Towards Circular Construction: Material and Component Stock Assessment in Montréal’s Residential Buildings

Abstract

1. Introduction

2. Literature Review

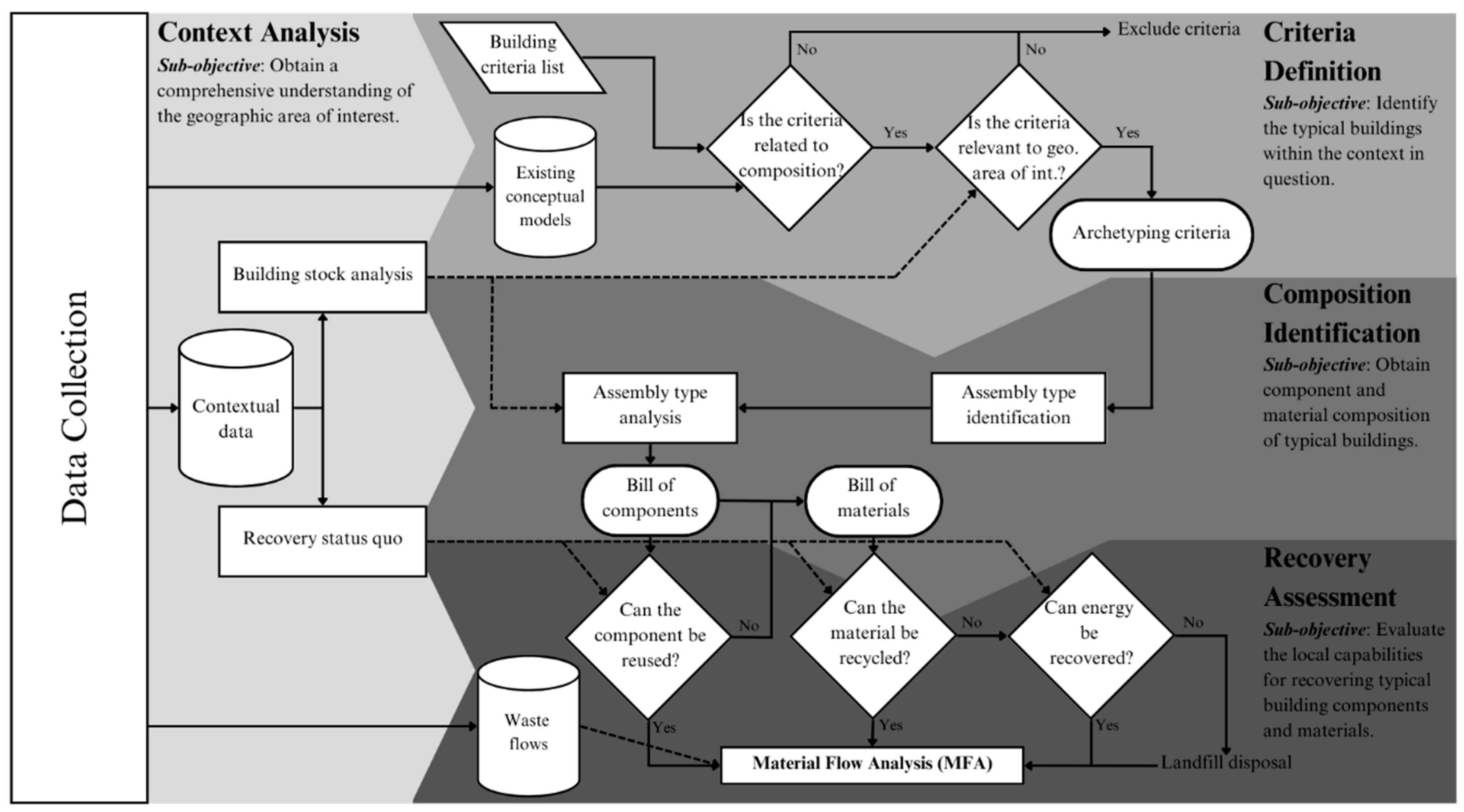

3. Materials and Methods

3.1. Context Analysis

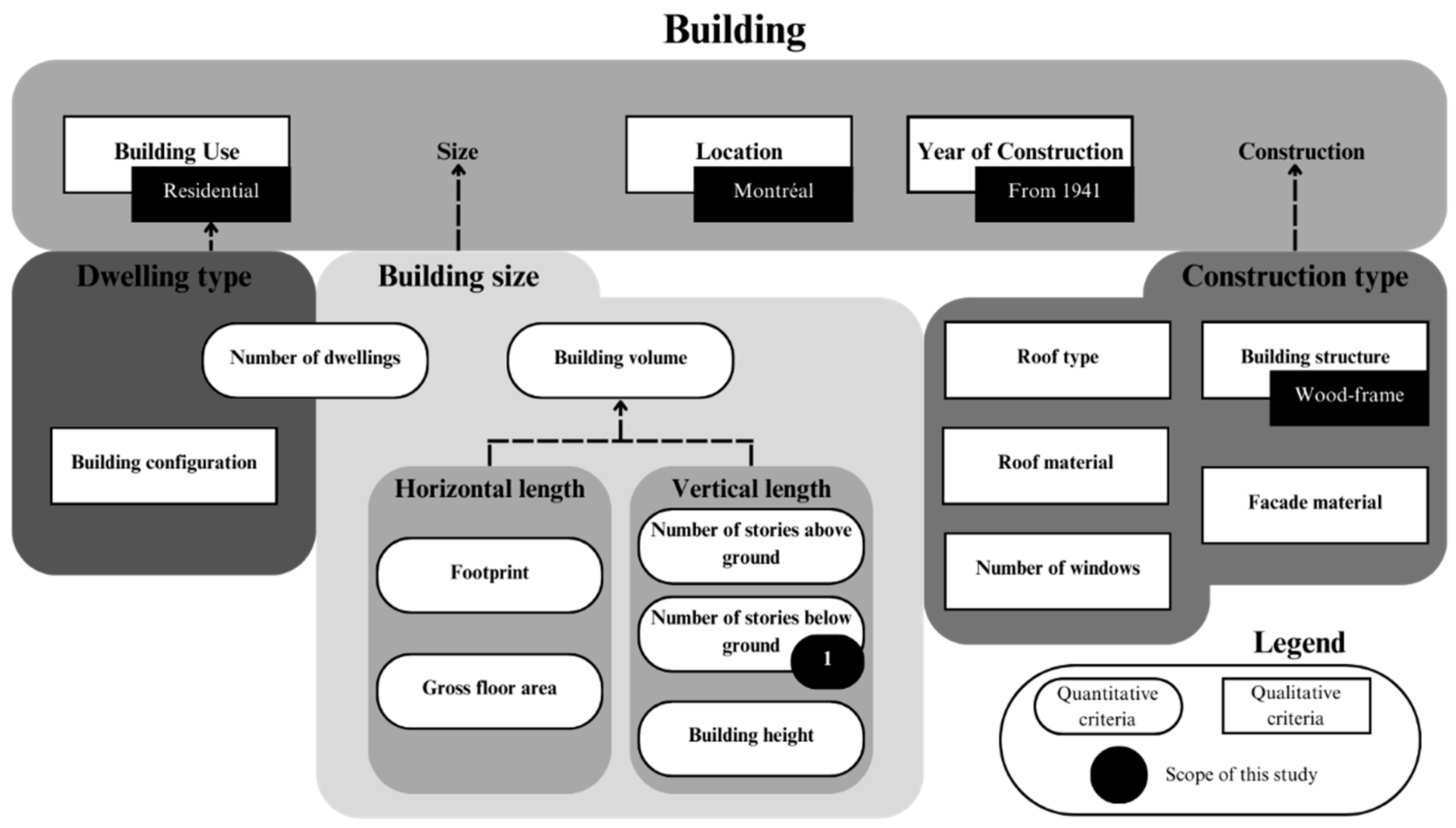

3.2. Criteria Definition

3.3. Composition Identification

3.4. Recovery Assessment

4. Results

4.1. Archetyping Criteria

4.2. Typical Low-Rise Residential Buildings

4.3. Shell Composition

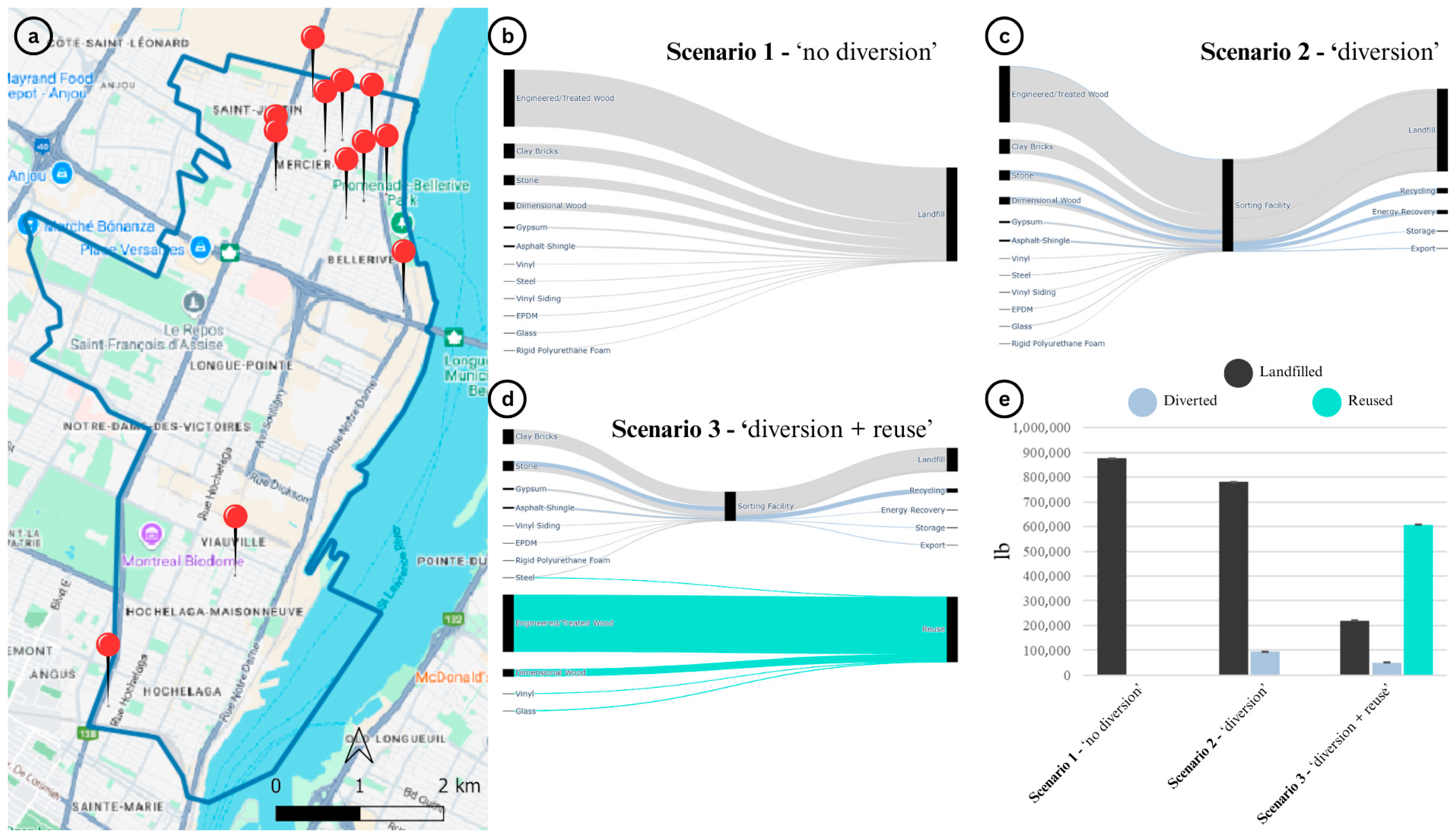

5. Practical Application

5.1. Recovery Pathways

5.2. Neighborhood Case Study

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CE | Circular Economy |

| CMHC | Central Mortgage and Housing Corporation |

| CRD | Construction, Renovation, and Demolition |

| HDB | Housing Development Board |

| MFA | Material Flow Analysis |

Appendix A

| Type of Study | Criteria | Source | Type of Study | Criteria | Source |

|---|---|---|---|---|---|

| Energy archetype | Building use | [25,26,27,49,50] | Composition estimation | Location | [23,24,30,51,52] |

| Energy archetype | Construction year | [25,26,27,28,53] | Composition estimation | Building structure | [14,23,24,30,51,52,54] |

| Energy archetype | Location | [25,28,53] | Composition estimation | Region | [23,24,30,51,52] |

| Energy archetype | Household size | [55,56,57] | Composition estimation | Number of dwellings | [11,14,34] |

| Energy archetype | Household type | [55,56,57] | Composition estimation | Building configuration | [11,22,34] |

| Energy archetype | Building height | [25,27,53] | Composition estimation | Number of bedrooms | [22] |

| Energy archetype | Surface-volume ratio | [49] | Composition estimation | Building height | [58] |

| Energy archetype | Building footprint | [25,27,53] | Composition estimation | Gross floor area | [11,14,22,23,24,34,51,59] |

| Energy archetype | Number of stories | [25,26,53] | Composition estimation | Building footprint | [59] |

| Energy archetype | Roof type | [25,27,53] | Composition estimation | Number of stories above ground | [14,22,51,54] |

| Energy archetype | Thermal insulation | [28] | Composition estimation | Number of stories below ground | [14,22] |

| Energy archetype | Window-to-wall ratio | [53] | Composition estimation | Volume | [34,51] |

| Composition estimation | Building use | [5,6,7,11,14,16,30,34,51,52,55,60,61] | Composition estimation | Exterior wall material | [23,24] |

| Composition estimation | Construction year | [5,11,14,16,30,52,59] | Composition estimation | Roof material | [23,24] |

| Façade System Type | Component (Unit of Size/10 ft2) | Material (lb/10 ft2) | Assumptions |

|---|---|---|---|

| Brick veneer wall | Framing—2″ × 4″ studs (75 linear ft) | Wood (97. 5 lb) |

|

| Sheathing—7/8″ plywood board (10 ft2) | Engineered wood (26 lb) | ||

| Wall cover—Bricks (65 units) | Bricks (252.2 lb) | ||

| Stone veneer wall | Framing—2″ × 4″ studs (75 linear ft) | Wood (97. 5 lb) | |

| Sheathing—7/8″ plywood board (10 ft2) | Engineered wood (26 lb) | ||

| Wall cover—Stone (10 ft2) | Stone (170 lb) | ||

| Wall siding wall | Framing—2″ × 4″ studs (75 linear ft) | Wood (97.5 lb) | |

| Sheathing—7/8″ plywood board (10 ft2) | Engineered wood (26 lb) | ||

| Wall cover—Vinyl siding panel (10 ft2) | Vinyl (4.44 lb) | ||

| Stucco wall | Framing—2″ × 4″ studs (75 linear ft) | Wood (97.5 lb) | |

| Sheathing—7/8″ plywood board (10 ft2) | Engineered wood (26 lb) | ||

| Wall cover—Stucco (10 ft2) | Stucco mix (32.8 lb) | ||

| Firewall | Framing—2″ × 4″ studs (75 linear ft) | Wood (97. 5 lb) | |

| Sheathing—2 × 1/2″ gypsum boards (20 ft2) | Gypsum (32 lb) |

| Roof System Type | Component (Unit of Size/10 ft2) | Material (lb/10 ft2) | Assumptions |

|---|---|---|---|

| Sloped roof (asphalt) | Framing—2″ × 10″ rafters (81.225 linear ft) | Wood (268 lb) |

|

| Sheathing—5/16″ Plywood board (10.83 ft2) | Engineered wood (10.83 lb) | ||

| Roof cover—Asphalt shingles (1/3 of a bundle) | Asphalt (20 lb) | ||

| Sloped roof (slate) | Framing—2″ × 10″ rafters (81.225 linear ft) | Wood (268 lb) | |

| Sheathing—5/16″ Plywood board (10.83 ft2) | Engineered wood (10.83 lb) | ||

| Roof cover—Slate shingles (10.83 ft2) | Slate (108.3 lb) | ||

| Sloped roof (wood) | Framing—2″ × 10″ rafters (81.225 linear ft) | Wood (268 lb) | |

| Sheathing—5/16″ Plywood board (10.83 ft2) | Engineered wood (43.32 lb) | ||

| Roof cover—Wood shingles (10.83 ft2) | |||

| Sloped roof (metal) | Framing—2″ × 10″ rafters (81.225 linear ft) | Wood (268 lb) | |

| Sheathing—5/16″ Plywood board (10.83 ft2) | Engineered wood (10.83 lb) | ||

| Roof cover—Metal tiles (10.83 ft2) | Metal (15.162 lb) | ||

| Sloped roof (clay) | Framing—2″ × 10″ rafters (81.225 linear ft) | Wood (268 lb) | |

| Sheathing—5/16″ Plywood board (10.83 ft2) | Engineered wood (10.83 lb) | ||

| Roof cover—Clay tiles (53 tiles) | Clay (97.47 lb) | ||

| Flat roof (built-up) | Framing—2″ × 10″ rafters (75 linear ft) | Wood (247.5 lb) | |

| Sheathing—5/16″ Plywood board (10 ft2) | Engineered wood (10 lb) | ||

| Roof cover—EPDM (10 ft2) | EPDM (14.75 lb) | ||

| Flat roof (built-up with gravel) | Framing—2″ × 10″ rafters (75 linear ft) | Wood (247.5 lb) | |

| Sheathing—5/16″ Plywood board (10 ft2) | Engineered wood (10 lb) | ||

| Roof cover—EPDM (10 ft2) | EPDM (14.75 lb) | ||

| Roof cover—Gravel (10 ft2) | Gravel (163.8 lb) |

| Opening System Type | Component (Unit of Size/Unit) | Material (lb/Unit) | Assumptions |

|---|---|---|---|

| PVC window | Vinyl frame (47.2 inches × 47.2 inches) | Vinyl (23.13 lb) |

|

| Vinyl casing (47.2 inches × 47.2 inches) | |||

| Double glazing (47.2 inches × 47.2 inches) | Glass (49.5 lb) | ||

| Wood window | Wood frame (47.2 inches × 47.2 inches) | Wood (21.75 lb) | |

| Wood casing (47.2 inches × 47.2 inches) | |||

| Double glazing (47.2 inches × 47.2 inches) | Glass (15.87 lb) | ||

| Wood door | Wood frame (36 inches × 84 inches) | Wood (98.78 lb) |

|

| Wood door (32 inches × 80 inches) | |||

| Steel door | Steel frame (36 inches × 84 inches) | Steel (92 lb) | |

| Steel door (32 inches × 80 inches) | |||

| Rigid polyurethane foam (5.18 lb) |

References

- Canadian Council of Ministers of the Environment. Guide for Identifying, Evaluating and Selecting Policies for Influencing Construction, Renovation and Demolition Waste Management; Canadian Council of Ministers of the Environment: Winnipeg, MB, Canada, 2019; ISBN 978-1-77202-054-0. [Google Scholar]

- Louise, L.; VanderPol, P.M. Characterization & Management of Construction, Renovation & Demolition Waste in Canada; Recycling Council of Alberta Conference: Lake Louise, AB, Canada, 2014. [Google Scholar]

- Government of Canada Construction, Transformation and Demolition Permits. Available online: https://open.canada.ca/data/en/dataset/d90eaf1b-2de8-43f0-923a-27a620ecdf41 (accessed on 11 May 2023).

- Al-Ashmori, Y.Y.; Othman, I.; Al-Aidrous, A.H.M.H. “Values, Challenges, and Critical Success Factors” of Building Information Modelling (BIM) in Malaysia: Experts Perspective. Sustainability 2022, 14, 3192. [Google Scholar] [CrossRef]

- Gontia, P.; Thuvander, L.; Ebrahimi, B.; Vinas, V.; Rosado, L.; Wallbaum, H. Spatial Analysis of Urban Material Stock with Clustering Algorithms: A Northern European Case Study. J. Ind. Ecol. 2019, 23, 1328–1343. [Google Scholar] [CrossRef]

- Miatto, A.; Schandl, H.; Forlin, L.; Ronzani, F.; Borin, P.; Giordano, A.; Tanikawa, H. A Spatial Analysis of Material Stock Accumulation and Demolition Waste Potential of Buildings: A Case Study of Padua. Resour. Conserv. Recycl. 2019, 142, 245–256. [Google Scholar] [CrossRef]

- Arora, M.; Raspall, F.; Cheah, L.; Silva, A. Buildings and the Circular Economy: Estimating Urban Mining, Recovery and Reuse Potential of Building Components. Resour. Conserv. Recycl. 2020, 154, 104581. [Google Scholar] [CrossRef]

- Mesta, C.; Kahhat, R.; Santa-Cruz, S. Geospatial Characterization of Material Stock in the Residential Sector of a Latin-American City. J. Ind. Ecol. 2019, 23, 280–291. [Google Scholar] [CrossRef]

- Orenga Panizza, R.; Nik-Bakht, M. Building Stock as a Future Supply of Second-Use Material–A Review of Urban Mining Methods. Waste Manag. Bull. 2024, 2, 19–31. [Google Scholar] [CrossRef]

- Arora, M.; Raspall, F.; Cheah, L.; Silva, A. Residential Building Material Stocks and Component-Level Circularity: The Case of Singapore. J. Clean. Prod. 2019, 216, 239–248. [Google Scholar] [CrossRef]

- Sprecher, B.; Verhagen, T.J.; Sauer, M.L.; Baars, M.; Heintz, J.; Fishman, T. Material Intensity Database for the Dutch Building Stock: Towards Big Data in Material Stock Analysis. J. Ind. Ecol. 2022, 26, 272–280. [Google Scholar] [CrossRef]

- Augiseau, V. La Dimension Matérielle de l’urbanisation-Flux et Stocks de Matériaux de Construction En Ile-de-France; Université Paris 1 Panthéon-Sorbonne: Paris, France, 2017. [Google Scholar]

- Ortlepp, R.; Gruhler, K.; Schiller, G. Materials in Germany’s Domestic Building Stock: Calculation Model and Uncertainties. Build. Res. Inf. 2018, 46, 164–178. [Google Scholar] [CrossRef]

- Gontia, P.; Nägeli, C.; Rosado, L.; Kalmykova, Y.; Österbring, M. Material-Intensity Database of Residential Buildings: A Case-Study of Sweden in the International Context. Resour. Conserv. Recycl. 2018, 130, 228–239. [Google Scholar] [CrossRef]

- Lanau, M.; Liu, G. Developing an Urban Resource Cadaster for Circular Economy: A Case of Odense, Denmark. Environ. Sci. Technol. 2020, 54, 4675–4685. [Google Scholar] [CrossRef]

- Kleemann, F.; Lederer, J.; Rechberger, H.; Fellner, J. GIS-Based Analysis of Vienna’s Material Stock in Buildings. J. Ind. Ecol. 2016, 21, 368–380. [Google Scholar] [CrossRef]

- Guo, J.; Miatto, A.; Shi, F.; Tanikawa, H. Spatially Explicit Material Stock Analysis of Buildings in Eastern China Metropoles. Resour. Conserv. Recycl. 2019, 146, 45–54. [Google Scholar] [CrossRef]

- Han, J.; Chen, W.Q.; Zhang, L.; Liu, G. Uncovering the Spatiotemporal Dynamics of Urban Infrastructure Development: A High Spatial Resolution Material Stock and Flow Analysis. Environ. Sci. Technol. 2018, 52, 12122–12132. [Google Scholar] [CrossRef]

- Tanikawa, H.; Hashimoto, S. Urban Stock over Time: Spatial Material Stock Analysis Using 4d-GIS. Build. Res. Inf. 2009, 37, 483–502. [Google Scholar] [CrossRef]

- Surahman, U.; Higashi, O.; Kubota, T. Evaluation of Current Material Stock and Future Demolition Waste for Urban Residential Buildings in Jakarta and Bandung, Indonesia: Embodied Energy and CO2 Emission Analysis. J. Mater. Cycles Waste Manag. 2017, 19, 657–675. [Google Scholar] [CrossRef]

- Stephan, A.; Athanassiadis, A. Quantifying and Mapping Embodied Environmental Requirements of Urban Building Stocks. Build. Environ. 2017, 114, 187–202. [Google Scholar] [CrossRef]

- Arceo, A.; Tham, M.; Guven, G.; MacLean, H.L.; Saxe, S. Capturing Variability in Material Intensity of Single-Family Dwellings: A Case Study of Toronto, Canada. Resour. Conserv. Recycl. 2021, 175, 105885. [Google Scholar] [CrossRef]

- Cha, G.W.; Kim, Y.C.; Moon, H.J.; Hong, W.H. New Approach for Forecasting Demolition Waste Generation Using Chi-Squared Automatic Interaction Detection (CHAID) Method. J. Clean. Prod. 2017, 168, 375–385. [Google Scholar] [CrossRef]

- Cha, G.W.; Moon, H.J.; Kim, Y.M.; Hong, W.H.; Hwang, J.H.; Park, W.J.; Kim, Y.C. Development of a Prediction Model for Demolition Waste Generation Using a Random Forest Algorithm Based on Small Datasets. Int. J. Environ. Res. Public Health 2020, 17, 6997. [Google Scholar] [CrossRef] [PubMed]

- HosseiniHaghighi, S.R.; de Uribarri, P.M.Á.; Padsala, R.; Eicker, U. Characterizing and Structuring Urban GIS Data for Housing Stock Energy Modelling and Retrofitting. Energy Build. 2022, 256, 111706. [Google Scholar] [CrossRef]

- Dochev, I.; Seller, H.; Peters, I. Assigning Energetic Archetypes to a Digital Cadastre and Estimating Building Heat Demand. An Example from Hamburg, Germany. Environ. Clim. Technol. 2020, 24, 233–253. [Google Scholar] [CrossRef]

- Abolhassani, S.S.; Amayri, M.; Bouguila, N.; Eicker, U. A New Workflow for Detailed Urban Scale Building Energy Modeling Using Spatial Joining of Attributes for Archetype Selection. J. Build. Eng. 2022, 46, 103661. [Google Scholar] [CrossRef]

- Shen, P.; Wang, H. Archetype Building Energy Modeling Approaches and Applications: A Review. Renew. Sustain. Energy Rev. 2024, 199, 114478. [Google Scholar] [CrossRef]

- Residential Archetyping for Energy Efficiency Programs: A Guide for Canadian Municipalities; Clean Air Partnership: Toronto, ON, Canada, 2022.

- Zhang, R.; Guo, J.; Yang, D.; Shirakawa, H.; Shi, F.; Tanikawa, H. What Matters Most to the Material Intensity Coefficient of Buildings? Random Forest-Based Evidence from China. J. Ind. Ecol. 2022, 26, 1809–1823. [Google Scholar] [CrossRef]

- Yu, K. Seismic Vulnerability Assessment for Montreal-An Application of HAZUS-MH4; McGill University: Montreal, QC, Canada, 2011. [Google Scholar]

- Auger, J.; Roquet, N. Mémoire de Bâtisseurs Du Québec: Répertoire Illustré de Systèmes de Construction Du 18e Siècle À Nos Jours; Méridien: Montreal, QC, Canada, 1998. [Google Scholar]

- Montréal Master Plan: Chapter 18–Pierrefonds-Roxboro, Ville de Montréal. 2007. Available online: https://ville.montreal.qc.ca/pls/portal/docs/page/plan_urbanisme_en/media/documents/110620_chapitre_18_en.pdf (accessed on 11 November 2025).

- Miatto, A.; Fasanella, Y.; Mainardi, M.; Borin, P. Correlation between Building Size and Material Intensity in Residential Buildings. Resour. Conserv. Recycl. 2023, 197, 107093. [Google Scholar] [CrossRef]

- Rutherford, D.H. Stud Spacing in Canadian Frame Houses; National Research Council: Ottawa, ON, Canada, 1953. [Google Scholar]

- Government of Canada Publications. Developments in Windows, Doors and Hardware for Northern Conditions; Larsson Consulting Ltd.: Ottawa, ON, Canada, 1990. [Google Scholar]

- Natural Resources Canada Technology Primer-Factors Affecting Energy Efficiency. Available online: https://natural-resources.canada.ca/energy-efficiency/products/windows-doors-and-skylights/technology-primer/14432 (accessed on 20 August 2024).

- Natural Resources Canada Keeping The Heat In-Section 8: Upgrading Windows and Exterior Doors. Available online: https://natural-resources.canada.ca/energy-efficiency/homes/make-your-home-more-energy-efficient/keeping-the-heat/section-8-upgrading-windows-and-exterior-doors/15643#a8-2 (accessed on 20 August 2024).

- Canada Mortgage and Housing Corporation Digitized Collection of CMHC Small and Modest House Plans Held by the Housing Knowledge Centre of CMHC. Available online: https://cmhc.ent.sirsidynix.net/client/en_US/CMHCLibrary/search/detailnonmodal/ent:$002f$002fSD_ILS$002f0$002fSD_ILS:111654/email?qu=house+plan+catalogues&te=ILS (accessed on 18 June 2025).

- Ecocentres. Available online: https://montreal.ca/en/topics/ecocentres (accessed on 26 August 2024).

- Bilan 2021 de La Gestion Des Matières Résiduelles Au Québec; Recyc-Quebec: Quebec, QC, Canada, 2021.

- Magasin Habitat Pour l’humanité. Available online: https://magasinhabitatqc.ca/en/home/ (accessed on 26 August 2024).

- RÉCO. Available online: https://recocentre.ca/ (accessed on 26 August 2024).

- Allam, A.S.; Nik-Bakht, M. From Demolition to Deconstruction of the Built Environment: A Synthesis of the Literature. J. Build. Eng. 2023, 64, 105679. [Google Scholar] [CrossRef]

- Allam, A.S.; Nik-Bakht, M. Supporting Circularity in Construction with Performance-Based Deconstruction. Sustain. Prod. Consum. J. 2023, 45, 1–14. [Google Scholar] [CrossRef]

- Centris. Available online: https://www.centris.ca/en/ (accessed on 8 April 2025).

- Scalia, S. The Best Neighborhoods to Live in Montreal. Available online: https://www.samcon.ca/the-best-neighborhoods-to-live-in-montreal/ (accessed on 8 April 2025).

- Microsoft CanadianBuildingFootprints. Available online: https://github.com/Microsoft/CanadianBuildingFootprints?tab=readme-ov-file (accessed on 10 September 2024).

- Kristensen, M.H.; Hedegaard, R.E.; Petersen, S. Hierarchical Calibration of Archetypes for Urban Building Energy Modeling. Energy Build. 2018, 175, 219–234. [Google Scholar] [CrossRef]

- Hachem-Vermette, C.; Singh, K. Optimization of Energy Resources in Various Building Cluster Archetypes. Renew. Sustain. Energy Rev. 2022, 157, 112050. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, A.O.; Oyedele, L.O.; Salami, R.O. Deep Learning Model for Demolition Waste Prediction in a Circular Economy. J. Clean. Prod. 2020, 274, 122843. [Google Scholar] [CrossRef]

- Yang, D.; Guo, J.; Sun, L.; Shi, F.; Liu, J.; Tanikawa, H. Urban Buildings Material Intensity in China from 1949 to 2015. Resour. Conserv. Recycl. 2020, 159, 104824. [Google Scholar] [CrossRef]

- Monteiro, C.S.; Pina, A.; Cerezo, C.; Reinhart, C.; Ferrão, P. The Use of Multi-Detail Building Archetypes in Urban Energy Modelling. Energy Procedia 2017, 111, 817–825. [Google Scholar] [CrossRef]

- Huang, R.Y.; Yeh, L.H.; Chen, H.H.; Lin, J.D.; Chen, P.F.; Sung, P.H.; Yau, J.T. Estimation of Construction Waste Generation and Management in Taiwan. Adv. Mater. Res. 2011, 243–249, 6292–6295. [Google Scholar] [CrossRef]

- Osman, M.; Saad, M.M.; Ouf, M.; Eicker, U. From Buildings to Cities: How Household Demographics Shape Demand Response and Energy Consumption. Appl. Energy 2024, 356, 122359. [Google Scholar] [CrossRef]

- Ben, H.; Steemers, K. Modelling Energy Retrofit Using Household Archetypes. Energy Build. 2020, 224, 110224. [Google Scholar] [CrossRef]

- Ben, H.; Steemers, K. Household Archetypes and Behavioural Patterns in UK Domestic Energy Use. Energy Effic. 2018, 11, 761–771. [Google Scholar] [CrossRef]

- Tanikawa, H.; Fishman, T.; Okuoka, K.; Sugimoto, K. The Weight of Society over Time and Space: A Comprehensive Account of the Construction Material Stock of Japan, 1945–2010. J. Ind. Ecol. 2015, 19, 778–791. [Google Scholar] [CrossRef]

- Nasiri, B.; Kaasalainen, T.; Hughes, M. Estimating the Material Intensity of Wooden Residential Houses in Finland. Resour. Conserv. Recycl. 2023, 198, 107142. [Google Scholar] [CrossRef]

- Villoria Sáez, P.; Del Río Merino, M.; Porras-Amores, C. Estimation of Construction and Demolition Waste Volume Generation in New Residential Buildings in Spain. Waste Manag. Res. 2012, 30, 137–146. [Google Scholar] [CrossRef]

- Yu, B.; Wang, J.; Li, J.; Zhang, J.; Lai, Y.; Xu, X. Prediction of Large-Scale Demolition Waste Generation during Urban Renewal: A Hybrid Trilogy Method. Waste Manag. 2019, 89, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Lumber-Weights. Available online: https://www.engineeringtoolbox.com/green-kiln-dried-pressure-treated-lumber-weights-d_1860.html (accessed on 22 August 2024).

- Clay Brick Association of Canada-Technical Notes. Available online: https://claybrick.ca/technical-notes/ (accessed on 22 August 2024).

- Adhikari, T.; Mellentine, J.; Lewis, K. Life Cycle Assessment (LCA) of Stone Cladding; Natural Stone Institute (NSI): Oberlin, OH, USA, 2022. [Google Scholar]

- Performance Panels-Lightness in Weight. Available online: https://www.performancepanels.com/lightness-in-weight (accessed on 22 August 2024).

- Environmental Product Declaration: Vinyl Siding-Industry Averaged Vinyl Siding; Vinyl Siding Institute: Alexandria, VA, USA, 2022.

- Venta, G.J. Cradle-To-Gate Life Cycle Inventory for Exterior Stucco Finishes; Athena: Ottawa, ON, Canada, 2001. [Google Scholar]

- Building Materials Weights Guide. Available online: https://www.soundproofingcompany.com/soundproofing_101/building-materials-weights-guide (accessed on 22 August 2024).

- RSMeans. Square Foot Costs, 32nd ed.; RSMeans: Greenville, SC, USA, 2011. [Google Scholar]

- Roof Hub. Available online: https://myroofhub.com/materials/bundle-shingles-weight-dumpster-ordering/ (accessed on 22 August 2024).

- Material Weights. Available online: https://www.dansmithpe.com/ (accessed on 22 August 2024).

- Gerard Metal & Tile Roofing. Available online: https://www.metalworkscanada.com/product/metal-roofing-calgary/gerard-metal-tile-roofing/ (accessed on 22 August 2024).

- Tile Roofs Canada: Clay Roof Tile. Available online: https://drive.google.com/file/d/1uHcYmd4DTT8Wi39U8mljqfwHp12npoy7/view (accessed on 11 November 2025).

- Ply, S.; Ndustry, R.I. Environmental Product Declaration: Reinforced EPDM Membrane; ASTM International: West Conshohocken, PA, USA, 2022. [Google Scholar]

- Gravel Ballasted Roofs. Available online: https://www.sika.com/en/construction/roof-systems/gravel-ballasted-roofs.html (accessed on 22 August 2024).

- Asif, M.; Davidson, A.; Muneer, T. Life Cycle of Window Materials—A Comparative Assessment; Millenium Fellow School of Engineering, Napier University: Edinburgh, Scotland, 2002. [Google Scholar]

- Maintenance, Repair and Replacement Effects for Building Envelope Materials; ATHENA™ Sustainable Materials Institute: Merrickville, ON, Canada, 2002.

- How Much Do Hollow Metal Doors Weigh? Available online: https://www.doorclosersusa.com/How-Much-Does-A-Hollow-Metal-Door-Weigh-s/34749.htm (accessed on 11 November 2025).

- Steel Door Institute. Environmental Product Declaration (EPD) SCS-EPD-05020: Steel Door Frame; Steel Door Institute: Westlake, OH, USA, 2018; Available online: https://steeldoor.org/wp-content/uploads/2020/04/SCS-EPD-05020_SDI_SteelDoorFrame_061418.pdf (accessed on 17 September 2025).

- Standard Exterior Door Size: A Comprehensive Guide; Canadian Choice Windows & Doors™. Available online: https://www.windowscanada.com/whitepages/standard-exterior-door-size.html (accessed on 11 November 2025).

- Rigid Polyurethane Foam. Available online: https://acoustafoam.com/rigid-foam/ (accessed on 22 August 2024).

| Context | Input | Output Type | Reference | ||

|---|---|---|---|---|---|

| Continent | Country | Source of Data | Material Stock | Component Stock | |

| Europe | Netherlands | Demolition reports | ✓ | [11] | |

| France | Literature | ✓ | [12] | ||

| Germany | Design documents | ✓ | [13] | ||

| Sweden | Design documents | ✓ | [14] | ||

| Denmark | City data and on-site survey | ✓ | [15] | ||

| Austria | On-site survey, design documents, and literature | ✓ | [16] | ||

| Italy | Construction manuals, architectural books, and experts’ opinions | ✓ | [6] | ||

| Asia | China | Literature | ✓ | [17,18] | |

| Japan | Building code | ✓ | [19] | ||

| Singapore | Building code | ✓ | ✓ | [10] | |

| Indonesia | On-site survey | ✓ | [20] | ||

| Oceania | Australia | Land-use and building footprint databases, and experts’ opinions | ✓ | [21] | |

| South America | Peru | Design documents, on-site survey, experts’ opinions, and the literature | ✓ | [8] | |

| North America | Canada | Design documents | ✓ | [22] | |

| Energy → Building Criteria Composition ↓ | Building Use | Construction Year | Location | Household Size | Household Type | Building Height | Surface-Volume Ratio | Building Footprint | Number of Stories | Roof Type | Thermal Insulation | Window-to-Wall Ratio |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Building use | → | |||||||||||

| Construction year | → | |||||||||||

| Location | → | |||||||||||

| Building structure | ||||||||||||

| Region | ||||||||||||

| Number of dwellings | ↝ | ↝ | ||||||||||

| Building configuration | ↝ | |||||||||||

| Number of bedrooms | ↝ | ↝ | ||||||||||

| Building height | → | |||||||||||

| Gross floor area | ↝ | ↝ | ||||||||||

| Building footprint | → | |||||||||||

| Number of stories above ground | ↝ | |||||||||||

| Number of stories below ground | ↝ | |||||||||||

| Volume | ↝ | |||||||||||

| Exterior wall material | ↝ | |||||||||||

| Roof material | ↝ |

| Material | Recycling | Energy Recovery | Storage | Export | Landfill |

|---|---|---|---|---|---|

| Dimensional wood | 12.9% | 34.1% | ✗ | 3.5% | 49.5% |

| Engineered wood | ✗ | 1.4% | ✗ | ✗ | 98.6% |

| Clay | ✗ | ✗ | ✗ | ✗ | 100% |

| Stone (aggregate) | 39.7% | ✗ | 6.8% | ✗ | 53.5% |

| Vinyl | ✗ | ✗ | ✗ | ✗ | 100% |

| Stucco mix (fine residue) | 5.3% | ✗ | 10.5% | 84.2% | ✗ |

| Gypsum | 2% | ✗ | ✗ | ✗ | 98% |

| Asphalt | 1.3% | 35.5% | ✗ | 6.6% | 56.6% |

| Slate | ✗ | ✗ | ✗ | ✗ | 100% |

| Metal | 41.4% | ✗ | ✗ | ✗ | 58.6% |

| EPDM | ✗ | ✗ | ✗ | ✗ | 100% |

| Gravel (aggregate) | 39.7% | ✗ | 6.8% | ✗ | 53.5% |

| Glass | 62.5% | ✗ | ✗ | ✗ | 37.5% |

| Steel | 41.4% | ✗ | ✗ | ✗ | 58.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orenga Panizza, R.; Jalaei, F.; Nik-Bakht, M. Towards Circular Construction: Material and Component Stock Assessment in Montréal’s Residential Buildings. Designs 2025, 9, 129. https://doi.org/10.3390/designs9060129

Orenga Panizza R, Jalaei F, Nik-Bakht M. Towards Circular Construction: Material and Component Stock Assessment in Montréal’s Residential Buildings. Designs. 2025; 9(6):129. https://doi.org/10.3390/designs9060129

Chicago/Turabian StyleOrenga Panizza, Rafaela, Farzad Jalaei, and Mazdak Nik-Bakht. 2025. "Towards Circular Construction: Material and Component Stock Assessment in Montréal’s Residential Buildings" Designs 9, no. 6: 129. https://doi.org/10.3390/designs9060129

APA StyleOrenga Panizza, R., Jalaei, F., & Nik-Bakht, M. (2025). Towards Circular Construction: Material and Component Stock Assessment in Montréal’s Residential Buildings. Designs, 9(6), 129. https://doi.org/10.3390/designs9060129