Study on the Mechanical Properties and Calculation Method of the Bearing Capacity of Concrete-Filled Steel Pipes under Axial Pressure Load

Abstract

1. Introduction

2. Test Process

2.1. Specimen Design

2.2. Material Properties

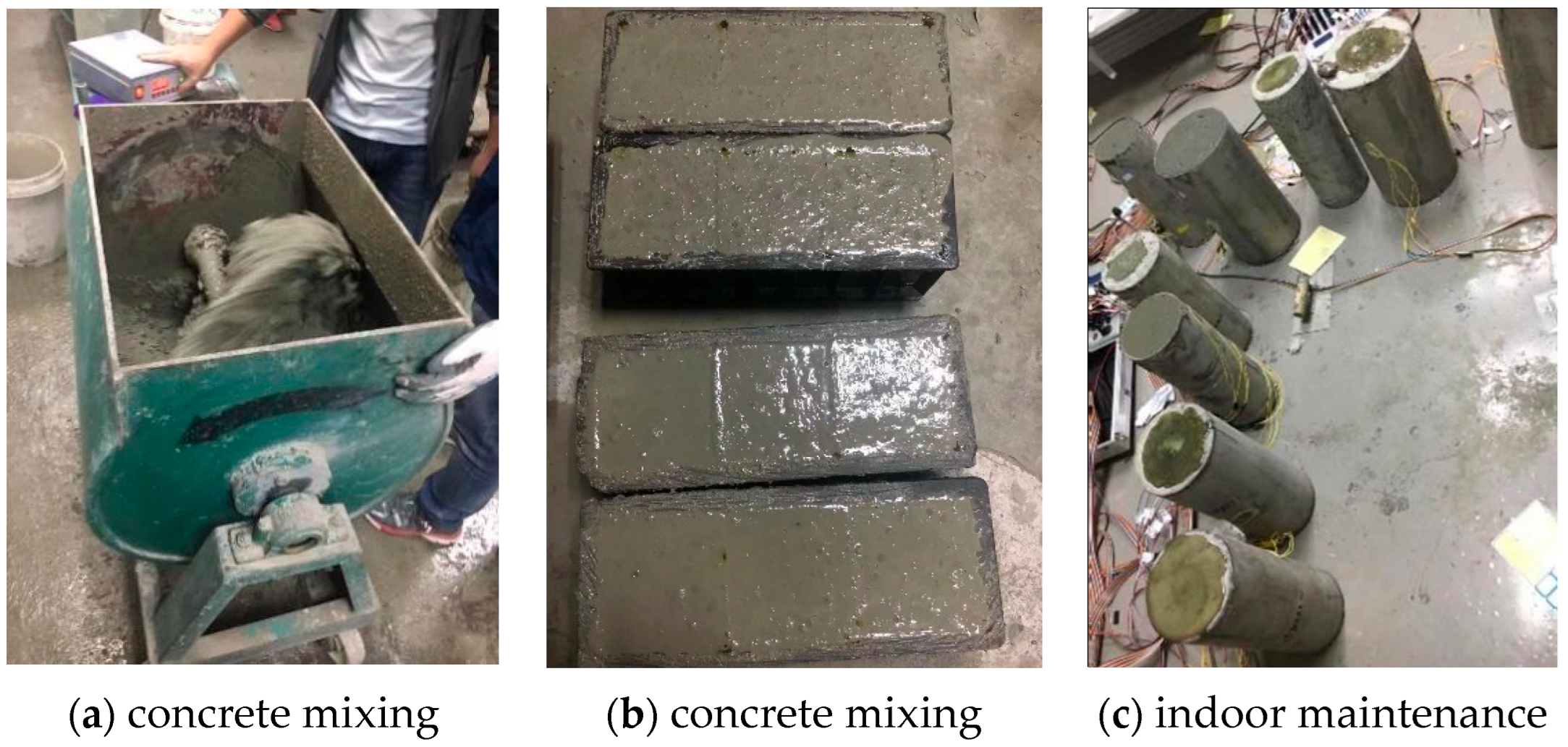

2.3. Specimen Preparation

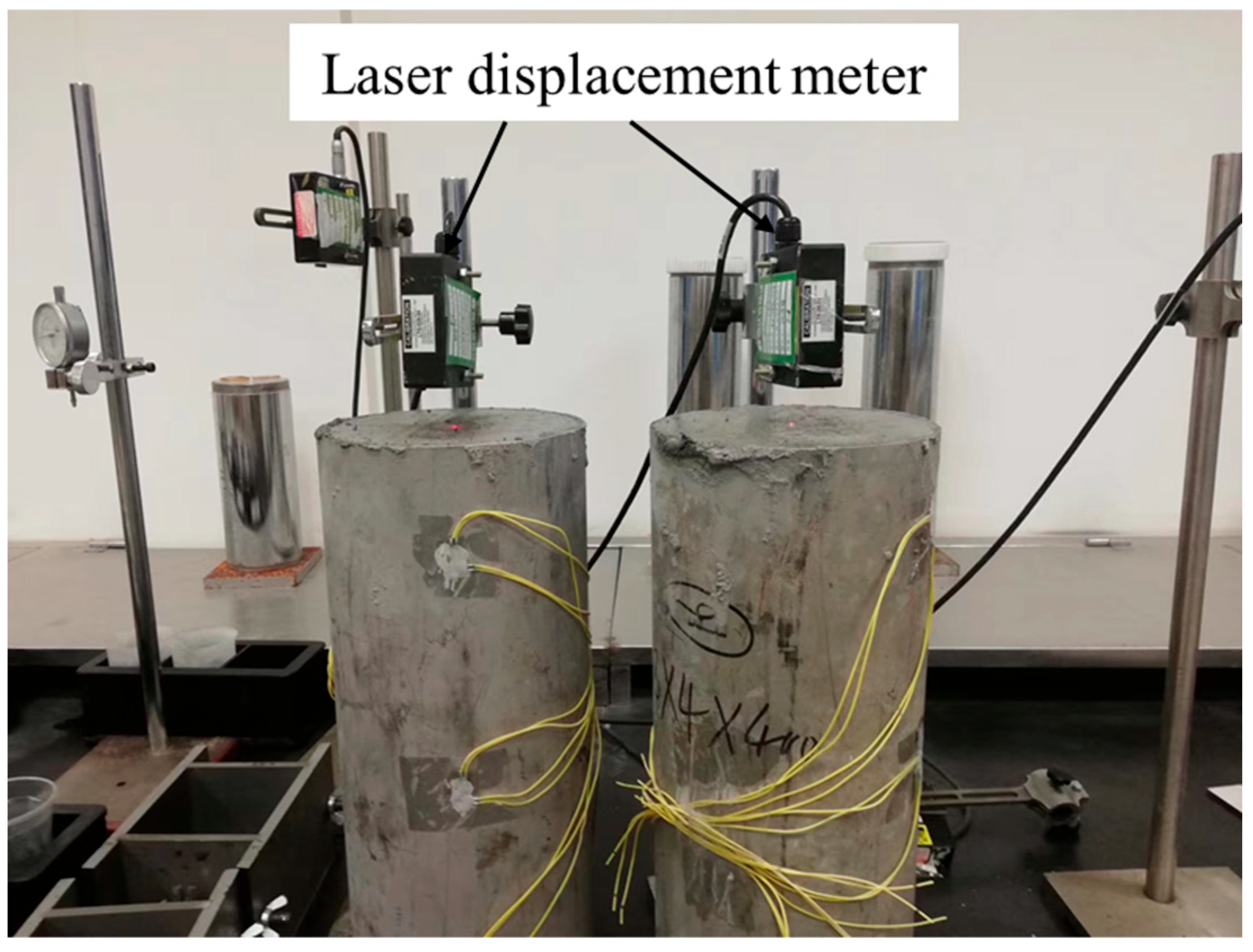

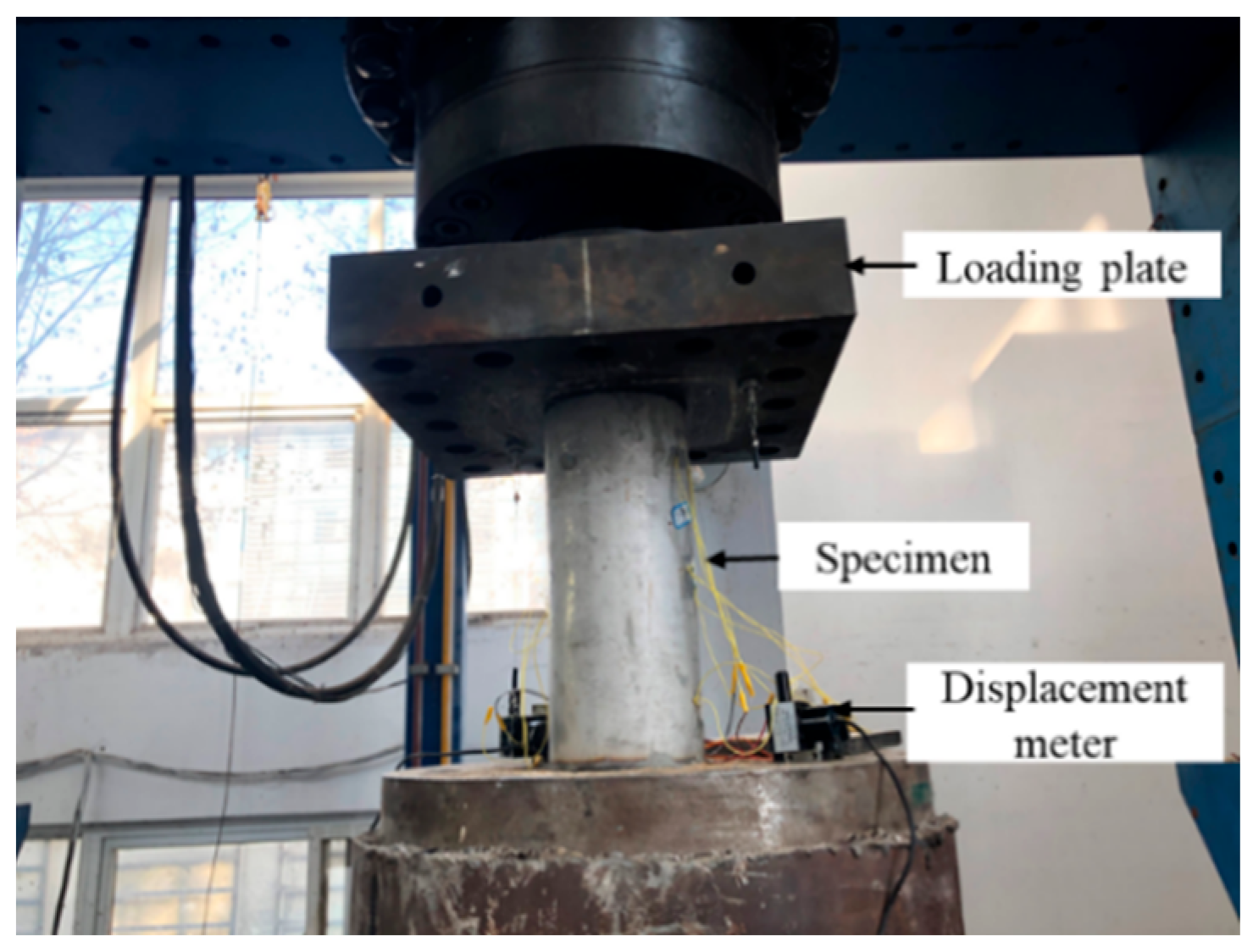

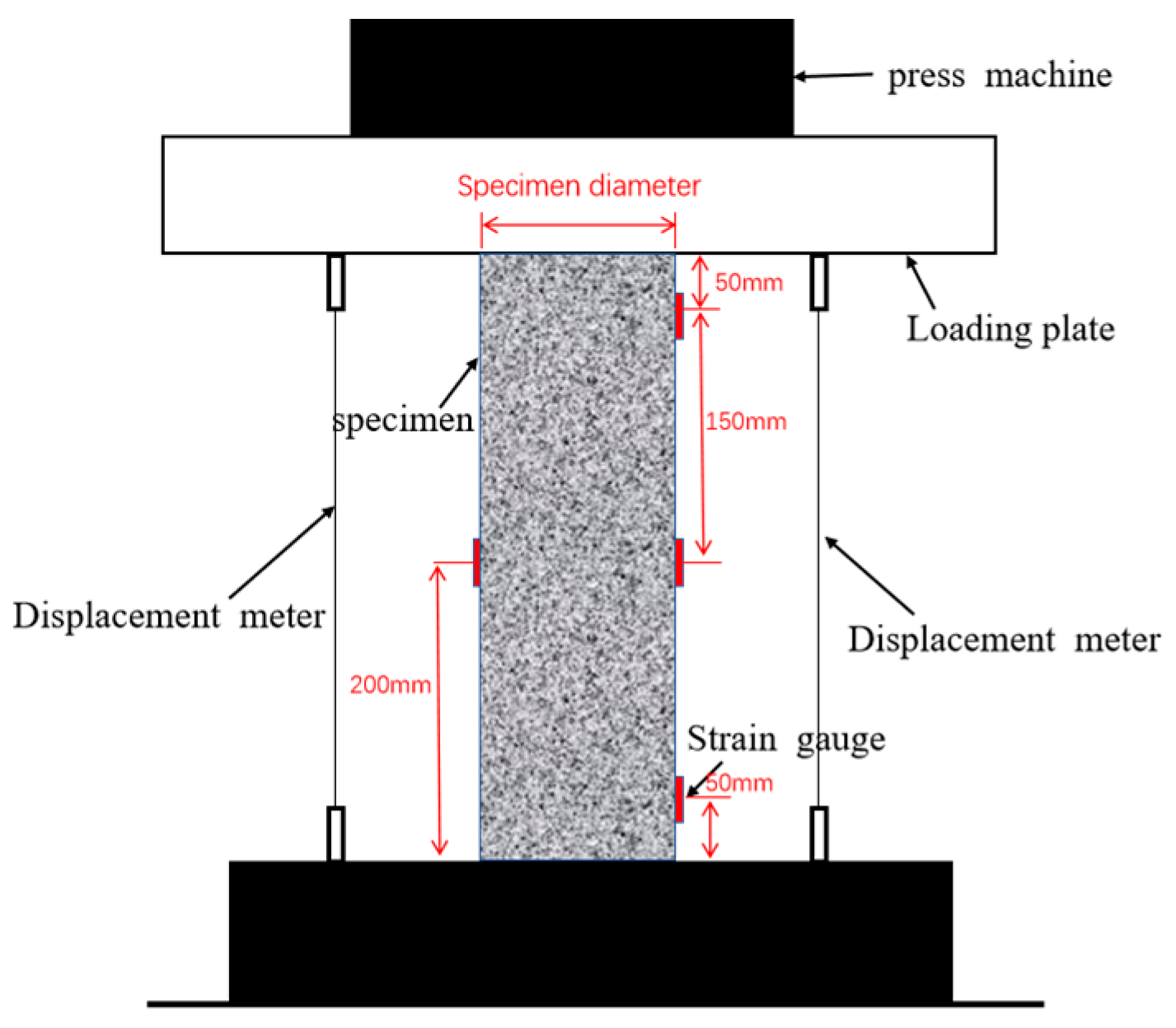

2.4. Test Setup and Loading Method

- (1)

- Prior to the axial compression test, the MCFST members were placed in such a way that the steel tubes and the micro-expanded concrete were in the same straight line, so that the steel tubes and the micro-expanded concrete could share the load and avoid eccentric compression of the members. Similarly, the steel pipe members filled with micro-expanded concrete were leveled where they were placed.

- (2)

- The center of the short micro-expansion CFST column was aligned with the loading center of the axial compression test apparatus to ensure that the member was subjected to axial compression rather than eccentric compression, and a displacement meter was placed between the test devices to measure the displacement, as shown in Figure 3 and Figure 4.

- (3)

- The steel pipe micro-expansion concrete member was placed on the testing machine, and the strain gauge was ground with a ten-color wire, and then connected to the static compound resistance strain gauge of Donghua Company for debugging. After debugging, the specimen was preloaded in the elastic range to ensure that the strain gauges worked properly. The strain gauge model was 120-5AA, which belonged to the terminal and did not require welding. The strain gauge above and below the specimen was mainly used to measure the changing trend of the end part of the specimen under load, while the strain gauge in the middle was mainly used to measure the changing trend of the middle part of the specimen under load. The upper and lower strain gauges were 50 mm away from the end, and the middle strain gauge divided the specimen into two equal parts. The preloading time was about 2 min. The preloading load should not exceed 30% of the theoretical calculated value of the load capacity of the specimen.

- (4)

- When the loading reached the yield point of the specimen, the displacement loading was adopted, and the experiment was finished when the displacement reached 100 mm.

3. Experiment Results

3.1. Failure Mode and Mechanism Analysis

- Longitudinal expansion experiment

- —Longitudinal free expansion rate of concrete after curing;

- —Base length of concrete (400 mm);

- —The initial length of concrete, 400 mm (the initial shrinkage of the concrete is not considered in this paper);

- —Displacement meter reading of concrete after curing (mm).

- 2.

- Axial compression experiment results

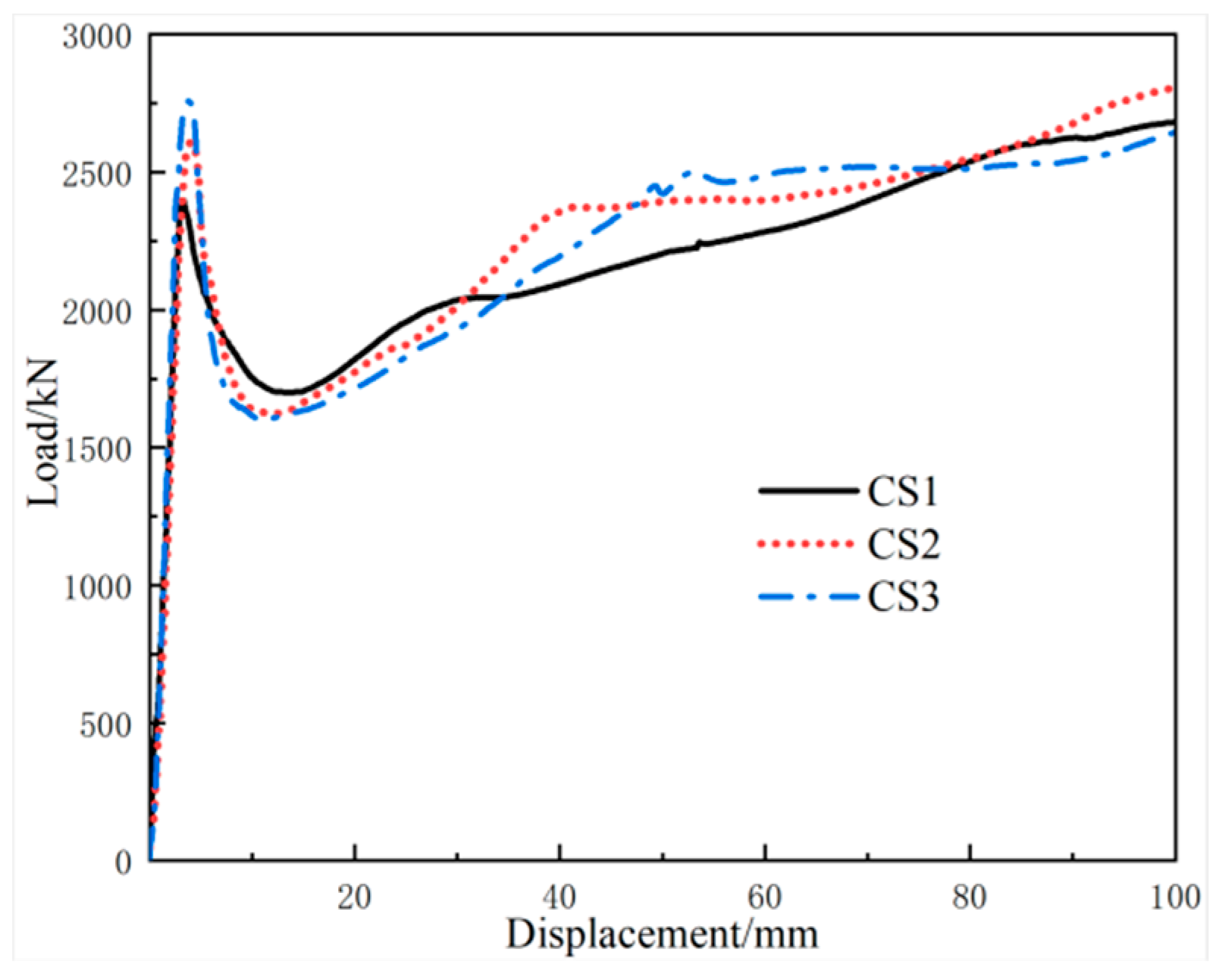

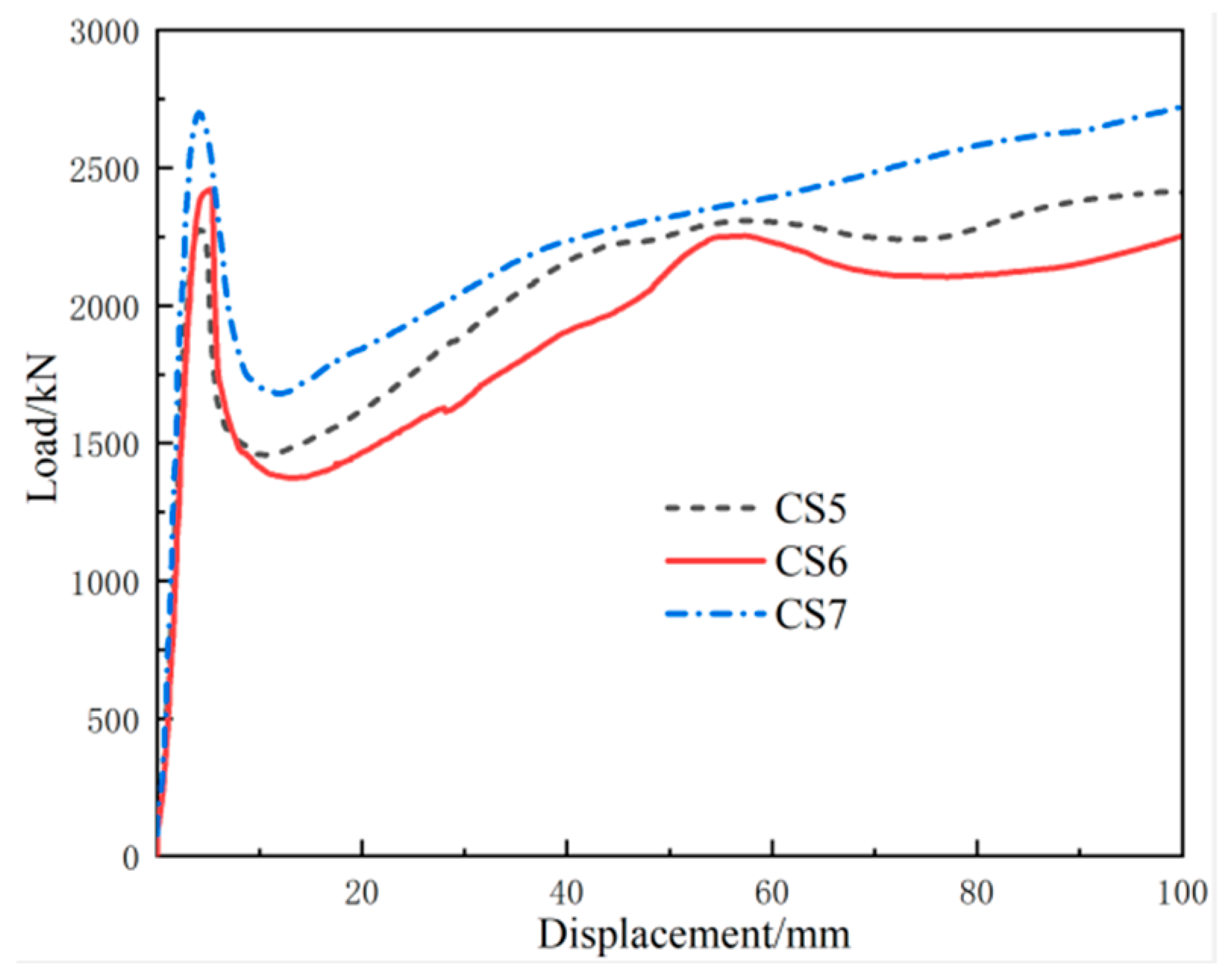

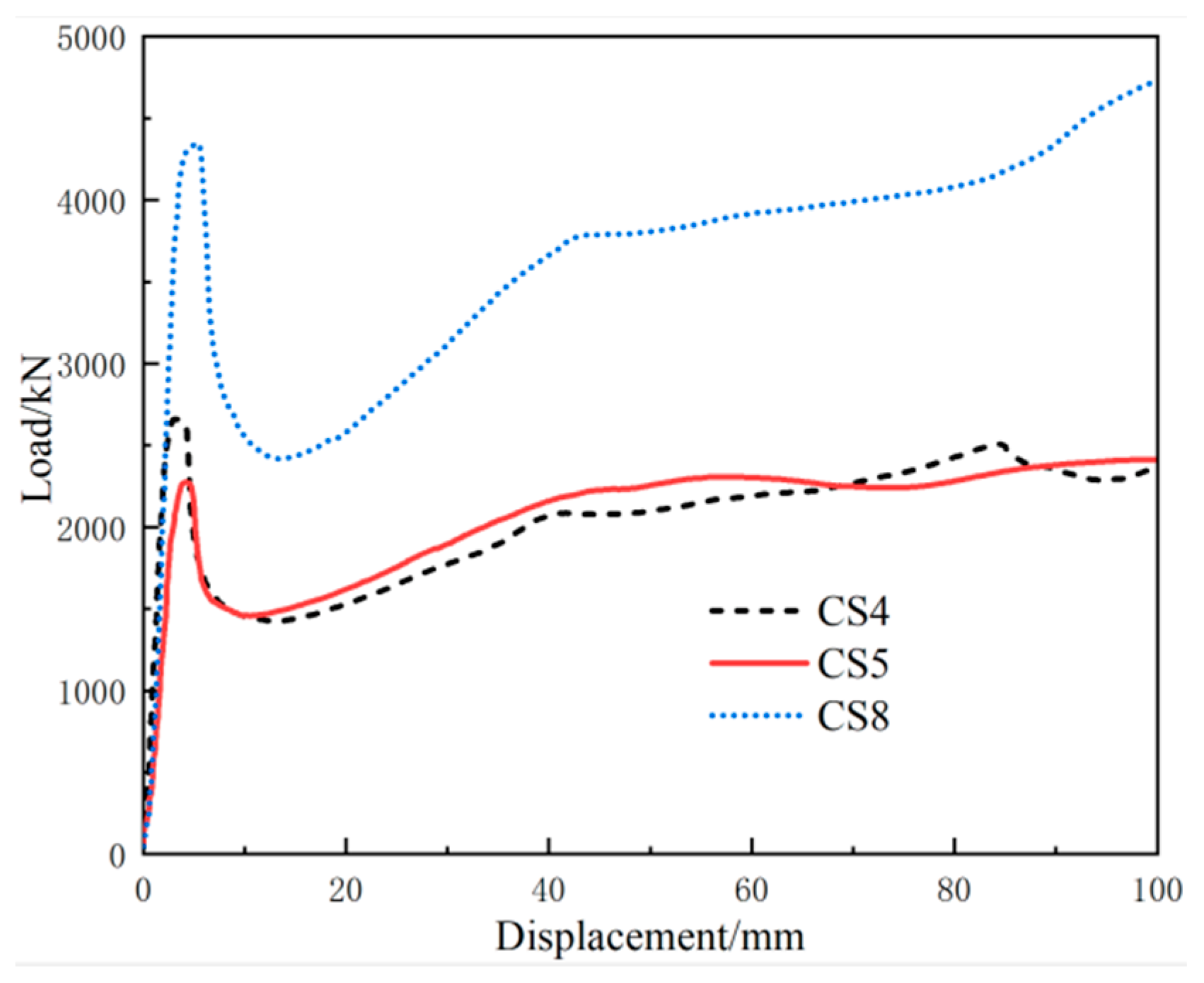

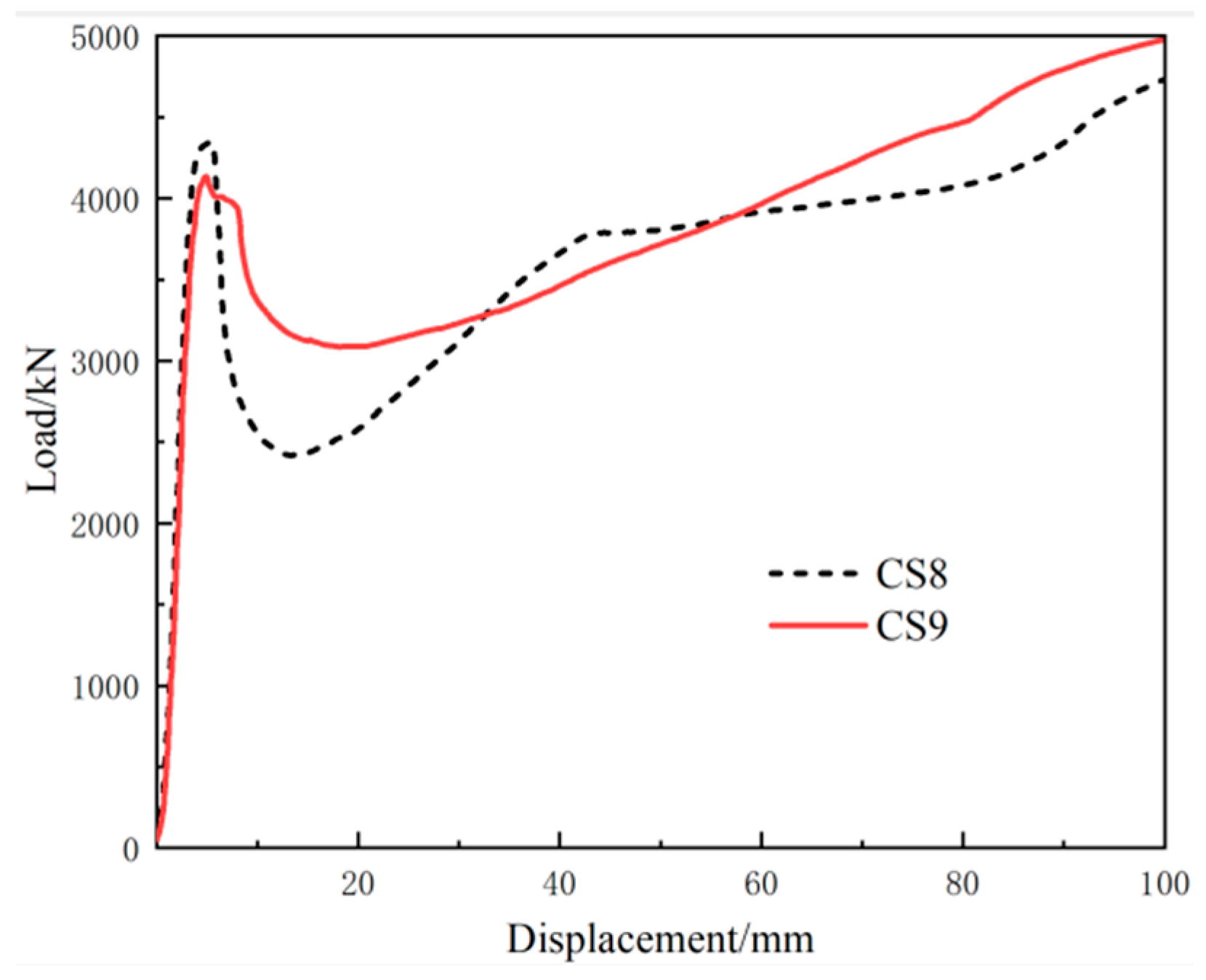

3.2. Load–Displacement Curve

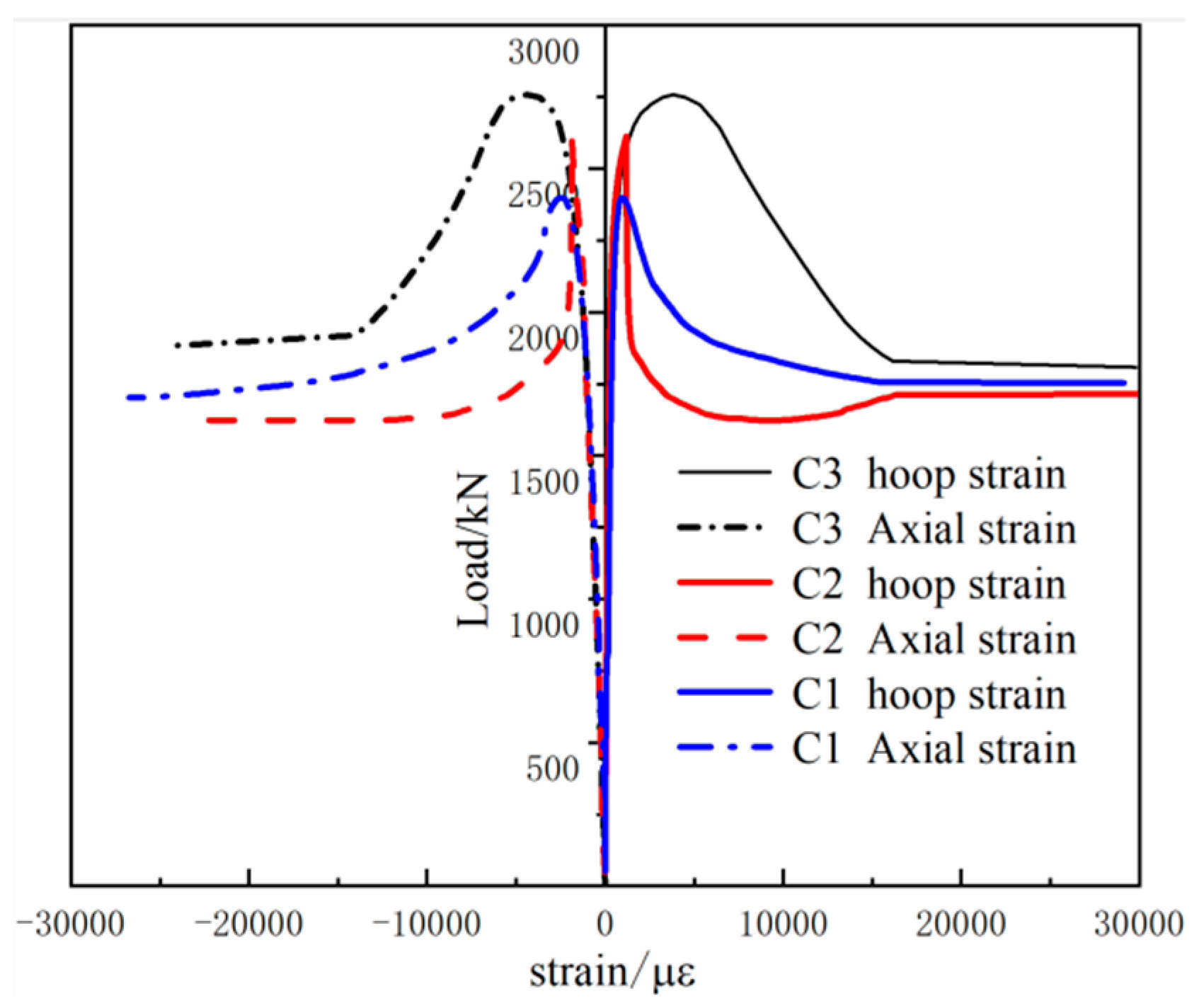

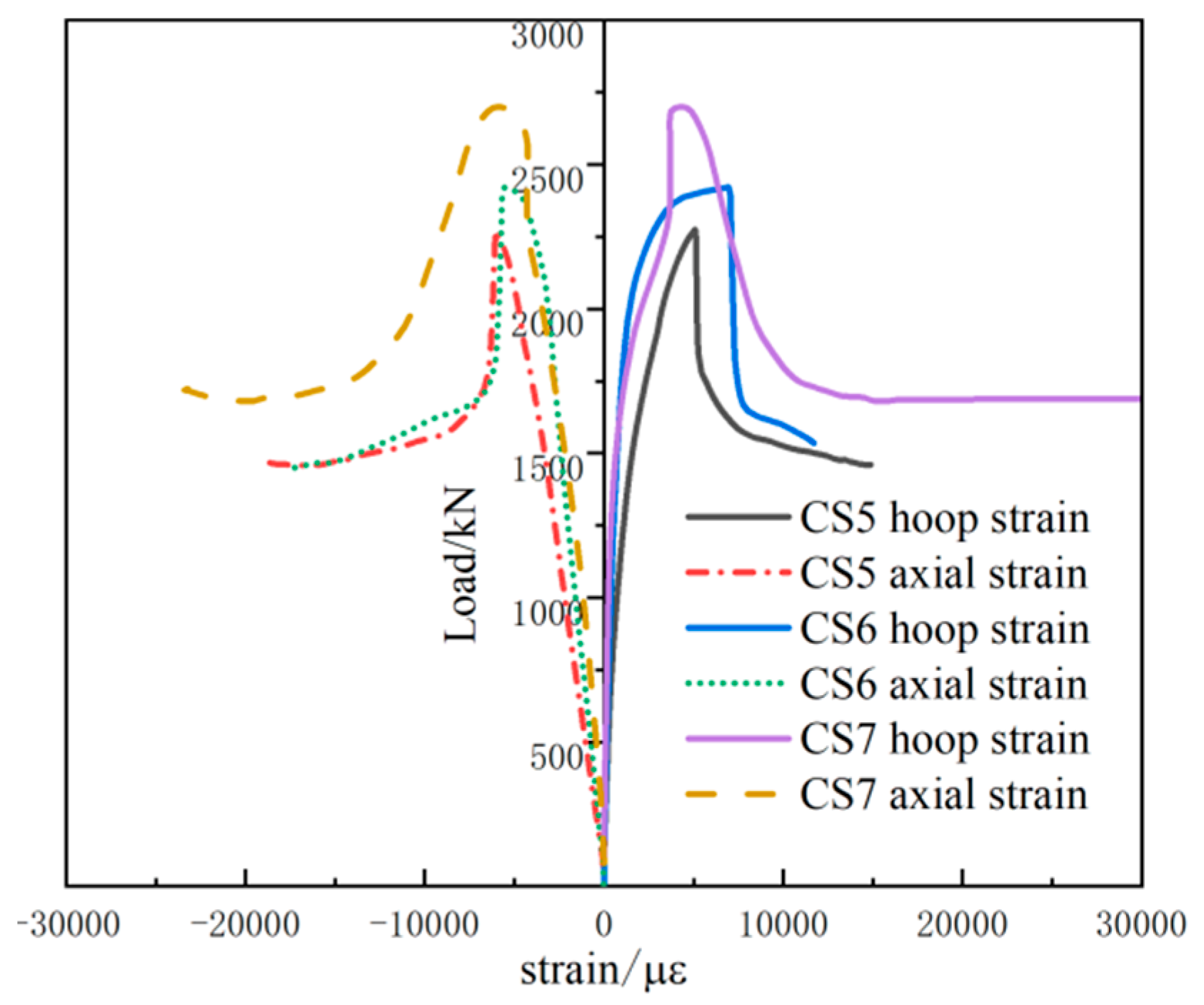

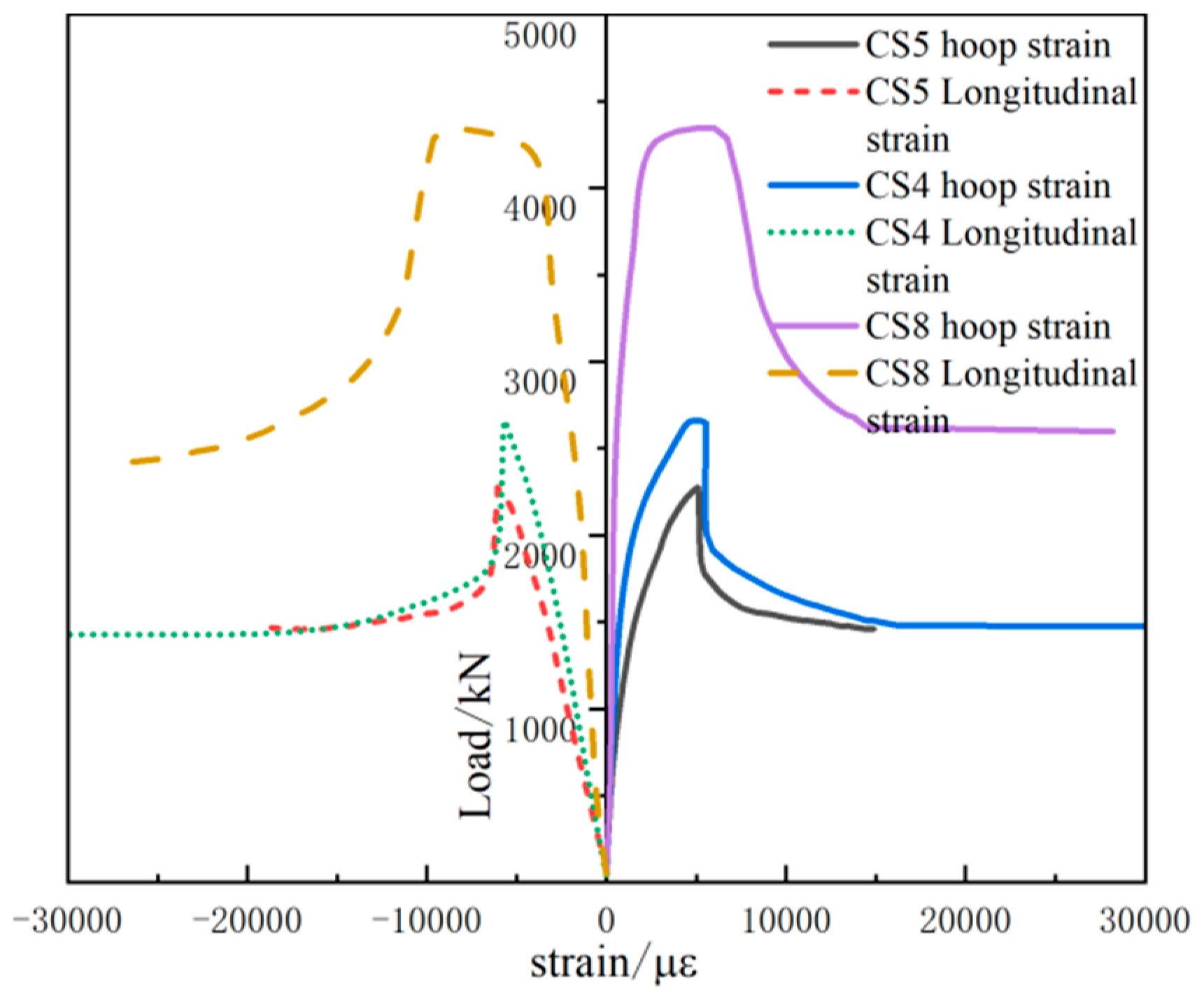

3.3. Load–Strain Curve

- —Design value of the axial compression bearing capacity of a concrete-filled steel tube;

- —The cross-sectional area of the concrete-filled steel tube composite structure is equal to the sum of the steel tube area and the concrete area;

- —Compressive strength value of CFST;

- —Confinement coefficient of specimen;

- —The steel content of the specimen is the ratio of the cross-sectional area of the steel tube to the cross-sectional area of the concrete;

- —The design values of the compressive strength of steel and concrete, respectively;

- B,C—The influence coefficient of the confinement coefficient (depending on different section shapes); value according to Table 4.

- —Variation coefficient of steel tube bearing capacity;

- —Variation coefficient of bearing capacity of concrete.

- —Formula for calculating the hoop coefficient;

- —Steel tube yield strength;

- —Compressive strength of concrete.

- N—Axial compression bearing capacity design value;

- Nu—Axial load bearing capacity limit.

- —The steel tube section area and concrete section area;

- —The yield strength of the steel pipe and compressive strength of the concrete;

- —The partial coefficient of steel (generally 1.0), partial coefficient of concrete (generally 1.5);

- —Coefficient.

3.4. Empirical Formula Based on Experimental Results

4. Conclusions

- The experiment results of the longitudinal volume expansion rate show that the displacement of concrete expansion increases with the increase in the expansion agent content.

- The damage pattern of all the specimens was bulging and curved in the center and concave at the ends. With the increase in the expansion agent content, the bearing capacity of the specimen increased. The yield strengths of micro-expansion concrete-filled steel tube columns added with 8% and 12% expansion agent were 8.9% and 14.9% higher than the concrete-filled steel tube short column. This indicates that the addition of an expansion agent to concrete has a positive effect on its axial compressive load-bearing capacity.

- When the expansion agent exceeded a certain size, the bearing capacity decreased. This indicates that there is an optimum content of expansion agent incorporated into concrete. The next step is to prepare an experimental study to ascertain the specific ratio of the optimum content.

- A practical bearing capacity calculation formula based on the test results is proposed, which provides a reference for practical engineering applications. The next step is to carry out the bearing capacity test on more specimens to optimize the formula, so that the formula can be used in a wider range of applications.

- While this study confirmed the reliability of micro-expansion concrete in filling steel tube members through experimental methods, the testing conditions limited the ability to conduct experiments on full-scale specimens with high slenderness ratios. Future research efforts could focus on establishing simulation methods for micro-expansion concrete and utilizing validated numerical simulation techniques to investigate the response of full-scale specimens. This approach would enhance the understanding of micro-expansion concrete performance in practical applications and improve the reliability and applicability of the research findings.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Güneyisi, E.M.; Nour, A.I. Axial compression capacity of circular CFST columns transversely strengthened by FRP. Eng. Struct. 2019, 191, 417–431. [Google Scholar] [CrossRef]

- Yan, J.-B.; Dong, X.; Wang, T. Axial compressive behaviours of square CFST stub columns at low temperatures. J. Constr. Steel Res. 2020, 164, 105812. [Google Scholar] [CrossRef]

- He, L.; Zhao, Y.; Lin, S. Experimental study on axially compressed circular CFST columns with improved confinement effect. J. Constr. Steel Res. 2018, 140, 74–81. [Google Scholar] [CrossRef]

- Dong, H.; Li, Y.; Cao, W.; Qiao, Q.; Li, R. Uniaxial compression performance of rectangular CFST columns with different internal construction characteristics. Eng. Struct. 2018, 176, 763–775. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Liu, A.-R.; Fu, J.-Y.; Pi, Y.-L. Experimental investigation of the flexural behavior of CFST trusses with interfacial imperfection. J. Constr. Steel Res. 2017, 137, 52–65. [Google Scholar] [CrossRef]

- Ouyang, Y.; Kwan, A. Finite element analysis of square concrete-filled steel tube (CFST) columns under axial compressive load. Eng. Struct. 2018, 156, 443–459. [Google Scholar] [CrossRef]

- Knowles, R.B.; Park, R. Strength of concrete filled steel tubular columns. J. Struct. Div. ASCE 1969, 95, 2565–2587. [Google Scholar] [CrossRef]

- Knowles, R.B.; Park, R. Axial load design for concrete filled steel tubes. J. Struct. Div. ASCE 1970, 96, 2125–2153. [Google Scholar] [CrossRef]

- Tomii, M. Experimental studies on concrete filled steel tubular stub columns under concentric loading. In Proceedings of the International Colloquium on Stability of Structures Under Static and Dynamic Loads, SSRC/ASCE, Washington, DC, USA, 17–19 May 1977. [Google Scholar]

- Luksha, L.K.; Nesterovich, A.P. Strength testing of large-diameter concrete filled steel tubular members. In Proceedings of the Third International Conference on Steel-Concrete Composite Structures, Fukuoka, Japan, 26–29 September 1991; Wakabayashi, M., Ed.; Association for International Cooperation and Research in Steel-Concrete Composite Structures: Fukuoka, Japan, 1991; pp. 67–72. [Google Scholar]

- Srinivasan, C.N.; Schneider, S.P. Axially loaded concrete-filled steel tubes. J. Struct. Eng. 1988, 125, 1202–1206. [Google Scholar] [CrossRef]

- Giakoumelis, G.; Lam, D. Axial capacity of circular concrete-filled tube columns. J. Constr. Steel Res. 2004, 60, 1049–1068. [Google Scholar] [CrossRef]

- Sakino, K.; Nakahara, H.; Morino, S.; Nishiyama, I. Behavior of centrally loaded concrete-filled steel-tube short columns. J. Struct. Eng. 2004, 130, 180–188. [Google Scholar] [CrossRef]

- Ellobody, E.; Young, B.; Lam, D. Behaviour of normal and high strength concrete-filled compact steel tube circular stub columns. J. Constr. Steel Res. 2006, 62, 706–715. [Google Scholar] [CrossRef]

- Gupta, P.; Sarda, S.; Kumar, M. Experimental and computational study of concrete filled steel tubular columns under axial loads. J. Constr. Steel Res. 2007, 63, 182–193. [Google Scholar] [CrossRef]

- Liang, Q.Q.; Fragomeni, S. Nonlinear analysis of circular concrete-filled steel tubular short columns under axial loading. J. Constr. Steel Res. 2009, 65, 2186–2196. [Google Scholar] [CrossRef]

- Abed, F.; AlHamaydeh, M.; Abdalla, S. Experimental and numerical investigations of the compressive behavior of concrete filled steel tubes (CFSTs). J. Constr. Steel Res. 2013, 80, 429–439. [Google Scholar] [CrossRef]

- Huang, C.K.; Xu, L.; Liu, Y. Experimental study on axial compressive properties of self-compacting and self-stressing concrete filled steel tube short columns. J. Dalian Univ. Technol. 2006, 77–82. (In Chinese) [Google Scholar]

- Lu, Y.Y.; Yan, B.; Li, N.; Li, S. Compressive Behavior of Steel Tube Columns Filled with Steel Fiber Reinforced Self-stressing and Self-compacting Concrete. J. Civ. Eng. Manag. 2017, 34, 1–4. [Google Scholar]

- Xu, L.H.; Wu, M.; Zhou, P.H. Experimental study on axial compression bearing capacity of self-stressing and self-compacting high strength concrete filled steel tubular short columns. Eng. Mech. 2017, 93–100. (In Chinese) [Google Scholar]

- Armaghani, D.J.; Safari, V.; Fahimifar, A.; Amin, M.F.M.; Monjezi, M.; Mohammadi, M.A. Uniaxial compressive strength prediction through a new technique based on gene expression programming. Neural Comput. Appl. 2018, 30, 3523–3532. [Google Scholar] [CrossRef]

- Sarir, P.; Chen, J.; Asteris, P.G.; Armaghani, D.J.; Tahir, M.M. Developing GEP tree-based, neuro-swarm, and whale optimization models for evaluation of bearing capacity of concrete-filled steel tube columns. Eng. Comput. 2021, 37, 1–19. [Google Scholar] [CrossRef]

- Sarir, P.; Shen, S.-L.; Wang, Z.-F.; Chen, J.; Horpibulsuk, S.; Pham, B.T. Optimum model for bearing capacity of concrete-steel columns with AI technology via incorporating the algorithms of IWO and ABC. Eng. Comput. 2021, 37, 797–807. [Google Scholar] [CrossRef]

- GB 50119-2013; Code for Utility Technical of Concrete Admixture. China Standard Press: Beijing, China, 2013.

- Zhong, S.T. Unified Theory of Concrete Filled Steel Tubular: Research and Application; Tsinghua University Press: Beijing, China, 2006. [Google Scholar]

- Han, L.H. Concrete Filled Steel Tube Structure-Theory and Practice; Science Press: Beijing, China, 1990. [Google Scholar]

- Cai, S.H. Modern Concrete Filled Steel Tube Structure; People’s Communications Press: Beijing, China, 2007. [Google Scholar]

- EN 1994-1-1; Eurocode4: Design of Composite Steel and Concrete Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- ACI-318R; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2005.

- AS3600; Australian Standards. Concrete Structures. Standards Association of Australia: Sydney, Australia, 2001.

- AIJ. Standards for Structural Calculation of Steel Reinforced Concrete Structures, 5th ed.; Architectural Institute of Japan: Tokyo, Japan, 2001. (In Japanese) [Google Scholar]

- CECS 28:2012; Technical Specification for Concrete Filled Steel Tube. China Planning Press: Beijing, China, 2012.

- GB 50936-2014; Code for Design of Concrete Filled Steel Tube Structures. China Construction Industry Press: Beijing, China, 2014.

| ID | D (mm) | Length (mm) | t (mm) | fc (MPa) | V | Remarks |

|---|---|---|---|---|---|---|

| CS1 | 168 | 400 | 4 | 80 | 0 | |

| CS2 | 168 | 400 | 4 | 80 | 8% | |

| CS3 | 168 | 400 | 4 | 80 | 12% | |

| CS4 | 168 | 400 | 3 | 80 | 12% | |

| CS5 | 159 | 400 | 3 | 80 | 12% | |

| CS6 | 159 | 400 | 4 | 80 | 12% | |

| CS7 | 159 | 400 | 5 | 80 | 12% | |

| CS8 | 219 | 400 | 3 | 80 | 12% | |

| CS9 | 219 | 400 | 3 | 80 | 12% | end restraint |

| ID | Cement (kg) | Ganister Sand (kg) | Slag (kg) | Zeeospheres (kg) | Expansion Agent (kg) | Sand (kg) | Big Cobble (kg) | Small Cobble (kg) | Water (kg) | Water-Reducing Admixture (kg) | fc (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| M0 | 16.5 | 0.89 | 1.08 | 1.91 | / | 22.7 | 23.93 | 10.25 | 6.19 | 0.12 | 83.6 |

| M8 | 12.6 | 0.75 | 0.92 | 1.62 | 1.38 | 19.3 | 20.30 | 8.70 | 4.03 | 0.07 | 85.2 |

| M12 | 11.9 | 0.75 | 0.92 | 1.62 | 2.08 | 19.3 | 20.36 | 8.70 | 4.03 | 0.07 | 86.2 |

| Specimens | Final Failure Mode | Description of Failure Mode |

|---|---|---|

| CS1 |  | (1) No expansion agent (2) The yield bearing capacity is 2399 kN (3) The specimen shows the failure mode of bulging in the middle and concave at both ends (4) The displacement of the specimen is loaded to 130 mm, which is more serious than other specimens. |

| CS2 |  | (1) 8% expansion agent (2) The yield bearing capacity is 2612 kN (3) The specimen shows the failure mode of bulging in the middle and concave at both ends (4) The lower concave deformation is larger than the upper one. |

| CS3 |  | (1) 12% expansion agent (2) The yield bearing capacity is 2758 kN (3) The specimen shows the failure mode of bulging in the middle and concave at both ends (4) Obvious shear slip lines. |

| CS4 |  | (1) 12% expansion agent (2) The yield bearing capacity is 2661 kN (3) The specimen shows the failure mode of bulging in the middle and concave at both ends (4) Significant shear slip lines. |

| CS5 |  | (1) 12% expansion agent (2) The yield bearing capacity is 2275 kN (3) The specimen shows the failure mode of bulging in the middle and concave at both ends (4) No significant shear slip lines. |

| CS6 |  | (1) 12% expansion agent (2) The yield bearing capacity is 2422 kN (3) The specimen shows the failure mode of bulging in the middle and concave at both ends (4) No significant shear slip lines. |

| CS7 |  | (1) 12% expansion agent (2) The yield bearing capacity is 2700 kN (3) The specimen showed the failure mode of bulging in the middle and concave at both ends (4) No significant shear slip lines. |

| CS8 |  | (1) 12% expansion agent (2) The yield bearing capacity is 4345 kN (3) The specimen showed the failure mode of bulging in the middle and concave at both ends. |

| CS9 |  | (1) 12% expansion agent (2) The yield bearing capacity is 4134 kN (3) The specimen showed the failure mode of bulging in the middle and concave at both ends. |

| Section Shapes | B | C | |

|---|---|---|---|

| solid | circle and dodecagon | ||

| regular octagon | |||

| square | |||

| hollow | circle and dodecagon | ||

| regular octagon | |||

| square | |||

| Design Code | Calculation Formula | Remarks |

|---|---|---|

| ACI [29]/AS [30] | ||

| AIJ [31] | = 0 for square steel tube; = 0.27 for circular steel tube | |

| Eurocode 4 [28] | Simplified formula without regard to the slenderness ratio | |

| CECS28:2012 [32] | , , | is coefficient; is limit value of hoop coefficient |

| GB50936 [33] | ; B, C as shown Table 4 |

| Design Code | Calculation Formula | Error Rate |

|---|---|---|

| ACI [29]/AS [30] | 1935.9 kN | 25.9% |

| AIJ [31] | 2322.9 kN | 11.1% |

| Eurocode 4 [28] | 2656 kN | 9.8% |

| CECS28:2012 [32] | θ does not fit the formula | Inapplicable |

| GB50936 [33] | 1646.2 kN | 36.9% |

| Specimen | Coefficient |

|---|---|

| CS2 | 1.20 |

| CS3 | 1.28 |

| CS4 | 1.28 |

| CS5 | 1.48 |

| CS6 | 1.24 |

| CS7 | 1.32 |

| CS8 | 1.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Hu, J.; Zheng, Y. Study on the Mechanical Properties and Calculation Method of the Bearing Capacity of Concrete-Filled Steel Pipes under Axial Pressure Load. Designs 2024, 8, 90. https://doi.org/10.3390/designs8050090

Liu X, Hu J, Zheng Y. Study on the Mechanical Properties and Calculation Method of the Bearing Capacity of Concrete-Filled Steel Pipes under Axial Pressure Load. Designs. 2024; 8(5):90. https://doi.org/10.3390/designs8050090

Chicago/Turabian StyleLiu, Xin, Jisheng Hu, and Yuzhou Zheng. 2024. "Study on the Mechanical Properties and Calculation Method of the Bearing Capacity of Concrete-Filled Steel Pipes under Axial Pressure Load" Designs 8, no. 5: 90. https://doi.org/10.3390/designs8050090

APA StyleLiu, X., Hu, J., & Zheng, Y. (2024). Study on the Mechanical Properties and Calculation Method of the Bearing Capacity of Concrete-Filled Steel Pipes under Axial Pressure Load. Designs, 8(5), 90. https://doi.org/10.3390/designs8050090