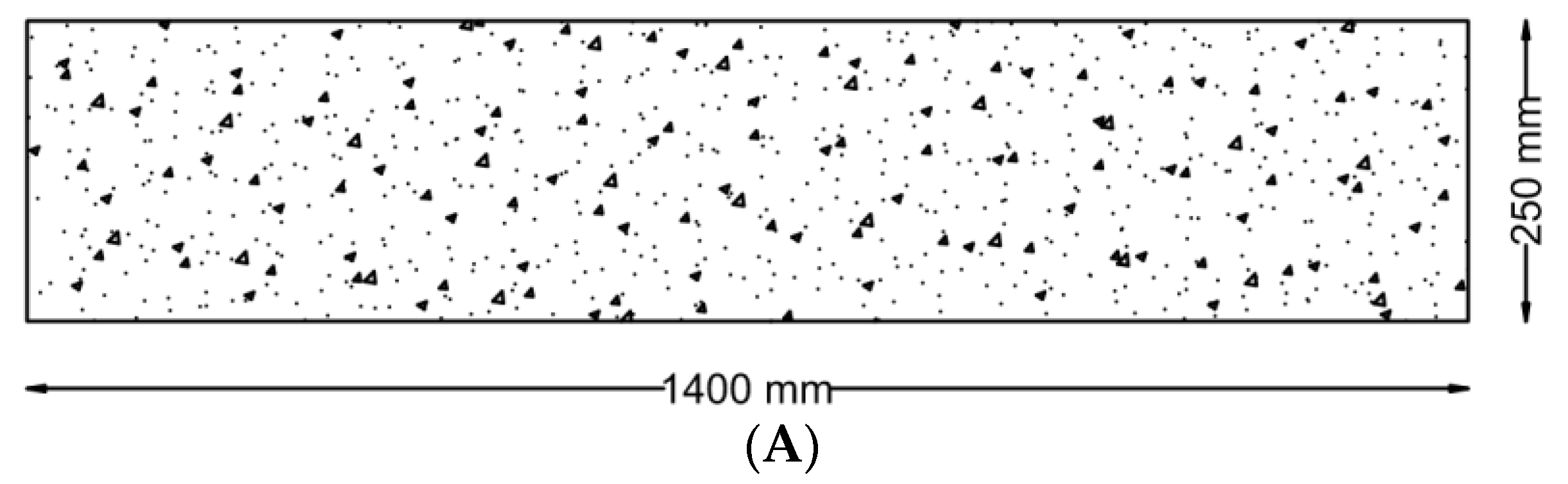

2.3. Installation of NSM-BFRP Materials

2.4. Testing Procedure

3. Experimental Results

3.1. Group One

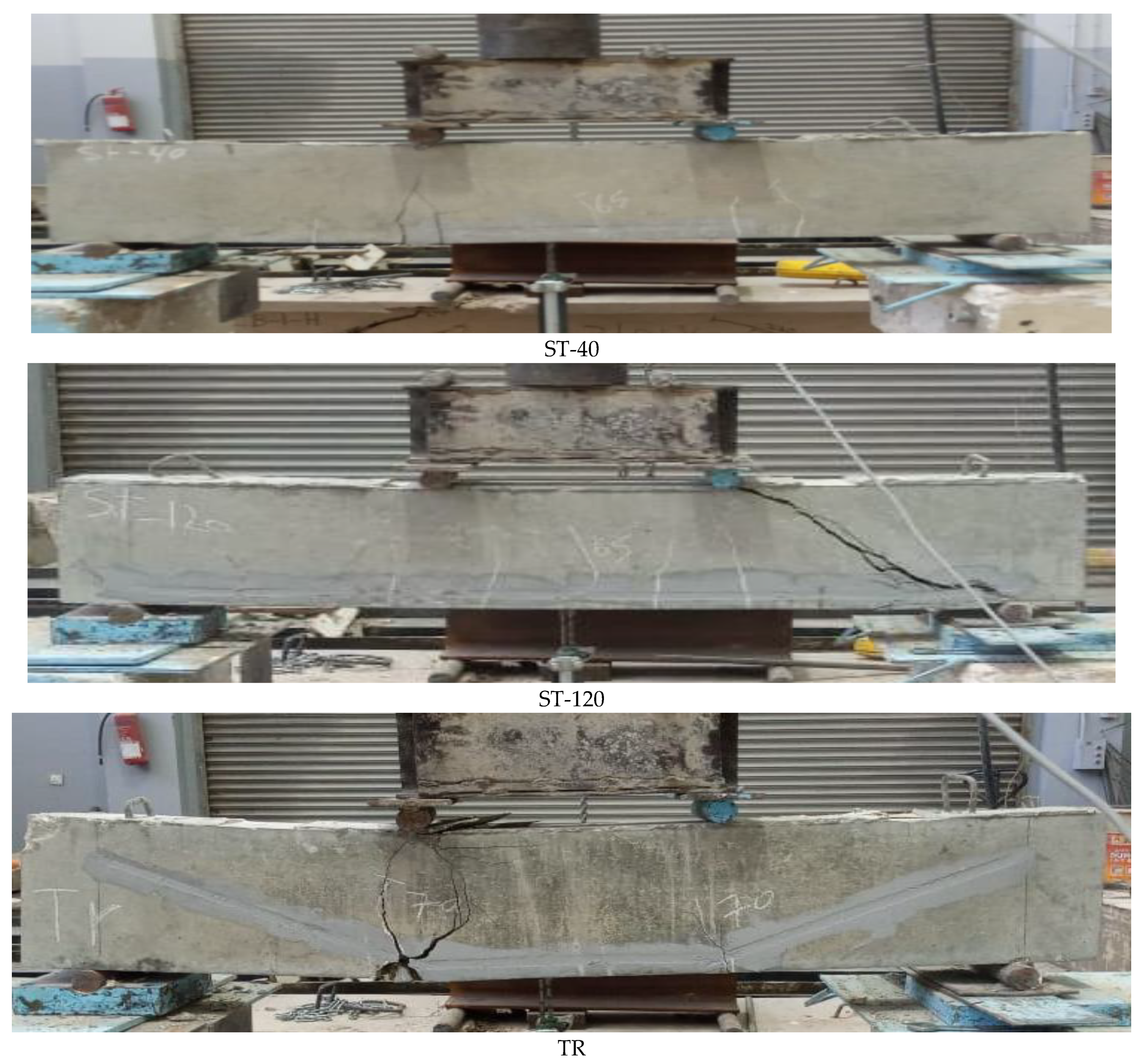

3.1.1. Failure Mode and Crack Pattern for Group One

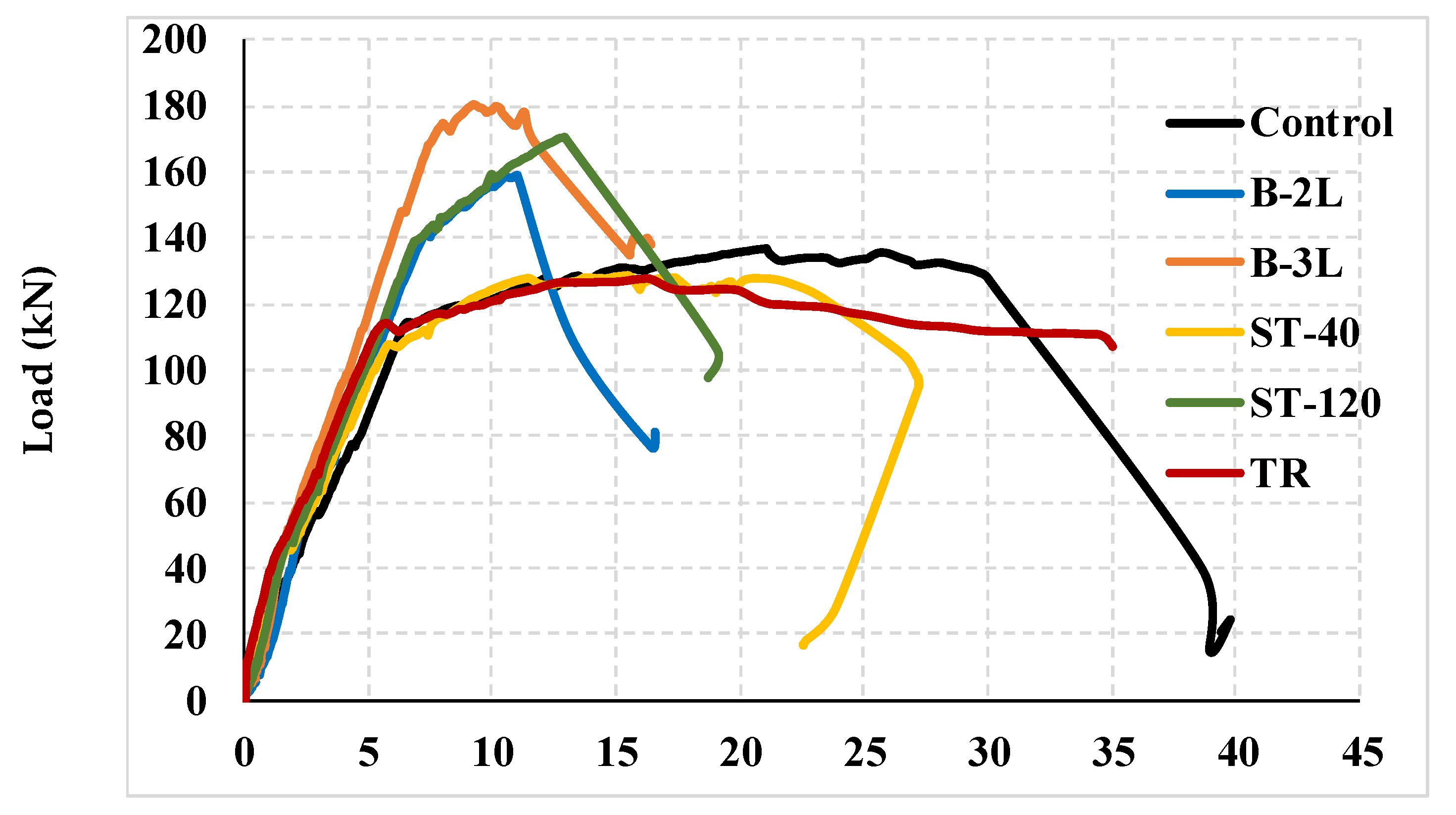

3.1.2. Flexural Load Displacement Response of the Strengthened Beam

3.2. Group Two

3.2.1. Failure Mode and Crack Pattern for Groupe Two

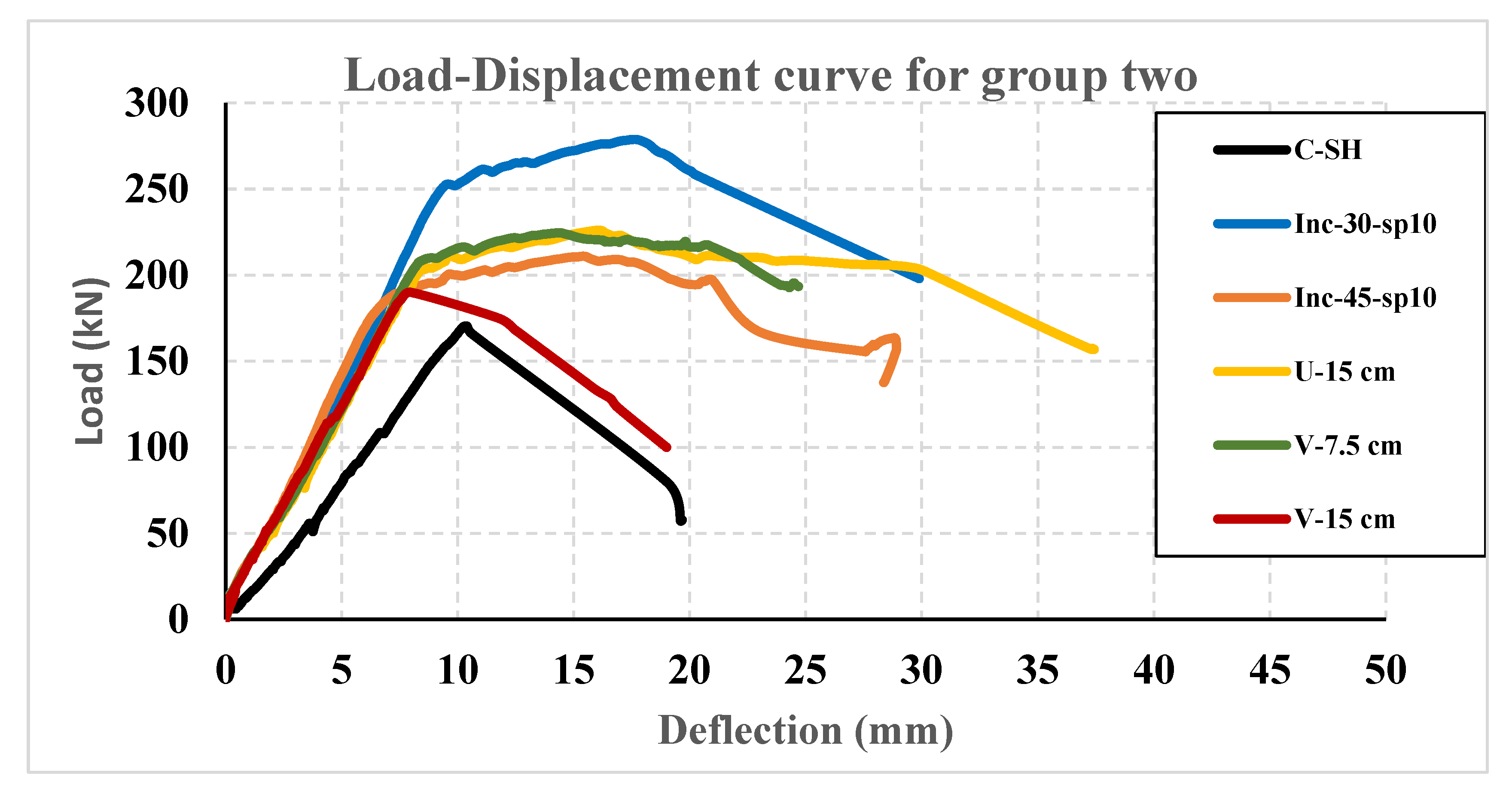

3.2.2. Shear Load Displacement Response of the Strengthened Beam

4. Effectiveness of NSM-Basalt Fiber Reinforced Polymer Bars in High-Strength Concrete Beams

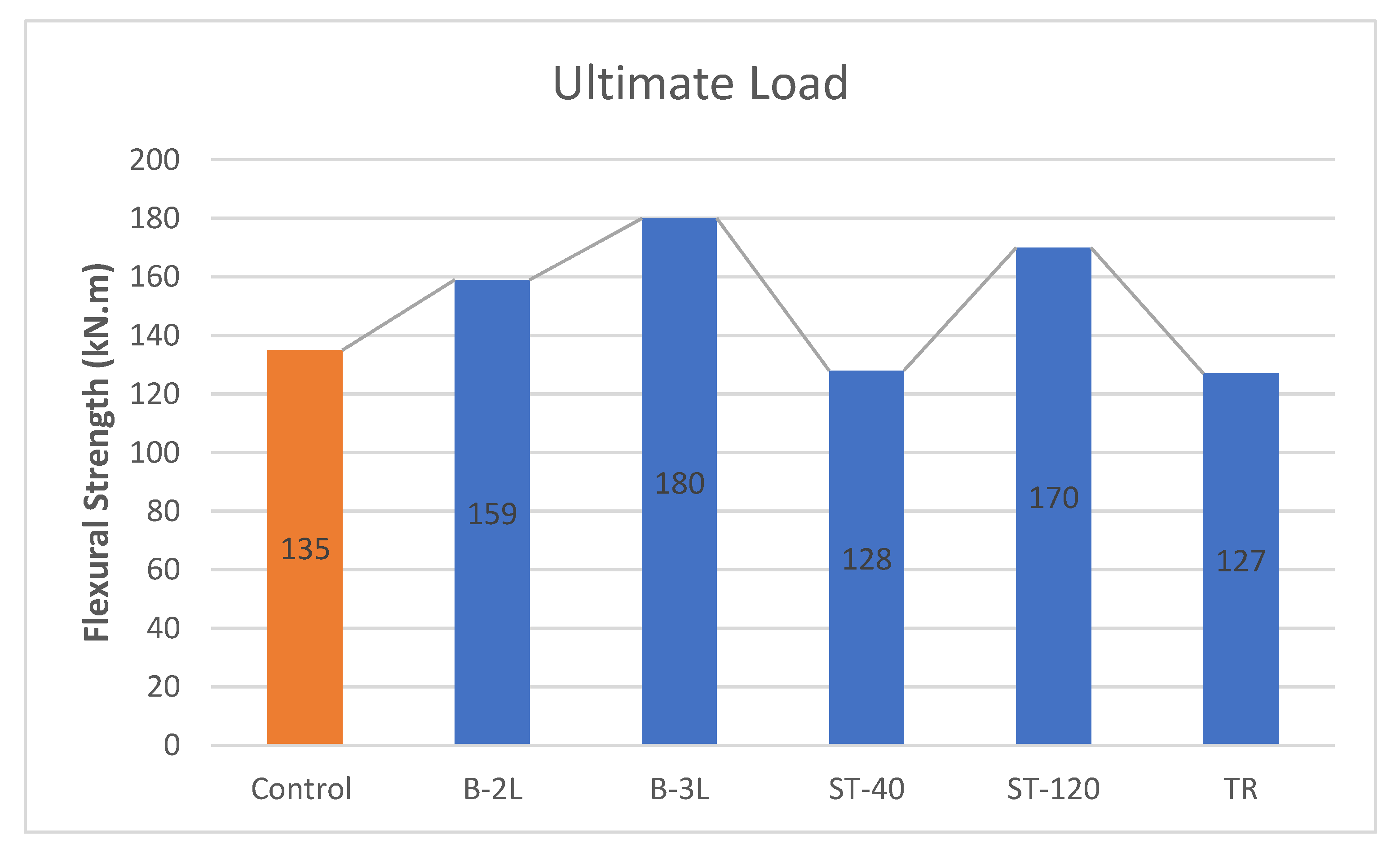

4.1. Flexural Strength Enhancement

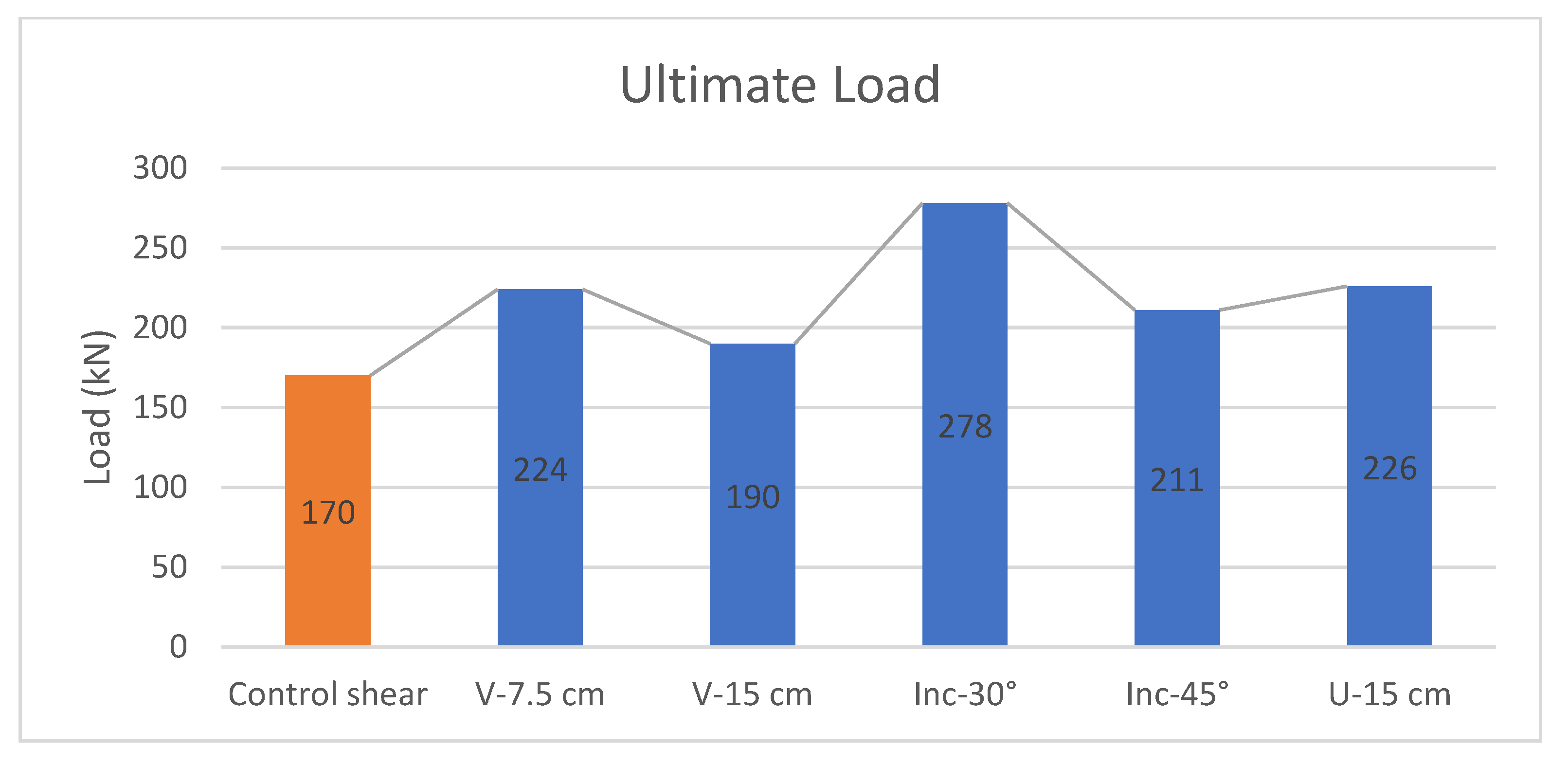

4.2. Shear Strength and Failure Mode Shift

4.3. Ductility and Structural Integrity

5. Conclusions

- The application of NSM-BFRP bars resulted in notable increases in flexural capacity, with enhancements of up to 33.33% compared to unreinforced control specimens. However, the increased flexural capacity also led to a reduction in ductility, indicating a trade-off between strength and flexibility that must be managed in design.

- The results showed that using BFRP reinforcement can significantly increase shear capacity, with a maximum enhancement of 63.5%. However, the introduction of BFRP bars also altered the failure modes, shifting them from shear to flexural or to complex modes involving concrete cover spalling and de-bonding. This shift underscores the need for careful reinforcement design to balance flexural and shear strengths.

- The study found that different configurations of BFRP reinforcement produced varying results, with closely spaced and inclined bars generally providing better performance. However, certain configurations, such as wider bar spacing, led to mixed or less desirable failure modes, emphasizing the importance of optimizing reinforcement layout.

- While NSM-BFRP bars effectively increased load capacity, they also reduced the ductility of the beams, particularly in flexural strengthening applications. This reduction in ductility suggests a need for additional measures, such as supplementary shear reinforcement, to maintain structural resilience.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| fc′ | Compressive strength of concrete (MPa). |

| Ec | Modulus of elasticity of concrete (GPa). |

| d | Effective depth of the beam (mm). |

| h | Total depth of the beam (mm). |

| a/d | Shear span-to-depth ratio. |

| As | Area of steel reinforcement (mm2) |

| P | Applied load (kN). |

| NSM-BFRP | Near-Surface-Mounted Basalt Fiber Reinforced Polymer bars. |

References

- Abdallah, M.; Al Mahmoud, F.; Khelil, A.; Mercier, J.; Almassri, B. Assessment of the flexural behavior of continuous RC beams strengthened with NSM-FRP bars, experimental and analytical study. Compos. Struct. 2020, 242, 112127. [Google Scholar] [CrossRef]

- Al-Obaidi, S.; Saeed, Y.M.; Rad, F.N. Flexural strengthening of reinforced concrete beams with NSM-CFRP bars using mechanical interlocking. J. Build. Eng. 2020, 31, 101422. [Google Scholar] [CrossRef]

- Attia, K.; El Refai, A.; Alnahhal, W. Flexural behavior of basalt fiber–reinforced concrete slab strips with BFRP bars: Experimental testing and numerical simulation. J. Compos. Constr. 2020, 24, 04020007. [Google Scholar] [CrossRef]

- Zhang, Y.; Elsayed, M.; Zhang, L.; Nehdi, M. Flexural behavior of reinforced concrete T-section beams strengthened by NSM FRP bars. Eng. Struct. 2021, 233, 111922. [Google Scholar] [CrossRef]

- Yaqub, M.; Bailey, C. Repair of fire damaged circular reinforced concrete columns with FRP composites. Constr. Build. Mater. 2011, 25, 359–370. [Google Scholar] [CrossRef]

- Al Rjoub, Y.; Obaidat, A.; Ashteyat, A.; Alshboul, K. Experimental and analytical investigation of using externally bonded, hybrid, fiber-reinforced polymers to repair and strengthen heated, damaged RC beams in flexure. J. Struct. Fire Eng. 2022, 13, 391–417. [Google Scholar] [CrossRef]

- Liu, I.S.; Oehlers, D.J.; Seracino, R. Tests on the ductility of reinforced concrete beams retrofitted with FRP and steel near surface mounted plates. J. Compos. Constr. 2006, 10, 106–114. [Google Scholar] [CrossRef]

- Nanni, A.; Ludovico, M.D.; Parretti, R. Shear strengthening of a PC bridge girder with NSM CFRP rectangular bars. Adv. Struct. Eng. 2004, 7, 297–309. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Torres, L.; Sallam, H. Experimental and analytical investigation into the flexural performance of RC beams with partially and fully bonded NSM FRP bars/strips. Compos. Struct. 2015, 122, 113–126. [Google Scholar] [CrossRef]

- Sundarraja, M.; Rajamohan, S. Strengthening of RC beams in shear using GFRP inclined strips–An experimental study. Constr. Build. Mater. 2009, 23, 856–864. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Torres, L.; Baena, M.; Miàs, C. An experimental study of different factors affecting the bond of NSM FRP bars in concrete. Compos. Struct. 2013, 99, 350–365. [Google Scholar] [CrossRef]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R.; Sanjayan, J. A state-of-the-art review: Near-surface mounted FRP composites for reinforced concrete structures. Constr. Build. Mater. 2019, 209, 748–769. [Google Scholar] [CrossRef]

- da Costa, L.M.; Pires, T.A.d.C.; Silva, J.J.R. Shear strengthening of fire-damaged reinforced concrete beams using NSM CFRP. laminates. Eng. Struct. 2023, 287, 116175. [Google Scholar] [CrossRef]

- Pan, Y.; Xian, G.; Li, H. Effects of Freeze-Thaw Cycles on the Behavior of the Bond between CFRP Plates and Concrete Substrates. J. Compos. Constr. 2018, 22, 04018011. [Google Scholar] [CrossRef]

- Al-Zu’bi, M.; Fan, M.; Al Rjoub, Y.; Ashteyat, A.; Al-Kheetan, M.J.; Anguilano, L. The effect of length and inclination of carbon fiber reinforced polymer laminates on shear capacity of near-surface mounted retrofitted reinforced concrete beams. Struct. Concr. 2021, 22, 3677–3691. [Google Scholar] [CrossRef]

- Qaisi, O.A.L.; Ashteyat, A.M.; Murad, Y.Z. Experimental study of flexural behaviour of RC beams strengthened using near surface mounted CFRP strips and ropes. Eur. J. Environ. Civ. Eng. 2023, 27, 2116–2135. [Google Scholar] [CrossRef]

- Al-khreisat, A.; Abdel-Jaber, M.T.; Ashteyat, A. Shear strengthening and repairing of reinforced concrete deep beams damaged by heat using NSM–CFRP ropes. Fibers 2023, 11, 35. [Google Scholar] [CrossRef]

- Gopinath, S.; Murthy, A.R.; Patrawala, H. Near surface mounted strengthening of RC beams using basalt fiber reinforced polymer bars. Constr. Build. Mater. 2016, 111, 35. [Google Scholar] [CrossRef]

- Saribiyik, A.; Abodan, B.; Balci, M.T. Experimental study on shear strengthening of RC beams with basalt FRP strips using different wrapping methods. Eng. Sci. Technol. Int. J. 2021, 24, 192–204. [Google Scholar] [CrossRef]

- Kamonna, H.H.; Abd Al-Sada, D.J. Strengthening of one-way reinforced concrete slabs using near surface mounted bars. Mater. Today Proc. 2021, 42, 1843–1853. [Google Scholar] [CrossRef]

- Diab, H.M.; Sayed, A.M. An anchorage technique for shear strengthening of RC T-beams using NSM-BFRP bars and BFRP sheet. Int. J. Concr. Struct. Mater. 2020, 14, 49. [Google Scholar] [CrossRef]

- Al-Nsour, R.; Abdel-Jaber, M.; Ashteyat, A.; Shatarat, N. Flexural repairing of heat damaged reinforced concrete beams using NSM-BFRP bars and NSM-CFRP ropes. Compos. Part C Open Access 2023, 12, 100404. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Yuan, T.; Yang, J.-M.; Yoon, Y.-S. Feasibility of replacing minimum shear reinforcement with steel fibers for sustainable high-strength concrete beams. Eng. Struct. 2017, 147, 207–222. [Google Scholar] [CrossRef]

- Xia, J.; Mackie, K.R.; Saleem, M.A.; Mirmiran, A. Shear failure analysis on ultra-high performance concrete beams reinforced with high strength steel. Eng. Struct. 2011, 33, 3597–3609. [Google Scholar] [CrossRef]

- Khan, M.I.; Abbass, W. Flexural behavior of high-strength concrete beams reinforced with a strain hardening cement-based composite layer. Constr. Build. Mater. 2016, 125, 927–935. [Google Scholar] [CrossRef]

- Maghsoudi, A.; Rahgozar, R.; Hashemi, S.H. Flexural testing of high strength reinforced concrete beams strengthened with CFRP sheets. Int. J. Eng. 2009, 22, 131–146. [Google Scholar]

- Aziz, O.Q.; Taha, B.O. Flexure behavior of high strength concrete (HSC) beams reinforced with carbon fiber reinforced polymer (CFRP) rebars with and without chopped carbon fiber (CCF). Int. J. Sci. Res. 2013, 1, 123–139. [Google Scholar] [CrossRef]

- Hussein, L.; Amleh, L. Structural behavior of ultra-high performance fiber reinforced concrete-normal strength concrete or high strength concrete composite members. Constr. Build. Mater. 2015, 93, 1105–1116. [Google Scholar] [CrossRef]

- Li, C.; Aoude, H. Effect of UHPC Jacketing on the Shear and Flexural Behaviour of High-Strength Concrete Beams. Structure 2023, 51, 1972–1996. [Google Scholar] [CrossRef]

- Dawood, M.B.; Nabbat, R.A.-A. Flexural and shear strength of non-prismatic reinforced high strength concrete beams with openings and strengthened with NSM-CFPR bars. Int. J. Civ. Eng. Technol. 2015, 6, 93–103. [Google Scholar]

| Materials for Proportioning | Weight (kg/m3) |

|---|---|

| Cement OPC | 450.0 |

| Water | 171.3 (Total water) |

| Coarse Aggregate | 827.1 |

| Fine Aggregate | 946.5 |

| Admixture (Adcon PC550) | 8.0 |

| Size, mm | Cross-Sectional Area mm2 | Ultimate Tensile Strength, MPa | Elastic Modulus GPa | Ultimate Strain mm/mm |

|---|---|---|---|---|

| 16 | 180 | 1089 | 58 | 0.020 |

| Properties | Standard | |||

| Modulus of Elasticity in Flexure | ~3800 N/mm2 (7 d, +23 °C) | (EN 1465) | ||

| Tensile Strength | ~30 N/mm2 (7 d, +23 °C) | (ISO 527) | ||

| Modulus of Elasticity in Tension | ~4500 N/mm2 (7 d, +23 °C) | (ISO 527) | ||

| Elongation at Break | ~0.9% (7 d, +23 °C) | (ISO 527) | ||

| Tensile Adhesion Strength | Concrete fracture (>4 N/mm2) on a sandblasted substrate | (EN ISO 4624) | ||

| Coefficient of Thermal Expansion | 4.5 × 10−5 1/K (Temperature range −10 °C min./+40 °C max.) | (EN 1770) | ||

| Glass Transition Temperature | Curing time | Curing temperature | TG | (EN 12614) |

| 30 d | +30° | +58 °C | ||

| Heat Deflection Temperature | Curing time | Curing temperature | HDT | (ASTM D 648) |

| 7 d | +10 °C | +36 °C | ||

| 7 d | +23 °C | +47 °C | ||

| 7 d | +35 °C | +53 °C | ||

| Resistance to continuous exposure up to +45 °C | ||||

| Service Temperature | −400 °C min./+45 °C max. | |||

| Group | Intended Failure | Specimen ID | Details | BFRP Type | Strengthening Layout Based on |

|---|---|---|---|---|---|

| One | Flexural | Control | No rods | Bars | Figure 3A |

| B-2L | Two rods at the bottom surface | Bars | Figure 3B | ||

| B-3L | Three rods at the bottom surface | Bars | Figure 3C | ||

| ST-40 | One rod in each side with a length of 40 cm | Bars | Figure 3D | ||

| ST-120 | One rod in each side with a length of 120 cm | Bars | Figure 3E | ||

| TR | Rod in trapezoidal shape in both sides | Bars | Figure 3F | ||

| Two | Shear | Control shear | No rods | Bars | Figure 4A |

| V-7.5 cm | Vertical bars spaced at 7.5 cm | Bars | Figure 4B | ||

| V-15 cm | Vertical bars spaced at 15 cm | Bars | Figure 4C | ||

| Inc-30° | Inclined bars oriented at 30° | Bars | Figure 4D | ||

| Inc-45° | Inclined bars oriented at 45° | Bars | Figure 4E | ||

| U-15 cm | Full circulation bars spaced at 15 cm | Bars | Figure 5b |

| Group one | Specimen ID | First Crack (kN) | Yield Load (kN) | Yield Displacement (mm) | Ultimate Load (kN) | Ultimate Displacement (mm) | %UL | %UD | Ductility | Mode of Failure |

| Control | 45 | 113 | 6.8 | 135 | 22 | - | 0 | 169 | Flexural shear | |

| B-2L | 40 | 143 | 11.5 | 159 | 22 | 17.7 | 21.80 | 184 | Shear failure | |

| B-3L | 50 | 149 | 10 | 180 | 20 | 33.33 | −28.91 | 182 | Shear failure | |

| ST-40 | 65 | 110 | 10 | 128 | 30 | −5 | −38.38 | 300 | Flexural failure | |

| ST-120 | 65 | 145 | 13 | 170 | 22 | 25.9 | −14.69 | 220 | Shear failure | |

| TR | 70 | 117 | 8.5 | 127 | 30 | −5 | −24.17 | 375 | Flexural failure |

| Group Two | Specimen ID | First Crack (kN) | Yield Load (kN) | Yield Displacement (mm) | Ultimate Load (kN) | Yield Displacement (mm) | Ultimate Displacement (mm) | %UL | %UD | %Ductility | Mode of Failure |

| Control shear | 57 | 110 | 6.9 | 170 | 10 | 18 | - | 0 | 180 | Shear failure | |

| V-7.5 cm | 40 | 120 | 7.5 | 224 | 8 | 25 | 31.7 | 39.42 | 312 | Flexural failure | |

| V-15 cm | 35 | 118 | 5 | 190 | 7 | 22 | 11.7 | −23.07 | 315 | Shear- Flexural failure | |

| Inc-30° | 67 | 170 | 8.5 | 278 | 9 | 25 | 63.5 | 70.19 | 278 | Shear failure, CS, De-bonding | |

| Inc-45° | 65 | 180 | 6.5 | 211 | 8 | 23 | 24.1 | 47.12 | 288 | Flexural failure | |

| U-15 cm | 50 | 205 | 8.9 | 226 | 7 | 35 | 32.9 | 53.85 | 500 | Shear failure |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ashteyat, A.; Obaidat, A.T.; Al-Khreisat, A.; Abdel-Jaber, M. Flexural and Shear Strengthening of High-Strength Concrete Beams Using near Surface Basalt Fiber Bars. Infrastructures 2025, 10, 1. https://doi.org/10.3390/infrastructures10010001

Ashteyat A, Obaidat AT, Al-Khreisat A, Abdel-Jaber M. Flexural and Shear Strengthening of High-Strength Concrete Beams Using near Surface Basalt Fiber Bars. Infrastructures. 2025; 10(1):1. https://doi.org/10.3390/infrastructures10010001

Chicago/Turabian StyleAshteyat, Ahmed, Ala’ Taleb Obaidat, Ahmad Al-Khreisat, and Mu’tasime Abdel-Jaber. 2025. "Flexural and Shear Strengthening of High-Strength Concrete Beams Using near Surface Basalt Fiber Bars" Infrastructures 10, no. 1: 1. https://doi.org/10.3390/infrastructures10010001

APA StyleAshteyat, A., Obaidat, A. T., Al-Khreisat, A., & Abdel-Jaber, M. (2025). Flexural and Shear Strengthening of High-Strength Concrete Beams Using near Surface Basalt Fiber Bars. Infrastructures, 10(1), 1. https://doi.org/10.3390/infrastructures10010001