Smart Design Aided by Mathematical Approaches: Adaptive Manufacturing, Sustainability, and Biomimetic Materials

Abstract

1. Introduction

2. Biomimetic Smart Materials: Principles and Classifications

2.1. Definitions and Typologies

2.2. Stimuli–Response Mechanisms

2.3. Examples from Nature and Their Engineered Analogs

3. Temporal Design and 4D Printing: Technologies and Trends

3.1. From Static to Dynamic Objects

3.2. Four-Dimensional Printing Methods and Materials

3.3. Comparative Analysis with Traditional Additive Manufacturing

4. Application Domains

4.1. Regenerative Medicine and Bioactive Devices

4.2. Architecture and Built Environment

4.3. Wearables, Mobility, and Consumer Products

5. Challenges and Research Gaps

5.1. Technical Challenges: Material Limitations and Process Control

5.2. Educational Barriers: Integration into Design Curricula

5.3. Ethical and Societal Considerations: Material Autonomy, Transparency, Cultural Impact

6. Mathematical Modeling and Simulation Tools for Smart Design

7. Future Outlook: Toward Regenerative Design Systems

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-Dimensional |

| 4D | Four-Dimensional (Three-Dimensional + Time-Dependent Behavior) |

| AM | Additive Manufacturing |

| CAD | Computer-Aided Design |

| CAM | Computer-Aided Manufacturing |

| DIW | Direct Ink Writing |

| EAP | Electroactive Polymer |

| FDM | Fused Deposition Modeling |

| FE | Finite Element |

| SMP | Shape-Memory Polymer |

| SLA | Stereolithography |

| pH | Potential of Hydrogen (Acidity/Alkalinity Indicator) |

| Tg | Glass Transition Temperature |

| HVAC | Heating, Ventilation, and Air Conditioning |

| IoT | Internet of Things |

| FE Simulation | Finite Element Simulation |

| UV | Ultraviolet |

| PLA | Polylactic Acid (commonly used thermoplastic in AM) |

| TPU | Thermoplastic Polyurethane |

| ELS | Environmental Lifecycle Sustainability |

References

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T. Transforming Object Design and Creation: Biomaterials and Contemporary Manufacturing Leading the Way. Biomimetics 2024, 9, 48. [Google Scholar] [CrossRef] [PubMed]

- Sofias, K.; Kanetaki, Z.; Stergiou, C.; Jacques, S. Combining CAD Modeling and Simulation of Energy Performance Data for the Retrofit of Public Buildings. Sustainability 2023, 15, 2211. [Google Scholar] [CrossRef]

- Ibrahim, I.; Al Shomely, K.; Eltarabishi, F. Sustainability Implications of Utilizing Islamic Geometric Patterns in Contemporary Designs, a Systematic Analysis. Buildings 2023, 13, 2434. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Ganetsos, T. From Stents to Smart Implants Employing Biomimetic Materials: The Impact of 4D Printing on Modern Healthcare. Biomimetics 2025, 10, 125. [Google Scholar] [CrossRef]

- Drevet, R.; Benhayoune, H. New Insights into Biomaterials and Coatings. Coatings 2025, 15, 332. [Google Scholar] [CrossRef]

- Jamil, H.; Faizan, M.; Adeel, M.; Jesionowski, T.; Boczkaj, G.; Balčiūnaitė, A. Recent Advances in Polymer Nanocomposites: Unveiling the Frontier of Shape Memory and Self-Healing Properties-A Comprehensive Review. Molecules 2024, 29, 1267. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 4D Printing: Technology Overview and Smart Materials Utilized. J. Mechatron. Robot. 2023, 7, 1–14. [Google Scholar] [CrossRef]

- Drevet, R.; Benhayoune, H. Biomaterials Design for Human Body Repair. Designs 2024, 8, 65. [Google Scholar] [CrossRef]

- Kontiza, A.; Kartsonakis, I.A. Smart Composite Materials with Self-Healing Properties: A Review on Design and Applications. Polymers 2024, 16, 2115. [Google Scholar] [CrossRef] [PubMed]

- Dallaev, R. Advances in Materials with Self-Healing Properties: A Brief Review. Materials 2024, 17, 2464. [Google Scholar] [CrossRef]

- Medina, H.; Farmer, C.; Liu, I. Dielectric Elastomer-Based Actuators: A Modeling and Control Review for Non-Experts. Actuators 2024, 13, 151. [Google Scholar] [CrossRef]

- Koutsanitis, S.; Sinou, M.; Kanetaki, Z.; Tousi, E.; Varelidis, G. Thermal Performance Investigation in Historical Urban Neighborhoods Using ENVI-Met Simulation Software. Land 2025, 14, 284. [Google Scholar] [CrossRef]

- Qalati, S.A.; Barbosa, B.; Deshwal, P. Consumer Behavior and Sustainable Marketing Development in Online and Offline Settings. Sustainability 2024, 16, 2829. [Google Scholar] [CrossRef]

- Sajid, M.; Ertz, M. Blueprints to Benefits: Towards an Index to Measure the Impact of Sustainable Product Development on the Firm’s Bottom Line. Sustainability 2024, 16, 537. [Google Scholar] [CrossRef]

- Ighodaro, A.; Osarobo, J.A.; Onuguh, I.C.; Ogbeide, O.K.; Ifijen, I.H. Challenges and Future Perspectives of Biomimetic Materials for Biomedical Applications: Bridging the Gap between Nature and Medicine. In The Minerals, Metals & Materials Series; Springer Nature: Cham, Switzerland, 2024; pp. 877–896. ISBN 9783031503481. [Google Scholar]

- Speck, O.; Speck, T. Biomimetics and Education in Europe: Challenges, Opportunities, and Variety. Biomimetics 2021, 6, 49. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T.; Alysandratou, E. Bioprinting and Intellectual Property: Challenges, Opportunities, and the Road Ahead. Bioengineering 2025, 12, 76. [Google Scholar] [CrossRef]

- Ciulla, M.G.; Massironi, A.; Sugni, M.; Ensign, M.A.; Marzorati, S.; Forouharshad, M. Recent Advances in the Development of Biomimetic Materials. Gels 2023, 9, 833. [Google Scholar] [CrossRef] [PubMed]

- Lima, E.; Ferreira, H.; Mateus, L.; Arruda, A. Integration of Thermo-Responsive Materials Applied to Bio-Inspired Structures. Biomimetics 2025, 10, 68. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 3D and 4D Printing as Integrated Manufacturing Methods of Industry 4.0. Am. J. Eng. Appl. Sci. 2023, 16, 12–22. [Google Scholar] [CrossRef]

- Kantaros, A. Bio-Inspired Materials: Exhibited Characteristics and Integration Degree in Bio-Printing Operations. Am. J. Eng. Appl. Sci. 2022, 15, 255–263. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Filippova, O.V.; Tcherdyntsev, V.V.; Telyshev, D.V. Shape Memory Polymers as Smart Materials: A Review. Polymers 2022, 14, 3511. [Google Scholar] [CrossRef]

- Yang, S.; He, Y.; Song, Z.; Li, Y. Research Status and Potential Direction for Thermoplastic Shape Memory Polymers and Composites: A Review. Polymers 2025, 17, 1360. [Google Scholar] [CrossRef]

- Narvaez, D.; Newell, B. A Review of Electroactive Polymers in Sensing and Actuator Applications. Actuators 2025, 14, 258. [Google Scholar] [CrossRef]

- Parvin, N.; Joo, S.W.; Jung, J.H.; Mandal, T.K. Electroactive Polymers for Self-Powered Actuators and Biosensors: Advancing Biomedical Diagnostics through Energy Harvesting Mechanisms. Actuators 2025, 14, 257. [Google Scholar] [CrossRef]

- Protsak, I.S.; Morozov, Y.M. Fundamentals and Advances in Stimuli-Responsive Hydrogels and Their Applications: A Review. Gels 2025, 11, 30. [Google Scholar] [CrossRef] [PubMed]

- Khuzin, A.A.; Galimov, D.I.; Tulyabaev, A.R.; Khuzina, L.L. Synthesis, Photochromic and Luminescent Properties of Ammonium Salts of Spiropyrans. Molecules 2022, 27, 8492. [Google Scholar] [CrossRef]

- Abedi-Firoozjah, R.; Yousefi, S.; Heydari, M.; Seyedfatehi, F.; Jafarzadeh, S.; Mohammadi, R.; Rouhi, M.; Garavand, F. Application of Red Cabbage Anthocyanins as pH-Sensitive Pigments in Smart Food Packaging and Sensors. Polymers 2022, 14, 1629. [Google Scholar] [CrossRef] [PubMed]

- Baral, A.; Basu, K. Supramolecular Adhesives Inspired by Nature: Concept and Applications. Biomimetics 2025, 10, 87. [Google Scholar] [CrossRef]

- Sringam, J.; Kajornprai, T.; Trongsatitkul, T.; Suppakarn, N. Shape Memory Performance and Microstructural Evolution in PLA/PEG Blends: Role of Plasticizer Content and Molecular Weight. Polymers 2025, 17, 225. [Google Scholar] [CrossRef]

- Visan, A.I.; Negut, I. Environmental and Wastewater Treatment Applications of Stimulus-Responsive Hydrogels. Gels 2025, 11, 72. [Google Scholar] [CrossRef]

- Gribkova, O.L.; Nekrasov, A.A. Spectroelectrochemistry of Electroactive Polymer Composite Materials. Polymers 2022, 14, 3201. [Google Scholar] [CrossRef]

- Kanaan, A.F.; Pinho, A.C.; Piedade, A.P. Electroactive Polymers Obtained by Conventional and Non-Conventional Technologies. Polymers 2021, 13, 2713. [Google Scholar] [CrossRef] [PubMed]

- Chandra Adak, N.; Lee, W. A Comprehensive Review of 4D-Printed Thermo-Responsive Hydrogel-Based Smart Actuators for Solar Steam Generation: Advanced Design, Modeling, Manufacturing, and Finite Element Analysis. Prog. Mater. Sci. 2025, 148, 101377. [Google Scholar] [CrossRef]

- Pandeya, S.P.; Zou, S.; Roh, B.-M.; Xiao, X. Programmable Thermo-Responsive Self-Morphing Structures Design and Performance. Materials 2022, 15, 8775. [Google Scholar] [CrossRef]

- Imam, S.S.; Hussain, A.; Altamimi, M.A.; Alshehri, S. Four-Dimensional Printing for Hydrogel: Theoretical Concept, 4D Materials, Shape-Morphing Way, and Future Perspectives. Polymers 2021, 13, 3858. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, Y.; Ma, Y.; Wang, J. Bioinspired Stimuli-Responsive Materials for Soft Actuators. Biomimetics 2024, 9, 128. [Google Scholar] [CrossRef] [PubMed]

- Serna, J.A.; Rueda-Gensini, L.; Céspedes-Valenzuela, D.N.; Cifuentes, J.; Cruz, J.C.; Muñoz-Camargo, C. Recent Advances on Stimuli-Responsive Hydrogels Based on Tissue-Derived ECMs and Their Components: Towards Improving Functionality for Tissue Engineering and Controlled Drug Delivery. Polymers 2021, 13, 3263. [Google Scholar] [CrossRef] [PubMed]

- Agbna, G.H.D.; Zaidi, S.J. Hydrogel Performance in Boosting Plant Resilience to Water Stress—A Review. Gels 2025, 11, 276. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Song, H.; Wang, F.; Su, X.; Zhang, D.; Xu, J. Biomimetic Superhydrophobic Surfaces: From Nature to Application. Materials 2025, 18, 2772. [Google Scholar] [CrossRef]

- Baharuddin, N.S.; Roslan, M.A.M.; Bawzer, M.A.M.; Mohamad Azzeme, A.; Rahman, Z.A.; Khayat, M.E.; Rahman, N.A.A.; Sobri, Z.M. Response Surface Optimization of Extraction Conditions and in Vitro Antioxidant and Antidiabetic Evaluation of an Under-Valued Medicinal Weed, Mimosa Pudica. Plants 2021, 10, 1692. [Google Scholar] [CrossRef]

- Horstmann, M.; Speck, T.; Poppinga, S. Orchestrated Movement Sequences and Shape-Memory-like Effects in Pine Cones. Plants 2024, 13, 2078. [Google Scholar] [CrossRef]

- Song, J.; Li, B.; Zeng, L.; Ye, Z.; Wu, W.; Hu, B. A Mini-Review on Reflectins, from Biochemical Properties to Bio-Inspired Applications. Int. J. Mol. Sci. 2022, 23, 15679. [Google Scholar] [CrossRef]

- Stella, D.; Kleisner, K. Visible beyond Violet: How Butterflies Manage Ultraviolet. Insects 2022, 13, 242. [Google Scholar] [CrossRef] [PubMed]

- Maksimkin, A.V.; Dayyoub, T.; Telyshev, D.V.; Gerasimenko, A.Y. Electroactive Polymer-Based Composites for Artificial Muscle-like Actuators: A Review. Nanomaterials 2022, 12, 2272. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Zhou, Z.; Xie, Y.; Zhu, X.; Huang, G.; Zhang, Z. A Microactuator Array Based on Ionic Electroactive Artificial Muscles for Cell Mechanical Stimulation. Biomimetics 2024, 9, 281. [Google Scholar] [CrossRef] [PubMed]

- Collins, C.M.; Safiuddin, M. Lotus-Leaf-Inspired Biomimetic Coatings: Different Types, Key Properties, and Applications in Infrastructures. Infrastructures 2022, 7, 46. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Zielecka, M.; Klapsa, W.; Dziechciarz, A. Self-Cleaning Coatings and Surfaces of Modern Building Materials for the Removal of Some Air Pollutants. Materials 2021, 14, 2161. [Google Scholar] [CrossRef]

- Branković, M.; Zivic, F.; Grujovic, N.; Stojadinovic, I.; Milenkovic, S.; Kotorcevic, N. Review of Spider Silk Applications in Biomedical and Tissue Engineering. Biomimetics 2024, 9, 169. [Google Scholar] [CrossRef]

- Uklejewski, R.; Winiecki, M. Advances in Biomimetic Scaffolds for Hard Tissue Surgery. Biomimetics 2024, 9, 279. [Google Scholar] [CrossRef]

- Nestor, T.; Belazi, A.; Abd-El-Atty, B.; Aslam, M.N.; Volos, C.; De Dieu, N.J.; Abd El-Latif, A.A. A New 4D Hyperchaotic System with Dynamics Analysis, Synchronization, and Application to Image Encryption. Symmetry 2022, 14, 424. [Google Scholar] [CrossRef]

- Biswas, M.C.; Chakraborty, S.; Bhattacharjee, A.; Mohammed, Z. 4D Printing of Shape Memory Materials for Textiles: Mechanism, Mathematical Modeling, and Challenges. Adv. Funct. Mater. 2021, 31, 2100257. [Google Scholar] [CrossRef]

- Park, H.-J.; Hong, H.; Thangam, R.; Song, M.-G.; Kim, J.-E.; Jo, E.-H.; Jang, Y.-J.; Choi, W.-H.; Lee, M.-Y.; Kang, H.; et al. Static and Dynamic Biomaterial Engineering for Cell Modulation. Nanomaterials 2022, 12, 1377. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Zhao, T.; Aldaghri, O.; Eisa, M.H. Polymer/Graphene Nanocomposites via 3D and 4D Printing—Design and Technical Potential. Processes 2023, 11, 868. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Bodaghi, M.; Kouzani, A.Z.; Gharaie, S.; Nahavandi, S. Control-Based 4D Printing: Adaptive 4D-Printed Systems. Appl. Sci. 2020, 10, 3020. [Google Scholar] [CrossRef]

- Imrie, P.; Jin, J. Multimaterial Hydrogel 3D Printing. Macromol. Mater. Eng. 2024, 309, 2300272. [Google Scholar] [CrossRef]

- Vatanparast, S.; Boschetto, A.; Bottini, L.; Gaudenzi, P. New Trends in 4D Printing: A Critical Review. Appl. Sci. 2023, 13, 7744. [Google Scholar] [CrossRef]

- Pan, H.M. Advanced Materials in 3D/4D Printing Technology. Polymers 2022, 14, 3255. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yang, Y.; Yang, Z.; Ma, R.; Aimaijiang, M.; Xu, J.; Zhang, Y.; Zhou, Y. Four-Dimensional Printing and Shape Memory Materials in Bone Tissue Engineering. Int. J. Mol. Sci. 2023, 24, 814. [Google Scholar] [CrossRef]

- Ge, Q.; Qi, H.J.; Dunn, M.L. Active Materials by Four-Dimension Printing. Appl. Phys. Lett. 2013, 103, 131901. [Google Scholar] [CrossRef]

- Sagias, V.D.; Papageorgiou, D.G.; Pappas, A.; Stergiou, C.I. Mechanical Properties of AM Polymer Specimens under Bending Stress. Appl. Mech. 2025, 6, 25. [Google Scholar] [CrossRef]

- Kantaros, A.; Karalekas, D. FBG Based in Situ Characterization of Residual Strains in FDM Process. In Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems, Volume 8; Springer International Publishing: Cham, Switzerland, 2014; pp. 333–337. ISBN 9783319008752. [Google Scholar]

- Tsang, A.C.H.; Zhang, J.; Hui, K.N.; Hui, K.S.; Huang, H. Recent Development and Applications of Advanced Materials via Direct Ink Writing. Adv. Mater. Technol. 2022, 7, 2101358. [Google Scholar] [CrossRef]

- Unkovskiy, A.; Schmidt, F.; Beuer, F.; Li, P.; Spintzyk, S.; Kraemer Fernandez, P. Stereolithography vs. Direct Light Processing for Rapid Manufacturing of Complete Denture Bases: An in Vitro Accuracy Analysis. J. Clin. Med. 2021, 10, 1070. [Google Scholar] [CrossRef]

- Zhuo, S.; Geever, L.M.; Halligan, E.; Tie, B.S.H.; Breheny, C. A Development of New Material for 4D Printing and the Material Properties Comparison between the Conventional and Stereolithography Polymerised NVCL Hydrogels. J. Funct. Biomater. 2022, 13, 262. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Evaluating Benchtop Additive Manufacturing Processes Considering Latest Enhancements in Operational Factors. Processes 2024, 12, 2334. [Google Scholar] [CrossRef]

- Antezana, P.E.; Municoy, S.; Ostapchuk, G.; Catalano, P.N.; Hardy, J.G.; Evelson, P.A.; Orive, G.; Desimone, M.F. 4D Printing: The Development of Responsive Materials Using 3D-Printing Technology. Pharmaceutics 2023, 15, 2743. [Google Scholar] [CrossRef] [PubMed]

- Valvez, S.; Reis, P.N.B.; Susmel, L.; Berto, F. Fused Filament Fabrication-4D-Printed Shape Memory Polymers: A Review. Polymers 2021, 13, 701. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Lv, Q.; Wu, W. Application and Prospects of Hydrogel Additive Manufacturing. Gels 2022, 8, 297. [Google Scholar] [CrossRef]

- Kantaros, A.; Katsantoni, M.; Ganetsos, T.; Petrescu, N. The Evolution of Thermoplastic Raw Materials in High-Speed FFF/FDM 3D Printing Era: Challenges and Opportunities. Materials 2025, 18, 1220. [Google Scholar] [CrossRef]

- Marcinkowska, A.; Gajewski, P. 4D Printing of Polyurethane Actuators and Sensors. In Smart Materials in Additive Manufacturing, Volume 3; Elsevier: Amsterdam, The Netherlands, 2024; pp. 355–395. ISBN 9780443136733. [Google Scholar]

- Malekmohammadi, S.; Sedghi Aminabad, N.; Sabzi, A.; Zarebkohan, A.; Razavi, M.; Vosough, M.; Bodaghi, M.; Maleki, H. Smart and Biomimetic 3D and 4D Printed Composite Hydrogels: Opportunities for Different Biomedical Applications. Biomedicines 2021, 9, 1537. [Google Scholar] [CrossRef]

- Razzaq, M.Y.; Gonzalez-Gutierrez, J.; Farhan, M.; Das, R.; Ruch, D.; Westermann, S.; Schmidt, D.F. 4D Printing of Electroactive Triple-Shape Composites. Polymers 2023, 15, 832. [Google Scholar] [CrossRef] [PubMed]

- Pivar, M.; Vrabič-Brodnjak, U.; Leskovšek, M.; Gregor-Svetec, D.; Muck, D. Material Compatibility in 4D Printing: Identifying the Optimal Combination for Programmable Multi-Material Structures. Polymers 2024, 16, 2138. [Google Scholar] [CrossRef]

- The 17 Goals. Available online: https://sdgs.un.org/goals (accessed on 18 June 2025).

- Blasiak, S.; Bochnia, J.; Takosoglu, J.; Kozior, T.; Nowakowski, L.; Skrzyniarz, M.; Krzysztofik, I.; Blasiak, M.; Dindorf, R.; Wos, P. 3D/4D Printing in Advanced Robotics Systems—Recent Developments and Applications. Sustainability 2024, 16, 11174. [Google Scholar] [CrossRef]

- Aronne, M.; Polano, M.; Bertana, V.; Ferrero, S.; Frascella, F.; Scaltrito, L.; Marasso, S.L. Application of 3D and 4D Printing in Electronics. J. Manuf. Mater. Process. 2024, 8, 164. [Google Scholar] [CrossRef]

- Mahmood, A.; Akram, T.; Chen, H.; Chen, S. On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges. Polymers 2022, 14, 4698. [Google Scholar] [CrossRef] [PubMed]

- Pourmasoumi, P.; Moghaddam, A.; Nemati Mahand, S.; Heidari, F.; Salehi Moghaddam, Z.; Arjmand, M.; Kühnert, I.; Kruppke, B.; Wiesmann, H.-P.; Khonakdar, H.A. A Review on the Recent Progress, Opportunities, and Challenges of 4D Printing and Bioprinting in Regenerative Medicine. J. Biomater. Sci. Polym. Ed. 2023, 34, 108–146. [Google Scholar] [CrossRef]

- Pei, E.; Loh, G.H.; Nam, S. Concepts and Terminologies in 4D Printing. Appl. Sci. 2020, 10, 4443. [Google Scholar] [CrossRef]

- Kantaros, A. 3D Printing in Regenerative Medicine: Technologies and Resources Utilized. Int. J. Mol. Sci. 2022, 23, 14621. [Google Scholar] [CrossRef] [PubMed]

- Arvizu Alonso, A.K.; Armendáriz Mireles, E.N.; Calles Arriaga, C.A.; Rocha Rangel, E. Control of the Properties of the Voronoi Tessellation Technique and Biomimetic Patterns: A Review. Designs 2024, 8, 93. [Google Scholar] [CrossRef]

- Andreucci, C.A.; Fonseca, E.M.M.; Jorge, R.N. Biomechanics of a Novel 3D Mandibular Osteotomy Design. Designs 2024, 8, 57. [Google Scholar] [CrossRef]

- Pais, A.; Moreira, C.; Belinha, J. The Biomechanical Analysis of Tibial Implants Using Meshless Methods: Stress and Bone Tissue Remodeling Analysis. Designs 2024, 8, 28. [Google Scholar] [CrossRef]

- Chiesa, I.; Ceccarini, M.R.; Bittolo Bon, S.; Codini, M.; Beccari, T.; Valentini, L.; De Maria, C. 4D Printing Shape-Morphing Hybrid Biomaterials for Advanced Bioengineering Applications. Materials 2023, 16, 6661. [Google Scholar] [CrossRef]

- Aufa, A.N.; Ismail, Z.; Zaki Hassan, M. Emerging Trends in 4d Printing of Hydrogels in the Biomedical Field: A Review. Mater. Today Proc. 2023, 1–6. [Google Scholar] [CrossRef]

- Garcia-Villen, F.; López-Zárraga, F.; Viseras, C.; Ruiz-Alonso, S.; Al-Hakim, F.; Diez-Aldama, I.; Saenz-Del-Burgo, L.; Scaini, D.; Pedraz, J.L. Three-Dimensional Printing as a Cutting-Edge, Versatile and Personalizable Vascular Stent Manufacturing Procedure: Toward Tailor-Made Medical Devices. Int. J. Bioprint. 2023, 9, 664. [Google Scholar] [CrossRef] [PubMed]

- Nigro, V.; Angelini, R.; Bertoldo, M.; Buratti, E.; Franco, S.; Ruzicka, B. Chemical-Physical Behaviour of Microgels Made of Interpenetrating Polymer Networks of PNIPAM and Poly(Acrylic Acid). Polymers 2021, 13, 1353. [Google Scholar] [CrossRef]

- Dering, L.M.; Fernandes, B.L.; Pedro, M.K.F.; Leal, A.G.; de Souza, M.A. 3D and 4D Printing for Biomedical Applications. In 3D Printing; CRC Press: Boca Raton, FL, USA, 2023; pp. 325–338. ISBN 9781003296676. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.; Abdoli, H.; Diegel, O.; Chan, S.; Iliescu, M.; Ganetsos, T.; Munteanu, I.; Ungureanu, L. Additive Manufacturing for Surgical Planning and Education: A Review. Appl. Sci. 2024, 14, 2550. [Google Scholar] [CrossRef]

- Kim, J.; Gouripriya, D.A.; Saha, P. 4D-printed, Smart, Multiresponsive Structures and Their Applications. In 3D Bioprinting from Lab to Industry; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2024; pp. 231–250. [Google Scholar]

- Agarwal, T.; Chiesa, I.; Costantini, M.; Lopamarda, A.; Tirelli, M.C.; Borra, O.P.; Varshapally, S.V.S.; Kumar, Y.A.V.; Koteswara Reddy, G.; De Maria, C.; et al. Chitosan and Its Derivatives in 3D/4D (Bio) Printing for Tissue Engineering and Drug Delivery Applications. Int. J. Biol. Macromol. 2023, 246, 125669. [Google Scholar] [CrossRef] [PubMed]

- Frascio, M.; Morchio, S.; Musiari, F.; Muhammad Usman, K.; Dittamo, F.; Minuto, M.; Avalle, M. Investigating Multi-Material Additive Manufacturing for Disassembly and Reparability of Adhesive Joints by Precision Heating. Adhesives 2025, 1, 4. [Google Scholar] [CrossRef]

- Kantaros, A. Intellectual Property Challenges in the Age of 3D Printing: Navigating the Digital Copycat Dilemma. Appl. Sci. 2024, 14, 11448. [Google Scholar] [CrossRef]

- Kappou, S.; Souliotis, M.; Papaefthimiou, S.; Panaras, G.; Paravantis, J.A.; Michalena, E.; Hills, J.M.; Vouros, A.P.; Ntymenou, A.; Mihalakakou, G. Cool Pavements: State of the Art and New Technologies. Sustainability 2022, 14, 5159. [Google Scholar] [CrossRef]

- Tousi, E.; Tseliou, A.; Mela, A.; Sinou, M.; Kanetaki, Z.; Jacques, S. Exploring Thermal Discomfort during Mediterranean Heatwaves through Softscape and Hardscape ENVI-Met Simulation Scenarios. Sustainability 2024, 16, 6240. [Google Scholar] [CrossRef]

- Spanodimitriou, Y.; Ciampi, G.; Tufano, L.; Scorpio, M. Flexible and Lightweight Solutions for Energy Improvement in Construction: A Literature Review. Energies 2023, 16, 6637. [Google Scholar] [CrossRef]

- Gaspari, J.; Fabbri, K. Exploring the Effects of Climate-Adaptive Building Shells: An Applicative Time-Saving Algorithm on a Case Study in Bologna, Italy. Energies 2022, 15, 8168. [Google Scholar] [CrossRef]

- Khosromanesh, R. Towards Refining Bio-Inspired Hydro-Actuated Building Facades by Emphasising the Importance of Hybrid Adaptability. Sustainability 2024, 16, 959. [Google Scholar] [CrossRef]

- El-Dabaa, R.; Abdelmohsen, S. Hygroscopy and Adaptive Architectural Façades: An Overview. Wood Sci. Technol. 2023, 57, 557–582. [Google Scholar] [CrossRef]

- Farham, B.; Baltazar, L. A Review of Smart Materials in 4D Printing for Hygrothermal Rehabilitation: Innovative Insights for Sustainable Building Stock Management. Sustainability 2024, 16, 4067. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Firoozi, A.A. A Systematic Review of the Role of 4D Printing in Sustainable Civil Engineering Solutions. Heliyon 2023, 9, e20982. [Google Scholar] [CrossRef] [PubMed]

- Niazy, D.; Elsabbagh, A.; Ismail, M.R. Mono-Material 4D Printing of Digital Shape-Memory Components. Polymers 2021, 13, 3767. [Google Scholar] [CrossRef]

- Yang, D.; Mei, H.; Yao, L.; Yang, W.; Yao, Y.; Cheng, L.; Zhang, L.; Dassios, K.G. 3D/4D Printed Tunable Electrical Metamaterials with More Sophisticated Structures. J. Mater. Chem. C Mater. Opt. Electron. Devices 2021, 9, 12010–12036. [Google Scholar] [CrossRef]

- Jin, Z.; Wei, X.; He, X.; Wang, Z.; Zhao, Z.; He, H.; Yang, Y.; Chen, N. Research Progress and Emerging Directions in Stimulus Electro-Responsive Polymer Materials. Materials 2024, 17, 4204. [Google Scholar] [CrossRef]

- Trovato, V.; Sfameni, S.; Rando, G.; Rosace, G.; Libertino, S.; Ferri, A.; Plutino, M.R. A Review of Stimuli-Responsive Smart Materials for Wearable Technology in Healthcare: Retrospective, Perspective, and Prospective. Molecules 2022, 27, 5709. [Google Scholar] [CrossRef]

- Alkahtani, M.E.; Elbadawi, M.; Chapman, C.A.R.; Green, R.A.; Gaisford, S.; Orlu, M.; Basit, A.W. Electroactive Polymers for On-Demand Drug Release. Adv. Healthc. Mater. 2024, 13, e2301759. [Google Scholar] [CrossRef] [PubMed]

- Jeewantha, L.H.J. Shape Memory Polymer Composite for Adaptive Components for Orthosis and Lower Limb Fracture Fixators. Ph.D. Thesis, University of Southern Queensland, Toowoomba, Australia, 2023. [Google Scholar]

- Srivastava, R.; Alsamhi, S.H.; Murray, N.; Devine, D. Shape Memory Alloy-Based Wearables: A Review, and Conceptual Frameworks on HCI and HRI in Industry 4.0. Sensors 2022, 22, 6802. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Asyraf, M.R.M.; Syamsir, A.; Najeeb, M.I.; Alhayek, A.; Al-Dala’ien, R.N.; Manar, G.; Atiqah, A. Thermochromic Polymer Nanocomposites for the Heat Detection System: Recent Progress on Properties, Applications, and Challenges. Polymers 2024, 16, 1545. [Google Scholar] [CrossRef]

- Behera, A.; Sahoo, A.K.; Mohapatra, S.S. Nickel–Titanium Smart Hybrid Materials for Automotive Industry. In Nickel-Titanium Smart Hybrid Materials; Elsevier: Amsterdam, The Netherlands, 2022; pp. 271–295. ISBN 9780323911733. [Google Scholar]

- Raghunandan, K. Tracking, Monitoring, and Proximity Usage. In Introduction to Wireless Communications and Networks; Springer International Publishing: Cham, Switzerland, 2022; pp. 163–176. ISBN 9783030921873. [Google Scholar]

- Yang, X.; Sayono, J.; Xu, J.; Li, J.N.; Hester, J.; Zhang, Y. MiniKers: Interaction-Powered Smart Environment Automation. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 2022, 6, 1–22. [Google Scholar] [CrossRef]

- Liu, Y.; Nishikawa, S.; Seong, Y.A.; Niiyama, R.; Kuniyoshi, Y. ThermoCaress: A Wearable Haptic Device with Illusory Moving Thermal Stimulation. In Proceedings of the 2021 CHI Conference on Human Factors in Computing Systems, Online, 8–13 May 2021; ACM: New York, NY, USA, 2021. [Google Scholar]

- Su, M.; Song, Y. Printable Smart Materials and Devices: Strategies and Applications. Chem. Rev. 2022, 122, 5144–5164. [Google Scholar] [CrossRef]

- Bhanushali, H.; Amrutkar, S.; Mestry, S.; Mhaske, S.T. Shape Memory Polymer Nanocomposite: A Review on Structure–Property Relationship. Polym. Bull. 2022, 79, 3437–3493. [Google Scholar] [CrossRef]

- Petelinšek, N.; Mommer, S. Tough Hydrogels for Load-Bearing Applications. Adv. Sci. 2024, 11, e2307404. [Google Scholar] [CrossRef]

- Dong, X.; Wang, C.; Song, H.; Shao, J.; Lan, G.; Zhang, J.; Li, X.; Li, M. Advancement in Soft Hydrogel Grippers: Comprehensive Insights into Materials, Fabrication Strategies, Grasping Mechanism, and Applications. Biomimetics 2024, 9, 585. [Google Scholar] [CrossRef]

- Kruk, T.; Chojnacka-Górka, K.; Kolasińska-Sojka, M.; Zapotoczny, S. Stimuli-Responsive Polyelectrolyte Multilayer Films and Microcapsules. Adv. Colloid Interface Sci. 2022, 310, 102773. [Google Scholar] [CrossRef]

- McCune, J.A.; Mommer, S.; Parkins, C.C.; Scherman, O.A. Design Principles for Aqueous Interactive Materials: Lessons from Small Molecules and Stimuli-Responsive Systems. Adv. Mater. 2020, 32, e1906890. [Google Scholar] [CrossRef] [PubMed]

- Javaid, M.; Haleem, A.; Singh, R.P.; Rab, S.; Suman, R.; Kumar, L. Significance of 4D Printing for Dentistry: Materials, Process, and Potentials. J. Oral Biol. Craniofacial Res. 2022, 12, 388–395. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, F.A.; Werner, C.M.L. A Scoping Review of the Metaverse for Software Engineering Education: Overview, Challenges, and Opportunities. Presence 2022, 31, 107–146. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O.; Piromalis, D.; Tsaramirsis, G.; Khadidos, A.O.; Khadidos, A.O.; Khan, F.Q.; Jan, S. 3D Printing: Making an Innovative Technology Widely Accessible through Makerspaces and Outsourced Services. Mater. Today 2022, 49, 2712–2723. [Google Scholar] [CrossRef]

- Enyan, M.; Bing, Z.; Amu-Darko, J.N.O.; Issaka, E.; Otoo, S.L.; Agyemang, M.F. Advances in Smart Materials Soft Actuators on Mechanisms, Fabrication, Materials, and Multifaceted Applications: A Review. J. Thermoplast. Compos. Mater. 2025, 38, 302–370. [Google Scholar] [CrossRef]

- Dong, Y.; Ramey-Ward, A.N.; Salaita, K. Programmable Mechanically Active Hydrogel-Based Materials. Adv. Mater. 2021, 33, e2006600. [Google Scholar] [CrossRef]

- Xu, Y.; Xu, Z.-D.; Guo, Y.-Q.; Jia, H.; Huang, X.; Wen, Y. Mathematical Modeling and Test Verification of Viscoelastic Materials Considering Microstructures and Ambient Temperature Influence. Mech. Adv. Mater. Struct. 2022, 29, 7063–7074. [Google Scholar] [CrossRef]

- Stohlmann, M.; Yang, Y. Investigating the Alignment to Mathematical Modelling of Teacher-Created Mathematical Modelling Activities Available Online. Int. J. Math. Educ. Sci. Technol. 2023, 54, 671–686. [Google Scholar] [CrossRef]

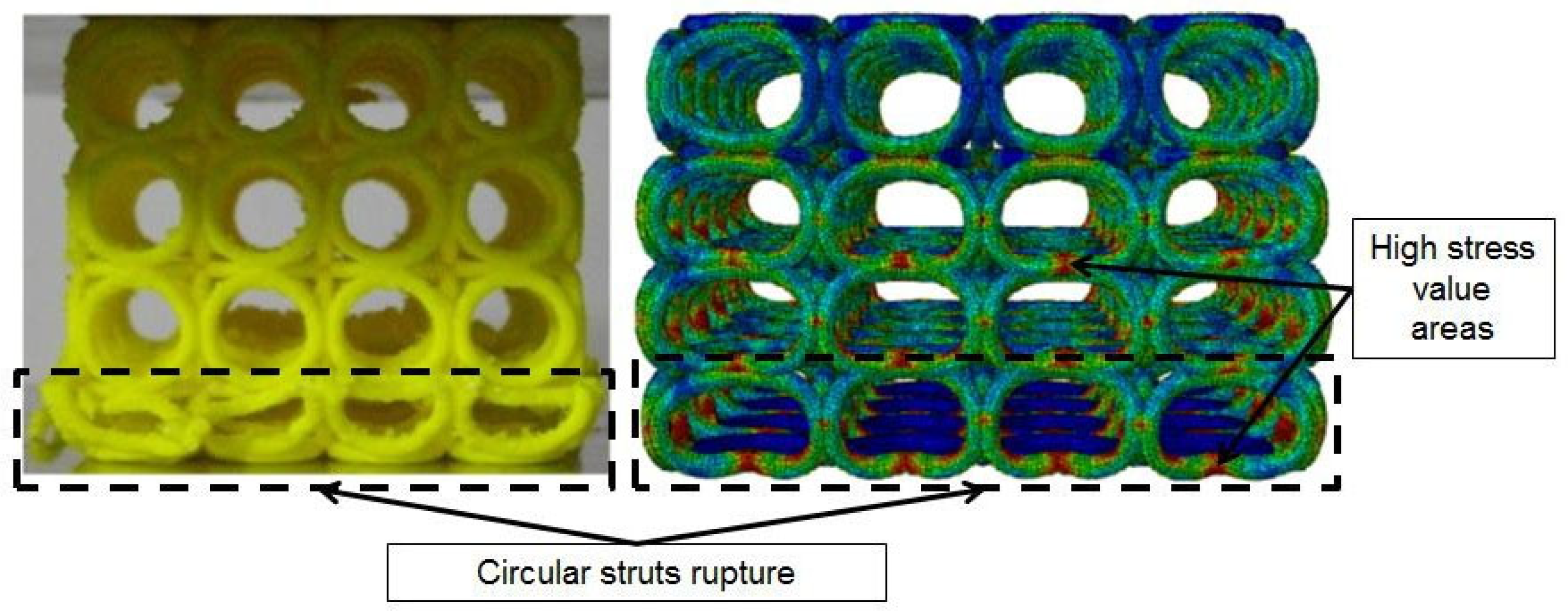

- Kaya, G.; Yıldız, F.; Solak, K.; Orhan, S.N. An Experimental and FEA Investigation of Deformation Characteristics of Additively Manufactured Ti6Al4V Lattice Structures. Eur. J. Mech. A Solids 2025, 112, 105657. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T. Integration of Cyber-Physical Systems, Digital Twins and 3D Printing in Advanced Manufacturing: A Synergistic Approach. Am. J. Eng. Appl. Sci. 2024, 17, 1–22. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D. Setting up a Digital Twin Assisted Greenhouse Architecture. Am. J. Eng. Appl. Sci. 2022, 15, 230–238. [Google Scholar] [CrossRef]

- Kantaros, A.; Chatzidai, N.; Karalekas, D. 3D Printing-Assisted Design of Scaffold Structures. Int. J. Adv. Manuf. Technol. 2016, 82, 559–571. [Google Scholar] [CrossRef]

- Design and Characterization of 3D Structures for Biomedical Applications. Available online: https://www.openarchives.gr/aggregator-openarchives/edm/phdtheses/000040-10442_38784 (accessed on 17 July 2025).

- Gibson, L.J. Biomechanics of Cellular Solids. J. Biomech. 2005, 38, 377–399. [Google Scholar] [CrossRef] [PubMed]

- Shahi, K.; Ramachandran, V. Theoretical and Experimental Investigation of Shape Memory Polymers Programmed below Glass Transition Temperature. Polymers 2022, 14, 2753. [Google Scholar] [CrossRef] [PubMed]

- Arricca, M.; Inverardi, N.; Pandini, S.; Toselli, M.; Messori, M.; Scalet, G. Finite Strain Continuum Phenomenological Model Describing the Shape-Memory Effects in Multi-Phase Semi-Crystalline Networks. J. Mech. Phys. Solids 2025, 195, 105955. [Google Scholar] [CrossRef]

| Material Type | Primary Stimulus | Response Mechanism | Representative Applications |

|---|---|---|---|

| Shape-Memory Polymers (SMPs) | Heat, Light | Thermo-induced phase transition | Self-deploying structures, soft robotics, medical devices |

| Hydrogels | Humidity, pH, Temperature | Water absorption/desorption, swelling | Wound dressings, drug delivery, passive actuators |

| Electroactive Polymers (EAPs) | Electric Field | Ionic/electronic displacement and actuation | Artificial muscles, sensors, haptic interfaces |

| Photochromic Materials | Light (UV/Visible) | Reversible molecular structure change | Smart windows, responsive coatings, wearable sensors |

| Magneto-responsive Polymers | Magnetic Field | Alignment/reorientation of magnetic nanoparticles | Controlled drug release, shape-shifting components |

| pH-responsive Polymers | pH Variation | Ionization/deionization of functional groups | Targeted drug delivery, biosensors |

| Application Domain | Primary Materials | Stimuli | Functional Objective |

|---|---|---|---|

| Regenerative Medicine | SMPs, Hydrogels, Bioactive Composites | Temperature, pH, Moisture | Scaffold actuation, drug release, tissue growth |

| Architecture | Hygromorphic Wood, Bilayer Composites | Humidity, Heat, Light | Passive regulation, climate adaptation |

| Wearables and Mobility | EAPs, SMPs, Thermo-responsive Textiles | Heat, Electrical Input, Movement | Personalization, ergonomic support |

| Consumer Products | SMPs, Photoresponsive Polymers | Heat, Light | Interaction, safety, adaptability |

| Domain | Challenge | Manifestation | Proposed Mitigation |

|---|---|---|---|

| Technical | Material limitations | Limited strength, fatigue behavior, narrow actuation range | Development of hybrid materials, enhanced mathematical simulation tools |

| Technical | Process control | Difficulty in precise deformation, inter-material compatibility | Improved CAD/CAM tools, real-time printing feedback, multi-material calibration |

| Educational | Curricular integration | Lack of exposure to responsive systems in design education | Interdisciplinary teaching modules, design-lab infrastructure |

| Educational | Limited access to tools | Scarcity of smart material libraries and multi-material printers | Funding for maker spaces, open-source educational platforms |

| Ethical/Societal | Material autonomy and user trust | Unpredictable behavior, loss of control, system black-boxing | Transparency in design, user-informed feedback loops |

| Ethical/Societal | Cultural oversights | Marginalization of traditional and ecological knowledge | Inclusion of local design practices, ethics in design curricula |

| Ethical/Societal | Data privacy and embedded sensing | Potential surveillance or data misuse through responsive materials | Development of clear privacy protocols, consent-driven design practices |

| Mathematical Model/Approach | Core Equation | Problem Type Solved | Representative Application | |

|---|---|---|---|---|

| Power Law for Cellular Structures (Ashby & Gibson) | (1) | Prediction of effective modulus from relative density | Mechanical optimization of lattice scaffolds | |

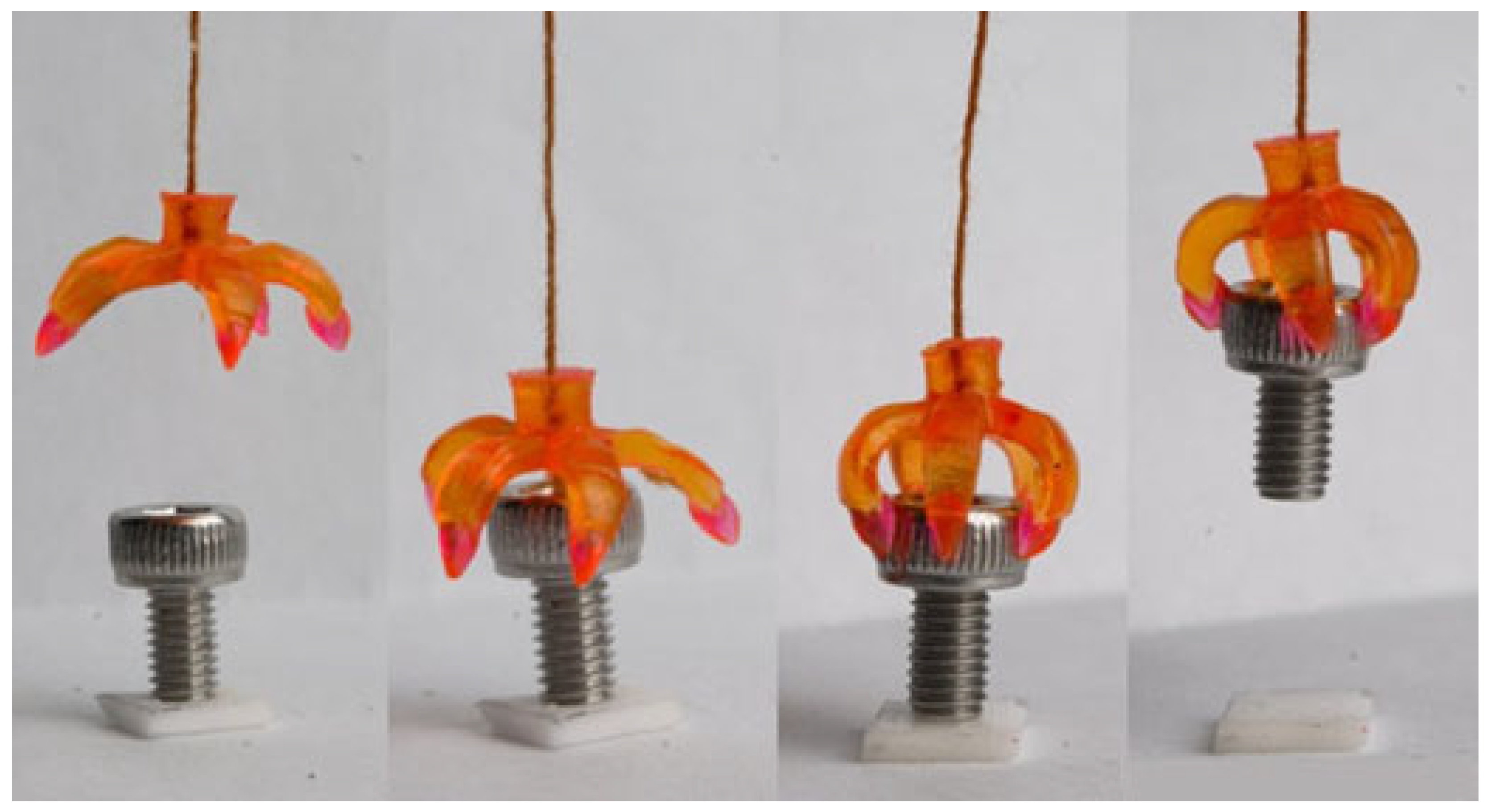

| Finite Element Analysis (FEA) | (2) | Stress–strain distribution, deformation paths under load | SMP microgrippers, biomedical scaffolds | |

| (Discretized governing equations of elasticity and thermomechanics) | ||||

| Viscoelastic Constitutive Models | (3) | Time-dependent mechanical response | SMPs under torsion, cyclic loading | |

| Multiphysics Coupling Models | σ = C(c,T):[ε(u) − εth(T) − εsw(c)] | (4) | Thermo-responsive actuation, hydrogel swelling | Climate-adaptive facades, soft actuators |

| Coupled PDEs for mechanical, thermal, and swelling effects | ||||

| Parametric Simulation and Optimization | X(ξ;p) = X0(ξ) + ψi(ξ) | (5) | Shape and performance optimization | Lightweight adaptive architectural components |

| Parametric function for geometry mapping | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kantaros, A.; Ganetsos, T.; Pallis, E.; Papoutsidakis, M. Smart Design Aided by Mathematical Approaches: Adaptive Manufacturing, Sustainability, and Biomimetic Materials. Designs 2025, 9, 102. https://doi.org/10.3390/designs9050102

Kantaros A, Ganetsos T, Pallis E, Papoutsidakis M. Smart Design Aided by Mathematical Approaches: Adaptive Manufacturing, Sustainability, and Biomimetic Materials. Designs. 2025; 9(5):102. https://doi.org/10.3390/designs9050102

Chicago/Turabian StyleKantaros, Antreas, Theodore Ganetsos, Evangelos Pallis, and Michail Papoutsidakis. 2025. "Smart Design Aided by Mathematical Approaches: Adaptive Manufacturing, Sustainability, and Biomimetic Materials" Designs 9, no. 5: 102. https://doi.org/10.3390/designs9050102

APA StyleKantaros, A., Ganetsos, T., Pallis, E., & Papoutsidakis, M. (2025). Smart Design Aided by Mathematical Approaches: Adaptive Manufacturing, Sustainability, and Biomimetic Materials. Designs, 9(5), 102. https://doi.org/10.3390/designs9050102