CFD Evaluation of Philippine Detached Structure with Different Roofing Designs

Abstract

:1. Introduction

2. Methodology

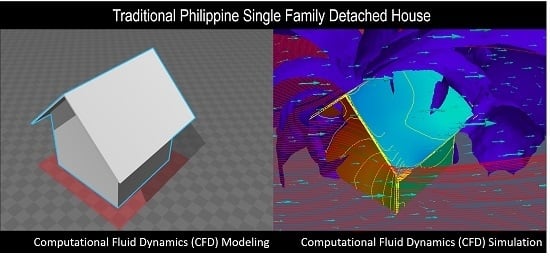

2.1. Computational Fluid Dynamics

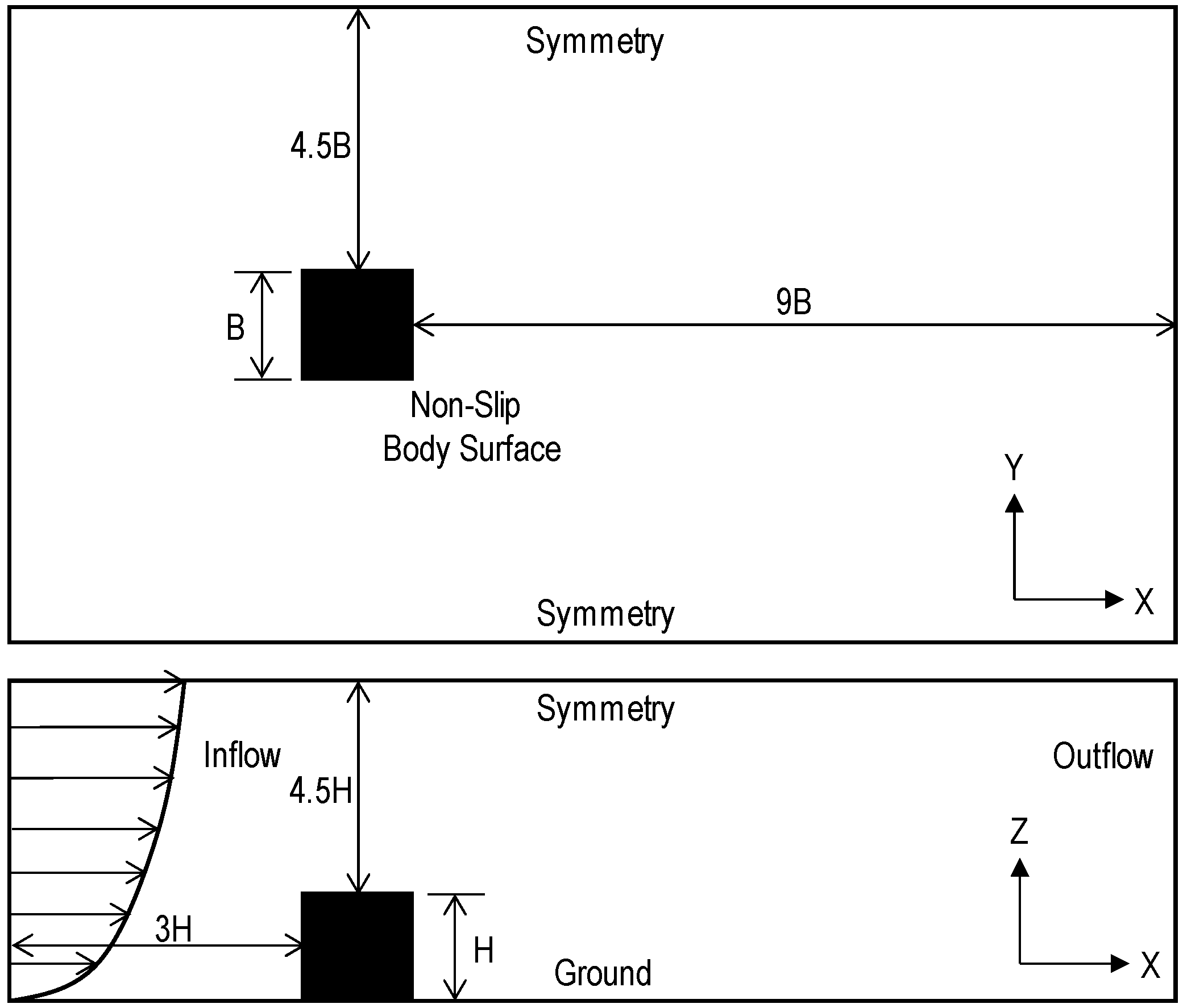

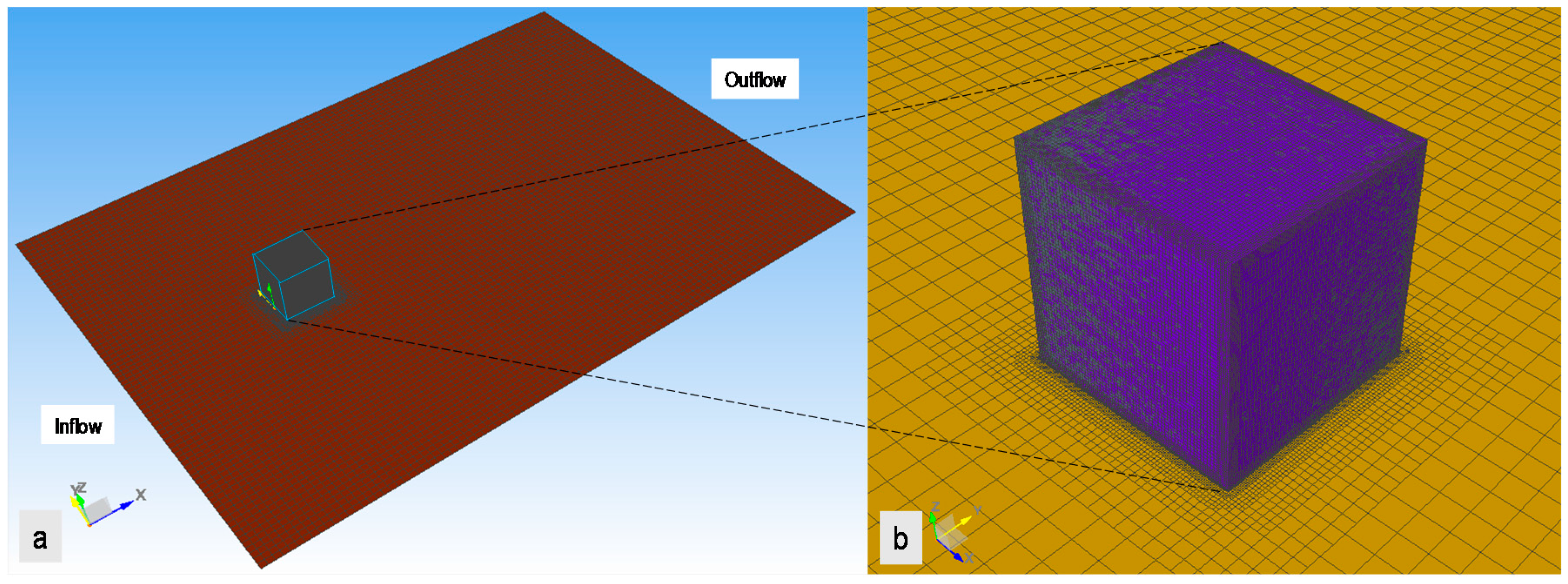

2.2. Numerical Modelling

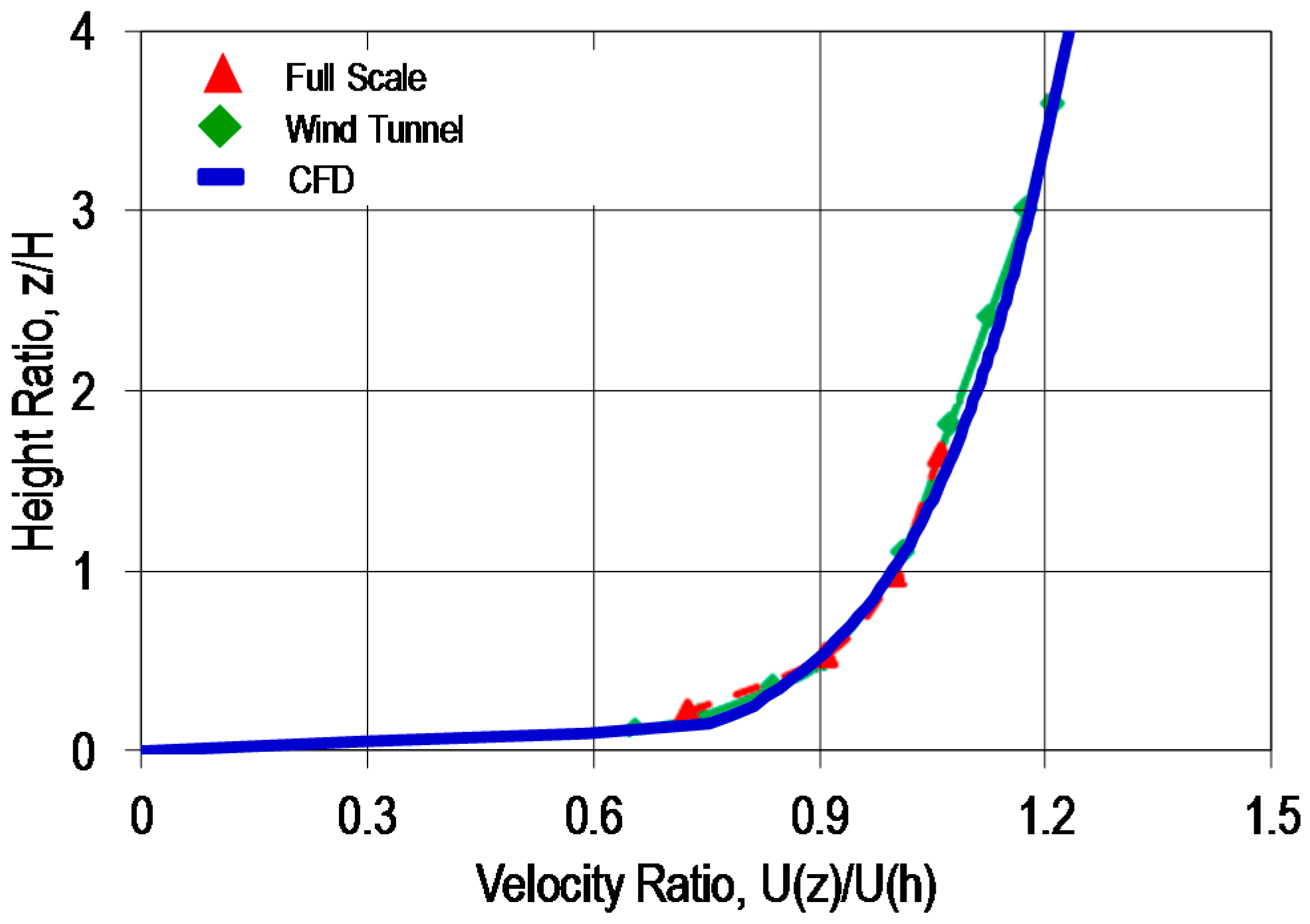

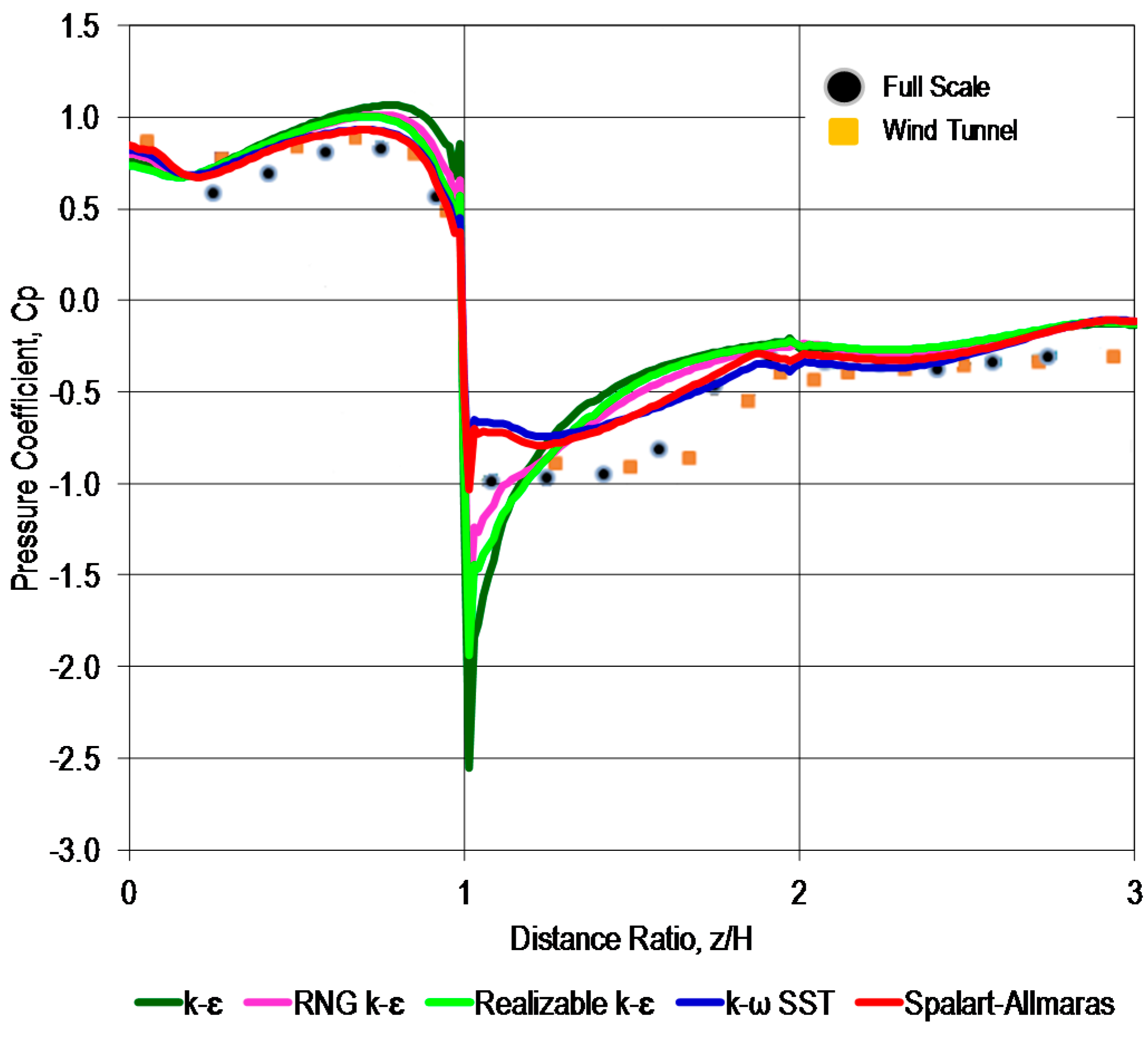

2.3. Model Validation

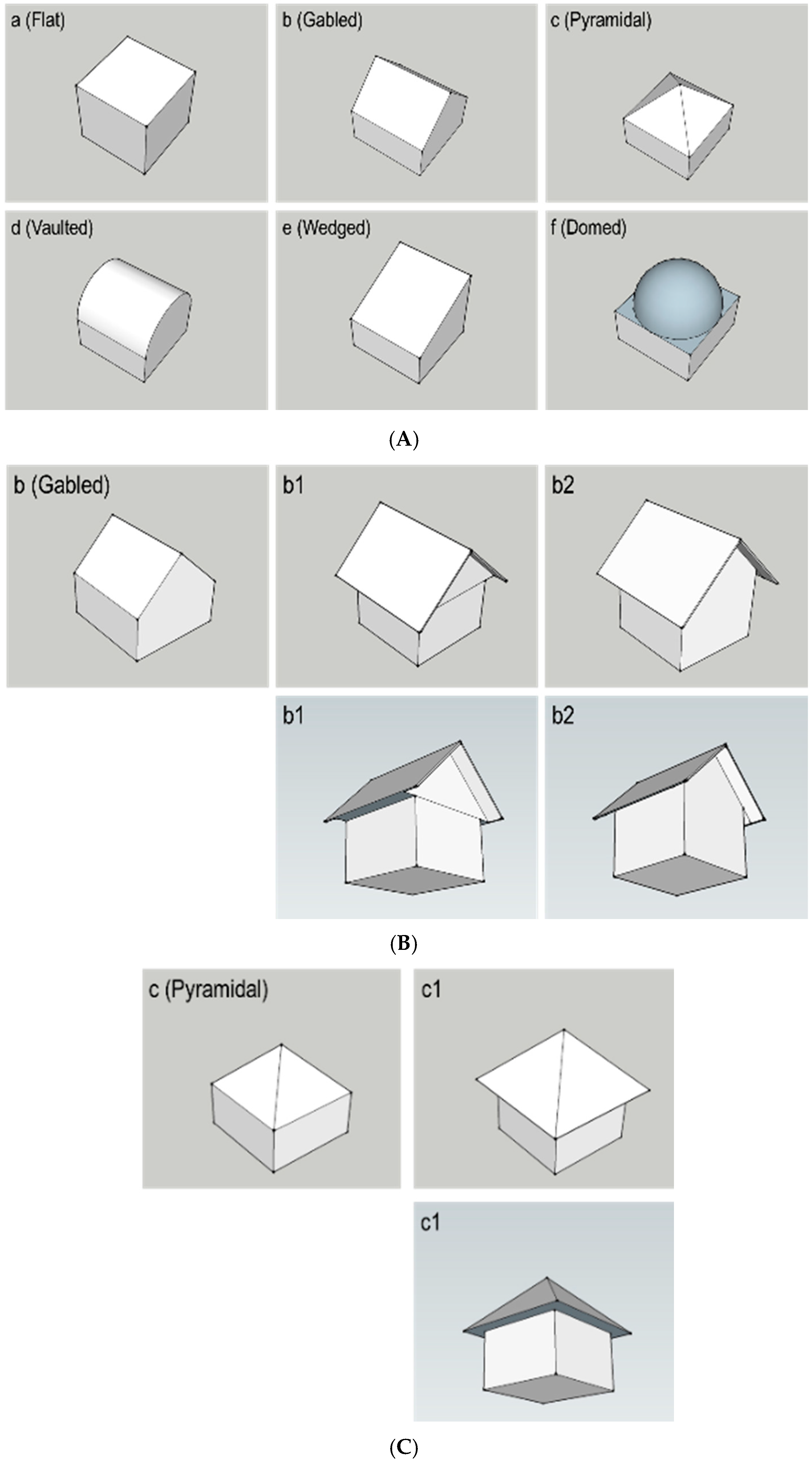

2.4. Simulation Cases

3. Results and Discussions

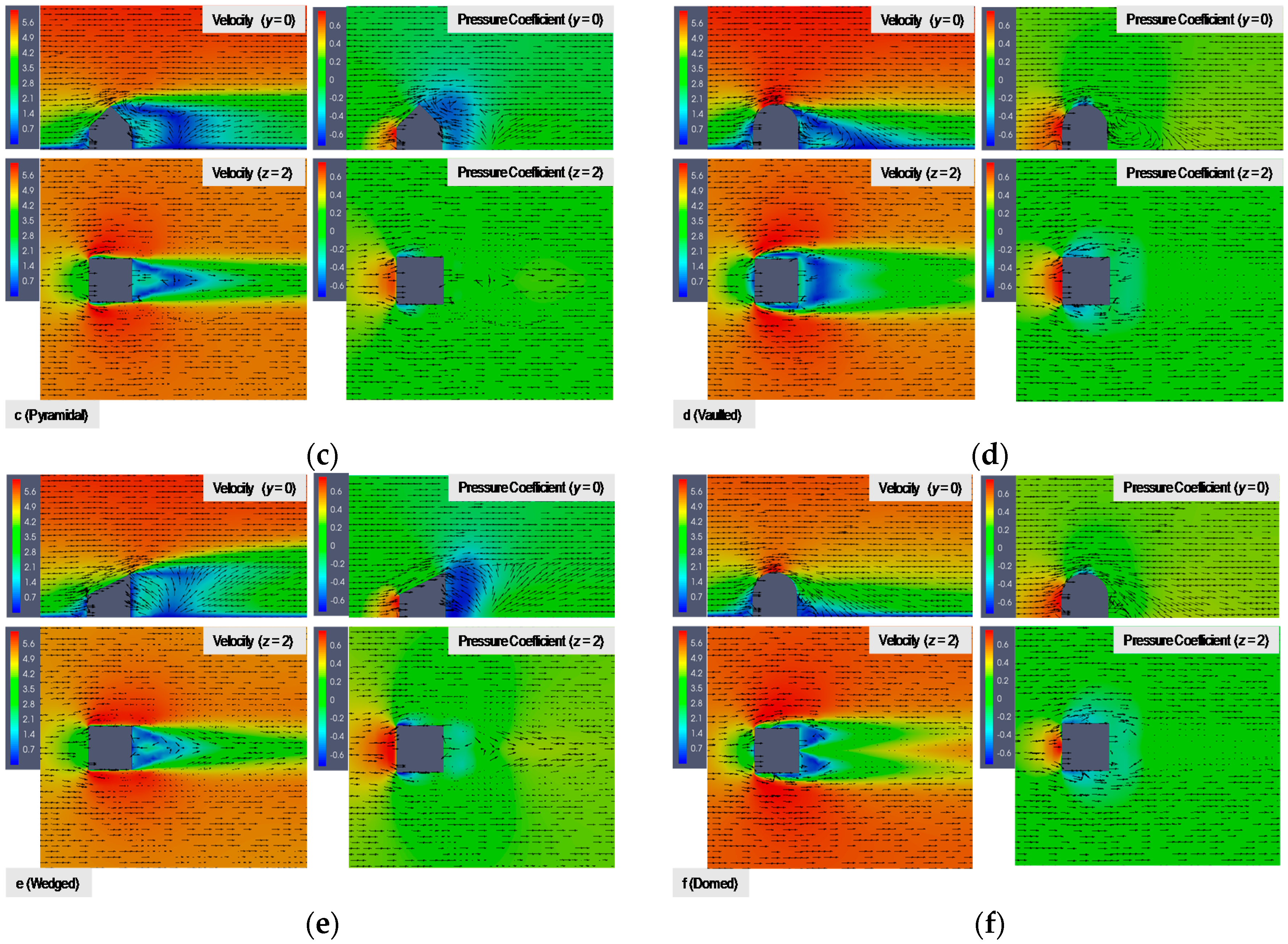

3.1. Flow Field Velocity

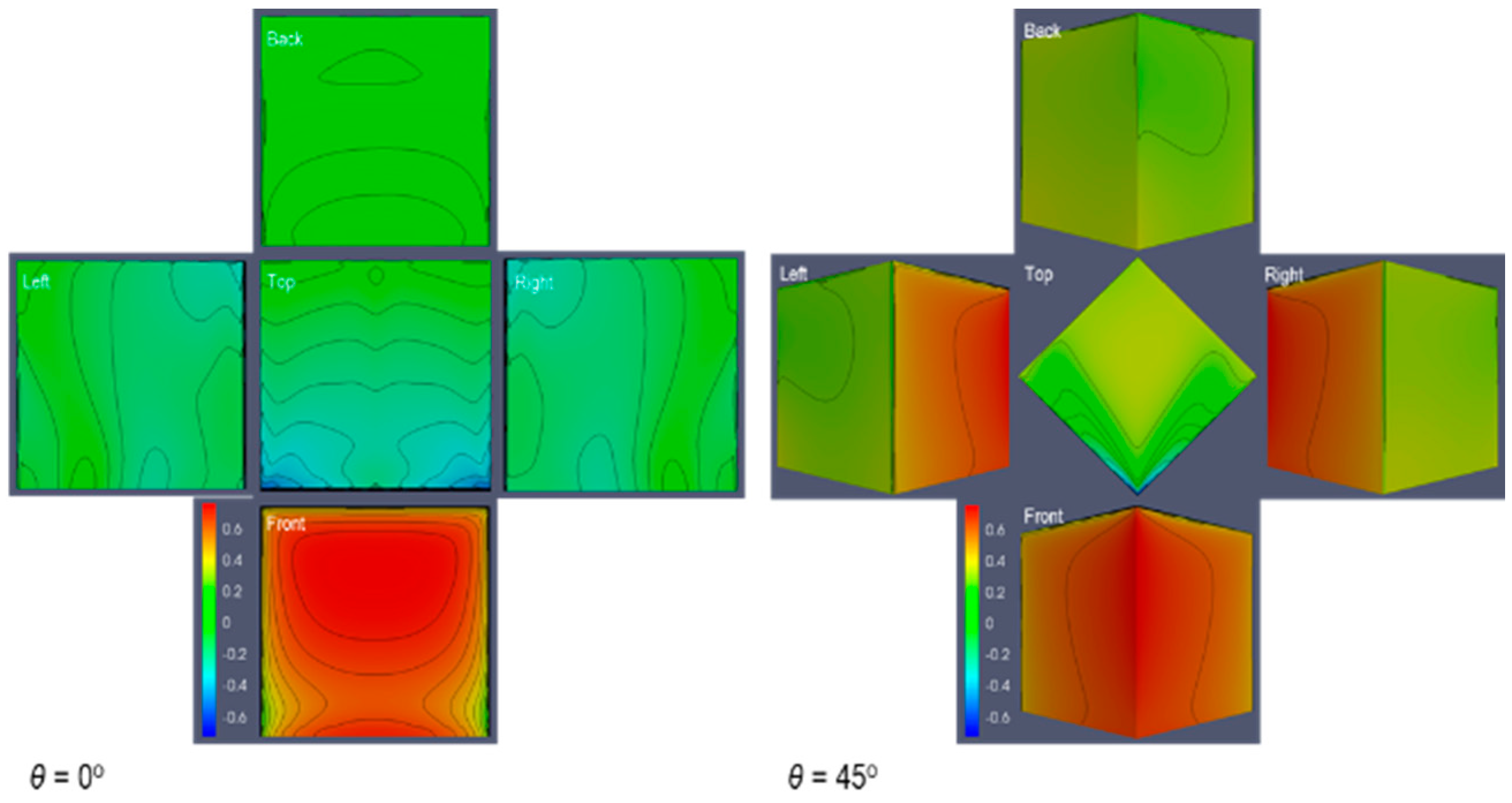

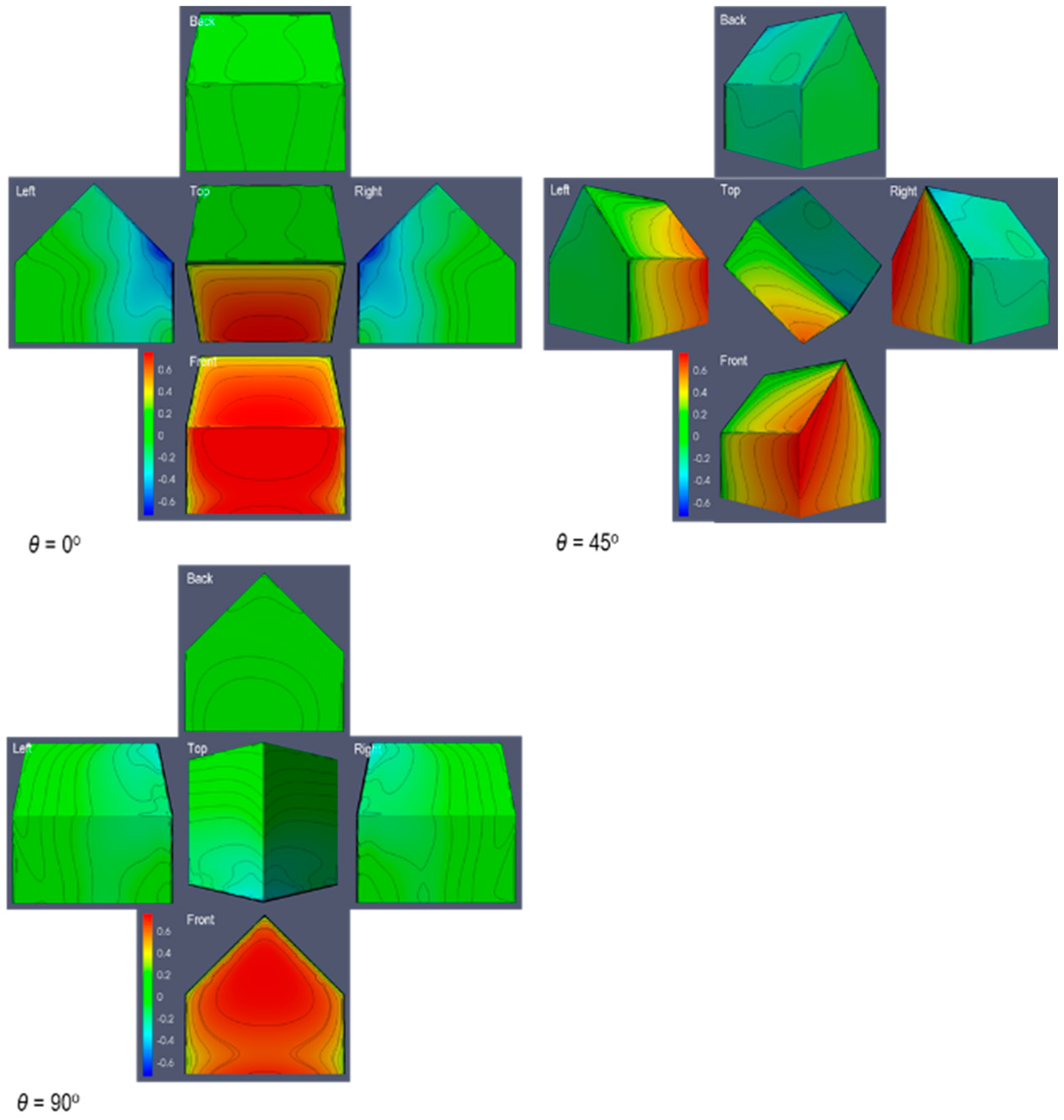

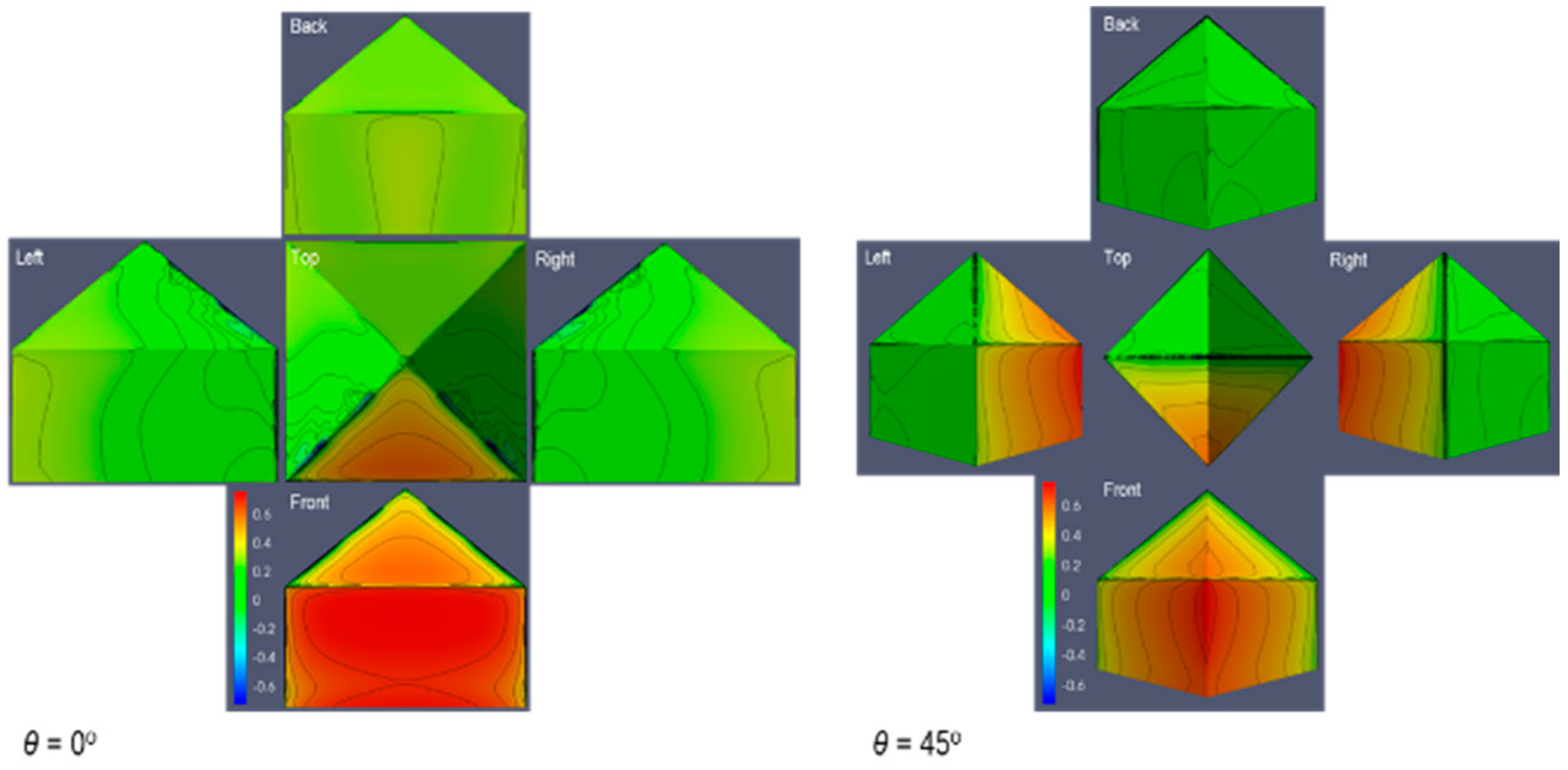

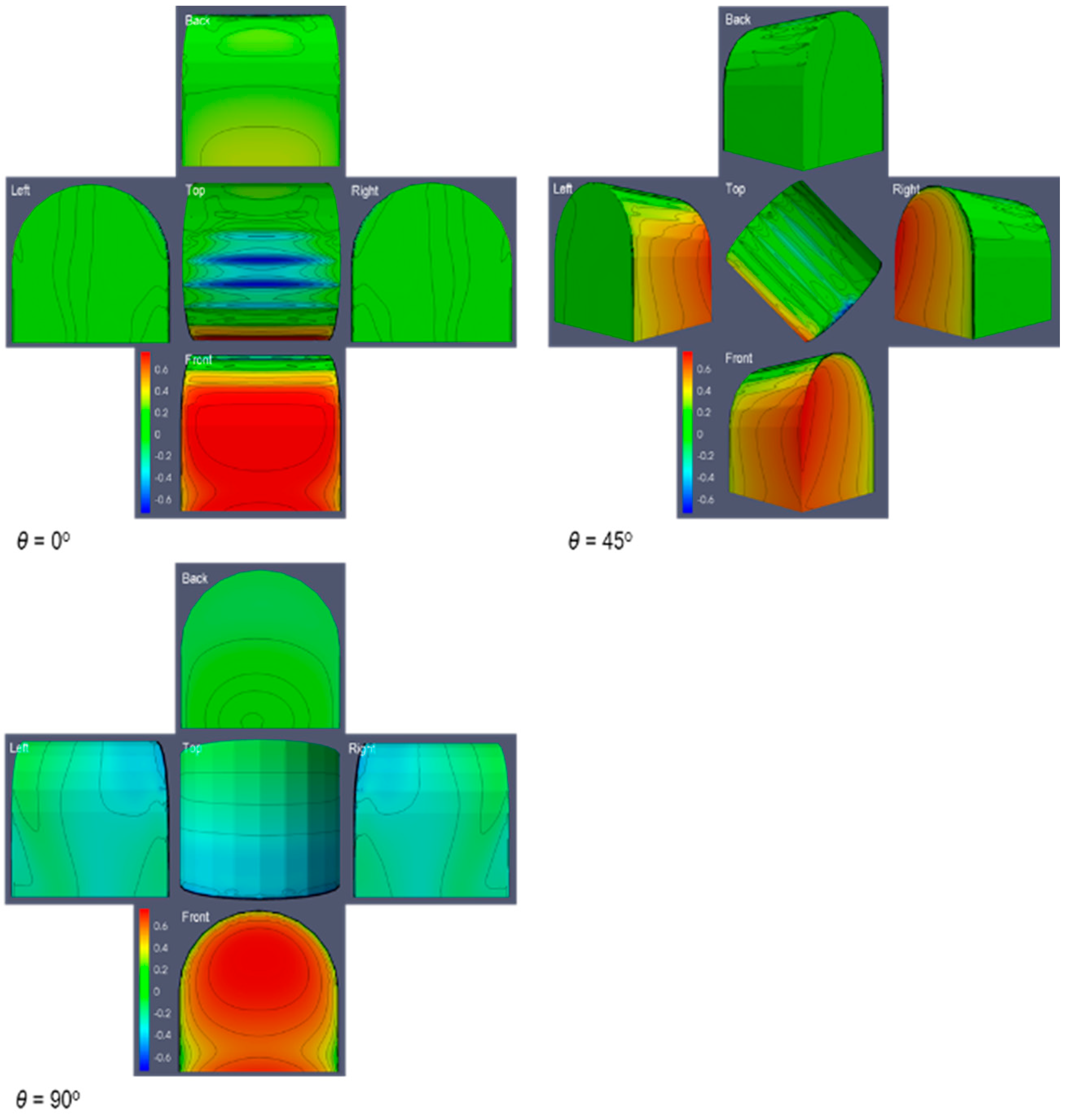

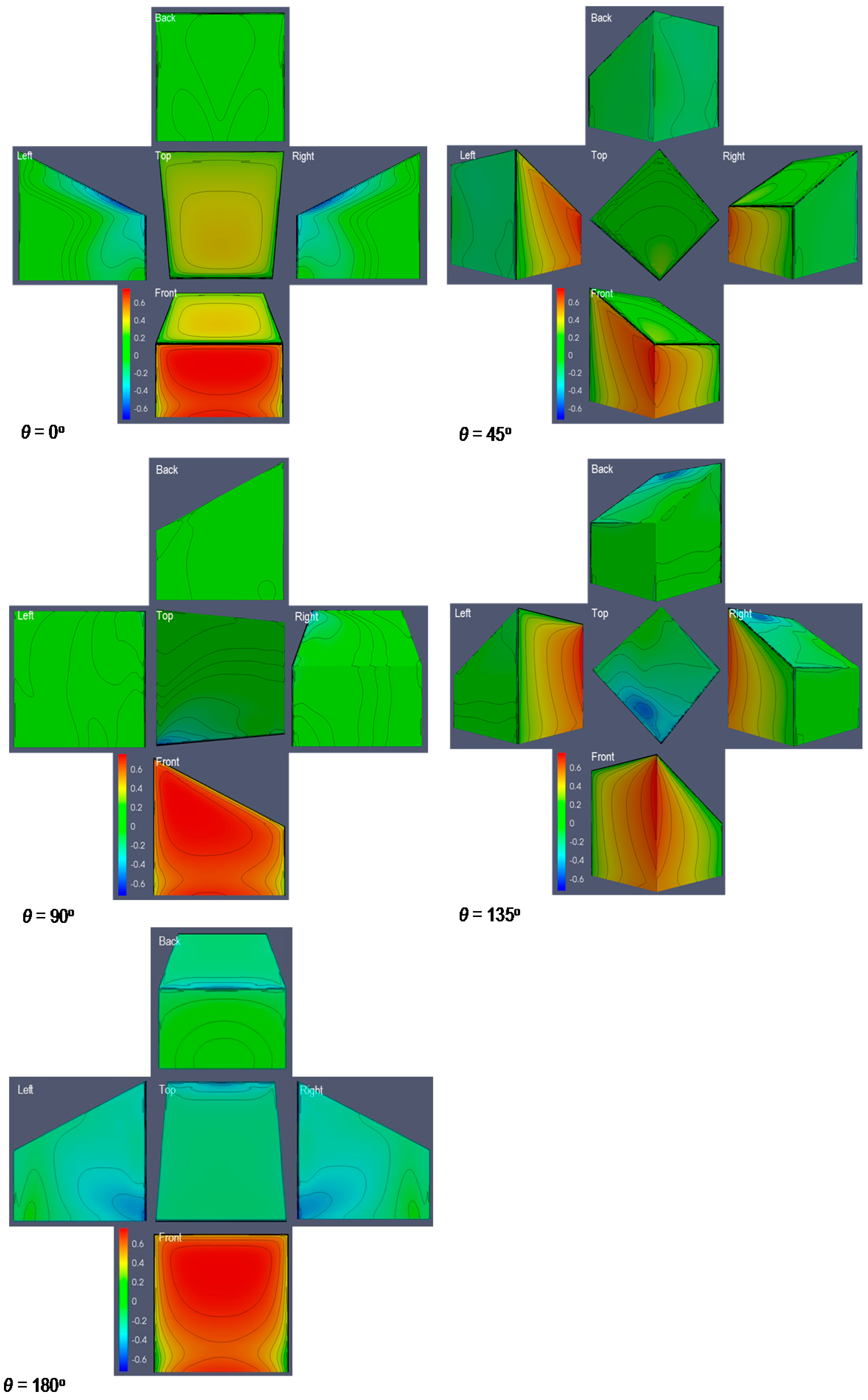

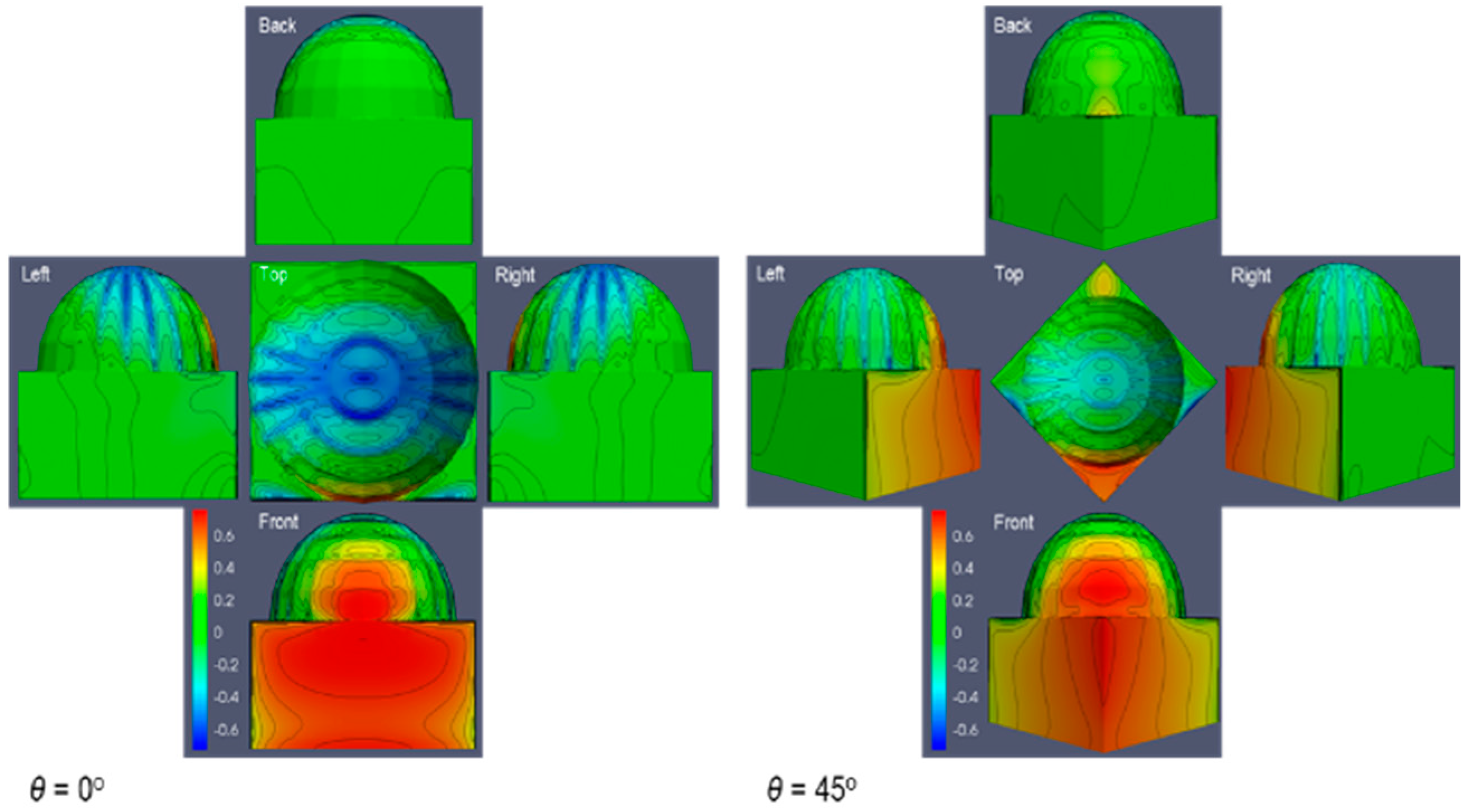

3.2. Surface Pressure Coefficient

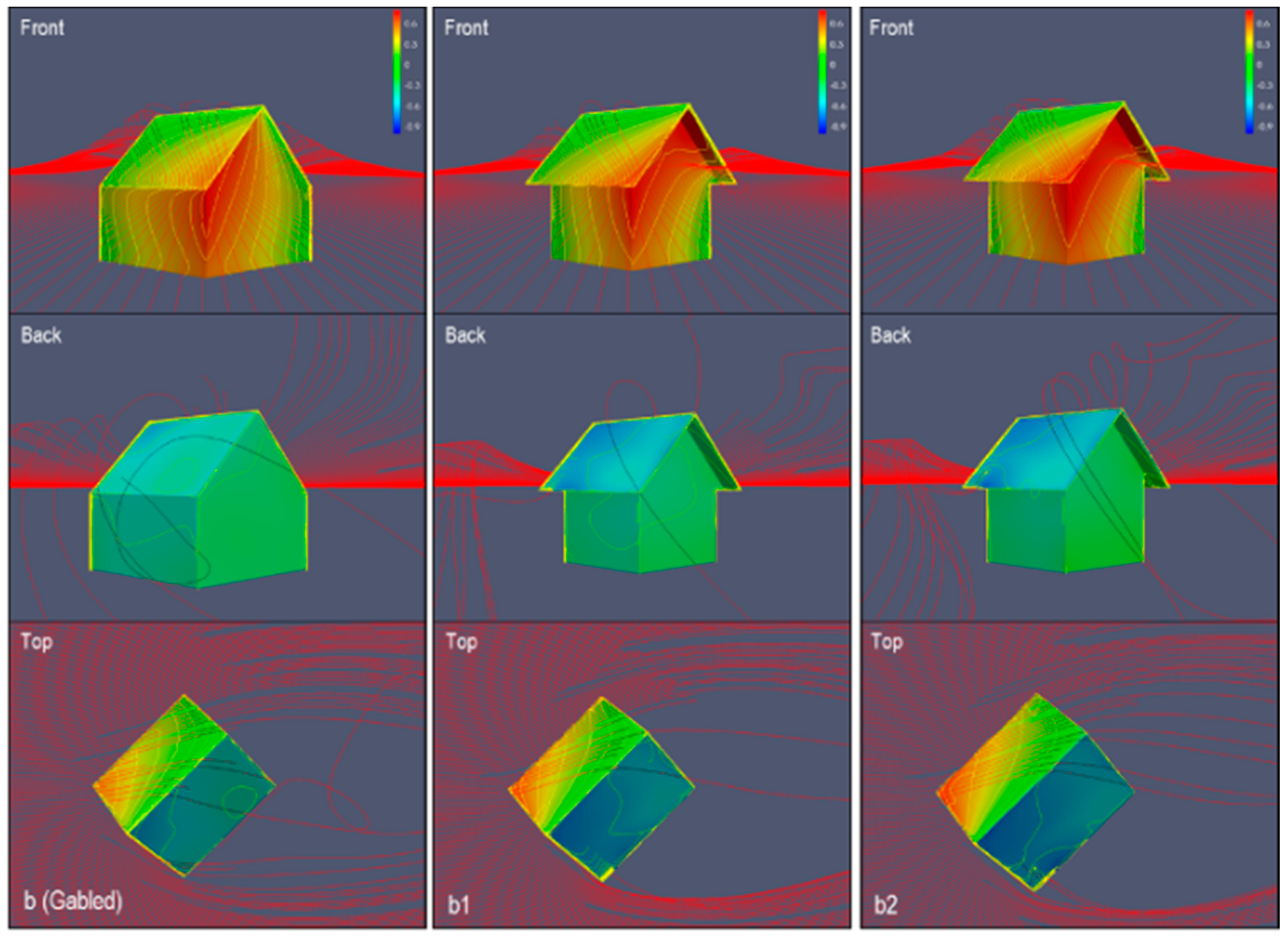

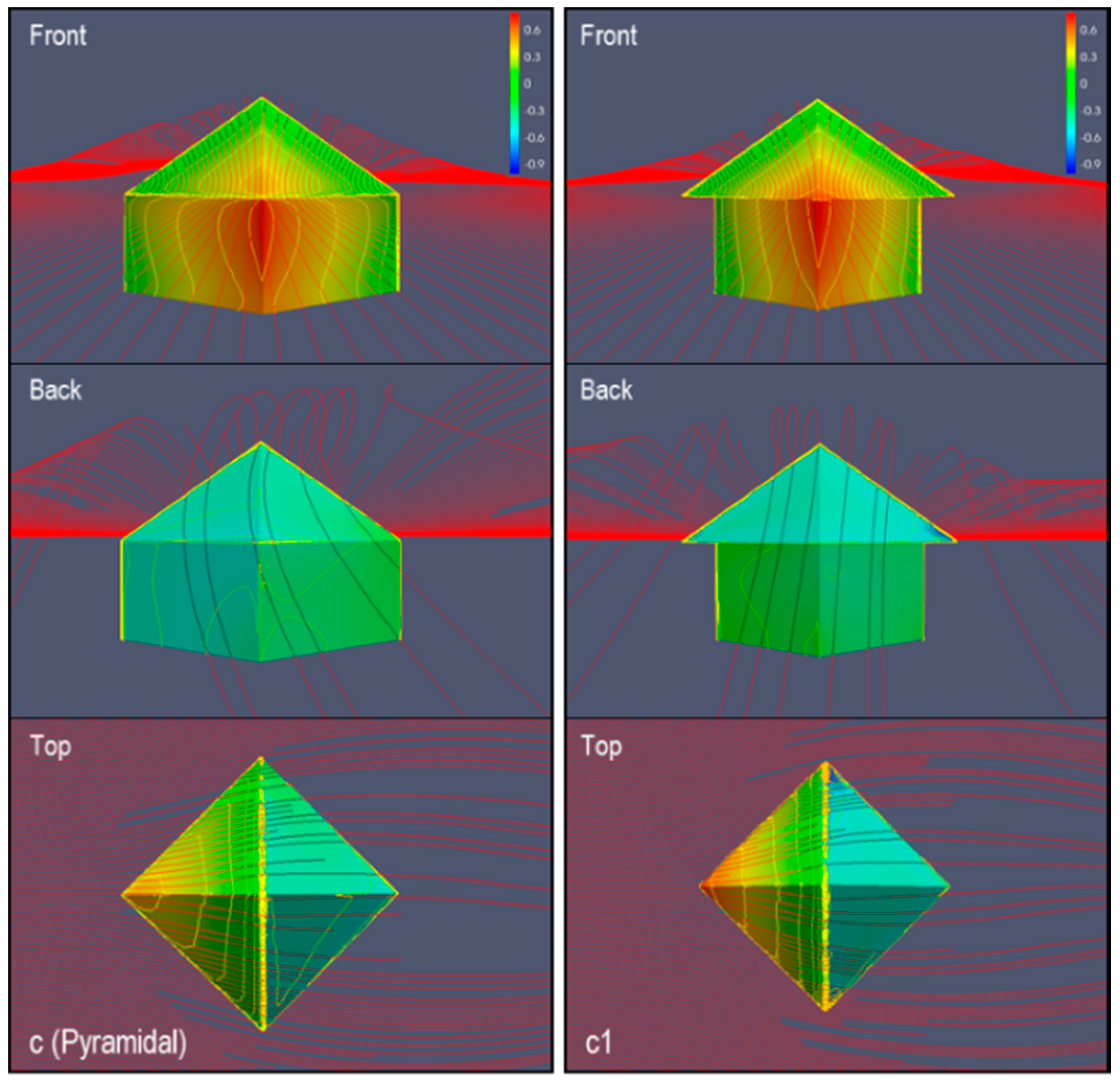

3.3. Gabled and Pyramidal Roofs Evaluation

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Enteria, N.; Awbi, H.; Yoshino, H. Application of renewable energy sources and new building technologies for the Philippine single family detached house. Int. J. Energy Environ. Eng. 2015, 6, 267–294. [Google Scholar] [CrossRef]

- Typhoon-Haiyan-Full-Horror-Destruction-Philippines-Revealed. Available online: http://www.dailymail.co.uk/news/article-2499851/Typhoon-Haiyan-Full-horror-destruction-Philippines-revealed.html (accessed on 8 October 2016).

- Typhoon Haiyan/Yolanda Destruction. Available online: http://o.canada.com/news/world/canadas-disaster-emergency-response-team-likely-to-be-in-philippines-on-friday (accessed on 8 October 2016).

- Li, J.Q.; Ward, I.C. Investigation of roof pitch and wind induced ventilation by computational fluid dynamics. In Proceedings of the 23rd Conference on Passive and Low Energy Architecture, Geneva, Switzerland, 6–8 September 2006.

- Ayata, T. Investigation of building height and roof effect on the air velocity and pressure distribution around the detached houses in Turkey. Appl. Therm. Eng. 2009, 29, 1752–1758. [Google Scholar] [CrossRef]

- Abohela, I.; Hamza, N.; Dehek, S. Effect of roof shape on energy yield and positioning of roof mounted turbines. In Proceedings of the 12th Conference of International Building Performance Simulation Association, Sydney, Australia, 14–16 November 2011.

- OpenFOAM. Available online: http://www.openfoam.com/ (accessed on 6 September 2015).

- simFlow. Available online: https://sim-flow.com/ (accessed on 15 November 2015).

- Dose, B.; Medjroubi, W.; Stoevesandt, B. CFD simulations of 2.5 MW turbine using ANSYS CFX and OpenFOAM. In Proceedings of the First Symposium on OpenFOAM in Wind Energy, Oldenburg, Germany, 21 March 2013; Available online: http://www.forwind.de/sowe/Site/Program_files/SOWE2013_Dose.pdf (accessed on 25 February 2016).

- Casella, L.; Langreder, W.; Fisher, A.; Ehlen, M.; Skoutelakos, D. Dynamic flow analysis using an OpenFOAM based CFD tool: Validation of turbulence Intensity in a testing site. ITM Web Conf. 2014, 2, 04002. [Google Scholar] [CrossRef]

- Irtaza, H.; Beale, R.G.; Godley, M.H.R.; Jameel, A. Comparison of wind pressure measurement on Silsoe experimental building from full-scale observation, wind-tunnel experiments and various CFD techniques. Int. J. Eng. Sci. Technol. 2013, 5, 28–41. [Google Scholar] [CrossRef]

- Franke, J.; Hellsten, A.; Schlunzen, H.; Carrissimo, B. Best Practice Guideline for the CFD Simulation of Flows in the Urban Environment; COST Office: Brussels, Belgium, 2007. [Google Scholar]

- Tamura, T.; Nozawa, K.; Kondo, K. AIJ guide for numerical prediction of wind loads on buildings. J. Wind Eng. Ind. Aerodyn. 2008, 96, 1974–1984. [Google Scholar] [CrossRef]

- Tominaga, Y.; Mochida, A.; Yoshie, R.; Kataoka, H.; Nozu, T.; Yoshikawa, M.; Shirasawa, T. AIJ guidelines for practical applications of CFD to pedestrian wind environment around buildings. J. Wind Eng. Ind. Aerodyn. 2008, 96, 1749–1761. [Google Scholar] [CrossRef]

- Krajnovic, S.; Davidson, L. Large-eddy simulation of the flow around a bluff body. AIAA J. 2002, 40, 927–936. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume a Method Approach; Pearson Limited: London, UK, 1995. [Google Scholar]

- Abohela, I.; Hamza, N.; Dudek, S. Effect of roof shape, wind direction, building height and urban configuration on the energy yield and position of roof mounted wind turbines. Renew. Energy 2013, 50, 1106–1118. [Google Scholar] [CrossRef]

- Blocken, B.; Stathopoulos, T.; Carmeliet, J. CFD simulation of the atmospheric boundary layer: Wall function problems. Atmos. Environ. 2007, 41, 238–252. [Google Scholar] [CrossRef]

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enteria, N.A. CFD Evaluation of Philippine Detached Structure with Different Roofing Designs. Infrastructures 2016, 1, 3. https://doi.org/10.3390/infrastructures1010003

Enteria NA. CFD Evaluation of Philippine Detached Structure with Different Roofing Designs. Infrastructures. 2016; 1(1):3. https://doi.org/10.3390/infrastructures1010003

Chicago/Turabian StyleEnteria, Napoleon A. 2016. "CFD Evaluation of Philippine Detached Structure with Different Roofing Designs" Infrastructures 1, no. 1: 3. https://doi.org/10.3390/infrastructures1010003

APA StyleEnteria, N. A. (2016). CFD Evaluation of Philippine Detached Structure with Different Roofing Designs. Infrastructures, 1(1), 3. https://doi.org/10.3390/infrastructures1010003