1. Introduction

Desiccation cracking in soil is multi-physic in nature and is a highly non-linear phenomenon which involves hydraulic, mechanical and thermal processes. Numerical models developed in the past have been able to capture specific elements of the desiccation cracking process, such as the number of cracks and the depth of cracks (e.g., [

1,

2,

3,

4], but were not able to model the complete process under given soil properties and boundary conditions. One limitation of numerical models is that they are often limited by the size of the computational domain that can be modeled. This is because the number of grid elements required to accurately model the domain increases exponentially with the domain size. As a result, numerical models of desiccation cracking are often limited to small-scale laboratory experiments or to simplified geometries. Another limitation of numerical models is that they require accurate input parameters, such as material properties and boundary conditions, which can be difficult to measure experimentally. Inaccurate input parameters can lead to inaccurate predictions, and it can be challenging to identify the sources of error in the model.

Analytical models, on the other hand, often make simplifying assumptions to handle complicated equations and to make them solvable in a closed form. For example, some analytical models assume that the soil is homogeneous and isotropic, and that the cracks are straight and parallel [

5,

6,

7,

8,

9]. While these assumptions may be reasonable in some cases, they can lead to inaccuracies in the predictions. Another limitation of analytical models is that they often assume linear behavior, which is not often accurate for materials undergoing desiccation cracking [

10]. This can limit their usefulness in predicting the behavior of real-world materials.

The above-mentioned limitations of numerical and analytical models can be overcome by artificial intelligence (AI) and machine learning (ML) tools. AI algorithms, such as Artificial Neural Networks (ANNs), random forest (RD) and deep learning, can learn from data and make predictions without explicitly modeling the underlying physical and chemical processes. This allows for more accurate and efficient predictions of desiccation cracking. This can lead to new insights and a deeper understanding of the underlying processes that drive desiccation cracking.

AI has already been successfully applied in various geotechnical fields [

11], such as slope stability [

12,

13], tunneling [

14,

15], rock mechanics [

16,

17], foundations [

18], etc. For example, Luo et al. [

13] applied particle swarm optimization combined with cellular automata (PSO-CA) for slope stability prediction, while Jamhiri et al. [

19] used probabilistic machine learning methods to predict desiccation cracking under uncertainty. Sharma et al. [

17] employed machine learning models to predict rock fragmentation in coal seams. These studies demonstrate the growing utility of AI in handling geotechnical datasets characterized by complexity and non-linearity. Building upon these advances, the current study aims to refine the prediction of Crack and Shrinkage Intensity Factor (CSIF) and offers both improved accuracy and deeper insight into influential parameters.

Choudhury and Costa [

20] used ANN to predict desiccation cracks in thin, long clay layers. The output of the model was the number of cracks, which was predicted with a high accuracy (R) of 99% and a mean absolute error (MAE) of 0.11. However, the dataset used in this study was relatively small—16 samples. Baghbani et al. [

21] used a classification and regression tree (CART) model to examine a 31-set database of desiccation cracking. The results indicated that CART performed satisfactorily. In both studies ([

20,

21]), four inputs were considered: initial moisture content, specimen thickness, specimen length and specimen width, and the output was the number of cracks. However, not all influential parameters were considered in these studies. For example, drying rate and dry density were not among the inputs. The output used—number of cracks—is not a true representation of the severity of cracking and cannot be used for comparison as it does not describe the morphology of cracks. Another limitation is the size of the database, which affects prediction intervals.

This study contributes to the field by developing and comparing four mathematical models—MLR, CRRF, ANN and GP—for accurately predicting the Crack and Shrinkage Intensity Factor (CSIF) during clay soil desiccation. By generating a comprehensive experimental database of 100 drying tests across a range of soil types and environmental conditions, this research identifies the most influential parameters governing desiccation behavior. This study not only demonstrates the superior performance of AI-based models, particularly ANN with Bayesian Regularization, but also introduces a symbolic GP-based equation for practical use. Importantly, this is the first known study to successfully apply AI to predict the CSIF with such high accuracy, offering a scalable and interpretable framework for future field and laboratory applications in geotechnical engineering.

2. Methodology

A large number of soil drying tests were conducted to generate a sizeable database for the model. The scope of this study was limited to parallel cracks in clay, which are usually observed in long soil layers. Hence, the soil samples for drying were prepared in thin, long molds similar to the work of Nahlawi and Kodikara [

22] and Costa et al. [

23]. This type of crack can be considered one-dimensional (1D).

2.1. Materials

Two types of clay, kaolin and bentonite, were used to prepare a range of soil mixtures with different plasticity characteristics. According to

Table 1, the different weight percentages of these two types of clays were mixed. The Atterberg limit tests, including LL and PL, were performed on the 5 mixtures described in

Table 1.

2.2. Shrinkage and Cracking Test

The Australian Standard of linear shrinkage [

24] was followed for the shrinkage and crack testing of mixtures. According to

Table 1 and

Table 2, different dry mixtures were prepared based on different percentages of kaolinite and bentonite. The LL and PI were used as input parameters to quantify the mixture type.

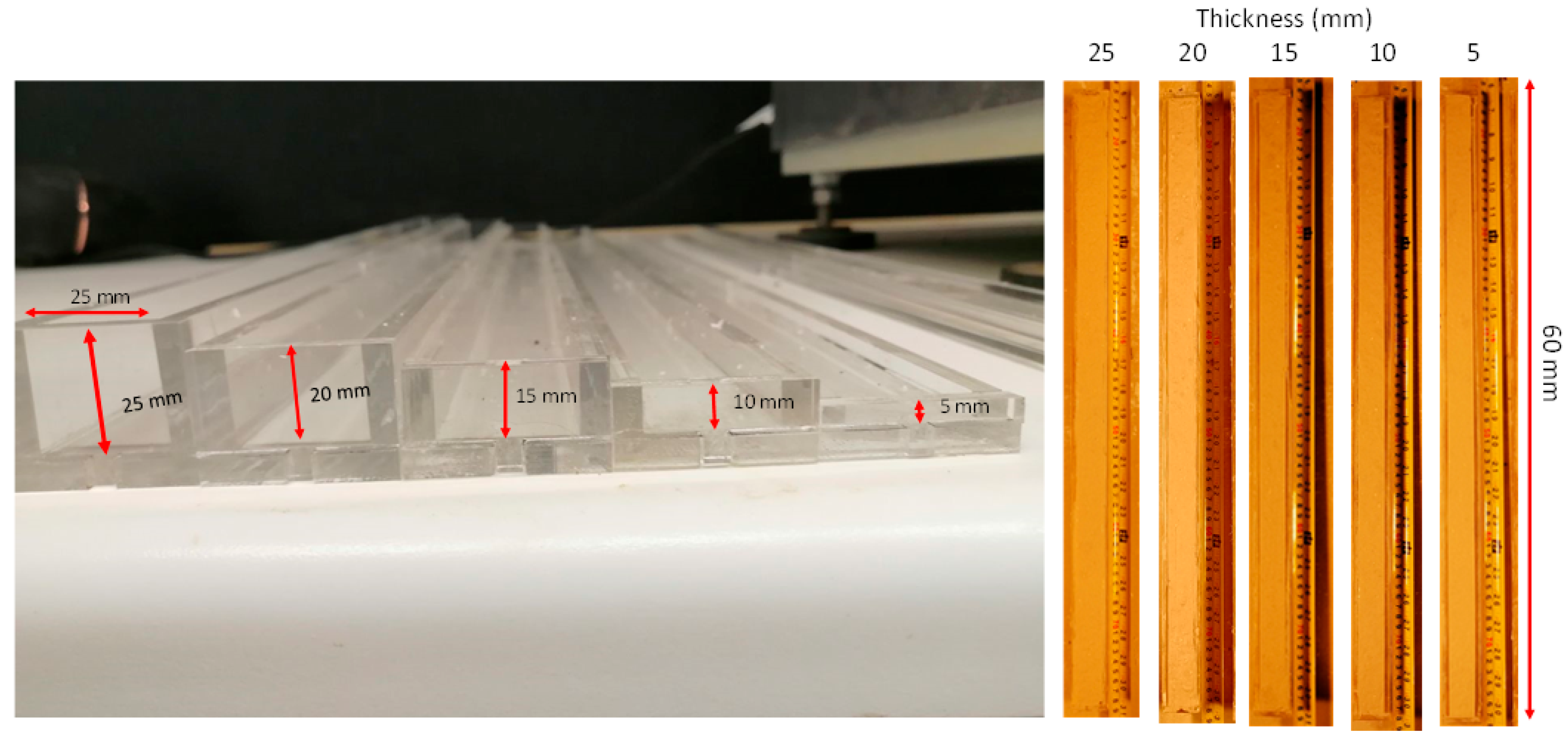

The cracking test plan included five different soil layer thicknesses, 5, 10, 15, 20 and 25 mm, based on previous laboratory tests on desiccation cracking [

25]. For achieving the desired thickness, rectangular acrylic molds with widths and lengths of 25 and 600 mm, respectively, and target heights were prepared (

Figure 1).

Soil mixtures were prepared at LL and 1.5 LL moisture contents and were cured for 24 h at room temperature to attain moisture equilibrium. During filling, air bubbles were removed from the sample by tapping for 30 s.

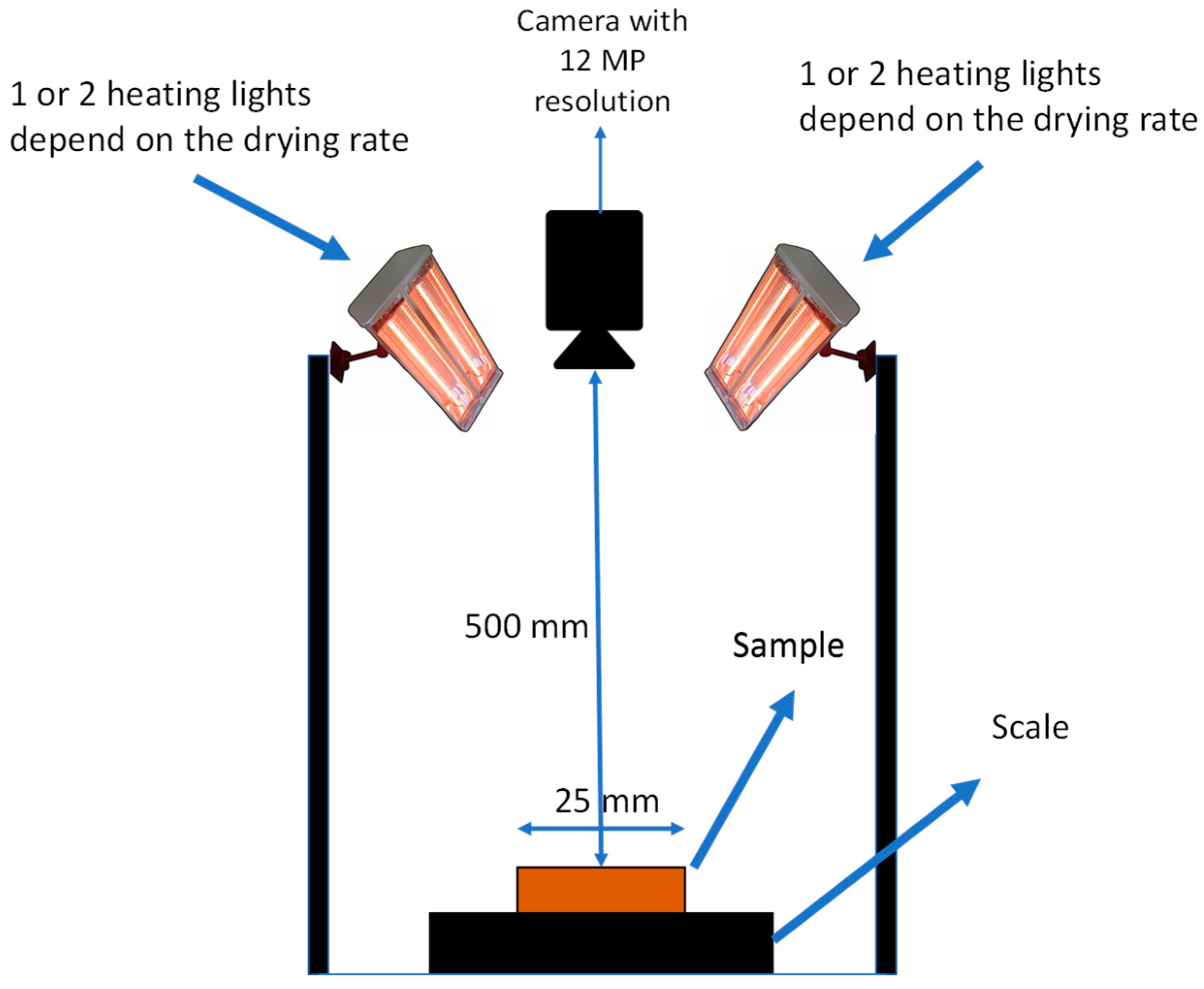

Two different drying rates were used, controlled by four lights over the length of the sample: for a higher drying rate (

D), all four lights were on, and for a lower drying rate (0.75

D), two lights were on.

Figure 2 shows the schematic drawing of the setup used for the drying tests.

All drying tests were conducted in a closed indoor laboratory environment to maintain consistency across experiments. While ambient temperature and relative humidity were allowed to vary slightly to reflect realistic conditions, their range was narrow—between 39.8 °C and 50.0 °C for temperature, and 15.9% to 17.9% for relative humidity—as listed in

Table 2. No airflow or wind sources were present during the tests. These conditions ensured minimal environmental noise and a high consistency in the drying process, providing a reliable basis for model training and validation.

All tests were conducted for a duration of 270 min, and the drying rate was measured accordingly by using Equation (1) for each test. The drying rate (

) was assumed to be uniform during the drying period, as given by Equation (1).

where

is the final sample mass,

is the initial sample mass and

t is the total test time. The surrounding ambient temperature and humidity were also recorded during the drying process.

2.3. Shrinkage and Crack Quantification

In order to quantify shrinkage and cracks, images were taken every 30 min with a 12-megapixel camera. The final Crack and Shrinkage Intensity Factor (

CSIF) was calculated using the final image taken after 270 min at the end of the test. The image analysis software ImageJ (Version 1.51) [

26] was used to analyze the images and to calculate

CSIF according to Equation (2).

2.4. Modeling Methods

2.4.1. Multiple Linear Regression (MLR)

Multiple Linear Regression (MLR) is a fundamental statistical technique used to model the relationship between a dependent variable and multiple independent variables through a linear equation. It estimates regression coefficients by minimizing the sum of the squared differences between observed and predicted values, allowing for the straightforward interpretation of each input’s contribution to the output. While MLR is computationally efficient and easy to implement, it inherently assumes linearity, independence and homoscedasticity among variables. These assumptions may limit its predictive performance when modeling highly non-linear processes such as soil desiccation cracking. Despite this, MLR serves as a useful baseline model for comparison with the more advanced machine learning techniques explored in this study.

2.4.2. Classification and Regression Random Forest (CRRF)

Breiman [

27] combined decision trees with bootstrap aggregation or bagging to reduce classification and regression errors. Classification and Regression Random Forest (CRRF) is an ensemble learning method that combines multiple decision trees to improve predictive performance and reduce overfitting. Developed by Breiman [

27], the random forest algorithm constructs numerous decision trees using bootstrap samples of the training data and random subsets of input variables at each split. For regression tasks, such as predicting the Crack and Shrinkage Intensity Factor (CSIF), the model aggregates the outputs of individual trees by averaging their predictions. This method is particularly robust when handling non-linear relationships, noisy data and complex interactions between variables. CRRF also provides insights into variable importance by evaluating the contribution of each input to the overall reduction in prediction error. Due to its simplicity, high accuracy and resistance to overfitting, CRRF is widely adopted in geotechnical engineering applications and serves as a reliable benchmark for evaluating model performance in this study.

2.4.3. Artificial Neural Network (ANN)

The ANN is a mathematical model composed of artificial neurons capable of finding complex, non-linear relationships between inputs and outputs. The ANN first identifies the relationship between inputs and outputs based on the weights that are the connecting power between two neurons [

28]. Second, the network seeks to optimize the obtained weights, which is called the paradigm. This study used a feedforward paradigm [

29], one of the strongest and most widely used paradigms. The feedforward paradigm has different algorithms. Bayesian Regularization (BR) [

30] and Levenberg–Marquardt (LM) [

31] algorithms with a strong ability in testing non-linear relationships were used in this study.

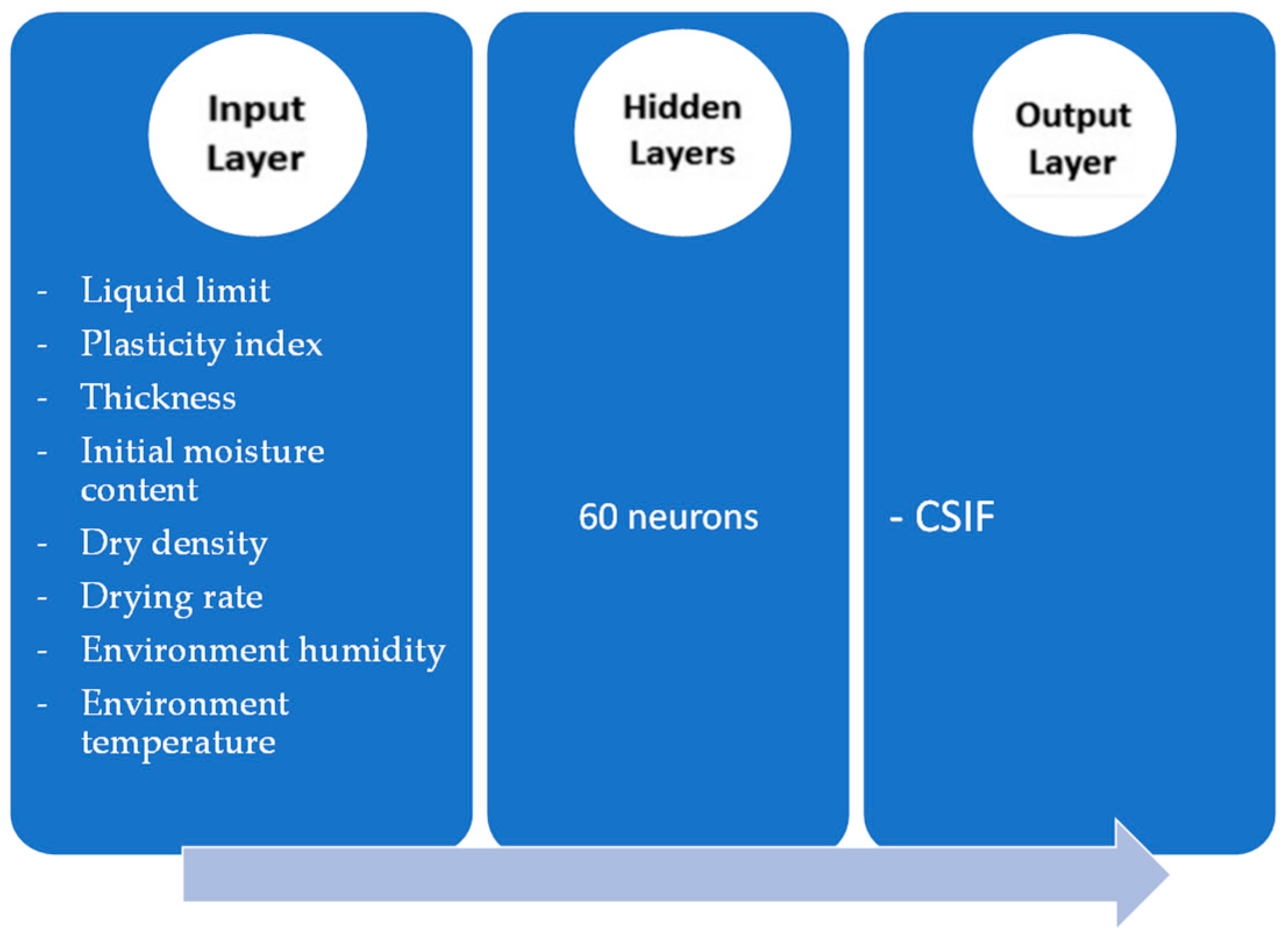

Input layers, hidden layers and output layers make up the ANN architecture. A total of five architecture types were considered, including one, two, three, four and five hidden layers, for each algorithm, LM and BR. The number of 60 neurons was selected after several trials. Each neuron was re-trained five times in every network.

Figure 3 shows the ANN schematic architecture used in this study.

2.4.4. Genetic Programming (GP)

Genetic Programming (GP) is an evolutionary algorithm-based method that automatically evolves mathematical models or symbolic expressions to solve complex regression or classification problems. Inspired by the principles of natural selection and genetics, GP iteratively refines a population of candidate solutions—represented as computer programs or symbolic equations—through operations such as selection, crossover and mutation. In this study, GP was employed to derive explicit mathematical expressions for predicting the Crack and Shrinkage Intensity Factor (CSIF) using normalized input variables. Unlike traditional black-box models, GP offers interpretable and deployable formulas that can be directly used in practical engineering design without requiring specialized software. While GP may require significant computational effort and careful tuning to avoid overfitting, its ability to discover non-linear relationships and generate human-readable equations makes it a powerful tool for knowledge discovery and predictive modeling in geotechnical applications.

2.5. Data Processing

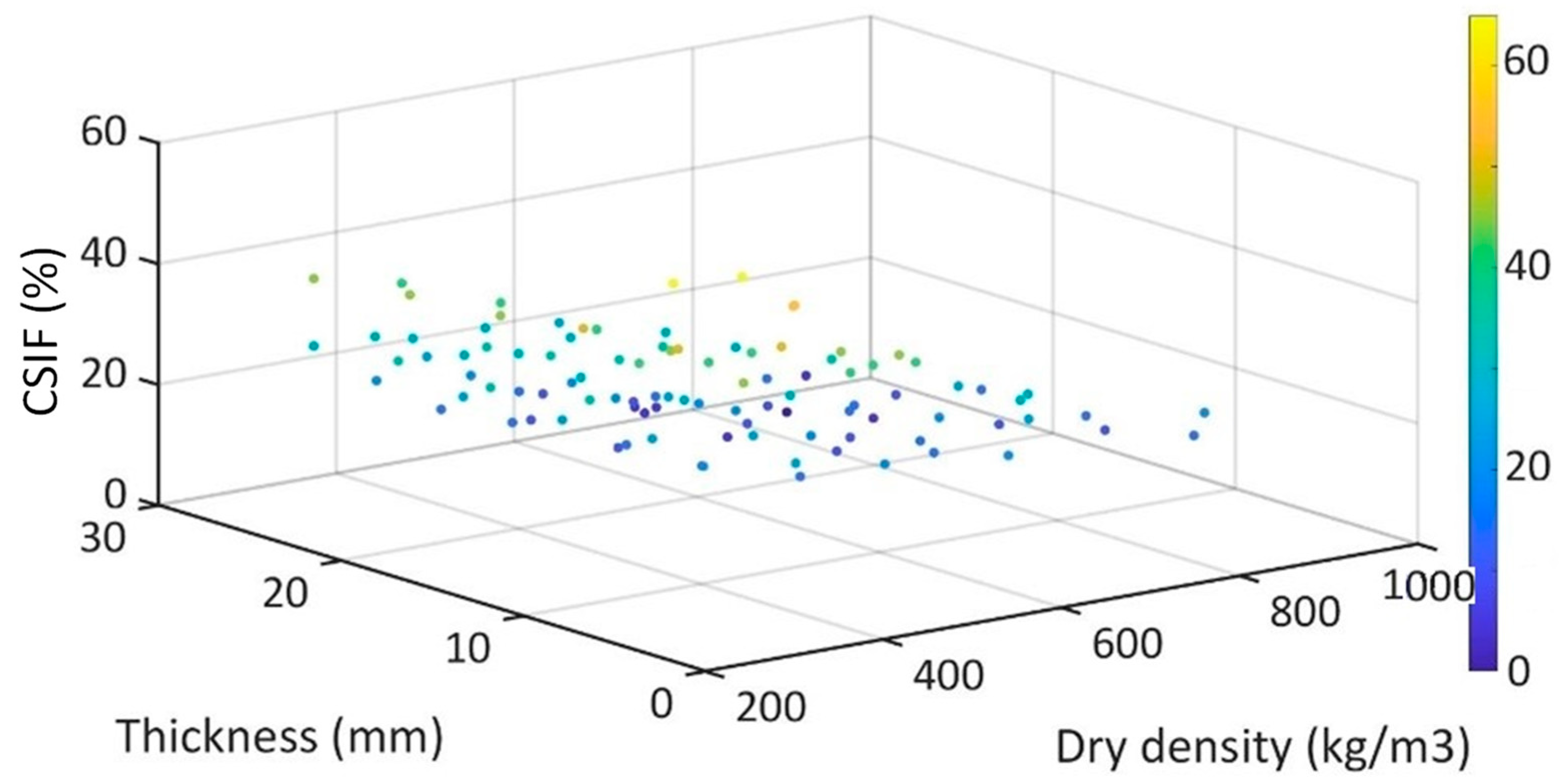

Drying tests resulted in 100 datasets with 8 effective inputs: dry density, initial water content, soil thickness, drying rate, LL, PI, ambient humidity and temperature; and one output parameter: the CSIF. The following steps were taken to prepare the database:

2.5.1. Normalization

In the existing database, each variable had its own unit. Data normalization reduces network error and increases the network training speed. Below is the normalization linear function which was used in this study.

where

Xmax,

Xmin,

X and

Xnorm are the maximum, minimum, actual and normalized values, respectively.

2.5.2. Testing and Training Databases

For all three mathematical models, the dataset was randomly divided into two subsets: 80% for training and 20% for testing. To ensure the consistency and reliability of the model performance, the statistical characteristics of both subsets, along with the minimum, maximum, mean and standard deviation, were examined. As shown in

Table 3 and

Table 4, the training and testing datasets exhibited similar statistical distributions, indicating that the data segmentation was balanced and suitable for accurate model evaluation.

For a more comprehensive assessment, k-fold cross-validation (e.g., 5-fold or 10-fold) could be implemented, especially in future studies involving larger and more diverse datasets. This would allow each data point to be used for both training and validation, thereby minimizing variance and better capturing the model’s generalization capability. Although computational constraints limited its implementation in the current work—especially given the extensive hyperparameter tuning and re-training required for the ANN and GP models—we recognize its importance and recommend cross-validation as a key component in future extensions of this research.

4. Discussion

4.1. Comparison of Mathematical Models

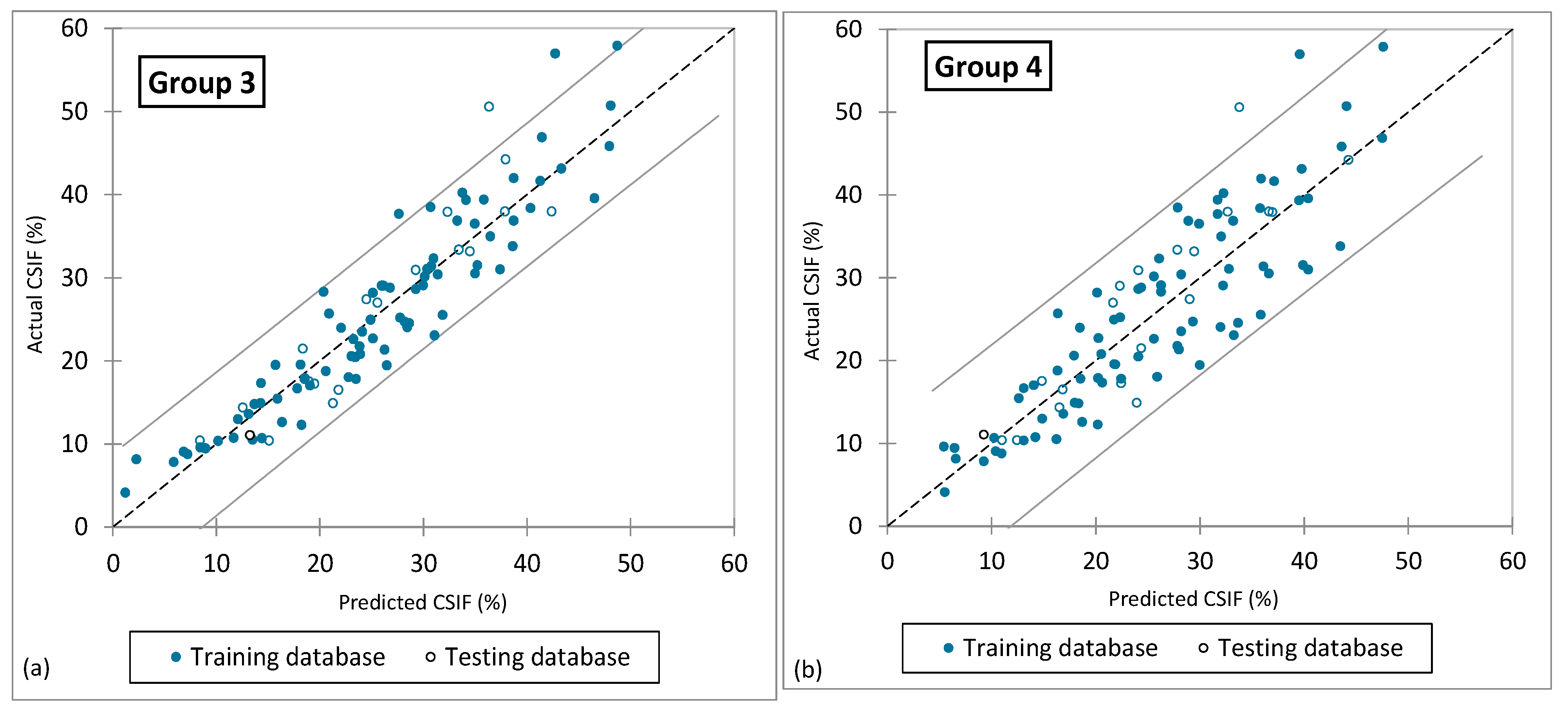

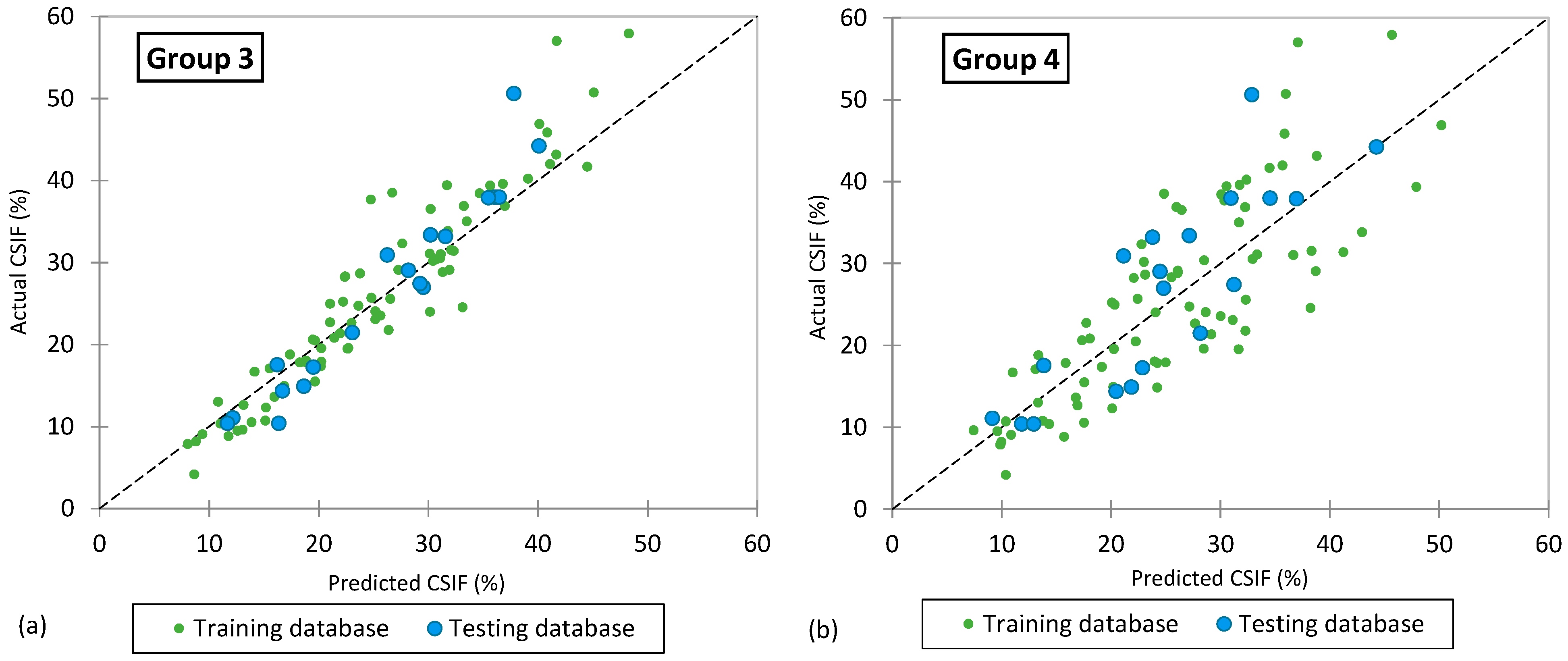

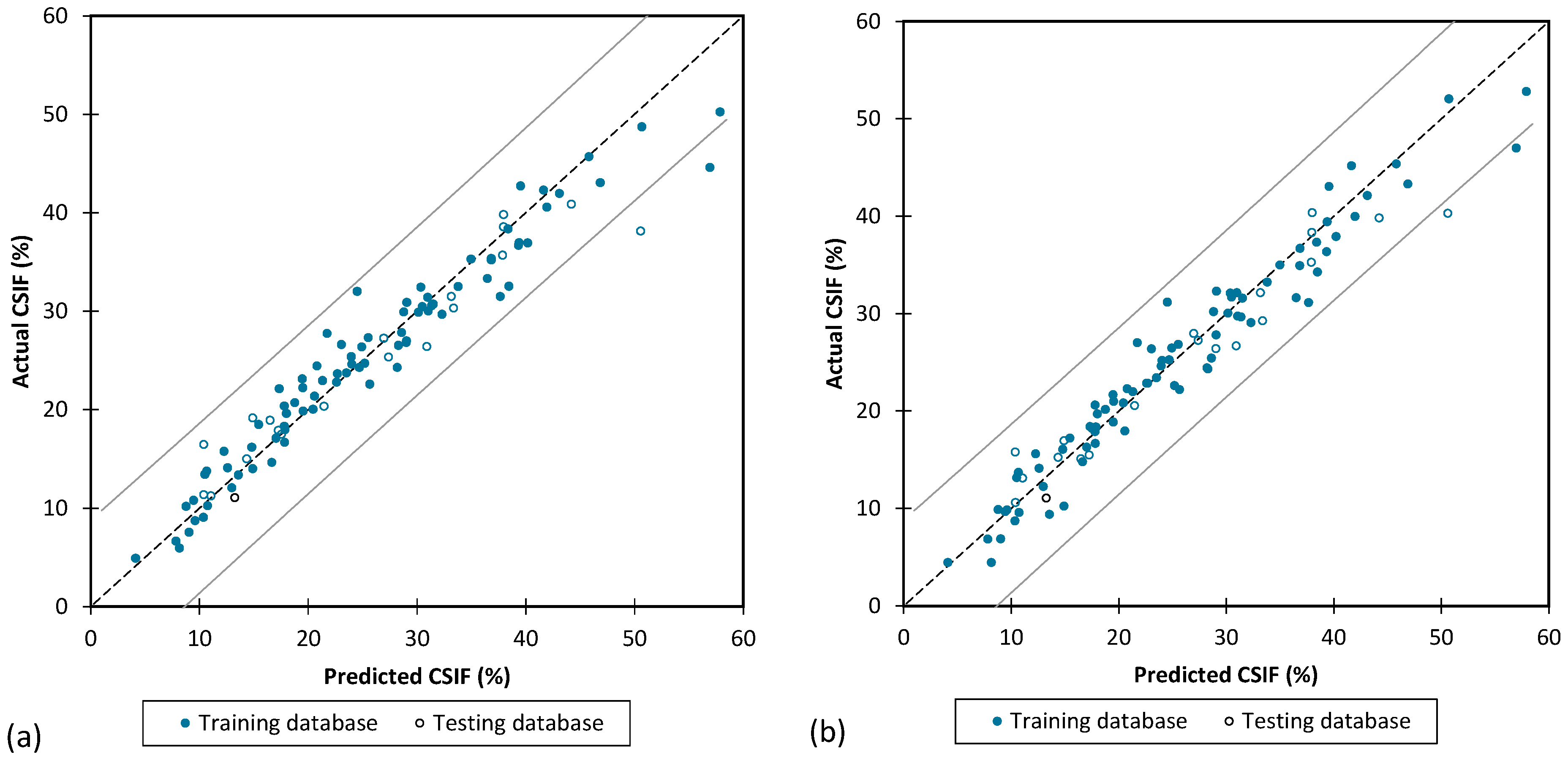

The results of the four mathematical models used to predict CSIF using the five input groups are presented in

Table 16. Based on the R values of the three mathematical models using the first three input groups, 1, 2 and 3, the initial moisture content, ambient temperature and humidity did not appear to have much impact on prediction when drying rate was included. When drying rate was removed, the accuracy of all three mathematical models was greatly reduced, indicating the importance of drying rate in predicting CSIF.

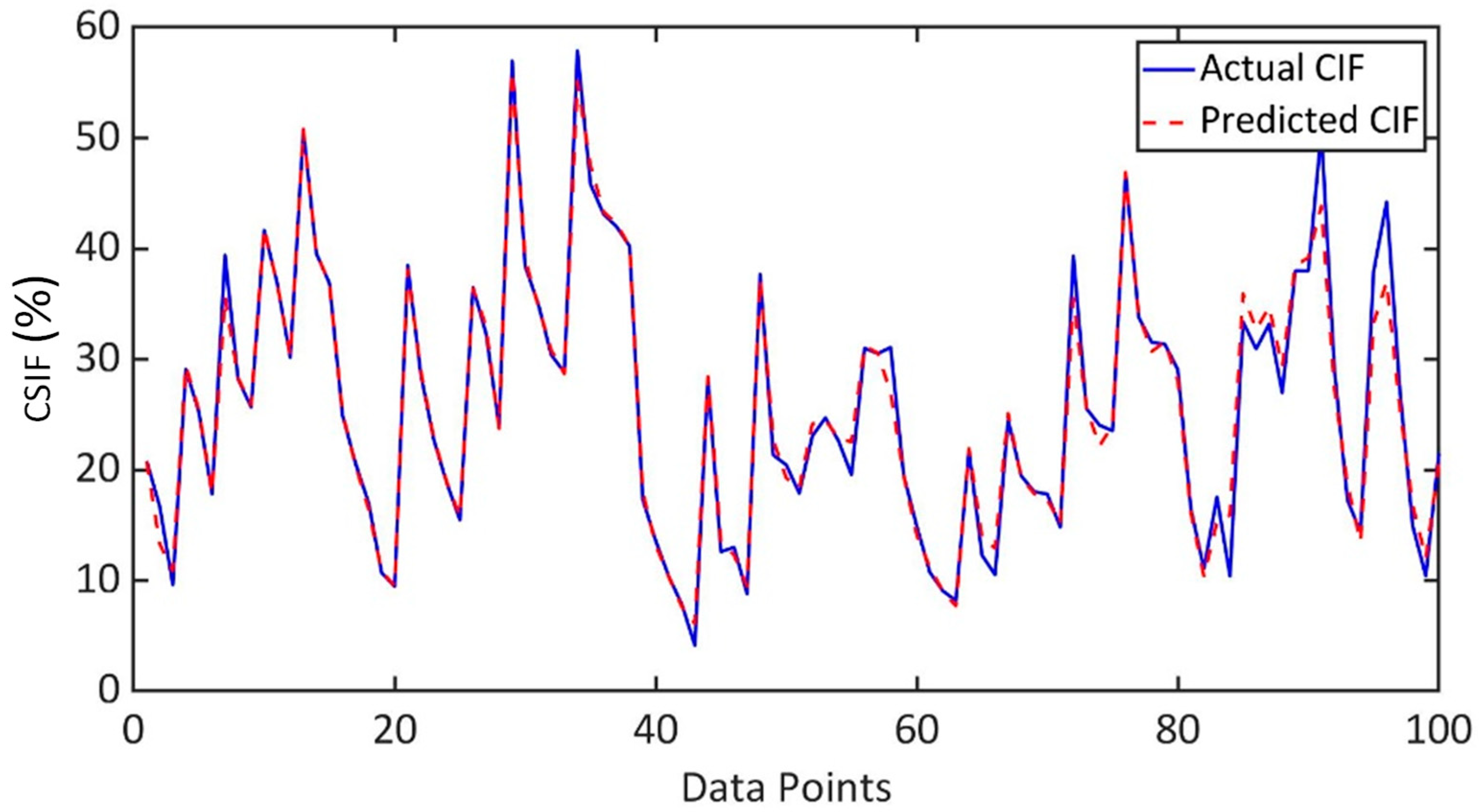

Among all five input groups, the Artificial Neural Network (ANN) consistently outperformed the other models, achieving the highest predictive accuracy with an R value of 0.99 and a mean absolute error (MAE) of approximately 5. The Classification and Regression Random Forest (CRRF) model ranked second in performance, particularly for input groups 1, 2 and 3, where it attained an R of 0.97 and an MAE close to 6. In contrast, the Multiple Linear Regression (MLR) model showed the lowest accuracy, with an R value around 0.84 and MAE value near 11 for the same input groups, highlighting its limitation in capturing the non-linear nature of this problem. Notably, the Genetic Programming (GP) model developed for input group 3 yielded an R of 0.958 and an exceptionally low MAE of 2.431, demonstrating strong predictive capability and enhanced interpretability.

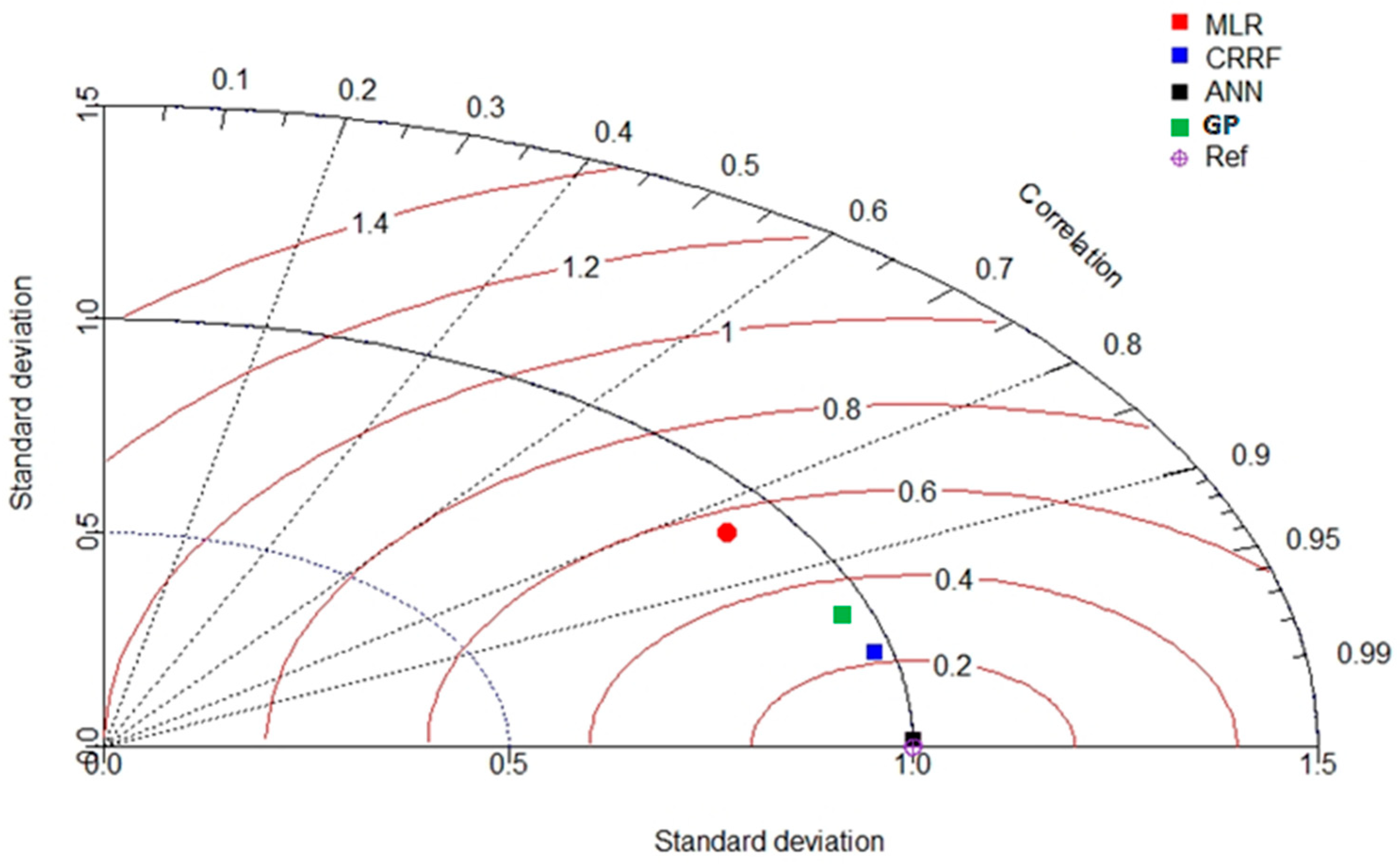

Figure 9 presents the Taylor diagram for input group 3, identified as being the most optimal input combination. This diagram was used to compare the predictive performance of the mathematical models against the actual laboratory results for the testing dataset (denoted as REF in the figure). Among all models, the ANN demonstrated the closest agreement with the experimental data, confirming its superior accuracy and reliability in predicting the Crack and Shrinkage Intensity Factor (CSIF).

The ANN model outperformed the other approaches across all input groups, particularly when trained using Bayesian Regularization. Unlike traditional algorithms that focus solely on minimizing error, BR introduces a Bayesian inference framework to optimize network weights while constraining overfitting. This allows the network to remain flexible enough to model complex, non-linear interactions (e.g., between LL, PI and drying rate) while avoiding noise fitting, which was a limitation in both the MLR and over-parameterized networks. These characteristics make BR especially effective for geotechnical problems involving coupled processes with limited datasets.

4.2. Sensitivity Analysis of Input Parameters in ANN Models

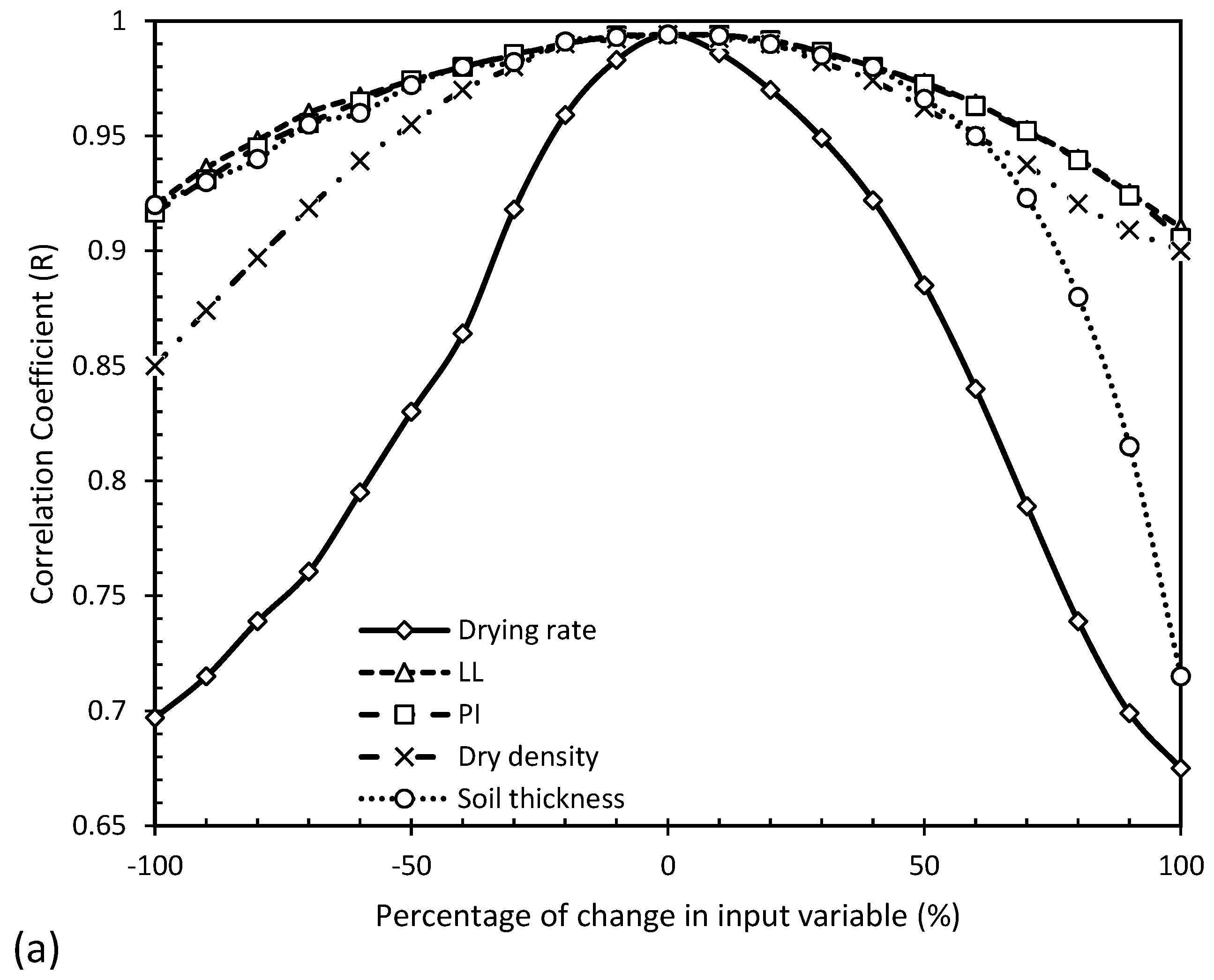

To assess the sensitivity, each input parameter was changed from −100% to +100% separately. The ANN model sensitivity analysis for the input parameters is shown in

Figure 10.

Increasing or decreasing the drying rate by 100% decreased the R of the model to about 0.675 and increased the MAE to about 12.5. For LL, MAE was almost symmetrical with LL changes. In the worst-case scenario, when LL increased by 100%, R was reduced to about 0.9 and MAE was increased to about 10. For PI, the MAE of the ANN increased most when PI increased by 100%, resulting in a change in MAE to 10.4. In response to changing the dry density by 100%, the model’s R and MAE reached 0.85 and 9. Finally, for soil thickness, a 100% increase in soil thickness caused the largest network error (MAE). As soil thickness increased, R decreased to 0.715 and MAE increased to 17.95.

4.3. The Number of Neurons and Re-Training in the Best ANN Model

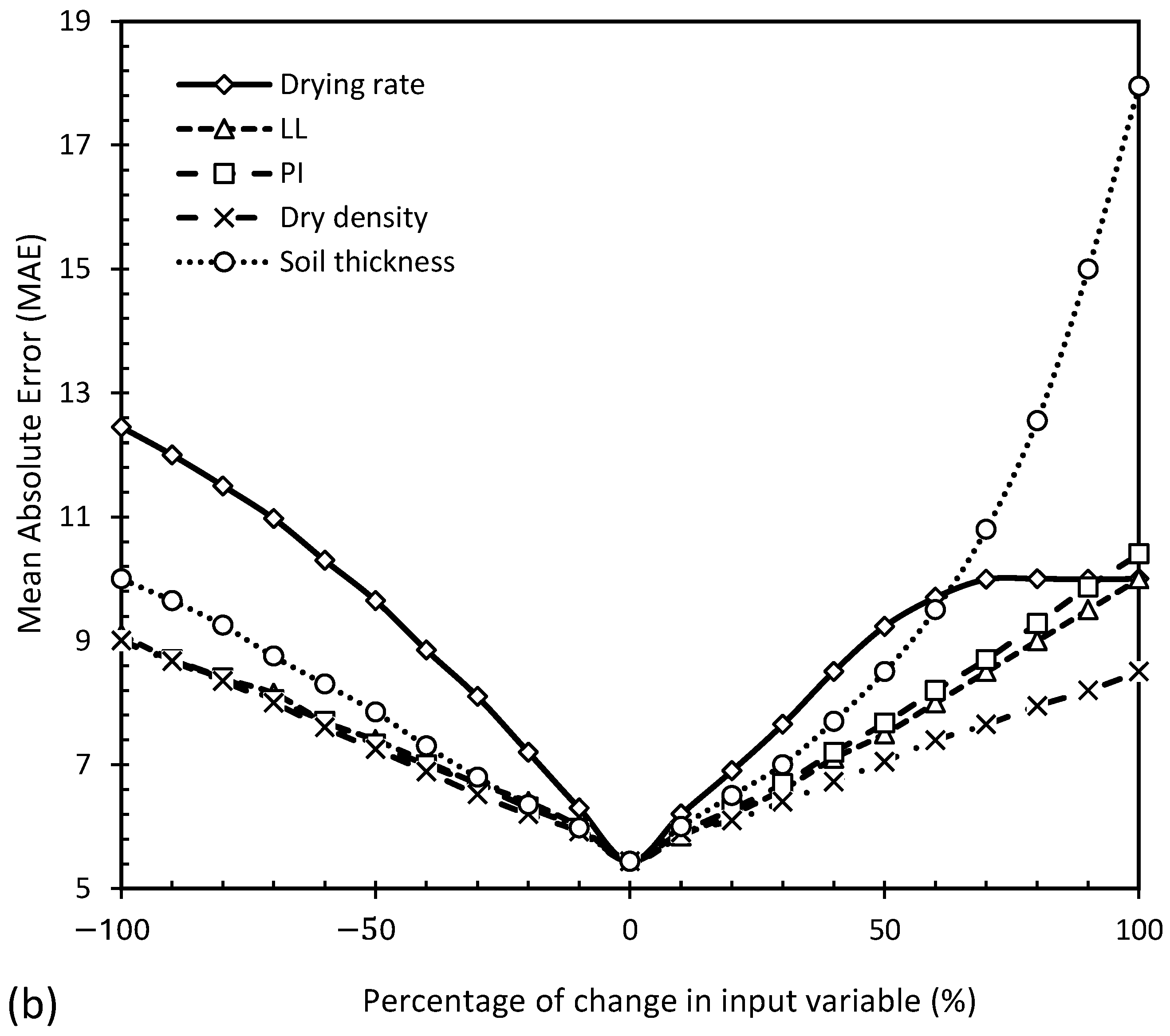

When modeling ANNs, layers, neurons and neuron re-training are important.

Figure 11 illustrates the best ANN model with two hidden layers, using the BR algorithm, for various hidden neurons and network training numbers. Consequently, the ANN model had the greatest error (MAE) in the first and third network re-trainings, but the lowest error (MAE) in the second and fifth.

4.4. The Importance of the Input Parameters

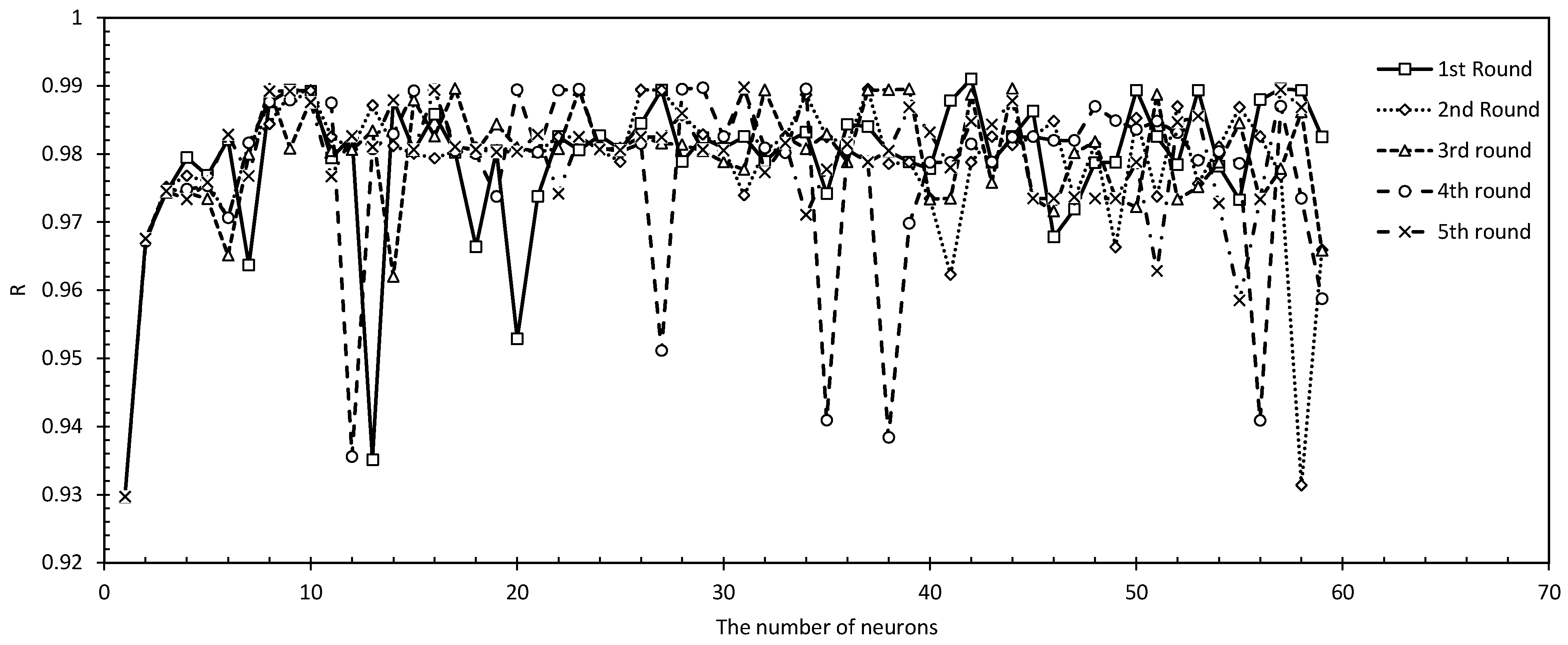

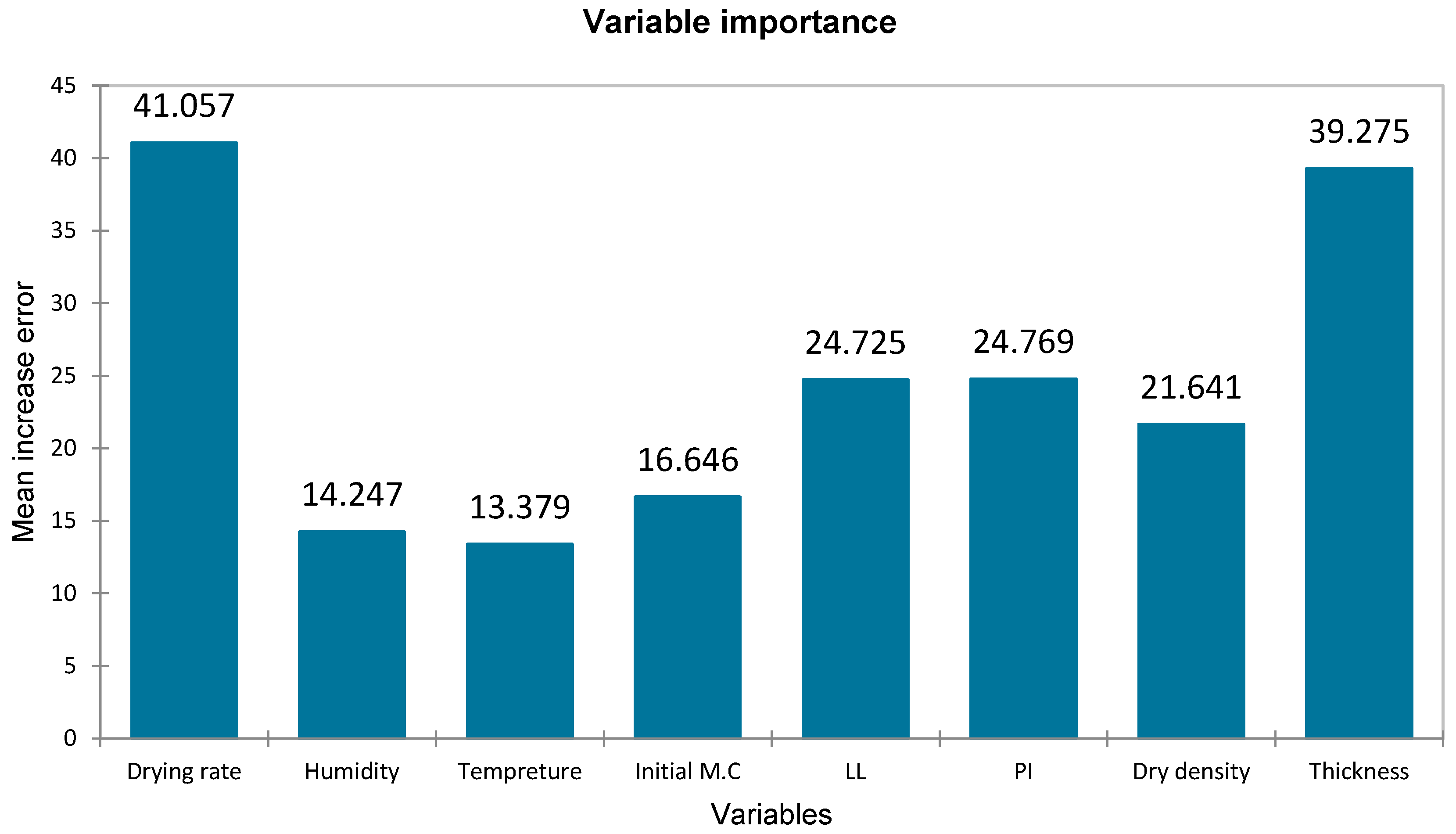

The CRRF and ANN models with two hidden layers using the BR algorithm were investigated for the influence of input parameters on MAE.

Figure 12 shows the sensitivity of the best CRRF model to input parameters. The highest sensitivity was related to soil thickness and drying rate, while the lowest sensitivity was related to ambient humidity and temperature. Jamhiri et al. [

19] also ranked temperature and relative humidity among the least influential parameters for desiccation cracking.

Table 17 presents the ranking of the importance of input parameters based on the increase in mean absolute error (MAE) observed in three AI models: ANN, CRRF and GP. Across all models, drying rate and soil thickness consistently emerged as the most critical factors influencing the prediction of the Crack and Shrinkage Intensity Factor (CSIF), with the lowest MAE rankings (1 or 2). In contrast, ambient humidity and temperature showed the lowest influence, receiving the highest MAE rankings (7 or 8), confirming their redundancy when drying rate was included. Intermediate significance was observed for the liquid limit (LL), plasticity index (PI), dry density and initial moisture content, with moderate MAE impacts across the models. These results aligned with the sensitivity analysis findings and emphasized the dominant role of drying dynamics and soil geometry in desiccation crack development.

Regarding the importance of drying rate, the results of Zhang et al. [

34] showed that the drying rate had a significant effect on the total pore volume. They found that samples dried at higher drying rates had larger total pore volumes than those at lower drying rates. In addition, the experimental results of Krisdani et al. [

35] confirmed that the changes in the proportion of empty space and the degree of soil saturation were strongly influenced by the rate of drying.

LL and PI were the third and fourth most significant and influential factors in predicting CSIF in three AI models, according to

Table 17. LL and PI play an important role in affecting pore water volume and contraction strain. PI increases the pore water volume and therefore the volumetric shrinkage strain during drying, according to Rayhani et al. [

36].

Dry density was the fifth most important parameter in both the ANN and CRRF and the third parameter in GP, followed by the initial moisture content, ambient humidity and temperature.

Section 3.3.1,

Section 3.3.2. and

Section 3.3.3 discuss how the removal of these three parameters affects model accuracy.

The dominance of soil thickness and drying rate as the most important variables is consistent across all AI models tested. Thicker soil layers are more susceptible to crack propagation due to the greater energy required to overcome tensile strength and form multiple fracture planes. In contrast, thinner layers are more constrained and develop fewer cracks. The drying rate governs the rate of moisture loss, which directly influences suction generation, shrinkage strain accumulation and the initiation of desiccation cracking. Higher drying rates often result in steeper moisture gradients, leading to rapid crack formation and wider fracture networks. These behaviors are supported by the experimental findings from Costa et al. [

37], Krisdani et al. [

35] and Zhang et al. [

34], all of whom observed significant changes in crack morphology with variations in thickness and drying conditions.

The effect of removing potentially redundant parameters, such as initial moisture content, was investigated through a comparison of different input groups. Notably, input group 3, which excluded initial moisture content, ambient temperature and humidity, achieved a nearly identical performance to groups 1 and 2, with an R of 0.991 and MAE of 5.44 for the testing dataset. This indicated that the removal of initial moisture content did not significantly affect the model’s predictive capability. This can be attributed to the experimental setup, in which initial moisture was fixed at either LL or 1.5 LL for each test case. As a result, the variation in initial moisture content was already embedded in the LL parameter, making its explicit inclusion redundant. This finding supports the idea that carefully reducing the number of input parameters can streamline the model, improve computational efficiency and reduce overfitting risks without compromising accuracy.

The sensitivity analysis results provide a clear understanding of how each input parameter affects prediction error and thus offers valuable insight for simplifying models without compromising accuracy. The dominant influence of drying rate and soil thickness aligns with physical observations from past studies, highlighting their role in controlling moisture migration and crack energy release. Such insights are useful for prioritizing field measurements when data availability is limited.

4.5. Sustainability and Future Research Directions

The application of AI-based models in predicting soil desiccation cracking contributes to sustainability in geotechnical engineering by minimizing the need for extensive physical testing and enabling the more efficient use of resources. The accurate prediction of crack intensity factors can assist engineers in proactively designing infrastructure and soil covers, thereby reducing long-term maintenance costs and the environmental impacts associated with soil failure and water seepage.

Furthermore, the reduced reliance on trial-and-error approaches for crack control in clayey soils promotes a more sustainable design methodology, especially in expansive soil regions where desiccation-related damage is common.

Future research should explore the generalization of these models to more complex crack geometries (2D and 3D patterns), as well as their validation in field-scale conditions under natural environmental variability. Incorporating additional environmental factors (e.g., wind speed, solar radiation), developing hybrid physical–AI models and creating lightweight predictive tools for field use (e.g., mobile apps or edge computing devices) are promising directions to enhance both the sustainability and practicality of this approach in real-world applications.

4.6. Comparison with Previous Studies

An ANN model was used by Choudhury and Costa [

20] to predict 1D cracks in thin, long layers.

Table 18 compares the accuracy of predictions from this study to Choudhury and Costa [

20]. The best performing model from each study has been selected for comparison. The current study achieved improved R and MAE values compared to Choudhury and Costa [

20].

Earlier studies in the domain of desiccation crack prediction primarily focused on limited datasets and fewer input parameters. For instance, Choudhury and Costa [

20] applied an ANN model to predict the number of cracks in long, thin clay layers based on only four input variables and a relatively small dataset of 16 samples. While they achieved high predictive accuracy (

R = 0.93), their output was limited to the number of cracks, which did not fully reflect the severity or morphology of desiccation cracking.

In contrast, the current study introduces the Crack and Shrinkage Intensity Factor (CSIF) as a more comprehensive and continuous output variable that better captures the extent of desiccation damage. By developing a larger experimental database (n = 100) with eight physical and environmental input parameters, and by testing multiple AI and regression models, we present a more robust framework for crack prediction.

The ANN model in this study achieves R = 0.99 and MAE = 5.44, which represents a notable improvement over previous studies—not just numerically, but in terms of the model generalizability, input diversity and output quality. Furthermore, unlike past research, this study performs a detailed input sensitivity analysis and explores parameter optimization, including the effect of removing redundant inputs.

Additionally, the introduction of a symbolic Genetic Programming (GP) model adds interpretability and usability by providing analytical equations that can be easily deployed in engineering calculations. The inclusion of residual plots and Taylor diagrams further strengthens the reliability of the findings, going beyond simple correlation metrics.

5. Conclusions

A series of drying tests were conducted on five types of clay (with different LLs and PIs) in different conditions, including initial moisture content, ambient temperature and humidity, dry density, drying rate and soil thickness. This experimental database was used to predict the Crack and Shrinkage Intensity Factor (CSIF) using four mathematical models, namely MLR, CRRF, ANN and GP.

The ANN models produced the most accurate predictions for CSIF, with an R of 0.99 and MAE of 5.44 for the testing database. Predictions from CRRF and GP were also satisfactory. A higher MAE was noticed in the MLR predictions, indicating the limitations of linear models in encapsulating non-linear processes in desiccation crack formation.

Critical input parameters for AI modeling of desiccation cracks were identified: liquid limit, plasticity index, dry density, soil layer thickness and drying rate. Ambient temperature and humidity were deemed redundant when drying rate was included. Similarly, initial moisture content could also be omitted when liquid limit was included.

The most sensitive input parameters to predict CSIF were soil layer thickness and drying rate followed by plasticity index, liquid limit and dry density.

From a practical engineering standpoint, the developed models can be used to support predictive assessments of soil cover performance, crack mitigation in clay liners and risk evaluations for expansive soil foundations. For example, the ANN model could be integrated into early-stage design tools to estimate the risk of shrinkage cracking under varying environmental conditions, enabling the more efficient selection of soil types or thicknesses. The symbolic GP equations further offer opportunities for fast estimations in field or design office settings without the need for complex software.

While the models developed in this study demonstrated excellent predictive performance under controlled laboratory conditions, further work is needed to assess their generalizability to real-world scenarios. Future research will aim to incorporate field data, explore climate variability and extend the models to 2D and 3D crack patterns. Additionally, integrating uncertainty quantification and cross-site validation will be essential for establishing the models as reliable tools in practical geotechnical applications.