1. Introduction

The Vietnamese apparel industry varies in size and scale. According to a report by FPT Securities in 2017, 98% of those manufacturers have fewer than 5000 workers and employees [

1]. Most of these manufacturers pursue the Cut-Make-Trim (CMT) model. In this business model, customers will provide materials, designs, and requirements, while the manufacturers are responsible for cutting, sewing, and packaging. Hence, the majority of profit comes mainly from labor costs, and companies gain a profit of 1–3% of the unit price [

1].

For most sample shops and apparel manufacturers, the completion and quality of an order would receive more attention than production planning and job allocation. Regularly, the unit price is estimated based on the production duration given by customers and design complexity rather than information relating to internal resources. This estimation causes unforeseen risks with labor costs. Because the labor resource has not been considered from the beginning, the production progress is relaxing at the start but rapid and rushing at the end. Some employees have to work overtime to catch up with the due date. These overtime hours additionally impact labor costs and profits.

Reasons preventing shop managers from planning are mathematical skills and computer skills. Missing data collection and storage hinder the computation. Furthermore, the design diversity and small volume are distinct features of apparel manufacturing, leading to changes in the production process and resources. Planners require significant time to update the processing data for every order. Another factor is the mathematical and computer skills of planners. Planners are unfamiliar with using mathematical models and computer programming to store data or write code. Current practice in sample shops is to use Excel spreadsheets to record worker productivity for monthly salary payments.

The above difficulties can be solved if there is a model for job allocation with the objective of optimizing labor costs. The shop managers can rely on the provided cost to discuss with customers and obtain the optimal profit. Not only does the model help managers estimate the labor cost in advance, but it also provides managers with performance data on employees for further training.

Integer Linear Programming has been adopted in a wide range of fields in the manufacturing industry [

2,

3]. J. Blazewicz presented a general paradigm for scheduling problems, considering various constraints [

4]. Peter Bucker then synthesized problems in scheduling algorithms and defined basic parameters for a scheduling problem, including task data, task characteristics, machine environment, and optimality criteria [

5]. Theresa Metty et al., studied the procurement process at Motorola, Inc., before developing and applying Mixed-Integer programming to a web-based negotiation platform in 2005 [

6]. The approach of Motorola, Inc., helped reduce the time and effort for travel, preparation, and negotiation with global suppliers and optimized contract awards across sectors. The approach saved more than

$600 million for the company. This project is a notable example of the association between algorithms, software solutions, and business processes.

Carlos Gomes da Silva et al., proposed a mixed-integer linear programming model to solve an aggregate production planning problem [

7]. The model considered constraints on plant operators, production capacity, and inventory level to define an optimal solution for profit, late orders, and workforce changes. The model assumes that the operator’s skill is equivalent for all operators. This assumption contradicts the situation in practice. The interactive feature of the proposed decision support system (DSS), which was not discussed, is another limitation of this research. Hadi Gökcen adopted integer linear programming that considered the subprocesses, available stations, and process cycle time to achieve balanced assembly lines [

8]. Sirikarn Chansombat presented a model for maintenance scheduling that considers maintenance, production, and order dimensions [

9]. The human resource dimension was not mentioned in this scheduling model. Joost T. de Kruijff studied the issue of a low-volume industry characterized by a moderate production quantity and the complexity of the supply chain [

10]. This paper proposes a model with two algorithms to solve complex problems with over 7000 constraints and 13,000 variables.

Recently, several new approaches have been proposed to tackle complex scheduling problems. Wang et al., presented a multi-objective optimization challenge to consider both energy consumption and makespan. This problem is tackled using an enhanced algorithm called multi-objective invasive weed optimization (MOIWO). The paper outcomes demonstrate the MOIWO algorithm’s effectiveness over other methods for the scheduling problem under consideration [

11]. The meta-heuristic algorithms, such as genetic algorithm (GA), particle swarm optimization (PSO), memetic algorithm (MA), and simulated annealing (SA), have been widely employed to effectively solve mixed integer linear programming (MILP) models in the context of production scheduling. These methods have been applied successfully in various industrial fields and demonstrate their advantages in tackling complex and large-scale problems [

12,

13,

14,

15]. However, the computational time is a big concern. To accelerate computing time, researchers have conducted extensive investigations into the integration of constraint programming concepts and problem decomposition methodologies [

16,

17].

Wong et al., also recognized the important role of operator skill. They applied operator skill and inventory capability in an optimization algorithm to achieve line balancing to minimize the overall operative idle time [

18]. Mok et al., introduced a genetic algorithm to assign job orders to sewing lines [

19]. This approach replaced the operator data with the sewing line data (number of lines, number of shifts, capacity constraints of production lines). Although the computational techniques in the above projects are quite advanced, their scope is limited to operational improvement [

20]. One of their objectives is the production cost, which is determined by the unit cost in a plant and the manufactured quantity. However, the unit production cost is a difficult question when the apparel style changes dynamically and the labor resources constantly vary. A combination of operator skills and the corresponding labor wage in planning could help achieve both optimal allocation and financial benefit.

This paper aims to develop a general mathematical model for task allocation for small and medium apparel companies. The primary objective is to minimize the overall labor cost, considering constraints such as operator skills, labor wages, workload balance, and processing time. The structure of this paper is organized as follows:

Section 2 provides a problem description and introduces the proposed mathematical model. In

Section 3, the focus is on evaluating the effectiveness of the proposed mathematical model through case studies. Finally,

Section 4 summarizes the findings and draws overall conclusions.

2. Problem Description and Proposed Mathematical Model

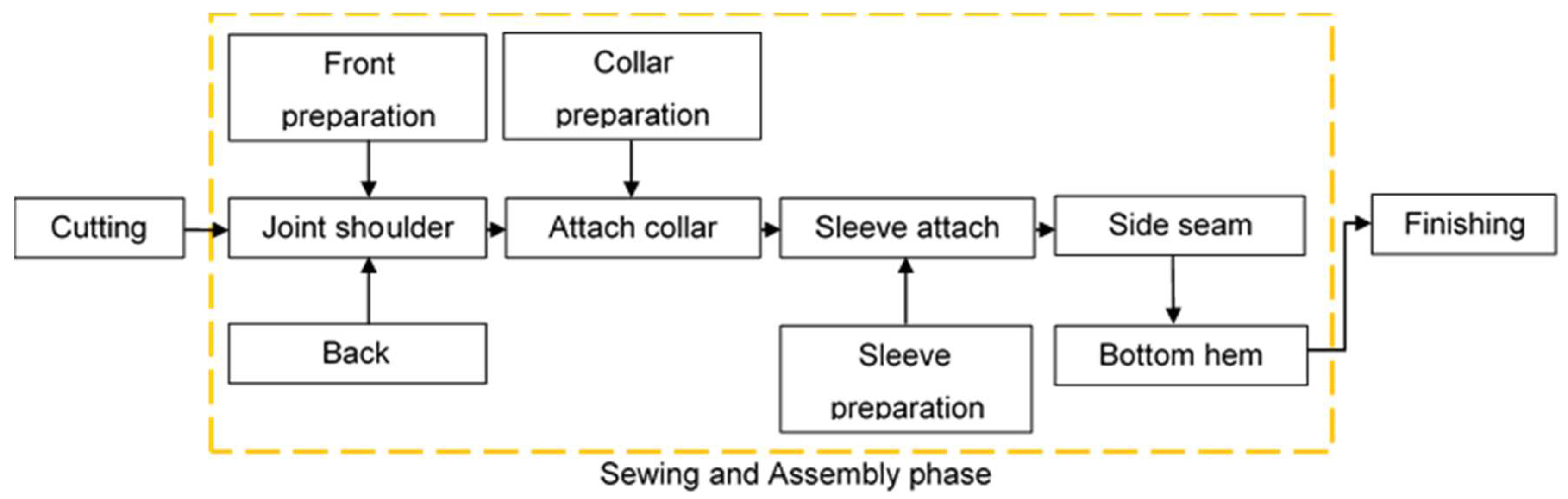

Cut-make-trim (CMT) is a model in the apparel production system in which manufacturers are responsible for cutting, sewing, and assembling the product [

1] (

Figure 1). In Vietnam, a vast majority of apparel manufacturers follow the CMT model, which will be the main objective of this paper.

An individual with multiple skills can execute all phases to complete the entire garment. However, this approach requires highly skilled labor, leading to costly pay. The approach is popular in sample rooms that produce in small quantities with a high focus on quality. Another approach is the group system, which is preferable in bulk production because it can save labor costs, employ more workers, and increase the potential for automation. In this system, an operator specializes in one major component and executes it from beginning to end [

21]. Particularly, a group of operators specializing in collars will prepare the hood and then assemble the hood, collar, and body. They are also required to perform all operations, such as marking and trimming, to complete their components.

The specialization of operators in specific components is considered a worker’s skill. An operator with a high skill level can handle complex parts well. Each level has a corresponding wage.

In addition to operator skills, there are other important attributes in costing and production planning:

Pool of operators;

Type and quantity of processing equipment;

The fund for working time;

Daily working time;

Time to produce a single product and time to produce each component piece;

Number of products to be produced.

For apparel manufacturing, workmanship is a critical factor, outweighing machinery and technology. The quality of a product depends mainly on the dexterity, experience, and delicacy of the operators. Although the support of machinery, fixtures, and tools makes the production process approachable for more professional levels, it appears impossible to achieve equivalence in expertise for all operators. Few operators might be able to complete the entire product by themselves, while some can perform certain types of components in a product. Hence, skill level is an indicator of the ability and wages of workers. Two assumptions could be drawn from this practice. First, an operator at a specific skill level can perform components with correspondingly lower difficulty. Second, the parameter corresponding to the difficulty level of the process may be deduced based on the cycle time because the complex process requires greater carefulness and delicacy from operators.

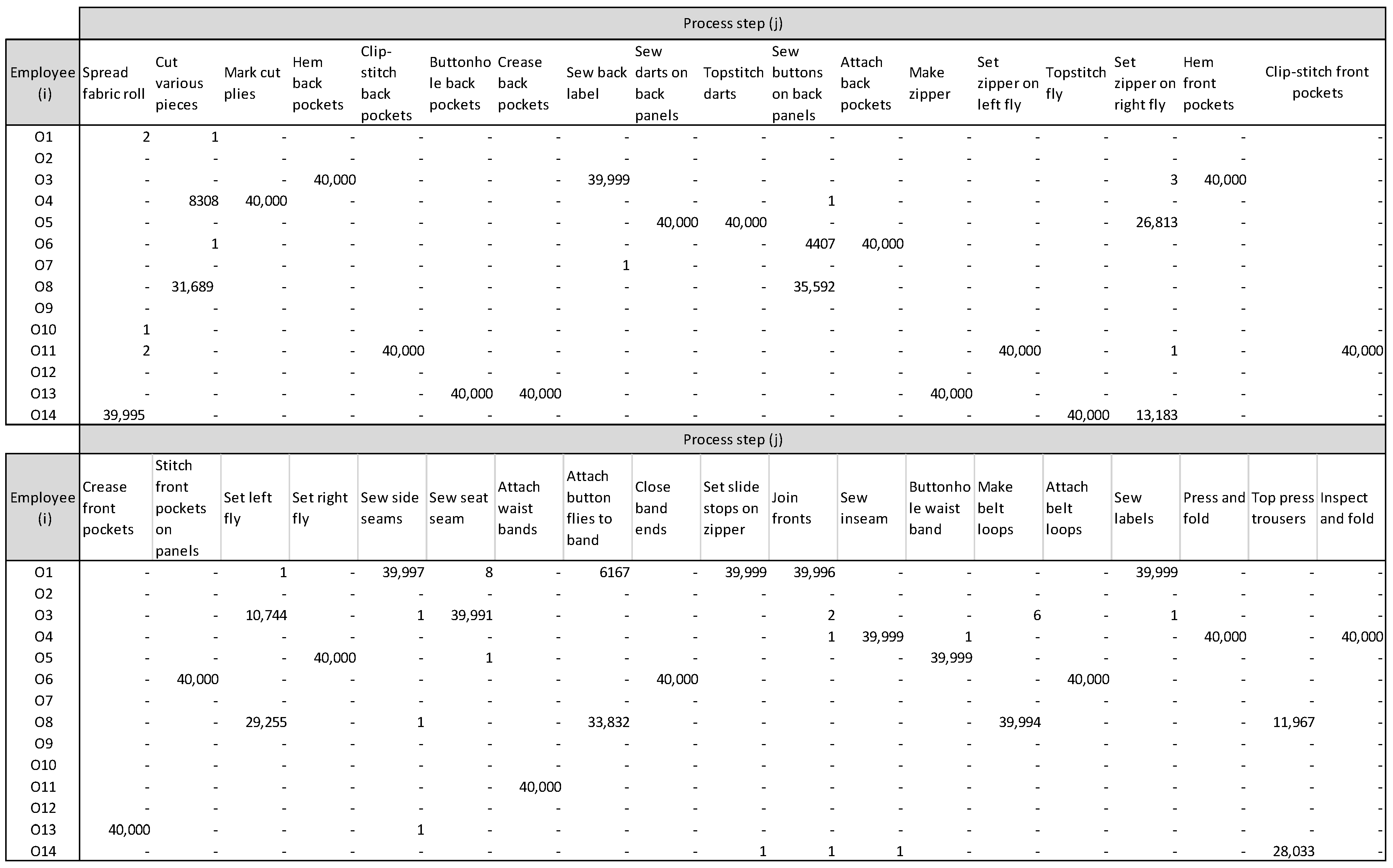

The mathematical model in this paper considers a manufacturer who employs operators for a production process consisting of smaller processes. An operator whose skill level is considered capable of the process if the difficulty level is denoted as ≤ There are five levels for apparel operator skills, corresponding to 5 levels of difficulty ranging from 1 to 5. A binary variable SMij will equal 1 if the operator is capable of component and 0 otherwise.

The hourly wage of operators, the cycle time , and the order demand O are considered to determine the labor cost. The model considers the duration D that a customer requested from the manufacturers, but it does not equal the production time. The total available production time equals the subtraction of the given duration and the order processing time, which is the time for order receiving and processing, varying from organization to organization. By multiplying the total available production time with the hourly working time Wt, the total production time in hours can be obtained. The working time Wt at the manufacturer per day is constant.

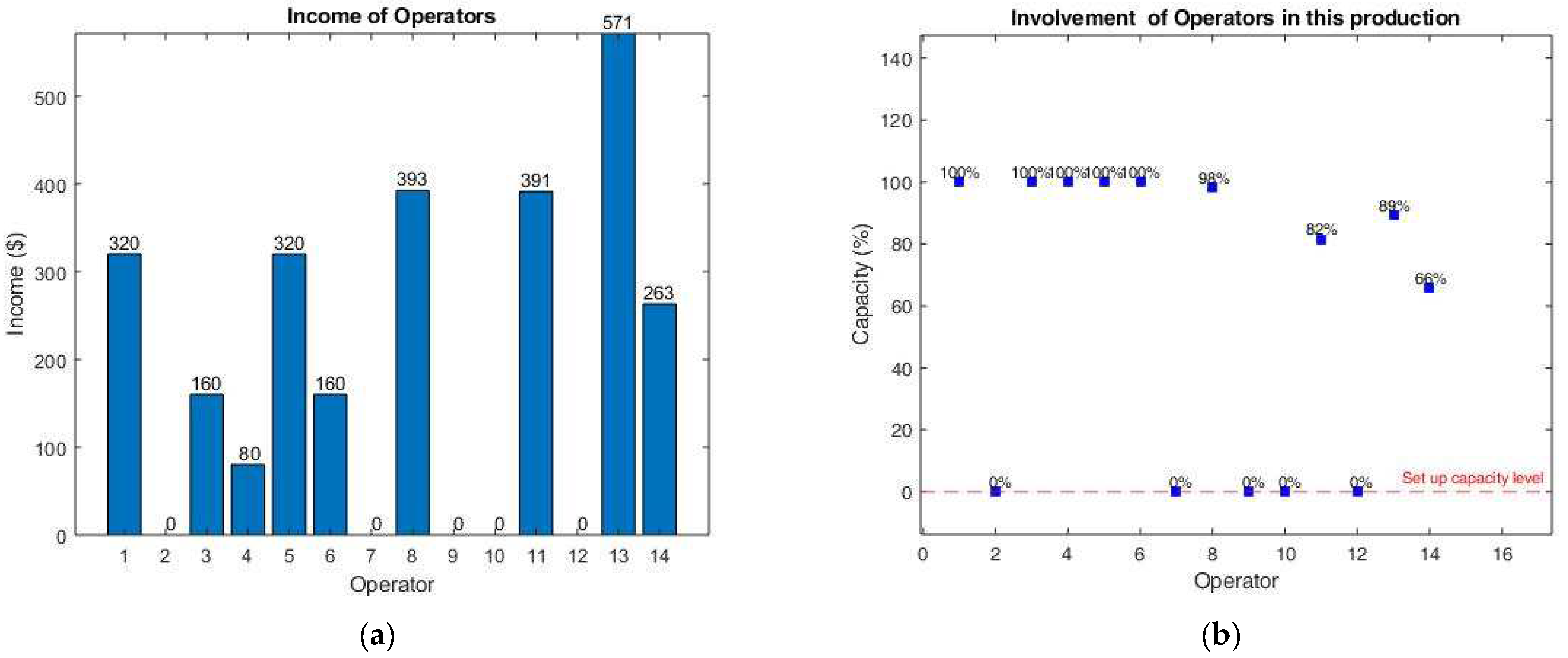

The workload should be balanced among operators. Thus, the model considers the target capacity level Cap for all operators who are intended for this production. This level will act as a lower limit on the involvement of each operator in the production. If this parameter equals 0, it means operators might or might not be involved in the production. The model will provide a solution with an optimal operator quantity and cost in that case.

The amount of available equipment for producing a component is considered in this model. In addition, there are some additional assumptions:

A process can be handled by one or more operators;

There is initially no work in the progress buffer;

There is no parallel process.

The objective of this model is to use the linear integer program principle to find an optimal labor cost and to obtain a job allocation plan. This plan can present the quantity of each component to be produced by a particular operator.

Objective: The objective function will consider the following components:

Labor cost;

Processing time;

Workload.

A practical and satisfactory allocation must ensure the time requirement and balance the workload for operators. Ultimately, the primary goal is to have the minimum labor cost so that decision-makers can estimate the optimal outsourcing price.

Variables:

SMij is a binary variable indicating the capability of operator to perform component j.

is an integer variable indicating the quantity of component j that shall be produced by operator

is a binary variable indicating whether operator i is assigned to component

Parameters:

: index of operators {1, 2, 3, …,}

: index of components {1, 2, 3, …,}

: skill level of operator {1,2,3,4,5}

: difficulty level of component {1,2,3,4,5}

: hourly wage of each operator ($)

: cycle time of a component (seconds)

Oj: number of semiproducts in each process (pcs)

D: duration given by customer (days)

OPT: order processing time (days)

APT: total available production time (days)

Wt: working time per day (hours)

Cap: target capacity level for all operators (%)

: quantity of available equipment for component

The objective is to allocate tasks to operators for optimal labor cost, and the objective function can be presented as:

The main goal of this model is to minimize the total labor cost, which is calculated using Equation (1). In the equation, represents an integer variable indicating the quantity of component j that should be produced by an operator i. The cost that is paid for an operator i to make component j is determined by the product of the component quantity , the cycle time of component j (in seconds), and the hourly wage of operator i (expressed in dollars) divided by 3600 (to convert it to seconds). In general, the problem has m different components and n operators. Therefore, the total cost is the sum of the payments for all n operators to produce all m different components.

Regarding constraints, the produced quantity at each component must equal the order amount from the customer, and only capable operators are allocated to the component.

In addition, the total working time of each operator must be within their working time fund:

where

APT = D − OPTTo meet time requirements and balance workload, operators should be involved in the production process at a certain level. Thus, their capacity must be greater than the defined capacity.

The number of operators involved in a component should be equal to or less than the amount of equipment available for that component. A binary decision variable

is needed so that if an operator

i is assigned to a component

j,

equals 1 and 0 otherwise. Therefore, the constraint is:

Constraints (5) and (6) show the relationship between variables

X and

Y:

where

M is a large positive number. In case an operator

i is allocated for a component process

j (

, then his allocation must be considered (

. In contrast, if (

, then (

. The number of operators that can be allocated to a process is limited by (Constraint (4)).

Other boundary constraints are:

The problem is solved in three steps:

Defining the capability of the operator;

Formulation of variables, objective functions, and constraints for the problem;

Solving the linear integer problem.

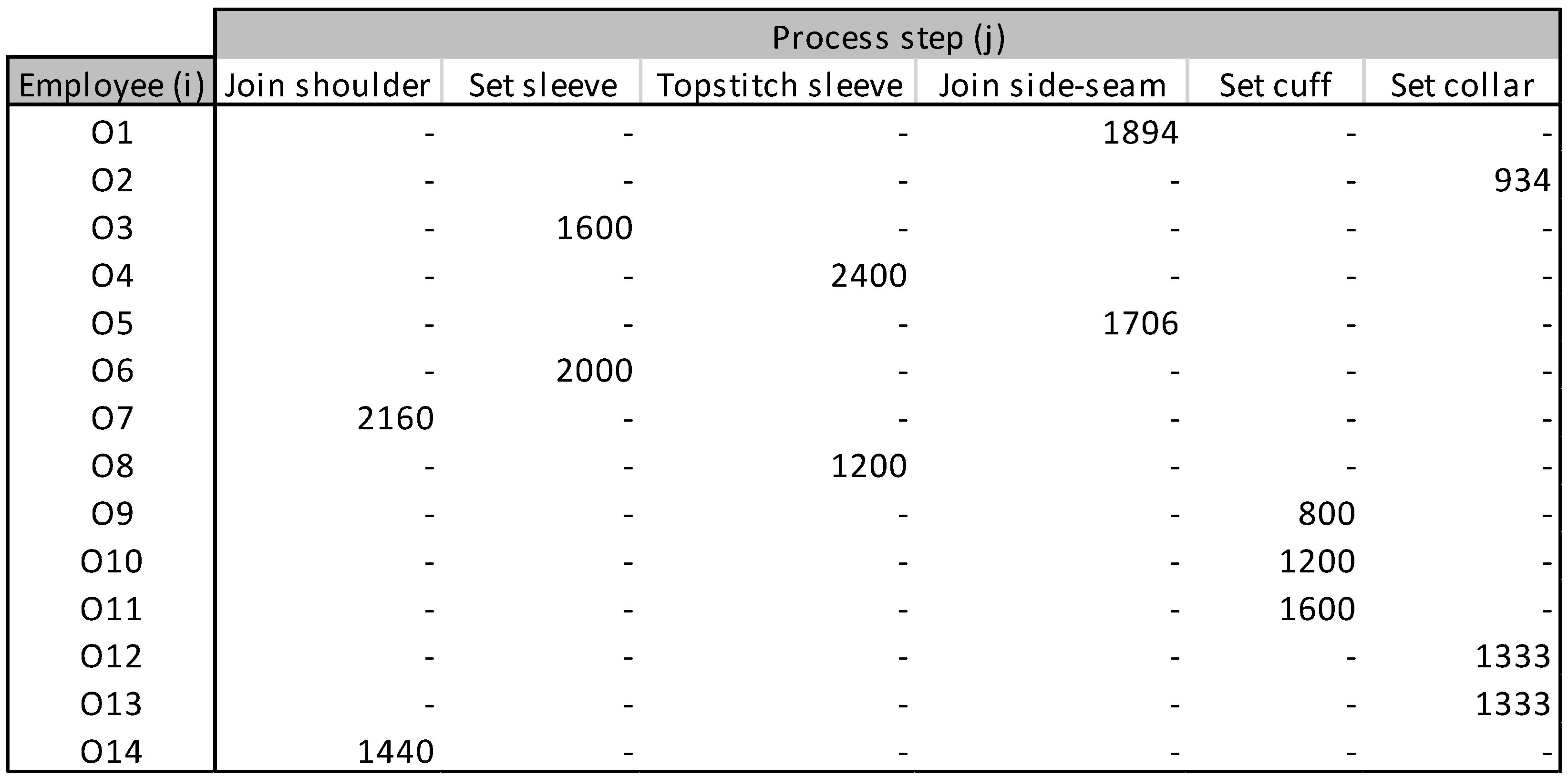

The operator’s skill and difficulty level are given in

Table 1 to define the operator’s capability. These steps can clearly define the pool of candidates for a particular process using a 0–1 indicator.

Subsequently, elements of the problem, such as decision variables and objective functions, are separately formulated. This approach is also known as the problem-based approach, which is more convenient and comprehensive for complex models [

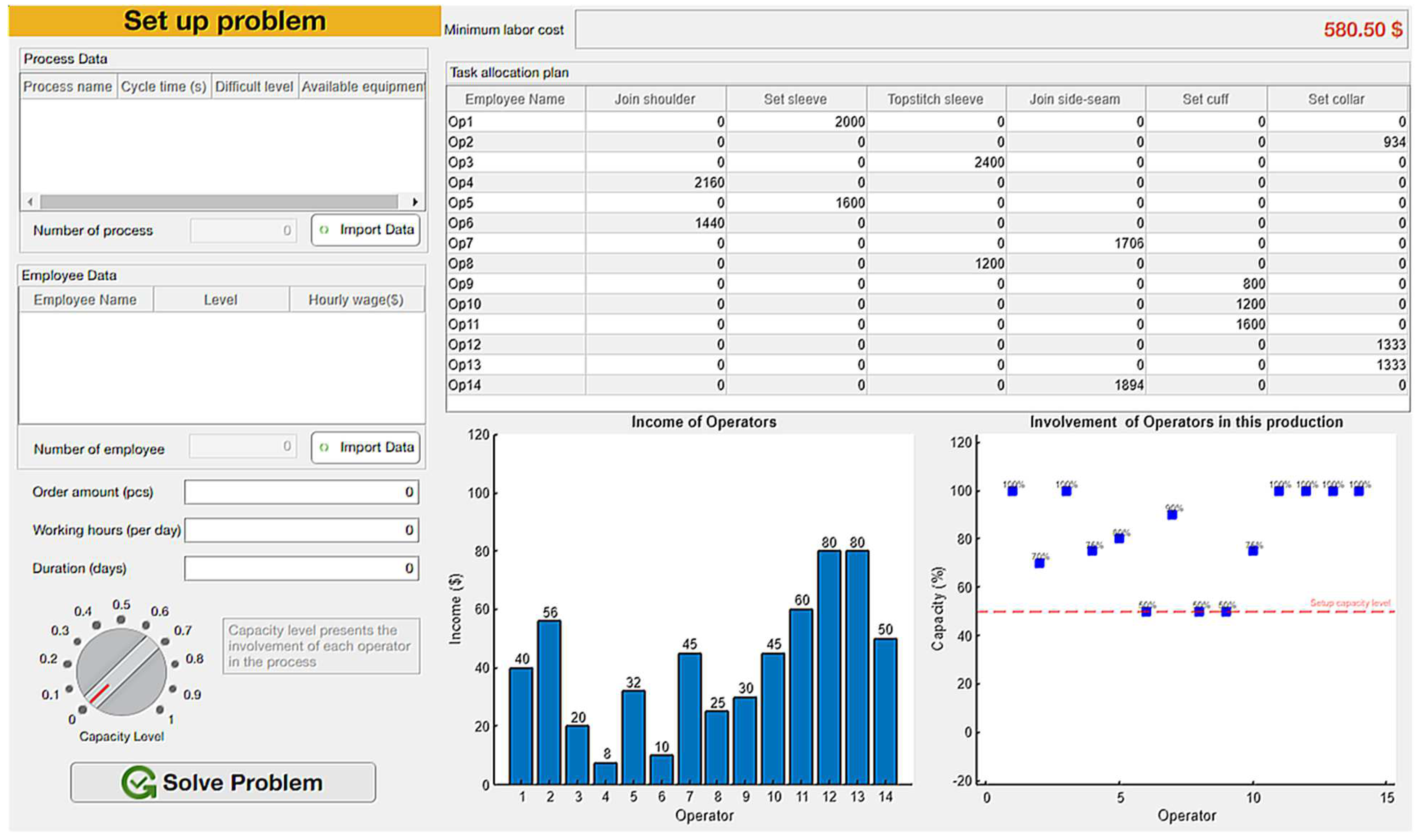

22]. As the model is programmed in MATLAB R2018b, all parameters must be declared as vectors and matrices. The quantity of

x and

y variables equals the number of operators and the number of processes. The lower bounds of

x and

y are also vectors, similar to their upper bounds. The value of these bounds is mentioned in the previous section. Then, the objective function and model constraints are formulated following the mathematical model in the previous section before being structured into an optimization problem. Subsequently, this problem will be solved by the “intlinprog” function.

“intlinprog” is a function provided by the MATLAB optimization toolbox

TM for Integer linear programming problems. This section is comprehensive with reference to MATLAB’s Optimization Toolbox User’s Guide [

15]. The mathematical model of IP in MATLAB is:

‘intlinprog’ is designed as a minimizer in the objective function. is the vector of integer decision variables. and are coefficients of the decision variable , while b and are right-hand side coefficients in inequalities and equalities. and represent the lower bound and upper bound of the decision variables.

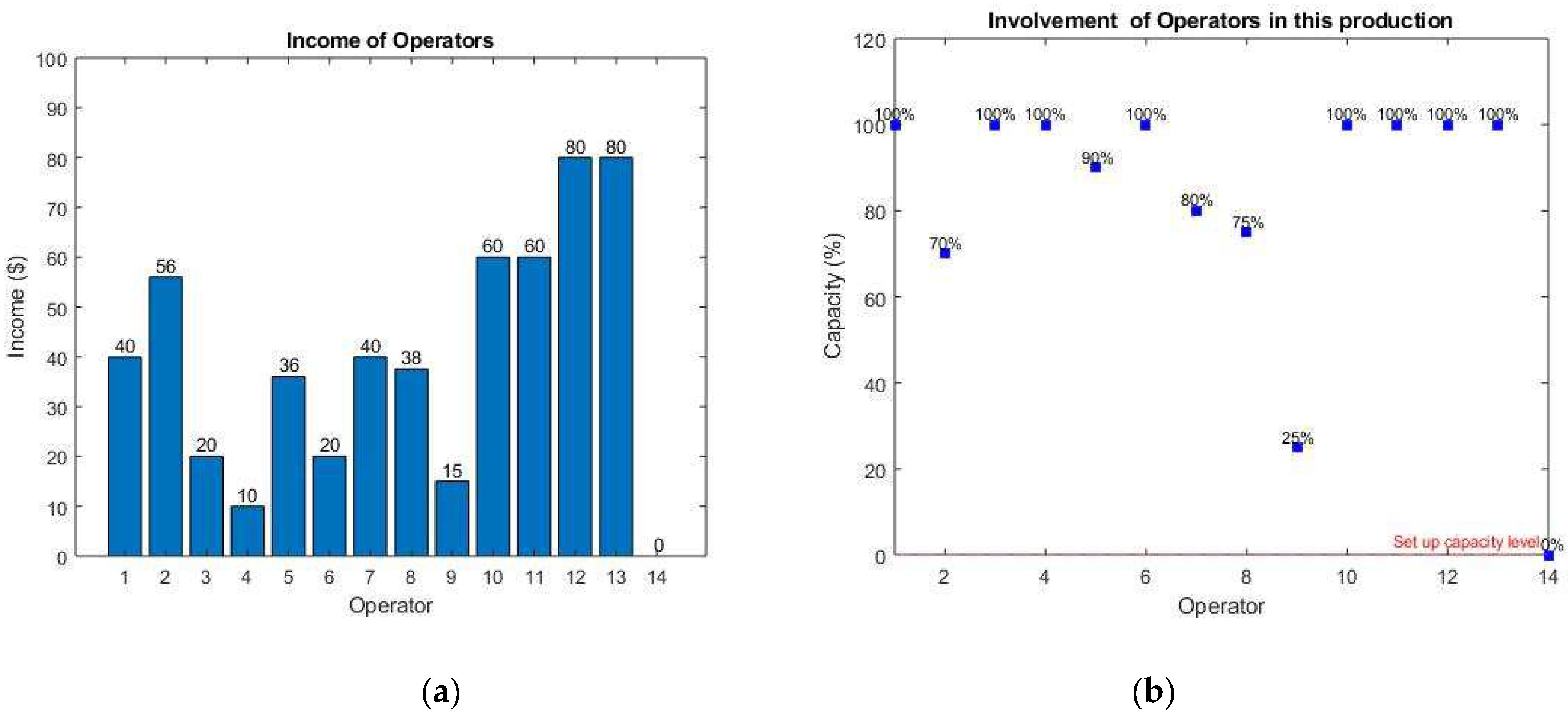

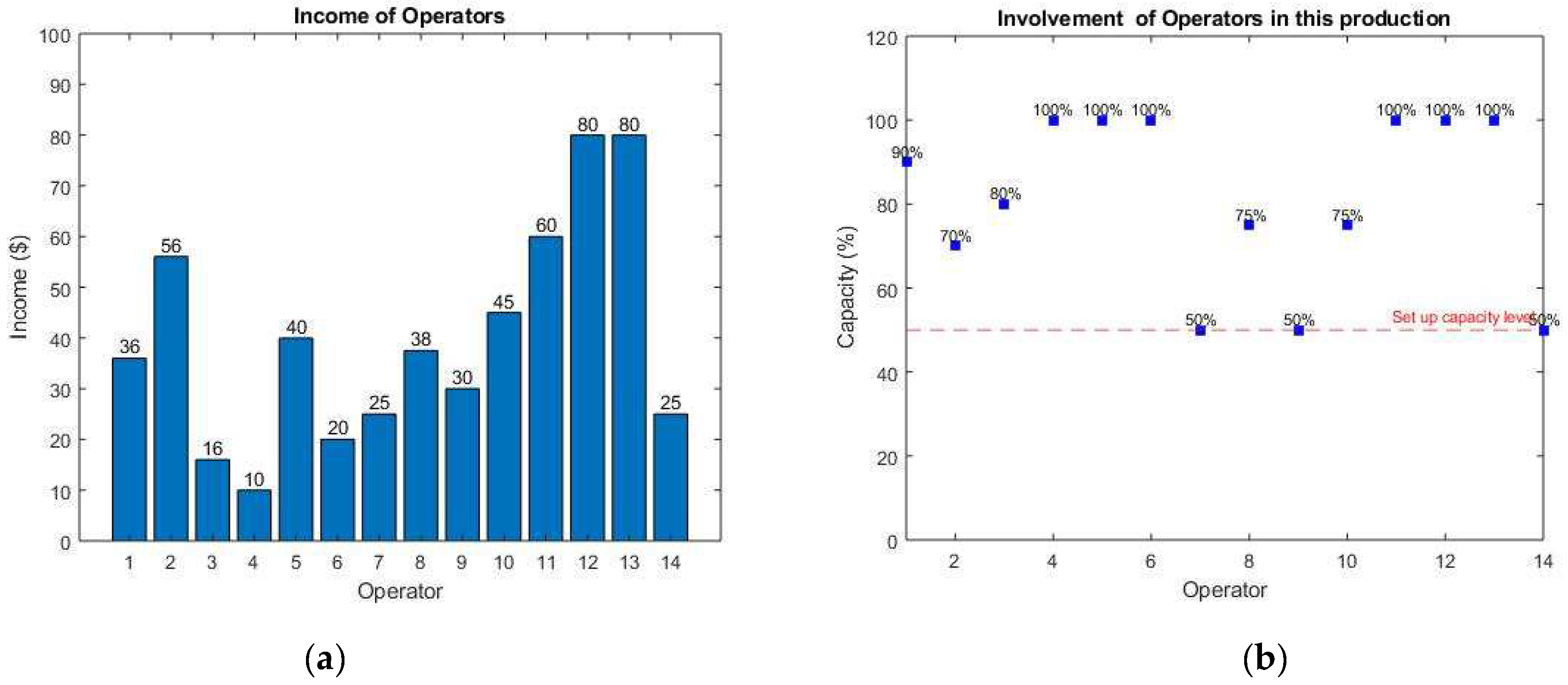

A linear integer problem can have multiple optimal solutions [

23]. In this case, there can be multiple allocation plans (or vectors of

x) with the same labor cost (or objective value). The difference among these solutions lies in the workload balance of operators. Here, the strategy of the algorithm is to use a constraint relating to the workload so that the integer problem must be solved once. Particularly, the capacity level Cap introduced to Constraint (3) ensures that all operators will be involved in the process with Cap% to 100% of their capacity. Therefore, the workload of operators will be balanced within a target range. With a smaller Cap, this range will be larger, and the workload balance will not be the priority. In that case, the priority will be the optimal labor cost and fewer participants, which are still satisfied by the algorithm.

In the next section, numerical datasets [

18,

24] are used to demonstrate the application of the model.

4. Summary

Amid the global pandemic that greatly affected manufacturing industries, Vietnam reached the top two countries of apparel exporters in early 2021, being valued at over

$29 billion [

28], signaling the great potential growth of the Vietnamese apparel industry if there is support and investment in this industry.

One of the competitive advantages of Vietnamese apparel is the labor resource, also known as the cheap labor advantage. However, from the perspective of management, there are challenges hindering the proper determination of the outsourcing price. Currently, data collection and analysis have not been applied in this process due to the lack of affordable and user-friendly information systems in apparel production. The fundamental mathematical and computer skills of apparel small and medium shop managers make them unable to develop a labor cost application. Currently, there are a variety of mathematical models and information systems providing resource planning, but operator resource planning with regard to cost and workload is not seen. By researching the background of Vietnamese apparel production, this paper has proposed a mathematical model regarding operator data, equipment data, process data, and operational data. Among operator data, operator skill played an important role in allocation so that the solution could ensure the labor cost and the feasibility of the plan.

The model was integrated into an application programmed in MATLAB that was designed for users unfamiliar with the computer so that time and effort could be saved for computation. The application’s graphical visualization also helps users grab the solution quickly and easily.

The desktop standalone application can be further developed to become a decision support system and interact with other information systems in the enterprise. This direction has been greatly applied in recent years, as it can bring complex mathematical techniques and models closer to people. For mathematical techniques, the paper used integer linear programming, which can be considered a classic technique in the optimization field. However, the model can meet all requirements of the problem, and it can also provide a solution within a short amount of time. The research can be an example of the efficiency of integer linear programming over other optimization techniques. The mathematical model can be further implemented and improved with different case studies in the Vietnamese apparel industry and other fields.

In conclusion, this paper proposes a comprehensive mathematical model that effectively solves task allocation and cost optimization, specifically tailored for small and medium-sized apparel companies. By addressing critical challenges such as task allocation, cost minimization, processing time requirements, and workload balancing, this model offers a robust solution to these complex problems. To validate the effectiveness of the proposed model, two compelling case studies were meticulously examined and compared. The results unequivocally demonstrate that, despite its simplicity, the proposed model exhibits remarkable applicability and efficiency in optimizing task allocation strategies.

Furthermore, the authors have seamlessly integrated the model’s formulations into a Standalone desktop application using the MATLAB “App Designer” module. This user-friendly app allows end-users, including those without computer expertise or programming background, to effortlessly engage with the tool and effectively tackle similar optimization challenges. The application underwent testing with a select group of users who worked in the planning area and possessed limited computer familiarity. The results conclusively demonstrate that the developed app is remarkably uncomplicated to use, garnering positive feedback for its intuitive interface accompanied by visual charts. Consequently, users can effortlessly modify resource allocations and easily assess various scenarios.

It is worth noting that the proposed mathematical model can easily expand to tackle even more intricate issues within the apparel industry and can serve as a valuable reference for optimization problems in various other domains.