Design, Construction, and Simulation-Based Validation of a High-Efficiency Electric Powertrain for a Shell Eco-Marathon Urban Concept Vehicle

Abstract

1. Introduction

Research Gap and Motivation

2. Powertrain Design

2.1. Initial Vehicle Calculations

Traction Force Calculation

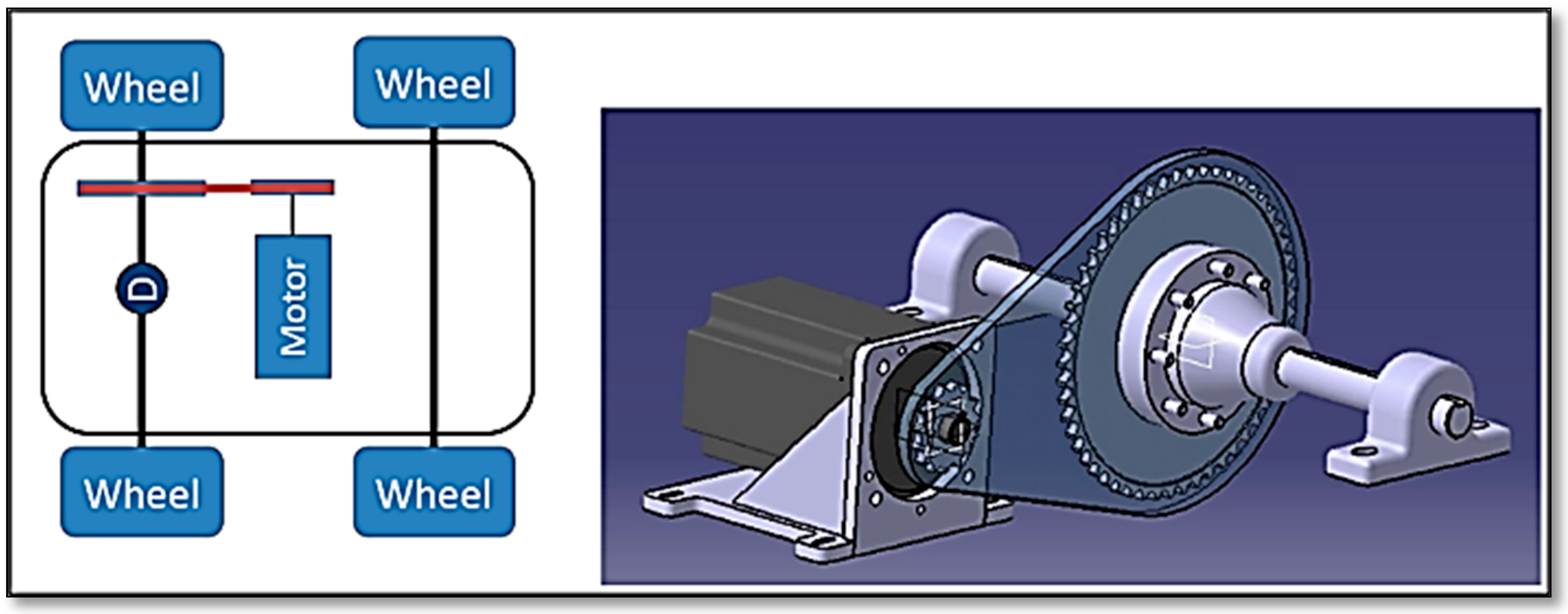

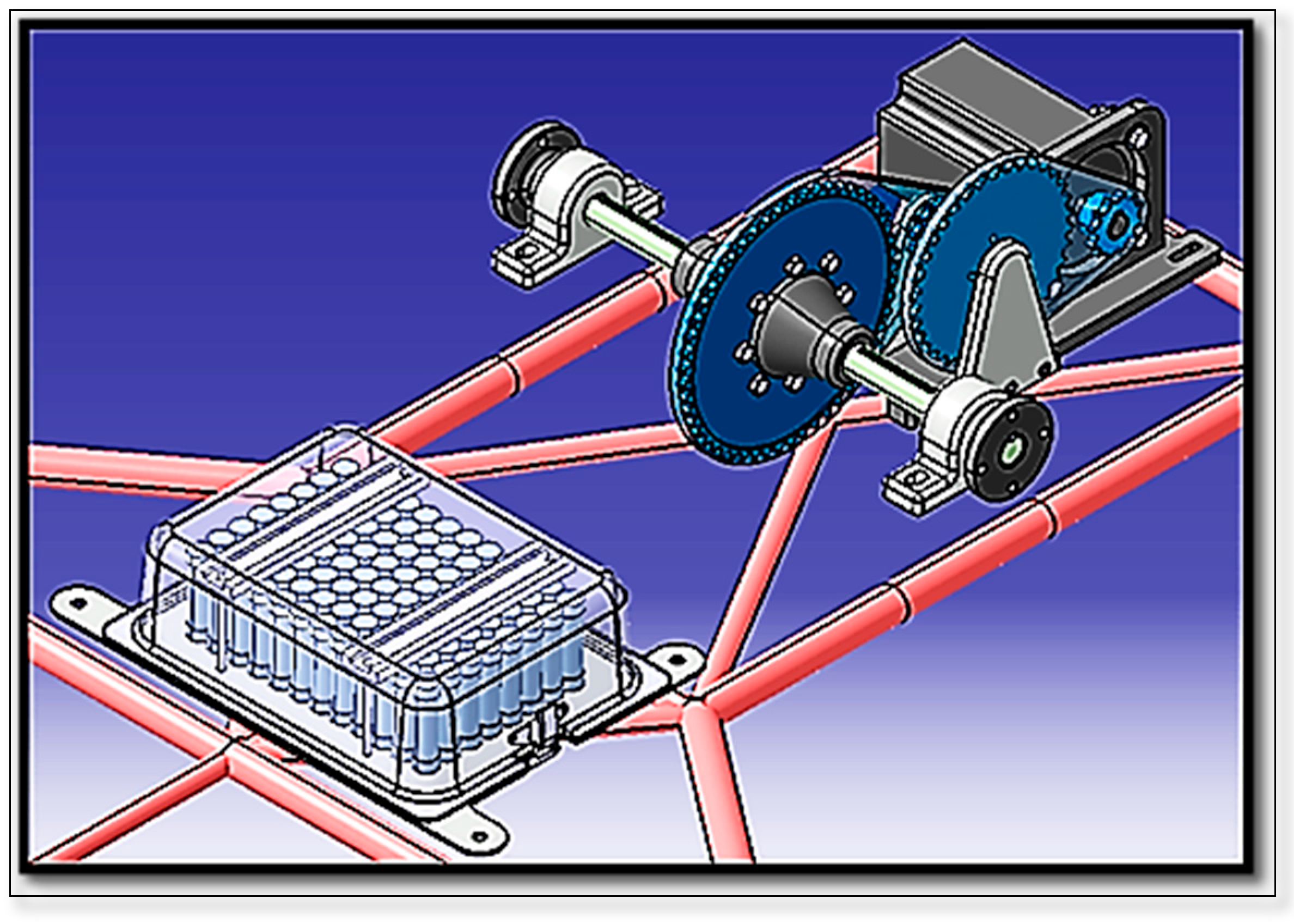

2.2. Design Overview

2.2.1. High-Level Architecture

- Brushless DC (BLDC) Motor: A 1500 W, 48 V BLDC motor (HPM-1500B, Golden Motor Co., Guangzhou, China) was chosen due to its high efficiency (~85%), strong power-to-weight ratio (5.5 kg), and minimal maintenance requirements. Mounted centrally, it delivers consistent propulsion and integrates seamlessly with the chassis design.

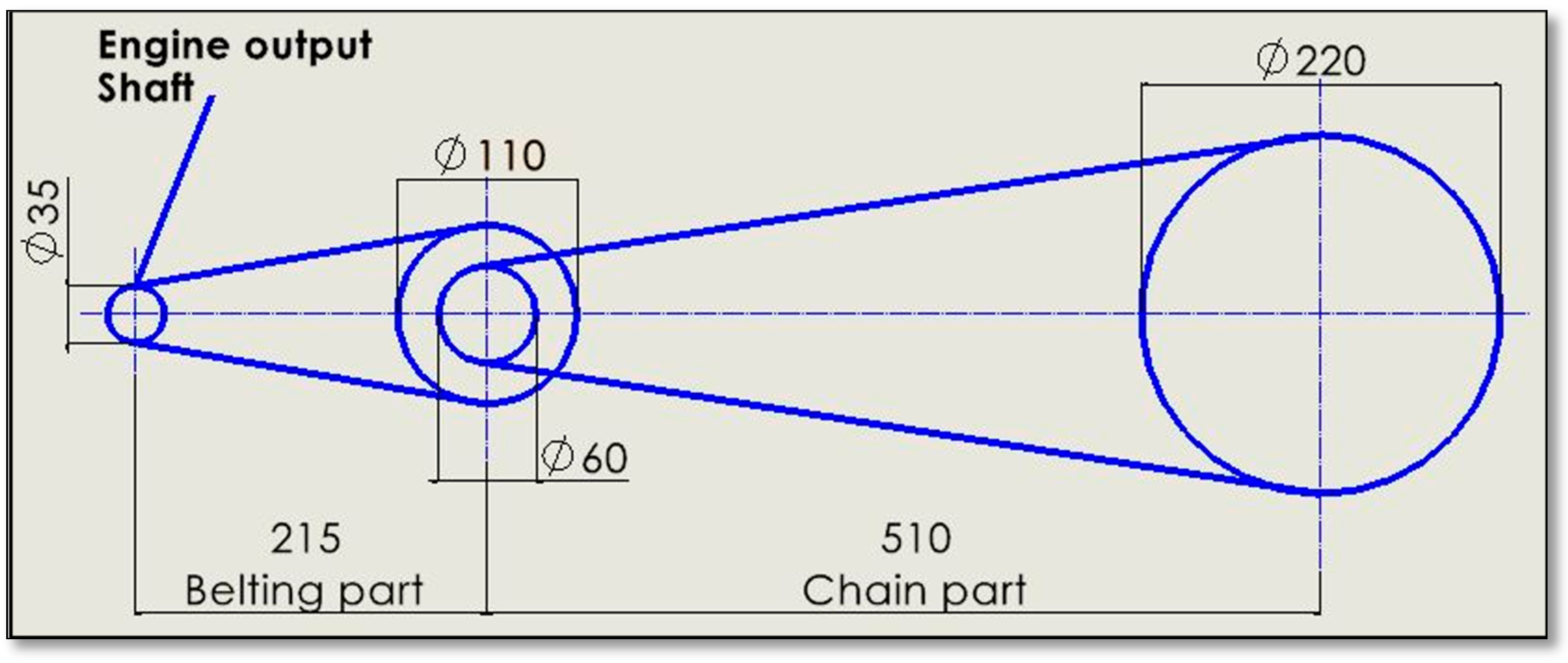

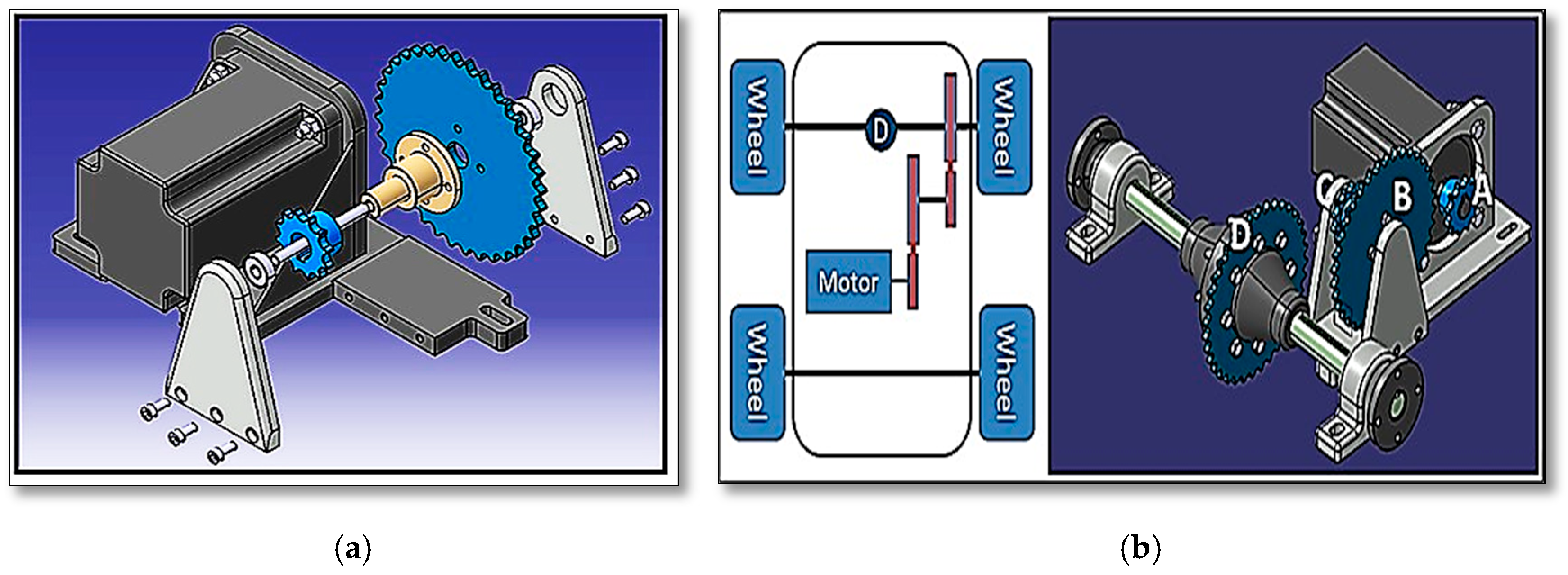

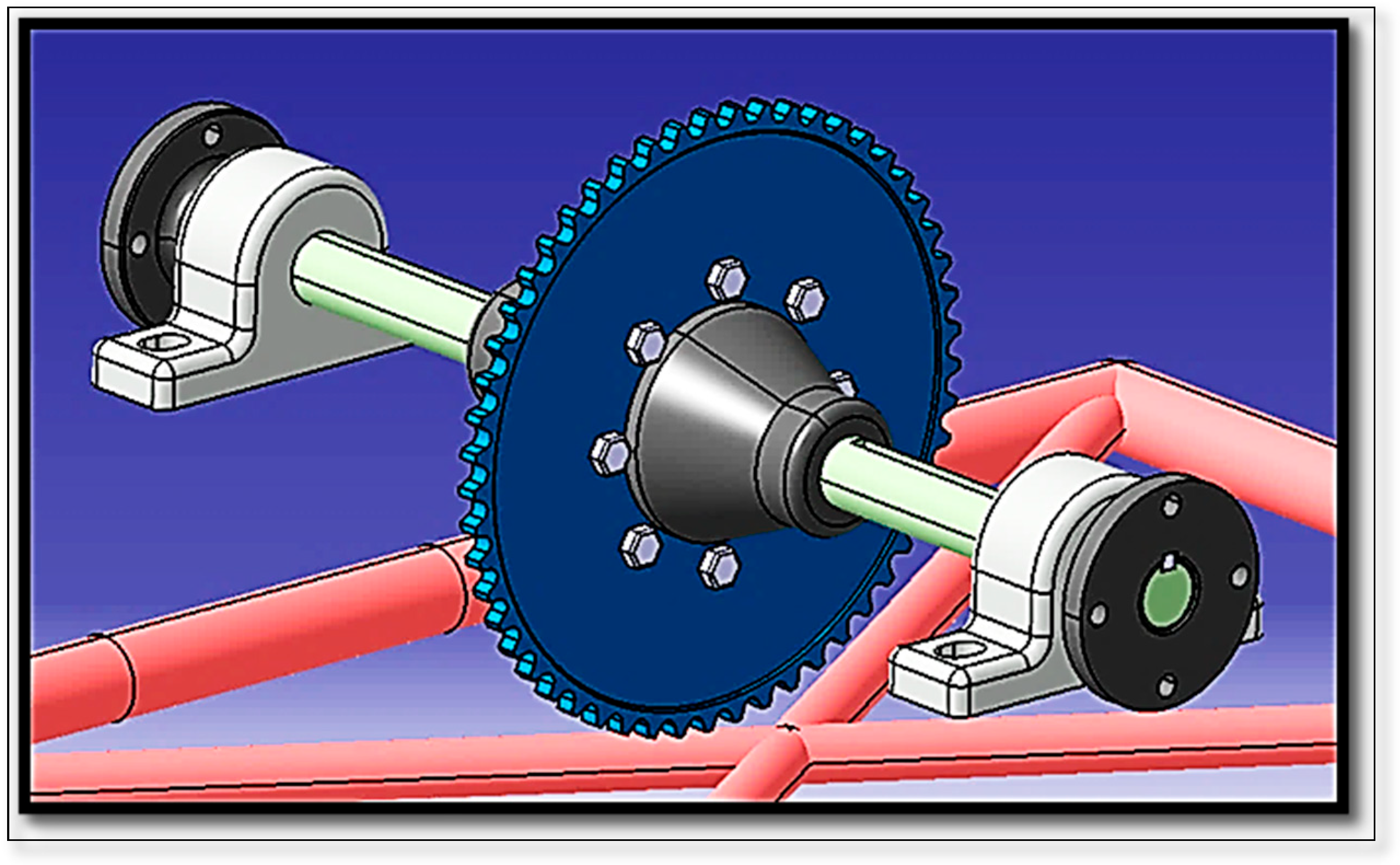

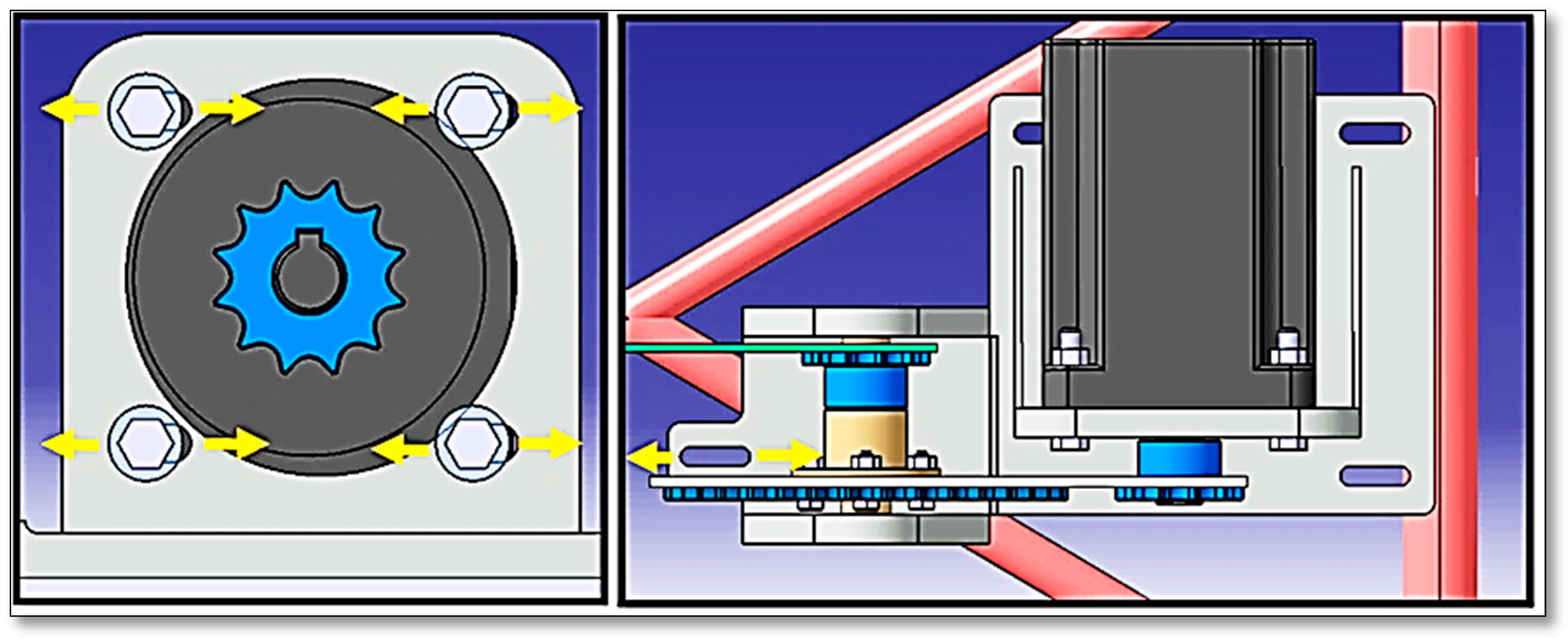

- Two-Stage Chain Drive Transmission: This modular system enables a high gear ratio (12:1) and a medium gear ratio (8:1) using compact sprockets, ideal for varied speed targets (e.g., 25 km/h and 40 km/h). It efficiently transfers power from the motor to the rear axle while minimizing mechanical losses and addressing spatial constraints within the chassis.

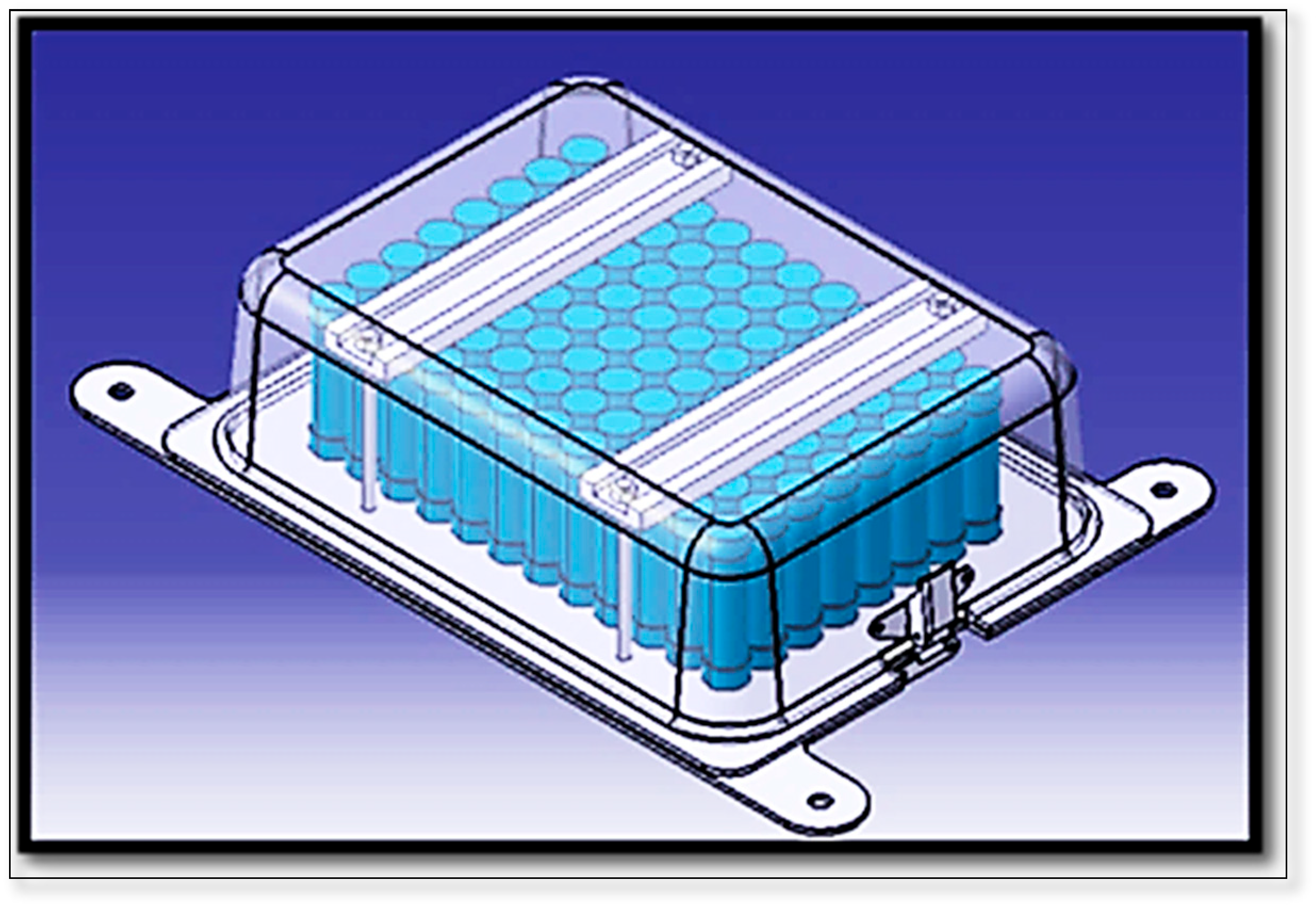

- Battery Pack: A custom 12S8P lithium-ion battery pack, built from Molicel P28A 18650 cells(Molicel, Taipei, Taiwan), serves as the energy source. It delivers a nominal 43.2 V and approximately 967 Wh—within the Shell Eco-marathon’s regulatory limit of 1000 Wh and 60 V.

- Motor Controller + DC-DC Converter: A programmable controller governs motor torque based on PID-calculated torque demand, while a Victron Orion-Tr 48/12-9A DC–DC converter (Victron Energy, Almere, The Netherlands) powers auxiliary systems. Integrated current, voltage, and State of Charge (SoC) monitoring ensures safe and efficient energy management throughout the drive cycle.

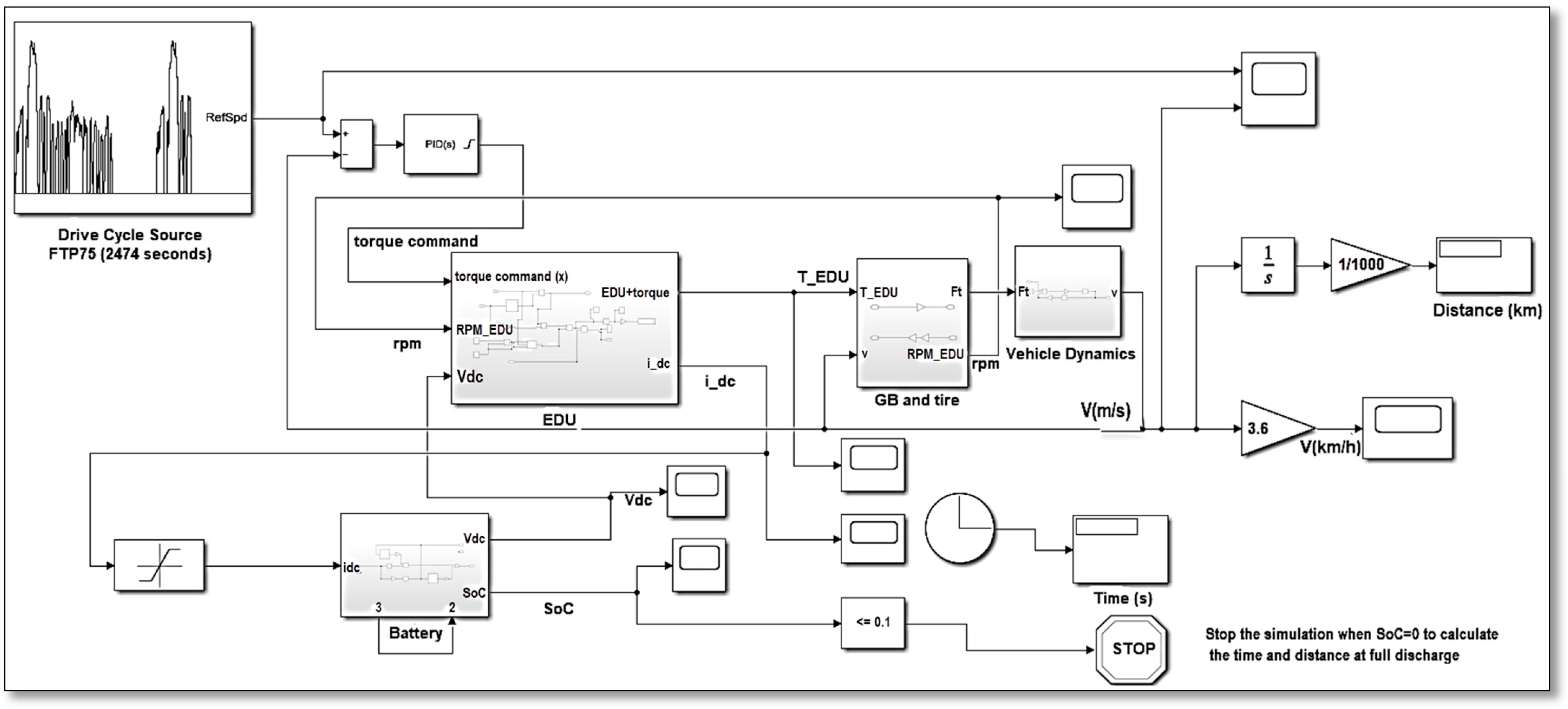

2.2.2. Block Diagram of the Full Powertrain System

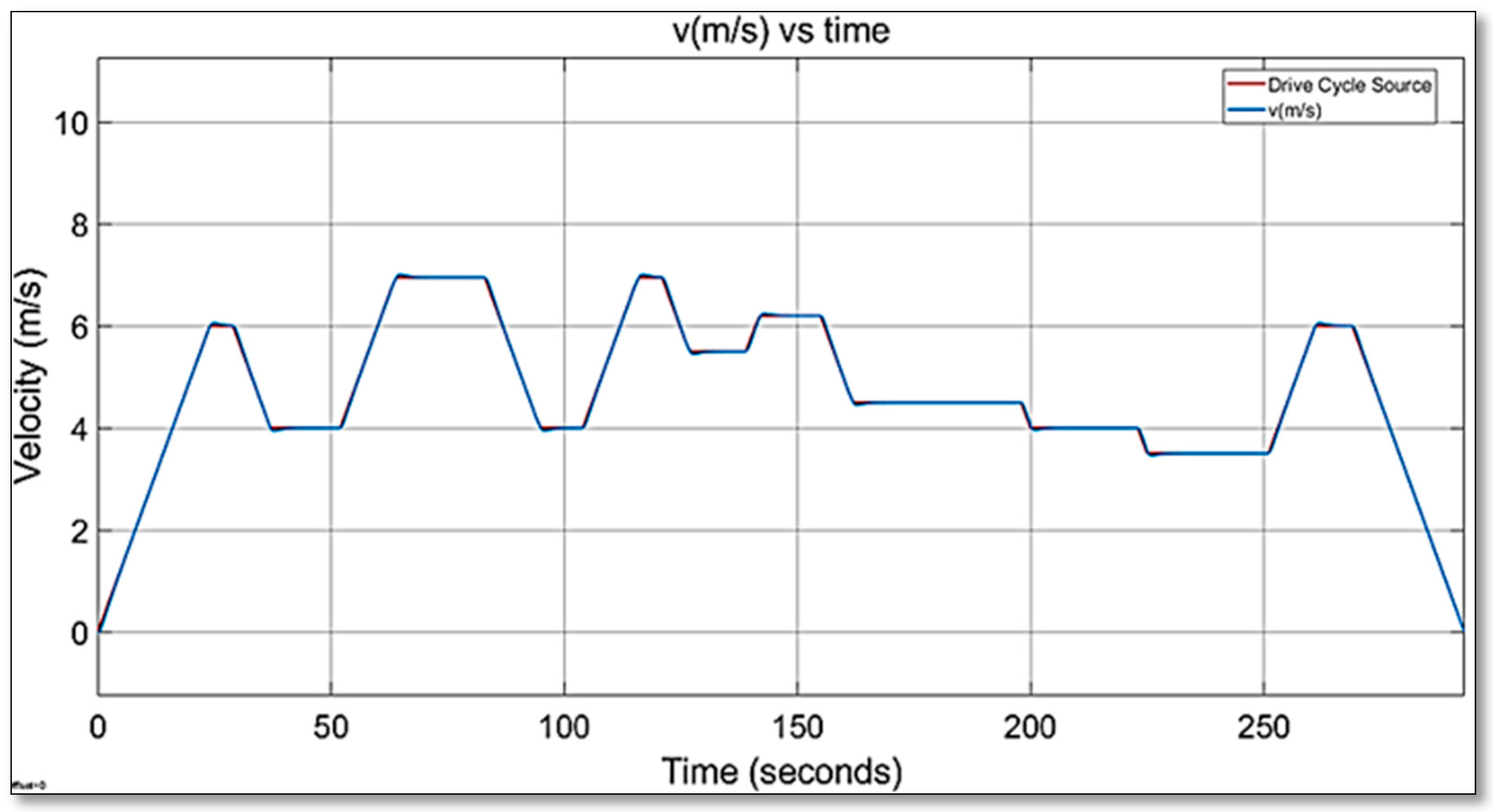

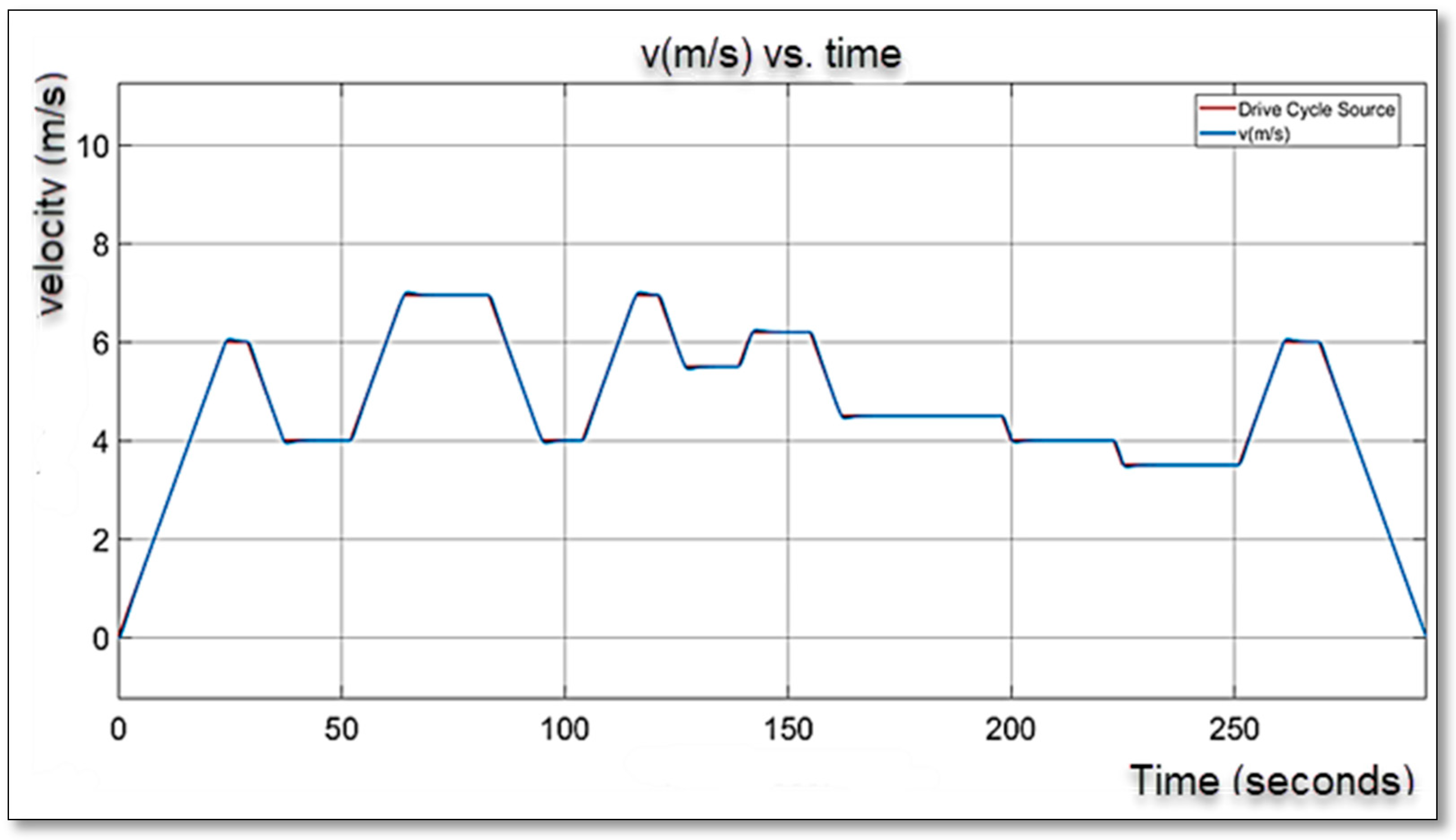

- Drive Cycle Source: This includes a 293 s drive cycle map with the vehicle’s target speed over time based on the Shell Eco-marathon track.

- Speed Control Loop: A PID controller compares the reference and actual speed to generate the torque demand.

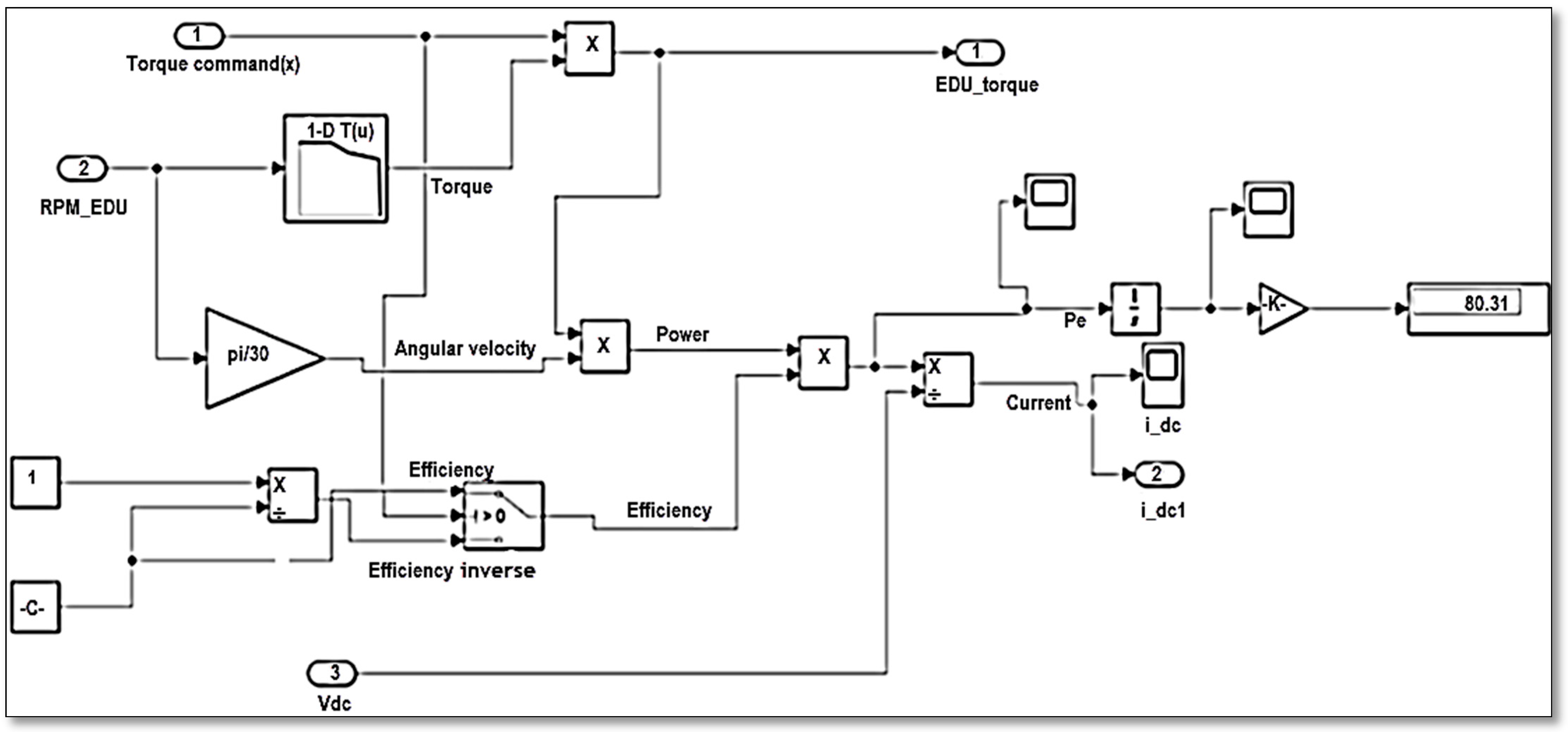

- Electric Drive Unit (EDU): This converts voltage and torque input into shaft speed and current drawing based on the motor’s performance characteristics.

- Battery Model: This simulates the voltage and State of Charge (SoC) dynamics using the input current and internal resistance logic.

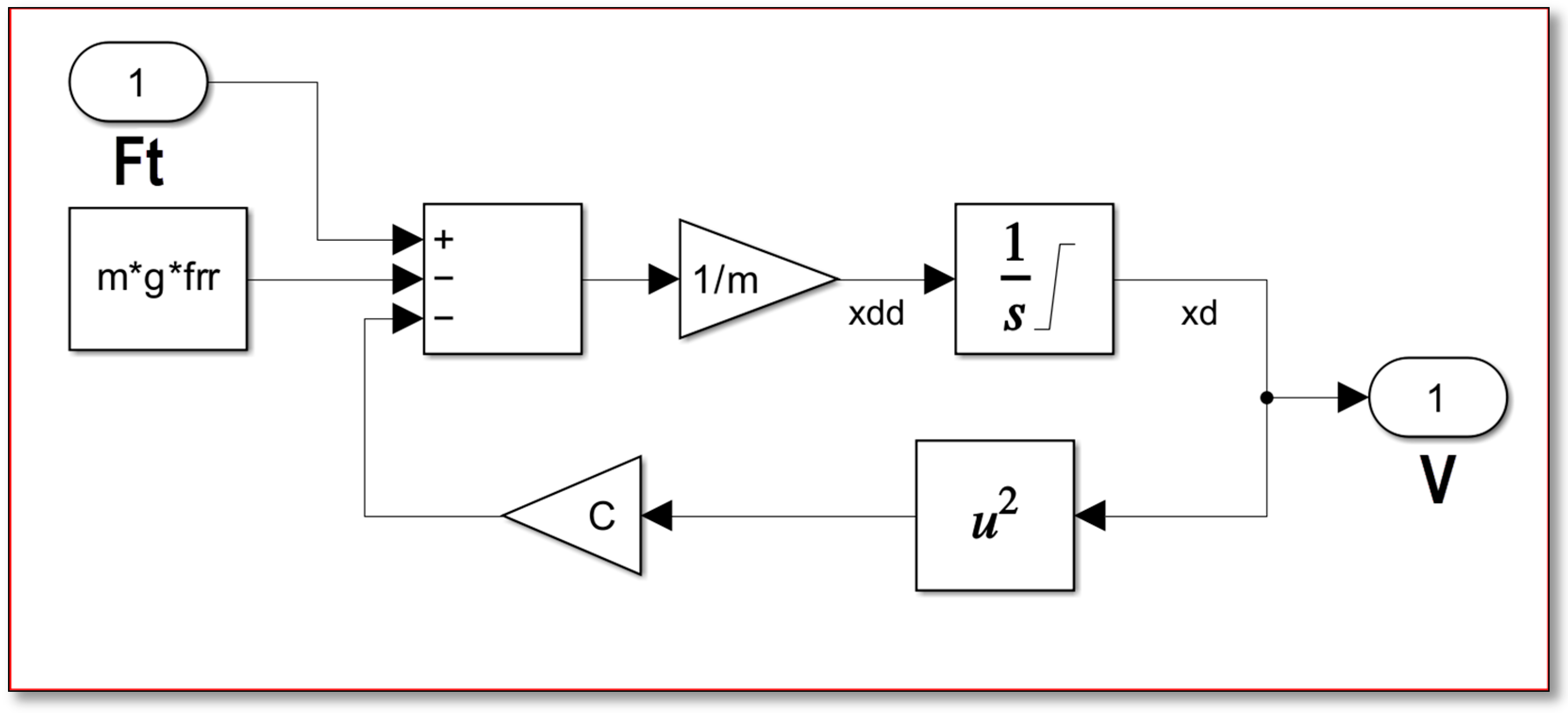

- Vehicle Dynamics Block: This transfers motor torque into forward motion, actoring in simplified drivetrain losses and rolling resistance.

- Distance and State of Charge (SoC) Tracking: The total distance travelled and SoC are calculated over time.

- This approach will allow estimation of how long the vehicle can run and how far it can travel on a full battery, under the idealized drive cycle.

2.3. Motor and Transmission Selection

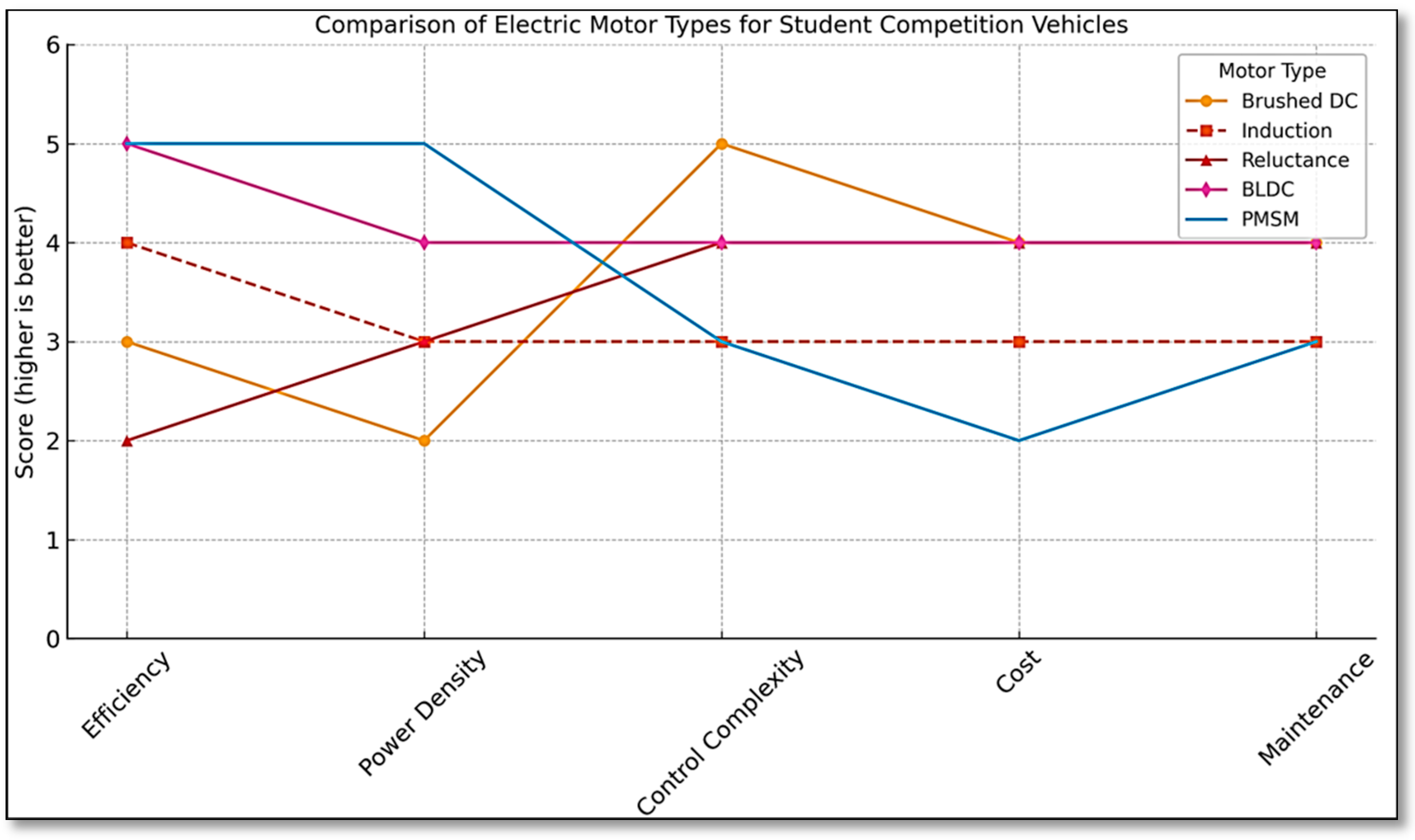

2.3.1. Motor Selection Justification

- Rated power = 1500 W;

- Rated voltage = 48 V;

- Rated current = 39.06 A;

- Rated torque = 4.78 Nm;

- Rated speed = 3000 rpm;

- Efficiency = 85%.

2.3.2. Gear Ratio Calculation

2.3.3. Comparative Decision

2.4. Battery Pack Design

2.4.1. Cell Layout

2.4.2. Electrical Specifications

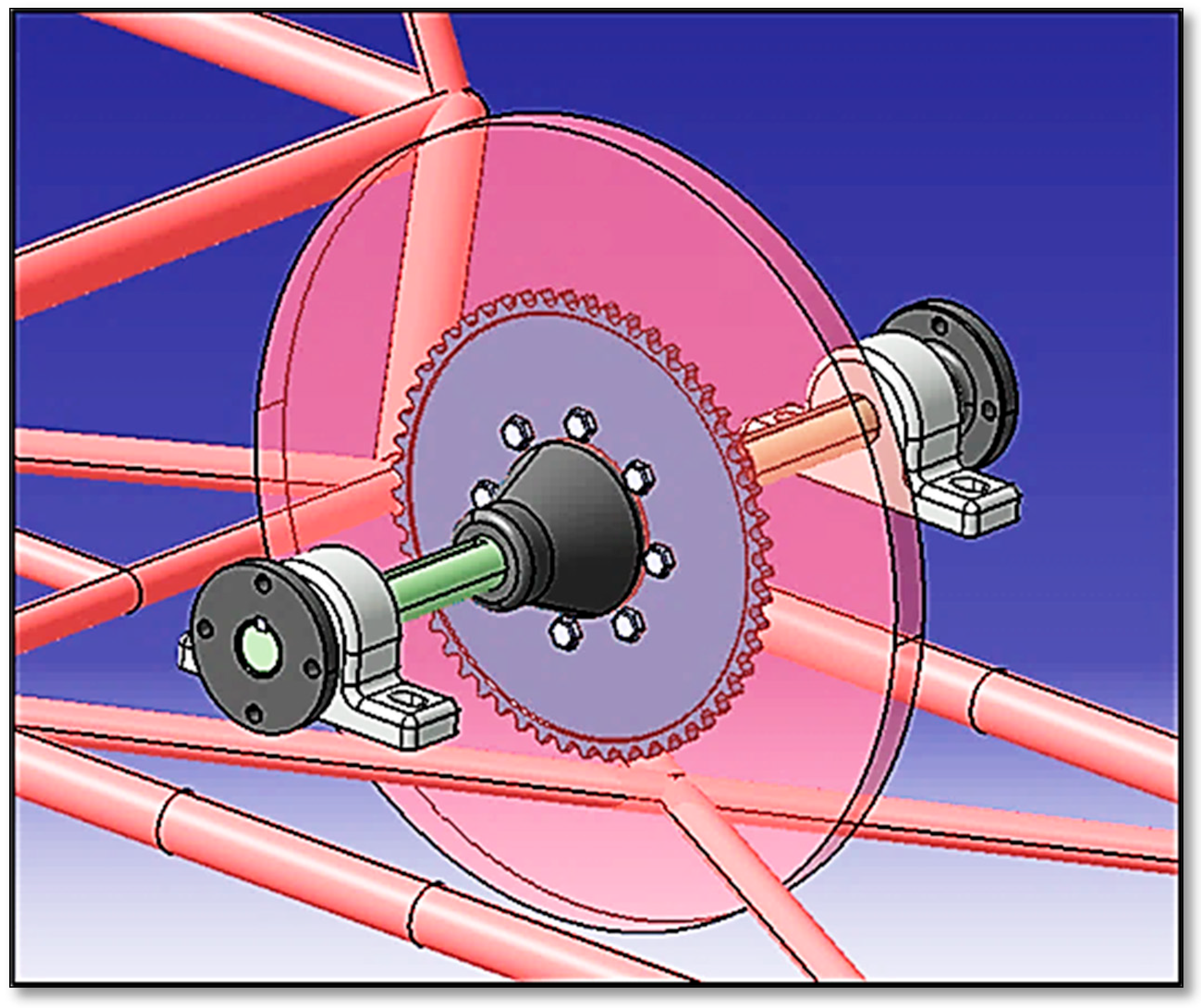

2.5. Structural Integration

CAD Models and Chassis Constraints

3. Build Instructions

3.1. Mechanical Assembly Procedure

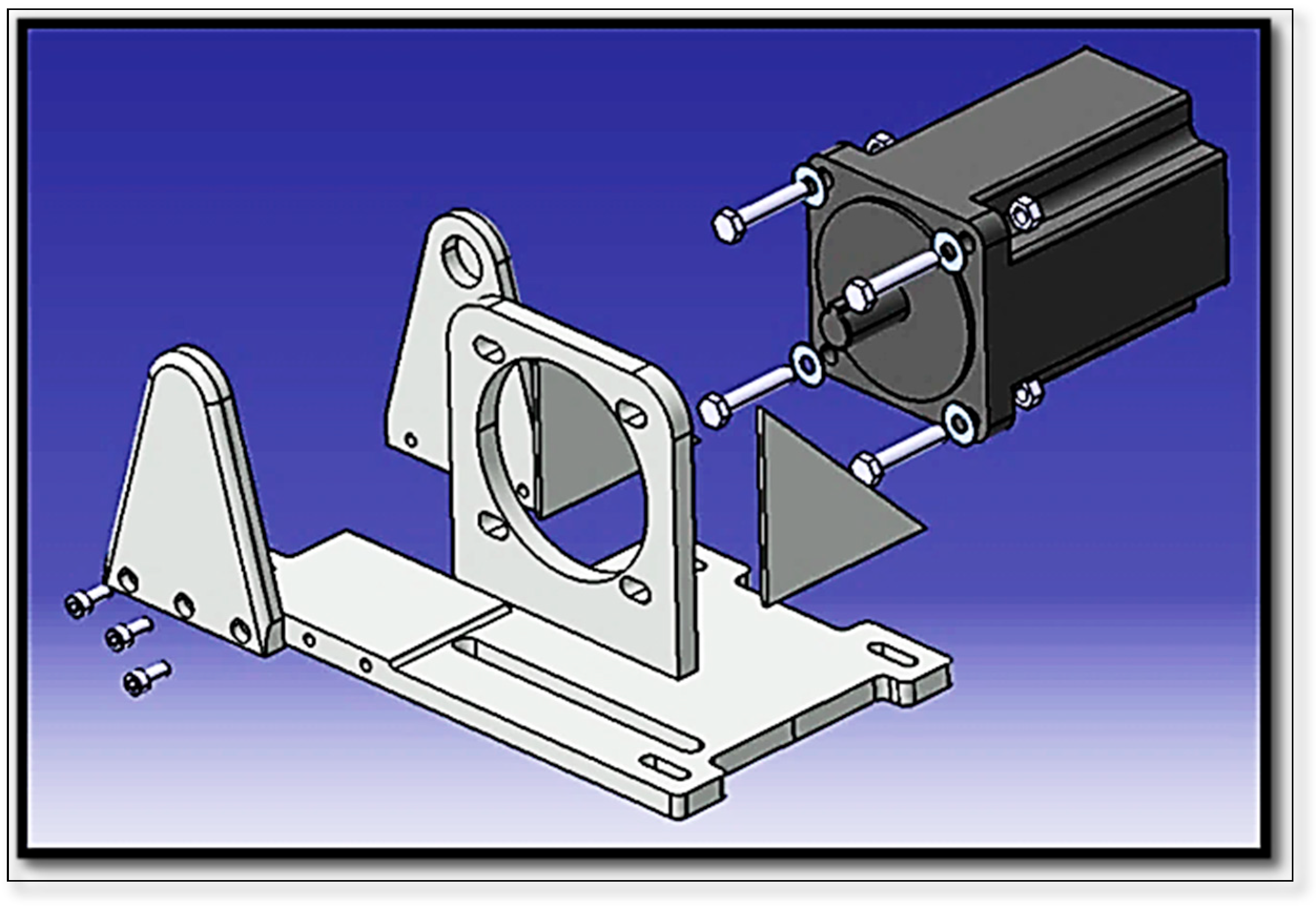

3.1.1. Motor Mount Installation

3.1.2. Two-Stage Chain Drive Setup

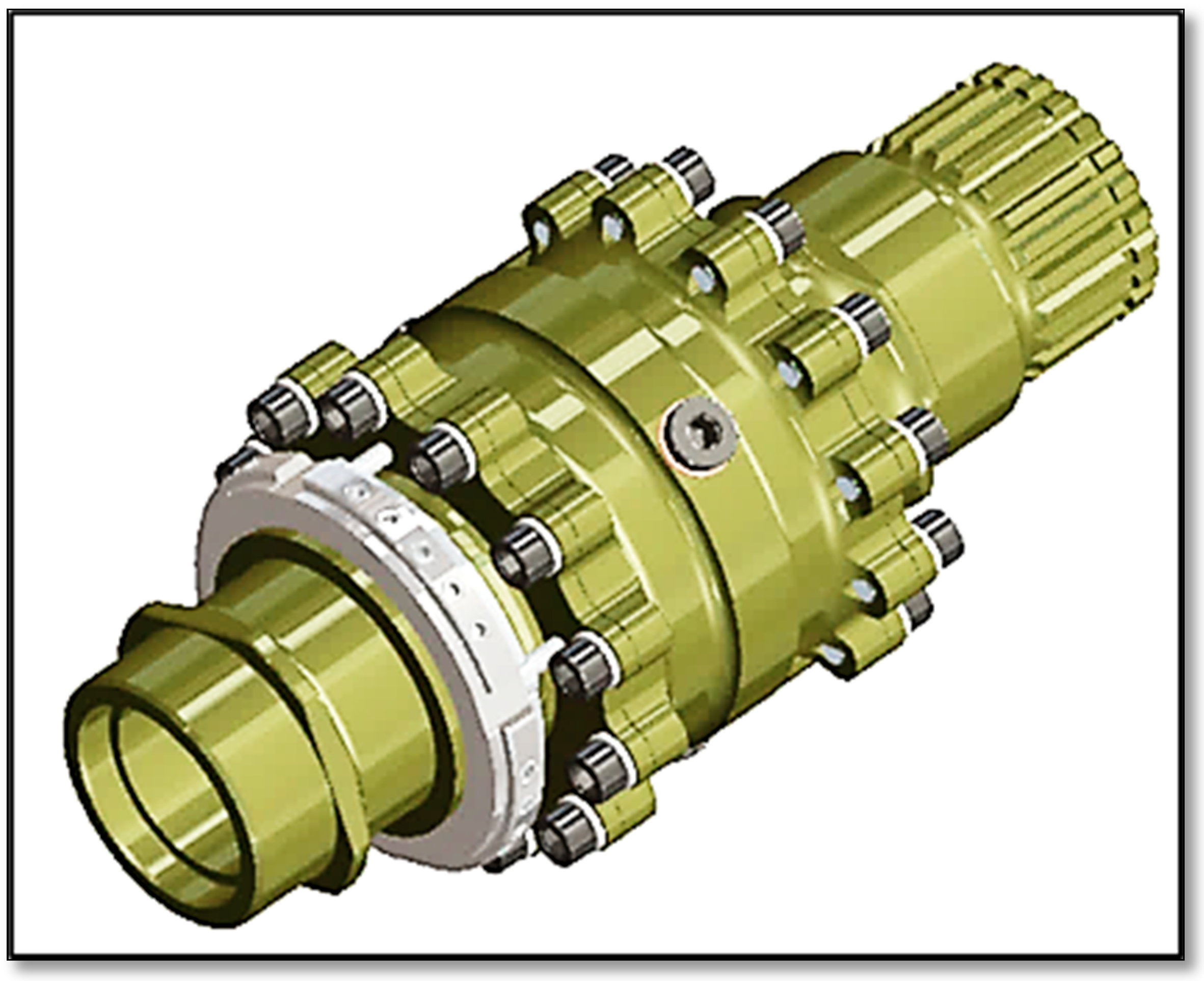

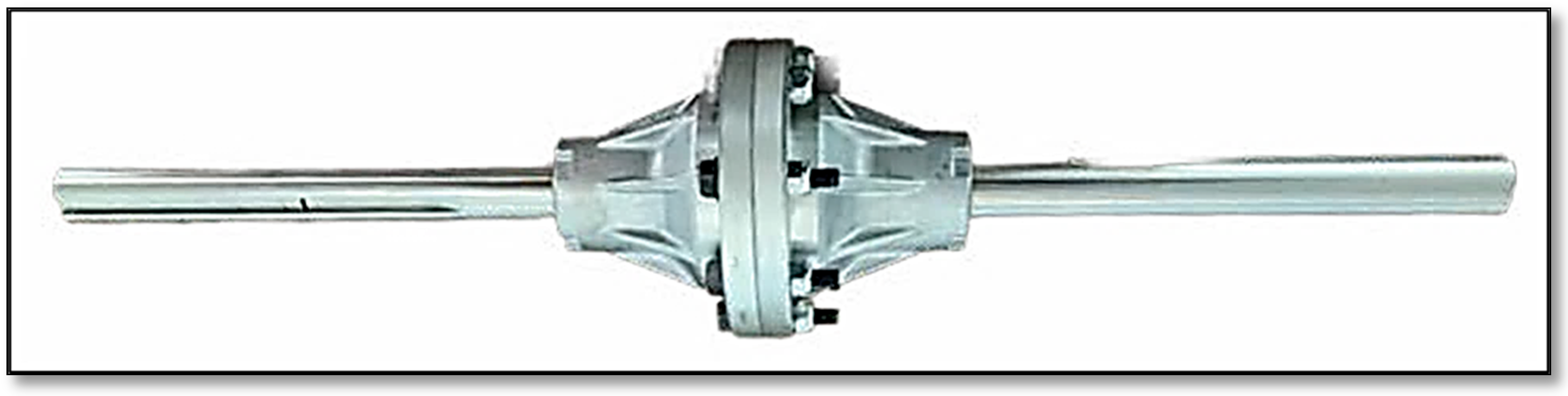

3.1.3. Differential Installation

- Output torque: 305 Nm.

- Weight on differential: 272.3 kg.

3.1.4. Modularity, Manufacturability, and Reliability

- Electrical Subsystem Assembly

3.1.5. Battery Pack Wiring, BMS, and DC-DC Converter Installation

- The vehicle must weigh a maximum of 225 kg, with the driver weighing a minimum of 70 kg.

- The voltage of the system should be 60 V or below.

- Maximum battery capacity is 1000 Wh.

- Only one lithium-based battery is allowed.

- Must be equipped with a solid metal containment tray underneath or be enclosed within a battery charging bag.

- Must be fixed outside the driver’s compartment behind the bulkhead.

- The charger must be either bought with the battery or purpose-built specifically suited to the battery.

- Must be tailored to chemistry to control and protect the battery.

- Must provide cell balancing and overvoltage protection during off-track charging.

- Must automatically isolate the battery (with an added requirement of providing cell-level over-discharge and overcurrent as part of the in-vehicle system).

- Must be in the physical battery package and be powered directly by the battery.

- A maximum of two electric motors can be equipped in the drivetrain.

- Electric motors can be either bought and changed or purpose-built.

- Motor control must be purpose-built.

3.1.6. Motor Controller Wiring Diagram

- MOSFET-based power switching.

- Potentiometer-based throttle input.

- Inputs from the BMS including battery voltage, motor temperature, and current sensing.

- External signals from the brake switch, ignition key, and cooling fan control.

3.1.7. Connection Schematics for Reverse Gear Logic

4. Operating Instructions

4.1. Power System Initialization

Battery Charging, Voltage Check, and Fuse Configuration

4.2. Drive System Operation

4.2.1. Motor Control via Throttle

4.2.2. Stop/Go Cycle Behaviours and Safe Shutdown

4.3. Safety Measures

Thermal Considerations

5. Validation and Discussion

5.1. Model Overview

- Drive Cycle Source: This provides the reference speed for one Shell Eco-marathon lap, derived from track geometry, elevation, and cornering. Uphill sections were modelled with added acceleration, downhill sections with controlled deceleration, and turns with safe cornering speeds. Transitions were smoothed using uniform acceleration/deceleration.

- PID Controller: This continuously compares actual and reference speeds, outputting a torque demand to minimize error.

- Electric Drive Unit (EDU): This represents a 48 V, 1500 W BLDC motor, converting torque demand into current draw and motor speed. Due to limited torque–speed–voltage data, the EDU was simplified to a fixed operating point using rated motor specifications (48 V, 1500 W, 4.78 Nm at 3000 rpm).

- Open-Circuit Voltage (OCV), which provides a voltage estimate based on the SoC.

- Internal resistance (Rint), which provides resistance variation across the SoC.

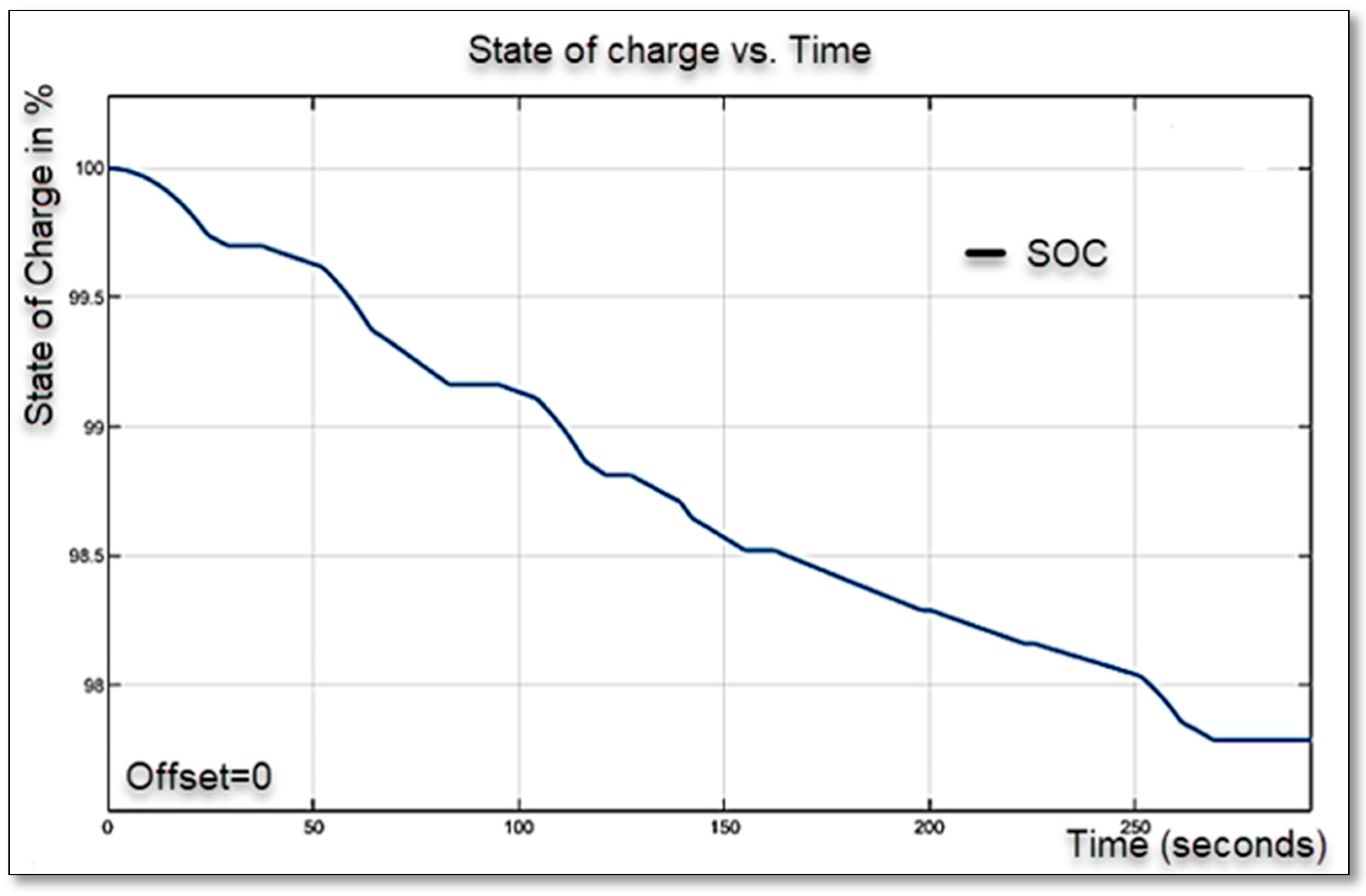

5.2. Simulation Results

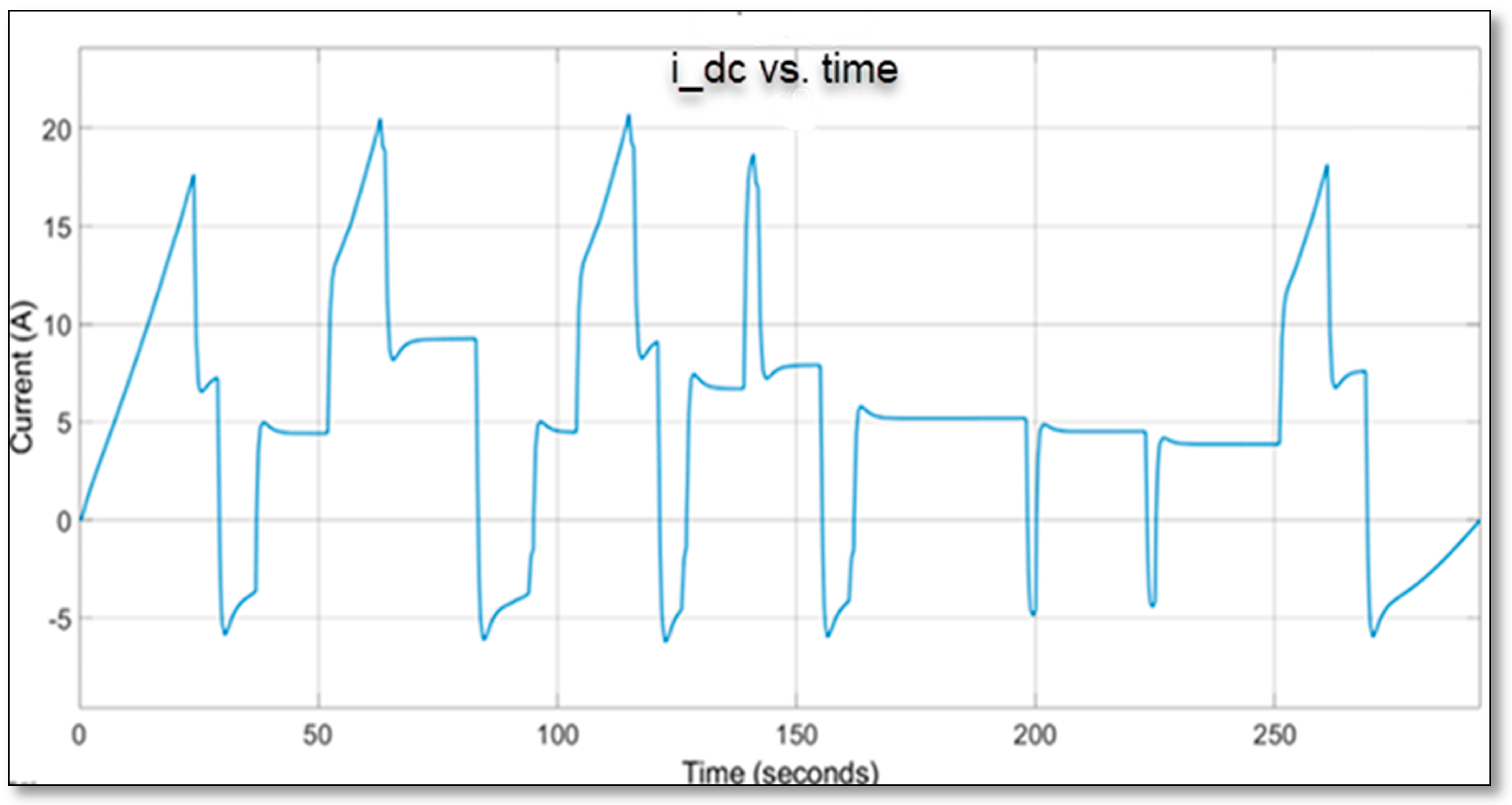

5.2.1. Battery Voltage and Current Behaviour

5.2.2. Limitations and Future Work

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. World Energy Outlook 2024. 2024. Available online: www.iea.org/terms (accessed on 16 October 2024).

- Shell Eco-Marathon. Shell Eco-Marathon Team. Available online: https://www.shellecomarathon.com/2025-programme/regional-europe-and-africa.html (accessed on 19 May 2025).

- Cichoński, K.; Jezierska-Krupa, K.; Gleń, M.; Skarka, W. The Comparative Study of Drivetrain of High-Performance Electric Vehicle. Diagnostyka 2014, 15, 65–70. [Google Scholar]

- Monteiro, A.M.M.M.L. Development of the Powertrain System for a Shell Eco-marathon Fuel Cell Electric Vehicle Mechanical Engineering Examination Committee. Master’s Thesis, University of Lisbon, Lisboa, Portugal, 2021. [Google Scholar]

- Bhatt, N.; Mehar, H.; Sahajwani, M. Electrical Motors for Electric Vehicle-A Comparative Study. 2018. Available online: SSRN: https://ssrn.com/abstract=3364887 (accessed on 1 September 2025).

- Shao, L.; Navaratne, R.; Popescu, M.; Liu, G. Design and Construction of Axial-Flux Permanent Magnet Motors for Electric Propulsion Applications-A Review. IEEE Access 2021, 9, 158998–159017. [Google Scholar] [CrossRef]

- Hao, Z.; Ma, Y.; Wang, P.; Luo, G.; Chen, Y. A Review of Axial-Flux Permanent-Magnet Motors: Topological Structures, Design, Optimization and Control Techniques. Machines 2022, 10, 1178. [Google Scholar] [CrossRef]

- Gebremariam, S.F.; Wondie, T.T. Comparative analysis of electric motor drives employed for propulsion purpose of Battery Electric Vehicle (BEV) systems. Int. J. Sci. Res. Arch. 2023, 10, 1097–1112. [Google Scholar] [CrossRef]

- Łebkowski, A. Light Electric Vehicle Powertrain Analysis. Sci. J. Silesian Univ. Technol. Ser. Transp. 2017, 94, 123–137. [Google Scholar] [CrossRef]

- Taha, Z.; Aydin, K. Comparative Analysis of Single, Double and Quad Electric Vehicle Powertrain Systems. Int. J. Automot. Sci. Technol. 2022, 6, 324–330. [Google Scholar] [CrossRef]

- Deepak, K.; Frikha, M.A.; Benômar, Y.; El Baghdadi, M.; Hegazy, O. In-Wheel Motor Drive Systems for Electric Vehicles: State of the Art, Challenges, and Future Trends. Energies 2023, 16, 3121. [Google Scholar] [CrossRef]

- Jneid, M.S.; Harth, P. Blended Regenerative Anti-Lock Braking System and Electronic Wedge Brake Coordinate Control Ensuring Maximal Energy Recovery and Stability of All-Wheel-Motor-Drive Electric Vehicles. J. Transp. Technol. 2023, 13, 465–495. [Google Scholar] [CrossRef]

- Hatletveit, S.R. Development of an Energy Efficient Powertrain for a Shell Eco-Marathon Vehicle. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2018. [Google Scholar]

- Smit, A.; van der Zwaard, S.; Janssen, I.; Janssen, T.W.J. Power loss of the chain drive in a race tandem bicycle. Sports Eng. 2023, 26, 49. [Google Scholar] [CrossRef]

- Dai, K.; Zhu, Z.; Shen, G.; Li, X.; Tang, Y.; Wang, W. Modelling and Adaptive Tension Control of Chain Transmission System with Variable Stiffness and Random Load. IEEE Trans. Ind. Electron. 2022, 69, 8335–8345. [Google Scholar] [CrossRef]

- Jacoby, C.L.; Jo, Y.S.; Jurewicz, J.; Pamanes, G.; Siegel, J.E.; Yen, P.X.; Dorsch, D.S.; Winter, A.G. Design of a Clutchless Hybrid Transmission for a High-Performance Vehicle. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; ASME International: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Spicer, J.B.; Richardson, C.J.K.; Ehrlich, M.J.; Bernstein, J.R.; Fukuda, M.; Terada, M. Effects of Frictional Loss on Bicycle Chain Drive Efficiency. J. Mech. Des. 2001, 123, 598–605. [Google Scholar] [CrossRef]

- Friction Facts, LLC. Gates Carbon Drive System vs. Traditional Chain Drive: Efficiency Test. 2012; rev. 1-2-13. Available online: https://www.lifeintravel.it/phocadownload/varie/Gates%20Carbon%20Belt%20Drive%20efficiency%20vs%20traditional%20single%20-%20Friction%20Facts.pdf (accessed on 1 September 2025).

- Haron, M.F.B. Engine Selection and Design of Powertrain for Simple Vehicle for Optimum Fuel Consumption; Final Year Project; Universiti Teknologi PETRONAS: Seri Iskandar, Perak, Malaysia, 2011; Available online: http://utpedia.utp.edu.my/id/eprint/10216/ (accessed on 1 September 2025).

- Zhang, R.; Xia, B.; Li, B.; Cao, L.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W. State of the art of lithium-ion battery SOC estimation for electrical vehicles. Energies 2018, 11, 1820. [Google Scholar] [CrossRef]

- Patil, M.S.; Seo, J.-H.; Panchal, S.; Jee, S.-W.; Lee, M.-Y. Investigation on thermal performance of water-cooled Li-ion pouch cell and pack at high discharge rate with U-turn type microchannel cold plate. Int. J. Heat Mass Transf. 2020, 155, 119728. [Google Scholar] [CrossRef]

- Tu, C.-C.; Hung, C.-L.; Hong, K.-B.; Elangovan, S.; Yu, W.-C.; Hsiao, Y.-S.; Lin, W.-C.; Kumar, R.; Huang, Z.-H.; Hong, Y.-H.; et al. Industry perspective on power electronics for electric vehicles. Nat. Rev. Electr. Eng. 2024, 1, 435–452. [Google Scholar] [CrossRef]

- Wang, H.; Sun, J.; Cheng, K.W.E. An Inductive Power Transfer System with Multiple Receivers Utilizing Diverted Magnetic Field and Two Transmitters for IoT-Level Automatic Catering Vehicles. IEEE Trans. Magn. 2023, 59, 8700206. [Google Scholar] [CrossRef]

- Tashen, T.; Birzhanuly, D.; Meldeshuly, S.; Almaty, K.; Kz, M.; Yessenzhanov, K. Design and Development of Electric Vehicle for Shell Eco-Marathon Design and Development of Electric Vehicle for Shell Eco-Marathon Kazakh-British Technical University. 2024. Available online: https://www.researchgate.net/publication/386212048 (accessed on 1 September 2025).

- Khorrami, F.; Krishnamurthy, P.; Melkote, H. Modeling and Adaptive Nonlinear Control of Electric Motors; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar] [CrossRef]

- Tsirogiannis, E.C.; Stavroulakis, G.E.; Makridis, S.S. Electric car chassis for Shell Eco Marathon competition: Design, modelling and finite element analysis. World Electr. Veh. J. 2019, 10, 8. [Google Scholar] [CrossRef]

- Open Motors (formerly OSVehicle). Tabby EVO—The First Ready-to-Use Open-Source Vehicle Platform. Available online: https://www.openmotors.co/product/tabbyevo/ (accessed on 28 July 2025).

- Nuro Inc. Nuro R2 Autonomous Delivery Vehicle. Available online: https://nuro.ai (accessed on 28 July 2025).

- Amazon. Meet Scout: Amazon’s Autonomous Delivery Robot. Available online: https://www.aboutamazon.com/news/transportation/meet-scout (accessed on 28 July 2025).

- International Energy Agency. Global EV Outlook 2024 Moving Towards Increased Affordability. 2024. Available online: www.iea.org (accessed on 14 May 2025).

- Hucho, W.; Sovran, G. Aerodynamics of Road Vehicles. Annu. Rev. Fluid Mech. 1993, 25, 485–537. [Google Scholar] [CrossRef]

- Victron Energy. Orion-Tr DC-DC Converters Isolated. Retrieved from Victron Energy Blue Power. Available online: https://www.sunshinesolar.co.uk/media/ecom/prodpdf/Datasheet-Orion-Tr-DC-DC-converters-isolated-100-250-400W-EN.pdf (accessed on 7 June 2025).

- Donaldson, P. DC-DC Converters. Retrieved from E-Mobility Engineering. Available online: https://www.emobility-engineering.com/dc-dc-converters/ (accessed on 7 June 2025).

- IndMALL. MOSFET PNP or NPN. Retrieved from Challaturu IndMALL Automation. Available online: https://www.indmall.in/faq/is-mosfet-pnp-or-npn/#:~:text=This%20distinction%20allows%20MOSFETs%20to,switching%20and%20amplification%20in%20circuits (accessed on 7 June 2025).

- Shell Eco-Marathon Official Results. Europe & Africa 2025—Urban Concept Battery Electric Rankings. Available online: https://results.sem-app.com/app/sem_2025_eu/UC/BE (accessed on 28 July 2025).

- Shell Eco-Marathon Official Results. Team EVA (NL0010002), 2025 Performance Summary. Available online: https://results.sem-app.com/app/sem_2025_eu/team/NL0010002 (accessed on 28 July 2025).

| Parameters | Value | Unit |

|---|---|---|

| 295 | kg | |

| 0.5715 | m | |

| 16 | km | |

| 40 | min | |

| 20 | s | |

| 0.015 | ||

| 0.3 | ||

| 1.69 | m2 | |

| 9.81 | m/s2 | |

| 1.225 | kg/m3 |

| Parameters | Value | Unit |

|---|---|---|

| 6.95 | m/s | |

| 0.35 | m/s2 | |

| 160.78 | N | |

| 22.97 | Nm | |

| 1116.52 | W | |

| 744.35 | Wh | |

| Energy consumption | 46.52 | Wh/km |

| Battery rating | 827.05 | Wh |

| Parameters | Speed (rpm) | Torque (Nm) |

|---|---|---|

| Maximum efficiency point | 2991 | 2.91 |

| Maximum torque point | 2944 | 5.15 |

| Gear Ratio | 12 | 8 |

| Most efficient vehicle speed (km/h) | 26.9 | 40.29 |

| Most efficient wheel torque (Nm) | 34.9 | 23.3 |

| Maximum vehicle speed (km/h) | 33.6 | 50.4 |

| Maximum wheel torque (Nm) | 61.8 | 41.2 |

| Brushless Motors | ||

|---|---|---|

| Motor | 1500 W 48 V | 750 W 48 V |

| Cost | GBP 334.29 | GBP 272.75 |

| Weight | 5.5 kg | 4.5 kg |

| Parameter | Value |

|---|---|

| Nominal pack voltage (V) | 43.2 |

| Total energy (W h) | 967.68 |

| Sprocket | Number of Teeth (Gear Ratio = 12) | Number of Teeth (Gear Ratio = 8) |

|---|---|---|

| Motor (small) | 10 | 10 |

| Axle (large) | 120 | 80 |

| Quantity | Part | Material Type | Product Code | Source/Supplier | Cost (GBP) |

|---|---|---|---|---|---|

| 1 | 1.5 kW brushless motor | Steel, copper, permanent magnets | Golden Motor HPM-1500B, 48 V, 3000 rpm | Buy OTS, Golden Motor Co. Guangzhou, China https://www.goldenmotor.com, accessed on 1 September 2025 | 450 |

| 1 | Upright motor mount | Aluminium 6061-T6 | Custom CAD part | In-house fabrication | 0 |

| 1 | Mount base | Aluminium 6061-T6 | Custom CAD part | In-house fabrication | 0 |

| 2 | Rib | Aluminium 6061-T6 | Custom CAD part | In-house fabrication | 0 |

| 2 | Side piece | Aluminium 6061-T6 | Custom CAD part | In-house fabrication | 0 |

| 2 | 12T sprocket | Steel | 428-12T sprocket | Buy OTS, JT Sprockets, Wuppertal, Germany https://www.jtsprockets.com, accessed on 1 September 2025, (JT Sprockets, Wuppertal, Germany) | 46.74 |

| 1 | 36T sprocket | Steel | 428-36T sprocket | Outsource then change | 50 |

| 1 | Gear connector | Aluminium 6061-T6 | Custom CAD part | Manufacture in house | 0 |

| 4 | 5 mm key | Steel | Parallel key 5 mm × 5 mm × 20 mm (DIN 6885) | Buy OTS, RS Components, Corby, UK https://uk.rs-online.com, accessed on 1 September 2025 | 20 |

| 2 | Bearing | Steel (with lubricant) | W6282Z Budget Stainless Steel Metal Shielded Deep Groove Ball Bearing 8 × 24 × 8 mm | Buy OTS https://simplybearings.co.uk/shop/p152973/W6282Z-Budget-Stainless-Steel-Metal-Shielded-Deep-Groove-Ball-Bearing-8x24x8mm/product_info.html, accessed on 1 September 2025 (Simply Bearings Ltd., Leigh, UK) | 6.72 |

| 1 | 8 mm silver steel rod | Steel | Silver steel Ø8 mm, grade BS1407 | In-house machining | 0 |

| 2 | 428 chain | Steel | DID 428H Roller Chain, 120 links | Buy OTS, STANDARD Chains—RK EUROPE, Heerlen, The Netherlands https://rk-europe.com/chain/standard-chains/, accessed on 1 September 2025 (RK EUROPE, Heerlen, The Netherlands) | 68 |

| 2 | Axle bearings and housings | Steel/aluminium | UCFL205 Flanged Bearing Housing | Buy OTS, SKF/Simply Bearings, https://simplybearings.co.uk/shop/ https://simplybearings.co.uk, accessed on 1 September 2025 (SKF, Gothenburg, Sweden) | 73.38 |

| 1 | Peerless 110 differential and axle | Steel/alloy | Peerless 110 Series Differential and Axle Assembly | Buy OTS then Modify Peerless 110 Series HD Differential—Gemini Karts, Northampton, UK https://www.geminikarts.co.uk/product/peerless-110-series-hd-differential/, accessed on 1 September 2025 (Peerless Gear, Salem, IN, USA) | 195 |

| 1 | 48T sprocket | Steel | 428-48T sprocket | Outsource then change, JT Sprockets | 50 |

| 2 | Half-shaft mounts | Aluminium 6061-T6 | Custom CAD part | In-house fabrication | 0 |

| 96 | Battery cells | Lithium ion (18650, Molicel P28A) | Molicel P28A 18650, 3.6 V, 2.8 Ah | Buy OTS, Nkon B.V. Eindhoven, The Netherlands https://eu.nkon.nl, accessed on 1 September 2025 | 312.96 |

| 1 | Battery connectors/bus bars | Copper | Copper bus bars, 5 mm × 20 mm | Buy OTS, RS Components | 332 |

| 1 | Wiring | Copper with PVC insulation | Silicone insulated wire, 10 AWG | Buy OTS, RS/Farnell | 30 |

| 1 | BMS | Mixed electronic components | ANT BMS 12S Li-ion, 60 A, UART/BT | Buy OTS, AliExpress/Daly BMS Store | 40 |

| 1 | Battery box cover | Plastic (ABS) | Custom vacuum-formed ABS, 3 mm | In-house fabrication | 0 |

| 1 | Battery plate | Aluminium 6061-T6 | Custom CAD part | In-house fabrication | 0 |

| 2 | Box clips | Steel | Toggle latch, 50 mm | Buy OTS, Amazon/RS | 10 |

| 1 | DC/DC converter | Mixed electronic components | Victron Orion-Tr 48/12-9A Isolated | Buy OTS https://www.sunshinesolar.co.uk/, accessed on 1 September 2025 | 57 |

| 1 | Charging components | Mixed electronic components | Li-ion Charger 48 V, CC/CV mode | Buy OTS, Nkon/AliExpress | 28.49 |

| 2 | Motor controller | Mixed electronic components | Sabvoton SVMC72150 FOC Controller (48–72 V) | Buy OTS, Sabvoton/AliExpress | 200 |

| 1 | Motor control unit | Mixed electronic components | VCU (Vehicle Control Unit), STM32-based custom PCB | Buy OTS In-house design + JLCPCB https://jlcpcb.com, accessed on 1 September 2025 | 100 |

| Sprocket | Number of Teeth (Gear Ratio = 12) | Number of Teeth (Gear Ratio = 8) |

|---|---|---|

| A | 12 | 12 |

| B | 32 | 48 |

| C | 12 | 12 |

| D | 36 | 36 |

| Parameter | Value |

|---|---|

| Total Distance (km) | 45.78 km |

| Total Simulation Time | 9788 s |

| Avg. Speed (km/h) | 25 km/h |

| Max Torque (T_EDU) | 5.9 Nm |

| Peak Current (i_dc) | 20.066 A |

| Initial SoC % | 100% |

| Final SoC % After 1 Lap | 97.77% |

| Final Voltage (V_dc) After 1 Lap | 47.72 V |

| Energy Consumed After 1 Lap | 20.95 Wh |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hazizi, K.; Erateb, S.; Delli Carri, A.; Jones, J.; Leung, S.H.; Sam, S.; Yau, R. Design, Construction, and Simulation-Based Validation of a High-Efficiency Electric Powertrain for a Shell Eco-Marathon Urban Concept Vehicle. Designs 2025, 9, 113. https://doi.org/10.3390/designs9050113

Hazizi K, Erateb S, Delli Carri A, Jones J, Leung SH, Sam S, Yau R. Design, Construction, and Simulation-Based Validation of a High-Efficiency Electric Powertrain for a Shell Eco-Marathon Urban Concept Vehicle. Designs. 2025; 9(5):113. https://doi.org/10.3390/designs9050113

Chicago/Turabian StyleHazizi, Kristaq, Suleiman Erateb, Arnaldo Delli Carri, Joseph Jones, Sin Hang Leung, Stefania Sam, and Ronnie Yau. 2025. "Design, Construction, and Simulation-Based Validation of a High-Efficiency Electric Powertrain for a Shell Eco-Marathon Urban Concept Vehicle" Designs 9, no. 5: 113. https://doi.org/10.3390/designs9050113

APA StyleHazizi, K., Erateb, S., Delli Carri, A., Jones, J., Leung, S. H., Sam, S., & Yau, R. (2025). Design, Construction, and Simulation-Based Validation of a High-Efficiency Electric Powertrain for a Shell Eco-Marathon Urban Concept Vehicle. Designs, 9(5), 113. https://doi.org/10.3390/designs9050113