A Review of Novel and Non-Conventional Propulsion Integrations for Next-Generation Aircraft

Abstract

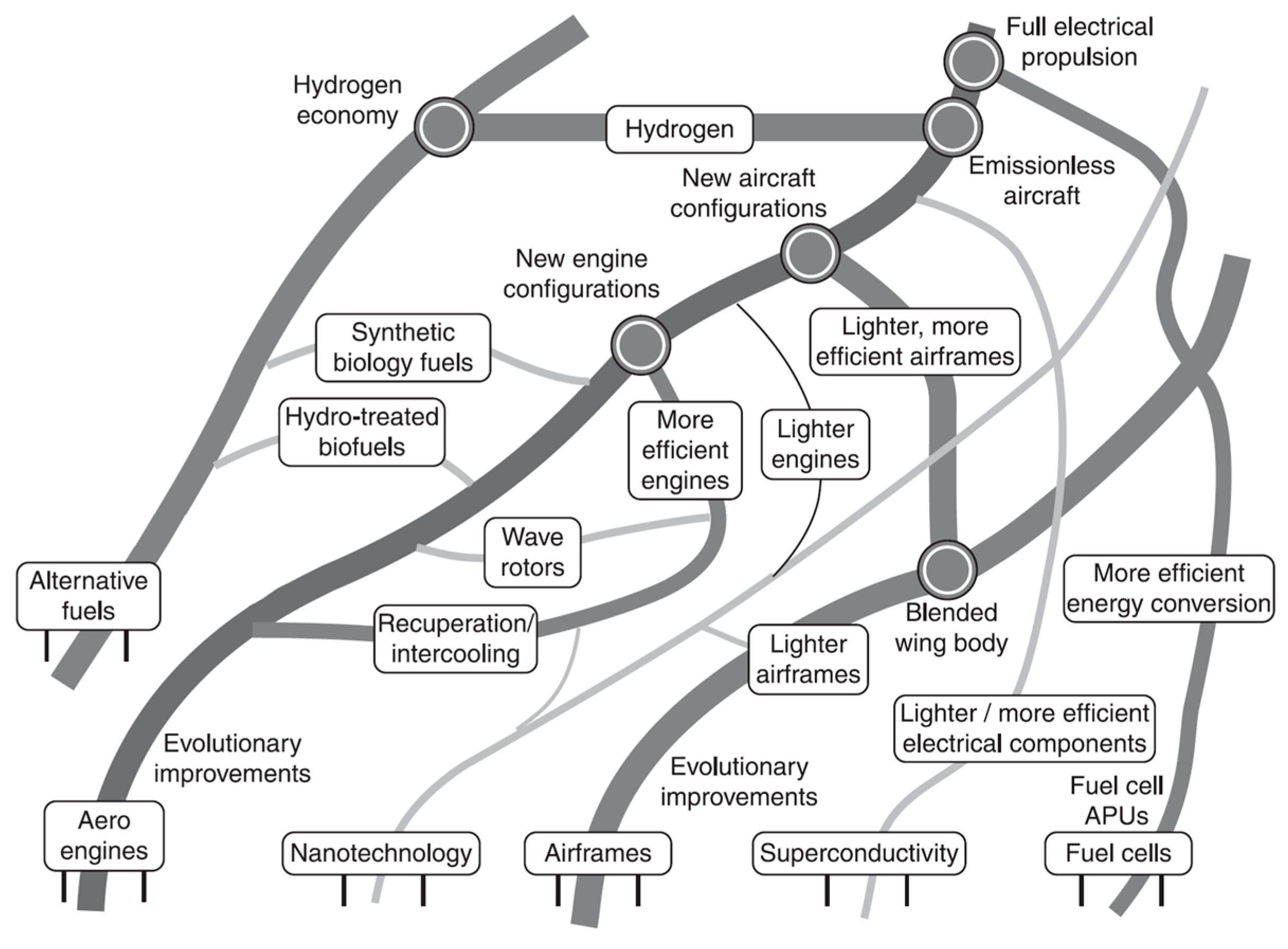

1. Introduction

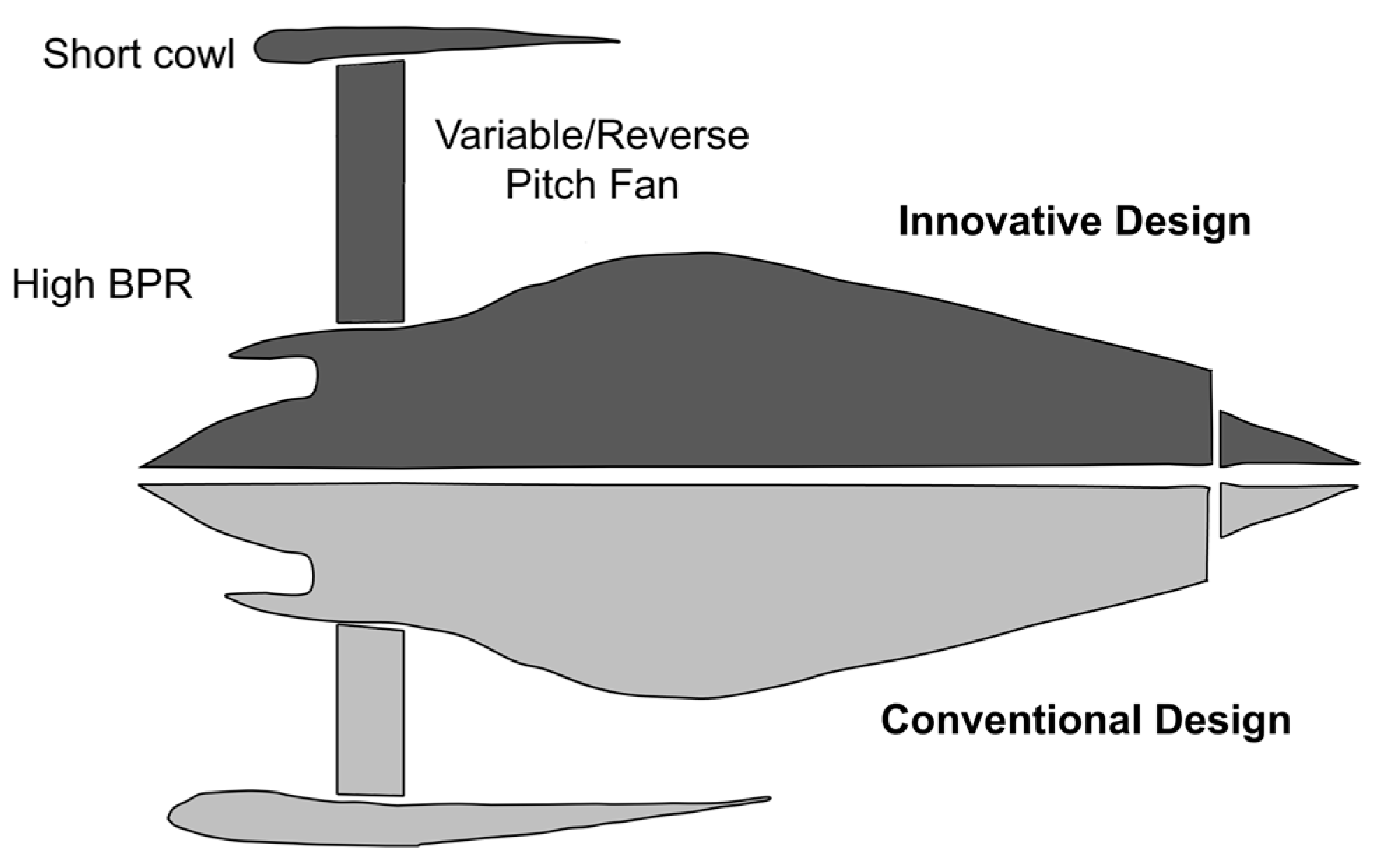

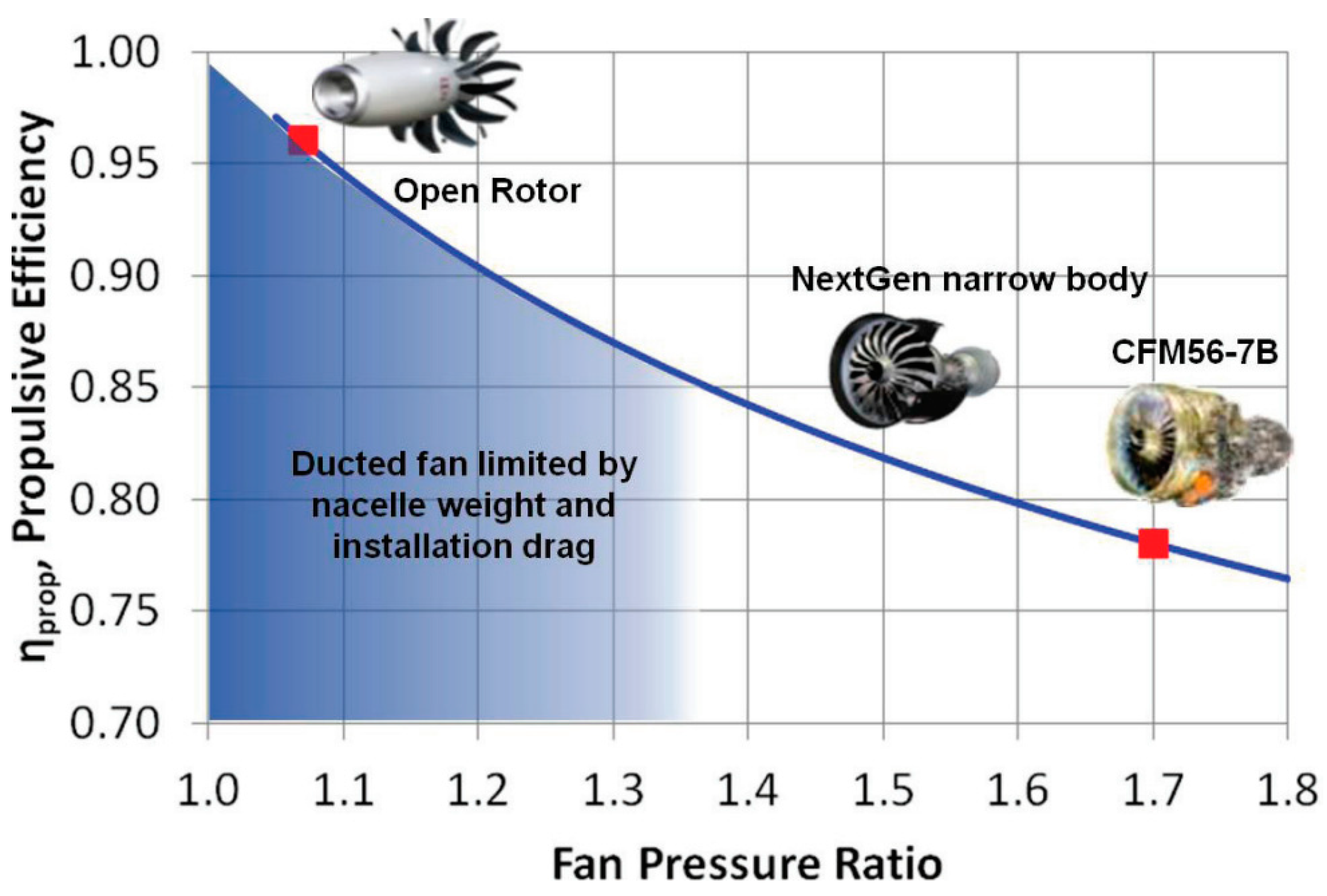

2. Advanced Turbofan

2.1. Overview of Ultra-High Bypass Ratio Turbofan

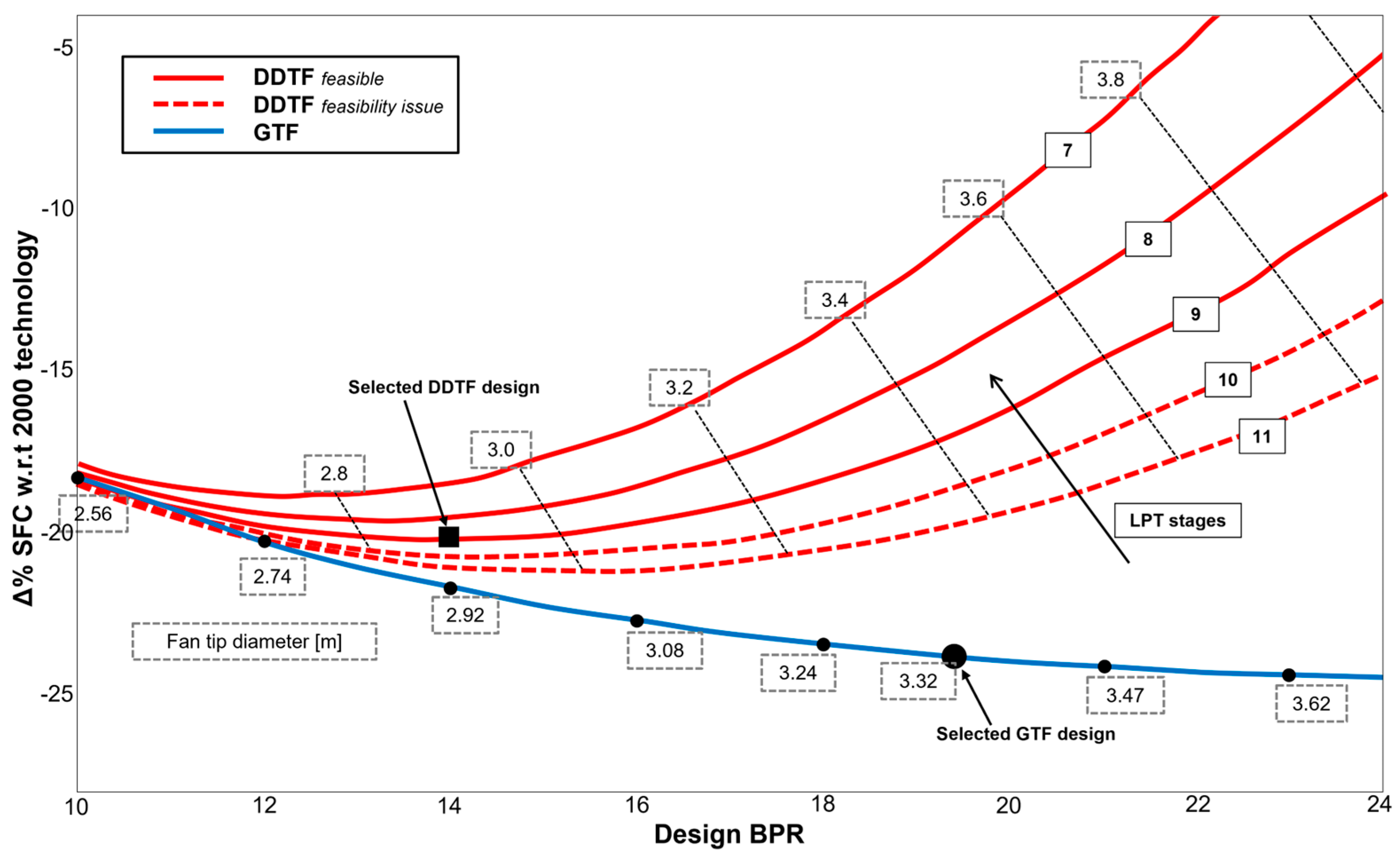

2.2. Uninstalled UHBR Turbofan Features

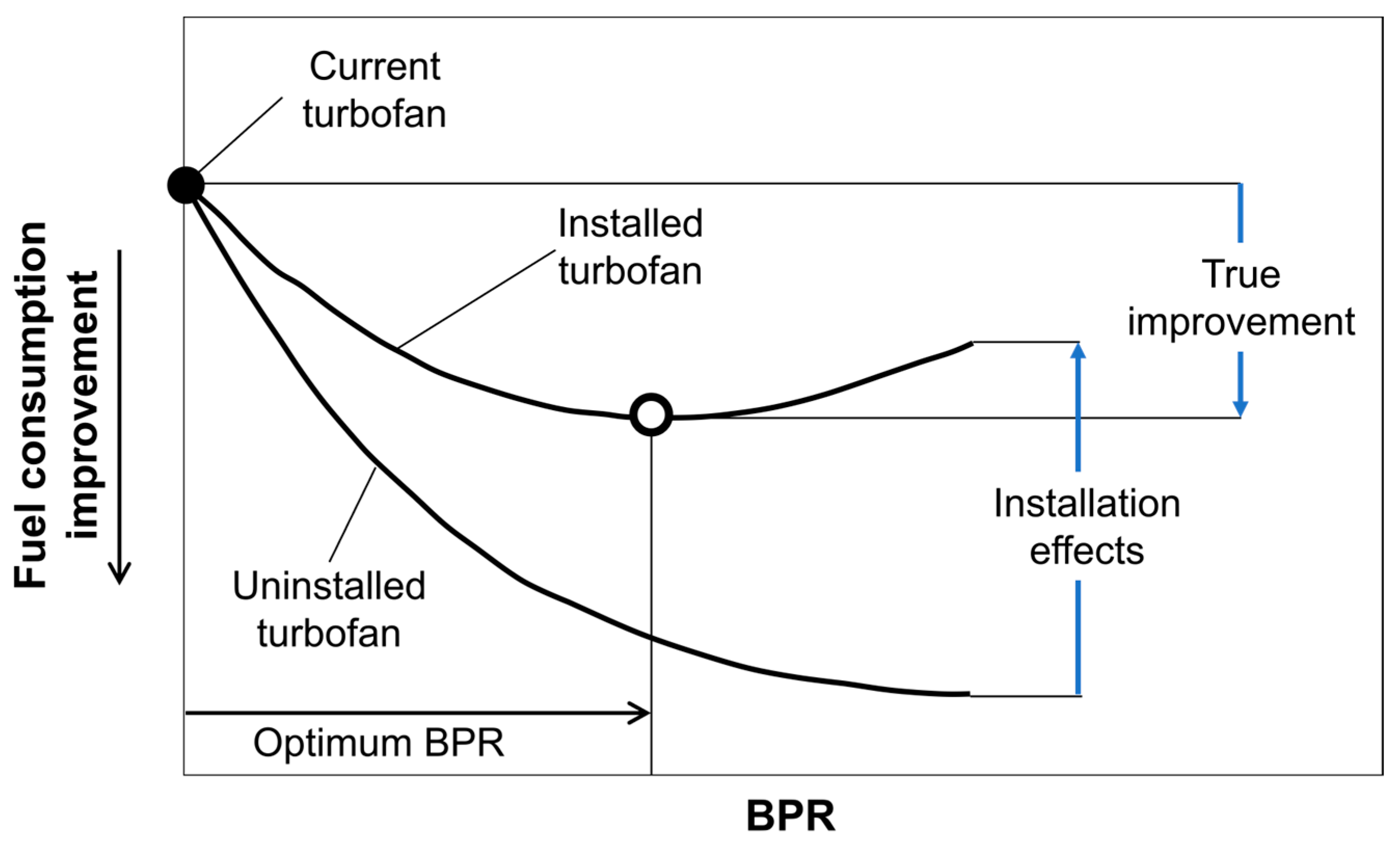

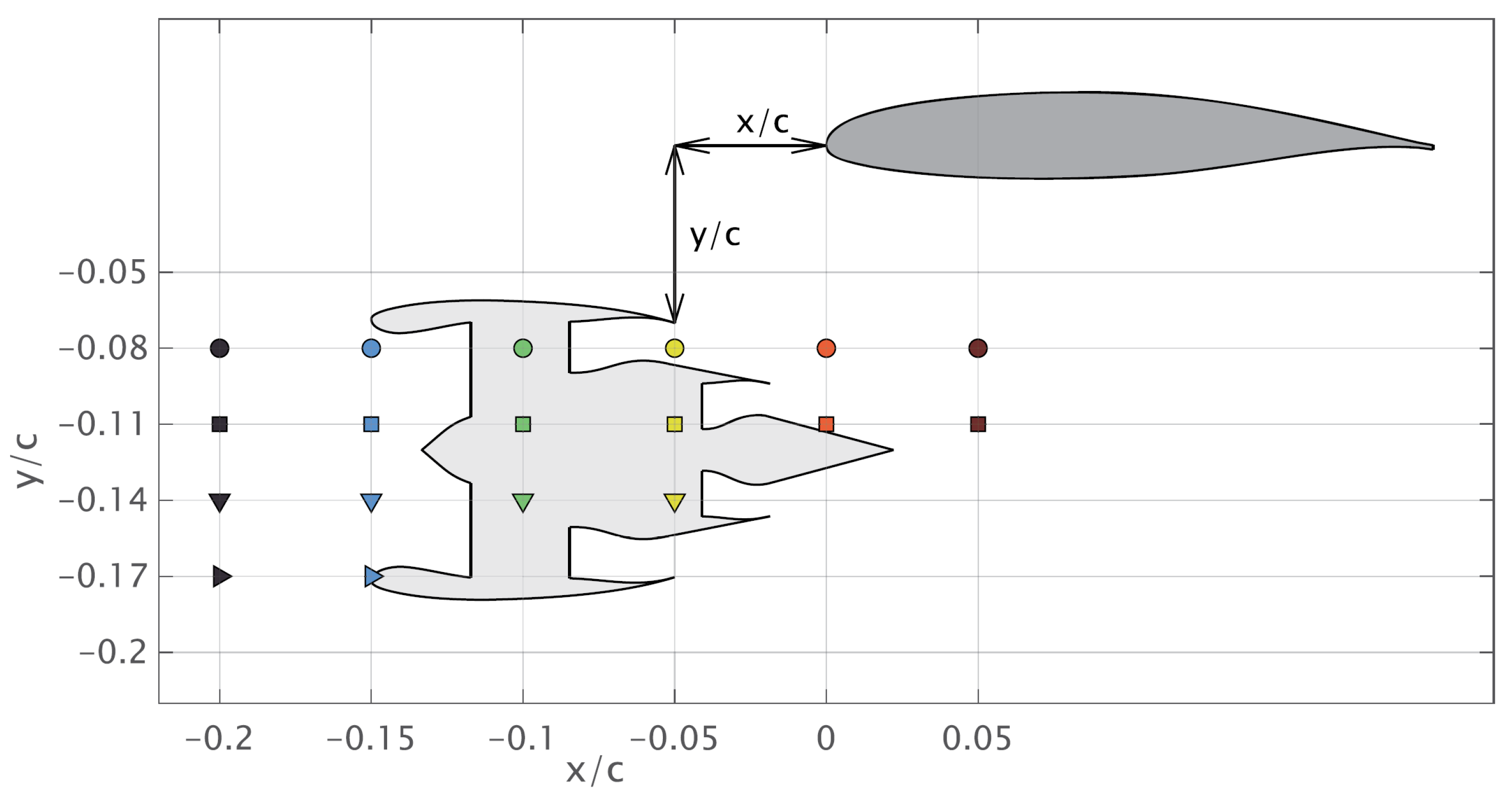

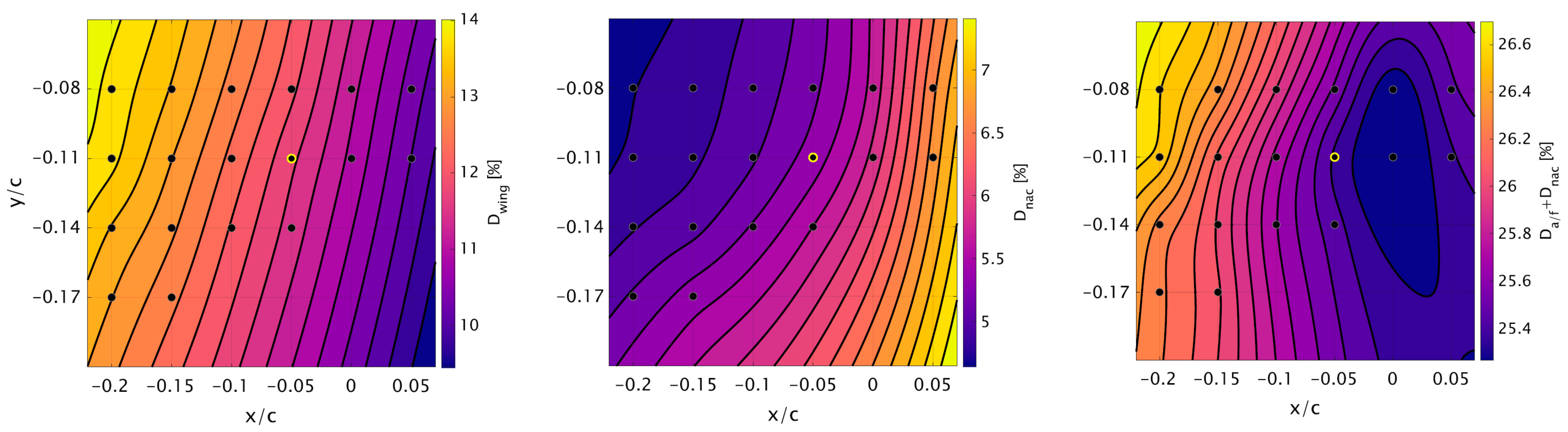

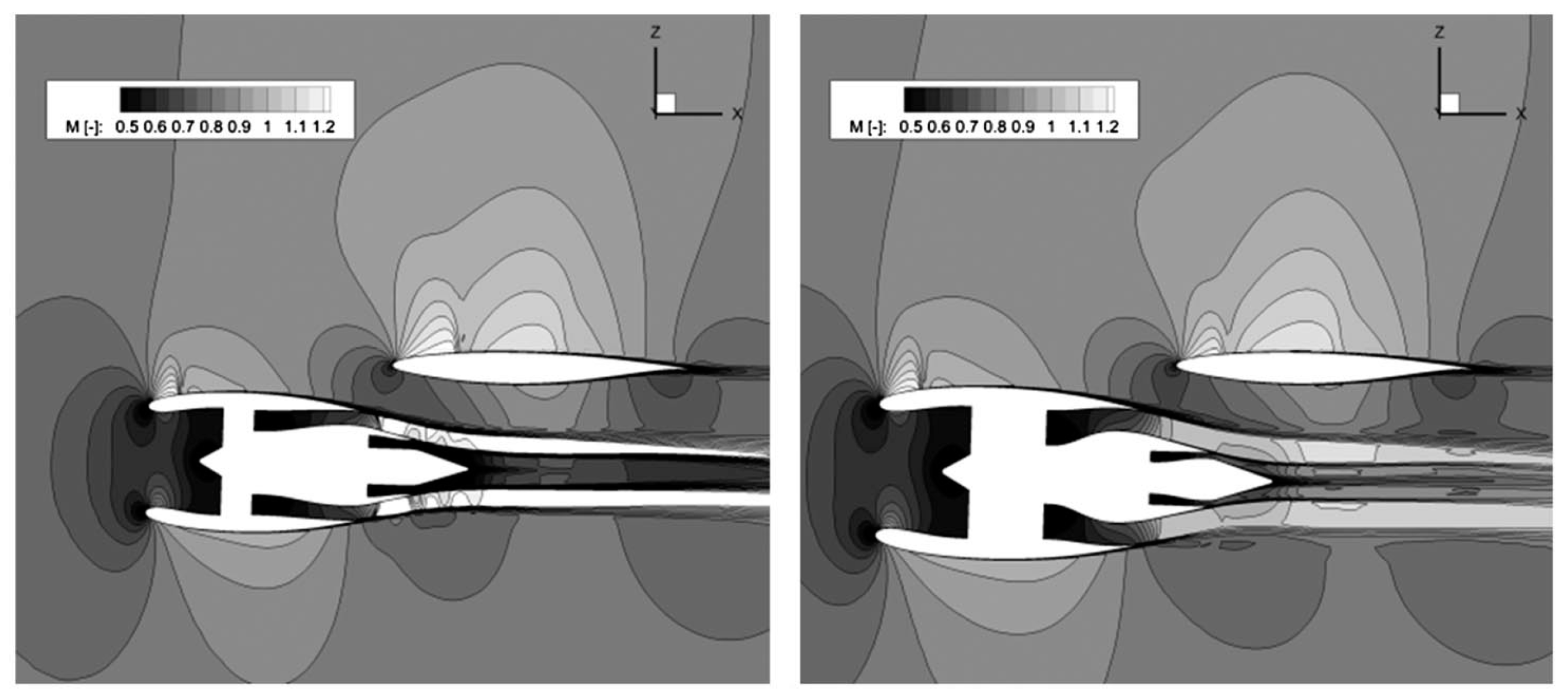

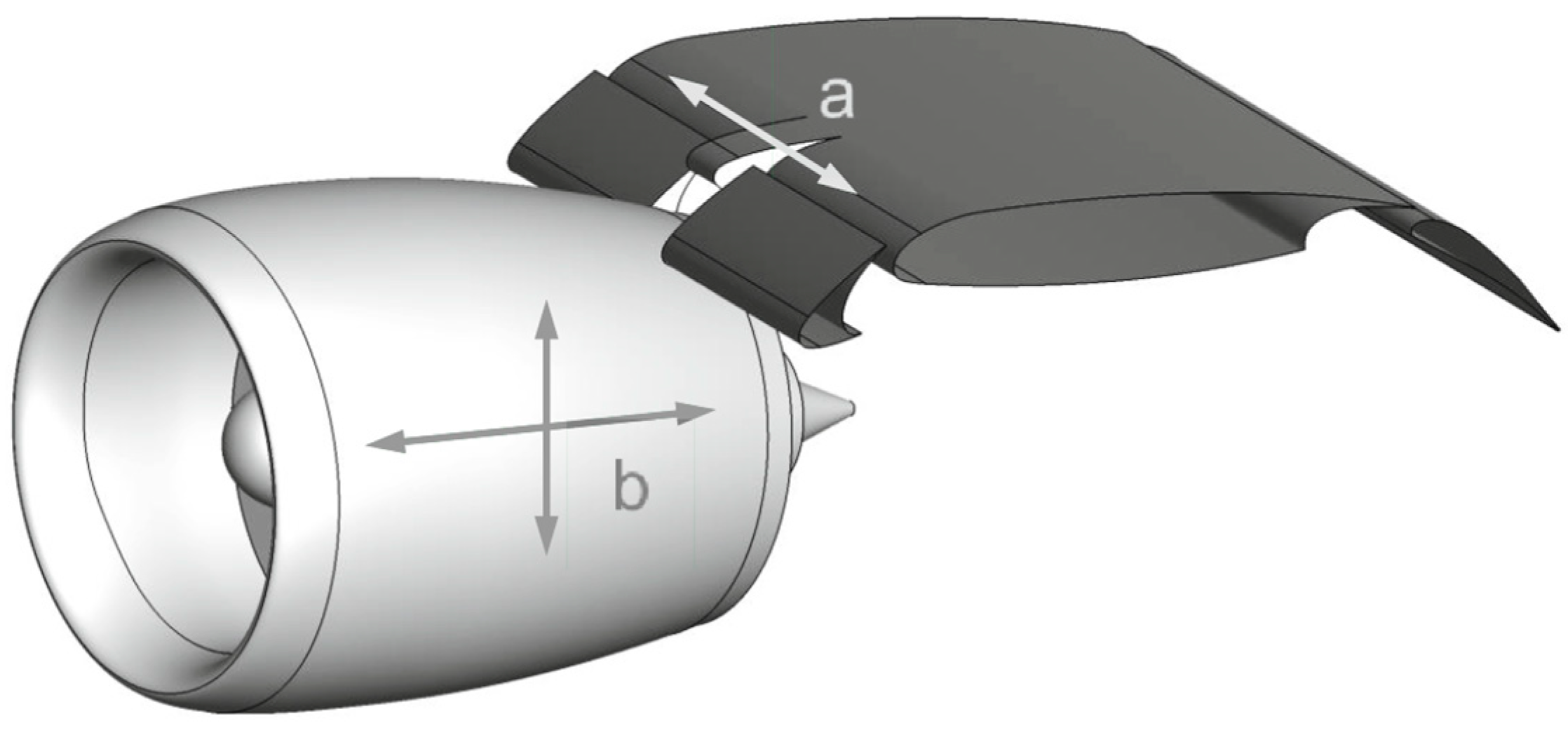

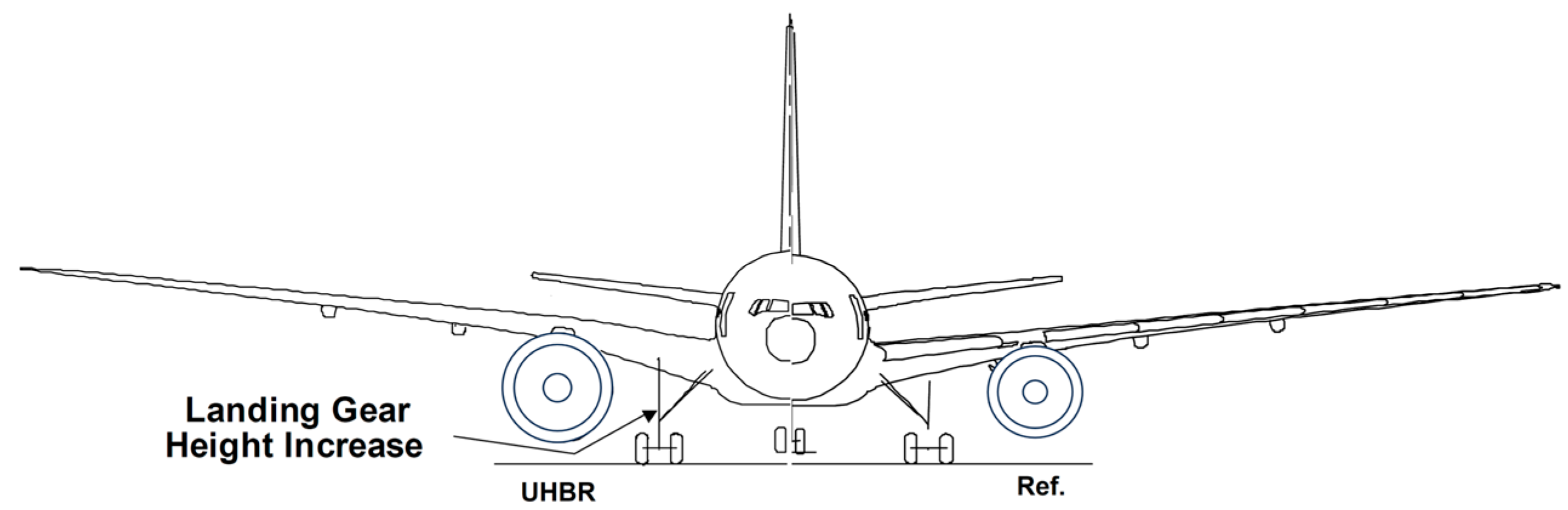

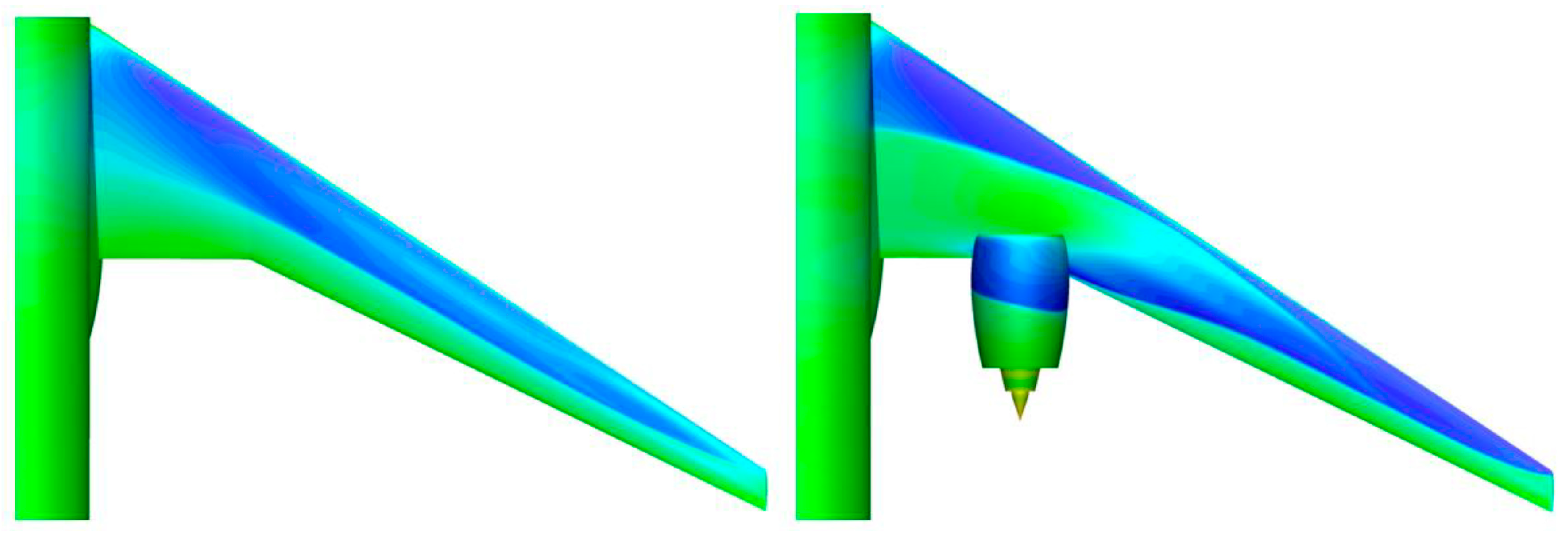

2.3. Assesment of UHBR Installation Effects

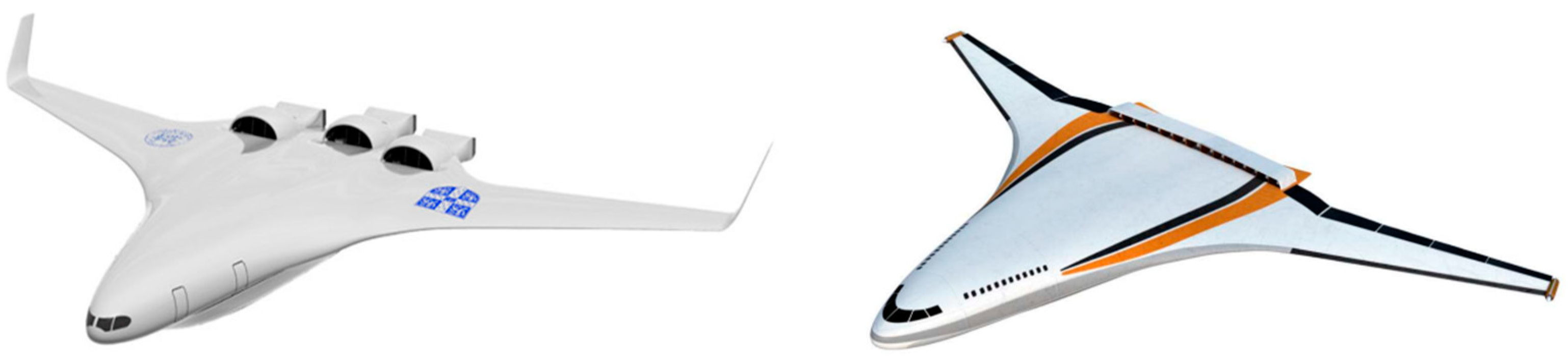

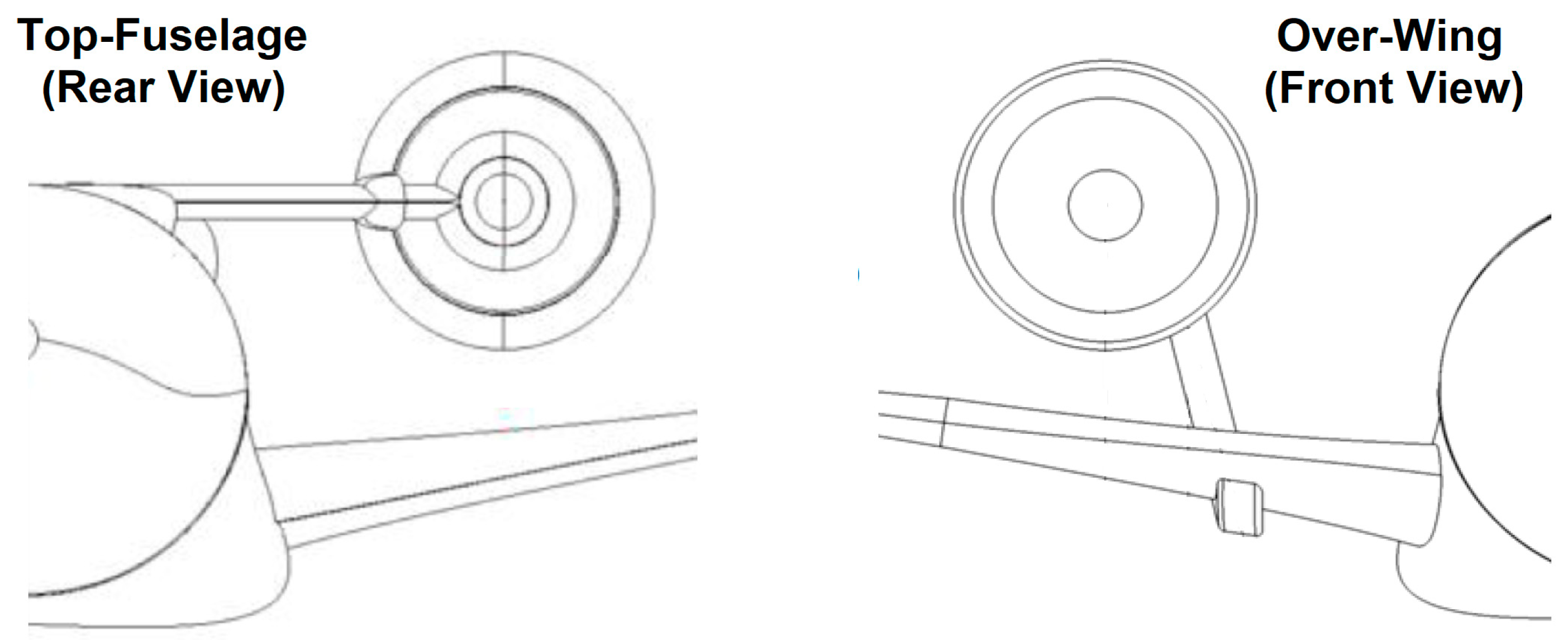

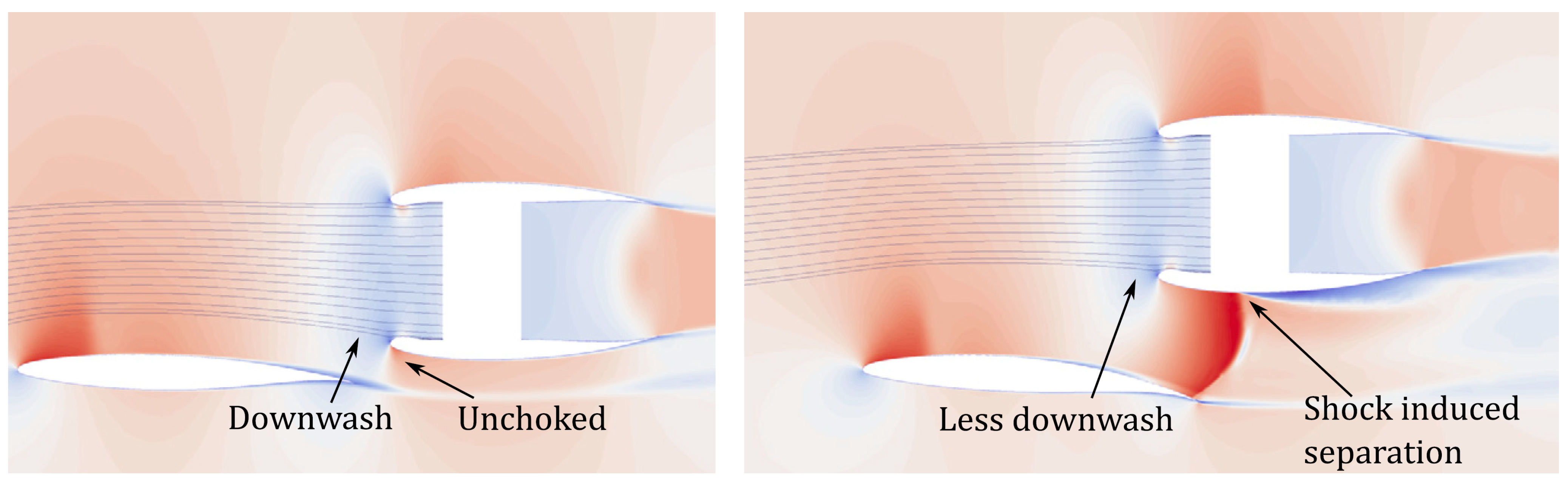

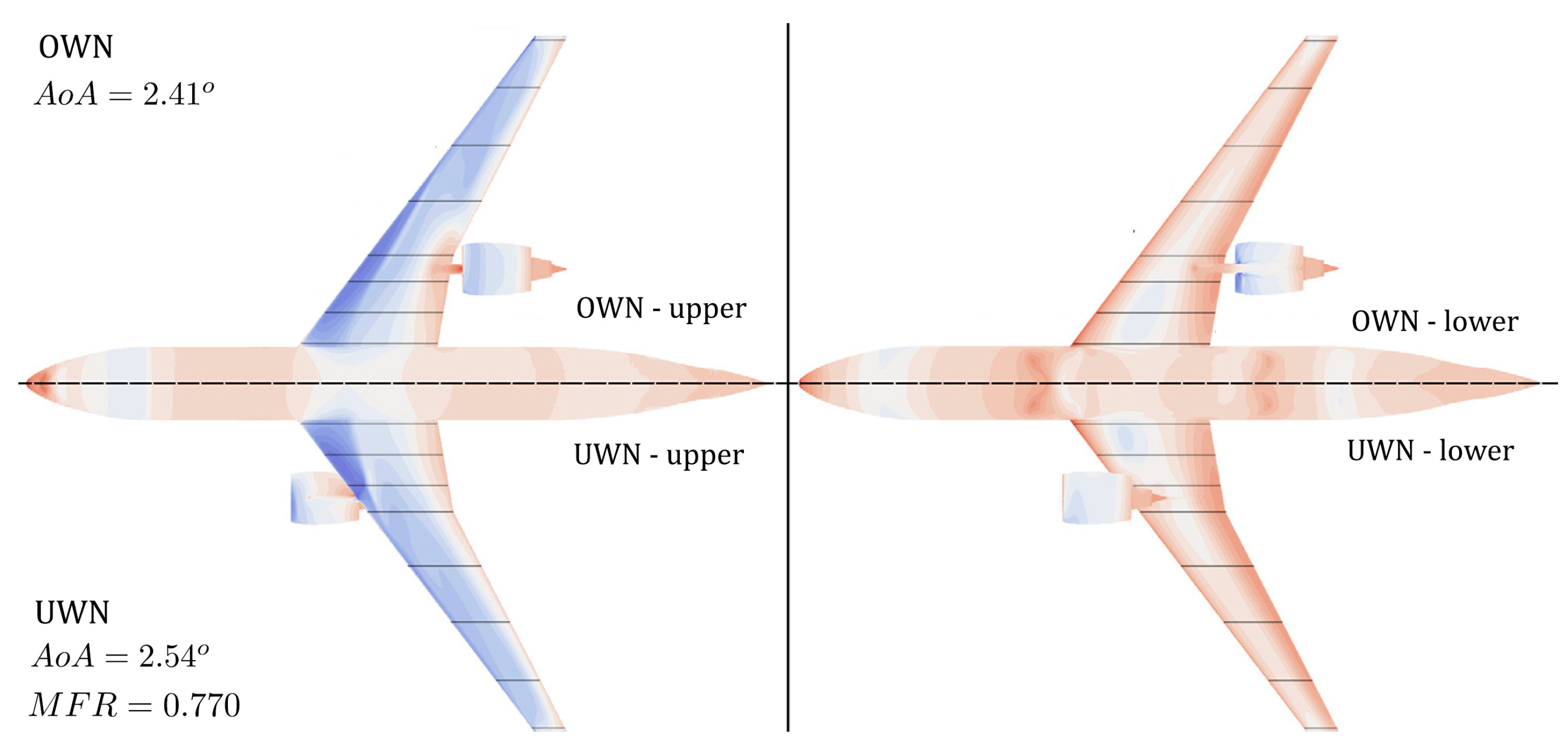

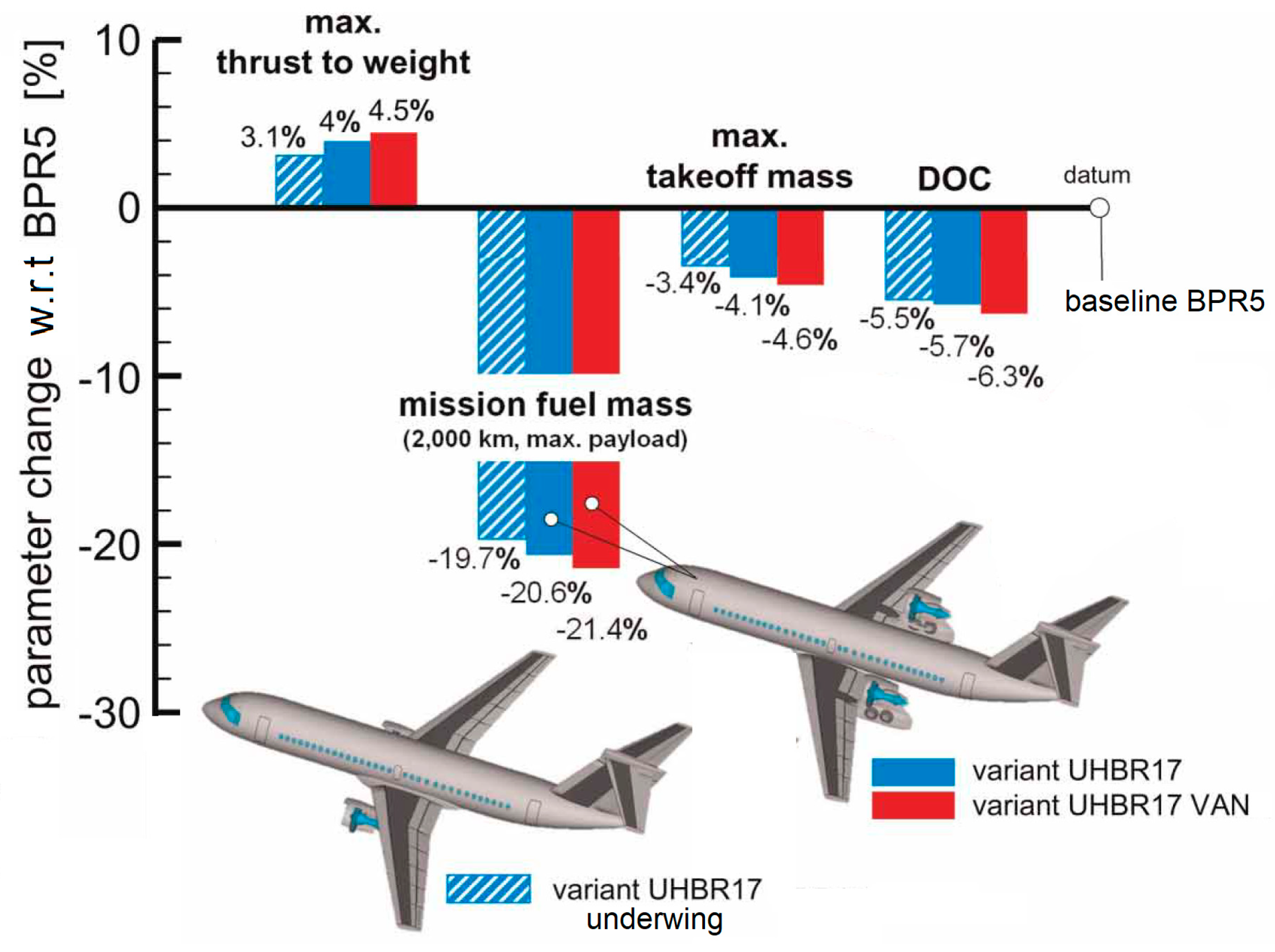

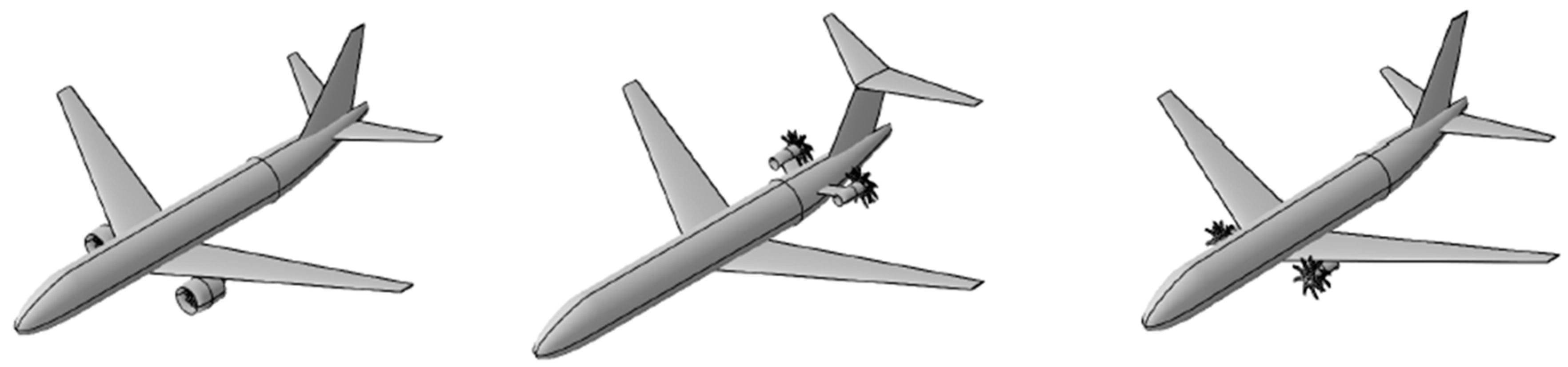

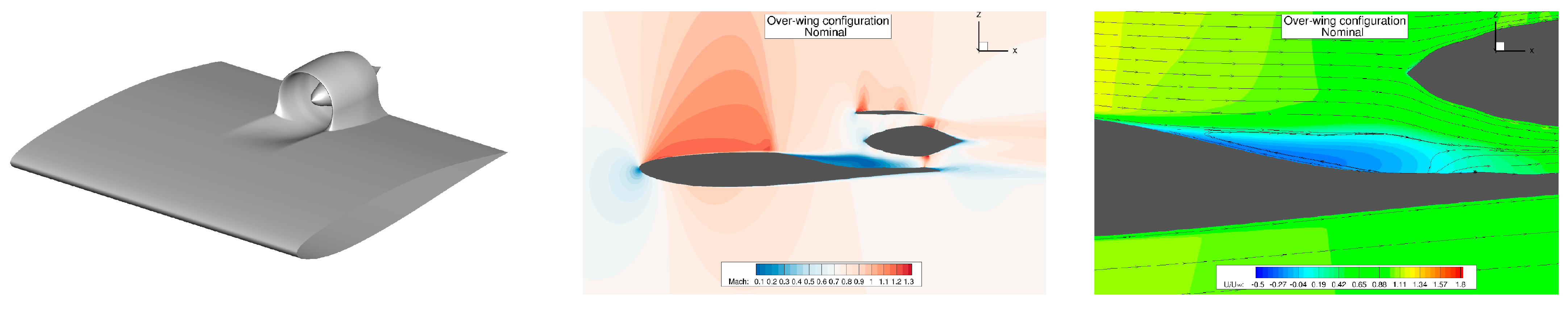

2.4. Unconventional UHBR Turbofan–Airframe Installations

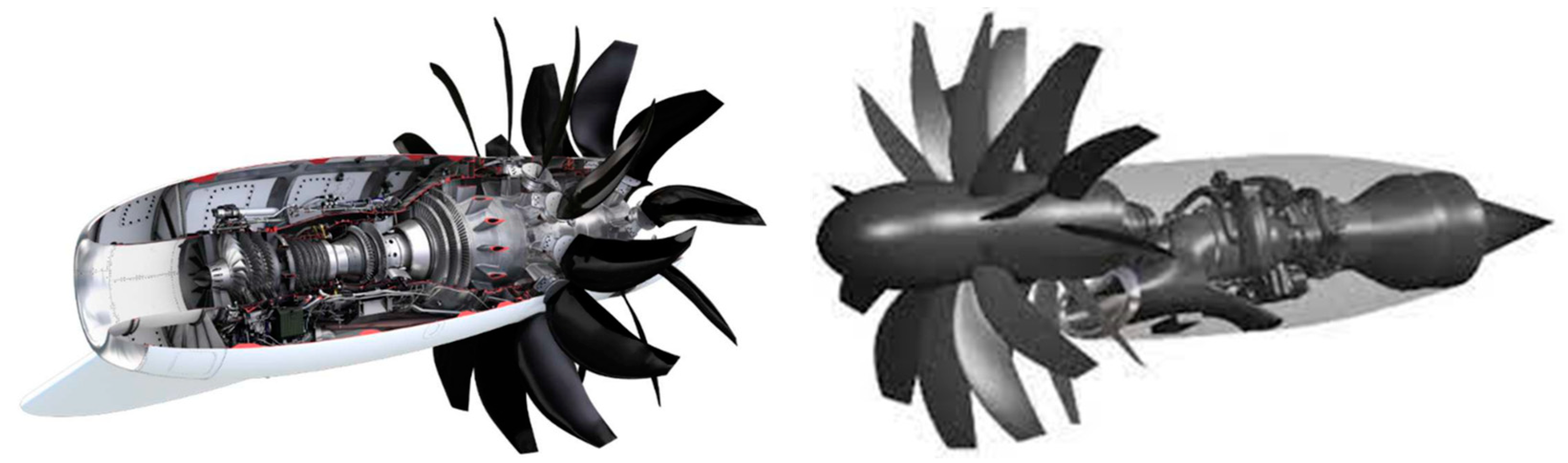

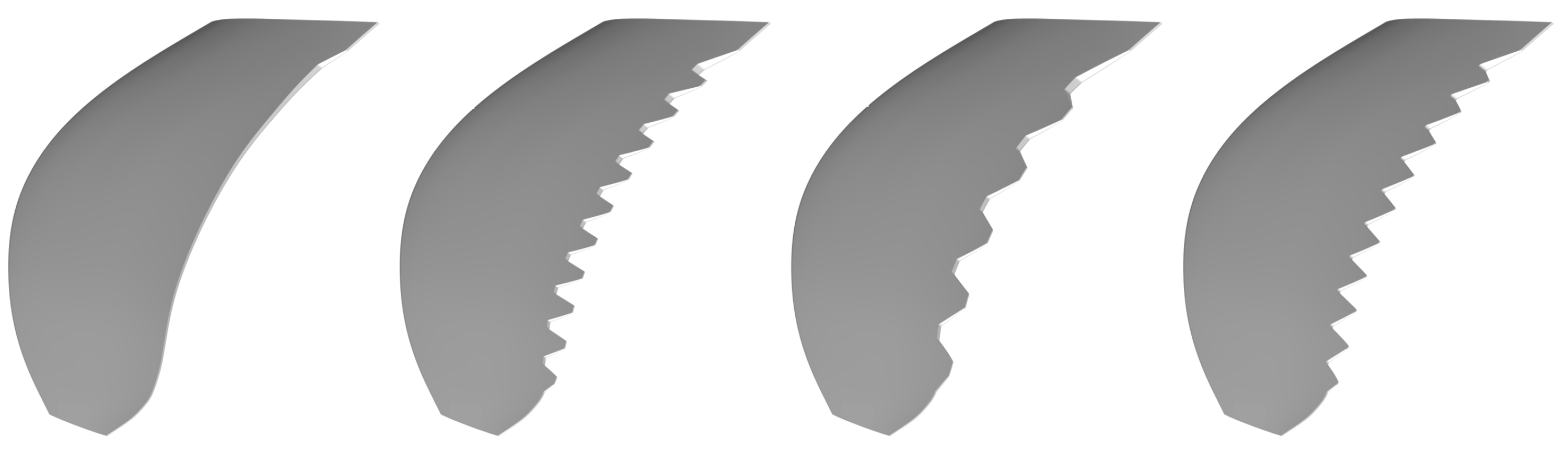

2.5. Open Rotor

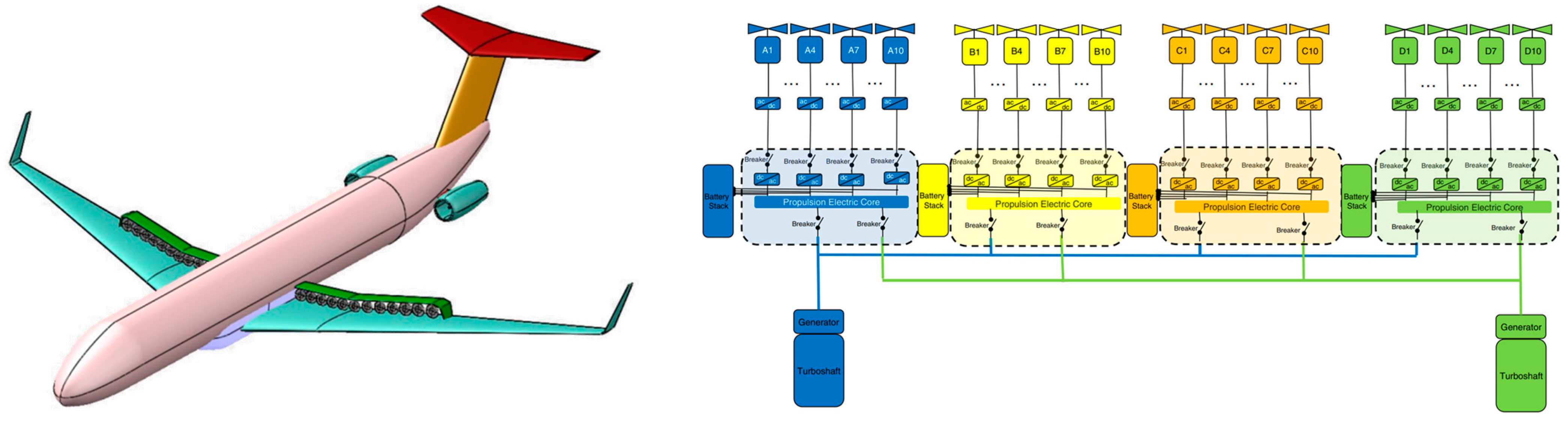

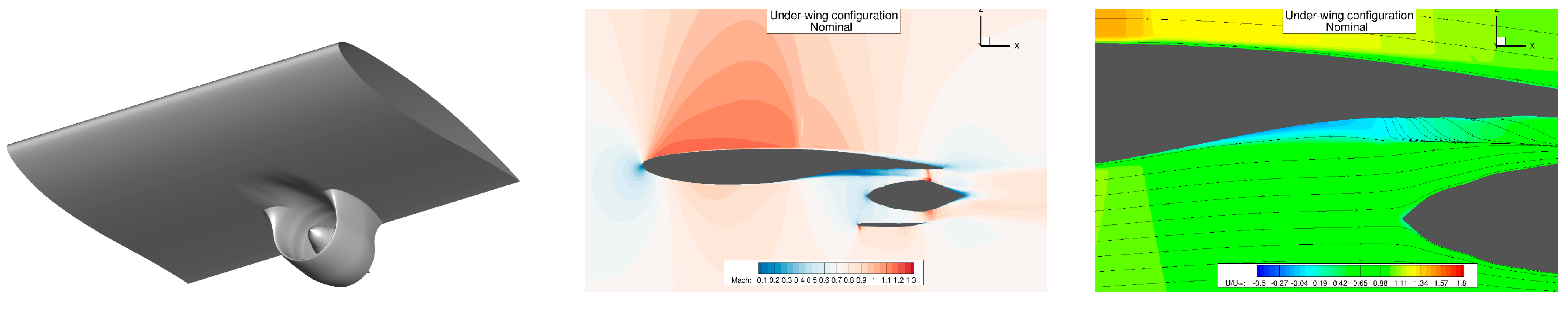

3. Distributed Propulsion

3.1. General Features of Distributed Propulsion

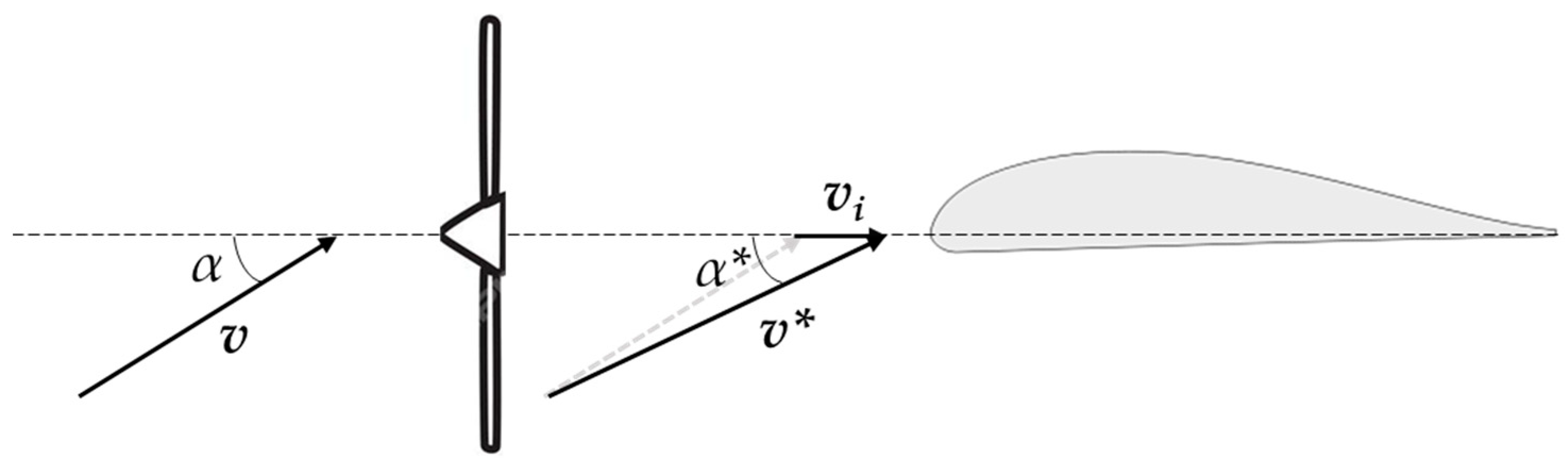

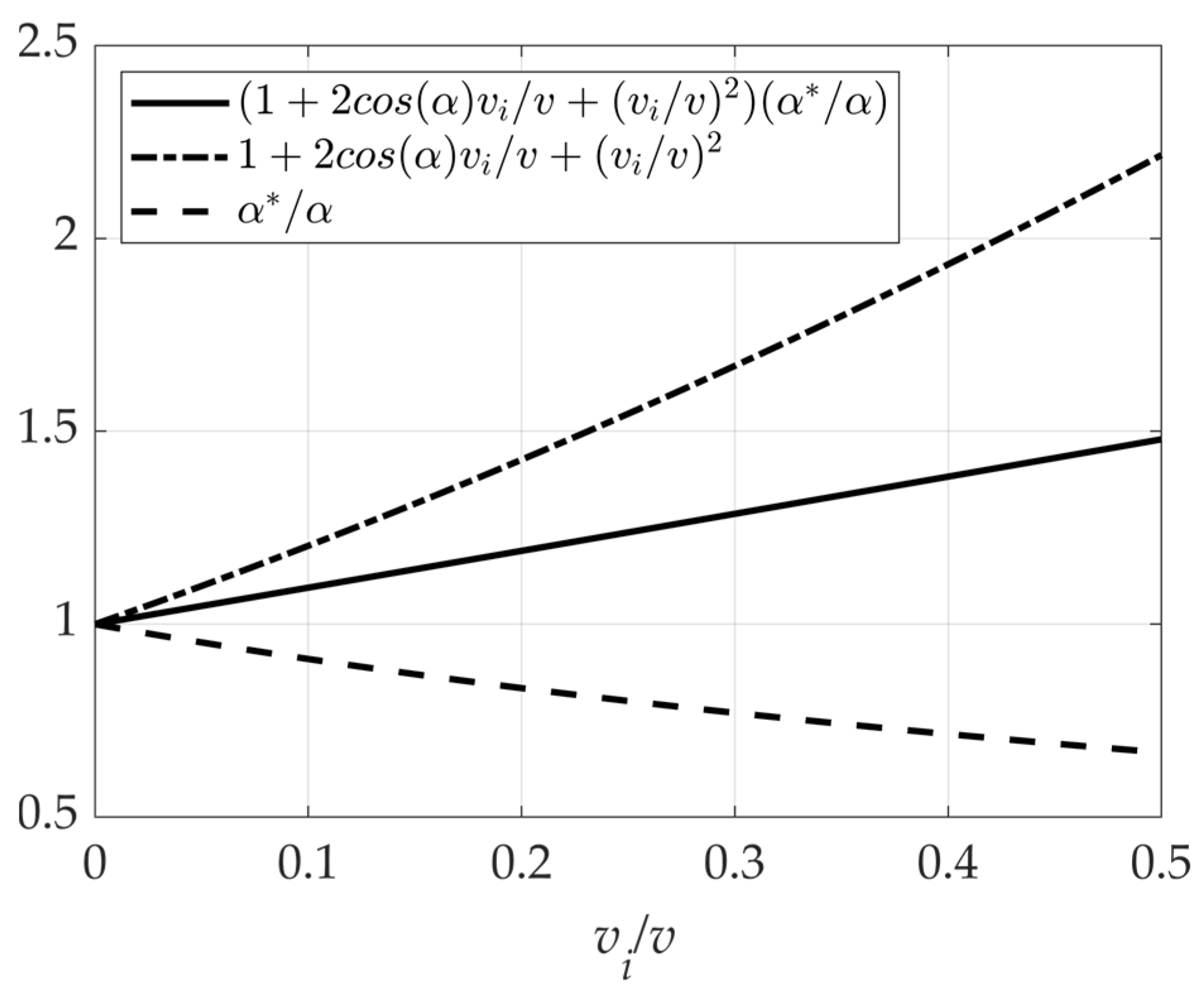

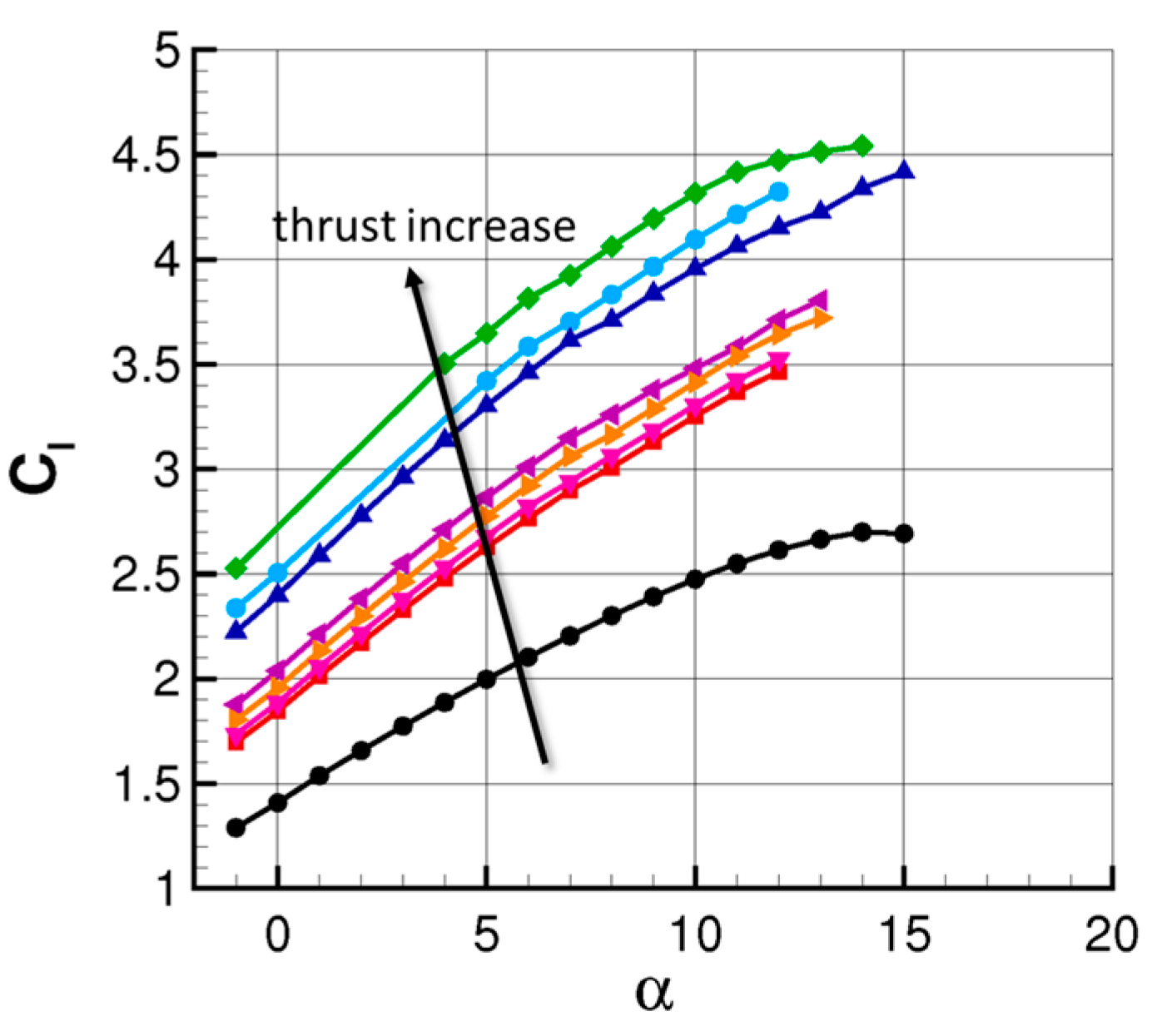

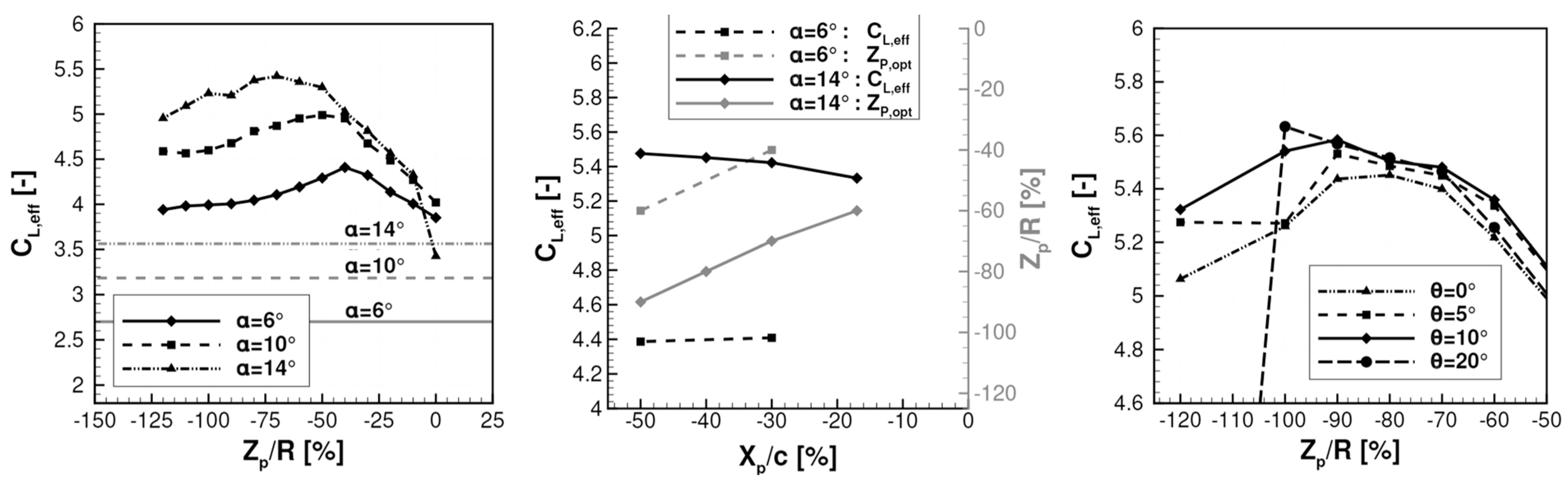

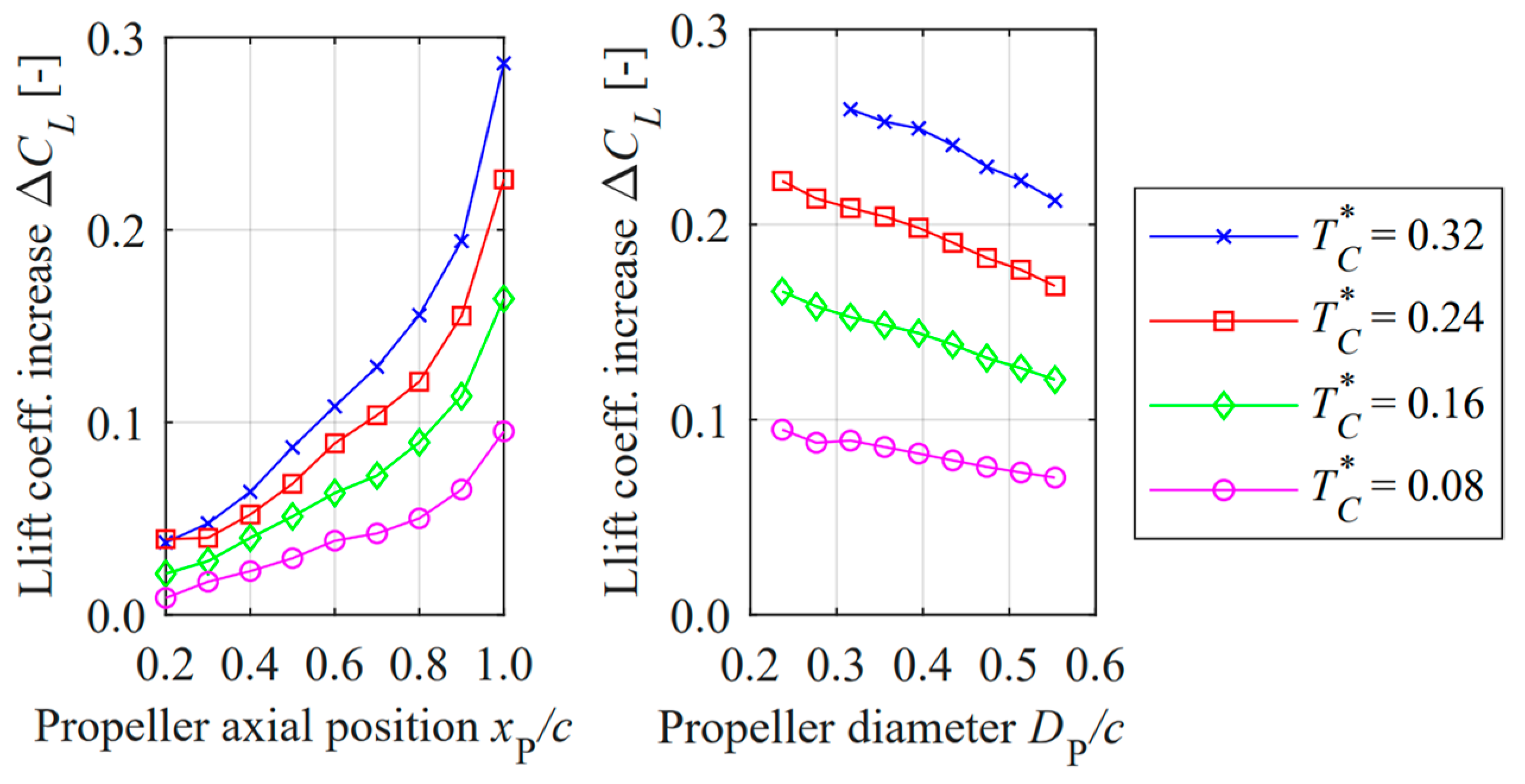

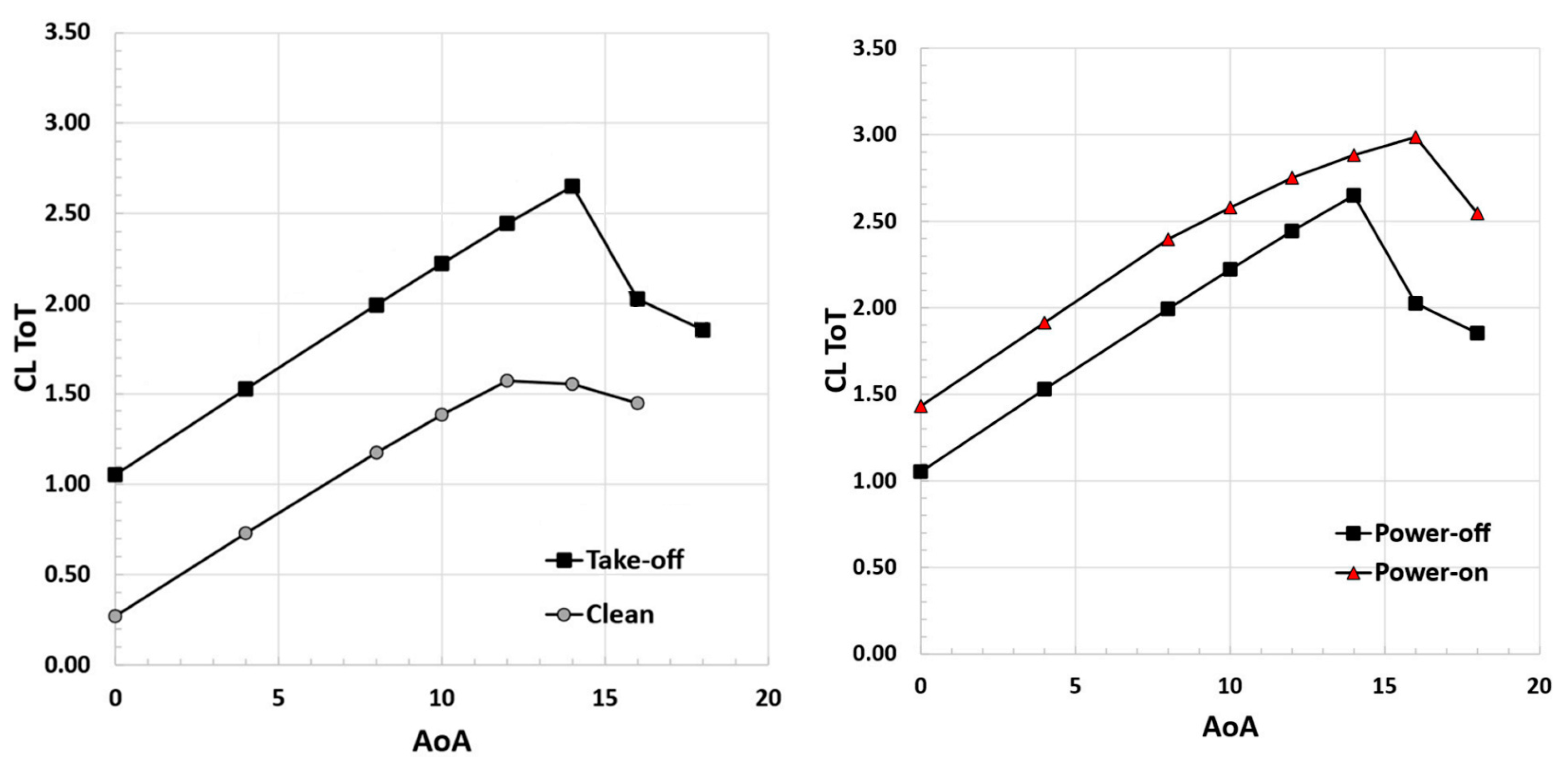

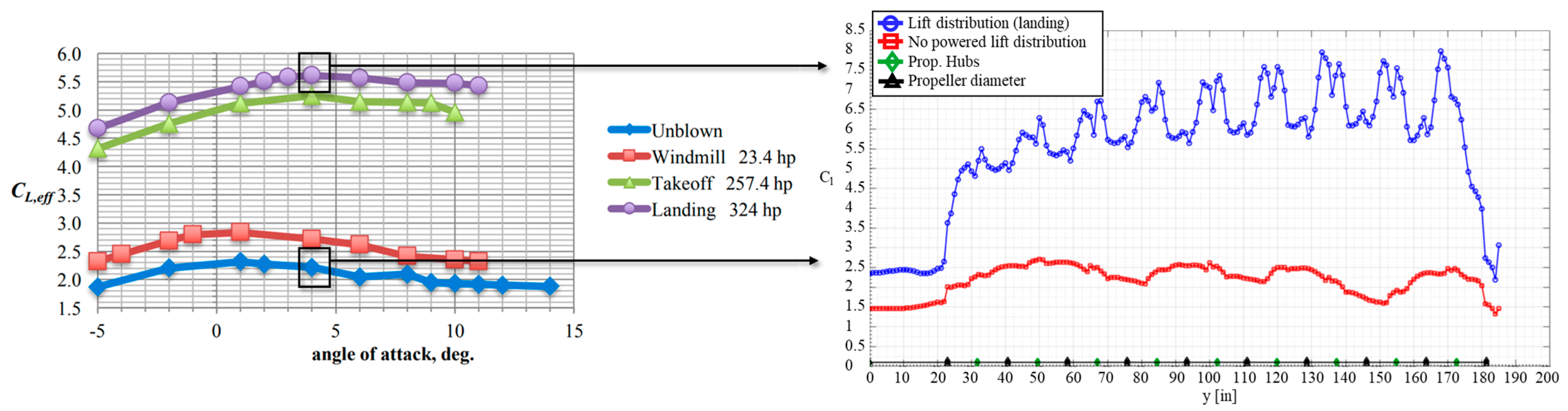

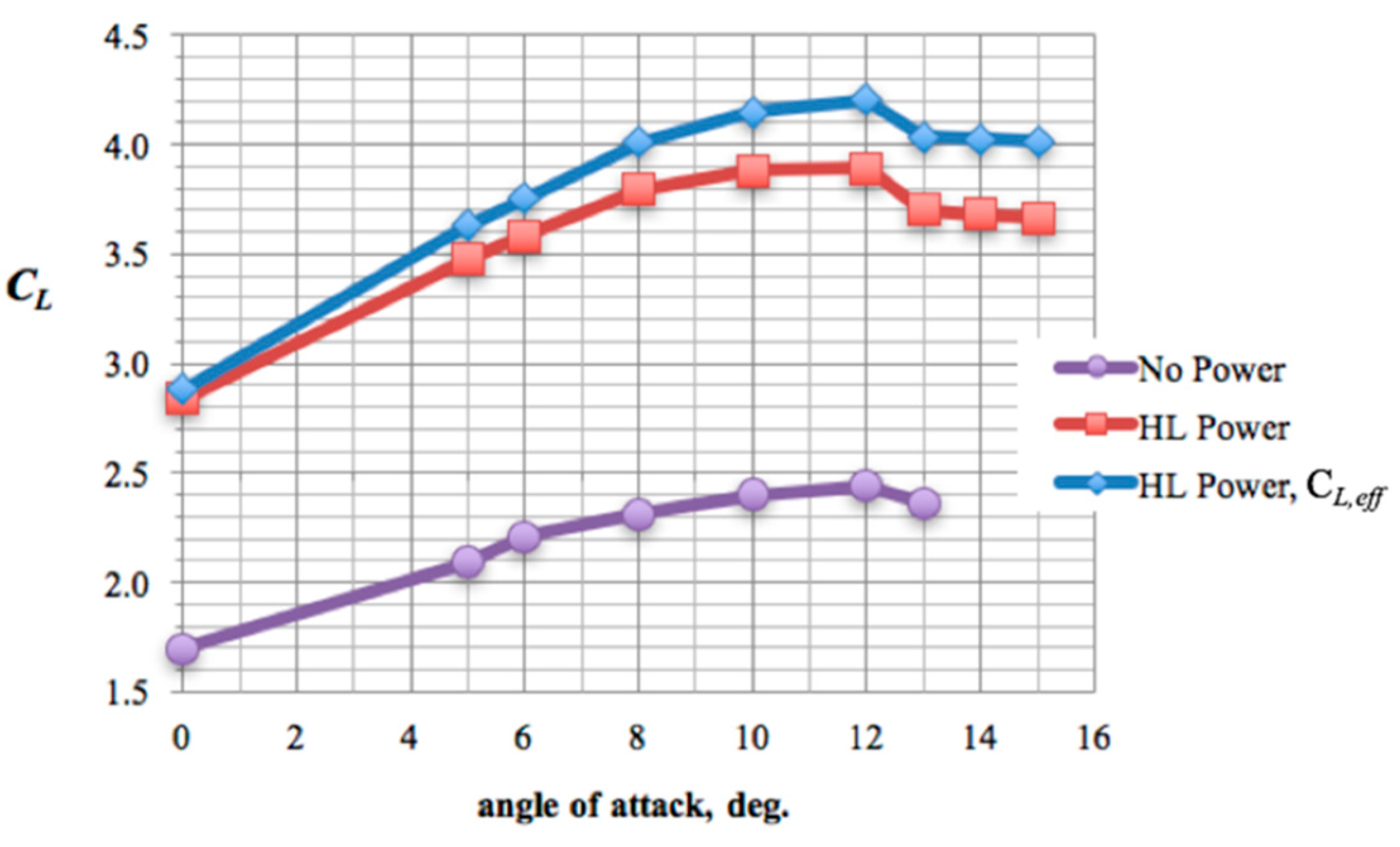

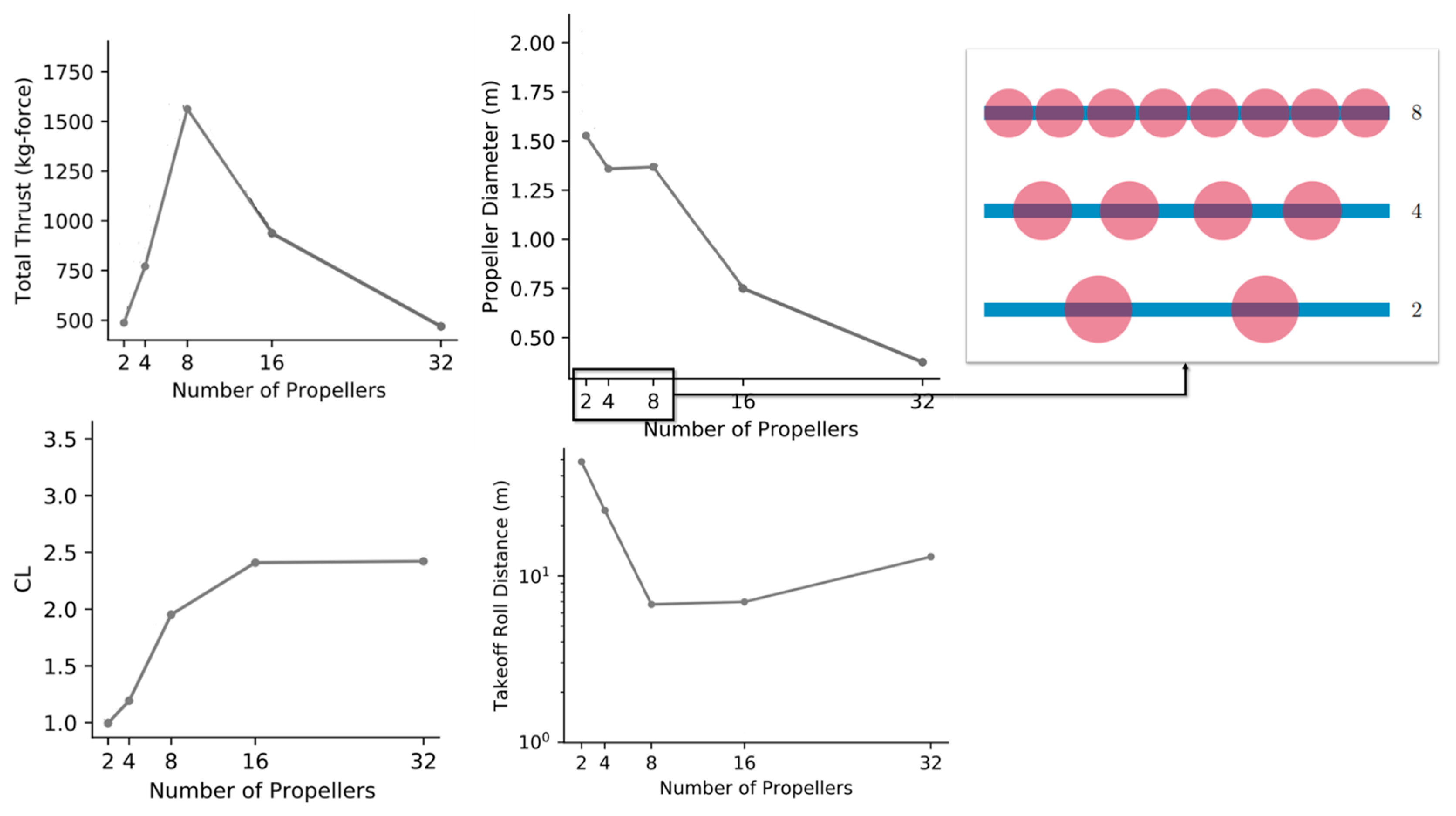

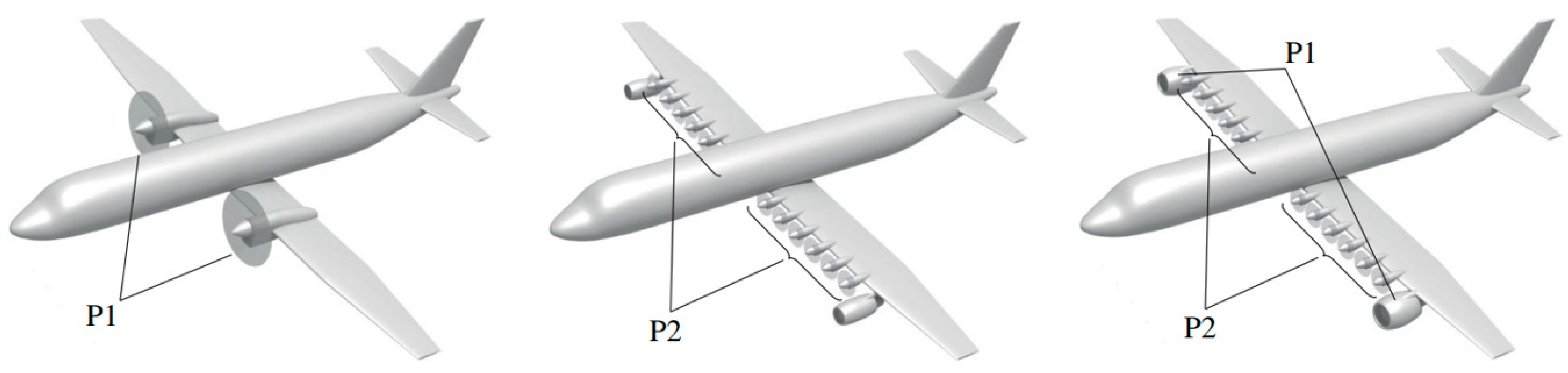

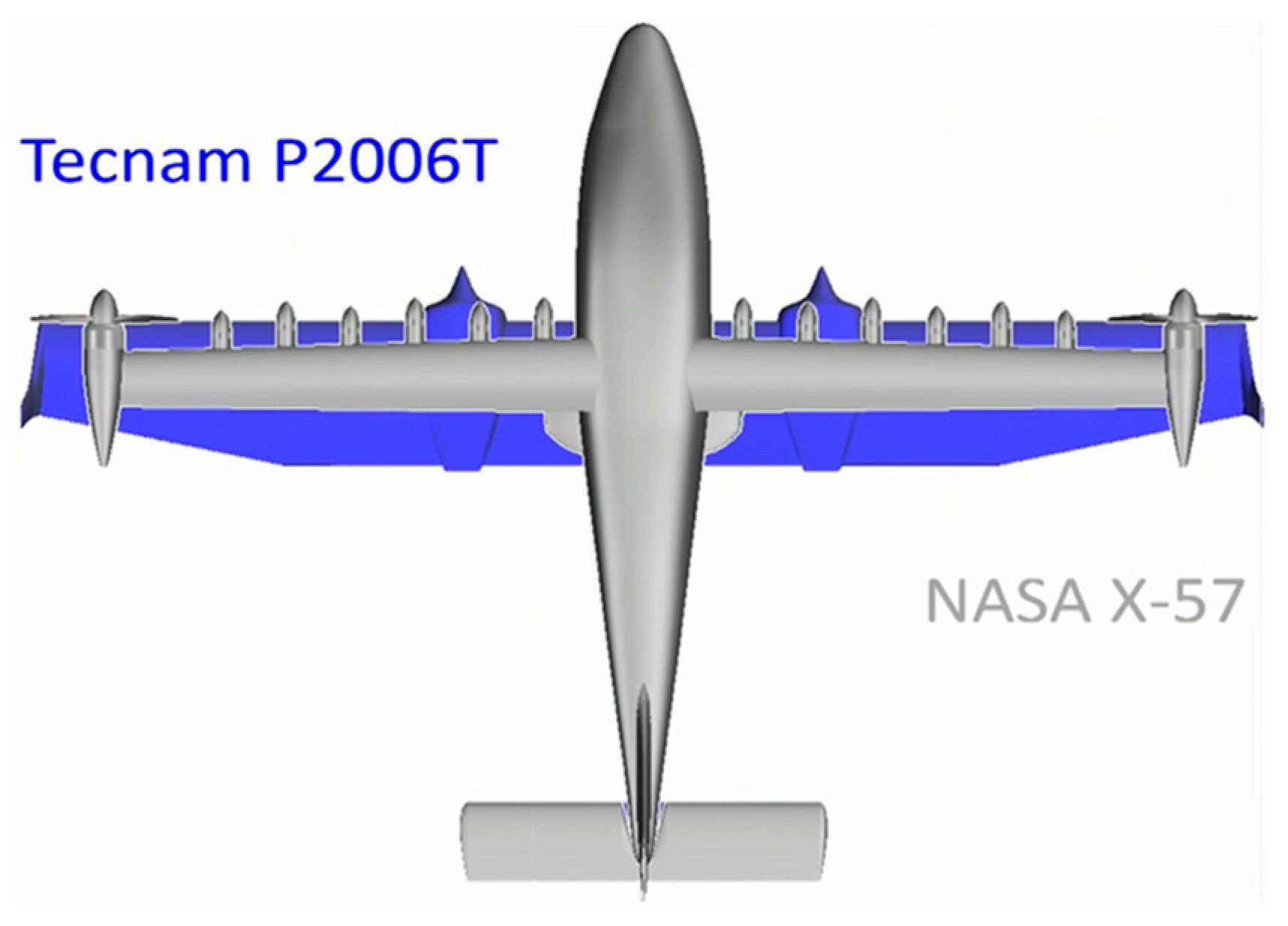

3.2. DP for Improvement of High-Lift Performance

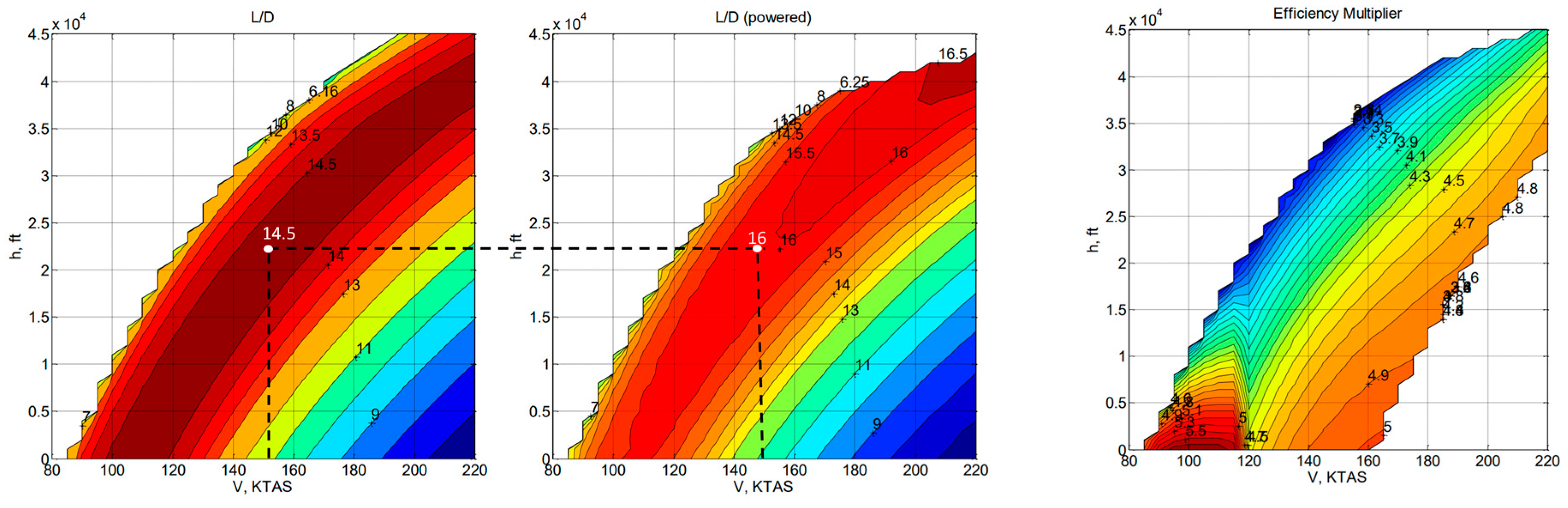

3.3. DP for Improvement of Lift-to-Drag Ratio

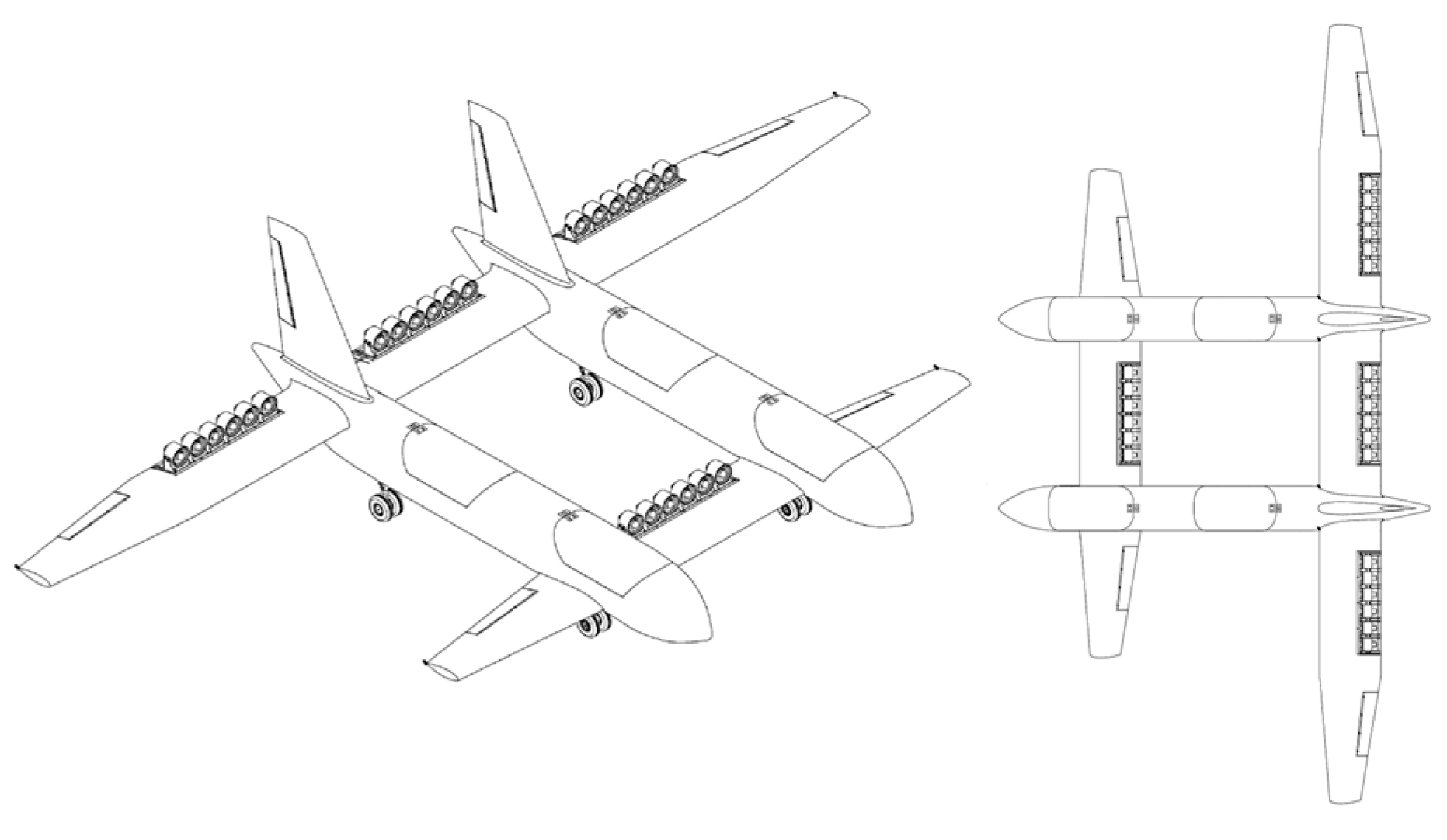

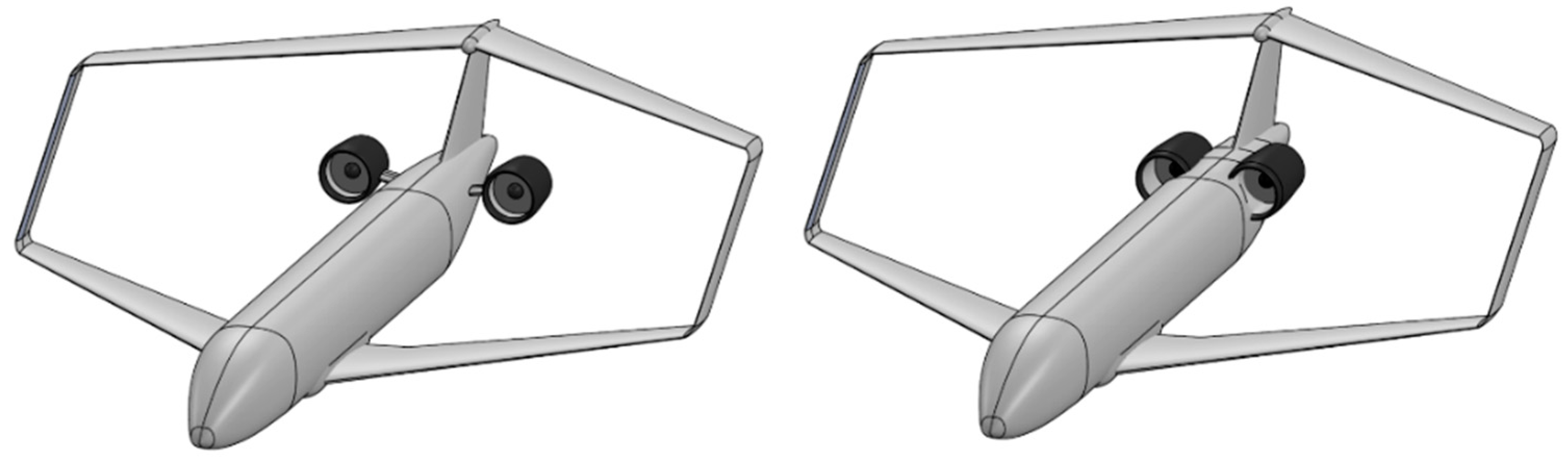

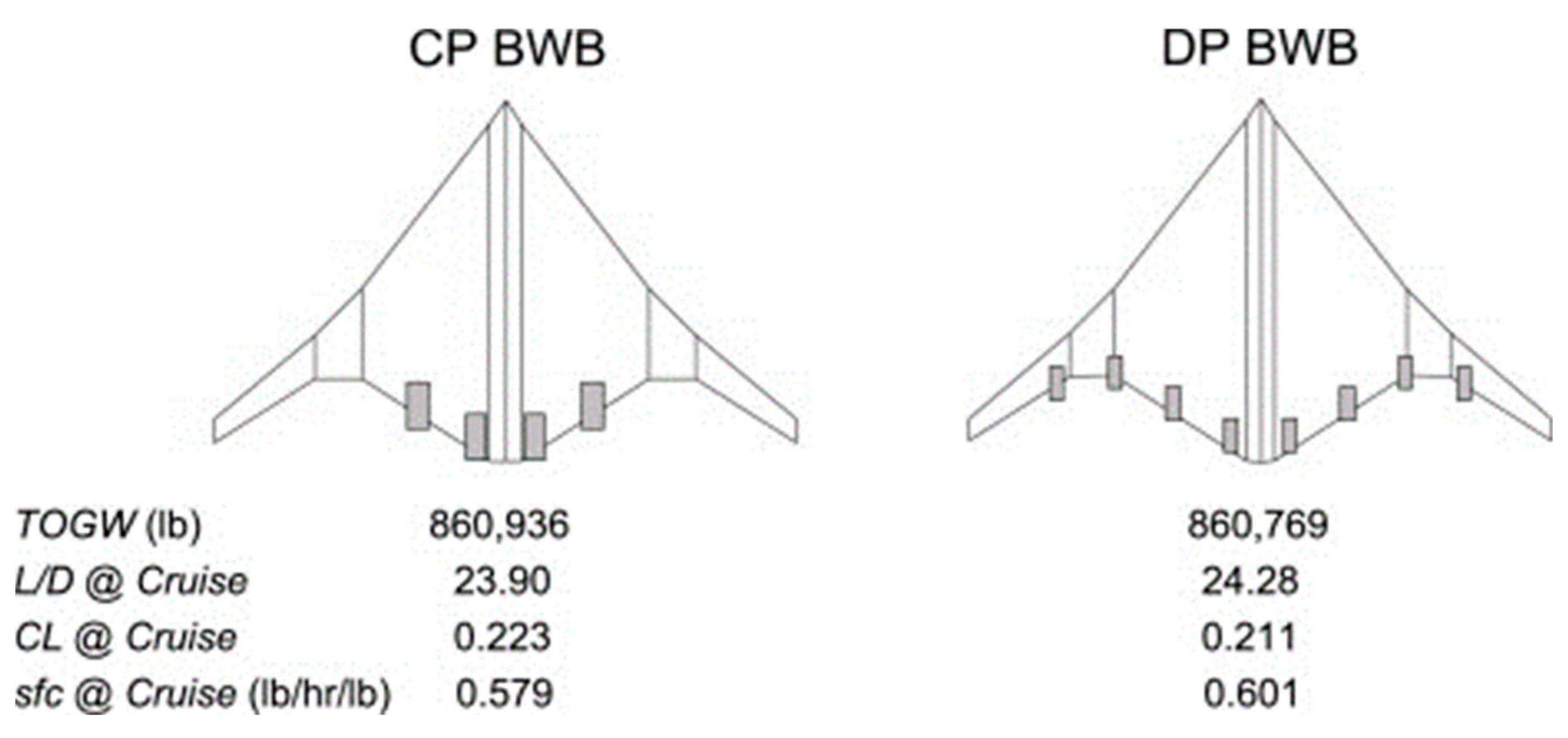

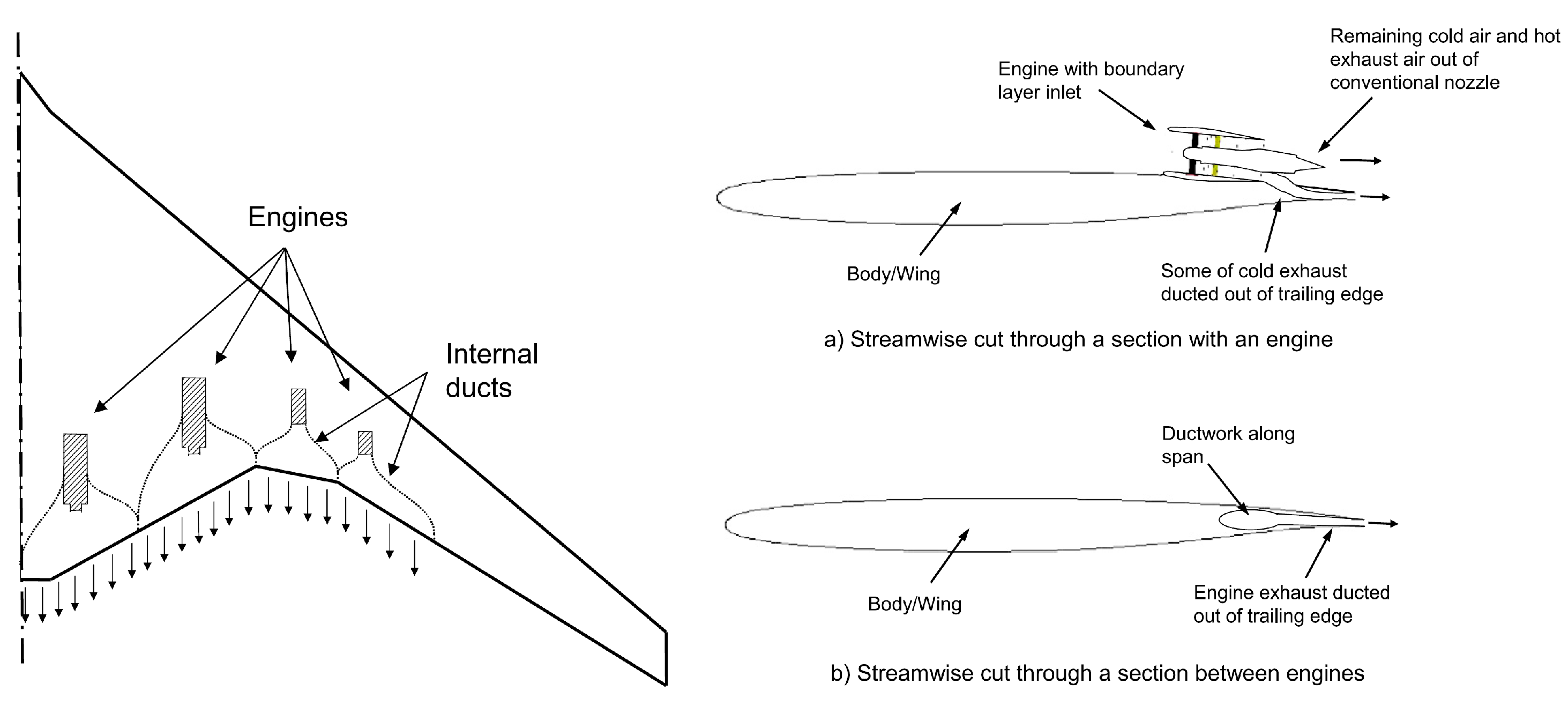

3.4. Multiple Discrete Propulsive Units

3.5. Experimental Assessment: Scaled Demonstrators

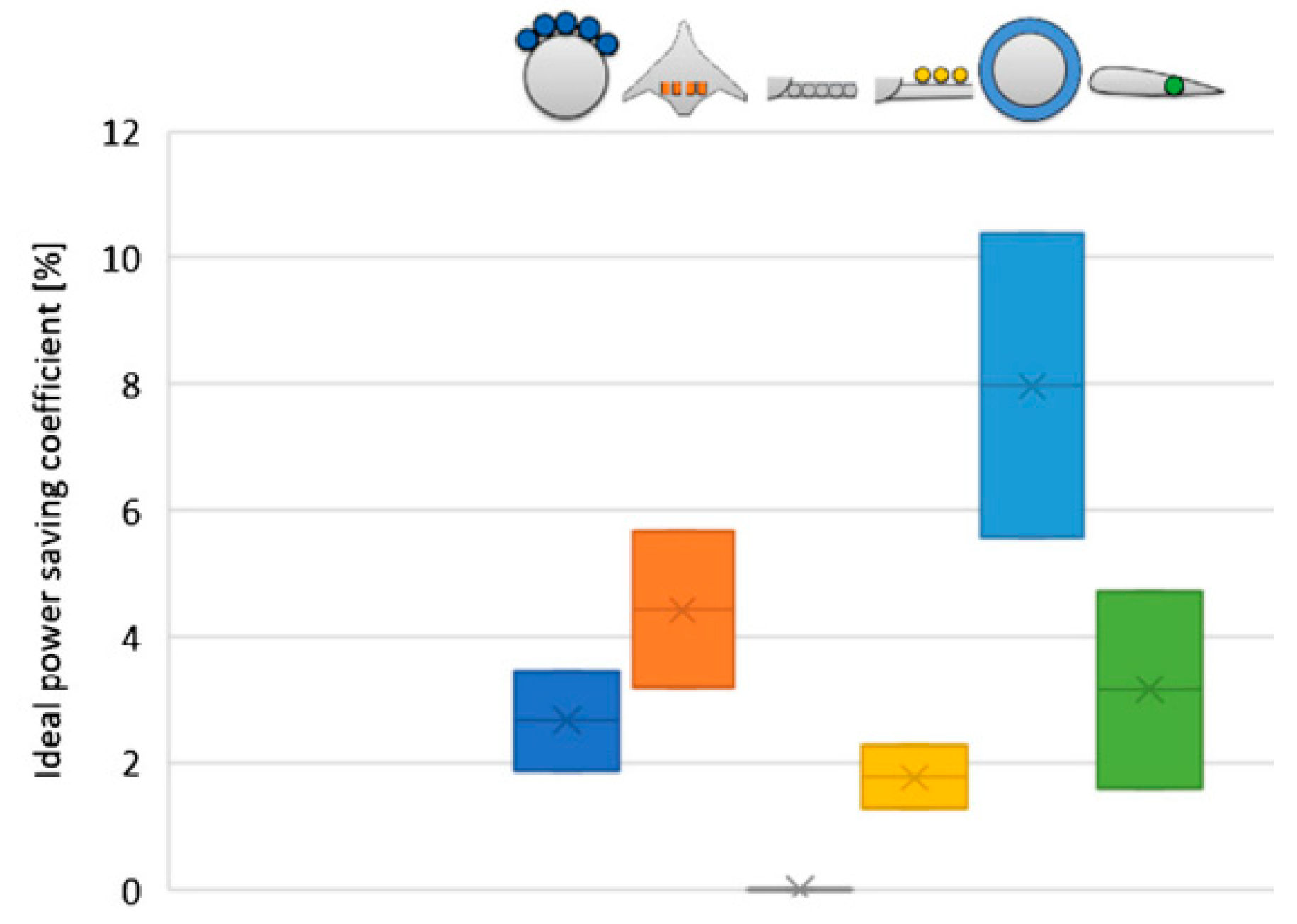

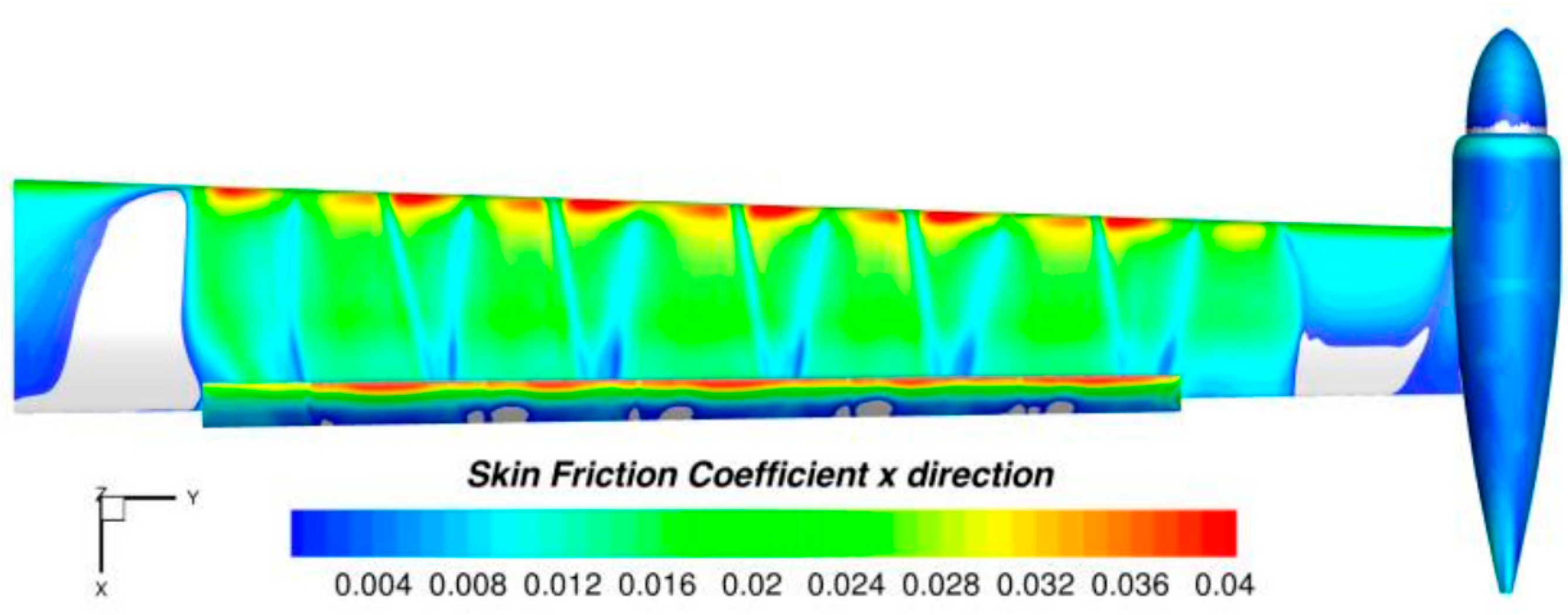

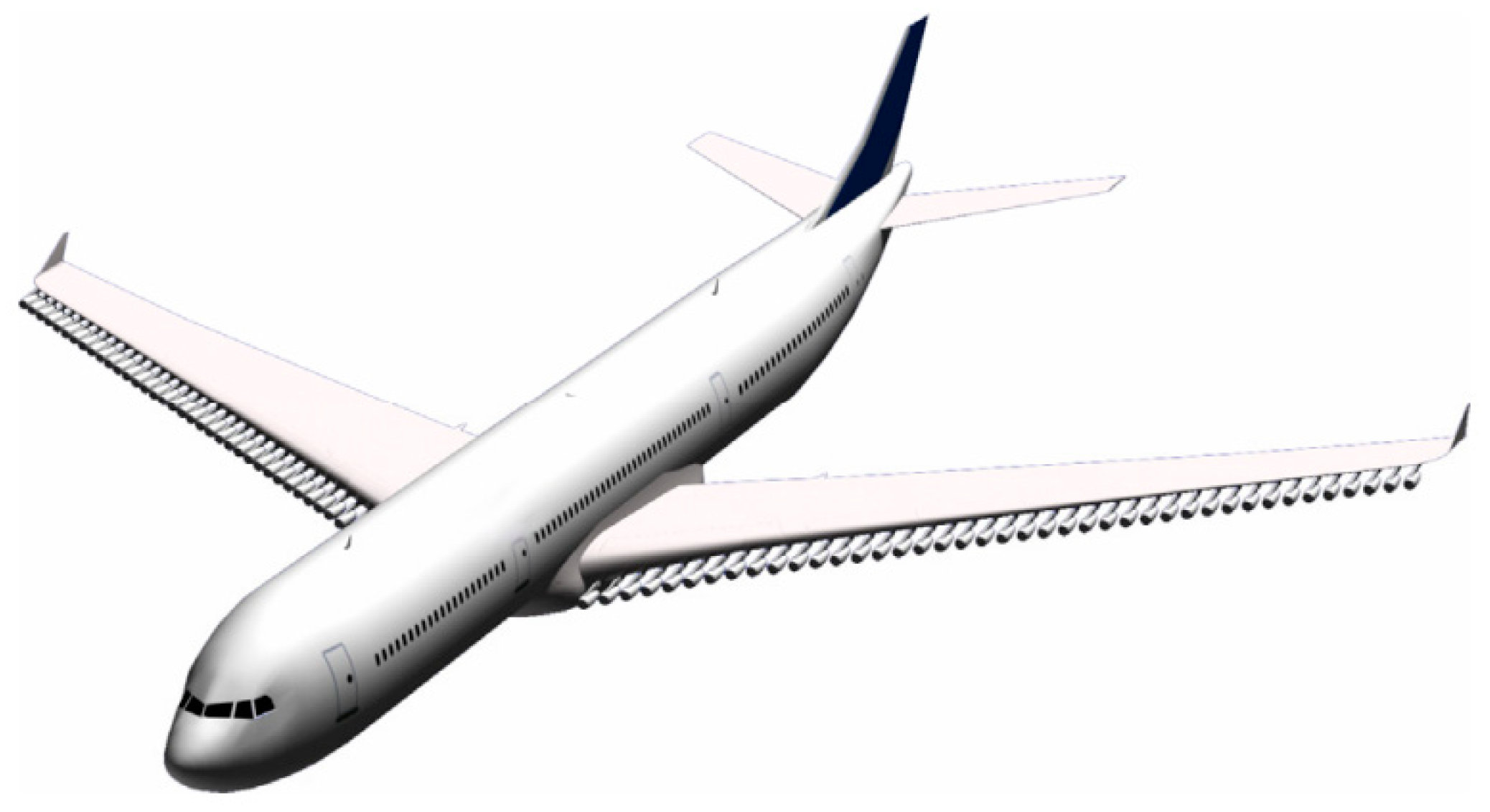

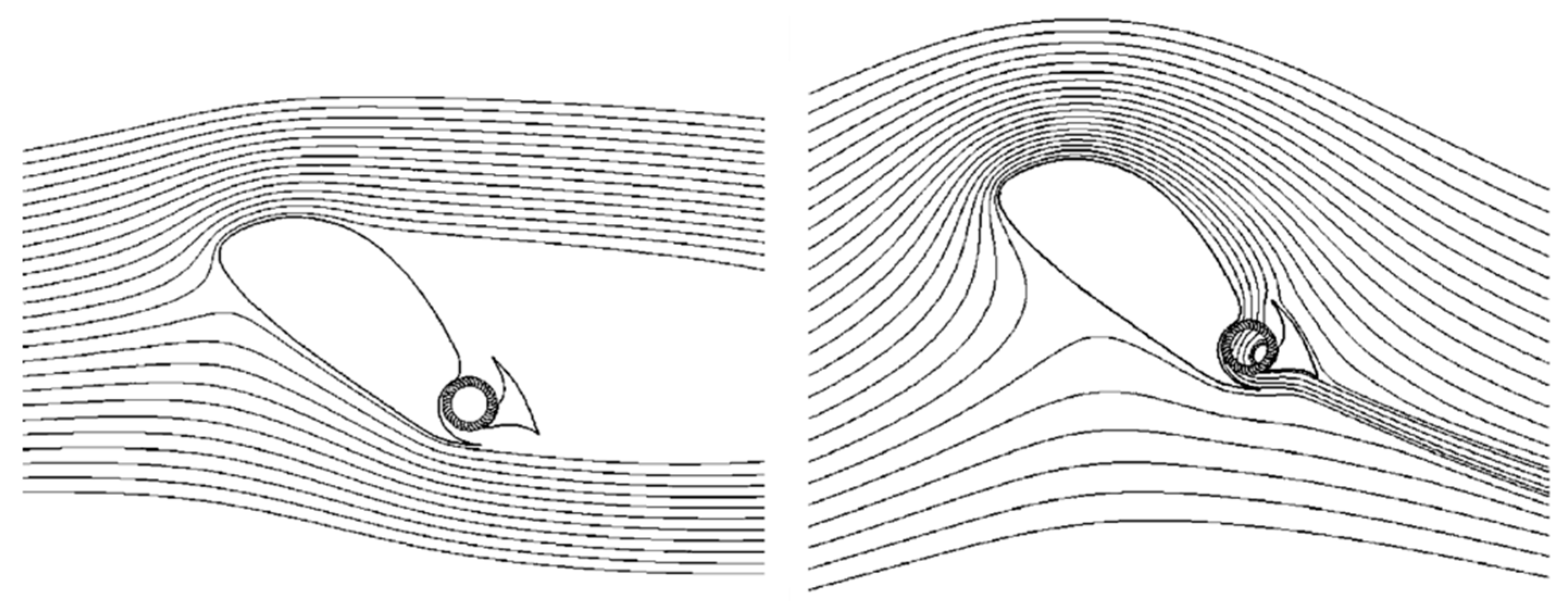

4. Boundary Layer Ingestion

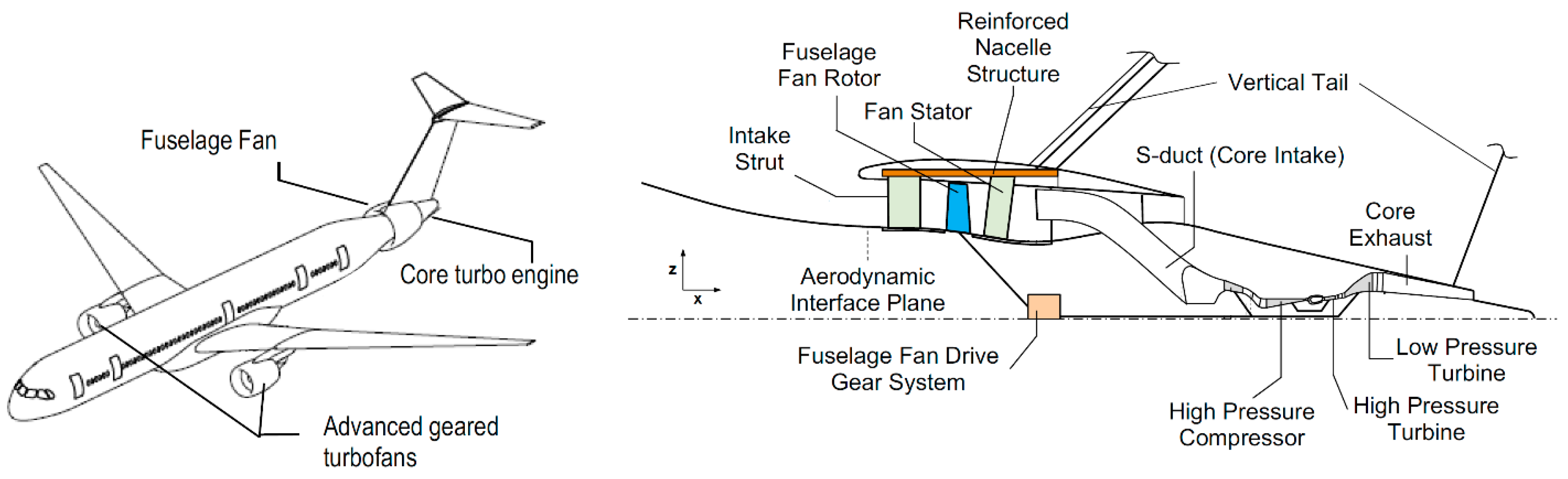

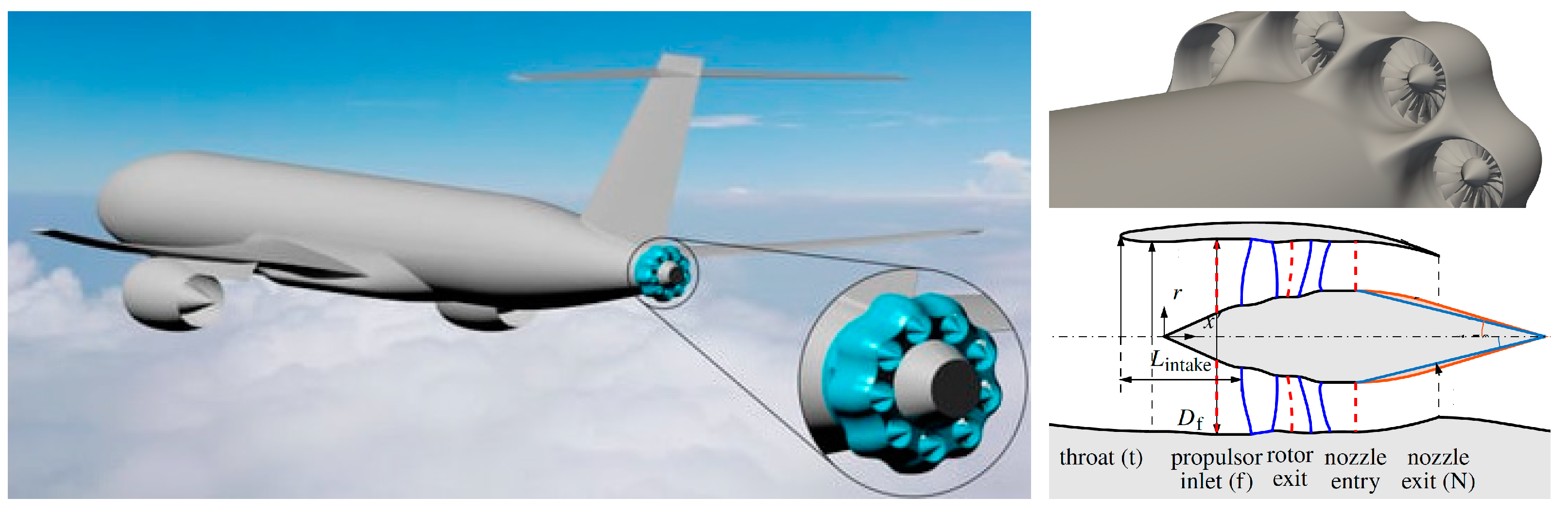

4.1. Propulsive Fuselage Concepts

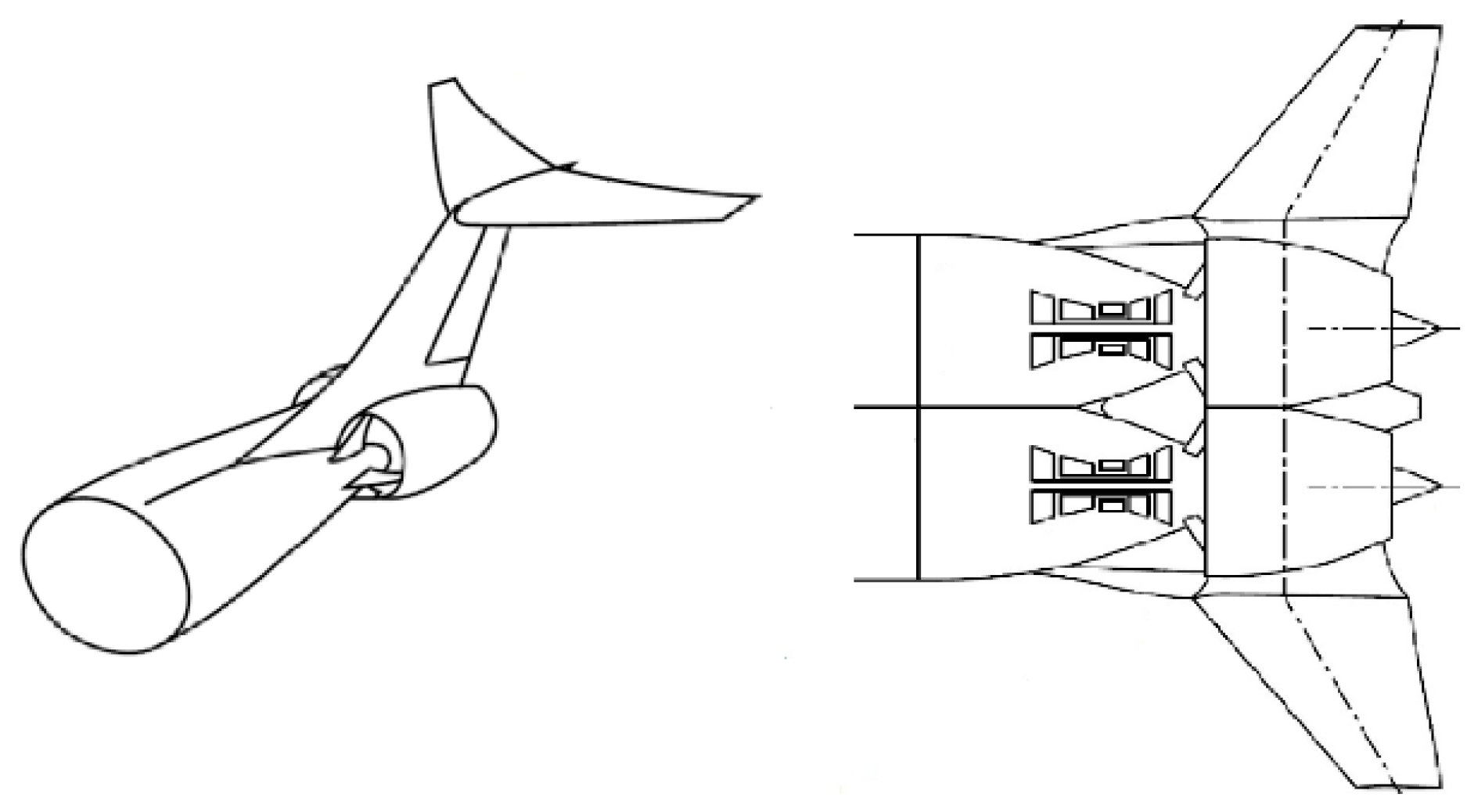

4.2. Rear-Mounted Engine(s) Concept

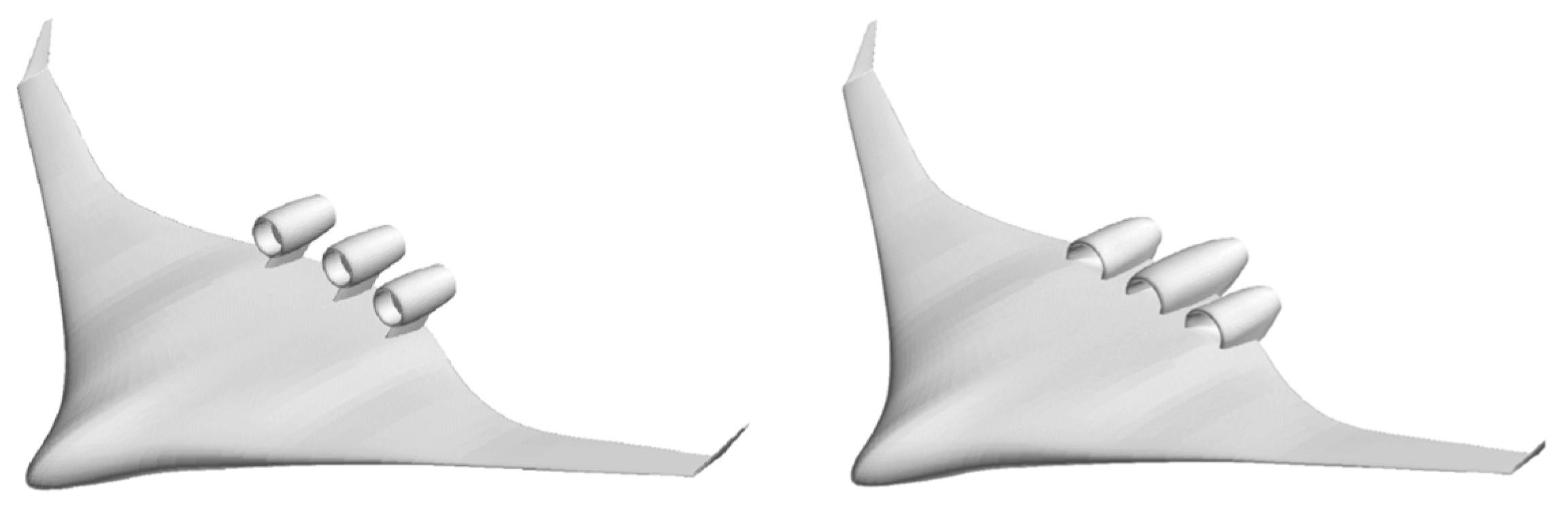

4.3. The Blended Wing Body Configuration

5. Other Non-Conventional Propulsion Integration Technologies

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Platzer, M.F. A perspective on the urgency for green aviation. Prog. Aerosp. Sci. 2023, 141, 100932. [Google Scholar] [CrossRef]

- Afonso, F.; Sohst, M.; Diogo, C.M.; Rodrigues, S.S.; Ferreira, A.; Ribeiro, I.; Marques, R.; Rego, F.F.; Sohouli, A.; Portugal-Pereira, J.; et al. Strategies towards a more sustainable aviation: A systematic review. Prog. Aerosp. Sci. 2023, 137, 100878. [Google Scholar] [CrossRef]

- Henderson, R.P.; Martins, J.R.R.A.; Perez, R.E. Aircraft conceptual design for optimal environmental performance. Aeronaut. J. 2012, 116, 1–22. [Google Scholar] [CrossRef]

- Schwartz, E.; Kroo, I. Aircraft Design for Reduced Climate Impact. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. [Google Scholar]

- Abrantes, I.; Ferreira, A.F.; Magalhães, L.B.; Costa, M.; Silva, A. The impact of revolutionary aircraft designs on global aviation emissions. Renew. Energy 2024, 223, 119937. [Google Scholar] [CrossRef]

- Tasca, A.L.; Cipolla, V.; Abu Salem, K.; Puccini, M. Innovative Box-Wing Aircraft: Emissions and Climate Change. Sustainability 2021, 13, 3282. [Google Scholar] [CrossRef]

- Proesmans, P.-J.; Vos, R. Airplane Design Optimization for Minimal Global Warming Impact. J. Aircr. 2022, 59, 1363–1381. [Google Scholar] [CrossRef]

- Ficca, A.; Marulo, F.; Sollo, A. An open thinking for a vision on sustainable green aviation. Prog. Aerosp. Sci. 2023, 141, 100928. [Google Scholar] [CrossRef]

- Abu Salem, K.; Palaia, G.; Quarta, A.A. Impact of Figures of Merit Selection on Hybrid–Electric Regional Aircraft Design and Performance Analysis. Energies 2023, 16, 7881. [Google Scholar] [CrossRef]

- Jensen, L.L.; Bonnefoy, P.A.; Hileman, J.I.; Fitzgerald, J.T. The carbon dioxide challenge facing U.S. aviation and paths to achieve net zero emissions by 2050. Prog. Aerosp. Sci. 2023, 141, 100921. [Google Scholar] [CrossRef]

- Adler, E.J.; Martins, J.R. Hydrogen-powered aircraft: Fundamental concepts, key technologies, and environmental impacts. Prog. Aerosp. Sci. 2023, 141, 100922. [Google Scholar] [CrossRef]

- Degirmenci, H.; Uludag, A.; Ekici, S.; Karakoc, T.H. Challenges, prospects and potential future orientation of hydrogen aviation and the airport hydrogen supply network: A state-of-art review. Prog. Aerosp. Sci. 2023, 141, 100923. [Google Scholar] [CrossRef]

- Khandelwal, B.; Karakurt, A.; Sekaran, P.R.; Sethi, V.; Singh, R. Hydrogen powered aircraft: The future of air transport. Prog. Aerosp. Sci. 2013, 60, 45–59. [Google Scholar] [CrossRef]

- Sethi, V.; Sun, X.; Nalianda, D.; Rolt, A.; Holborn, P.; Wijesinghe, C.; Xisto, C.; Jonsson, I.; Gronstedt, T.; Ingram, J.; et al. Enabling Cryogenic Hydrogen-Based CO2-Free Air Transport: Meeting the demands of zero carbon aviation. IEEE Electrification Mag. 2022, 10, 69–81. [Google Scholar] [CrossRef]

- Verstraete, D. Long range transport aircraft using hydrogen fuel. Int. J. Hydrogen Energy 2013, 38, 14824–14831. [Google Scholar] [CrossRef]

- Cipolla, V.; Zanetti, D.; Abu Salem, K.; Binante, V.; Palaia, G. A Parametric Approach for Conceptual Integration and Performance Studies of Liquid Hydrogen Short–Medium Range Aircraft. Appl. Sci. 2022, 12, 6857. [Google Scholar] [CrossRef]

- Prewitz, M.; Bardenhagen, A.; Beck, R. Hydrogen as the fuel of the future in aircrafts—Challenges and opportunities. Int. J. Hydrogen Energy 2020, 45, 25378–25385. [Google Scholar] [CrossRef]

- Rao, A.G.; Yin, F.; Werij, H.G. Energy Transition in Aviation: The Role of Cryogenic Fuels. Aerospace 2020, 7, 181. [Google Scholar] [CrossRef]

- Undavalli, V.; Olatunde, O.B.G.; Boylu, R.; Wei, C.; Haeker, J.; Hamilton, J.; Khandelwal, B. Recent advancements in sustainable aviation fuels. Prog. Aerosp. Sci. 2023, 136, 100976. [Google Scholar] [CrossRef]

- Ansell, P.J. Review of sustainable energy carriers for aviation: Benefits, challenges, and future viability. Prog. Aerosp. Sci. 2023, 141, 100919. [Google Scholar] [CrossRef]

- Abrantes, I.; Ferreira, A.F.; Silva, A.; Costa, M. Sustainable aviation fuels and imminent technologies—CO2 emissions evolution towards 2050. J. Clean. Prod. 2021, 313, 127937. [Google Scholar] [CrossRef]

- Zhang, L.; Butler, T.L.; Yang, B. Recent trends, opportunities and challenges of sustainable aviation fuel. In Green Energy to Sustainability: Strategies for Global Industries; Wiley: Hoboken, NJ, USA, 2020; pp. 85–110. [Google Scholar] [CrossRef]

- Abu Salem, K.; Palaia, G.; Quarta, A.A. Review of hybrid-electric aircraft technologies and designs: Critical analysis and novel solutions. Prog. Aerosp. Sci. 2023, 141, 100924. [Google Scholar] [CrossRef]

- Brelje, B.J.; Martins, J.R. Electric, hybrid, and turboelectric fixed-wing aircraft: A review of concepts, models, and design approaches. Prog. Aerosp. Sci. 2018, 104, 1–19. [Google Scholar] [CrossRef]

- Kuśmierek, A.; Galiński, C.; Stalewski, W. Review of the hybrid gas—Electric aircraft propulsion systems versus alternative systems. Prog. Aerosp. Sci. 2023, 141, 100925. [Google Scholar] [CrossRef]

- Sahoo, S.; Zhao, X.; Kyprianidis, K. A Review of Concepts, Benefits, and Challenges for Future Electrical Propulsion-Based Aircraft. Aerospace 2020, 7, 44. [Google Scholar] [CrossRef]

- Marciello, V.; Di Stasio, M.; Ruocco, M.; Trifari, V.; Nicolosi, F.; Meindl, M.; Lemoine, B.; Caliandro, P. Design Exploration for Sustainable Regional Hybrid-Electric Aircraft: A Study Based on Technology Forecasts. Aerospace 2023, 10, 165. [Google Scholar] [CrossRef]

- Pornet, C.; Isikveren, A. Conceptual design of hybrid-electric transport aircraft. Prog. Aerosp. Sci. 2015, 79, 114–135. [Google Scholar] [CrossRef]

- Palaia, G.; Abu Salem, K. Mission Performance Analysis of Hybrid-Electric Regional Aircraft. Aerospace 2023, 10, 246. [Google Scholar] [CrossRef]

- Xie, Y.; Savvarisal, A.; Tsourdos, A.; Zhang, D.; Gu, J. Review of hybrid electric powered aircraft, its conceptual design and energy management methodologies. Chin. J. Aeronaut. 2020, 34, 432–450. [Google Scholar] [CrossRef]

- Riboldi, C.E. An optimal approach to the preliminary design of small hybrid-electric aircraft. Aerosp. Sci. Technol. 2018, 81, 14–31. [Google Scholar] [CrossRef]

- Hoelzen, J.; Liu, Y.; Bensmann, B.; Winnefeld, C.; Elham, A.; Friedrichs, J.; Hanke-Rauschenbach, R. Conceptual Design of Operation Strategies for Hybrid Electric Aircraft. Energies 2018, 11, 217. [Google Scholar] [CrossRef]

- Liebeck, R.H. Design of the Blended Wing Body Subsonic Transport. J. Aircr. 2004, 41, 10–25. [Google Scholar] [CrossRef]

- Ammar, S.; Legros, C.; Trépanier, J.-Y. Conceptual design, performance and stability analysis of a 200 passengers Blended Wing Body aircraft. Aerosp. Sci. Technol. 2017, 71, 325–336. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, M.; Chen, Y.; Sang, W.; Tan, Z.; Li, D.; Zhang, B. Assessment on critical technologies for conceptual design of blended-wing-body civil aircraft. Chin. J. Aeronaut. 2019, 32, 1797–1827. [Google Scholar] [CrossRef]

- Okonkwo, P.; Smith, H. Review of evolving trends in blended wing body aircraft design. Prog. Aerosp. Sci. 2016, 82, 1–23. [Google Scholar] [CrossRef]

- Li, P.; Zhang, B.; Chen, Y.; Yuan, C.; Lin, Y. Aerodynamic Design Methodology for Blended Wing Body Transport. Chin. J. Aeronaut. 2012, 25, 508–516. [Google Scholar] [CrossRef][Green Version]

- Frediani, A.; Cipolla, V.; Rizzo, E. The PrandtlPlane Configuration: Overview on Possible Applications to Civil Aviation. In Variational Analysis and Aerospace Engineering: Mathematical Challenges for Aerospace Design; Springer: Berlin/Heidelberg, Germany, 2012; Volume 66. [Google Scholar] [CrossRef]

- Schiktanz, D.; Scholz, D. Box Wing Fundamentals—An Aircraft Design Perspective. In Proceedings of the DGLR: Deutscher Luft-und Raumfahrtkongress, Bremen, Germany, 27–29 September 2011. [Google Scholar]

- Cipolla, V.; Frediani, A.; Abu Salem, K.; Scardaoni, M.P.; Nuti, A.; Binante, V. Conceptual design of a box-wing aircraft for the air transport of the future. In Proceedings of the 2018 Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar]

- Andrews, S.A.; Perez, R.E. Comparison of box-wing and conventional aircraft mission performance using multidisciplinary analysis and optimization. Aerosp. Sci. Technol. 2018, 79, 336–351. [Google Scholar] [CrossRef]

- Abu Salem, K.; Palaia, G.; Carini, M.; Méheut, M.; Maganzi, M.; Falcone, C. A CFD-Based Collaborative Approach for Box-Wing Aircraft Aerodynamic Assessment: The PARSIFAL Study Case. Aerotec. Missili Spaz. 2023, 102, 385–407. [Google Scholar] [CrossRef]

- Sieber, G. European Technology Programs for Eco-Efficient Ducted Turbofans. In Proceedings of the 22nd International Symposium on Air Breathing Engines (ISABE), Phoenix, AZ, USA, 25–30 October 2015; Available online: https://hdl.handle.net/2374.UC/745652 (accessed on 17 January 2024).

- Epstein, A.H. Aeropropulsion for Commercial Aviation in the Twenty-First Century and Research Directions Needed. AIAA J. 2014, 52, 901–911. [Google Scholar] [CrossRef]

- Hughes, C.; Van Zante, D.; Heidmann, J. Aircraft Engine Technology for Green Aviation to Reduce Fuel Burn. In Proceedings of the 3rd AIAA Atmospheric Space Environments Conference, Honolulu, HI, USA, 27–30 June 2011. [Google Scholar]

- Razak, A.M. Gas turbine performance modelling, analysis and optimization. In Modern Gas Turbine Systems; Woodhead Publishing: Cambridge, UK, 2013; pp. 423–514. [Google Scholar] [CrossRef]

- Hill, P.G.; Peterson, C.R. Mechanics and Thermodynamics of Propulsion; Addison-Wesley Publishing Co.: Reading, MA, USA, 1992; ISBN 9788131729519. [Google Scholar]

- Kors, E.; Collin, D. Perspective on 25 Years of European Aircraft Noise Reduction Technology Efforts and Shift Towards Global Research Aimed at Quieter Air Transport. In Aviation Noise Impact Management; Springer: Berlin/Heidelberg, Germany, 2022; pp. 57–116. [Google Scholar] [CrossRef]

- Huff, D.L. Noise reduction technologies for turbofan engines. In Proceedings of the 35th International Congress and Exposition on Noise Control Engineering (INTER-NOISE), Honolulu, HI, USA, 3–6 December 2006; Available online: https://ntrs.nasa.gov/citations/20080001448 (accessed on 17 January 2024).

- Blech, C.; Appel, C.K.; Ewert, R.; Delfs, J.W.; Langer, S.C. Numerical prediction of passenger cabin noise due to jet noise by an ultra–high–bypass ratio engine. J. Sound Vib. 2019, 464, 114960. [Google Scholar] [CrossRef]

- Magrini, A.; Benini, E.; Yao, H.-D.; Postma, J.; Sheaf, C. A review of installation effects of ultra-high bypass ratio engines. Prog. Aerosp. Sci. 2020, 119, 100680. [Google Scholar] [CrossRef]

- Singh, R.; Ameyugo, G.; Noppel, F. Jet engine design drivers: Past, present and future. In Innovation in Aeronautics; Woodhead Publishing: Cambridge, UK, 2012; pp. 56–82. [Google Scholar] [CrossRef]

- Kozaczuk, K. Engine nacelles design—Problems and challenges. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2017, 231, 2259–2265. [Google Scholar] [CrossRef]

- Peters, A.; Spakovszky, Z.S.; Lord, W.K.; Rose, B. Ultrashort Nacelles for Low Fan Pressure Ratio Propulsors. J. Turbomach. 2014, 137, 021001. [Google Scholar] [CrossRef]

- Robinson, M.; MacManus, D.G.; Christie, R.; Sheaf, C.; Grech, N. Nacelle design for ultra-high bypass ratio engines with CFD based optimisation. Aerosp. Sci. Technol. 2020, 113, 106191. [Google Scholar] [CrossRef]

- Benjamin, L.; Heykena, C.; Friedrichs, J.; Marquez, C. Design and Optimization of a Nacelle for a UHBR Turbofan engine using a Class Shape Transformation based parameterization. In Proceedings of the Global Power and Propulsion Society, Chania, Greece, 7–9 September 2020. [Google Scholar] [CrossRef]

- Magrini, A.; Benini, E. Aeropropulsive assessment of engine installation at cruise for UHBPR turbofan with body force fan modelling. Aerosp. Sci. Technol. 2023, 132, 108048. [Google Scholar] [CrossRef]

- Alexiou, A.; Aretakis, N.; Kolias, I.; Mathioudakis, K. Novel Aero-Engine Multi-Disciplinary Preliminary Design Optimization Framework Accounting for Dynamic System Operation and Aircraft Mission Performance. Aerospace 2021, 8, 49. [Google Scholar] [CrossRef]

- Borradaile, J. Towards the optimum ducted UHBR engine. In Proceedings of the 24th AIAA/SAE/ASME/ASEE Joint Propulsion Conference, Boston, MA, USA, 11–13 July 1988. [Google Scholar]

- Zimbrick, R.A.; Colehour, J.L. Investigation of very high bypass ratio engines for subsonic transports. J. Propuls. Power 1990, 6, 490–496. [Google Scholar] [CrossRef]

- Kurzke, J. Fundamental Differences Between Conventional and Geared Turbofans. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009; pp. 145–153. [Google Scholar]

- Dewanji, D.; Rao, G.A.; van Buijtenen, J. Feasibility study of some novel concepts for high bypass ratio turbofan engines. In Proceedings of the ASME Turbo Expo: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009. [Google Scholar] [CrossRef]

- Mazzawy, R.S.; Virkler, J. Variable Pitch Fan-the Solution to Achieving High Propulsive Efficiency Turbofan Engines; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Michel, U. The benefits of variable area fan nozzles on turbofan engines. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. [Google Scholar] [CrossRef]

- Yang, X.; Tang, H.; Chen, M. Performance modeling and optimization assessment of variable pitch fan for ultrafan engine. In Proceedings of the AIAA Propulsion and Energy Forum, Joint Propulsion Conference, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar] [CrossRef]

- Krishnan, G.; Perullo, C.; Mavris, D.N. An assessment of relative technology benefits of a variable pitch fan and variable area nozzle. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, San Jose, CA, USA, 14–17 July 2013. [Google Scholar] [CrossRef]

- Bijewitz, J.; Seitz, A.; Hornung, M. Architectural Comparison of Advanced Ultra-High Bypass Ratio Turbofans for Medium to Long Range Application. Deutscher Luft-und Raumfahrtkongress, 2014. Available online: http://www.dglr.de/publikationen/2015/340105.pdf (accessed on 17 January 2024).

- Seitz, A. Advanced Methods for Propulsion System Integration in Aircraft Conceptual Design. Ph.D. Thesis, Technische Universität München, München, Germany, 2012. Available online: https://mediatum.ub.tum.de/?id=1079430 (accessed on 17 January 2024).

- Kestner, B.K.; Schutte, J.S.; Gladin, J.C.; Mavris, D.N. Ultra High Bypass Ratio Engine Sizing and Cycle Selection Study for a Subsonic Commercial Aircraft in the N+2 Timeframe. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011; pp. 127–137. [Google Scholar]

- Rudnik, R.; Rossow, C.-C.; Geyr, H.F.V. Numerical simulation of engine/airframe integration for high-bypass engines. Aerosp. Sci. Technol. 2002, 6, 31–42. [Google Scholar] [CrossRef]

- Goulos, I.; Otter, J.; Tejero, F.; Rebassa, J.H.; MacManus, D.; Sheaf, C. Civil turbofan propulsion aerodynamics: Thrust-drag accounting and impact of engine installation position. Aerosp. Sci. Technol. 2021, 111, 106533. [Google Scholar] [CrossRef]

- Lange, F. Aerodynamic Optimization of an UHBR Engine Position on a Representative Short Range Aircraft Configuration at Cruise Flight Conditions. In Proceedings of the 2018 Applied Aerodynamics Conference, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar]

- Magrini, A.; Buosi, D.; Benini, E. Analysis of installation aerodynamics and comparison of optimised configuration of an ultra-high bypass ratio turbofan nacelle. Aerosp. Sci. Technol. 2022, 128, 107756. [Google Scholar] [CrossRef]

- Magrini, A.; Buosi, D.; Benini, E. Maximisation of installed net resulting force through multi-level optimisation of an ultra-high bypass ratio engine nacelle. Aerosp. Sci. Technol. 2021, 119, 107169. [Google Scholar] [CrossRef]

- Vassberg, J.; Dehaan, M.; Rivers, M.; Wahls, R. Development of a Common Research Model for Applied CFD Validation Studies. In Proceedings of the 26th AIAA Applied Aerodynamics Conference, Honolulu, HI, USA, 18–21 August 2008. [Google Scholar]

- Magrini, A.; Buosi, D.; Poltronieri, F.; De Leo, E.; Benini, E. CFD-Based Analysis of Installed Fuel Consumption and Aerodynamics of Transonic Transport Aircraft during Cruise Flight. Energies 2023, 16, 3323. [Google Scholar] [CrossRef]

- Stankowski, T.P.; MacManus, D.G.; Robinson, M.; Sheaf, C.T. Aerodynamic Effects of Propulsion Integration for High Bypass Ratio Engines. J. Aircr. 2017, 54, 2270–2284. [Google Scholar] [CrossRef]

- Ritter, S. Impact of Different UHBR-Engine Positions on the Aerodynamics of a High-Lift Wing. In Advances in Simulation of Wing and Nacelle Stall, Notes on Numerical Fluid Mechanics and Multidisciplinary Design; Springer: Cham, Switzerland, 2016; Volume 131. [Google Scholar] [CrossRef]

- Daggett, D.; Brown, S.; Kawai, R. Ultra-efficient Engine Diameter Study. NASA Contract Report, NAS3–01140, 2003. Available online: https://ntrs.nasa.gov/search.jsp?R=20030061085 (accessed on 17 January 2024).

- Aloyo, K.C.; Perullo, C.; Mavris, D.N. An Assessment of Ultra High Bypass Engine Architecture and Installation Considerations. In Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014. [Google Scholar]

- Wegener, P. Integration of fuselage-mounted over-wing engines on a midrange aircraft. In Proceedings of the 32th Congress of International Council of the Aeronautical Sciences ICAS, Shanghai, China, 6–10 September 2021; Available online: https://www.icas.org/ICAS_ARCHIVE/ICAS2020/data/papers/ICAS2020_1194_paper.pdf (accessed on 17 January 2024).

- Arkell, D. Moving toward the Middle. Boeing Frontiers Magazine, 2003. Available online: https://www.boeing.com/news/frontiers/archive/2003/march/cover.html (accessed on 17 January 2024).

- Wegener, P.; Lange, F. Integration of wing-mounted over-wing engines on a mid-range aircraft. In Proceedings of the AIAA SciTech Forum, San Diego, CA, USA, 3–7 January 2022. [Google Scholar] [CrossRef]

- Savoni, L.; Rudnik, R. Pylon design for a short range transport aircraft with over-the-wing mounted UHBR engines. In Proceedings of the AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar] [CrossRef]

- Silva, V.T.; Lundbladh, A.; Xisto, C.; Grönstedt, T. Over-wing integration of ultra-high bypass ratio engines: A coupled wing redesign and engine position study. Aerosp. Sci. Technol. 2023, 138, 108350. [Google Scholar] [CrossRef]

- Ahuja, J.; Renganathan, S.A.; Mavris, D.N. Sensitivity Analysis of the Overwing Nacelle Design Space. J. Aircr. 2022, 59, 1478–1492. [Google Scholar] [CrossRef]

- Ahuja, J.; Lee, C.H.; Perron, C.; Mavris, D.N. Comparison of Overwing and Underwing Nacelle Aeropropulsion Optimization for Subsonic Transport Aircraft. J. Aircr. 2023, 1–16. [Google Scholar] [CrossRef]

- Hussin, R.; Ismail, N.; Mustapa, S. A study of foreign object damage (FOD) and prevention method at the airport and aircraft maintenance area. IOP Conf. Series Mater. Sci. Eng. 2016, 152, 012038. [Google Scholar] [CrossRef]

- Giesecke, D.; Lehmler, M.; Friedrichs, J.; Blinstrub, J.; Bertsch, L.; Heinze, W. Evaluation of ultra-high bypass ratio engines for an over-wing aircraft configuration. J. Glob. Power Propuls. Soc. 2018, 2, 493–515. [Google Scholar] [CrossRef]

- Hooker, J.R.; Wick, A.; Zeune, C.H.; Agelastos, A. Over Wing Nacelle Installations for Improved Energy Efficiency. In Proceedings of the 31st AIAA Applied Aerodynamics Conference, San Diego, CA, USA, 24–27 June 2013. [Google Scholar]

- Bravo-Mosquera, P.D.; Catalano, F.M.; Zingg, D.W. Unconventional aircraft for civil aviation: A review of concepts and design methodologies. Prog. Aerosp. Sci. 2022, 131, 100813. [Google Scholar] [CrossRef]

- Cavallaro, R.; Demasi, L. Challenges, Ideas, and Innovations of Joined-Wing Configurations: A Concept from the Past, an Opportunity for the Future. Prog. Aerosp. Sci. 2016, 87, 1–93. [Google Scholar] [CrossRef]

- Knobloch, K.; Manoha, E.; Atinault, O.; Barrier, R.; Polacsek, C.; Lorteau, M.; Casalino, D.; Ragni, D.; Romani, G.; Centracchio, F.; et al. Future aircraft and the future of aircraft noise. In Aviation Noise Impact Management; Springer: Berlin/Heidelberg, Germany, 2022; pp. 117–139. [Google Scholar] [CrossRef]

- ARTEM Project Constortium, “Project overview and Final Achievements of Month 54”, 2022. Available online: https://www.dlr.de/at/en/desktopdefault.aspx/tabid-12783/22337_read-51396/ (accessed on 17 January 2024).

- Legriffon, I.; Bertsch, L.; Centracchio, F.; Weintraub, D. Flyover noise evaluation of low-noise technologies applied to a blended wing body aircraft. Inter-Noise Noise-Con Congr. Conf. Proc. 2023, 265, 1305–1316. [Google Scholar] [CrossRef]

- Pieren, R.; Le Griffon, I.; Bertsch, L.; Heusser, A.; Centracchio, F.; Weintraub, D.; Lavandier, C.; Schäffer, B. Perception-based noise assessment of a future blended wing body aircraft concept using synthesized flyovers in an acoustic VR environment—The ARTEM study. Aerosp. Sci. Technol. 2024, 144, 108767. [Google Scholar] [CrossRef]

- Flamm, J.D.; James, K.; Bonet, J.T. Overview of ERA Integrated Technology Demonstration (ITD) 51A Ultra-High Bypass (UHB) Integration for Hybrid Wing Body (HWB) (Invited). In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar]

- Abu Salem, K.; Cipolla, V.; Palaia, G.; Binante, V.; Zanetti, D. A Physics-Based Multidisciplinary Approach for the Preliminary Design and Performance Analysis of a Medium Range Aircraft with Box-Wing Architecture. Aerospace 2021, 8, 292. [Google Scholar] [CrossRef]

- Voskuijl, M.; de Klerk, J.; van Ginneken, D. Flight Mechanics Modeling of the PrandtlPlane for Conceptual and Preliminary Design. In Variational Analysis and Aerospace Engineering: Mathematical Challenges for Aerospace Design; Springer Optimization and Its Applications; Springer: Berlin/Heidelberg, Germany, 2012; Volume 66. [Google Scholar] [CrossRef]

- Rudnik, R. Stall Behaviour of the EUROLIFT High Lift Configurations. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008. [Google Scholar]

- Geyr, H.F.; Schade, N. Prediction of Maximum Lift Effects on Realistic High-Lift-Commercial-Aircraft-Configurations within the European project EUROLIFT II. In Proceedings of the Second symposium Simulation of Wing Nacelle Stall, Braunschweig, Germany, 22–23 June 2010. [Google Scholar]

- Hue, D.; François, C.; Dandois, J.; Gebhardt, A. Simulations of an aircraft with constant and pulsed blowing flow control at the engine/wing junction. Aerosp. Sci. Technol. 2017, 69, 659–673. [Google Scholar] [CrossRef]

- Elmendorp, R. Feasibility study on the use of very large bypass ratio turbofan engines for the PrandtlPlane. PARSIFAL project, Deliverable 7.2, 2020. Available online: https://cordis.europa.eu/project/id/723149/results/en (accessed on 17 January 2024).

- Proesmans, P.J. Preliminary Propulsion System Design and Integration for a Box-Wing Aircraft Configuration: A Knowledge Based Engineering Approach. Master Thesis, TU Delft, Delftm, The Netherlands, 2019. Available online: http://resolver.tudelft.nl/uuid:0d2ebc46-09ee-493f-bb4c-c871133bff6f (accessed on 17 January 2024).

- Cipolla, V.; Abu Salem, K.; Scardaoni, M.P.; Binante, V.; Frediani, A.; Nuti, A.; Lammering, T.; Anton, E.; Risse, K.; Franz, K.; et al. Preliminary design and performance analysis of a box-wing transport aircraft. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Montgomery, R.C.; Moul, M.T. Analysis of deep-stall characteristics of T- tailed aircraft configurations and some recovery procedures. J. Aircr. 1966, 3, 562–566. [Google Scholar] [CrossRef]

- Abu Salem, K.; Palaia, G.; Quarta, A.A.; Chiarelli, M.R. Preliminary Analysis of the Stability and Controllability of a Box-Wing Aircraft Configuration. Aerospace 2023, 10, 874. [Google Scholar] [CrossRef]

- Cipolla, V.; Abu Salem, K.; Palaia, G.; Binante, V.; Zanetti, D. A DoE-based approach for the implementation of structural surrogate models in the early stage design of box-wing aircraft. Aerosp. Sci. Technol. 2021, 117, 106968. [Google Scholar] [CrossRef]

- Wiart, L.; Atinault, O.; Grenon, R.; Paluch, B.; Hue, D. Development of NOVA aircraft configurations for large engine integration studies. In Proceedings of the 33rd AIAA Applied Aerodynamics Conference, Dallas, TX, USA, 22–26 June 2015. [Google Scholar] [CrossRef]

- Drela, M. Development of the D8 transport configuration. In Proceedings of the 29th AIAA Applied Aerodynamics Conference, Honolulu, HI, USA, 27–30 June 2011. [Google Scholar] [CrossRef]

- Van Zante, D.E. Progress in open rotor research: A US perspective. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Van Zante, D.E.; Collier, F.; Orton, A.; Khalid, S.A.; Wojno, J.P.; Wood, T.H. Progress in open rotor propulsors: The FAA/GE/NASA open rotor test campaign. Aeronaut. J. 2014, 118, 1181–1213. [Google Scholar] [CrossRef]

- Tantot, N.; Lambey, M.; Lebrun, A.; Binder, A. Open-rotor engines architectures & full scale demonstrator by safran. In Proceedings of the Aerospace Technology Congress, Stockolm, Sweden, 8–9 October 2019. [Google Scholar]

- Bellocq, P.; Garmendia, I.; Sethi, V.; Patin, A.; Capodanno, S.; Lucas, F.R. Multidisciplinary Assessment of the Control of the Propellers of a Pusher Geared Open Rotor—Part I: Zero-Dimensional Performance Model for Counter-Rotating Propellers. J. Eng. Gas Turbines Power 2016, 138, 072602. [Google Scholar] [CrossRef]

- Bellocq, P.; Garmendia, I.; Sethi, V.; Patin, A.; Capodanno, S.; Lucas, F.R. Multidisciplinary Assessment of the Control of the Propellers of a Pusher Geared Open Rotor—Part II: Impact on Fuel Consumption, Engine Weight, Certification Noise, and NOx Emissions. J. Eng. Gas Turbines Power 2016, 138, 072603. [Google Scholar] [CrossRef]

- Larsson, L.; Gro¨nstedt, T.; Kyprianidis, K.G. Conceptual Design and Mission Analysis for a Geared Turbofan and an Open Rotor Configuration. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011; pp. 359–370. [Google Scholar]

- Hendricks, E.; Tong, M. Performance and Weight Estimates for an Advanced Open Rotor Engine; NASA/TM—2012-217710; NASA: Hanover, MD, USA, 2012.

- Guynn, M.D.; Berton, J.J.; Fisher, K.L.; Haller, W.J.; Tong, M.T.; Thurman, D.R. Refined Exploration of Turbofan Design Options for an Advanced Single-Aisle Transport; NASA/TM–2011-216883; NASA: Hanover, MD, USA, 2011.

- Yang, X.; Cheng, S.; Lang, J.; Xu, R.; Lv, Z. Characterization of aircraft emissions and air quality impacts of an international airport. J. Environ. Sci. 2018, 72, 198–207. [Google Scholar] [CrossRef]

- Guérin, S.; Schnell, R.; Becker, R.G. Performance prediction and progress towards multi-disciplinary design of contra-rotating open rotors. Aeronaut. J. 2014, 118, 1159–1179. [Google Scholar] [CrossRef]

- Mastropierro, F.S.; Sebastiampillai, J.; Jacob, F.; Rolt, A. Modeling Geared Turbofan and Open Rotor Engine Performance for Year-2050 Long-Range and Short-Range Aircraft. J. Eng. Gas Turbines Power 2020, 142, 041016. [Google Scholar] [CrossRef]

- Larsson, L.; Lundbladh, A.; Grönstedt, T. A Conceptual Design Study of an Open Rotor Powered Regional Aircraft. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar] [CrossRef]

- Dorsey, A.; Uranga, A. Design Space Exploration of Future Open Rotor Configurations. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual, 24–28 August 2020. [Google Scholar] [CrossRef]

- Farassat, F.; Dunn, M.; Tinetti, A.; Nark, D. Open rotor noise prediction methods at NASA langley: A technology review. In Proceedings of the 15th AIAA/CEAS Aeroacoustics Conference, Miami, FL, USA, 11–13 May 2009. [Google Scholar] [CrossRef]

- Busch, E.R.; Keßler, M.; Krämer, E. Numerical Investigation of Counter-Rotating Open Rotor Noise Emission in Different Flight Conditions. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar] [CrossRef]

- Dürrwächter, L.; Keßler, M.; Krämer, E. Numerical Assessment of Open-Rotor Noise Shielding with a Coupled Approach. AIAA J. 2019, 57, 1930–1940. [Google Scholar] [CrossRef]

- Ricouard, J.; Julliard, E.; Omais, M.; Regnier, V.; Parry, A.; Baralon, S. Installation effects on contra-rotating open rotor noise. In Proceedings of the 16th AIAA/CEAS Aeroacoustics Conference, Stockholm, Sweden, 7–9 June 2010. [Google Scholar] [CrossRef]

- Stuermer, A.W. Validation of Installation Effect Predictions through Simulations of Contra-Rotating Open Rotors at Low-Speed Flight Conditions. In Proceedings of the 33rd AIAA Applied Aerodynamics Conference, Dallas, TX, USA, 22–26 June 2015. [Google Scholar] [CrossRef]

- Peters, A.; Spakovszky, Z.N. Rotor interaction noise in counter-rotating propfan propulsion systems. In Proceedings of the ASME Turbo Expo: Power for Land, Sea, and Air, Glasgow, UK, 14–18 June 2010. [Google Scholar] [CrossRef]

- Parry, A.B.; Vianello, S. A Project Study of Open Rotor Noise. Int. J. Aeroacoustics 2012, 11, 247–258. [Google Scholar] [CrossRef]

- Smith, D.A.; Filippone, A.; Bojdo, N. A parametric study of counter rotating open rotor noise. In Proceedings of the 25th AIAA/CEAS Aeroacoustics Conference, Delft, The Netherlands, 20–23 May 2019. [Google Scholar] [CrossRef]

- Weckmüller, C.; Guérin, S. On the influence of trailing-edge serrations on open-rotor tonal noise. In Proceedings of the 18th AIAA/CEAS Aeroacoustics Conference, Colorado Springs, CO, USA, 4–6 June 2012. [Google Scholar] [CrossRef]

- Smith, D.; Filippone, A.; Bojdo, N. Noise reduction of a Counter Rotating Open Rotor through a locked blade row. Aerosp. Sci. Technol. 2019, 98, 105637. [Google Scholar] [CrossRef]

- Smith, D.A.; Filippone, A.; Barakos, G.N. Acoustic Analysis of Counter-Rotating Open Rotors with a Locked Blade Row. AIAA J. 2020, 58, 4401–4414. [Google Scholar] [CrossRef]

- Gohardani, A.S.; Doulgeris, G.; Singh, R. Challenges of future aircraft propulsion: A review of distributed propulsion technology and its potential application for the all electric commercial aircraft. Prog. Aerosp. Sci. 2011, 47, 369–391. [Google Scholar] [CrossRef]

- Pelz, P.F.; Leise, P.; Meck, M. Sustainable aircraft design—A review on optimization methods for electric propulsion with derived optimal number of propulsors. Prog. Aerosp. Sci. 2021, 123, 100714. [Google Scholar] [CrossRef]

- Fard, M.T.; He, J.; Huang, H.; Cao, Y. Aircraft Distributed Electric Propulsion Technologies—A Review. IEEE Trans. Transp. Electrification 2022, 8, 4067–4090. [Google Scholar] [CrossRef]

- Burston, M.; Ranasinghe, K.; Gardi, A.; Parezanović, V.; Ajaj, R.; Sabatini, R. Design principles and digital control of advanced distributed propulsion systems. Energy 2021, 241, 122788. [Google Scholar] [CrossRef]

- Kim, H.D. Distributed propulsion vehicles. In Proceedings of the 27th International Congress of the Aeronautical Sciences, Nice, France, 19–24 September 2010; Available online: https://www.icas.org/ICAS_ARCHIVE/ICAS2010/PAPERS/225.PDF (accessed on 17 January 2024).

- Eisenhut, D.; Moebs, N.; Windels, E.; Bergmann, D.; Geiß, I.; Reis, R.; Strohmayer, A. Aircraft Requirements for Sustainable Regional Aviation. Aerospace 2021, 8, 61. [Google Scholar] [CrossRef]

- Nguyen, E.; Troillard, P.; Jézégou, J.; Alazard, D.; Pastor, P. Reduction of vertical tail using differential thrust: Influence on flight control and certification. In Proceedings of the Global Air Transport System Conference 2018, Toulouse, France, 23–25 October 2018. [Google Scholar]

- Van Eric, N.; Daniel, A.; Döll, C.; Pastor, P. Co-design of aircraft vertical tail and control laws with distributed electric propulsion and flight envelop constraints. CEAS Aeronaut. J. 2021, 12, 101–113. [Google Scholar] [CrossRef]

- Klunk, G.T.; Freeman, J.L. Vertical Tail Area Reduction for Aircraft with Spanwise Distributed Electric Propulsion. In Proceedings of the 2018 AIAA/IEEE Electric Aircraft Technologies Symposium, Cincinnati, OH, USA, 9–11 July 2018; p. 5022. [Google Scholar] [CrossRef]

- Łukasik, B. Turboelectric Distributed Propulsion System As a Future Replacement for Turbofan Engines. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Izaguirre, A.O.T.; González, L.M.G.-C.; Igeño, P.Q.; Martínez, P.V. Series-hybridisation, distributed electric propulsion and boundary layer ingestion in long-endurance, small remotely piloted aircraft: Fuel consumption improvements. Aerosp. Sci. Technol. 2021, 120, 107227. [Google Scholar] [CrossRef]

- Schäfer, A.W.; Barrett, S.R.H.; Doyme, K.; Dray, L.M.; Gnadt, A.R.; Self, R.; O’sullivan, A.; Synodinos, A.P.; Torija, A.J. Technological, economic and environmental prospects of all-electric aircraft. Nat. Energy 2018, 4, 160–166. [Google Scholar] [CrossRef]

- Hill, G.A.; Thomas, R.H. Challenges and Opportunities for Noise Reduction Through Advanced Aircraft Propulsion Airframe Integration and Configuration. In Proceedings of the 8th CEAS Workshop on Aeroacoustics of New Aircraft and Engine Configurations, Budapest, Hungary, 11–12 November 2004. [Google Scholar]

- Synodinos, A.; Self, R.; Torija, A. Preliminary Noise Assessment of Aircraft with Distributed Electric Propulsion. In Proceedings of the 2018 AIAA/CEAS Aeroacoustics Conference, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar]

- Synodinos, A.P.; Self, R.H.; Torija, A.J. Framework for Predicting Noise–Power–Distance Curves for Novel Aircraft Designs. J. Aircr. 2018, 55, 781–791. [Google Scholar] [CrossRef]

- Ameyugo, G.; Taylor, M.; Singh, R. Distributed propulsion feasibility studies. In Proceedings of the 25th International Congress of the Aeronautical Sciences, Hamburg, Germany, 3–8 September 2006. [Google Scholar]

- Patterson, M.D.; Borer, N.K. Approach Considerations in Aircraft with High-Lift Propeller Systems. In Proceedings of the 17th AIAA Aviation Technology, Integration, and Operations Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar]

- Lundbladh, A.; Grönstedt, T. Distributed propulsion and turbofan scale effects. In Proceedings of the XVII International Symposium on Air Breathing Engines, Munich, Germany, 4–9 September 2005. [Google Scholar]

- Svoboda, C. Turbofan engine database as a preliminary design tool. Aircr. Des. 2000, 3, 17–31. [Google Scholar] [CrossRef]

- Leifsson, L.; Ko, A.; Mason, W.; Schetz, J.; Grossman, B.; Haftka, R. Multidisciplinary design optimization of blended-wing-body transport aircraft with distributed propulsion. Aerosp. Sci. Technol. 2013, 25, 16–28. [Google Scholar] [CrossRef]

- Doctor, F.; Budd, T.; Williams, P.D.; Prescott, M.; Iqbal, R. Modelling the effect of electric aircraft on airport operations and infrastructure. Technol. Forecast. Soc. Chang. 2022, 177, 121553. [Google Scholar] [CrossRef]

- Salucci, F.; Trainelli, L.; Faranda, R.; Longo, M. An optimization Model for Airport Infrastructures in Support to Electric Aircraft. In Proceedings of the 2019 IEEE Milan PowerTech, Milan, Italy, 23–27 June 2019; pp. 1–5. [Google Scholar]

- Guo, Z.; Zhang, X.; Balta-Ozkan, N.; Luk, P. Aviation to Grid: Airport Charging Infrastructure for Electric Aircraft. In Proceedings of the International Conference on Applied Energy, Bangkok, Thailand, 1–10 December 2020. [Google Scholar]

- Grunditz, E.A.; Thiringer, T.; Saadat, N. Acceleration, Drive Cycle Efficiency, and Cost Tradeoffs for Scaled Electric Vehicle Drive System. IEEE Trans. Ind. Appl. 2020, 56, 3020–3033. [Google Scholar] [CrossRef]

- Kim, H.D.; Perry, A.T.; Ansell, P.J. Progress in Distributed Electric Propulsion Vehicles and Technologies Distributed Pro-pulsion Technology, 2020. Available online: https://ntrs.nasa.gov/api/citations/20200011461/downloads/20200011461.pdf (accessed on 21 December 2023).

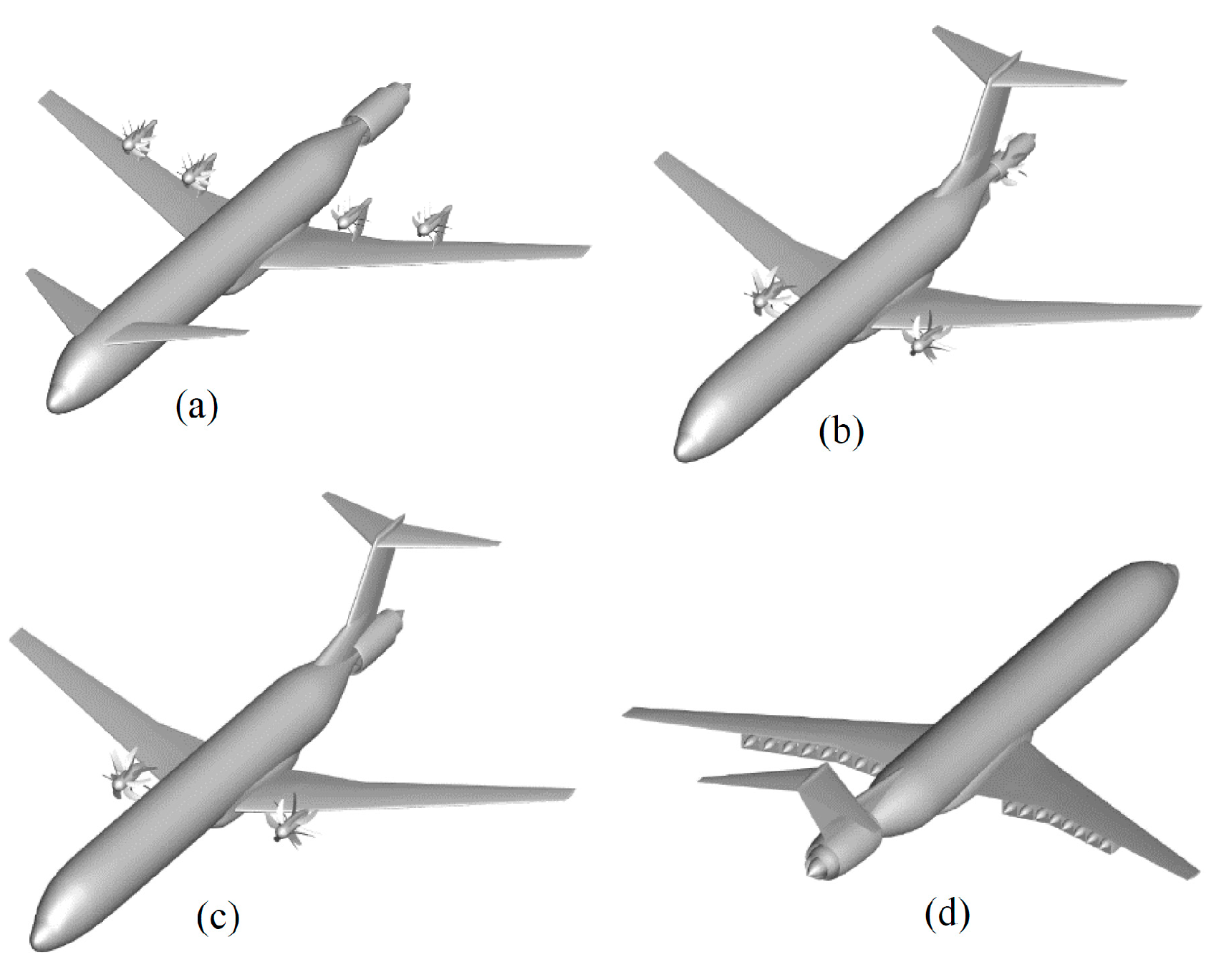

- de Rosa, D.; Tirado, E.M.; Mingione, G. Parametric Investigation of a Distributed Propulsion System on a Regional Aircraft. Aerospace 2022, 9, 176. [Google Scholar] [CrossRef]

- Beckers, M.F.; Schollenberger, M.; Lutz, T.; Bongen, D.; Radespiel, R.; Florenciano, J.L.; Funes-Sebastian, D.E. Numerical Investigation of High-Lift Propeller Positions for a Distributed Propulsion System. J. Aircr. 2023, 60, 995–1006. [Google Scholar] [CrossRef]

- Marcus, E.A.; de Vries, R.; Kulkarni, A.R.; Veldhuis, L.L. Aerodynamic Investigation of an Over-the-Wing Propeller for Distributed Propulsion. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; p. 2053. [Google Scholar] [CrossRef]

- Cusati, V.; Corcione, S.; Nicolosi, F.; Zhang, Q. Improvement of Take-Off Performance for an Electric Commuter Aircraft Due to Distributed Electric Propulsion. Aerospace 2023, 10, 276. [Google Scholar] [CrossRef]

- Moens, F.; Gardarein, P. Numerical simulation of the propeller/wing interactions for transport aircraft. In Proceedings of the 19th AIAA Applied Aerodynamics Conference, Anaheim, CA, USA, 11–14 June 2001. [Google Scholar]

- Keller, D. Aerodynamic Investigation of the High-Lift Performance of a Propeller-Driven Regional Transport Aircraft with Distributed Propulsion. In Proceedings of the 12th EASN International Conference on Innovation in Aviation & Space for opening New Horizons, Barcellona, Spain, 18-21 October 2022. [Google Scholar] [CrossRef]

- Moore, M.; Clark, S. Scalable Convergent Electric Propulsion Technology and Operations Research-SCEPTOR Project. Available online: https://ntrs.nasa.gov/api/citations/20160013855/downloads/20160013855.pdf (accessed on 12 December 2023).

- Moore, M.D.; Goodrich, K.H. High Speed Mobility through On-Demand Aviation. In Proceedings of the 2013 Aviation Technology, Integration, and Operations Conference, Los Angeles, CA, USA, 12–14 August 2013. [Google Scholar]

- Deere, K.A.; Viken, S.A.; Carter, M.B.; Viken, J.K. Computational Analysis of Powered Lift Augmentation for the LEAPTech Distributed Electric Propulsion Wing. In Proceedings of the 35th AIAA Applied Aerodynamics Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar] [CrossRef]

- Deere, K.A.; Viken, J.K.; Viken, S.; Carter, M.B.; Wiese, M.; Farr, N. Computational Analysis of a Wing Designed for the X-57 Distributed Electric Propulsion Aircraft. In Proceedings of the 35th AIAA Applied Aerodynamics Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar] [CrossRef]

- Moore, K.R.; Ning, A. Distributed Electric Propulsion Effects on Existing Aircraft Through Multidisciplinary Optimization. In Proceedings of the 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar] [CrossRef]

- Moore, K.G.; Ning, A. Takeoff and Performance Tradeoffs of Retrofit Distributed Electric Propulsion for Urban Transport. J. Aircr. 2019, 56, 3248. [Google Scholar] [CrossRef]

- Brooks, T.F.; Pope, D.S.; Marcolini, M.A. Airfoil Self-Noise and Prediction; Technical Reports 1218; NASA: Hanover, MD, USA, 1989.

- Biser, S.; Atanasov, G.; Hepperle, M.; Filipenko, M.; Keller, D.; Vechtel, D.; Boll, M.; Kastner, N.; Noe, M. Design Space Exploration Study and Optimization of a Distributed Turbo-Electric Propulsion System for a Regional Passenger Aircraft. In Proceedings of the AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), New Orleans, LA, USA, 24–28 August 2020. [Google Scholar]

- Keller, D. Towards higher aerodynamic efficiency of propeller-driven aircraft with distributed propulsion. CEAS Aeronaut. J. 2021, 12, 777–791. [Google Scholar] [CrossRef]

- Sgueglia, A.; Schmollgruber, P.; Bartoli, N.; Benard, E.; Morlier, J.; Jasa, J.; Martins, J.R.R.A.; Hwang, J.T.; Gray, J.S. Multidisciplinary Design Optimization Framework with Coupled Derivative Computation for Hybrid Aircraft. J. Aircr. 2020, 57, 715–729. [Google Scholar] [CrossRef]

- de Vries, R.; Brown, M.; Vos, R. Preliminary Sizing Method for Hybrid-Electric Distributed-Propulsion Aircraft. J. Aircr. 2019, 56, 2172–2188. [Google Scholar] [CrossRef]

- Borer, N.K.; Patterson, M.D.; Viken, J.K.; Moore, M.D.; Bevirt, J.; Stoll, A.M.; Gibson, A.R. Design and Performance of the NASA SCEPTOR Distributed Electric Propulsion Flight Demonstrator. In Proceedings of the 16th AIAA Aviation Technology, Integration, and Operations Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar] [CrossRef]

- Wu, J.; Gao, F.; Li, S.; Yang, F. Conceptual Design and Optimization of Distributed Electric Propulsion General Aviation Aircraft. Aerospace 2023, 10, 387. [Google Scholar] [CrossRef]

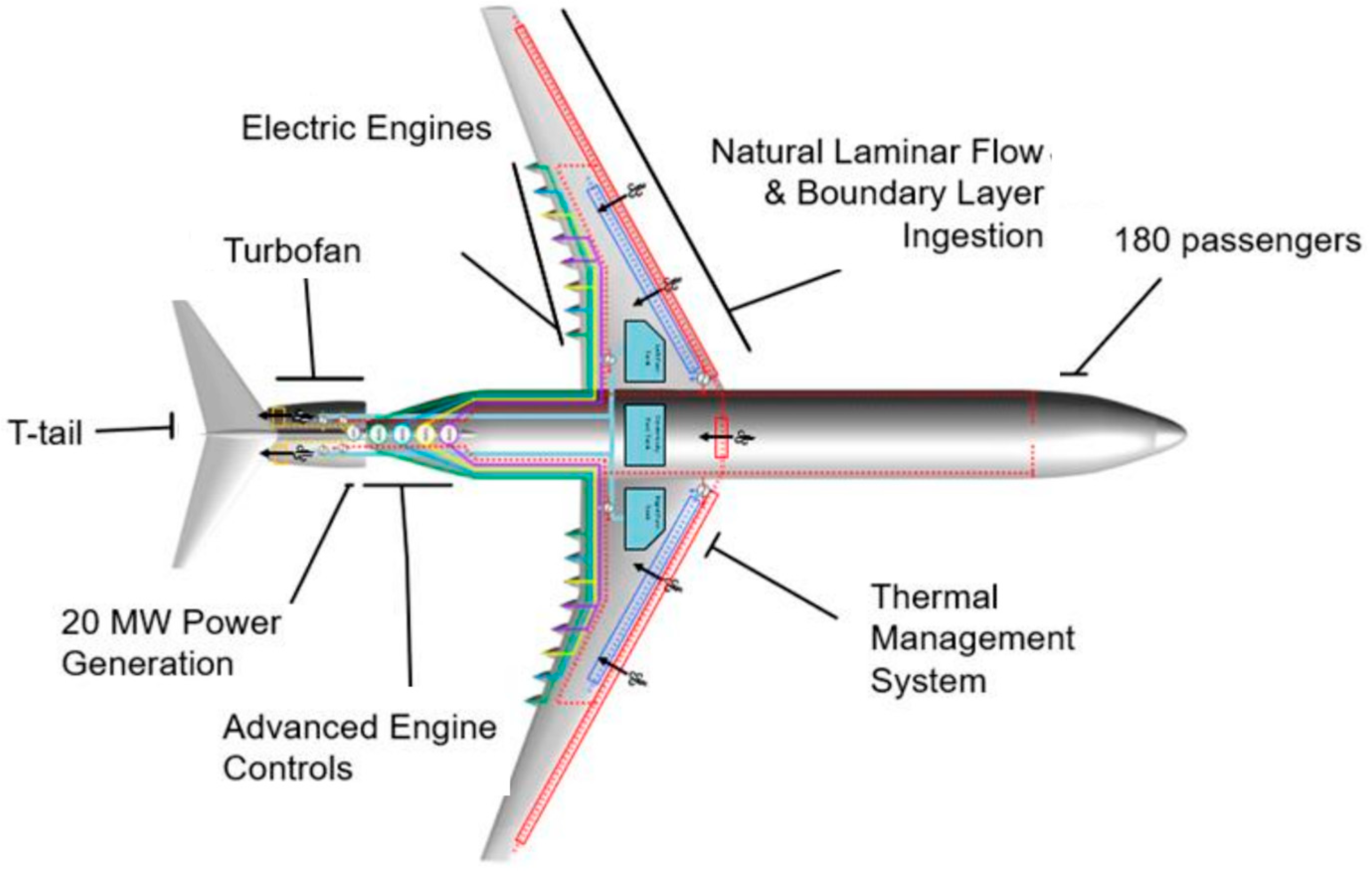

- Jansen, R.; Kiris, C.C.; Chau, T.; Machado, L.M.; Duensing, J.C.; Mirhashemi, A.; Chapman, J.; French, B.D.; Miller, L.; Litt, J.S.; et al. Subsonic single aft engine (SUSAN) transport aircraft concept and trade space exploration. In Proceedings of the AIAA SciTech Forum, San Diego, CA, USA, 3–7 January 2022. [Google Scholar] [CrossRef]

- Chau, T.; Duensing, J. Conceptual Design of the Hybrid-Electric Subsonic Single Aft Engine (SUSAN) Electrofan Transport Aircraft. In Proceedings of the AIAA SciTech Forum, Orlando, FL, USA, 8–12 January 2024. [Google Scholar] [CrossRef]

- Machado, L.; Chau, T.; Kenway, G.; Duensing, J.; Kiris, C. High-Fidelity Aerodynamic Analysis and Optimization of the SUSAN Electrofan Concept. In Proceedings of the AIAA SciTech Forum, San Diego, CA, USA, 3–7 January 2022. [Google Scholar] [CrossRef]

- Antonov An-225 Mriya. Available online: https://en.wikipedia.org/wiki/Antonov_An-225_Mriya (accessed on 22 December 2023).

- Kim, H.; Berton, J.; Jones, S. Low Noise Cruise Efficient Short Take-Off and Landing Transport Vehicle Study. In Proceedings of the 6th AIAA Aviation Technology, Integration and Operations Conference (ATIO), Wichita, KS, USA, 25–27 September 2006. [Google Scholar] [CrossRef]

- Cao, W.; Mecrow, B.C.; Atkinson, G.J.; Bennett, J.W.; Atkinson, D.J. Overview of Electric Motor Technologies Used for More Electric Aircraft (MEA). IEEE Trans. Ind. Electron. 2011, 59, 3523–3531. [Google Scholar] [CrossRef]

- Gnadt, A.R.; Speth, R.L.; Sabnis, J.S.; Barrett, S.R. Technical and environmental assessment of all-electric 180-passenger commercial aircraft. Prog. Aerosp. Sci. 2018, 105, 1–30. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, W.; Zhang, Y.; Ma, Y.; Bai, Z. Preliminary Design and Experimental Investigation of a Distributed Electric Propulsion Aircraft. In Proceedings of the 32nd Congress of the International Council of the Aeronautical Sciences (ICAS), Shanghai, China, 6–10 September 2021. [Google Scholar]

- Ma, Y.; Zhang, W.; Elham, A. Multidisciplinary Design Optimization of Twin-Fuselage Aircraft with Boundary-Layer-Ingesting Distributed Propulsion. J. Aircr. 2022, 59, 1588–1602. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, W.; Zhang, Y.; Zhang, X.; Zhong, Y. Sizing Method and Sensitivity Analysis for Distributed Electric Propulsion Aircraft. J. Aircr. 2020, 57, 730–741. [Google Scholar] [CrossRef]

- Perry, A.T.; Bretl, T.; Ansell, P.J. System Identification of a Subscale Distributed Electric Propulsion Aircraft. J. Aircr. 2023, 60, 702–715. [Google Scholar] [CrossRef]

- Pieper, K.; Perry, A.; Ansell, P.; Bretl, T. Design and development of a dynamically, scaled distributed electric propulsion aircraft testbed. In Proceedings of the AIAA/IEEE Electric Aircraft Technologies Symposium, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar] [CrossRef]

- Rothhaar, P.; Murphy, P.; Bacon, B.J.; Gregory, I.M.; Grauer, J.A.; Busan, R.C.; Croom, M.A. NASA Langley distributed propulsion VTOL tiltwing aircraft testing, modeling, simulation, control, and flight test development. In Proceedings of the 14th AIAA Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 16–20 June 2014. [Google Scholar] [CrossRef]

- Anemaat, W.; Brewer, K.; Darrah, D.T.; Ink, J.F.; Liu, W.; Moorthamers, B. Design, Build and Flight Testing of the MAVRIK with Distributed Electric Propulsion. In Proceedings of the AIAA Aviation Forum, Chicago, IL, USA, 27 June–1 July 2022. [Google Scholar] [CrossRef]

- Doll, C.; Hoogreef, M.; Iannelli, P.; Jentink, H.; Kierbel, D. Final Design, Manufacturing and Testing of the Clean Sky 2 Distributed Electric Propulsion Scaled Flight Demonstrator D08 DEP-SFD. In Proceedings of the AIAA SciTech Forum, Orlando, FL, USA, 8–12 January 2024. [Google Scholar] [CrossRef]

- Hall, D.K.; Huang, A.C.; Uranga, A.; Greitzer, E.M.; Drela, M.; Sato, S.; Yildirim, A.; Gray, J.S.; Mader, C.A.; Martins, J.R.R.A.; et al. Boundary Layer Ingestion Propulsion Benefit for Transport Aircraft. J. Propuls. Power 2017, 33, 1118–1129. [Google Scholar] [CrossRef]

- Doll, U.; Migliorini, M.; Baikie, J.; Zachos, P.K.; Röhle, I.; Melnikov, S.; Steinbock, J.; Dues, M.; Kapulla, R.; MacManus, D.G.; et al. Non-intrusive flow diagnostics for unsteady inlet flow distortion measurements in novel aircraft architectures. Prog. Aerosp. Sci. 2022, 130, 100810. [Google Scholar] [CrossRef]

- Laskaridis, P.; Pachidis, V.; Pilidis, P. Opportunities and challenges for distributed propulsion and boundary layer ingestion. Aircr. Eng. Aerosp. Technol. 2014, 86, 451–458. [Google Scholar] [CrossRef]

- Gohardani, A.S. A synergistic glance at the prospects of distributed propulsion technology and the electric aircraft concept for future un-manned air vehicles and commercial/military aviation. Prog. Aerosp. Sci. 2013, 57, 25–70. [Google Scholar] [CrossRef]

- Plas, A.; Crichton, D.; Sargeant, M.; Hynes, T.; Greitzer, E.; Hall, C.; Madani, V. Performance of a Boundary Layer Ingesting (BLI) Propulsion System. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2007. [Google Scholar]

- Hall, D.K.; Greitzer, E.M.; Uranga, A.; Drela, M.; Pandya, S.A. Inlet Flow Distortion in an Advanced Civil Transport Boundary Layer Ingesting Engine Installation. J. Turbomach. 2022, 144, 101002. [Google Scholar] [CrossRef]

- Moirou, N.G.; Sanders, D.S.; Laskaridis, P. Advancements and prospects of boundary layer ingestion propulsion concepts. Prog. Aerosp. Sci. 2023, 138, 100897. [Google Scholar] [CrossRef]

- Menegozzo, L.; Benini, E. Boundary Layer Ingestion Propulsion: A Review on Numerical Modeling. J. Eng. Gas Turbines Power 2020, 142, 120801. [Google Scholar] [CrossRef]

- Diamantidou, D.E.; Hosain, L.; Kyprianidis, K.G. Recent Advances in Boundary Layer Ingestion Technology of Evolving Powertrain Systems. Sustainability 2022, 14, 1731. [Google Scholar] [CrossRef]

- Castillo Pardo, A.; Hall, C.A. Aerodynamics of Boundary Layer Ingesting Fuselage Fans. J. Turbomach. 2021, 143, 041007. [Google Scholar] [CrossRef]

- Steiner, H.J.; Seitz, A.; Wieczorek, K.; Plötner, K.; Isikveren, A.T.; Hornung, M. Multi-disciplinary design and feasibility study of distributed propulsion systems. In Proceedings of the 28th International Congress of the Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012; pp. 23–28. [Google Scholar]

- Samuelsson, S.; Grönstedt, T. Performance analysis of turbo-electric propulsion system with fuselage boundary layer ingestion. Aerosp. Sci. Technol. 2020, 109, 106412. [Google Scholar] [CrossRef]

- Seitz, A.; Gologan, C. Parametric design studies for propulsive fuselage aircraft concepts. CEAS Aeronaut. J. 2014, 6, 69–82. [Google Scholar] [CrossRef]

- Bijewitz, J.; Seitz, A.; Isikveren, A.T.; Hornung, M. Multi-disciplinary design investigation of propulsive fuselage aircraft concepts. Aircr. Eng. Aerosp. Technol. 2016, 88, 257–267. [Google Scholar] [CrossRef]

- Bijewitz, J.; Seitz, A.; Hornung, M.; Isikveren, A.T. Progress in Optimizing the Propulsive Fuselage Aircraft Concept. J. Aircr. 2017, 54, 1979–1989. [Google Scholar] [CrossRef]

- Bijewitz, J.; Seitz, A.; Hornung, M. Extended Design Studies for a Mechanically Driven Propulsive Fuselage Aircraft Concept. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January.

- Seitz, A.; Habermann, A.L.; Peter, F.; Troeltsch, F.; Castillo Pardo, A.; Della Corte, B.; Van Sluis, M.; Goraj, Z.; Kowalski, M.; Zhao, X.; et al. Proof of Concept Study for Fuselage Boundary Layer Ingesting Propulsion. Aerospace 2021, 8, 16. [Google Scholar] [CrossRef]

- Bijewitz, J.; Seitz, A.; Hornung, M. Power Plant Pre-Design Exploration for a Turbo-Electric Propulsive Fuselage Concept. In Proceedings of the 2018 Joint Propulsion Conference, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar]

- Habermann, A.L.; Bijewitz, J.; Seitz, A.; Hornung, M. Performance bookkeeping for aircraft configurations with fuselage wake-filling propulsion integration. CEAS Aeronaut. J. 2019, 11, 529–551. [Google Scholar] [CrossRef]

- Habermann, A.L.; Zahn, R.; Seitz, A.; Hornung, M. Multidimensional Parametric Study of a Propulsive Fuselage Concept Using OpenFOAM. In Proceedings of the AIAA AVIATION 2020 FORUM, Online, 15–19 June 2020. [Google Scholar]

- Habermann, A.L.; Gokhale, A.; Hornung, M. Numerical investigation of the effects of fuselage upsweep in a propulsive fuselage concept. CEAS Aeronaut. J. 2021, 12, 173–189. [Google Scholar] [CrossRef]

- Della Corte, B.; van Sluis, M.; Veldhuis, L.L.M.; Rao, A.G. Power Balance Analysis Experiments on an Axisymmetric Fuselage with an Integrated Boundary-Layer-Ingesting Fan. AIAA J. 2021, 59, 5211–5224. [Google Scholar] [CrossRef]

- Della Corte, B.; Perpignan, A.A.; van Sluis, M.; Rao, A.G. Experimental and Computational Analysis of Model–Support Interference in Low-Speed Wind-Tunnel Testing of Fuselage-Boundary-Layer Ingestion. MATEC Web Conf. 2019, 304, 02020. [Google Scholar] [CrossRef]

- Della Corte, B.; van Sluis, M.; Rao, A.G.; Veldhuis, L.L.M. Aerodynamic Performance of an Aircraft with Aft-Fuselage Boundary-Layer-Ingestion Propulsion. In Proceedings of the AIAA AVIATION 2021 FORUM, Virtual, 2–6 August 2021; p. 2467. [Google Scholar]

- Kowalski, M.; Goraj, Z.J.; Goliszek, B. The use of FEA and semi-empirical equations for weight estimation of a passenger aircraft. Aircr. Eng. Aerosp. Technol. 2021, 93, 1412–1420. [Google Scholar] [CrossRef]

- Welstead, J.; Felder, J.L. Conceptual Design of a Single-Aisle Turboelectric Commercial Transport with Fuselage Boundary Layer Ingestion. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar] [CrossRef]

- Bradley, M.K.; Droney, C.K. Subsonic Ultra Green Aircraft Research: Phase 2. Hybrid Electric Design Exploration; Technical Report NASA/CR-2015-218704/VOL2; National Aeronautics and Space Administration (NASA): Washington, DC, USA, 2015; Volume 2.

- Gray, J.S.; Mader, C.A.; Kenway, G.K.W.; Martins, J.R.R.A. Modeling Boundary Layer Ingestion Using a Coupled Aeropropulsive Analysis. J. Aircr. 2018, 55, 1191–1199. [Google Scholar] [CrossRef]

- Gray, J.S.; Martins, J.R.R.A. Coupled aeropropulsive design optimisation of a boundary-layer ingestion propulsor. Aeronaut. J. 2018, 123, 121–137. [Google Scholar] [CrossRef]

- Gray, J.S.; Mader, C.A.; Kenway, G.K.W.; Martins, J.R.R.A. Coupled Aeropropulsive Optimization of a Three-Dimensional Boundary-Layer Ingestion Propulsor Considering Inlet Distortion. J. Aircr. 2020, 57, 1014–1025. [Google Scholar] [CrossRef]

- Yildirim, A.; Gray, J.S.; Mader, C.A.; Martins, J.R.R.A. Boundary-Layer Ingestion Benefit for the STARC-ABL Concept. J. Aircr. 2022, 59, 896–911. [Google Scholar] [CrossRef]

- Kenway, G.K.; Kiris, C.C. Aerodynamic Shape Optimization of the STARC-ABL Concept for Minimal Inlet Distortion. In Proceedings of the 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Blumenthal, B.T.; Elmiligui, A.A.; Geiselhart, K.A.; Campbell, R.L.; Maughmer, M.D.; Schmitz, S. Computational Investigation of a Boundary-Layer-Ingestion Propulsion System. J. Aircr. 2019, 55, 1141–1153. [Google Scholar] [CrossRef]

- Brown, K.A.; Fleming, J.L.; Langford, M.; Ng, W.; Schwartz, K.; Combs, C. Development of a Ducted Propulsor for BLI Electric Regional Aircraft—Part I: Aerodynamic Design and Analysis. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Schnell, R.; Zhao, X.; Rallis, E.; Kavvalos, M.; Sahoo, S.; Schnoes, M.; Kyprianidis, K. Assessment of a Turbo-Electric Aircraft Configuration with Aft-Propulsion Using Boundary Layer Ingestion. Aerospace 2019, 6, 134. [Google Scholar] [CrossRef]

- Ahuja, J.; Mavris, D.N.; Gray, J.S.; Mader, C.A.; Kenway, G.K.W.; Martins, J.R.R.A.; Ochs, S.S.; Tillman, G.; Joo, J.; Voytovych, D.; et al. Sensitivity of Boundary Layer Ingestion Effects to Tube and Wing Airframe Design Features. In Proceedings of the AIAA Scitech, Orlando, OH, USA, 6–10 January 2020. [Google Scholar]

- Fernández, A.M.; Smith, H. Effect of a fuselage boundary layer ingesting propulsor on airframe forces and moments. Aerosp. Sci. Technol. 2020, 100, 105808. [Google Scholar] [CrossRef]

- Secchi, M.; Lacava, P.T.; Trapp, L.G.; Ribeiro, R.F.G. Evaluation of a Regional Aircraft with Boundary Layer Ingestion and Electric-Fan Propulsor. J. Aircr. 2021, 58, 1204–1215. [Google Scholar] [CrossRef]

- Tse, T.S.; Hall, C.A. Aerodynamics and Power Balance of a Distributed Aft-Fuselage Boundary Layer Ingesting Aircraft. Aerospace 2023, 10, 122. [Google Scholar] [CrossRef]

- Yutko, B.M.; Titchener, N.; Courtin, C.; Lieu, M.; Wirsing, L.; Tylko, J.; Chambers, J.T.; Roberts, T.W.; Church, C.S. Conceptual Design of a D8 Commercial Aircraft. In Proceedings of the 17th AIAA Aviation Technology, Integration, and Operations Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar]

- Pandya, S.A.; Uranga, A.; Espitia, A.; Huang, A. Computational Assessment of the Boundary Layer Ingesting Nacelle Design of the D8 Aircraft. In Proceedings of the 52nd Aerospace Sciences Meeting, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar]

- Uranga, A.; Drela, M.; Greitzer, E.M.; Hall, D.K.; Titchener, N.A.; Lieu, M.K.; Siu, N.M.; Casses, C.; Huang, A.C.; Gatlin, G.M.; et al. Boundary Layer Ingestion Benefit of the D8 Transport Aircraft. AIAA J. 2017, 55, 3693–3708. [Google Scholar] [CrossRef]

- Uranga, A.; Drela, M.; Hall, D.K.; Greitzer, E.M. Analysis of the Aerodynamic Benefit from Boundary Layer Ingestion for Transport Aircraft. AIAA J. 2018, 56, 4271–4281. [Google Scholar] [CrossRef]

- Drela, M. Power Balance in Aerodynamic Flows. AIAA J. 2009, 47, 1761–1771. [Google Scholar] [CrossRef]

- Smith, L.H., Jr. Wake Ingestion Propulsion Benefit. In Proceedings of the 27th Joint Propulsion Conference, AIAA, Washington DC, USA, 24–26 June 1991. [Google Scholar] [CrossRef]

- Bravo-Mosquera, P.D.; Cerón-Muñoz, H.D.; Catalano, F.M. Design, aerodynamic analysis and optimization of a next-generation commercial airliner. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 1–22. [Google Scholar] [CrossRef]

- Bravo-Mosquera, P.D.; Cerón-Muñoz, H.D.; Catalano, F.M. Potential Propulsive and Aerodynamic Benefits of a New Aircraft Concept: A Low-Speed Experimental Study. Aerospace 2023, 10, 651. [Google Scholar] [CrossRef]

- Wiart, L.; Atinault, O.; Boniface, J.C.; Barrier, R. Aeropropulsive performance analysis of the NOVA configurations. In Proceedings of the 30th Congress of the International Council of the Aeronautical Sciences, Daejeon, Republic of Korea, 25–30 September 2016. [Google Scholar]

- Wiart, L.; Negulescu, C. Exploration of the airbus “Nautilius” engine integration concept. In Proceedings of the 31st Congress of the International Council of the Aeronautical Sciences, Belo Horizonte, Brazil, 9–14 September 2018. [Google Scholar]

- Arntz, A.; Atinault, O.; Merlen, A. Exergy-Based Formulation for Aircraft Aeropropulsive Performance Assessment: Theoretical Development. AIAA J. 2015, 53, 1627–1639. [Google Scholar] [CrossRef]

- Schmollgruber, P.; Donjat, D.; Ridel, M.; Cafarelli, I.; Atinault, O.; François, C.; Paluch, B.; Cinar, G.; Mavris, D.N.; Emeneth, M.; et al. Multidisciplinary Design and performance of the ONERA Hybrid Electric Distributed Propulsion concept (DRAGON). In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Mennicken, M.; Schoenweitz, D.; Schnoes, M.; Schnell, R. Fan design assessment for BLI propulsion systems. CEAS Aeronaut. J. 2021, 13, 3–19. [Google Scholar] [CrossRef]

- Ahuja, J.; Mavris, D.N. A Method for Modeling the Aero-Propulsive Coupling Characteristics of BLI Aircraft in Conceptual Design. In Proceedings of the AIAA Scitech 2021 Forum, Online, 11–15, 19–21 January 2021. [Google Scholar]

- Carter, M.B.; Campbell, R.L.; Pendergraft, O.C.; Friedman, D.M.; Serrano, L. Designing and Testing a Blended Wing Body with Boundary-Layer Ingestion Nacelles. J. Aircr. 2006, 43, 1479–1489. [Google Scholar] [CrossRef]

- Ko, A.; Leifsson, L.; Schetz, J.; Mason, W.; Grossman, B.; Haftka, R. MDO of a Blended-Wing-Body Transport Aircraft with Distributed Propulsion. In Proceedings of the AIAA’s 3rd Annual Aviation Technology, Integration, and Operations (ATIO) Forum, Denver, CO, USA, 17–19 November 2003. [Google Scholar]

- Rodriguez, D.L. Multidisciplinary Optimization Method for Designing Boundary-Layer-Ingesting Inlets. J. Aircr. 2009, 46, 883–894. [Google Scholar] [CrossRef]

- Rumsey, C.; Sanetrik, M.; Biedron, R.; Melson, N.; Parlette, E. Efficiency and accuracy of time-accurate turbulent Navier-Stokes computations. Comput. Fluids 1996, 25, 217–236. [Google Scholar] [CrossRef]

- Klann, C.A.J. Snyder, Nepp Programmers Manual; NASA TM-106575 lI; NASA: Hanover, MD, USA, 1994.

- Gill, P.E.; Murray, W.; Saunders, M.A.; Wright, M.H. User’s Guide for NPSOL 5.0: A Fortran Package for Nonlinear Programming. Technical Report, NA 98-2; Department of Mathematics, University of California: San Diego, CA, USA, 1998. [Google Scholar]

- Ciampa, P.D.; Nagel, B. AGILE Paradigm: The next generation collaborative MDO for the development of aeronautical systems. Prog. Aerosp. Sci. 2020, 119, 100643. [Google Scholar] [CrossRef]

- Fioriti, M.; Boggero, L.; Prakasha, P.; Mirzoyan, A.; Aigner, B.; Anisimov, K. Multidisciplinary aircraft integration within a collaborative and distributed design framework using the AGILE paradigm. Prog. Aerosp. Sci. 2020, 119, 100648. [Google Scholar] [CrossRef]

- Prakasha, P.; Ciampa, P.; Della Vecchia, P.; Ciliberti, D.; Voskuijl, M.; Charbonnier, D.; Jungo, A.; Fioriti, M.; Anisimov, K.; Mirzoyan, A. Multidisciplinary design analysis of Blended Wing Body through collaborative design approach: AGILE EU Project. In Proceedings of the ICAS Conference Proceedings, Belo Horizonte, Brazil, 9–14 September 2018. [Google Scholar]

- Prakasha, P.S.; Della Vecchia, P.; Ciampa, P.; Ciliberti, D.; Charbonnier, D.; Jungo, A.; Fioriti, M.; Boggero, L.; Mirzoyan, A.; Anisimov, K.; et al. Model based collaborative design & optimization of blended wing body aircraft configuration: AGILE EU project. In Proceedings of the Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 25–29 June 2018; Available online: https://www.agile-project.eu/use-case-blended-wing-body-bli/ (accessed on 17 January 2024).

- Kok, H.; Voskuijl, M.; van Tooren, M. Distributed propulsion featuring boundary layer ingestion engines for the blended wing body subsonic transport. In Proceedings of the 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 18th AIAA/ASME/AHS Adaptive Structures Conference 12th, Orlando, FL, USA, 12–15 April 2010; p. 3064. [Google Scholar]

- Kim, H.J.; Liou, M.S. Optimal Inlet Shape Design of N2B Hybrid Wing Body Configuration. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Atlanta, GA, USA, 30 July–1 August 2012. [Google Scholar]

- Kim, H.; Liou, M.-S. Shape design optimization of embedded engine inlets for N2B hybrid wing-body configuration. Aerosp. Sci. Technol. 2013, 30, 128–149. [Google Scholar] [CrossRef]

- Ashcraft, S.W.; Padron, A.S.; Pascioni, K.A.; Stout, G.W., Jr.; Huff, D.L. Review of Propulsion Technologies for N + 3 Subsonic Vehicle Concepts; NASA Technical Report; NASA: Hanover, MD, USA, 2011; Volume NASA/TM-2011-217239.

- Drela, M.; Youngren, H. Athena Vortex Lattice (AVL); Computer Software; AVL: 2008; Volume 4. Available online: https://www.google.co.th/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwif2snE9LiEAxVXSmwGHSkICSYQFnoECBIQAQ&url=https%3A%2F%2Fweb.mit.edu%2Fdrela%2FPublic%2Fweb%2Favl%2FAVL_User_Primer.pdf&usg=AOvVaw08O76pR5MJa6sD59VsEIDe&opi=89978449 (accessed on 17 January 2024).

- Krist, S.L. CFL3D User’s Manual (Version 5.0); National Aeronautics and Space Administration, Langley Research Center: Hampton, VA, USA, 1998.

- Hileman, J.I.; Spakovszky, Z.S.; Drela, M.; Sargeant, M.A.; Jones, A. Airframe Design for Silent Fuel-Efficient Aircraft. J. Aircr. 2010, 47, 956–969. [Google Scholar] [CrossRef]

- Hardin, L.W.; Tillman, G.; Sharma, O.P.; Berton, J.; Arend, D.J. Aircraft System Study of Boundary Layer Ingesting Propulsion. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Atlanta, GA, USA, 30 July–1 August 2012. paper no. AIAA-2012-3993. [Google Scholar]

- Felder, J.; Kim, H.; Brown, G. Turboelectric distributed propulsion engine cycle analysis for hybrid-wing-body aircraft. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; p. 1132. [Google Scholar]

- Felder, J. NASA N3-X with Turboelectric Distributed Propulsion; Technical Report GRC-E-DAA-TN19290; National Aeronautics and Space Administration (NASA): Washington, DC, USA, 2014.

- Law, C.; Doty, J.; Schutte, J.; Jimenez, H.; Szaruga, S.; Doyle, S.; Alston, K.; Winter, T.; Hur, D.Y.; Kwak, M.-H.; et al. Weights and efficiencies of electric components of a turboelectric aircraft propulsion system. In Proceedings of the 49th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011; p. 225. [Google Scholar]

- Armstrong, M.J.; Ross, C.A.H.; Blackwelder, M.J.; Rajashekara, K. Propulsion System Component Considerations for NASA N3-X Turboelectric Distributed Propulsion System. SAE Int. J. Aerosp. 2012, 5, 344–353. [Google Scholar] [CrossRef]

- Berton, J.J.; Haller, W.J. A Noise and Emissions Assessment of the N3-X Transport. In Proceedings of the 52nd Aerospace Sciences Meeting, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar] [CrossRef]

- Felder, J.; Kim, H.; Brown, G.; Kummer, J. An Examination of the Effect of Boundary Layer Ingestion on Turboelectric Distributed Propulsion Systems. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2009. [Google Scholar]

- Liu, C.; Ihiabe, D.; Laskaridis, P.; Singh, R. A preliminary method to estimate impacts of inlet flow distortion on boundary layer ingesting propulsion system design point performance. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2013, 228, 1528–1539. [Google Scholar] [CrossRef]

- Arntz, A.; Atinault, O. Exergy-Based Performance Assessment of a Blended Wing–Body with Boundary-Layer Ingestion. AIAA J. 2015, 53, 3766–3776. [Google Scholar] [CrossRef]

- A Valencia, E.; Nalianda, D.; Laskaridis, P.; Singh, R. Methodology to assess the performance of an aircraft concept with distributed propulsion and boundary layer ingestion using a parametric approach. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2014, 229, 682–693. [Google Scholar] [CrossRef]

- Valencia, E.; Alulema, V.; Rodriguez, D.; Laskaridis, P.; Roumeliotis, I. Novel fan configuration for distributed propulsion systems with boundary layer ingestion on an hybrid wing body airframe. Therm. Sci. Eng. Prog. 2020, 18, 100515. [Google Scholar] [CrossRef]

- Schetz, J.A.; Hosder, S.; Dippold, V.; Walker, J. Propulsion and aerodynamic performance evaluation of jet-wing distributed propulsion. Aerosp. Sci. Technol. 2010, 14, 1–10. [Google Scholar] [CrossRef]

- Ko, A.; Schetz, J.A.; Mason, W.H. Assessment of the Potential Advantages of Distributed-Propulsion for Aircraft. In Proceedings of the XVI International Symposium on Air Breathing Engines (ISABE), Cleveland, OH, USA, 31 August–5 September 2003. [Google Scholar]

- Dang, T.Q.; Bushnell, P.R. Aerodynamics of cross-flow fans and their application to aircraft propulsion and flow control. Prog. Aerosp. Sci. 2009, 45, 1–29. [Google Scholar] [CrossRef]

- Kummer, J.D.; Dang, T.Q. High-Lift Propulsive Airfoil with Integrated Crossflow Fan. J. Aircr. 2006, 43, 1059–1068. [Google Scholar] [CrossRef]

- Chau, T.; Kenway, G.K.; Kiris, C.C.; Jansen, R.; Machado, L.M.; Duensing, J.C.; Mirhashemi, A.; Chapman, J.; French, B.D.; Miller, L.; et al. Conceptual Exploration of Aircraft Configurations for the SUSAN Electrofan. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022. [Google Scholar]

- Rohacs, J.; Kale, U.; Rohacs, D. Radically new solutions for reducing the energy use by future aircraft and their operations. Energy 2021, 239, 122420. [Google Scholar] [CrossRef]

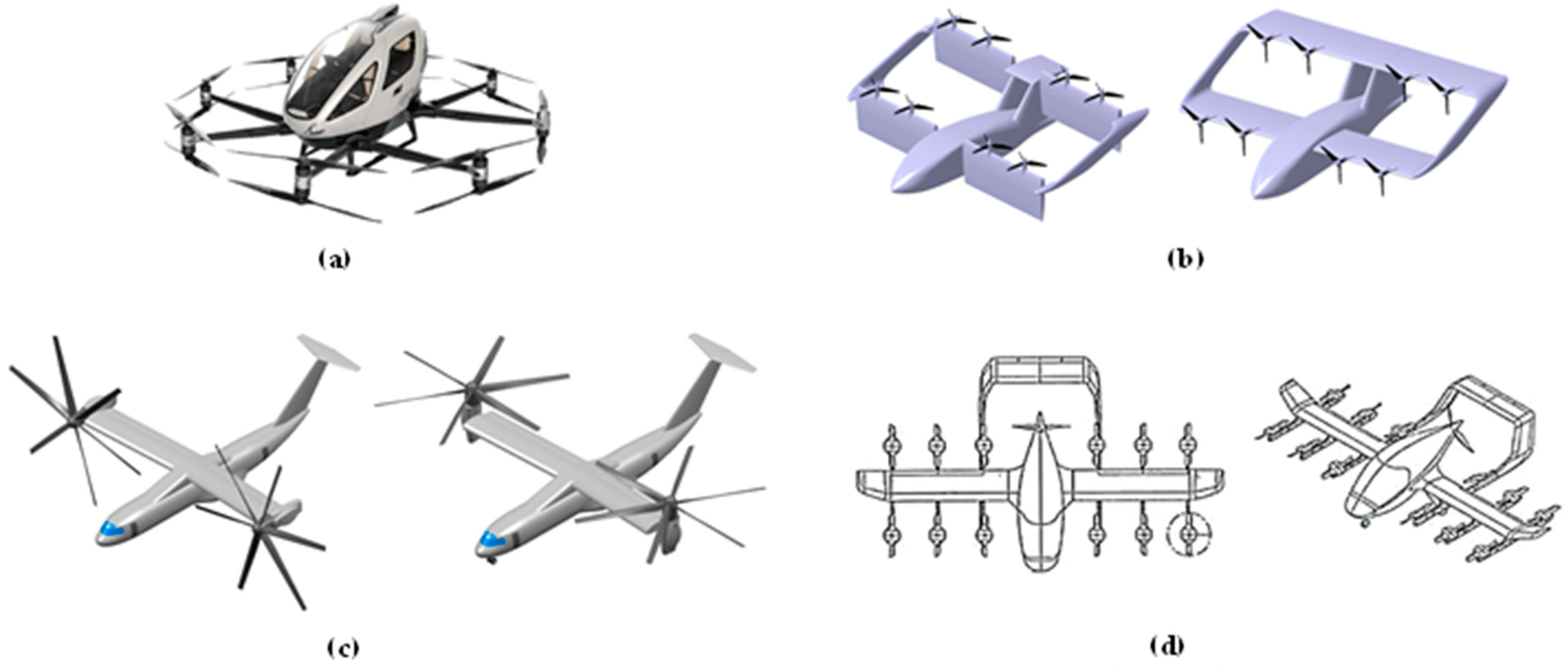

- Bacchini, A.; Cestino, E. Electric VTOL Configurations Comparison. Aerospace 2019, 6, 26. [Google Scholar] [CrossRef]

- Finger, D.F.; Braun, C.; Bil, C. A review of configuration design for distributed propulsion transitioning VTOL aircraft. In Proceedings of the Asia-Pacific International Symposium on Aerospace Technology, Seoul, Republic of Korea, 15–17 November 2017. [Google Scholar]

- Finger, D.F.; Götten, F.; Braun, C.; Bil, C. Initial sizing for a family of hybrid-electric VTOL general aviation aircraft. In Proceedings of the Deutsche Gesellschaft für Luftund Raumfahrt, Lilienthal-Oberth e.V., Bonn, Germany, 4–6 September 2018. [Google Scholar] [CrossRef]

- Vieira, D.R.; Silva, D.; Bravo, A. Electric VTOL aircraft: The future of urban air mobility (background, advantages and challenges). Int. J. Sustain. Aviat. 2019, 5, 101–118. [Google Scholar] [CrossRef]

- Bauranov, A.; Rakas, J. Designing airspace for urban air mobility: A review of concepts and approaches. Prog. Aerosp. Sci. 2021, 125, 100726. [Google Scholar] [CrossRef]

- Mueller, E.R.; Kopardekar, P.H.; Goodrich, K.H. Enabling Airspace Integration for High-Density On-Demand Mobility Operations. In Proceedings of the 17th AIAA Aviation Technology, Integration, and Operations Conference, Denver, CO, USA, 5-9 June 2017. [Google Scholar]

- Straubinger, A.; Rothfeld, R.; Shamiyeh, M.; Büchter, K.-D.; Kaiser, J.; Plötner, K.O. An overview of current research and developments in urban air mobility—Setting the scene for UAM introduction. J. Air Transp. Manag. 2020, 87, 101852. [Google Scholar] [CrossRef]

- EHang. The Future of Transportation: White Paper on Urban Air Mobility Systems. Available online: https://www.ehang.com/app/en/EHang%20White%20Paper%20on%20Urban%20Air%20Mobility%20Systems.pdf (accessed on 17 January 2024).

- Barra, F.; Scanavino, M.; Guglieri, G. A methodology for multirotor aircraft power budget analysis. Aircr. Eng. Aerosp. Technol. 2020, 92, 909–916. [Google Scholar] [CrossRef]

- Palaia, G.; Abu Salem, K.; Cipolla, V.; Binante, V.; Zanetti, D. A Conceptual Design Methodology for e-VTOL Aircraft for Urban Air Mobility. Appl. Sci. 2021, 11, 10815. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Martins, J.R.R.A. Tilt-Wing eVTOL Takeoff Trajectory Optimization. J. Aircr. 2020, 57, 93–112. [Google Scholar] [CrossRef]

- Young, L.; Chung, W.; Paris, A.; Salvano, D.; Young, R.; Gao, H.; Wright, K.; Miller, D.; Cheng, V. A Study of Civil Tiltrotor Aircraft in NextGen Airspace. In Proceedings of the 10th AIAA Aviation Technology, Integration, and Operations (ATIO) Conference, Fort Worth, TX, USA, 13–15 September 2010. [Google Scholar]

- Chung, W.W.; Salvano, D.; Rinehart, D.; Young, R.; Cheng, V.; Lindsey, J. An Assessment of Civil Tiltrotor Concept of Operations in the Next Generation Air Transportation System; NASA Contractor Report, CR–2012-215999; NASA: Hanover, MD, USA, 2012. Available online: https://ntrs.nasa.gov/citations/20120015068 (accessed on 17 January 2024).

- Chakraborty, I.; Mishra, A.A. Sizing and Analysis of a Lift-Plus-Cruise VTOL Aircraft with Electrified Propulsion Systems. In Proceedings of the AIAA AVIATION 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022. [Google Scholar]

- Bacchini, A.; Cestino, E.; Van Magill, B.; Verstraete, D. Impact of lift propeller drag on the performance of eVTOL lift+cruise aircraft. Aerosp. Sci. Technol. 2020, 109, 106429. [Google Scholar] [CrossRef]

- Electric VTOL News. Available online: http://evtol.news/aircraft/kitty-hawk-cora (accessed on 17 January 2024).

). Thrust level: 4745 N (

). Thrust level: 4745 N ( ), 5250 N (

), 5250 N ( ), 6100 N (

), 6100 N ( ), 7500 N (

), 7500 N ( ), 12,200 (

), 12,200 ( ), 13,700 N (

), 13,700 N ( ), and 16,700 (

), and 16,700 ( ).

).

). Thrust level: 4745 N (

). Thrust level: 4745 N ( ), 5250 N (

), 5250 N ( ), 6100 N (

), 6100 N ( ), 7500 N (

), 7500 N ( ), 12,200 (

), 12,200 ( ), 13,700 N (

), 13,700 N ( ), and 16,700 (

), and 16,700 ( ).

).

| GTF | GOR | |

|---|---|---|

| Engine core | 180 kg | 230 kg |

| Low pressure turbine and turbine exhaust frame | 420 kg | 510 kg |

| Gearbox | 215 kg | 505 kg |

| Propeller/fan including related structures | 770 kg | 1335 kg |

| Nacelle | 800 kg | 95 kg |

| Accessories, nozzles, bypass duct, bearings | 270 kg | 275 kg |

| Total mass | 2655 kg | 2950 kg |

| Main Data | |

|---|---|

| MTOW | |

| Wing surface | 34 m2 |

| AR | 13 |

| Length fuselage | 18 m |

| 1.9 | |

| Num. pax | 19 |

| 2 Props. Config. | 6 Props. Config. | 12 Props. Config. | |

|---|---|---|---|

| Transmission | geared | geared | geared |

| Propulsion weight [kgf] | 1634 | 1351 | 1335 |

| MTOW [kgf] | 24,700 | 23,950 | 23,890 |

| Wing area [m2] | 63.6 | 58.6 | 55.6 |

| Vertical tail area [m2] | 12.16 | 9.29 | 5.84 |

| AR | 14 | 14 | 14 |

| Wingspan [m] | 29.9 | 28.7 | 27.9 |

| 2.7 | 2.85 | 3 | |

| L/D | 17.4 | 17.3 | 17.5 |

| Block fuel [kg] | 2114 | 2078 | 2056 |

| Baseline | = 16 | = 32 | = 48 | |||||

|---|---|---|---|---|---|---|---|---|

| R [nm] | 600 | 900 | 600 | 900 | 600 | 900 | 600 | 900 |

| MTOW [×103 kgf] | 56.76 | 57.89 | 72.8 | 74.4 | 77.7 | 78.4 | 80.5 | 82.4 |

| Wing area [m2] | 116.21 | 116.47 | 104.26 | 106.71 | 119.89 | 121.26 | 118.26 | 124.12 |

| L/D | 18.47 | 18.46 | 18.05 | 18.03 | 17.81 | 17.82 | 17.49 | 17.47 |

| Block fuel [×103 kg] | 4.77 | 5.74 | 4.18 | 5.78 | 3.91 | 5.37 | 4.45 | 6.31 |

| Baseline | Serial | Turboelectric | |

|---|---|---|---|

| MTOW [×103 kgf] | 21.9 | 22.7 (+26.5%) | 22.4 (+2.3%) |

| OEW/MTOW | 43% | 42% | 42% |

| W/S [kgf/m2] | 367 | 562 (+53.1%) | 500 (+36.2%) |

| Wing area [m2] | 60 | 49 (−18.3%) | 44 (−26.7%) |

| L/D (cruise) | 17.5 | 18.4 (+5.1%) | 18.5 (+5.7%) |

| Block fuel [×103 kg] | 2.19 | 3.05 (+39.3%) | 2.24 (+2.3%) |

| P2006T | X-57 | |

|---|---|---|

| Wing area [m2] | 14.7 | 6.1 |

| AR | 8.8 | 15 |

| Wingspan [m] | 11.4 | 9.6 |

| Numb. of prop. | 2 | 14 (12 + 2) |

| MTOW [kgf] | 1230 | 1360 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abu Salem, K.; Palaia, G.; Bravo-Mosquera, P.D.; Quarta, A.A. A Review of Novel and Non-Conventional Propulsion Integrations for Next-Generation Aircraft. Designs 2024, 8, 20. https://doi.org/10.3390/designs8020020

Abu Salem K, Palaia G, Bravo-Mosquera PD, Quarta AA. A Review of Novel and Non-Conventional Propulsion Integrations for Next-Generation Aircraft. Designs. 2024; 8(2):20. https://doi.org/10.3390/designs8020020

Chicago/Turabian StyleAbu Salem, Karim, Giuseppe Palaia, Pedro D. Bravo-Mosquera, and Alessandro A. Quarta. 2024. "A Review of Novel and Non-Conventional Propulsion Integrations for Next-Generation Aircraft" Designs 8, no. 2: 20. https://doi.org/10.3390/designs8020020

APA StyleAbu Salem, K., Palaia, G., Bravo-Mosquera, P. D., & Quarta, A. A. (2024). A Review of Novel and Non-Conventional Propulsion Integrations for Next-Generation Aircraft. Designs, 8(2), 20. https://doi.org/10.3390/designs8020020