Optimized Green Unrelated Parallel Machine Scheduling Problem Subject to Preventive Maintenance

Abstract

1. Introduction

- Minimizing the number of tardily returned products as an objective function of the proposed mathematical model while considering the machines’ availability.

- Considering preventive maintenance and the average reprocessing times of the returned products.

- Developing a heuristic algorithm to tackle the large size of the problem and evaluate the performance of the proposed mathematical model.

- Determining the returned product allocation to each machine

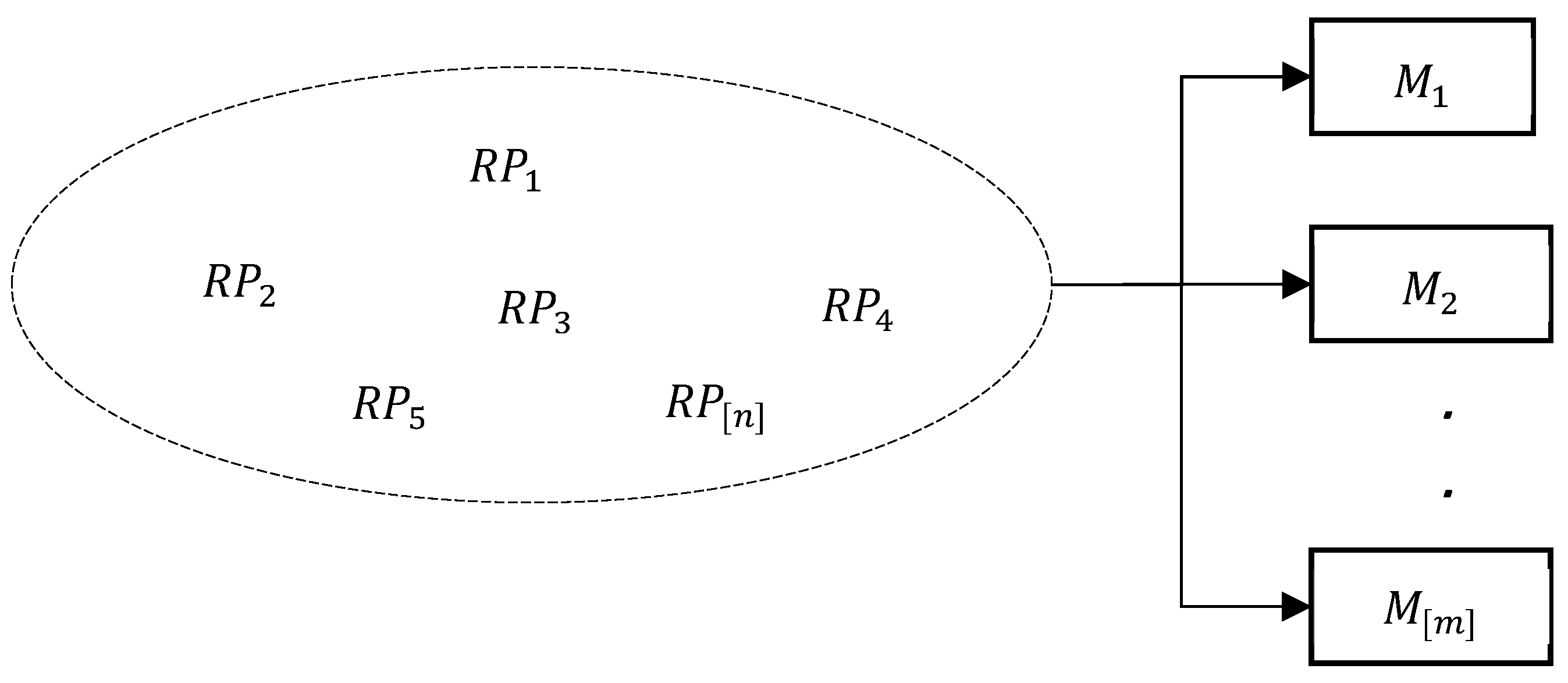

2. Problem Statement and Notation

- Returned products are independent.

- No preemption is allowed; once reprocessing begins on a returned product, it is processed to completion without interruption.

- All returned products are available at time zero.

- All returned products are equally important.

- No cancellation is allowed. Each returned product must be processed to completion.

3. Methodology

3.1. Mathematical Model

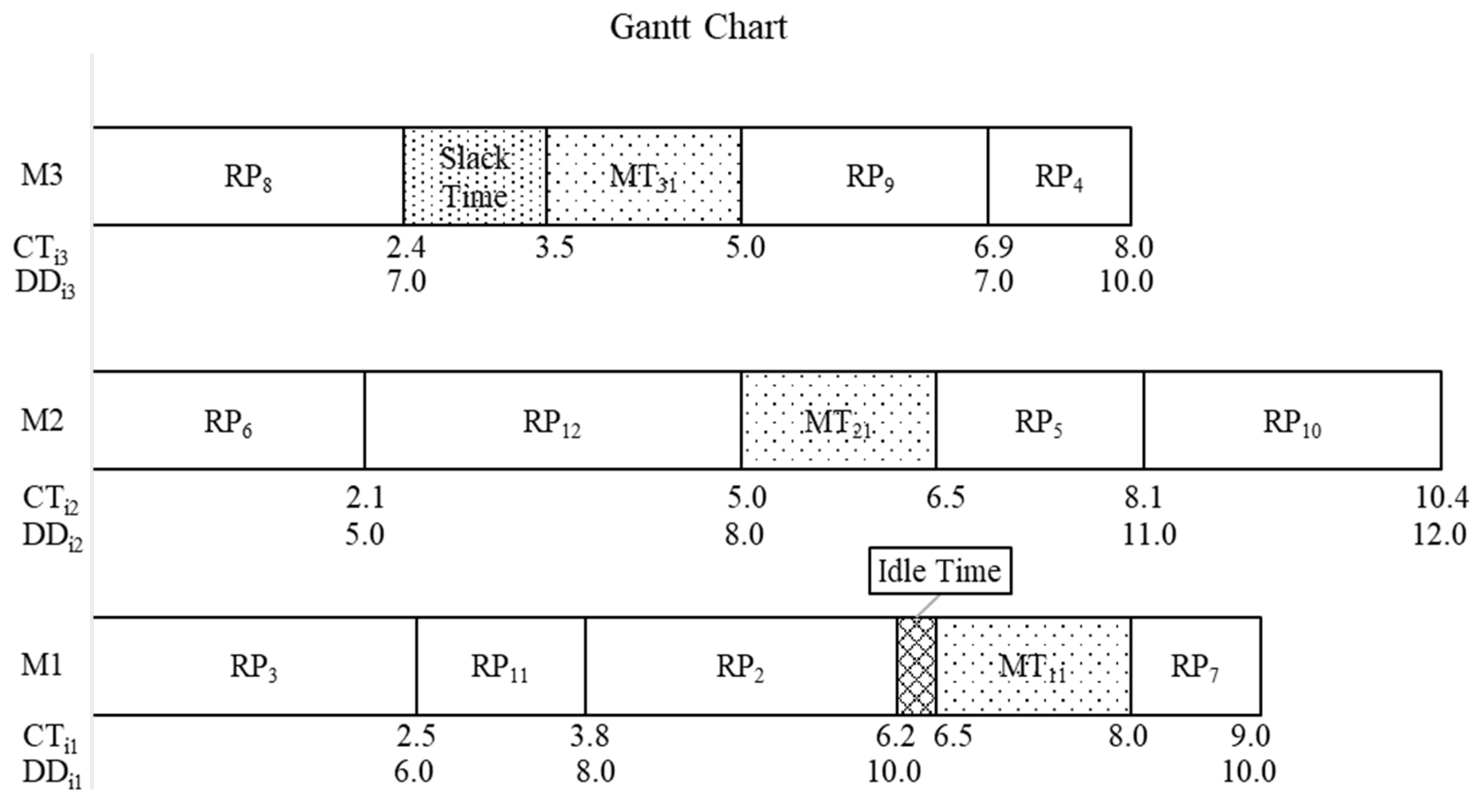

3.2. Modified Moore’s Heuristic Algorithm

- Order returned products using EDD.

- Assign returned products for the EDD list and minimum completion time until there is a tardily returned product () and then go to step 3. If none, go to step 4.

- Find the returned product with the maximum average reprocessing time returned product () among the returned products already assigned in sequences of unrelated parallel machines and then remove from the timetable of the unrelated machines. Shift the returned products following to the left and then go to step 2.

- Find the optimal sequence by taking the current schedule and adding the removed returned products to it.

- All returned products should be assigned to unrelated parallel machines.

- If the , the should be placed in the set , and then the next step is implemented.

- The is classified as a tardily returned product in case ; thus, is removed from the unrelated machines schedule, where it should be added to , where represents the group of tardily returned products.

- Repeat this step by applying step 2 in this stage.

- The slacking time for each set at every unrelated machine should be calculated to determine the unscheduled time (idle time) at the sets in the unrelated machines.

- The returned products in are sorted based on EDD.

- To minimize , the returned products in could be rescheduled during the slack time if possible.

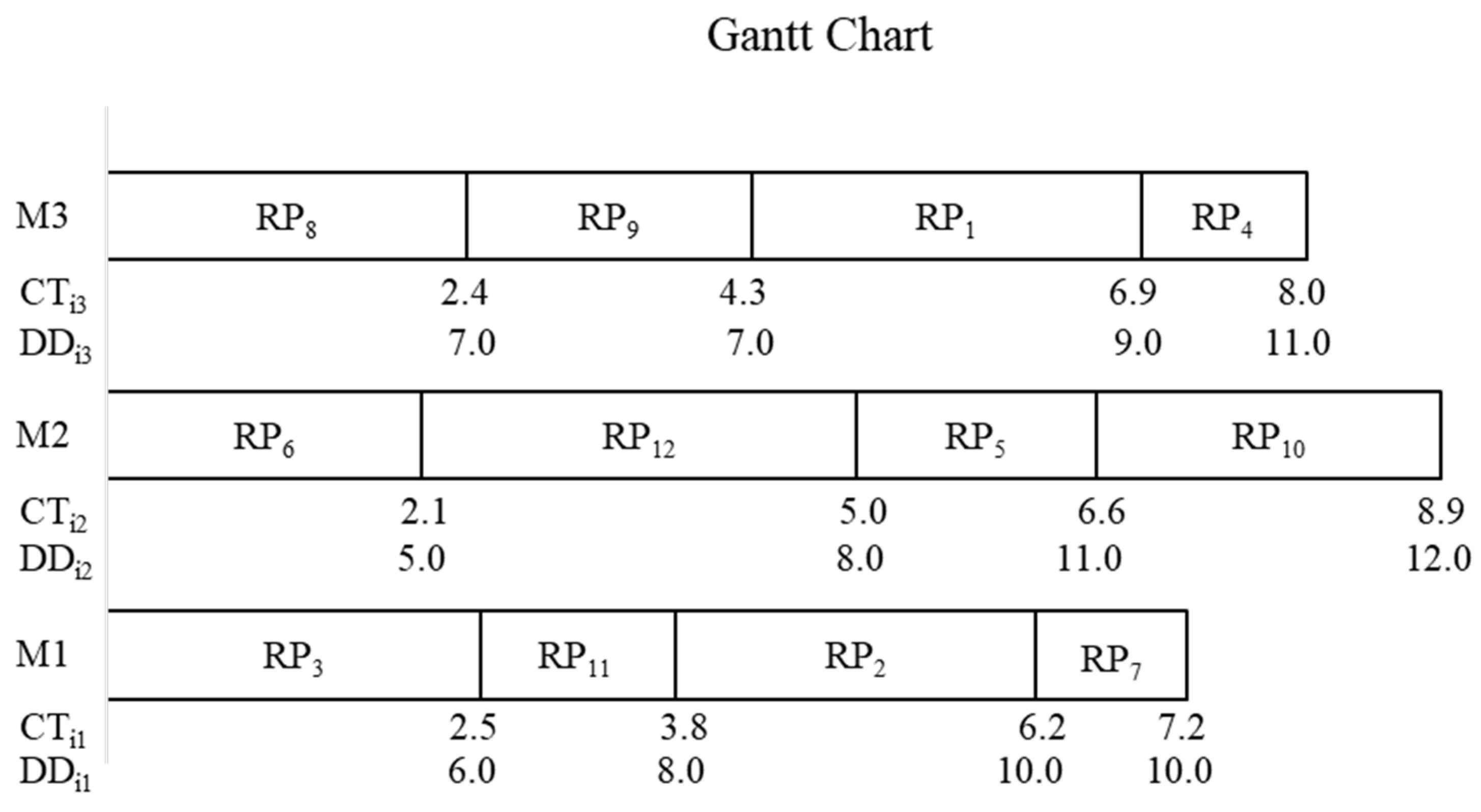

4. Numerical Example

5. Experimentation and Results

5.1. Datasets

- The total number of unrelated parallel machines: 2, 2, 4, and 5.

- The total number of returned products: 10, 20, 20, and 20.

- The uniform distribution is utilized to generate the average reprocessing time for the returned products following the intervals [1.0, 3.5] and [1.5, 5.0].

- The length of each period of preventive maintenance is identical and equal to 1.5 and non-synchrony.

- Available time of set 1 at , , , , and is 6.5, 5.0, 3.5, 2.0, and 0.5. Meanwhile, the available time of other sets at other machines is 6.5.

- The parameter of tardiness factor () and the parameter of range factor () are considered when the deadlines are created, where , and . Three values for each parameter are considered to estimate the values of deadlines to guarantee a variety of tightness. Table 4 represents the classification of data sets considering the values of (. However, the returned product’s deadlines were generated from the uniform distribution The value of is computed using Equation (6); is the average of the average reprocessing time. Equation (7) is utilized to calculate the value of [35]. The first three categories of data are categorized as the most favorable case, where the gap between the average reprocessing times and deadlines is high.

5.2. Analysis of Results

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yaghtin, M.; Javid, Y. Multiobjective unrelated parallel machines scheduling problem with periodic maintenance activities and dependent processing times. J. Model. Manag. 2024, 20, 477–494. [Google Scholar] [CrossRef]

- Xue, Y.; Rui, Z.; Yu, X.; Sang, X.; Liu, W. Estimation of distribution evolution memetic algorithm for the unrelated parallel-machine green scheduling problem. Memetic Comput. 2019, 11, 423–437. [Google Scholar] [CrossRef]

- Ghaderi, H.; Dullaert, W.; Amstel, W.P. Reducing lead-times and lead-time variance in cooperative distribution networks. Int. J. Shipp. Transp. Logist. 2016, 8, 51–65. [Google Scholar] [CrossRef]

- Fleszar, K.; Hindi, K.S. Algorithms for the unrelated parallel machine scheduling problem with a resource constraint. Eur. J. Oper. Res. 2018, 271, 839–848. [Google Scholar] [CrossRef]

- Soleimani, H.; Ghaderi, H.; Tsai, P.W.; Zarbakhshnia, N.; Maleki, M. Scheduling of unrelated parallel machines considering sequence-related setup time, start time-dependent deterioration, position-dependent learning and power consumption minimization. J. Clean. Prod. 2020, 249, 119428. [Google Scholar] [CrossRef]

- Ezugwu, A.E. Metaheuristic Optimization for Sustainable Unrelated Parallel Machine Scheduling: A concise overview with a proof-of-concept study. IEEE Access 2023, 12, 3386–3416. [Google Scholar] [CrossRef]

- Ɖurasević, M.; Jakobović, D. Heuristic and metaheuristic methods for the parallel unrelated machines scheduling problem: A survey. Artif. Intell. Rev. 2023, 56, 3181–3289. [Google Scholar] [CrossRef]

- Wang, H.; Li, R.; Gong, W. Minimizing tardiness and makespan for distributed heterogeneous unrelated parallel machine scheduling by knowledge and Pareto-based memetic algorithm. Egypt. Inform. J. 2023, 24, 100383. [Google Scholar] [CrossRef]

- Fanjul-Peyro, L.; Perea, F.; Ruiz, R. Models and matheuristics for the unrelated parallel machine scheduling problem with additional resources. Eur. J. Oper. Res. 2017, 260, 482–493. [Google Scholar] [CrossRef]

- Vallada, E.; Ruiz, R. A genetic algorithm for the unrelated parallel machine scheduling problem with sequence dependent setup times. Eur. J. Oper. Res. 2011, 211, 612–622. [Google Scholar] [CrossRef]

- Cota, L.P.; Coelho, V.N.; Guimarães, F.G.; Souza, M.J. Bi-criteria formulation for green scheduling with unrelated parallel machines with sequence-dependent setup times. Int. Trans. Oper. Res. 2021, 28, 996–1017. [Google Scholar] [CrossRef]

- Frid, N.; Ɖurasević, M.; Gil-Gala, F.J. Automated generation of dispatching rules for the green unrelated machines scheduling problem. Complex Intell. Syst. 2025, 11, 67. [Google Scholar] [CrossRef]

- Parichehreh, M.; Gholizadeh, H.; Fathollahi-Fard, A.M.; Wong, K.Y. An energy-efficient unrelated parallel machine scheduling problem with learning effect of operators and deterioration of jobs. Int. J. Environ. Sci. Technol. 2024, 15, 9651–9676. [Google Scholar] [CrossRef]

- Yaghtin, M.; Javid, Y. Genetic algorithm based on greedy strategy in unrelated parallel-machine scheduling problem using fuzzy approach with periodic maintenance and process constraints. Int. J. Supply Oper. Manag. 2023, 10, 319–336. [Google Scholar]

- Shen, J.; Zhu, Y. A parallel-machine scheduling problem with periodic maintenance under uncertainty. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 3171–3179. [Google Scholar] [CrossRef]

- Khalili, S. Unrelated parallel-machine scheduling with preventive and emergency maintenance. J. Decis. Oper. Res. 2021, 6, 25–40. [Google Scholar]

- Lei, D.; He, S. An adaptive artificial bee colony for unrelated parallel machine scheduling with additional resource and maintenance. Expert Syst. Appl. 2022, 205, 117577. [Google Scholar] [CrossRef]

- Hsu, C.J.; Ji, M.; Guo, J.Y.; Yang, D.L. Unrelated parallel-machine scheduling problems with aging effects and deteriorating maintenance activities. Inf. Sci. 2013, 253, 163–169. [Google Scholar] [CrossRef]

- Ghaleb, M.; Taghipour, S.; Zolfagharinia, H. Joint optimization of maintenance and production scheduling for unrelated parallel-machine system. In Proceedings of the 2020 Asia-Pacific International Symposium on Advanced Reliability and Maintenance Modeling (APARM), Vancouver, BC, Canada, 20–23 August 2020; pp. 1–6. [Google Scholar]

- Fu, Y.; Wang, Y.; Gao, K.; Huang, M. Review on ensemble meta-heuristics and reinforcement learning for manufacturing scheduling problems. Comput. Electr. Eng. 2024, 120, 109780. [Google Scholar] [CrossRef]

- Yang, D.L.; Cheng, T.C.; Yang, S.J.; Hsu, C.J. Unrelated parallel-machine scheduling with aging effects and multi-maintenance activities. Comput. Oper. Res. 2012, 39, 1458–1464. [Google Scholar] [CrossRef]

- Avalos-Rosales, O.; Angel-Bello, F.; Álvarez, A.; Cardona-Valdés, Y. Including preventive maintenance activities in an unrelated parallel machine environment with dependent setup times. Comput. Ind. Eng. 2018, 123, 364–377. [Google Scholar] [CrossRef]

- Su, L.H.; Tsai, H.L. Flexible preventive maintenance planning for two parallel machines problem to minimize makespan. J. Qual. Maint. Eng. 2010, 16, 288–302. [Google Scholar] [CrossRef]

- Poongothai, V.; Godhandaraman, P.; Anitha, K. Unrelated parallel machine scheduling with multi-maintenance activities using CPLEX. AIP Conf. Proc. 2019, 2112, 020133. [Google Scholar]

- Tavana, M.; Zarook, Y.; Santos-Arteaga, F.J. An integrated three-stage maintenance scheduling model for unrelated parallel machines with aging effect and multi-maintenance activities. Comput. Ind. Eng. 2015, 83, 226–236. [Google Scholar] [CrossRef]

- Zarook, Y.; Abedi, M. JIT-scheduling in unrelated parallel-machine environment with aging effect and multi-maintenance activities. Int. J. Serv. Oper. Manag. 2014, 18, 99–113. [Google Scholar] [CrossRef]

- Muniasamy, K.; Venugopal, P.; Pakkirisamy, G. Genetic Algorithm-Driven Optimization of Scheduling and Preventive Measures in Parallel Machines. Math. Model. Eng. Probl. 2023, 10, 1811–1816. [Google Scholar] [CrossRef]

- Geurtsen, M.; Adan, J.; Akçay, A. Integrated maintenance and production scheduling for unrelated parallel machines with setup times. Flex. Serv. Manuf. J. 2023, 18, 1046–1079. [Google Scholar] [CrossRef]

- Liu, C.L.; Wang, J.J. Unrelated parallel-machine scheduling with controllable processing times and impact of deteriorating maintenance activities under consideration. Asia-Pac. J. Oper. Res. 2016, 33, 1650001. [Google Scholar] [CrossRef]

- Wang, H.; Alidaee, B. Effective heuristic for large-scale unrelated parallel machines scheduling problems. Omega 2019, 83, 261–274. [Google Scholar] [CrossRef]

- Santoro, M.C.; Junqueira, L. Unrelated parallel machine scheduling models with machine availability and eligibility constraints. Comput. Ind. Eng. 2023, 179, 109219. [Google Scholar] [CrossRef]

- Najat, A.; Yuan, C.; Gursel, S.; Tao, Y. Minimizing the number of tardy jobs on identical parallel machines subject to periodic maintenance. Procedia Manuf. 2019, 38, 1409–1416. [Google Scholar] [CrossRef]

- French, S. Sequencing and scheduling. An Introduction to the Mathematics of the Job-shop. J. Oper. Res. Soc. 1982, 33, 862. [Google Scholar]

- Moore, J.M. An n job, one machine sequencing algorithm for minimizing the number of late jobs. Manag. Sci. 1968, 15, 102–109. [Google Scholar] [CrossRef]

- Suresh, V.; Chaudhuri, D. Minimizing maximum tardiness for unrelated parallel machines. Int. J. Prod. Econ. 1994, 34, 223–229. [Google Scholar] [CrossRef]

| Reference | Objective | Machine Type | Consideration of Green Scheduling | Preventive Maintenance | Solution Approach |

|---|---|---|---|---|---|

| Avalos-Rosales et al. [22] | Minimize completion time | Unrelated parallel machine | No | Yes | Mixed integer programming and metaheuristic |

| Su et al. [23] | Minimize makespan | Identical parallel machine | No | Yes | Analytical algorithm |

| Poongothai et al. [24] | Minimize completion time | Unrelated parallel machine | No | Yes | Mixed integer programming |

| Tavana et al. [25] | Minimize total maintenance cost and completion time and maximum earliness and tardiness times | Unrelated parallel machine | No | Yes | Fuzzy analytic hierarchy process and goal programming |

| Zarook et al. [26] | Minimize the total early and tardy coat and minimize the cost of maintenance | Unrelated parallel machine | No | Yes | Genetic Algorithm |

| Muniasamy et al. [27] | Minimize makespan | Identical parallel machine | No | Yes | Genetic Algorithm and mixed-integer programming |

| Geurtsen et al. [28] | Minimize completion time and total tardiness | Unrelated parallel machine | No | Yes | Hybrid genetic algorithm and mixed-integer programming |

| Liu et al. [29] | Minimize completion time | Unrelated parallel machine | No | Yes | Assignment problem |

| Wang et al. [30] | Total weighted completion times | Unrelated parallel machine | No | No | Tabu Search |

| Santoro et al. [31] | Minimize makespan | Unrelated parallel machine | No | Yes | Mixed integer linear programming |

| This Research | Maximize the number of products returned early | Unrelated parallel machine | Yes | Yes | Mathematical model and heuristic algorithm |

| Indices: | |

| Index for the returned product. | |

| Index for unrelated machine. | |

| Index for set. | |

| Parameters: | |

| Maintenance period of unrelated machine . | |

| Set of unrelated machine . | |

| Total number of returned products to be reprocessed at time zero. | |

| Total number of unrelated machines available. | |

| Group of tardily returned products. | |

| Tardily returned product. | |

| Returned product with maximum average reprocessing time. | |

| Returned product . | |

| Re-processing time of returned product at unrelated machine . | |

| Deadline of returned product . | |

| Set available time of set at unrelated machine between two maintenance periods. | |

| Maintenance time. | |

| Decision variables: | |

| 1 if returned product is assigned to set of unrelated machine . 0 otherwise. | |

| Completion time of returned product at unrelated machine . | |

| Tardiness of returned product at unrelated machine . | |

| Completion time of set time interval of set at unrelated machine . | |

| Total number of tardily returned products. | |

| Returned Product | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| hours | 4.1 | 2.4 | 2.5 | 3.3 | 1.3 | 4.4 | 1 | 4.8 | 4.7 | 1.7 | 1.3 | 3.4 |

| hours | 2.5 | 1.7 | 2.4 | 3.1 | 1.6 | 2.1 | 5 | 4.3 | 4.3 | 2.3 | 4.8 | 2.9 |

| hours | 2.6 | 3.8 | 2.9 | 1.1 | 1.3 | 4.2 | 1.3 | 2.4 | 1.9 | 4.2 | 1.8 | 4.2 |

| Deadline hours | 9.0 | 10.0 | 6.0 | 11.0 | 11.0 | 5.0 | 10.0 | 7.0 | 7.0 | 12.0 | 8.0 | 8.0 |

| Category of Dataset | Tardiness of Deadline | The Range of Deadline | Remarks | ||

|---|---|---|---|---|---|

| 1 | 0.20 | 0.20 | L | N | Most Favorable Case |

| 2 | 0.20 | 0.50 | L | M | |

| 3 | 0.20 | 0.80 | L | W | |

| 4 | 0.50 | 0.20 | M | N | Average Case |

| 5 | 0.50 | 0.50 | M | M | |

| 6 | 0.50 | 0.80 | M | W | |

| 7 | 0.80 | 0.20 | T | N | Least Favorable Case |

| 8 | 0.80 | 0.50 | T | M | |

| 9 | 0.80 | 0.80 | T | W |

| ) | ) | Average Reprocessing Time | Average Number of Products Returned Early | |

|---|---|---|---|---|

| Mathematical Model | Modified Moore’s Heuristic Algorithm | |||

| 10 | 2 | [1.5, 5.0] | 8.00 | 8.00 |

| 20 | 2 | [1.5, 5.0] | 15.00 | 15.00 |

| 20 | 4 | [1.5, 5.0] | 17.67 | 17.00 |

| 20 | 5 | [1.5, 5.0] | 18.00 | 17.33 |

| 10 | 2 | [1.0, 3.5] | 8.00 | 8.00 |

| 20 | 2 | [1.0, 3.5] | 16.00 | 15.00 |

| 20 | 4 | [1.0, 3.5] | 19.33 | 18.00 |

| 20 | 5 | [1.0, 3.5] | 17.33 | 16.00 |

| ) | Average Reprocessing Time | Number of Products Returned Early | ||

|---|---|---|---|---|

| Mathematical Model | Modified Moore’s Heuristic Algorithm | |||

| 10 | 2 | [1.5, 5.0] | 5.00 | 4.00 |

| 20 | 2 | [1.5, 5.0] | 11.00 | 10.00 |

| 20 | 4 | [1.5, 5.0] | 12.33 | 11.67 |

| 20 | 5 | [1.5, 5.0] | 9.00 | 9.00 |

| 10 | 2 | [1.0, 3.5] | 6.00 | 5.00 |

| 20 | 2 | [1.0, 3.5] | 11.33 | 10.67 |

| 20 | 4 | [1.0, 3.5] | 12.00 | 11.33 |

| 20 | 5 | [1.0, 3.5] | 9.33 | 8.00 |

| Number of Returned Products | Number of Machines | Average Reprocessing Time | Number of Products Returned Early | |

|---|---|---|---|---|

| Mathematical Model | Modified Moore’s Heuristic Algorithm | |||

| 10 | 2 | [1.5, 5.0] | 1.67 | 1.00 |

| 20 | 2 | [1.5, 5.0] | 4.67 | 4.00 |

| 20 | 4 | [1.5, 5.0] | 4.30 | 3.00 |

| 20 | 5 | [1.5, 5.0] | 4.00 | 3.00 |

| 10 | 2 | [1.0, 3.5] | 2.67 | 2.00 |

| 20 | 2 | [1.0, 3.5] | 5.67 | 5.00 |

| 20 | 4 | [1.0, 3.5] | 5.00 | 4.67 |

| 20 | 5 | [1.0, 3.5] | 4.00 | 3.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almasarwah, N. Optimized Green Unrelated Parallel Machine Scheduling Problem Subject to Preventive Maintenance. Designs 2025, 9, 26. https://doi.org/10.3390/designs9020026

Almasarwah N. Optimized Green Unrelated Parallel Machine Scheduling Problem Subject to Preventive Maintenance. Designs. 2025; 9(2):26. https://doi.org/10.3390/designs9020026

Chicago/Turabian StyleAlmasarwah, Najat. 2025. "Optimized Green Unrelated Parallel Machine Scheduling Problem Subject to Preventive Maintenance" Designs 9, no. 2: 26. https://doi.org/10.3390/designs9020026

APA StyleAlmasarwah, N. (2025). Optimized Green Unrelated Parallel Machine Scheduling Problem Subject to Preventive Maintenance. Designs, 9(2), 26. https://doi.org/10.3390/designs9020026