Abstract

The increased importance of sustainability imperatives has required a profound reconsideration of the interaction between materials, manufacturing, and design fields. Biomimetic smart materials such as shape-memory polymers, hydrogels, and electro-active composites represent an opportunity to combine adaptability, responsiveness, and ecological intelligence in systems and products. This work reviews the confluence of such materials with leading-edge manufacturing technologies, notably additive and 4D printing, and how their combining opens the door to the realization of time-responsive, low-waste, and user-adaptive design solutions. Through computational modeling and mathematical simulations, the adaptive performance of these materials can be predicted and optimized, supporting functional integration with high precision. On the basis of case studies in regenerative medicine, architecture, wearables, and sustainable product design, this work formulates the possibility of biomimetic strategies in shifting design paradigms away from static towards dynamic, from fixed products to evolvable systems. Major material categories of stimuli-responsive materials are systematically reviewed, existing 4D printing workflows are outlined, and the way temporal design principles are revolutionizing production, interaction, and lifecycle management is discussed. Quantitative advances such as actuation efficiencies exceeding 85%, printing resolution improvements of up to 50 μm, and lifecycle material savings of over 30% are presented where available, to underscore measurable impact. Challenges such as material scalability, process integration, and design education shortages are critically debated. Ethical and cultural implications such as material autonomy, transparency, and cross-cultural design paradigms are also addressed. By identifying existing limitations and proposing a future-proof framework, this work positions itself within the ongoing discussion on regenerative, interdisciplinary design. Ultimately, it contributes to the advancement of sustainable innovation by equipping researchers and practitioners with a set of adaptable tools grounded in biomimicry, computational intelligence, and temporal design thinking.

1. Introduction

In recent years, the role of design has been redefined, evolving from a primarily aesthetic and functional pursuit into a strategic instrument for advancing sustainability, innovation, and systemic resilience [1]. This transformation has been driven by mounting ecological and societal pressures, which have necessitated the development of materials and production methods that align more closely with long-term environmental and ethical imperatives [2,3]. Within this emerging landscape, biomimetic smart materials have been increasingly recognized for their potential to emulate the adaptive, regenerative, and resource-efficient behaviors observed in natural systems [4,5].

Through the engineering of responsive functionalities—such as shape transformation, self-healing capabilities, and environmental sensitivity—these materials have introduced a new sector in design thinking [6]. When integrated into advanced fabrication technologies, including additive and four-dimensional (4D printing), such materials have enabled the creation of objects capable of evolving over time [7]. This evolution is achieved through stimuli-responsiveness to external conditions such as heat, moisture, light, or chemical environment, thereby embedding dynamic behavior directly within the physical structure of the artifact [8]. As a result, a temporal dimension has been incorporated into the design process, wherein objects are no longer perceived as static entities but as systems capable of adaptation throughout their lifecycle [9,10]. The distinction between conventional additive manufacturing and 4D printing is illustrated in Figure 1, where the inclusion of time-responsive behavior marks a significant shift in how material properties and functions are programmed into designed objects.

Figure 1.

Comparison between conventional 3D printing and 4D printing. Unlike static 3D-printed objects, 4D-printed structures incorporate stimuli-responsive materials that enable shape or property transformations over time in response to environmental triggers.

While Figure 1 offers a conceptual overview of the transition from static to time-responsive fabrication, it is important to recognize the performance boundaries of various smart material classes. Recent comparative studies report maximum deformation rates ranging from 10%/s in hydrogel-based systems to over 50%/s in electroactive polymers, with cycle life spanning from 100 to 1000 cycles for thermo-responsive composites to over 10,000 cycles in magneto-rheological elastomers under controlled loading conditions [11]. Responsiveness, actuation force, and recovery time vary widely depending on composition, environmental conditions, and fabrication method. Although a comprehensive quantitative table is beyond the scope of this review, the literature offers detailed datasets that can support targeted material selection for specific applications. By framing these metrics in design-relevant terms, future research can better bridge laboratory performance with real-world functional requirements.

This temporal approach to design has opened new opportunities in fields where responsiveness and material efficiency are essential, including regenerative medicine [11], climate-adaptive architecture [12], and sustainable consumer product development [13]. It has allowed for the emergence of solutions that are not only functionally sophisticated but also environmentally integrative—reducing material redundancy, extending product lifespan, and enabling disassembly or reuse without extensive resource input [14].

Nonetheless, several limitations continue to hinder the widespread implementation of biomimetic smart materials and temporal design principles. Challenges have been encountered in material scalability, cross-disciplinary integration, and the development of intuitive design tools capable of simulating time-dependent behaviors [15]. In addition, traditional pedagogical and industrial frameworks have remained predominantly focused on static form-making, thereby restricting the conceptualization and execution of dynamic, performance-driven design strategies [16]. Ethical considerations related to material autonomy, user agency, and systemic transparency have further complicated the discourse surrounding adaptive artifacts [17].

In response to these multifaceted challenges, this work has been composed to offer a critical synthesis of the state of the art in biomimetic smart materials and their application within advanced manufacturing contexts. Emphasis has been placed on the classification and behavior of stimuli-responsive materials, the integration of such materials into additive manufacturing workflows, and the exploration of their implications in practical application domains. Through a comprehensive examination of current research and emerging practices, a framework is proposed to support the continued development of sustainable, interdisciplinary design methodologies. In this way, biomimetic materials are positioned not only as functional innovations, but as foundational elements in the construction of responsive, regenerative, and human-centered design features.

By integrating mathematical modeling frameworks, designers can predict stimuli-responsive transformations, simulate structural behaviors, and optimize fabrication strategies for biomimetic materials and smart products. This perspective therefore emphasizes not only the material and technological advances, but also the mathematical foundations that enable adaptive design and sustainable innovation. Building upon this foundation, the present work introduces a multi-level synthesis that advances the discourse on biomimetic smart materials and their role in shaping adaptive, sustainable design futures. By bridging material typologies with temporal design frameworks, the study provides a structured perspective on how stimuli-responsive systems can inform design strategies across scales and disciplines. Furthermore, the integration of these materials within additive and 4D manufacturing workflows is examined through representative application domains, offering insight into real-world deployment potentials and limitations. Central to this content is the incorporation of mathematical modeling as a means to simulate, predict, and optimize the behavior of smart materials under varying stimuli, reinforcing the argument for data-driven, performance-aware design methodologies.

2. Biomimetic Smart Materials: Principles and Classifications

2.1. Definitions and Typologies

Biomimetic smart materials have been defined as synthetic or hybrid substances engineered to replicate the adaptive, responsive, and efficient properties observed in biological systems [18]. Unlike conventional industrial materials, which tend to exhibit passive and inert behaviors, these advanced materials are capable of responding dynamically to specific environmental stimuli [19]. Within the context of sustainable design, biomimetic smart materials have been increasingly utilized for their ability to self-adjust, self-heal, or perform programmed transformations, making them ideal candidates for time-sensitive or resource-efficient applications [20]. These materials are frequently characterized by their ability to operate within complex, multi-functional roles, thereby enabling the replacement of mechanically intensive components with lighter, more efficient alternatives [21].

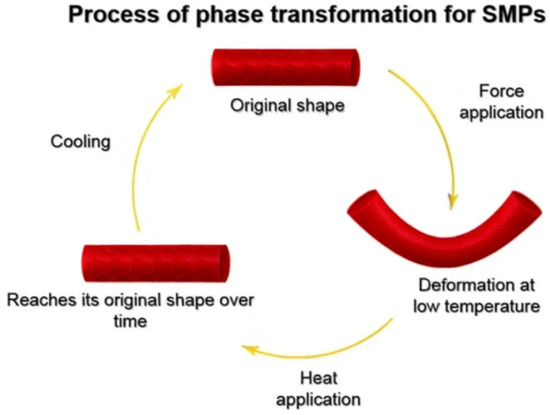

Several primary classes of biomimetic smart materials have been widely studied for integration into design and manufacturing processes. Shape-memory polymers (SMPs) have been developed to undergo reversible deformation in response to thermal or optical cues, while hydrogels have been engineered to exhibit significant volumetric expansion or contraction upon changes in humidity, temperature, or pH [22,23].

Among these smart materials, thermo-responsive hydrogels are notable for exhibiting a phenomenon known as the Low Critical Solution Temperature (LCST). Below their LCST, the polymer chains are hydrated and expanded, resulting in a swollen hydrogel network; above this temperature, the polymer undergoes a phase transition, expelling water and collapsing in volume. This behavior enables the design of thermal switches or actuators that respond to body temperature or environmental heat. A classic example is poly(N-isopropylacrylamide) (PNIPAM), which has an LCST around 32 °C, making it highly relevant for biomedical applications. Similarly, pH-responsive polymers incorporate ionizable functional groups—such as carboxylic or amino groups—that accept or release protons in response to environmental pH shifts. This ionization causes the polymer chains to expand or contract, inducing controlled swelling or shrinking of the material. Such characteristics are fundamental for targeted drug delivery, biosensors, and tissue engineering where localized pH variations are leveraged for functional response.

Electroactive polymers (EAPs), which deform in response to electrical stimulation, have also attracted attention due to their high actuation strain and relatively low weight [24,25]. Additional categories such as magneto-responsive materials [26], photochromic compounds [27], and pH-sensitive composites [28] have broadened the typological scope of biomimetic materials, offering a diverse palette of programmable behaviors. These classifications are not rigidly distinct; rather, they represent overlapping functionalities that can be strategically selected and combined depending on the application context.

2.2. Stimuli–Response Mechanisms

The core functionality of biomimetic smart materials lies in their ability to undergo controlled physical or chemical transformations when exposed to predefined external stimuli. These transformations are governed by internal mechanisms such as polymer chain mobility, crosslinking density, phase transitions, or ionic conductivity, depending on the material class [29]. For instance, in shape-memory polymers, temporary deformations are fixed by cooling or chemical treatment and are subsequently reversed upon heating above a critical transition temperature [30]. In hydrogels, stimulus-induced water absorption or release drives rapid changes in shape or porosity, mediated by the polymer’s affinity to hydrophilic or hydrophobic interactions [31]. Electroactive polymers, on the other hand, utilize ion migration or electron flow to induce bending, contraction, or expansion under applied electric fields [32,33].

Each stimuli–response mechanism offers distinct advantages and constraints that must be considered during material selection and design integration. Thermal responsiveness, as exhibited by SMPs and some hydrogels, allows for programmable actuation but may be limited by the energy requirements for heating [34,35]. pH and ionic sensitivity, commonly used in biomedical applications, enable precise control in chemically complex environments but are highly dependent on local conditions [36]. For example, in thermo-responsive hydrogels based on poly(N-isopropylacrylamide) (PNIPAM), derived from the monomer N-isopropylacrylamide (NIPAAm), the LCST phase transition can be precisely exploited to trigger volume changes near physiological temperatures, enabling temperature-controlled actuation or drug release. Similarly, pH-sensitive hydrogels such as poly(acrylic acid) (PAAc), derived from acrylic acid (AAc), exhibit swelling behavior that depends on the ionization state of pendant functional groups, providing predictable, reversible responses within specific acidic or alkaline environments. Light-responsive materials offer non-contact actuation and spatial resolution, though their performance is restricted by penetration depth and wavelength specificity [37]. Similarly, electrically responsive materials provide rapid and controllable deformation, though they may necessitate embedded circuitry or conductive layers [38]. Understanding the underlying stimuli–response dynamics is therefore essential to ensure compatibility between material behavior and intended design functions.

The responsive behavior of smart hydrogels, especially those exhibiting LCST or pH sensitivity, is commonly characterized by measuring the swelling ratio as a function of temperature or pH [39]. This involves determining the volume or weight change in the hydrogel network when exposed to different external conditions, offering insight into the material’s phase transition point, responsiveness speed, and reversibility. Such swelling–deswelling cycles are essential for validating the functional reliability of hydrogels in biomedical and soft robotics applications.

Another widely used method involves contact angle measurements under varying stimuli, which provide quantitative information on changes in surface wettability [40]. In thermo- or pH-responsive materials, a change in temperature or pH can trigger conformational rearrangements in polymer chains, resulting in measurable shifts in hydrophilicity or hydrophobicity. These surface transitions are particularly important for applications involving controlled adhesion, anti-fouling surfaces, or drug release, and are typically analyzed using goniometry under controlled environmental conditions.

2.3. Examples from Nature and Their Engineered Analogs

Biomimetic smart materials have often been inspired by specific biological models that exemplify evolutionary efficiency in adaptability and responsiveness. The behavior of the Mimosa pudica plant, which closes its leaves upon touch, has informed the development of tactile-responsive actuators [41]. The hygroscopic movement observed in pinecones and seed pods, which open and close based on ambient humidity, has led to the design of humidity-driven passive ventilation systems using hydrogels and bilayer composites [42]. Similarly, the iridescent color change in cephalopods [43] and certain butterfly species [44] has provided templates for structurally colored materials that respond to mechanical or thermal stimuli. These examples underscore how precise, energy-efficient, and material-conserving behaviors found in nature can be abstracted and translated into engineered systems.

The engineered analogs derived from these natural phenomena often replicate not only the functionality but also the hierarchical structuring and multi-scale organization seen in biological systems. For instance, synthetic muscle actuators have been constructed using EAPs to mimic the contractile function of human muscle fibers, offering promising applications in soft robotics and adaptive wearables [45,46]. Self-cleaning surfaces based on the micro/nano-structured lotus leaf have been replicated in hydrophobic coatings for packaging and textiles [47,48]. In another case, spider silk’s high tensile strength and elasticity have guided the design of biodegradable, high-performance fibers for biomedical scaffolds [49,50]. Through these analogs, it is exhibited that nature has not only served as a source of design inspiration but also as a blueprint for sustainable, high-performance design solutions that merge material behavior with system-level function.

To provide a comparative overview of the biomimetic smart materials discussed above, Table 1 summarizes their primary stimuli-responsiveness, underlying mechanisms, and representative application areas. This synthesis highlights the diversity and functional versatility of these materials, underscoring their potential for integration into adaptive, sustainable design systems across domains such as healthcare, architecture, and product innovation.

Table 1.

Summary of key biomimetic smart materials, their stimuli, response mechanisms, and applications.

The integration of biomimetic smart materials into contemporary design and manufacturing offers numerous transformative advantages. These materials exhibit tailored responsiveness to specific environmental stimuli—such as heat, light, moisture, magnetic fields, and pH—enabling functionalities that surpass the capabilities of traditional passive materials. Their ability to undergo reversible changes in shape, volume, surface properties, or mechanical performance facilitates the development of self-deploying, self-healing, or environmentally adaptive systems. This versatility supports lightweight design, energy efficiency, and reduced mechanical complexity across fields as diverse as regenerative medicine, climate-adaptive architecture, and interactive consumer products.

However, alongside these promising capabilities lie several limitations that warrant careful consideration. Challenges include limited mechanical strength or fatigue resistance in certain classes (e.g., hydrogels), sensitivity to environmental noise, slower response times, and complex multi-material processing requirements. Furthermore, integrating these materials into functional devices often requires sophisticated modeling, precise stimuli control, and customized fabrication setups—factors that can hinder scalability and commercial adoption. Ethical questions around material autonomy and user transparency also emerge, particularly as materials gain the ability to act without continuous user input.

In conclusion, while biomimetic smart materials present a compelling example for designing responsive and sustainable systems, their practical implementation depends on a nuanced understanding of both their potentials and constraints. As the following sections will illustrate, the true value of these materials emerges when their unique behaviors are purposefully matched to the contextual needs of the application—transforming design from a static exercise into a dynamic, time-aware process.

3. Temporal Design and 4D Printing: Technologies and Trends

The increasing demand for adaptable and sustainable design solutions has led to the emergence of temporal design as a distinct and evolving example. Temporal design is characterized by the intentional incorporation of time-dependent behavior into the lifecycle of designed objects, enabling modifications in form, function, or performance in response to external stimuli. Unlike traditional static artifacts, temporally designed systems are conceived as dynamic entities whose operational characteristics may evolve throughout their use phase [51]. This approach change has been facilitated by advances in stimuli-responsive materials and additive manufacturing technologies, which together support the development of objects capable of autonomous adaptation to environmental conditions.

Recent studies increasingly employ mathematical models to describe the time-dependent responses of shape-memory polymers and other stimuli-responsive systems [52]. Finite element analysis (FEA), parametric equations, and data-driven mathematical simulations are commonly used to predict deformation pathways, stress distribution, and functional lifespan under varying environmental triggers. Embedding these mathematical methods into the design process helps bridge the gap between material science and real-world adaptive performance.

Among the most significant developments enabling temporal design is the advent of 4D printing, an extension of additive manufacturing in which material behavior over time is embedded during the fabrication process [52]. In this context, the “fourth dimension” refers to the programmed transformation of objects post-fabrication, typically triggered by thermal, chemical, mechanical, or electromagnetic stimuli. This capability allows for the creation of structures that are not only geometrically complex but also functionally programmable, with potential applications in architecture, biomedical engineering, robotics, and consumer product design. The following sections examine the conceptual shift from static to dynamic artifacts, describe key 4D printing methods and materials, and provide a comparative assessment of 4D printing relative to traditional additive manufacturing.

3.1. From Static to Dynamic Objects

Traditional design methodologies have long been rooted in the production of static objects—artifacts whose shape, structure, and function are predetermined and remain unchanged throughout their lifecycle. In such systems, adaptability is often externally imposed through mechanical assemblies, user interventions, or replacement strategies. These approaches, while effective in many contexts, often result in over-engineering, increased material consumption, and limited responsiveness to changing environmental or user conditions. Consequently, once produced, the object becomes a fixed solution to a fixed problem, rendering it vulnerable to obsolescence in the face of evolving needs or contexts.

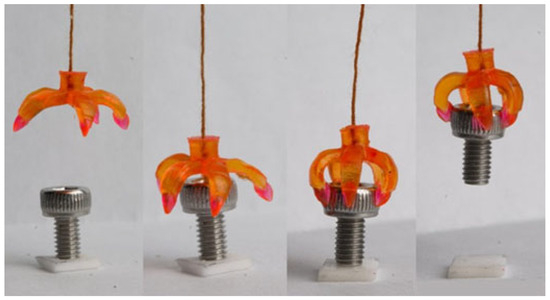

Temporal design offers an alternative paradigm by embedding the potential for transformation directly into the object itself. Through the use of biomimetic smart materials and digitally driven fabrication processes, objects can be designed to respond autonomously to temperature, humidity, pH, or other environmental cues. This enables functions such as shape change, self-deployment, or performance optimization without additional hardware or power sources [53]. Rather than designing for a single optimal state, the focus shifts to designing a behavioral envelope—an orchestrated range of potential states that the object may adopt over time [54]. Such dynamic behavior introduces new forms of interaction, personalization, and sustainability, as the object becomes co-constitutive with its environment and capable of continuous adaptation [55]. Figure 2 depicts a characteristic case, in the published literature work of Ge et al. [56], exhibiting the capabilities of multi-material 4D printing to produce functionally graded and programmable actuators as exemplified in the development of shape-memory polymer (SMP)-based microgrippers.

Figure 2.

Three-dimensional printed multi-material grippers. Time-lapsed snapshots of the gripper performing an object-grabbing action. Source: Adapted from Ge et al., 2016, Scientific Reports, under open-access license (CC BY 4.0) [56].

3.2. Four-Dimensional Printing Methods and Materials

The implementation of temporal design principles has been made possible through the development of 4D printing technologies [57], which combine additive manufacturing with stimuli-responsive materials [58,59,60]. Various printing techniques have been adapted to support 4D capabilities, including fused deposition modeling (FDM) [61,62], direct ink writing (DIW) [63], stereolithography (SLA) [64,65,66], and inkjet-based systems [67]. In each case, the key requirement lies in the compatibility between the printing process and the functional properties of the smart material being used. For example, SMPs are often processed through FDM due to their thermoplastic nature [68], whereas hydrogels and other soft composites are more effectively deployed using DIW or extrusion-based methods [69]. Additionally, printing parameters such as temperature, layer orientation, and interfacial adhesion play a critical role in determining the fidelity and repeatability of the programmed transformations [70].

A wide range of stimuli-responsive materials has been incorporated into 4D printing workflows, each selected for its unique actuation properties. SMPs remain one of the most commonly employed materials due to their relatively low cost, tunable transition temperatures, and processability [71]. Hydrogels are also widely used, particularly in biomedical applications, for their high swelling capacity and biocompatibility [72]. Electroactive polymers, although more technically demanding, provide rapid and reversible deformation under electrical input, making them suitable for applications requiring precision actuation [73]. Emerging classes of multi-material systems and composite structures have been developed to combine active and passive layers, enabling more complex and programmable behavior [74].

As 4D printing progresses, increased attention is being given to the development of bio-based, recyclable, and energy-efficient materials to ensure alignment with broader sustainability goals. The integration of 4D printing with bio-based and stimuli-responsive materials supports a broad spectrum of Sustainable Development Goals (SDGs) through its transformative impact on design, production, and application. As a driver of advanced manufacturing, 4D printing aligns with SDG 9 by fostering innovation and enabling resilient infrastructure. Its emphasis on recyclable and energy-efficient materials directly supports SDG 12, while the reduction in energy use and material waste contributes to SDG 13 and broader climate action efforts. In biomedical contexts, personalized and minimally invasive 4D-printed devices advance SDG 3, promoting health and well-being. Smart materials used in responsive architectural systems enhance urban adaptability, resonating with SDG 11, and the incorporation of these technologies into design education encourages interdisciplinary competence and innovation, contributing to SDG 4 [75]. These alignments underscore the systemic value of 4D printing in advancing sustainable development across sectors. Figure 3 depicts the relevant SDGs.

Figure 3.

Alignment of 4D printing and biomimetic smart materials with selected United Nations Sustainable Development Goals (SDGs). The integration of bio-based, recyclable, and energy-efficient materials into advanced manufacturing processes contributes to responsible production (SDG 12), industrial innovation (SDG 9), climate action (SDG 13), improved health outcomes (SDG 3), sustainable urban systems (SDG 11), and future-ready education (SDG 4) [75].

3.3. Comparative Analysis with Traditional Additive Manufacturing

Compared to traditional additive manufacturing, which excels at fabricating complex geometries and minimizing waste, 4D printing offers additional advantages in functionality, responsiveness, and lifecycle performance. While conventional AM techniques primarily focus on form generation, 4D printing introduces behavior as a design parameter—allowing objects to evolve after fabrication without requiring external assemblies or interventions [76]. This novel element reduces the need for mechanical components, enhances part integration, and facilitates novel applications in fields ranging from self-assembling medical devices to deployable architectural structures. Moreover, the integration of environmental responsiveness into the object’s material structure promotes greater alignment between function and context, particularly in systems requiring adaptability over time [77].

However, the transition from static to dynamic manufacturing is not without challenges. Limitations in material availability, print resolution, actuation precision, and mathematical simulation capabilities currently constrain the scope of 4D printing in real-world applications [78]. Furthermore, the complexity of predicting and controlling multi-material deformation behaviors across diverse stimuli introduces additional design and validation burdens [79]. Despite these barriers, early adopters have demonstrated significant potential in replacing static assemblies with single-material, stimulus-responsive constructs, achieving both material efficiency and functional enrichment [80]. With the continued refinement of computational design tools, mathematical models frameworks, and multi-material fabrication technologies, 4D printing is expected to assume a more prominent role in enabling sustainable and adaptive design strategies.

4. Application Domains

As prior mentioned, the integration of biomimetic smart materials and 4D printing technologies has created new opportunities for adaptive and sustainable solutions across a range of sectors. These applications exploit the responsive behavior of materials to enhance functionality, reduce environmental impact, and improve user interaction. By enabling self-actuation, reconfigurability, and context-sensitive performance, temporally designed systems offer advantages over traditional rigid and static designs. Their interdisciplinary nature allows them to traverse conventional boundaries between medicine, architecture, product design, and mobility systems. The following subsections provide a focused review of selected domains where the deployment of time-responsive materials and 4D fabrication has begun to deliver measurable benefits and transformative outcomes.

4.1. Regenerative Medicine and Bioactive Devices

The field of regenerative medicine has been significantly impacted by the adoption of smart biomimetic materials, particularly through their use in bioactive scaffolds and implantable devices [81,82,83,84]. These materials have been employed to fabricate structures that respond to physiological stimuli such as temperature, pH, and moisture, thereby enabling more dynamic interactions with the biological environment [85]. Hydrogels, for instance, have been utilized to create tissue scaffolds that expand or contract based on hydration levels, facilitating improved cell proliferation, nutrient transport, and wound closure [86]. Similarly, shape-memory polymers have been integrated into minimally invasive devices that deploy upon reaching body temperature, such as self-expanding stents, wound-closure systems, and scaffolds for bone or nerve regeneration [87].

One widely studied example involves poly(N-isopropylacrylamide) (PNIPAM)-based hydrogels, which exhibit a lower critical solution temperature (LCST) near physiological levels [88]. These have been successfully used in drug delivery systems, where a slight increase in body temperature triggers the release of embedded therapeutics. Similarly, pH-sensitive hydrogels based on poly(acrylic acid) (PAAc) are employed in wound dressings and gastrointestinal applications, where their swelling behavior enables localized, responsive drug diffusion [88].

Four-dimensional printing technologies have further advanced this area by allowing the creation of anatomically conforming, patient-specific implants that change configuration post-implantation [89,90]. In situ programming of smart polymers enables controlled drug release, localized actuation, or the staged transformation of scaffold morphology, which can accelerate tissue regeneration and reduce surgical interventions [91,92]. Recent studies have demonstrated the feasibility of sequential shape recovery in multi-material systems to guide tissue growth in complex anatomical regions [93]. However, challenges remain in terms of biocompatibility, long-term stability, and regulatory compliance [94]. Nevertheless, the convergence of responsive materials and advanced manufacturing exhibits great potential for a new generation of medical devices that are not only functional but adaptive to the changing needs of the biological systems they support.

4.2. Architecture and Built Environment

In the architectural domain, biomimetic smart materials and temporal design strategies have been introduced as a means of optimizing building performance while reducing reliance on mechanical systems [95,96]. Hygroscopic and thermo-responsive materials have been embedded in facade elements, shading systems, and ventilation modules to passively respond to environmental changes such as humidity, temperature, and solar radiation [97,98]. For example, wood-based bilayer composites have been employed in facade panels that curl or expand depending on ambient humidity, enabling self-regulating daylight control without electrical input [99,100]. These systems emulate plant movement mechanisms and contribute to reduced energy consumption in climate-responsive buildings.

Four-dimensional printing has further extended these possibilities by enabling the fabrication of large-scale components that can adapt post-installation. This includes kinetic structures with embedded actuation logic, soft robotic membranes for shading or acoustic control, and reconfigurable partitions for space optimization [101,102]. In particular, the use of smart composite materials allows for on-demand transformation of building elements without external actuation, facilitating resilient responses to weather events or user preferences [103]. Although these approaches remain largely experimental, pilot projects and academic prototypes have demonstrated their feasibility [104]. The integration of such systems into mainstream architecture remains contingent on advances in structural modeling, material durability, and code compliance, but the trajectory points toward increasingly autonomous and responsive built environments.

4.3. Wearables, Mobility, and Consumer Products

The application of biomimetic smart materials in the design of wearable technologies and mobility-related products has enabled greater personalization, comfort, and adaptive performance. Electro-active polymers and thermo-responsive materials have been integrated into garments and accessories capable of altering their form in response to body heat, muscle movement, or environmental conditions [105]. Examples include shape-changing sportswear, posture-correcting garments, and temperature-regulating fabrics [106]. These applications benefit from the lightweight and flexible nature of the materials, which support both functional augmentation and improved user ergonomics [107]. Additionally, shape-memory components have been embedded into orthopedic braces and footwear, allowing for personalized fit and dynamic support [108].

In industrial and mechanical systems, magneto-rheological elastomers (MREs) have gained attention for their tunable stiffness properties, enabling real-time vibration control in automotive suspensions and precision manufacturing equipment [109]. Additionally, smart coatings based on thermo-responsive polymers are being developed for self-cleaning surfaces and adaptive heat exchangers, where the material properties shift with environmental conditions to optimize performance [110].

In the mobility and consumer electronics sectors, smart materials have facilitated the development of reconfigurable components, self-assembling elements, and adaptable enclosures. Automotive interiors, for example, have incorporated shape-memory-based actuators to allow seats, dashboards, and control surfaces to morph according to user preferences or safety protocols [111]. Similarly, in the field of portable devices, casings and buttons have been designed to respond to user proximity or ambient temperature [112,113]. These developments underscore the potential of temporal design to move beyond novelty and toward genuine enhancement of user experience, durability, and system integration [114]. However, challenges regarding mass manufacturing, cost efficiency, and user safety must be addressed before wide-scale adoption can occur.

To consolidate the insights from the previous sections, a comparative analysis of selected application areas is presented in Table 2. This table summarizes the material types, dominant stimuli, functional objectives, and representative use cases associated with each domain. The juxtaposition highlights the versatility of smart materials across scales and industries, as well as the alignment between stimulus behavior and design intent.

Table 2.

Summary of key application domains for biomimetic smart materials and 4D printing.

5. Challenges and Research Gaps

Despite the exhibited potential of biomimetic smart materials and 4D printing technologies across application sectors, several barriers continue to prevent their widespread adoption and practical integration. These challenges refer to technical, educational, and societal dimensions, reflecting the interdisciplinary nature of temporal design. While proof-of-concept studies and experimental applications are proliferating, the transition from laboratory-scale prototypes to commercially viable, ethically responsible, and educationally supported innovations remains scarce. Addressing these gaps is of paramount importance to ensure that the potential benefits of temporal design are realized across sectors and aligned with sustainability, inclusivity, and long-term system resilience.

5.1. Technical Challenges: Material Limitations and Process Control

One of the primary technical limitations in the deployment of smart materials lies in their restricted range of mechanical and chemical performance characteristics [115]. Many commonly used shape-memory polymers and hydrogels exhibit issues related to brittleness, limited load-bearing capacity, slow recovery times, or degradation under prolonged environmental exposure [116]. These limitations reduce their applicability in structural or long-term systems, particularly in fields such as construction, automotive design, or aerospace [117]. Additionally, the long-term fatigue behavior and multi-cycle actuation reliability of such materials remain underexplored, posing concerns regarding durability, safety, and predictability in practical contexts [118].

Process-related challenges further complicate the translation of 4D printing into routine manufacturing. The behavior of stimuli-responsive materials is highly sensitive to printing parameters such as layer orientation, thermal gradients, and inter-material adhesion [119]. Controlling the precision of the programmed deformations requires not only advanced printhead calibration and post-processing protocols, but also mathematical simulation tools capable of modeling time-dependent, multi-material interactions [120]. Current computer-aided design (CAD) software is poorly equipped to handle the complexity of these interactions, resulting in a mismatch between design intent and physical behavior. Moreover, the integration of multiple stimuli-responsive materials in a single print—especially those requiring conflicting processing conditions—remains a formidable task that limits scalability.

5.2. Educational Barriers: Integration into Design Curricula

The advancement of biomimetic and temporal design approaches is also hindered by a lack of curricular integration in design education. Traditional design programs often emphasize form, aesthetics, and static function, while offering limited exposure to material science, mathematical simulation, or responsive systems. As a result, students are not adequately trained to conceptualize, model, or prototype with dynamic materials or processes. This knowledge gap creates a disconnect between emerging material capabilities and the creative professionals responsible for implementing them in meaningful ways [120].

Furthermore, interdisciplinary collaboration is rarely embedded structurally within educational institutions. While projects involving engineers, biologists, and designers are encouraged in theory, logistical, administrative, and epistemological differences often prevent sustained engagement [121,122]. The lack of access to multi-material printers, wet labs, and parametric design tools exacerbates this issue, making it difficult for students to experiment with smart materials in hands-on ways [123]. To support the next generation of sustainable and adaptive design practitioners, curricula must be restructured to include modules on stimuli-responsive materials, computational modeling, and cross-disciplinary co-design methodologies.

5.3. Ethical and Societal Considerations: Material Autonomy, Transparency, Cultural Impact

The introduction of self-actuating and adaptive materials raises novel ethical and societal questions related to transparency, responsibility, and user agency. As materials gain the capacity to change their behavior autonomously, questions emerge regarding who controls these transformations and under what conditions [124]. Users may not fully understand or anticipate the behaviors of temporally responsive artifacts, leading to potential confusion, misuse, or unintended consequences. In critical contexts such as medicine or infrastructure, these uncertainties could result in safety hazards, legal ambiguities, or mistrust in adaptive technologies.

Cultural implications also deserve closer scrutiny. Many smart material examples are rooted in technocentric, Western design logics that prioritize automation, novelty, and formal complexity. This may marginalize alternative knowledge systems—particularly Indigenous or vernacular design traditions—that emphasize continuity, low-tech resilience, and holistic integration with ecosystems [125]. The development of ethical frameworks for temporal design must therefore include pluralistic perspectives, foregrounding issues of equity, inclusiveness, and long-term societal impacts. In addition, data privacy concerns may arise if smart materials are embedded with sensing capabilities, necessitating careful consideration of user rights and systemic transparency.

To further synthesize the aforementioned elements, Table 3 provides a comparative summary of the main challenges faced in advancing biomimetic smart materials and 4D printing. It categorizes the challenges by domain, specifies their manifestations, and suggests preliminary strategies for mitigation.

Table 3.

Summary of key challenges in temporal design and 4D printing.

6. Mathematical Modeling and Simulation Tools for Smart Design

Smart design and fabrication of adaptive, biomimetic structures rely increasingly on robust mathematical modeling and advanced simulation tools. Mathematical approaches provide the predictive basis for understanding and optimizing the behavior of complex materials, especially those that respond dynamically to environmental stimuli [126]. By embedding these methods early in the design workflow, engineers and designers can reduce prototyping cycles, minimize material waste, and ensure functional reliability in real-world conditions.

One key area is the mathematical modeling of shape-memory polymers (SMPs) and other stimuli-responsive materials. Governing equations often describe the thermomechanical behavior, stress–strain relationships, and time-dependent deformation under external triggers such as temperature, humidity, or pH variation [127]. FEA is widely applied to simulate structural transformations, stress distribution, and multiphysics coupling effects in adaptive systems. Parametric studies using FEA help optimize lattice geometries, internal scaffolds, or complex surface morphologies to achieve targeted performance and structural stability [128].

In parallel, digital twins and simulation-driven design are gaining ground as essential enablers for validating smart material applications [129]. A digital twin framework can integrate real-time data with predictive models to monitor and adapt the behavior of printed structures throughout their service life [130]. Combined with computational optimization algorithms, these mathematical tools support multi-scale analysis—from microstructural behavior to large-scale urban applications.

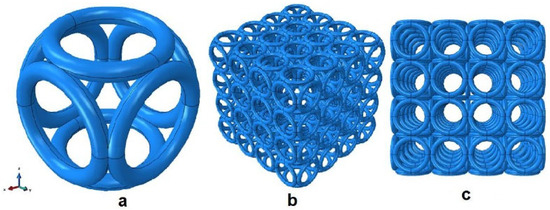

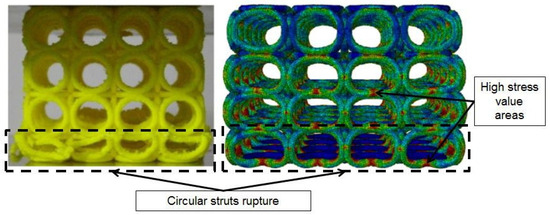

In this context, the figures below present an example of the aforementioned workflow from design to finite element simulation of a lattice scaffold structure used for biomedical applications, illustrating how stress and deformation fields can be visualized and refined before fabrication from a published literature work by Kantaros, Chatzidai and Karalekas in 2016 [131] and PhD Thesis from Kantaros 2015 [132].

More specifically, Figure 4 presents the structure’s 3D design elements, comprising the initial subunit and views of the final 3D lattice design [131,132].

Figure 4.

(a) The subunit, (b) the side view, and (c) the plan view of the lattice scaffold structure design [131,132].

Before applying FEA and experimental testing, power laws for predicting mechanical properties like mechanical strength and structural modulus can be considered as additional validation tools. Based on Ashby’s and Gibson’s formula [133] for cellular materials the effective modulus of a cellular structure can be obtained using the following equation [131]:

where E stands for the elastic modulus of the solid structure, ρsc/ρ0 stands for the relative density of the cellular structure, Eeff for the modulus of the cellular structure, and C1 for the proportionality constant related to the cell geometry. The C1 constant is calculated by fitting the equation to experimental data.

The lattice scaffold structure design was subsequently 3D printed and subjected to mechanical experimental testing while in the same time a FEA computational analysis was also conducted [131,132]. Figure 5 depicts snapshots of this workflow indicating experimental and FEM generated scaffold snapshots with failure pattern and high stress value areas highlighted. The circular struts rupture and collapse of the first pore network row predicted in the computational analysis can be observed in the actual specimen [131,132].

Figure 5.

Experimental and FEM generated scaffold snapshots with failure pattern and high stress value areas highlighted [131,132].

Beyond structural analysis, a growing body of recent literature focuses on the development of constitutive equations and multiphysics coupling models—particularly in thermo-responsive, electro-active, and hydrogel-based smart materials. These models simulate time-dependent deformation, swelling, and phase transitions under various environmental stimuli. For instance, Shahi et al. [134] proposed a finite strain viscoelastic constitutive model calibrated for shape-memory polymers under torsion, achieving simulation–experiment error rates within 5%, thereby demonstrating the robustness of validated predictive frameworks. Similarly, Arricca et al. [135] developed a finite strain continuum model for multiphase, semi-crystalline polymer networks, successfully capturing shape-memory behavior across thermal cycles and confirming high agreement with experimental results. While the present work does not introduce novel modeling algorithms, it emphasizes the importance of integrating established and validated simulation approaches into smart design workflows to enhance reliability, optimize material performance, and reduce prototyping iterations.

Mathematical models form the backbone of adaptive manufacturing and biomimetic material design, as they provide the governing equations that describe physical behavior under different stimuli and conditions. These equations are not merely symbolic representations; they encapsulate conservation laws, constitutive relations, and multiphysics couplings that allow designers to predict performance, optimize geometries, and validate functional reliability before fabrication. For instance, discretized governing equations (Equation (2)) derive from elasticity and thermomechanical principles and form the foundation of finite element formulations, while hereditary integral models (Equation (3)) describe time-dependent viscoelastic responses that are crucial for capturing the memory effects of smart polymers. Similarly, coupled PDEs (Equation (4)) extend these frameworks by incorporating mechanical, thermal, and diffusive interactions, thus enabling the study of complex multiphysics phenomena such as swelling or heat-driven expansion. Finally, parametric optimization functions (Equation (5)) mathematically define how geometry evolves as a function of design parameters, linking computational models directly with adaptive design strategies. In the context of adaptive manufacturing and biomimetic smart materials, different mathematical models address specific classes of design and simulation problems, ranging from purely mechanical property prediction to coupled multiphysics simulations. Table 4 summarizes representative mathematical models, the primary equations (numbered in the text), the types of problems they solve, and typical applications. The corresponding model geometries and domains are illustrated in Figure 4 and Figure 5, which serve as the schema of the modeling approach. In the case of Equation (2) (can be found in Table 4), are nodal displacements, nodal temperatures, mass structural damping, elastic stiffness, thermoelastic coupling, and is external mechanical vector. In Equation (3), denotes the stress as a function of time, while represents the strain rate history. The function ) the relaxation modulus that characterizes the time-dependent viscoelastic response of the material, describing how stress decays with time under constant strain. The integral formulation accounts for the hereditary nature of viscoelastic materials, where the present stress depends not only on the current strain but also on the full history of strain changes. In Equation (4) (can be found in Table 4), stands for displacement, temperature, concentration (or volume fraction), moduli (possibly dependent on ), conductivity, diffusivity, heat capacity, external heat source, dissipation-induced heating, thermal expansion, swelling coefficient, and body force. In addition, in Equation (5) (can be found in Table 4), stands for physical coordinates of the geometry after parameterization, for reference (initial) geometry, for reference (parametric) coordinates in the design domain, for geometric design parameters (e.g., thickness, curvature, pore size), for shape basis functions defining how each parameter modifies the geometry, for the total number of design parameters controlling the geometry.

Table 4.

Summary of mathematical models, problem types, and applications in smart material design.

The aforementioned example drawn from published literature [131,132], showcases that the use of mathematical power laws for solids, combined with FEA computational analysis can be used to predict mechanical behavior of three-dimensional solid structures. The subsequent mechanical experimental testing confirmed the predicted behavior patterns under mechanical load application. The results convergence of these three methods, mathematical, computational and experimental showcases the added value of utilizing such methods. The continuous development of accessible computational tools and open-source modeling platforms further empowers designers to incorporate mathematical rigor into innovative product development. By combining material science, computational mechanics, and real-world fabrication, mathematical modeling will remain a cornerstone technology for advancing smart design and adaptive manufacturing in sustainable and inclusive systems.

7. Future Outlook: Toward Regenerative Design Systems

Ongoing advancements in biomimetic smart materials and 4D printing technologies are anticipated to significantly influence the evolution of sustainable and adaptive design cases. As fabrication systems become more sophisticated and responsive materials more accessible, a broader spectrum of disciplines will be able to integrate temporal behavior into their design logic. The future of design will likely be characterized not only by form and function, but also by responsiveness, reconfigurability, and interaction over time. This shift requires a fundamental redefinition of performance criteria, production cycles, and design evaluation metrics. Static benchmarks of dimensional accuracy or mechanical strength must be complemented by assessments of transformability, lifecycle adaptability, and environmental integration.

Advances in computational modeling and mathematical simulation are anticipated to significantly enhance the reliability and predictability of time-dependent material behavior. As digital twins and machine learning algorithms are increasingly deployed to anticipate stimulus–response dynamics, the fidelity of design-to-fabrication pipelines will improve, reducing trial-and-error development cycles. These tools will support designers in generating parametric models that incorporate temporal functions, enabling efficient prototyping of smart systems tailored to specific stimuli and use conditions. Moreover, new multi-material printing platforms, capable of co-processing materials with distinct mechanical and thermal properties, will expand the range of achievable transformations, further broadening the applicability of 4D printed systems.

In parallel, interdisciplinary collaboration will be essential in ensuring that technological innovations align with societal and ecological priorities. The convergence of design, biology, engineering, and ethics will be required to foster the development of artifacts that are not only functional and aesthetically compelling but also equitable and ecologically attuned. Future research initiatives should emphasize inclusivity, user co-creation, and the integration of diverse knowledge systems. Policies and funding mechanisms should prioritize open-access innovation ecosystems that encourage experimentation with responsive, sustainable technologies, particularly in education, healthcare, and public infrastructure.

Additionally, a critical outlook must be maintained regarding the long-term cultural and ethical implications of increasingly autonomous material systems. As the boundary between the artificial and the organic continues to blur, careful attention must be given to the consequences of delegating decision-making to responsive systems. Questions related to material agency, user empowerment, and environmental accountability must be addressed proactively through design education, public discourse, and cross-sector governance. If adequately supported, the fusion of biomimetic intelligence, adaptive manufacturing, and temporal design holds the potential to redefine the way human societies interact with the built and natural environment—moving toward a more regenerative, resilient, and context-aware design context.

Future work should deepen the integration of advanced mathematical modeling tools, sophisticated mathematical simulation workflows, and digital twin technologies to rigorously validate the performance of smart materials and structures under real-world conditions. By combining predictive models with real-time monitoring and iterative feedback, future research can optimize the design, fabrication, and lifecycle management of adaptive systems, ensuring reliable functionality, resilience, and scalability across diverse applications.

8. Conclusions

The present work has examined the convergence of biomimetic smart materials, additive manufacturing technologies, and temporal design principles as a transformative framework for sustainable and adaptive innovation. Through the systematic integration of stimuli-responsive materials—such as shape-memory polymers, hydrogels, and electro-active composites—into advanced fabrication workflows, particularly those enabled by 4D printing, it has been demonstrated that the traditional paradigm of static, single-function objects can be reconceptualized into dynamic, time-encoded systems. These systems are capable of altering their configuration, behavior, or functionality in response to environmental cues, thereby extending their utility, performance, and ecological alignment across their operational lifespan.

The implications of this material–temporal integration span multiple sectors, including regenerative medicine, climate-adaptive architecture, wearable technologies, and responsive consumer products. In each domain, temporal design offers substantial potential to reduce material waste, enhance personalization, and improve functional longevity by enabling adaptive behavior within the artifact itself. Beyond performance gains, this approach supports the development of design ecosystems grounded in circularity, resilience, and regenerative logic—concepts increasingly recognized as essential in confronting the complex challenges of environmental degradation and resource scarcity. However, the realization of this potential is contingent upon the resolution of critical challenges, including limitations in material performance, lack of predictive mathematical model tools, and insufficient integration within design education and ethics discourse.

To enable a transition toward scalable and responsible adoption of biomimetic and temporally responsive design systems, a new methodological and epistemological framework must be adopted—one that actively fosters transdisciplinary collaboration, open innovation, and critical reflection on the socio-cultural dimensions of emerging technologies. The design of future material systems must move beyond reductionist models of utility and control, toward approaches that acknowledge the agency of matter, the contextual nature of performance, and the necessity for inclusive, systems-level thinking. Thus, design practice is repositioned as a mediator of relationships between biology, computation, fabrication, and society—capable not only of producing objects, but of shaping dynamic, situated, and regenerative interactions between people, materials, and environments. Ultimately, the synergy between biomimetic material design, adaptive manufacturing, and robust mathematical modeling will be key to realizing practical, sustainable, and truly intelligent products for future applications.

Author Contributions

Conceptualization, A.K., M.P., E.P. and T.G.; methodology, A.K., M.P., E.P. and T.G.; validation, A.K.; formal analysis, A.K., M.P., E.P. and T.G.; investigation, A.K.; resources, A.K.; writing—original draft preparation, A.K.; writing—review and editing, A.K., M.P., E.P. and T.G.; visualization, A.K.; supervision, M.P., E.P. and T.G.; project administration, A.K., M.P., E.P. and T.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors gratefully acknowledge the Editors, Richard Drevet, and Hicham Benhayoune, and the Designs Editorial Office for their kind invitation to contribute to the “Editorial Board Members’ Collection Series: Biomaterials Design”.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| 3D | Three-Dimensional |

| 4D | Four-Dimensional (Three-Dimensional + Time-Dependent Behavior) |

| AM | Additive Manufacturing |

| CAD | Computer-Aided Design |

| CAM | Computer-Aided Manufacturing |

| DIW | Direct Ink Writing |

| EAP | Electroactive Polymer |

| FDM | Fused Deposition Modeling |

| FE | Finite Element |

| SMP | Shape-Memory Polymer |

| SLA | Stereolithography |

| pH | Potential of Hydrogen (Acidity/Alkalinity Indicator) |

| Tg | Glass Transition Temperature |

| HVAC | Heating, Ventilation, and Air Conditioning |

| IoT | Internet of Things |

| FE Simulation | Finite Element Simulation |

| UV | Ultraviolet |

| PLA | Polylactic Acid (commonly used thermoplastic in AM) |

| TPU | Thermoplastic Polyurethane |

| ELS | Environmental Lifecycle Sustainability |

References

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T. Transforming Object Design and Creation: Biomaterials and Contemporary Manufacturing Leading the Way. Biomimetics 2024, 9, 48. [Google Scholar] [CrossRef] [PubMed]

- Sofias, K.; Kanetaki, Z.; Stergiou, C.; Jacques, S. Combining CAD Modeling and Simulation of Energy Performance Data for the Retrofit of Public Buildings. Sustainability 2023, 15, 2211. [Google Scholar] [CrossRef]

- Ibrahim, I.; Al Shomely, K.; Eltarabishi, F. Sustainability Implications of Utilizing Islamic Geometric Patterns in Contemporary Designs, a Systematic Analysis. Buildings 2023, 13, 2434. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Ganetsos, T. From Stents to Smart Implants Employing Biomimetic Materials: The Impact of 4D Printing on Modern Healthcare. Biomimetics 2025, 10, 125. [Google Scholar] [CrossRef]

- Drevet, R.; Benhayoune, H. New Insights into Biomaterials and Coatings. Coatings 2025, 15, 332. [Google Scholar] [CrossRef]

- Jamil, H.; Faizan, M.; Adeel, M.; Jesionowski, T.; Boczkaj, G.; Balčiūnaitė, A. Recent Advances in Polymer Nanocomposites: Unveiling the Frontier of Shape Memory and Self-Healing Properties-A Comprehensive Review. Molecules 2024, 29, 1267. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 4D Printing: Technology Overview and Smart Materials Utilized. J. Mechatron. Robot. 2023, 7, 1–14. [Google Scholar] [CrossRef]

- Drevet, R.; Benhayoune, H. Biomaterials Design for Human Body Repair. Designs 2024, 8, 65. [Google Scholar] [CrossRef]

- Kontiza, A.; Kartsonakis, I.A. Smart Composite Materials with Self-Healing Properties: A Review on Design and Applications. Polymers 2024, 16, 2115. [Google Scholar] [CrossRef] [PubMed]

- Dallaev, R. Advances in Materials with Self-Healing Properties: A Brief Review. Materials 2024, 17, 2464. [Google Scholar] [CrossRef]

- Medina, H.; Farmer, C.; Liu, I. Dielectric Elastomer-Based Actuators: A Modeling and Control Review for Non-Experts. Actuators 2024, 13, 151. [Google Scholar] [CrossRef]

- Koutsanitis, S.; Sinou, M.; Kanetaki, Z.; Tousi, E.; Varelidis, G. Thermal Performance Investigation in Historical Urban Neighborhoods Using ENVI-Met Simulation Software. Land 2025, 14, 284. [Google Scholar] [CrossRef]

- Qalati, S.A.; Barbosa, B.; Deshwal, P. Consumer Behavior and Sustainable Marketing Development in Online and Offline Settings. Sustainability 2024, 16, 2829. [Google Scholar] [CrossRef]

- Sajid, M.; Ertz, M. Blueprints to Benefits: Towards an Index to Measure the Impact of Sustainable Product Development on the Firm’s Bottom Line. Sustainability 2024, 16, 537. [Google Scholar] [CrossRef]

- Ighodaro, A.; Osarobo, J.A.; Onuguh, I.C.; Ogbeide, O.K.; Ifijen, I.H. Challenges and Future Perspectives of Biomimetic Materials for Biomedical Applications: Bridging the Gap between Nature and Medicine. In The Minerals, Metals & Materials Series; Springer Nature: Cham, Switzerland, 2024; pp. 877–896. ISBN 9783031503481. [Google Scholar]

- Speck, O.; Speck, T. Biomimetics and Education in Europe: Challenges, Opportunities, and Variety. Biomimetics 2021, 6, 49. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T.; Alysandratou, E. Bioprinting and Intellectual Property: Challenges, Opportunities, and the Road Ahead. Bioengineering 2025, 12, 76. [Google Scholar] [CrossRef]

- Ciulla, M.G.; Massironi, A.; Sugni, M.; Ensign, M.A.; Marzorati, S.; Forouharshad, M. Recent Advances in the Development of Biomimetic Materials. Gels 2023, 9, 833. [Google Scholar] [CrossRef] [PubMed]

- Lima, E.; Ferreira, H.; Mateus, L.; Arruda, A. Integration of Thermo-Responsive Materials Applied to Bio-Inspired Structures. Biomimetics 2025, 10, 68. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 3D and 4D Printing as Integrated Manufacturing Methods of Industry 4.0. Am. J. Eng. Appl. Sci. 2023, 16, 12–22. [Google Scholar] [CrossRef]

- Kantaros, A. Bio-Inspired Materials: Exhibited Characteristics and Integration Degree in Bio-Printing Operations. Am. J. Eng. Appl. Sci. 2022, 15, 255–263. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Filippova, O.V.; Tcherdyntsev, V.V.; Telyshev, D.V. Shape Memory Polymers as Smart Materials: A Review. Polymers 2022, 14, 3511. [Google Scholar] [CrossRef]

- Yang, S.; He, Y.; Song, Z.; Li, Y. Research Status and Potential Direction for Thermoplastic Shape Memory Polymers and Composites: A Review. Polymers 2025, 17, 1360. [Google Scholar] [CrossRef]

- Narvaez, D.; Newell, B. A Review of Electroactive Polymers in Sensing and Actuator Applications. Actuators 2025, 14, 258. [Google Scholar] [CrossRef]

- Parvin, N.; Joo, S.W.; Jung, J.H.; Mandal, T.K. Electroactive Polymers for Self-Powered Actuators and Biosensors: Advancing Biomedical Diagnostics through Energy Harvesting Mechanisms. Actuators 2025, 14, 257. [Google Scholar] [CrossRef]

- Protsak, I.S.; Morozov, Y.M. Fundamentals and Advances in Stimuli-Responsive Hydrogels and Their Applications: A Review. Gels 2025, 11, 30. [Google Scholar] [CrossRef] [PubMed]

- Khuzin, A.A.; Galimov, D.I.; Tulyabaev, A.R.; Khuzina, L.L. Synthesis, Photochromic and Luminescent Properties of Ammonium Salts of Spiropyrans. Molecules 2022, 27, 8492. [Google Scholar] [CrossRef]

- Abedi-Firoozjah, R.; Yousefi, S.; Heydari, M.; Seyedfatehi, F.; Jafarzadeh, S.; Mohammadi, R.; Rouhi, M.; Garavand, F. Application of Red Cabbage Anthocyanins as pH-Sensitive Pigments in Smart Food Packaging and Sensors. Polymers 2022, 14, 1629. [Google Scholar] [CrossRef] [PubMed]

- Baral, A.; Basu, K. Supramolecular Adhesives Inspired by Nature: Concept and Applications. Biomimetics 2025, 10, 87. [Google Scholar] [CrossRef]

- Sringam, J.; Kajornprai, T.; Trongsatitkul, T.; Suppakarn, N. Shape Memory Performance and Microstructural Evolution in PLA/PEG Blends: Role of Plasticizer Content and Molecular Weight. Polymers 2025, 17, 225. [Google Scholar] [CrossRef]

- Visan, A.I.; Negut, I. Environmental and Wastewater Treatment Applications of Stimulus-Responsive Hydrogels. Gels 2025, 11, 72. [Google Scholar] [CrossRef]

- Gribkova, O.L.; Nekrasov, A.A. Spectroelectrochemistry of Electroactive Polymer Composite Materials. Polymers 2022, 14, 3201. [Google Scholar] [CrossRef]

- Kanaan, A.F.; Pinho, A.C.; Piedade, A.P. Electroactive Polymers Obtained by Conventional and Non-Conventional Technologies. Polymers 2021, 13, 2713. [Google Scholar] [CrossRef] [PubMed]

- Chandra Adak, N.; Lee, W. A Comprehensive Review of 4D-Printed Thermo-Responsive Hydrogel-Based Smart Actuators for Solar Steam Generation: Advanced Design, Modeling, Manufacturing, and Finite Element Analysis. Prog. Mater. Sci. 2025, 148, 101377. [Google Scholar] [CrossRef]

- Pandeya, S.P.; Zou, S.; Roh, B.-M.; Xiao, X. Programmable Thermo-Responsive Self-Morphing Structures Design and Performance. Materials 2022, 15, 8775. [Google Scholar] [CrossRef]

- Imam, S.S.; Hussain, A.; Altamimi, M.A.; Alshehri, S. Four-Dimensional Printing for Hydrogel: Theoretical Concept, 4D Materials, Shape-Morphing Way, and Future Perspectives. Polymers 2021, 13, 3858. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, Y.; Ma, Y.; Wang, J. Bioinspired Stimuli-Responsive Materials for Soft Actuators. Biomimetics 2024, 9, 128. [Google Scholar] [CrossRef] [PubMed]

- Serna, J.A.; Rueda-Gensini, L.; Céspedes-Valenzuela, D.N.; Cifuentes, J.; Cruz, J.C.; Muñoz-Camargo, C. Recent Advances on Stimuli-Responsive Hydrogels Based on Tissue-Derived ECMs and Their Components: Towards Improving Functionality for Tissue Engineering and Controlled Drug Delivery. Polymers 2021, 13, 3263. [Google Scholar] [CrossRef] [PubMed]

- Agbna, G.H.D.; Zaidi, S.J. Hydrogel Performance in Boosting Plant Resilience to Water Stress—A Review. Gels 2025, 11, 276. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Song, H.; Wang, F.; Su, X.; Zhang, D.; Xu, J. Biomimetic Superhydrophobic Surfaces: From Nature to Application. Materials 2025, 18, 2772. [Google Scholar] [CrossRef]

- Baharuddin, N.S.; Roslan, M.A.M.; Bawzer, M.A.M.; Mohamad Azzeme, A.; Rahman, Z.A.; Khayat, M.E.; Rahman, N.A.A.; Sobri, Z.M. Response Surface Optimization of Extraction Conditions and in Vitro Antioxidant and Antidiabetic Evaluation of an Under-Valued Medicinal Weed, Mimosa Pudica. Plants 2021, 10, 1692. [Google Scholar] [CrossRef]

- Horstmann, M.; Speck, T.; Poppinga, S. Orchestrated Movement Sequences and Shape-Memory-like Effects in Pine Cones. Plants 2024, 13, 2078. [Google Scholar] [CrossRef]

- Song, J.; Li, B.; Zeng, L.; Ye, Z.; Wu, W.; Hu, B. A Mini-Review on Reflectins, from Biochemical Properties to Bio-Inspired Applications. Int. J. Mol. Sci. 2022, 23, 15679. [Google Scholar] [CrossRef]

- Stella, D.; Kleisner, K. Visible beyond Violet: How Butterflies Manage Ultraviolet. Insects 2022, 13, 242. [Google Scholar] [CrossRef] [PubMed]

- Maksimkin, A.V.; Dayyoub, T.; Telyshev, D.V.; Gerasimenko, A.Y. Electroactive Polymer-Based Composites for Artificial Muscle-like Actuators: A Review. Nanomaterials 2022, 12, 2272. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Zhou, Z.; Xie, Y.; Zhu, X.; Huang, G.; Zhang, Z. A Microactuator Array Based on Ionic Electroactive Artificial Muscles for Cell Mechanical Stimulation. Biomimetics 2024, 9, 281. [Google Scholar] [CrossRef] [PubMed]

- Collins, C.M.; Safiuddin, M. Lotus-Leaf-Inspired Biomimetic Coatings: Different Types, Key Properties, and Applications in Infrastructures. Infrastructures 2022, 7, 46. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Zielecka, M.; Klapsa, W.; Dziechciarz, A. Self-Cleaning Coatings and Surfaces of Modern Building Materials for the Removal of Some Air Pollutants. Materials 2021, 14, 2161. [Google Scholar] [CrossRef]

- Branković, M.; Zivic, F.; Grujovic, N.; Stojadinovic, I.; Milenkovic, S.; Kotorcevic, N. Review of Spider Silk Applications in Biomedical and Tissue Engineering. Biomimetics 2024, 9, 169. [Google Scholar] [CrossRef]

- Uklejewski, R.; Winiecki, M. Advances in Biomimetic Scaffolds for Hard Tissue Surgery. Biomimetics 2024, 9, 279. [Google Scholar] [CrossRef]

- Nestor, T.; Belazi, A.; Abd-El-Atty, B.; Aslam, M.N.; Volos, C.; De Dieu, N.J.; Abd El-Latif, A.A. A New 4D Hyperchaotic System with Dynamics Analysis, Synchronization, and Application to Image Encryption. Symmetry 2022, 14, 424. [Google Scholar] [CrossRef]

- Biswas, M.C.; Chakraborty, S.; Bhattacharjee, A.; Mohammed, Z. 4D Printing of Shape Memory Materials for Textiles: Mechanism, Mathematical Modeling, and Challenges. Adv. Funct. Mater. 2021, 31, 2100257. [Google Scholar] [CrossRef]

- Park, H.-J.; Hong, H.; Thangam, R.; Song, M.-G.; Kim, J.-E.; Jo, E.-H.; Jang, Y.-J.; Choi, W.-H.; Lee, M.-Y.; Kang, H.; et al. Static and Dynamic Biomaterial Engineering for Cell Modulation. Nanomaterials 2022, 12, 1377. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Zhao, T.; Aldaghri, O.; Eisa, M.H. Polymer/Graphene Nanocomposites via 3D and 4D Printing—Design and Technical Potential. Processes 2023, 11, 868. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Bodaghi, M.; Kouzani, A.Z.; Gharaie, S.; Nahavandi, S. Control-Based 4D Printing: Adaptive 4D-Printed Systems. Appl. Sci. 2020, 10, 3020. [Google Scholar] [CrossRef]

- Imrie, P.; Jin, J. Multimaterial Hydrogel 3D Printing. Macromol. Mater. Eng. 2024, 309, 2300272. [Google Scholar] [CrossRef]

- Vatanparast, S.; Boschetto, A.; Bottini, L.; Gaudenzi, P. New Trends in 4D Printing: A Critical Review. Appl. Sci. 2023, 13, 7744. [Google Scholar] [CrossRef]

- Pan, H.M. Advanced Materials in 3D/4D Printing Technology. Polymers 2022, 14, 3255. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yang, Y.; Yang, Z.; Ma, R.; Aimaijiang, M.; Xu, J.; Zhang, Y.; Zhou, Y. Four-Dimensional Printing and Shape Memory Materials in Bone Tissue Engineering. Int. J. Mol. Sci. 2023, 24, 814. [Google Scholar] [CrossRef]

- Ge, Q.; Qi, H.J.; Dunn, M.L. Active Materials by Four-Dimension Printing. Appl. Phys. Lett. 2013, 103, 131901. [Google Scholar] [CrossRef]

- Sagias, V.D.; Papageorgiou, D.G.; Pappas, A.; Stergiou, C.I. Mechanical Properties of AM Polymer Specimens under Bending Stress. Appl. Mech. 2025, 6, 25. [Google Scholar] [CrossRef]

- Kantaros, A.; Karalekas, D. FBG Based in Situ Characterization of Residual Strains in FDM Process. In Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems, Volume 8; Springer International Publishing: Cham, Switzerland, 2014; pp. 333–337. ISBN 9783319008752. [Google Scholar]

- Tsang, A.C.H.; Zhang, J.; Hui, K.N.; Hui, K.S.; Huang, H. Recent Development and Applications of Advanced Materials via Direct Ink Writing. Adv. Mater. Technol. 2022, 7, 2101358. [Google Scholar] [CrossRef]

- Unkovskiy, A.; Schmidt, F.; Beuer, F.; Li, P.; Spintzyk, S.; Kraemer Fernandez, P. Stereolithography vs. Direct Light Processing for Rapid Manufacturing of Complete Denture Bases: An in Vitro Accuracy Analysis. J. Clin. Med. 2021, 10, 1070. [Google Scholar] [CrossRef]

- Zhuo, S.; Geever, L.M.; Halligan, E.; Tie, B.S.H.; Breheny, C. A Development of New Material for 4D Printing and the Material Properties Comparison between the Conventional and Stereolithography Polymerised NVCL Hydrogels. J. Funct. Biomater. 2022, 13, 262. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Evaluating Benchtop Additive Manufacturing Processes Considering Latest Enhancements in Operational Factors. Processes 2024, 12, 2334. [Google Scholar] [CrossRef]

- Antezana, P.E.; Municoy, S.; Ostapchuk, G.; Catalano, P.N.; Hardy, J.G.; Evelson, P.A.; Orive, G.; Desimone, M.F. 4D Printing: The Development of Responsive Materials Using 3D-Printing Technology. Pharmaceutics 2023, 15, 2743. [Google Scholar] [CrossRef] [PubMed]

- Valvez, S.; Reis, P.N.B.; Susmel, L.; Berto, F. Fused Filament Fabrication-4D-Printed Shape Memory Polymers: A Review. Polymers 2021, 13, 701. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Lv, Q.; Wu, W. Application and Prospects of Hydrogel Additive Manufacturing. Gels 2022, 8, 297. [Google Scholar] [CrossRef]

- Kantaros, A.; Katsantoni, M.; Ganetsos, T.; Petrescu, N. The Evolution of Thermoplastic Raw Materials in High-Speed FFF/FDM 3D Printing Era: Challenges and Opportunities. Materials 2025, 18, 1220. [Google Scholar] [CrossRef]

- Marcinkowska, A.; Gajewski, P. 4D Printing of Polyurethane Actuators and Sensors. In Smart Materials in Additive Manufacturing, Volume 3; Elsevier: Amsterdam, The Netherlands, 2024; pp. 355–395. ISBN 9780443136733. [Google Scholar]

- Malekmohammadi, S.; Sedghi Aminabad, N.; Sabzi, A.; Zarebkohan, A.; Razavi, M.; Vosough, M.; Bodaghi, M.; Maleki, H. Smart and Biomimetic 3D and 4D Printed Composite Hydrogels: Opportunities for Different Biomedical Applications. Biomedicines 2021, 9, 1537. [Google Scholar] [CrossRef]

- Razzaq, M.Y.; Gonzalez-Gutierrez, J.; Farhan, M.; Das, R.; Ruch, D.; Westermann, S.; Schmidt, D.F. 4D Printing of Electroactive Triple-Shape Composites. Polymers 2023, 15, 832. [Google Scholar] [CrossRef] [PubMed]

- Pivar, M.; Vrabič-Brodnjak, U.; Leskovšek, M.; Gregor-Svetec, D.; Muck, D. Material Compatibility in 4D Printing: Identifying the Optimal Combination for Programmable Multi-Material Structures. Polymers 2024, 16, 2138. [Google Scholar] [CrossRef]

- The 17 Goals. Available online: https://sdgs.un.org/goals (accessed on 18 June 2025).

- Blasiak, S.; Bochnia, J.; Takosoglu, J.; Kozior, T.; Nowakowski, L.; Skrzyniarz, M.; Krzysztofik, I.; Blasiak, M.; Dindorf, R.; Wos, P. 3D/4D Printing in Advanced Robotics Systems—Recent Developments and Applications. Sustainability 2024, 16, 11174. [Google Scholar] [CrossRef]

- Aronne, M.; Polano, M.; Bertana, V.; Ferrero, S.; Frascella, F.; Scaltrito, L.; Marasso, S.L. Application of 3D and 4D Printing in Electronics. J. Manuf. Mater. Process. 2024, 8, 164. [Google Scholar] [CrossRef]

- Mahmood, A.; Akram, T.; Chen, H.; Chen, S. On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges. Polymers 2022, 14, 4698. [Google Scholar] [CrossRef] [PubMed]

- Pourmasoumi, P.; Moghaddam, A.; Nemati Mahand, S.; Heidari, F.; Salehi Moghaddam, Z.; Arjmand, M.; Kühnert, I.; Kruppke, B.; Wiesmann, H.-P.; Khonakdar, H.A. A Review on the Recent Progress, Opportunities, and Challenges of 4D Printing and Bioprinting in Regenerative Medicine. J. Biomater. Sci. Polym. Ed. 2023, 34, 108–146. [Google Scholar] [CrossRef]

- Pei, E.; Loh, G.H.; Nam, S. Concepts and Terminologies in 4D Printing. Appl. Sci. 2020, 10, 4443. [Google Scholar] [CrossRef]

- Kantaros, A. 3D Printing in Regenerative Medicine: Technologies and Resources Utilized. Int. J. Mol. Sci. 2022, 23, 14621. [Google Scholar] [CrossRef] [PubMed]

- Arvizu Alonso, A.K.; Armendáriz Mireles, E.N.; Calles Arriaga, C.A.; Rocha Rangel, E. Control of the Properties of the Voronoi Tessellation Technique and Biomimetic Patterns: A Review. Designs 2024, 8, 93. [Google Scholar] [CrossRef]

- Andreucci, C.A.; Fonseca, E.M.M.; Jorge, R.N. Biomechanics of a Novel 3D Mandibular Osteotomy Design. Designs 2024, 8, 57. [Google Scholar] [CrossRef]

- Pais, A.; Moreira, C.; Belinha, J. The Biomechanical Analysis of Tibial Implants Using Meshless Methods: Stress and Bone Tissue Remodeling Analysis. Designs 2024, 8, 28. [Google Scholar] [CrossRef]

- Chiesa, I.; Ceccarini, M.R.; Bittolo Bon, S.; Codini, M.; Beccari, T.; Valentini, L.; De Maria, C. 4D Printing Shape-Morphing Hybrid Biomaterials for Advanced Bioengineering Applications. Materials 2023, 16, 6661. [Google Scholar] [CrossRef]