Abstract

The use of Reclaimed Asphalt Pavement (RAP) in asphalt mixtures offers environmental and economic advantages by reducing reliance on virgin aggregates and minimizing construction waste. However, the aged binder in RAP increases mixture stiffness, which can compromise fatigue resistance. This systematic review evaluates the influence of RAP content on fatigue performance compared to conventional mixtures, with a focus on the Indirect Tensile Test (IDT) as the primary assessment method. Following the parameters of Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines, five studies published between 2014 and 2024 were identified through searches in Web of Science, ScienceDirect, ASCE, and Scopus. Study quality was assessed using the Cochrane Risk of Bias tool. The results indicate that although RAP enhances rutting resistance, higher contents (>30%) often lead to reduced fatigue performance due to binder hardening and reduced mixture flexibility. The incorporation of rejuvenators—such as heavy paraffinic extracts—and modifiers, including high-modulus agents, polymers, and epoxy binders, can partially restore aged binder properties and improve performance. Sustainable innovations, such as lignin-based industrial by-products and warm-mix asphalt technologies, show promise in balancing mechanical performance with reduced environmental impact. Variability in material sources, modification strategies, and test protocols limits direct comparability among studies, underscoring the need for standardized evaluation frameworks. Overall, this review highlights that optimizing RAP content and selecting effective rejuvenation or modification strategies are essential for achieving durable, cost-effective, and environmentally responsible asphalt pavements. Future research should integrate advanced laboratory methods with performance-based design to enable high RAP utilization without compromising fatigue resistance.

1. Introduction

The increasing global emphasis on sustainability and efficient resource utilization in road construction has driven greater adoption of Reclaimed Asphalt Pavement (RAP) [1]. This material, sourced from recycled asphalt layers, enables the reuse of aged pavement materials while providing notable environmental and economic benefits [2,3]. Over the past decade, incorporating RAP into traditional bituminous mixtures has attracted significant interest for its ability to reduce the construction costs and environmental impacts [4,5] of road pavements. This interest has intensified in response to growing vehicular traffic and harsher weather conditions that challenge pavement performance and durability [6,7]. From an environmental perspective, RAP use contributes to waste minimization by promoting material reuse [5], reduces the need for landfill disposal through increased recycling [4,8], and lowers greenhouse gas emissions associated with virgin material production [9]. These advantages align with international sustainability objectives and address the technical challenge of meeting or exceeding the mechanical performance of conventional materials [1,10].

In pavement engineering, meeting these dual objectives requires designing mixtures that not only satisfy structural and functional requirements but also perform reliably under defined service conditions [11,12]. Within this context, RAP is a purposeful design component [13,14], integrated using modern approaches that strike a balance between durability, fatigue resistance, and environmental impact [15,16]. This perspective positions RAP as part of an intentional, performance-driven design process, rather than a direct replacement for virgin materials [17,18].

However, mixtures with high RAP content often display increased stiffness and reduced fatigue resistance [19,20,21,22]. Such mechanical shortcomings can shorten pavement service life by accelerating cracking and fatigue damage [23]. Therefore, it is essential to evaluate the mechanical performance of RAP-containing mixtures by varying RAP proportions using reliable and standardized testing methods. Among these, the Indirect Tensile Test (IDT) is widely recognized for fatigue evaluation due to its standardized procedure, reproducibility, and relevance [24]. Its frequent use in studies involving RAP-containing mixtures strengthens this review, as it allows for methodological consistency and reliable cross-study comparisons [25]. Although the IDT does not fully replicate the stress states of in-service pavements [26], it provides valuable insights into rheological behavior and critical mechanical thresholds [16]. In the scientific literature, recent studies suggest that RAP improves rutting resistance [27,28]; however, the higher stiffness of aged bitumen can diminish mixture flexibility and potentially reduce fatigue life [29,30].

To address these drawbacks, several modification strategies have been explored. These include incorporating high-modulus agents to improve structural stiffness [22,31], applying rejuvenators (e.g., oils and low-viscosity compounds) to restore binder properties [32,33,34], and adding advanced modifiers (e.g., polymers and nanomaterials) to improve cohesion and adhesion within the mixture [35,36,37,38]. Moreover, the use of industrial by-products and secondary raw materials in RAP-based mixtures is a promising approach to improve fatigue resistance and structural stability [39,40]. These innovations aim to balance the often-conflicting goals of sustainability and mechanical performance, enabling RAP-based asphalt mixtures to match or surpass conventional alternatives. Despite the notable progress, there remains a lack of comprehensive comparative studies that address the following key questions:

- (1)

- How does RAP content influence the fatigue behavior of asphalt mixtures when evaluated using the IDT?

- (2)

- How do RAP content and modification strategies interact to affect the mechanical performance of asphalt innovative mixtures compared to conventional ones?

- (3)

- How can technological enhancements be leveraged to optimize RAP performance, thereby guiding the design of durable, cost-effective, and environmentally responsible pavements?

2. Methods

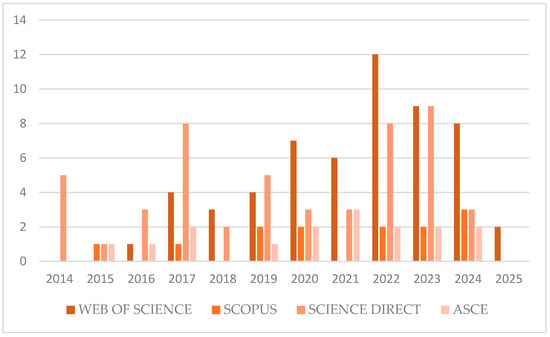

A systematic literature review was conducted to evaluate the influence of RAP content on fatigue resistance [41], with performance assessed via the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) protocol [42], ensuring transparency, replicability, and methodological rigor to identify, screen, and evaluate eligible scientific articles. Studies were included based on predefined criteria for thematic relevance and methodological quality, enabling the identification of research trends, gaps, and the validity of experimental approaches [43]. The search was performed in four major databases widely used in civil and pavement engineering: ASCE Library, ScienceDirect, Scopus, and Web of Science (WoS). The search strategy used the Boolean string (“Reclaimed Asphalt Pavement” OR “RAP”) AND (“Fatigue Resistance”) AND (“Indirect Tensile Test”). The search was limited to English-language papers published between 2014 and 2024 to capture recent advancements in RAP technology. Eligible studies were systematically classified by research objectives, methods, and outcomes, facilitating a robust synthesis of findings. Publication frequency has shown a marked increase from 2017 onward (Figure 1).

Figure 1.

Yearly publication distribution across databases.

The selected studies underwent a five-stage review process: identification, validation, extraction, comparison, and synthesis. Post-extraction, consensus validation was applied to detect patterns, inconsistencies, and methodological commonalities, excluding non-compliant studies. Study quality and reliability were evaluated through dual independent assessments based on criteria adapted from the Cochrane Handbook [44,45]. Discrepancies were resolved using the Kappa Free-Marginal Multirater Coefficient (Kfree) [46], requiring a minimum agreement of 75% (classified as “substantial”, Kfree = 0.61–0.80) for inclusion.

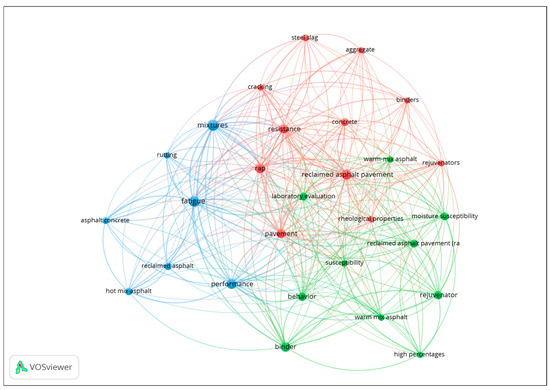

Keyword co-occurrence analysis was conducted using VOSviewer (v1.6.20). Three main thematic clusters emerged (Figure 2):

Figure 2.

VOS viewer network visualization.

Materials and Mechanical Strength (red cluster) includes the keywords “aggregate”, “cracking”, and “resistance”.

Pavement Performance and Deterioration (blue cluster) includes “fatigue”, “rutting”, and “performance”.

Binder Properties and Sustainability (green cluster) includes “binder”, “moisture susceptibility”, and “rejuvenator”.

The co-occurrence analysis identified RAP as a central term linking all three thematic clusters. The keyword “rejuvenator” also showed strong cross-cluster connections, reflecting its key role in improving RAP performance by restoring or modifying aged binder properties.

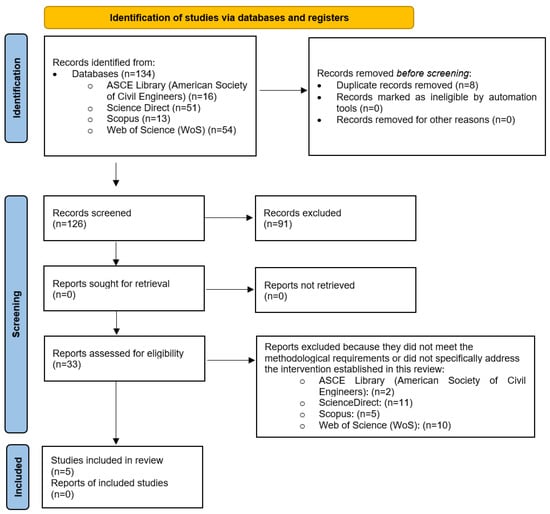

The initial database search retrieved 134 articles (Figure 3). After duplicate removal, 126 unique studies remained. In the first screening stage, 91 were excluded for not meeting the inclusion criteria. The second stage involved full-text assessment of 33 articles for methodological rigor, topic relevance, and alignment with the review scope. Twenty-eight were excluded for inadequate quality or insufficient focus on RAP content and fatigue resistance evaluated using IDT. The final selection comprised five original research studies that satisfied all criteria.

Figure 3.

PRISMA diagram of the study search and selection process in the systematic review.

Following article selection, study quality and bias risk were evaluated using a modified Cochrane Risk of Bias Tool [45], adapted for experimental research in asphalt materials. The assessment covered five domains: selection (clarity and representativeness of the inclusion criteria), implementation (accuracy of the test method and condition descriptions), detection (control of external factors such as climate and traffic), wear (transparent handling of missing data), and reporting (completeness of outcome reporting).

Two reviewers conducted independent evaluations, resolving disagreements through discussion. Bias classification was based on the highest risk level across domains, rating studies as Low Risk (1), Some Concerns (2), or High Risk (3) (Table 1).

Table 1.

Assessment of study quality and risk of bias.

Table 2 summarizes the concordance between the reviewers’ overall risk of bias ratings. Each cell indicates the number of studies assigned to a given combination of reviewer judgments, with perfect agreement represented along the diagonal. All five studies underwent evaluation. The interrater reliability results are shown in Table 3.

Table 2.

Comparison of results between evaluators.

Table 3.

Results of Kappa Free-Marginal Multirater Coefficient.

Interrater agreement beyond chance was quantified using the Cohen’s kappa (Table 3). The coefficient was Kfree = 1, indicating perfect agreement. This result demonstrates excellent consistency between the reviewers and supports the reliability of the bias assessments, confirming the inclusion of all five studies in this review.

3. Results

Table 4 synthesizes the most relevant information about the materials, methodologies, instrumentation, and key findings of the selected studies.

Table 4.

Synthesis of the selected studies.

Based on Table 4, the following sections focus on the main findings.

Notable results have been reported on the fatigue resistance of RAP-containing asphalt mixtures [47]. Florida IDT energy ratio testing at 10 °C showed that 100% RAP mixtures rejuvenated with a low dosage (7.9%) of RA1—a rejuvenating agent derived from distilled paraffin extract— exhibited substantially higher cracking resistance than virgin mixtures. Compared with virgin asphalt, summarizing the adhesive aging conditions and how they influenced the characteristics of the binder using oven aging [47], the strength increased by approximately 75% after the loose mixture was subjected to short-term aging (STA) for 1 hour at 165 °C, by 160% after the compacted mixture underwent long-term aging (LTA) for 5 days at 85 °C, and by 55% after long-term aging (LTA) for 10 days at 85 °C. This improvement is attributed to the rejuvenator’s ability to restore the ductility and flexibility of aged binders, thereby delaying the onset of cracking.

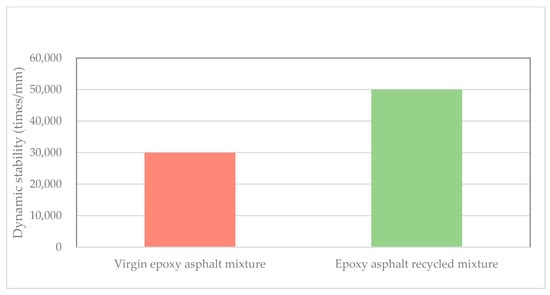

Although rutting resistance is not a measure of fatigue performance, it reflects structural integrity. In [20], high-temperature performance was evaluated using the WTT at 60 °C, comparing virgin and recycled epoxy asphalt mixtures. The recycled epoxy asphalt mixture demonstrated 67% greater rutting resistance than the traditional mix (Figure 4).

Figure 4.

Dynamic stability—adapted from [20] with permission from Elsevier. License number: 6072011489584, Copyright Clearance Center.

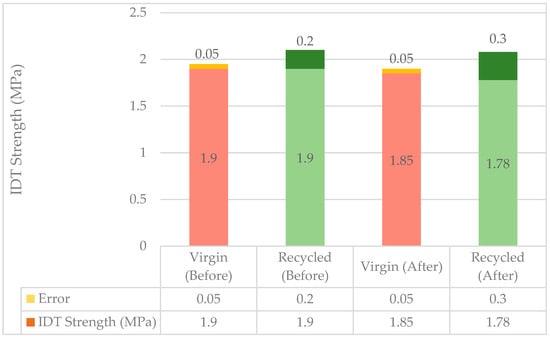

In [20], IDT was performed on virgin and recycled epoxy asphalt mixtures before and after a freeze–thaw cycle (Figure 5) to evaluate moisture sensitivity. No significant difference in IDT strength was observed. The virgin epoxy asphalt mixture shows an approximate decrease of 3%, whereas the recycled epoxy asphalt mixture shows an approximate increase of 4%.

Figure 5.

IDT strength—adapted from [20] with permission from Elsevier. License number: 6072011489584, Copyright Clearance Center.

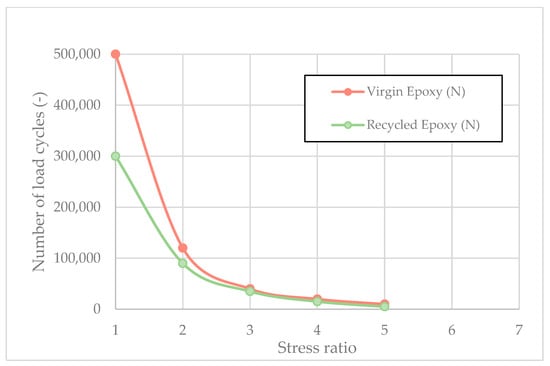

The recycled epoxy asphalt mixture exhibited lower fatigue performance than the control mixture (Figure 6).

Figure 6.

Loading cycle results—adapted from [20] with permission from Elsevier. License number: 6072011489584, Copyright Clearance Center.

Performance comparisons indicate that epoxy resin components have the potential to enable effective recycling of mixtures containing 100% RAP.

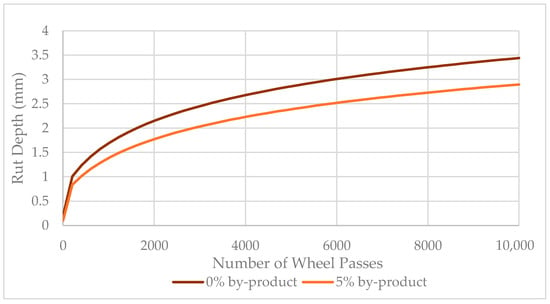

In [48], an industrial lignin-rich by-product was assessed as a partial replacement for asphalt emulsions in pavement applications. IDT results showed that incorporating 5.0% of this by-product at the optimal residual binder content (i.e., 3%) improved performance. Specifically, the TSR value was 1.35% higher than the control mixture (Table 5). However, high substitution levels of 10%, 15%, and 20% led to substantial reductions in TSR, falling below the 85% specification limit [52]. At these levels, TSR decreased by 35.19%, 21.61%, and 27.65%, respectively.

Table 5.

Water resistance—adapted from [48] with permission from Elsevier. License number: 6072030425481, Copyright Clearance Center.

The WTT results showed that, in areas where air temperatures range between 30 and 35 °C, the mixture incorporating 5% of the by-product had higher resistance to rutting than the control (Figure 7).

Figure 7.

Hamburg wheel tracking test results—adapted from [48] with permission from Elsevier. License number: 6072030425481, Copyright Clearance Center.

In [21], the performance of Hot Mix Asphalt (HMA) containing 100% RAP and no rejuvenators was compared to a control HMA with raw materials. The WTT results showed that, according to the specifications of the PG-3 for HMA surface course type AC 16 surf S [53], the RAP-based mixture exhibited higher rutting resistance than the control (Table 6).

Table 6.

Wheel tracking test results—adapted from [21] under a CC BY 4.0 license.

Additionally, an immersion-based IDT test, performed in accordance with [54], was carried out to assess water sensitivity [21]. The results indicated that both the control and the high-RAP HMA mixtures exhibited satisfactory resistance to moisture-induced damage (Table 7).

Table 7.

Moisture damage resistance—adapted from [21] under a CC BY 4.0 license.

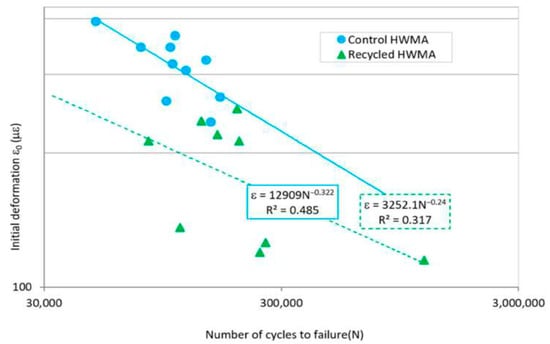

However, the control mixture exhibited 53% longer fatigue life compared to the high-RAP HMA without rejuvenators (Figure 8).

Figure 8.

Fatigue life results—reproduced from [21], under a CC BY 4.0 license.

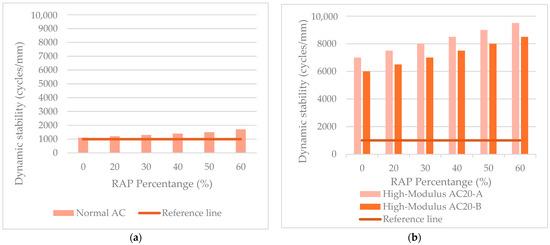

Similarly, ref. [22] investigated the characteristics of high-modulus recycled asphalt modified with high-modulus additives, comparing its performance to a conventional recycled asphalt. Wheel load tests indicated that, for standard AC20 mixtures, the dynamic stability of high-modulus asphalt, whether containing RAP or not, increased with higher RAP content. Specifically, raising the RAP content from 0% to 60% enhanced dynamic stability by roughly 330%, from about 400 cycles/mm to more than 1700 cycles/mm. The stiffening effect of the aged bitumen in RAP can justify this trend because it boosts mixture rigidity and rutting resistance.

For high-modulus mixtures, the AC20-A (4.3% asphalt content with high-modulus agents), achieved the greatest stability values: approximately 6800 cycles/mm at 0% RAP and over 9500 cycles/mm at 60% RAP, reflecting a 40% increase. The AC20-B mixture containing 4.5% asphalt raised from about 6000 cycles/mm at 0% RAP to 8600 cycles/mm at 60% RAP. At the 60% RAP content, the standard AC20 mixture achieved about 1700 cycles/mm, whereas the AC20-A and AC20-B attained between 8600 and 9500 cycles/mm, respectively. This represents 5–6 times increased rutting resistance compared with the standard mixture (Figure 9). The threshold values used by [22] were aligned with the minimum dynamic stability limits generally recognized in the literature [55].

Figure 9.

Test results from wheel loading tests: (a) conventional asphalt mixtures; (b) high-modulus asphalt mixtures—adapted from [22] with permission from Elsevier. License number: 6072040116678, Copyright Clearance Center.

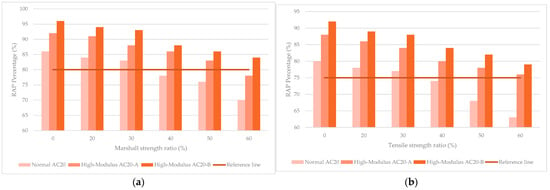

According to [22], the Marshall Strength Ratio (Figure 10a) and TSR (Figure 10b) of both conventional and high-modulus recycled asphalt mixtures decreased as the RAP content increased. This behavior indicated that higher RAP content causes greater moisture susceptibility and reduces mechanical performance.

Figure 10.

Test results for moisture susceptibility: (a) Marshall strength ratio using the Marshall test; (b) tensile strength ratio using the IDT test—adapted from [22] with permission from Elsevier. License number: 6072040116678, Copyright Clearance Center.

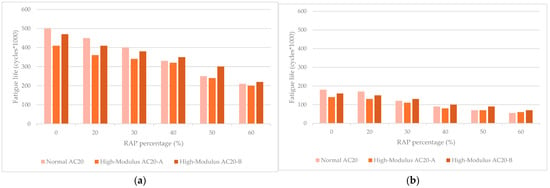

Four-point bending beam tests performed at 250 με, 350 με, 450με, and 550 με strain levels showed that the fatigue life of conventional AC20, high-modulus AC20-A, and high-modulus AC20-B mixtures decreases with increasing RAP content. As RAP levels rise, the fatigue life gap between the AC20 and the AC20-A narrows. This trend is attributed to the ability of high-modulus additives to improve asphalt binder adhesion, thereby mitigating some of the detrimental effects associated with RAP. A comparison between AC20-A and AC20-B revealed that increased bitumen content further extends service life. This benefit was evident when RAP content exceeded 30%, suggesting that additional binder enhances adhesion and mixture flexibility (Figure 11).

Figure 11.

Fatigue life results at different testing strains: (a) 250 µε; (b) 350 µε; (c) 450 µε; (d) 550 µε—adapted from [22] with permission from Elsevier. License number: 6072040116678, Copyright Clearance Center.

Table 8 synthesizes the RAP content, rejuvenator dosage, and fatigue resistance outcomes reported in the included studies.

Table 8.

RAP content, rejuvenator dosage, and fatigue resistance.

4. Discussion and Conclusions

A systematic literature review was conducted to examine the influence of RAP content on asphalt fatigue resistance as measured using the Indirect Tensile Test [26]. Although RAP improves sustainability in asphalt production, excessive use can increase brittleness and susceptibility to fatigue cracking under repeated loads [56,57,58] and reduce asphalt viscosity [20,59,60,61]. Current pavement design practices aim to maximize recycled content without compromising established performance standards [13,16,62]. Following PRISMA guidelines, five relevant studies were identified to address three key questions. However, inter-study variability in aging protocols, IDT procedures (e.g., Florida IDT [49], European standard [54]), and testing conditions, as well as potential publication bias and the lack of field validation compared to laboratory-based tests, limited statistical comparability. The included studies also encompassed a wide range of binders, modifiers, RAP contents, and rejuvenators, and these materials and mix design differences may further influence performance outcomes and complicate direct comparisons across studies.

Regarding the first question, multiple studies report that high RAP levels (>30%) often reduce fatigue resistance [22,63,64,65]. Although RAP increases mixture stiffness—e.g., high-RAP HWMA without rejuvenators can exhibit a resilient modulus 46% greater than the control mixture [21]—this comes at the expense of fatigue life. For instance, at an initial strain of 200 µε, control mixtures can last 275% longer than high-RAP HWMA; at 300 µε, the difference rises to 477% [21], consistent with other findings [20,46]. Dynamic modulus tests confirm that stiffness gains limit deformation capacity under cyclic loading [22,48]. Complementary four-point bending tests show fatigue life reductions of 15–20% as RAP content rises from 0% to 60% [22]. Similarly, trabecular fatigue testing on recycled epoxy asphalt mixtures found fatigue lives ~45% shorter than virgin epoxy asphalt at all stress ratios [20].

For the second question, combining RAP with rejuvenators or modifiers substantially improves mechanical performance, narrowing the gap with conventional mixtures [22,47,63,66,67,68,69]. Rejuvenators—such as heavy paraffinic extracts—can restore binder flexibility, improving cracking and fatigue resistance [47,48,70] by reducing stiffness [65,71]. Using ≥5% rejuvenator when RAP content exceeds 40% is recommended. Modifiers such as high-modulus agents [68,69] also enhance fatigue resistance while reducing rutting and moisture susceptibility [20,21]. Epoxy-modified 100% RAP mixes achieved 67% higher rutting resistance, but 45% lower fatigue life compared to virgin epoxy asphalt [20]. Notably, rejuvenated binders can achieve up to 29% more fatigue cycles to failure than untreated RAP binders [72,73]. Rejuvenator performance varies. Heavy paraffinic oils with high aromatic content show strong effects at 4.3–28.6% dosage, whereas semi-solid re-refined products require 6.2–67.0% [74]. Slow-aging rejuvenators have been shown to extend service life by up to 30% [46].

The third question explored technological innovations for optimizing RAP use. Warm-mix asphalt (HWMA) can lower production emissions by 25–50% while maintaining performance [75]. The incorporation of lignin-rich industrial by-products offers a sustainable alternative to commercial additives, improving stiffness, rutting resistance, and moisture performance at substitution rates as low as 5% by mass [48]. Such approaches support the valorization of industrial waste while enhancing RAP mixture performance, including in warm and semi-warm applications [75,76].

In summary, the beneficial effects of mixtures with high RAP content (up to 100%) [20,21,47,48] are more consistently observed in warm climates [21,48], where the increased stiffness of the aged binder contributed to improved rutting resistance and a dynamic modulus. These effects are further enhanced by the incorporation of rejuvenators or modifiers (e.g., RA1 at 7.9% [47], epoxy asphalt at 25% [20], lignin by-product at 5% [48], or high-modulus agents at 0.3% [22]). Although improvements in stiffness and rutting resistance can be considered generalizable trends across studies [20,22,47], the performance outcomes related to fatigue resistance, cracking, and moisture susceptibility remain highly dependent on the specific type and dosage of additives, as well as the mix design parameters. Consequently, findings in these domains should be regarded as more context-specific [20,21,47,48].

A limitation of this review is that only five studies were ultimately included. This restriction stems from the specific objectives of the research and the strict search and selection criteria applied to ensure methodological consistency. Nevertheless, the small number of studies highlights a gap in the scientific literature, as few investigations have examined the fatigue resistance of RAP-modified asphalt mixtures compared to conventional ones using the indirect tensile test.

Future advances are likely to focus on higher RAP incorporation, with tailored designs using optimized blends of modifiers and rejuvenators for specific traffic and climate conditions. Although IDTs are valuable tools for evaluating cracking and rutting resistance, more advanced methodologies (e.g., four-point bending, dynamic modulus testing, and accelerated aging protocols) should be used to replicate field conditions. Research should also pursue integrated design frameworks considering binder aging, additive synergy, and life-cycle performance [77], supported by multi-scale testing and numerical modeling. Combining industrial by-products with modern mixing technologies offers a pathway toward durable, resource-efficient, and environmentally responsible pavements.

Author Contributions

Conceptualization, M.S.D. and G.L.; methodology, M.S.D.; software, M.S.D.; formal analysis, M.S.D.; investigation, M.S.D.; data curation, M.S.D. and G.L.; writing—original draft preparation, M.S.D.; writing—review and editing, M.S.D., L.M. and G.L.; visualization, M.S.D.; supervision, G.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

This article includes the data presented in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| RAP | Reclaimed Asphalt Pavement |

| AC20 | asphalt concrete with a 20 mm aggregate size |

| IDT | Indirect Tensile Test |

| WTT | Wheel Tracking Test or Hamburg Wheel Test |

| HMA | Hot Mix Asphalt |

| TSR | Tensile Strength Ratio |

| HWMA | Hot–Warm Mix Asphalt |

| Kfree | Kappa Free-Marginal Multirater Coefficient |

References

- Wang, Y.D.; Keshavarzi, B.; Kim, Y.R. Fatigue Performance Analysis of Pavements with RAP Using Viscoelastic Continuum Damage Theory. KSCE J. Civ. Eng. 2018, 22, 2118–2125. [Google Scholar] [CrossRef]

- Bruno, S.; Loprencipe, G.; Di Mascio, P.; Cantisani, G.; Fiore, N.; Polidori, C.; Riccio, G.; D’Andrea, A.; Moretti, L. Eco-efficient asphalt recycling for urban slow mobility. Euro-Mediterr. J. Environ. Integr. 2024, 9, 957–964. [Google Scholar] [CrossRef]

- Fiore, N.; Bruno, S.; Del Serrone, G.; Iacobini, F.; Giorgi, G.; Rinaldi, A.; Moretti, L.; Duranti, G.; Peluso, P.; Vita, L. Experimental Analysis of Hot-Mix Asphalt (HMA) Mixtures with Reclaimed Asphalt Pavement (RAP) in Railway Sub-Ballast. Materials 2023, 16, 1335. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Radziszewski, P.; Nazarko, J.; Vilutiene, T.; Dębkowska, K.; Ejdys, J.; Gudanowska, A.; Halicka, K.; Kilon, J.; Kononiuk, A.; Kowalski, K.J.; et al. Future trends in road pavement technologies development in the context of environmental protection. Balt. J. Road Bridge Eng. 2016, 11, 160–168. [Google Scholar] [CrossRef]

- Mączka, E.; Mackiewicz, P. Asphalt mixtures degradation induced by water, frost, and road salt in the 4-PB bending test evaluated by stiffness variability. Road Mater. Pavement Des. 2023, 24, 389–408. [Google Scholar] [CrossRef]

- Olalekan, S.T.; Olatunde, A.A.; Kolapo, S.K.; Omolola, J.M.; Olukemi, O.A.; Mufutau, A.A.; Olaosebikan, O.O.; Saka, A.A. Durability of bitumen binder reinforced with polymer additives: Towards upgrading Nigerian local bitumen. Heliyon 2024, 10, e30825. [Google Scholar] [CrossRef]

- Tarbox, S.; Daniel, J.S. Effects of Long-Term Oven Aging on Reclaimed Asphalt Pavement Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2012, 2294, 1–15. [Google Scholar] [CrossRef]

- National Asphalt Pavement Association (NAPA). RAP Benefits for Pavement Owners. Available online: https://www.asphaltpavement.org/uploads/documents/Sustainability/NAPA_RAP_Benefits_for_Pavement_Owners_1121.pdf (accessed on 10 August 2025).

- Yin, F.; Arámbula-Mercado, E.; Epps Martin, A.E.; Newcomb, D.; Tran, N. Long-term ageing of asphalt mixtures. Road Mater. Pavement Des. 2017, 18, 2–27. [Google Scholar] [CrossRef]

- Huang, Y.H. Pavement Analysis and Design, 2nd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2004; ISBN 0-13-142473-4. [Google Scholar]

- AASHTO R 35; Standard Practice for Superpave Volumetric Design for Asphalt Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid life cycle assessment for asphalt mixtures with high RAP content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice; US Department of Transportation, Federal Highway Administration: McLean, VA, USA, 2011. [Google Scholar]

- Ramadan, S.; Kassem, H.; Elkordi, A.; Joumblat, R. Advancing Pavement Sustainability: Assessing Recycled Aggregates as Substitutes in Hot Mix Asphalt. Sustainability 2025, 17, 5472. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B. Review of very high-content reclaimed asphalt use in plant-produced pavements: State of the art. Int. J. Pavement Eng. 2015, 16, 39–55. [Google Scholar] [CrossRef]

- Zhang, K.; Muftah, A.; Wen, H.; Bayomy, F.; Santi, M. Performance-Related Design Method for Asphalt Mixes That Contain Reclaimed Asphalt Pavement (RAP) (No.16-4726). 2016. Available online: https://trid.trb.org/View/1393767 (accessed on 24 August 2025).

- Silva, H.M.R.D.; Oliveira, J.R.P.; Jesus, C.M.G. Are totally recycled hot mix asphalts a sustainable alternative for road paving? Resour. Conserv. Recycl. 2012, 60, 38–48. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Jia, X.; Woods, M. Laboratory Performance Evaluation of Warm-Mix Asphalt Containing High Percentages of Reclaimed Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2012, 2294, 98–105. [Google Scholar] [CrossRef]

- Yi, X.; Chen, H.; Wang, H.; Shi, C.; Yang, J. The feasibility of using epoxy asphalt to recycle a mixture containing 100% reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2022, 319, 126122. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I.; Gómez-Meijide, B. Performance of High RAP Half-Warm Mix Asphalt. Sustainability 2020, 12, 10240. [Google Scholar] [CrossRef]

- Ma, T.; Ding, X.; Zhang, D.; Huang, X.; Chen, J. Experimental study of recycled asphalt concrete modified by high-modulus agent. Constr. Build. Mater. 2016, 128, 128–135. [Google Scholar] [CrossRef]

- Zhang, J.; Sesay, T.; You, Q.; Jing, H. Maximizing the Application of RAP in Asphalt Concrete Pavements and Its Long-Term Performance: A Review. Polymers 2022, 14, 4736. [Google Scholar] [CrossRef] [PubMed]

- ASTM D6931-17; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2017.

- Wang, Z.; Lu, W.; Liu, K.; Lv, S.; Peng, X.; Yang, S.; Ding, S. Research on failure strength master curve and fatigue performance of asphalt mixture containing high-proportion reclaimed asphalt pavement. Constr. Build. Mater. 2023, 370, 130537. [Google Scholar] [CrossRef]

- Bennert, T.; Haas, E.; Wass, E. Indirect Tensile Test (IDT) to Determine Asphalt Mixture Performance Indicators during Quality Control Testing in New Jersey. Transp. Res. Board 2018, 2672, 394–403. [Google Scholar] [CrossRef]

- Antunes, V.; Neves, J.; Freire, A.C. Performance Assessment of Reclaimed Asphalt Pavement (RAP) in Road Surface Mixtures. Recycling 2021, 6, 32. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, C.; Chen, T.; Zhang, W.; Yao, K.; Fan, C.; Liang, M.; Guo, C.; Yao, Z. Evaluation on the mechanical performance of recycled asphalt mixtures incorporated with high percentage of RAP and self-developed rejuvenators. Constr. Build. Mater. 2021, 269, 121337. [Google Scholar] [CrossRef]

- Riccardi, C.; Wang, D.; Wistuba, M.P.; Walther, A. Effects of polyacrylonitrile fibres and high content of RAP on mechanical properties of asphalt mixtures in binder and base layers. Road Mater. Pavement Des. 2022, 24, 2133–2155. [Google Scholar] [CrossRef]

- Majidifard, H.; Tabatabaee, N.; Buttlar, W. Investigating Short-term and Long-term Binder Performance of High-RAP Mixtures Containing Waste Cooking Oil. J. Traffic Transp. Eng. 2019, 6, 396–406. [Google Scholar] [CrossRef]

- Xu, X.; Lu, G.; Yang, J.; Liu, X. Mechanism and Rheological Properties of High-Modulus Asphalt. Adv. Mater. Sci. Eng. 2020, 1, 8795429. [Google Scholar] [CrossRef]

- Suo, Z.; Chen, H.; Yan, Q.; Tan, Y.; Li, X.; Zhang, A. Laboratory Performance Evaluation on the Recovering of Aged Bitumen With Vegetable Oil Rejuvenator. Front. Mater. 2021, 8, 650809. [Google Scholar] [CrossRef]

- Mehmood, R.; Jakarni, F.M.; Muniandy, R.; Hassim, S.; Nik Daud, N.N.N.; Ansari, A.H. Waste engine oil as a sustainable approach for asphalt rejuvenation and modification: A review. Heliyon 2024, 10, e40737. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of Rejuvenator’s Effectiveness with Conventional Mix Testing for 100% Reclaimed Asphalt Pavement Mixtures. Transp. Res. Rec. 2013, 2370, 17–25. [Google Scholar] [CrossRef]

- Kim, Y.-M.; Kim, K.; Le, T.H.M. Development of Sustainable Cement Asphalt Mortar Using Agricultural Waste-Derived Bio-Oil and Latex–Acrylic Polymers for Enhanced Durability. Polymers 2024, 16, 3210. [Google Scholar] [CrossRef]

- Albayati, A.H.; Latief, R.H.; Al-Mosawe, H.; Wang, Y. Nano-Additives in Asphalt Binder: Bridging the Gap between Traditional Materials and Modern Requirements. Appl. Sci. 2024, 14, 3998. [Google Scholar] [CrossRef]

- Jwaida, Z.; Dulaimi, A.; Mydin, M.A.O.; Özkılıç, Y.O.; Jaya, R.P.; Ameen, A. The Use of Waste Polymers in Asphalt Mixtures: Bibliometric Analysis and Systematic Review. J. Compos. Sci. 2023, 7, 415. [Google Scholar] [CrossRef]

- Masri, K.A.; Nur Syafiqah, S.M.Z.; Seman, M.A.; Ramadhansyah, P.J.; Yaacob, H.; Mashros, N. A review on nanomaterials as additive in asphalt binder. IOP Conf. Ser. Earth Environ. Sci. 2021, 682, 012055. [Google Scholar] [CrossRef]

- Zhu, C.; Yang, Y.; Zhang, K.; Yu, D. Study on the Road Performance and Compaction Characteristics of Fiber-Reinforced High-RAP Plant-Mixed Hot Recycled Asphalt Mixtures. Polymers 2024, 16, 2016. [Google Scholar] [CrossRef]

- Valdes-Vidal, G.; Calabi-Floody, A.; Mignolet-Garrido, C.; Bravo-Espinoza, C. Enhancing Fatigue Resistance in Asphalt Mixtures with a Novel Additive Derived from Recycled Polymeric Fibers from End-of-Life Tyres (ELTs). Polymers 2024, 16, 385. [Google Scholar] [CrossRef]

- Phillips, M.; Reed, J.B.; Zwicky, D.; Van Epps, A.S.; Buhler, A.G.; Rowley, E.M.; Zakharov, W. Systematic Reviews in the Engineering Literature: A Scoping Review. IEEE Access 2024, 12, 62648–62663. Available online: https://ieeexplore.ieee.org/document/10509688 (accessed on 24 August 2025). [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. Declaración PRISMA 2020: Una guía actualizada para la publicación de revisiones sistemáticas. Rev. Española Cardiol. 2021, 74, 790–799. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Prisma Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Ann. Intern. Med. 2009, 151, 264–269. [Google Scholar] [CrossRef]

- Boutron, I.; Page, M.J.; Higgins, J.P.; Altman, D.G.; Lundh, A.; Hróbjartsson, A. Chapter 7: Considering bias and conflicts of interest among the included studies. Cochrane Handb. Syst. Rev. Interv. 2019, 177–204. Available online: https://www.cochrane.org/authors/handbooks-and-manuals/handbook (accessed on 24 August 2025).

- Higgins, J.; Thomas, J.; Chandler, J.; Cumpston, M.; Li, T.; Page, M.; Welch, V. Cochrane Handbook for Systematic Reviews of Interventions, 2nd ed.; John Wiley & Sons: London, UK, 2019. [Google Scholar]

- Randolph, J.J. Free-Marginal Multirater Kappa (multirater K[free]): An Alternative to Fleiss’ Fixed-Marginal Multirater Kappa; Oensuu University Learning and Instruction Symposium: Joensuu, Finland, 2005. Available online: https://files.eric.ed.gov/fulltext/ED490661.pdf (accessed on 24 August 2025).

- Ali, H.A.; Mohammad, L.; Mohammadafzali, M.; Haddadi, F.; Akentuna, M.; Sholar, G.; Moseley, H.; Rilko, W.; Allen, C. Investigating the effect of degree of blending on performance of high RAP content mixtures. J. Mater. Civ. Eng. 2021, 33, 04021048. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Nardi, E.; Pérez-Barge, N.; Toraldo, E. Valorisation of lignin-rich industrial byproduct into half-warm mix reclaimed asphalt with enhanced performance. Constr. Build. Mater. 2022, 315, 125770. [Google Scholar] [CrossRef]

- Florida DOT. Flexible Pavement Design Manual; Florida Department of Transportation: Tallahassee, FL, USA, 2021. [Google Scholar]

- AENOR Asociación Española de Normalización y Certificación. EN 1426 Bitumen and Bituminous Binders. Determination of Needle Penetration; AENOR: Madrid, Spain, 2007. (In Spanish) [Google Scholar]

- ENOR Asociación Española de Normalización y Certificación. EN 1427 Bitumen and Bituminous Binders. Determination of the Softening Point. Ring and Ball Method; AENOR: Madrid, Spain, 2007. (In Spanish) [Google Scholar]

- ATEB Asociación Técnica de Emulsiones Bituminosas. Half-Warm Mix Asphalt with Bitumen Emulsion; ATEB: Madrid, Spain, 2014. (In Spanish) [Google Scholar]

- MFOM Ministry of Public Works. Article 542 (Asphalt Concrete) of the General Technical Specifications for Road and Bridge Works (PG3) from the Spanish Ministry of Public Works; MFOM: Madrid, Spain, 2015. (In Spanish)

- AENOR Asociación Española de Normalización y Certificación. EN 12697-12 Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Determination of the Water Sensitivity of Bituminous Specimens; AENOR: Madrid, Spain, 2006. (In Spanish) [Google Scholar]

- JTG F40-2004; Standard Specification for Construction of Highway Asphalt Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- Ma, X.; Wang, J.; Xu, Y. Investigation on the Effects of RAP Proportions on the Pavement Performance of Recycled Asphalt Mixtures. Front. Mater. 2022, 8, 842809. [Google Scholar] [CrossRef]

- Ding, L.; Li, Y.; Han, Z.; Zhang, M.; Wang, X.; He, L. The effect of RAP content on fatigue damage property of hot reclaimed asphalt mixtures. Math. Biosci. Eng. 2024, 21, 3037–3062. [Google Scholar] [CrossRef]

- Abdel-Jaber, M.T.; Al-shamayleh, R.A.; Ibrahim, R.; Alkhrissat, T.; Alqatamin, A. Mechanical properties evaluation of asphalt mixtures with variable contents of reclaimed asphalt pavement (RAP). Results Eng. 2022, 14, 100463. [Google Scholar] [CrossRef]

- Obaid, A.; Nazzal, M.D.; Abu Qtaish, L.; Kim, S.S.; Abbas, A.; Arefin, M.; Quasem, T. Effect of RAP source on cracking resistance of asphalt mixtures with high RAP contents. J. Mater. Civ. Eng. 2019, 31, 04019213. [Google Scholar] [CrossRef]

- Khan, M.Z.H.; Koting, S.; Katman, H.Y.B.; Ibrahim, M.R.; Babalghaith, A.M.; Asqool, O. Performance of High Content Reclaimed Asphalt Pavement (RAP) in Asphaltic Mix with Crumb Rubber Modifier and Waste Engine Oil as Rejuvenator. Appl. Sci. 2021, 11, 5226. [Google Scholar] [CrossRef]

- Zhang, C.; Ren, Q.; Qian, Z.; Wang, X. Evaluating the Effects of High RAP Content and Rejuvenating Agents on Fatigue Performance of Fine Aggregate Matrix through DMA Flexural Bending Test. Materials 2019, 12, 1508. [Google Scholar] [CrossRef]

- Jin, D.; Yin, L.; Nedrich, S.; Boateng, K.A.; You, Z. Resurface of rubber modified asphalt mixture with stress absorbing membrane interlayer: From laboratory to field application. Constr. Build. Mater. 2024, 441, 137452. [Google Scholar] [CrossRef]

- Mannan, U.A.; Faisal, H.M.; Hasan, M.M.; Tarefder, R.A. Evaluating the effect of high RAP content on asphalt mixtures and binders fatigue behavior. J. Test. Eval. 2018, 46, 1749–1761. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Austerman, A.; Roque, R.; Underwood, S.; Mohammad, L.; Zou, J. Ageing and rejuvenators: Evaluating their impact on high RAP mixtures fatigue cracking characteristics using advanced mechanistic models and testing methods. Road Mater. Pavement Des. 2015, 16 (Suppl. S2), 1–28. [Google Scholar] [CrossRef]

- Mullapudi, R.S.; Aparna Noojilla, S.L.; Reddy, K.S. Fatigue and healing characteristics of rap mixtures. J. Mat. Civ. Eng. 2020, 32, 04020390. [Google Scholar] [CrossRef]

- Iwama, M.; Hayano, K. Influence of combined aging on the mechanical and physical properties of reclaimed asphalt pavement mixtures blended with rejuvenator agents. J. Mater. Cycles Waste Manag. 2023, 25, 1417–1433. [Google Scholar] [CrossRef]

- Jiang, L.; Shen, J.; Wang, W. Performance of High-Dose Reclaimed Asphalt Mixtures (RAPs) in Hot In-Place Recycling Based on Balanced Design. Materials 2024, 17, 2096. [Google Scholar] [CrossRef]

- Huang, G.; Zhang, J.; Hui, B.; Zhang, H.; Guan, Y.; Guo, F.; Li, Y.; He, Y.; Wang, D. Analysis of Modulus Properties of High-Modulus Asphalt Mixture and Its New Evaluation Index of Rutting Resistance. Sustainability 2023, 15, 7574. [Google Scholar] [CrossRef]

- Izaks, R.; Rathore, M.; Haritonovs, V.; Zaumanis, M. Performance properties of high modulus asphalt concrete containing high reclaimed asphalt content and polymer modified binder. Int. J. Pavement Eng. 2020, 23, 2255–2264. [Google Scholar] [CrossRef]

- Pham, N.H.; Sauzéat, C.; Di Benedetto, H.; González-León, J.A.; Barreto, G.; Nicolaï, A. Fatigue and Thermal Cracking of Hot and Warm Bituminous Mixtures with Different RAP Contents. Sustainability 2020, 12, 9812. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Katman, H.Y.; Mohd Satar, M.K.I.; Bilema, M.; Putra Jaya, R.; Eltwati, A.S.; Radeef, H.R. A Review on the Durability of Recycled Asphalt Mixtures Embraced with Rejuvenators. Sustainability 2021, 13, 8970. [Google Scholar] [CrossRef]

- Wu, J.; Sun, H.; Wan, L.; Yang, J.; Wang, S. Study on Low-Temperature and Fatigue Performance of High RAP Content Hot Recycled Asphalt Mixture Based on the Degree of Blending (DOB). Polymers 2022, 14, 4520. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Le, T.H.M. Feasibility and Sustainable Performance of RAP Mixtures with Low-Viscosity Binder and Castor Wax–Corn Oil Rejuvenators. Buildings 2023, 13, 1578. [Google Scholar] [CrossRef]

- Mohammadafzali, M.; Ali, H.; Musselman, J.A.; Sholar, G.A.; Rilko, W.A. Aging of Rejuvenated Asphalt Binders. Adv. Mater. Sci. Eng. 2017, 2017, 8426475. [Google Scholar] [CrossRef]

- Tutu, K.; Tuffour, Y. Warm-Mix Asphalt and Pavement Sustainability: A Review. J. Civ. Eng. 2016, 6, 84–93. [Google Scholar] [CrossRef]

- Manke, N.D.; Williams, R.C.; Sotoodeh-Nia, Z.; Cochran, E.W.; Porot, L.; Chailleux, E.; Pouget, S.; Olard, F.; Jiménez del Barco Carrión, A.; Planche, J.-P.; et al. Performance of a sustainable asphalt mix incorporating high RAP content and novel bio-derived binder. Road Mater. Pavement Des. 2019, 22, 812–834. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Elseifi, M.; Carpenter, S.H. Reclaimed Asphalt Pavement—A Literature Review; No. FHWA-ICT-07-001; Illinois Center for Transportation: Urbana, IL, USA, 2007. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).