Apparatus Design of One-Step Double-Side Friction Stir Welding for Aluminum Plates

Abstract

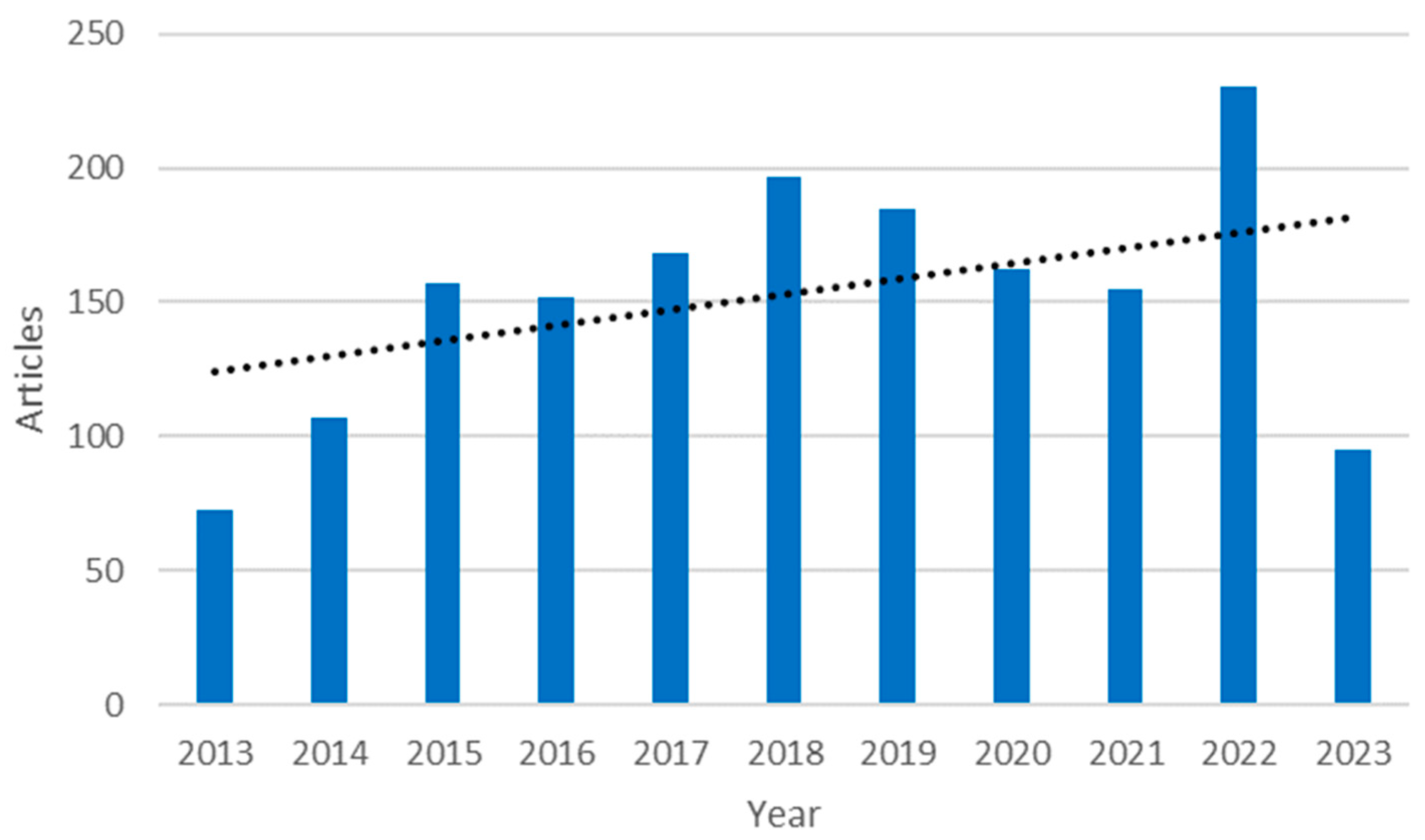

1. Introduction

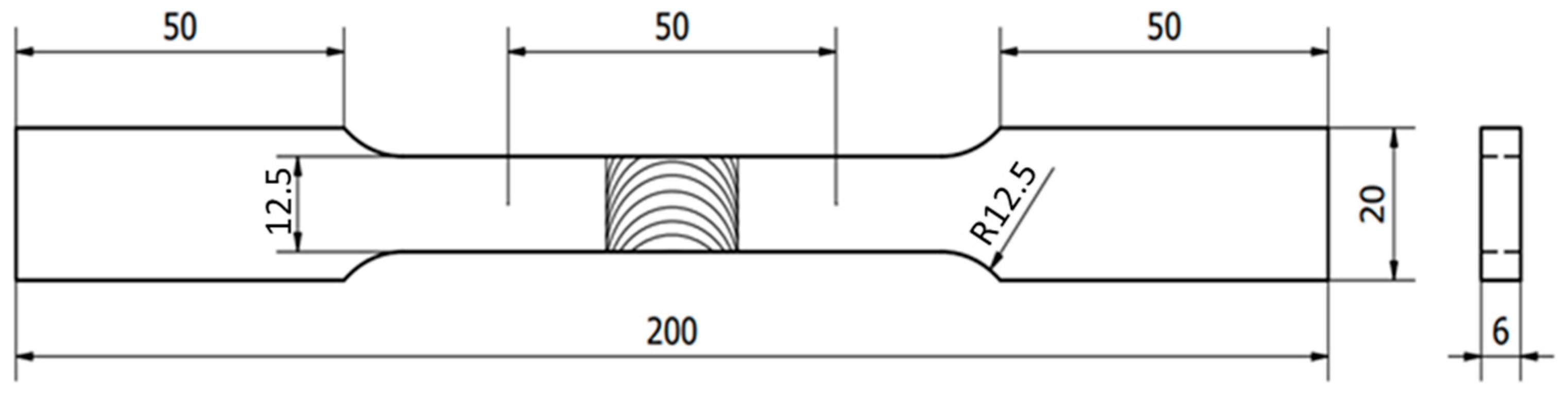

2. Materials and Methods

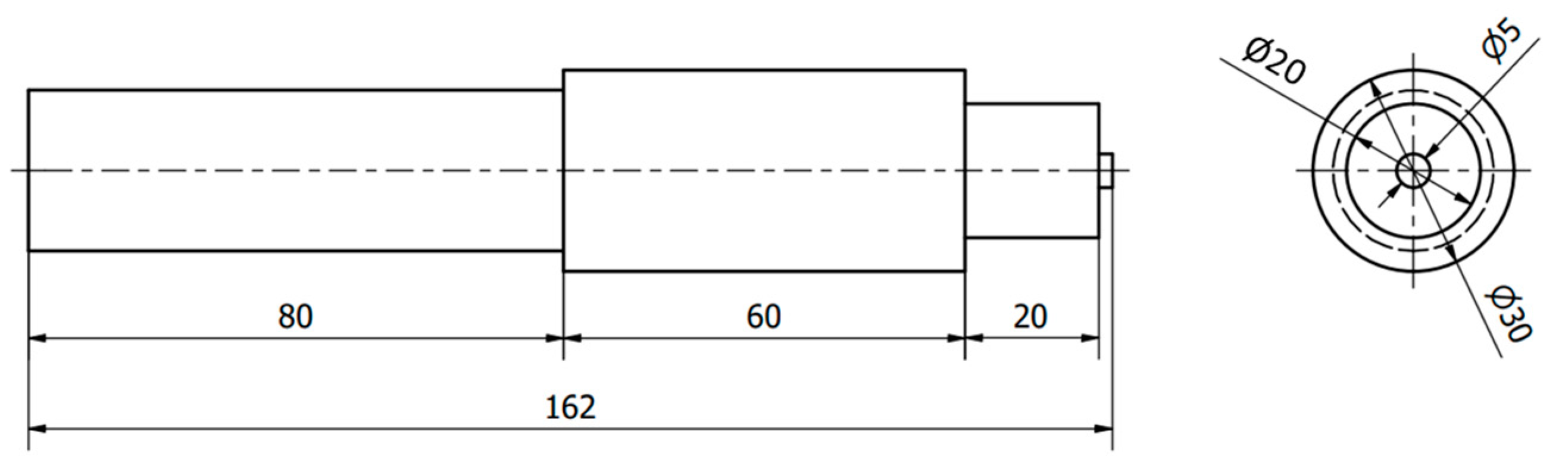

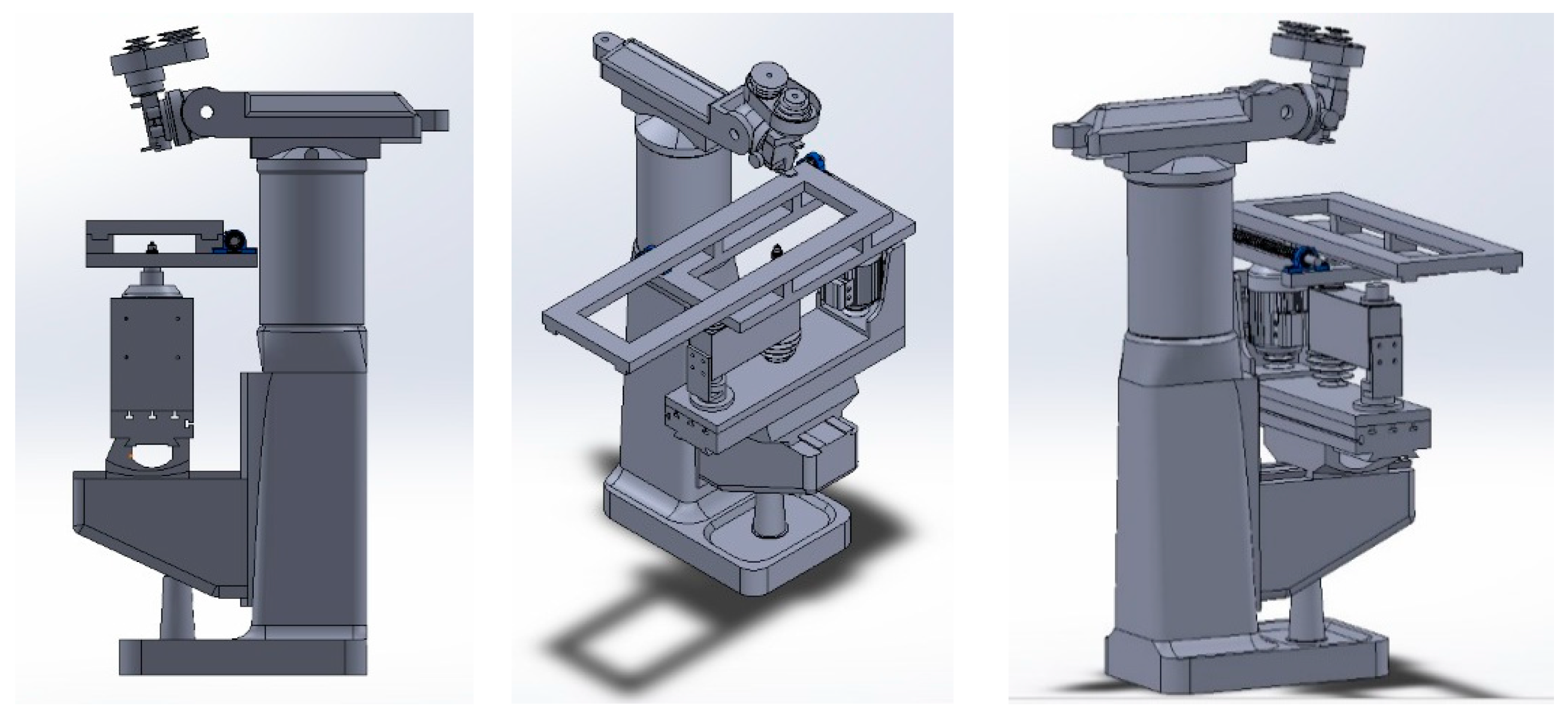

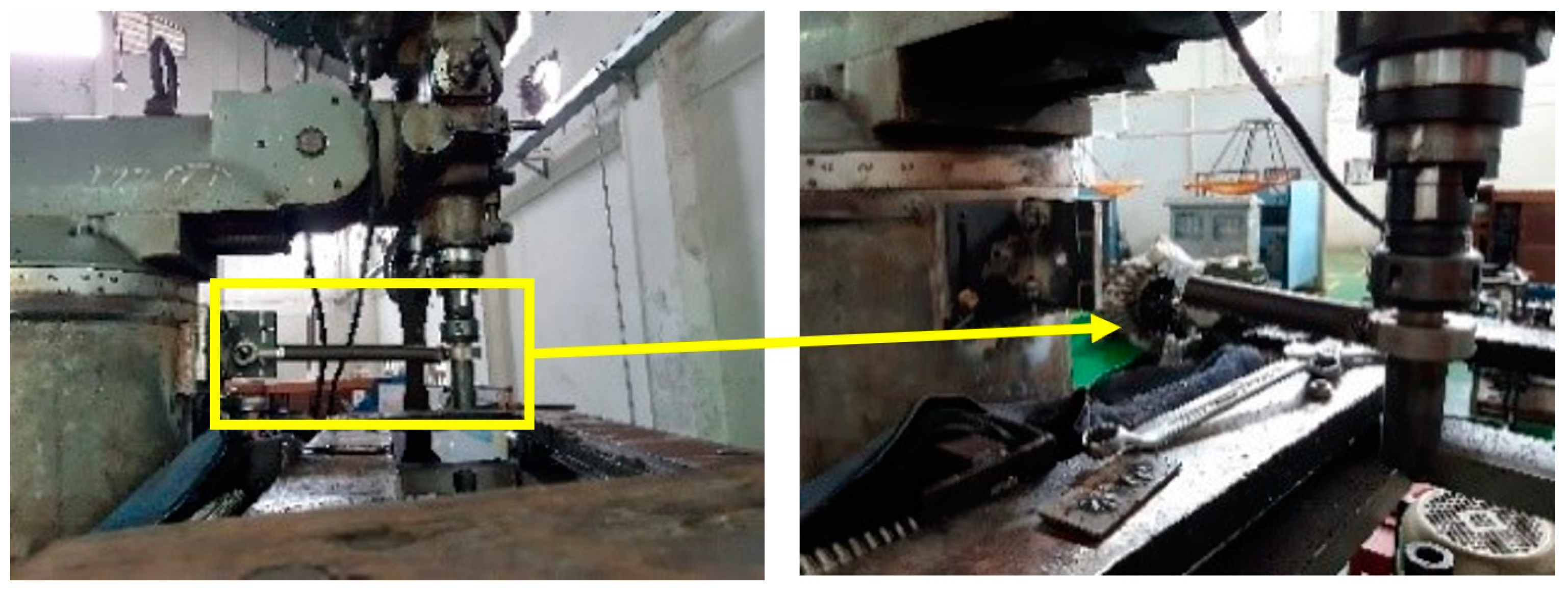

2.1. Apparatus Design and Assembling

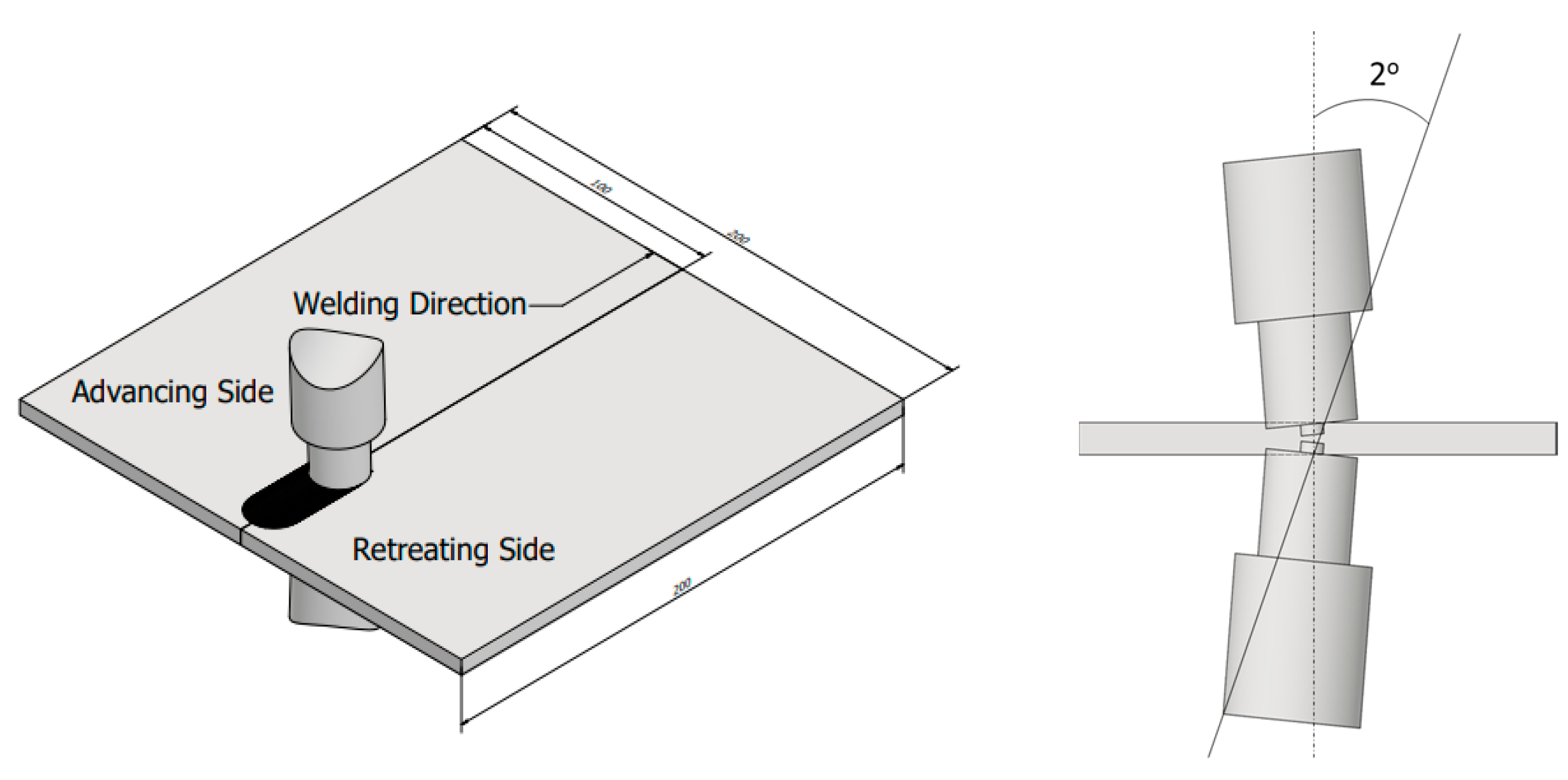

2.2. Welding Trials and Parameter Process Evaluation

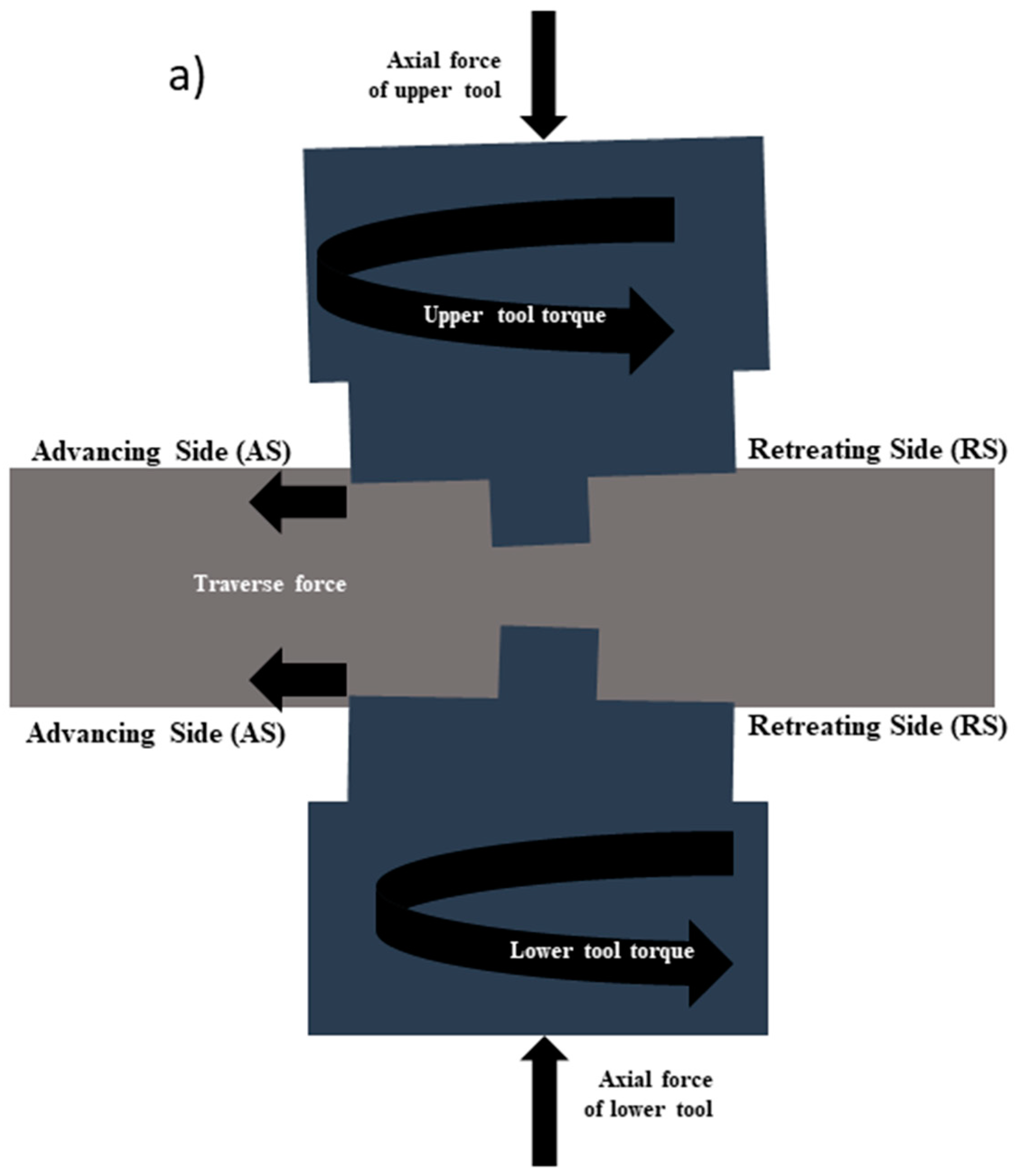

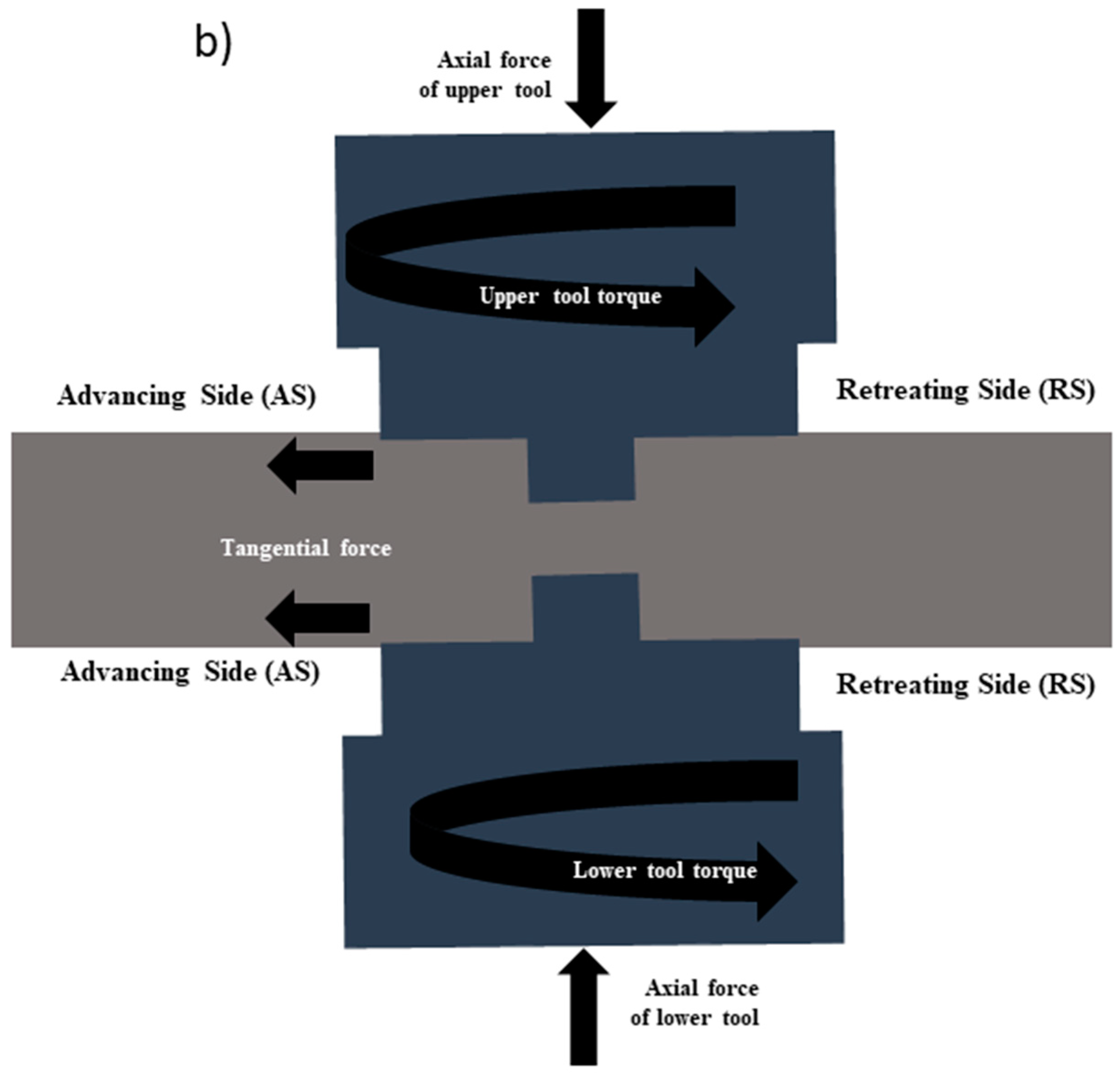

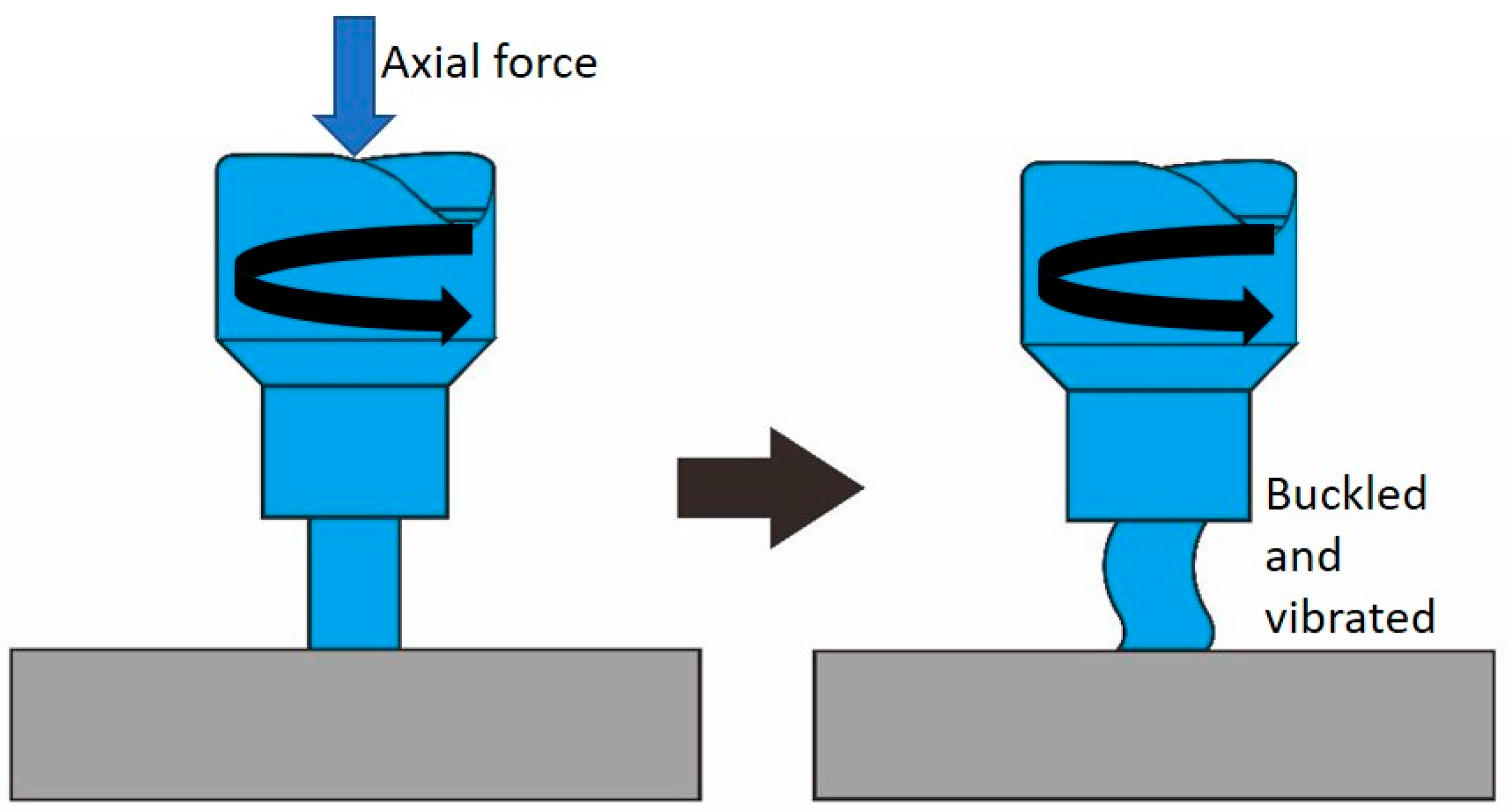

3. Apparatus Design on One-Step Double-Side FSW

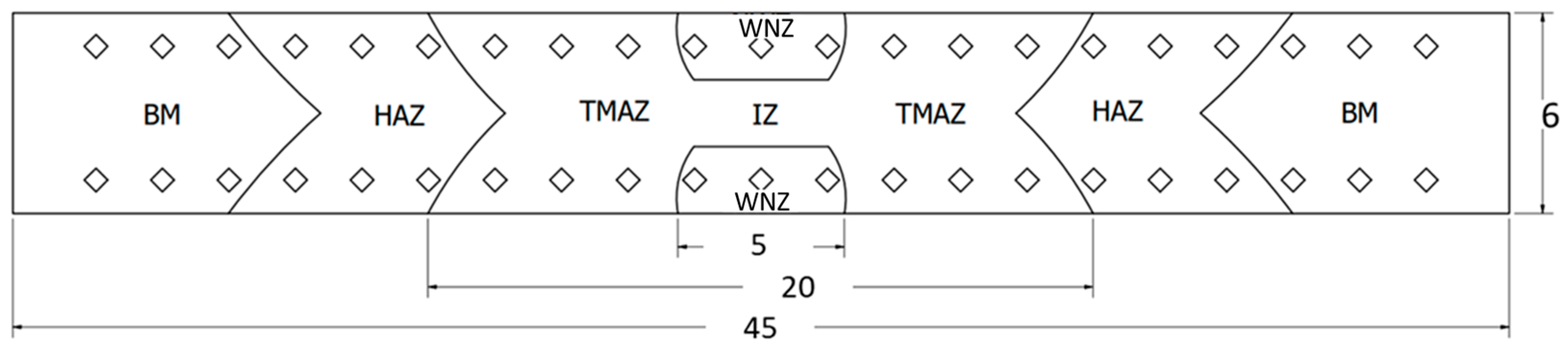

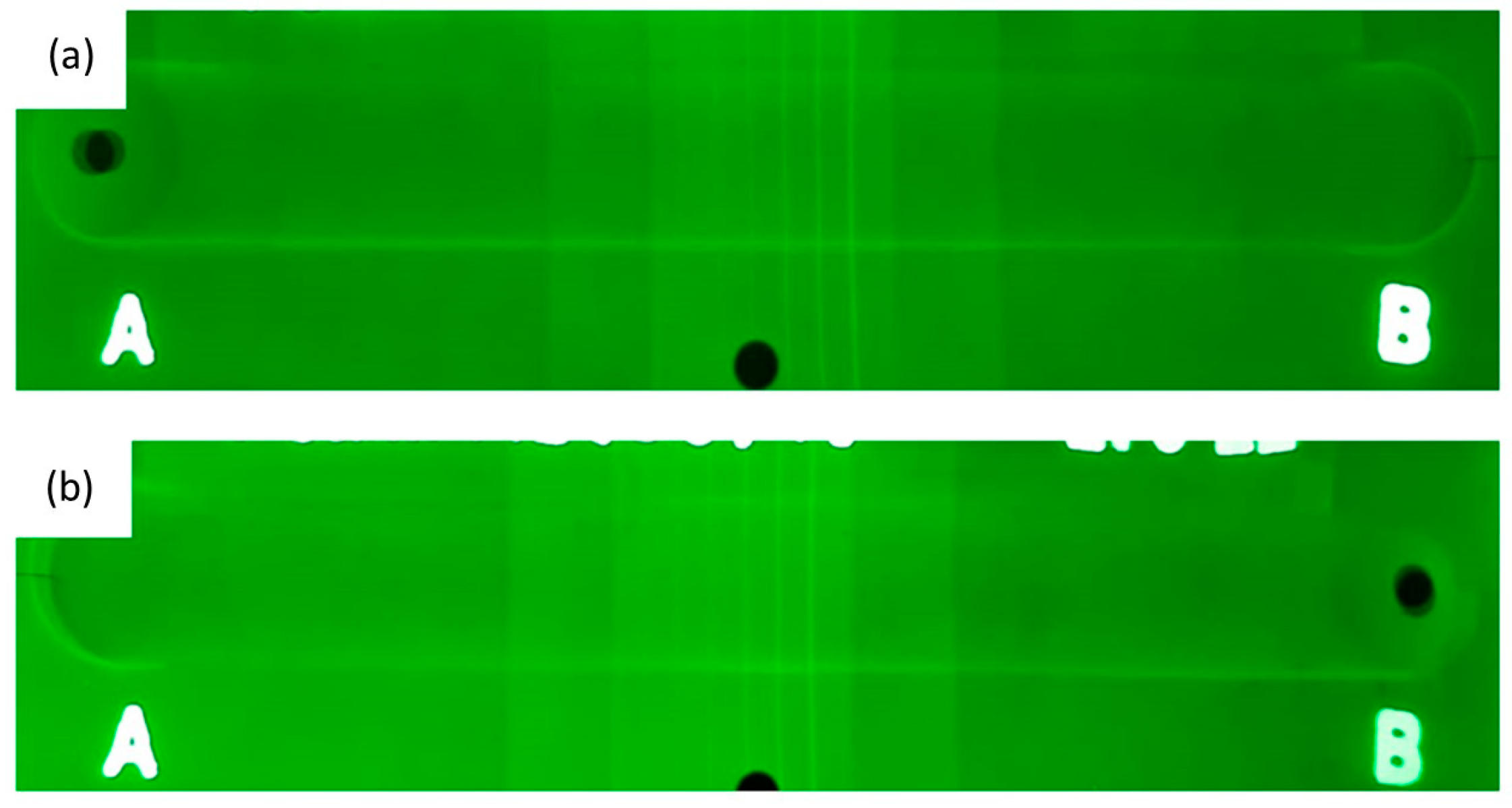

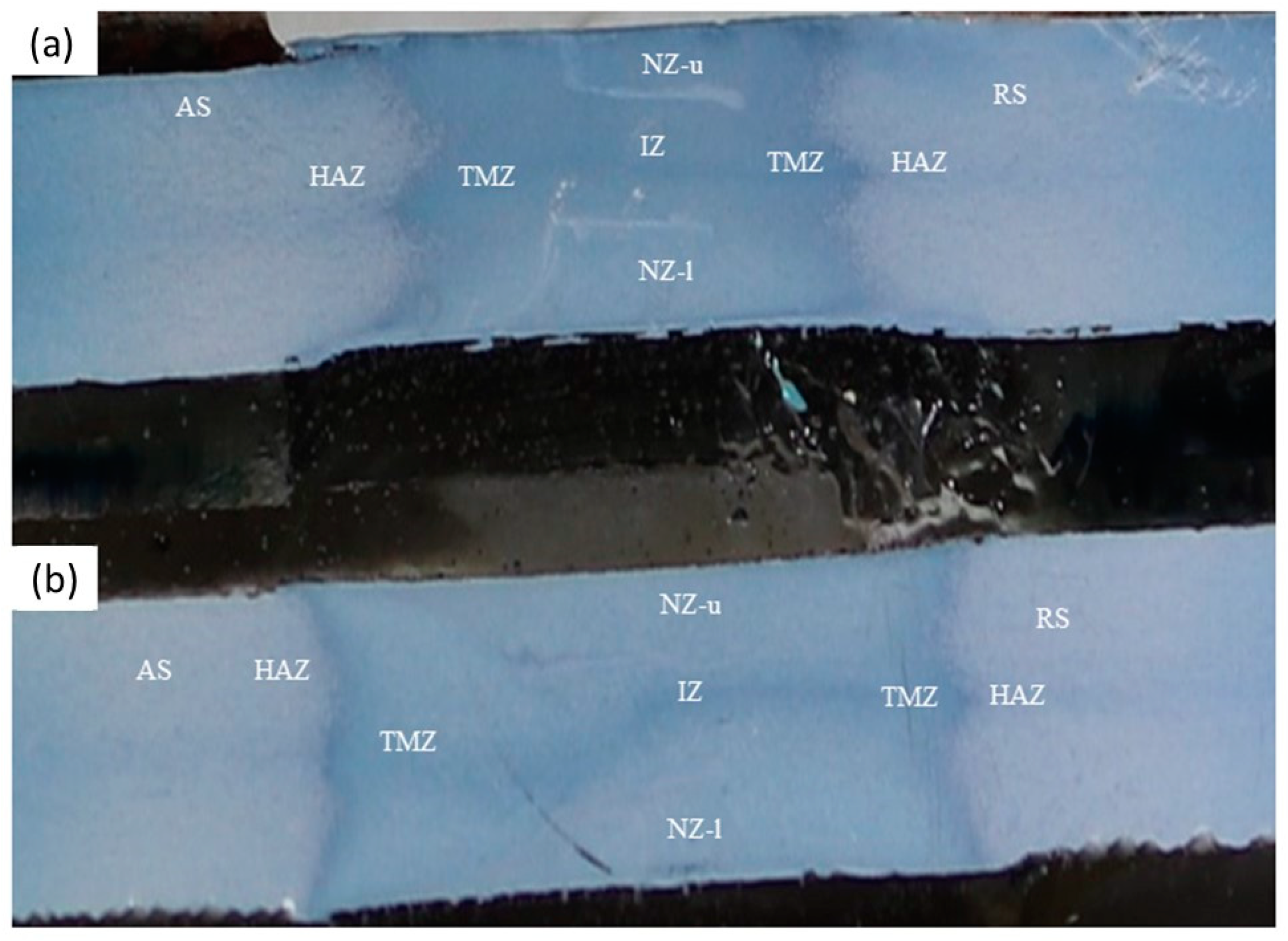

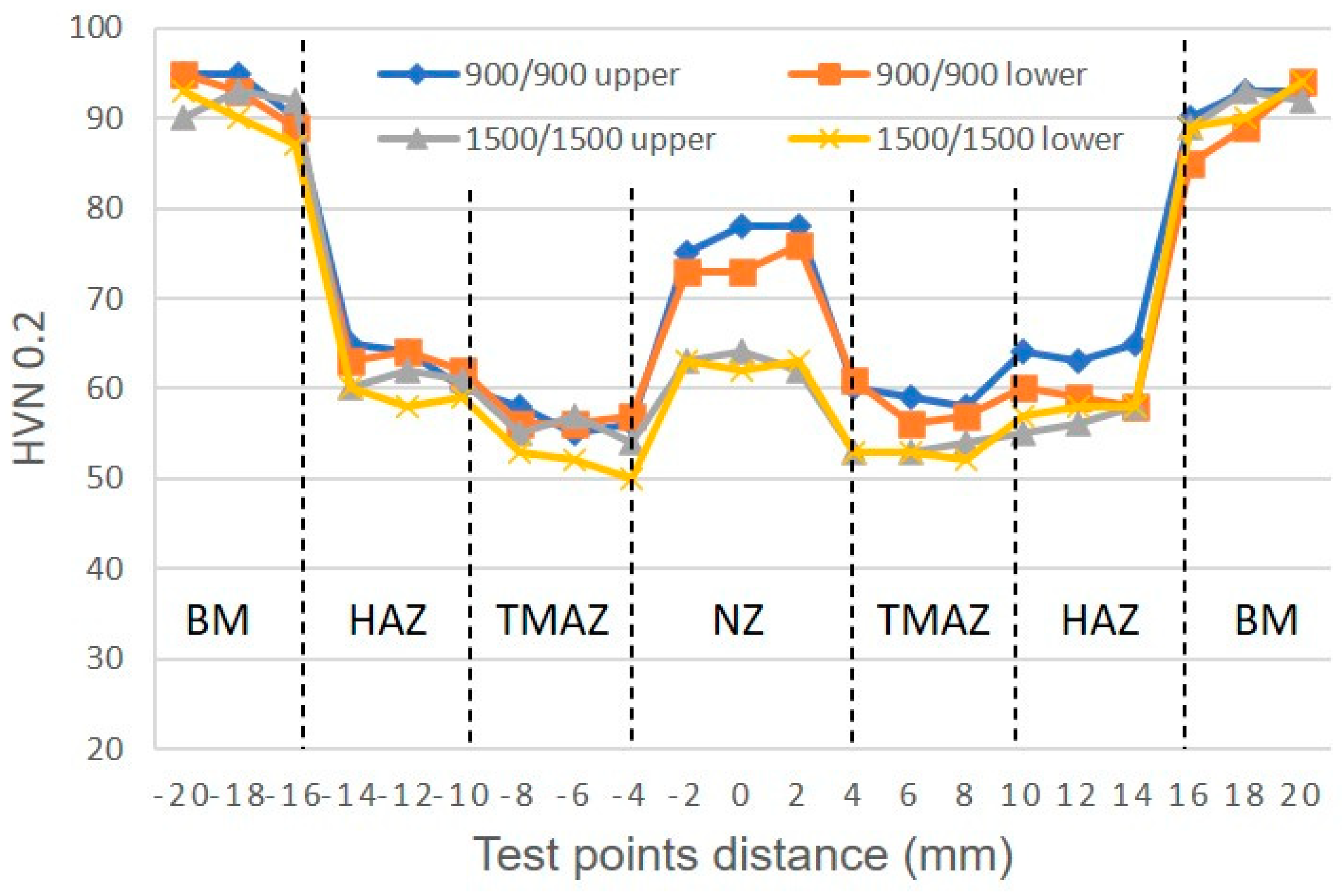

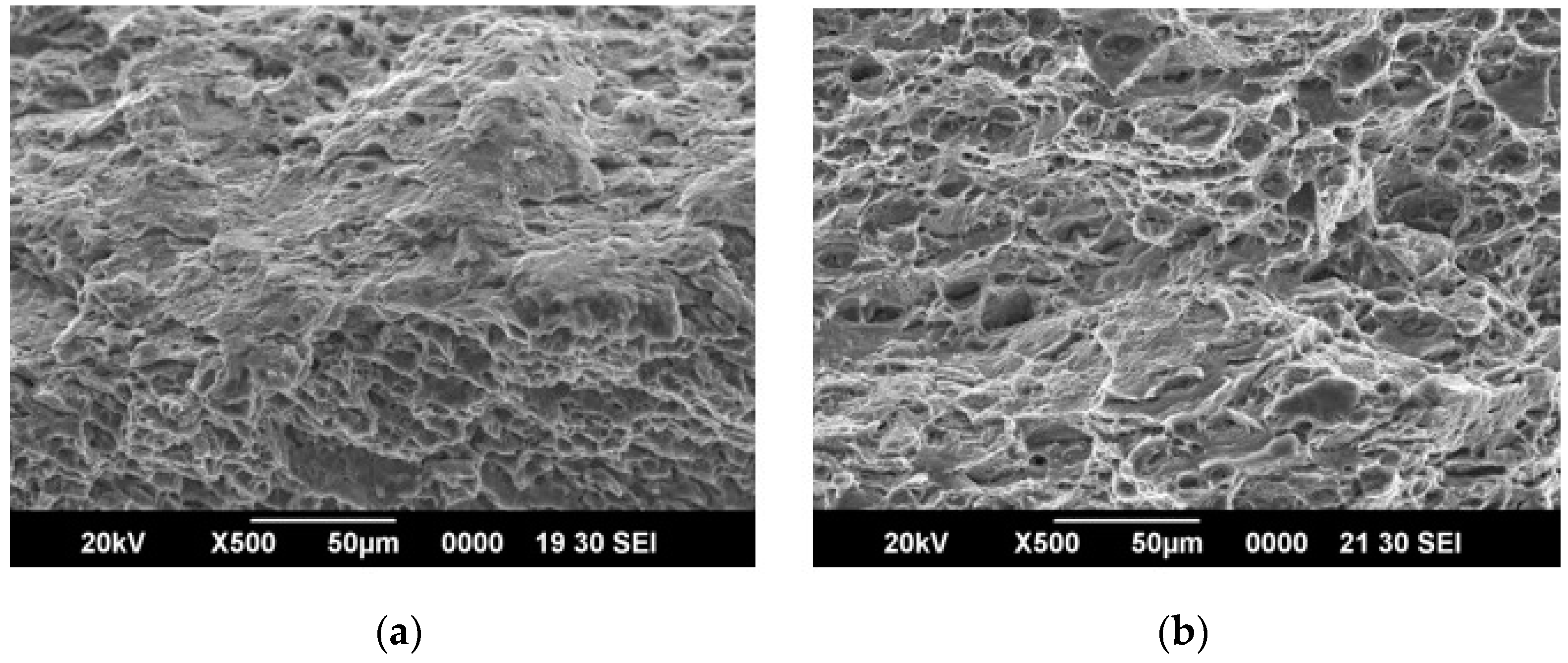

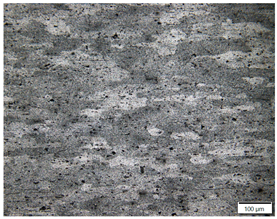

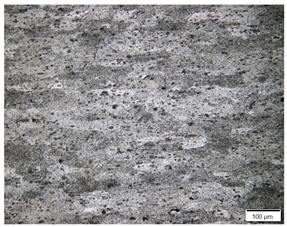

4. Characteristics of One-Step Double-Side FSW Joint

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, J.; Chen, H.; Li, Y.; Chen, J.; Zhang, Y.; Dave, K.; Huang, Y. Fuel consumption and exhaust emissions of diesel vehicles in worldwide harmonized light vehicles test cycles and their sensitivities to eco-driving factors. Energy Convers. Manag. 2019, 196, 605–613. [Google Scholar] [CrossRef]

- Krishna, G.V.T.N.; De, R.K.; Burman; Sekhar, B.V.; Rao, V.G. Numerical and experimental comparative study of Aluminum and hybrid mounting interfaces of launch vehicle avionics for weight reduction. Procedia Struct. 2019, 14, 820–829. [Google Scholar] [CrossRef]

- Sun, W.; Chen, X.; Wang, L. Analysis of Energy Saving and Emission Reduction of Vehicles Using Light Weight Materials. Energy Procedia 2016, 88, 889–893. [Google Scholar]

- Carlson, K.D.; Lin, Z.; Beckermann, C. Modeling the Effect of Finite-Rate Hydrogen Diffusion on Porosity Formation in Aluminum Alloys. Metal. Mater. Trans. B 2007, 38, 541–555. [Google Scholar] [CrossRef]

- Yan, B.; Gao, H.M.; Wu, L.; Ma, Z.H.; Cao, N. Influence of Plasma-MIG Welding Parameters on Aluminum Weld Porosity by Orthogonal Test. Trans. Nonferrous Met. 2010, 20, 8. [Google Scholar]

- Lee, P.D.; Chirazi, A.; See, D. Modeling Microporosity in Aluminum-Silicon Alloys: A Review Modeling Microporosity in Aluminum ± Silicon Alloys: A Review. J. Light Met. 2017, 5317, 15–30. [Google Scholar]

- Pakdil, M.; Cam, G.; Kocak, M.; Erim, S. Microstructural and Mechanical Characterization of Laser Beam Welded AA6056 Al-Alloy. Mater. Sci. Eng. A 2011, 528, 7350–7356. [Google Scholar] [CrossRef]

- Pastor, M.H.; Zhao, R.P.; Martukanitz, R.P.; Debroy, T. Porosity, Underfill and Magnesium Loss during Continuous Wave Nd:YAG Laser Welding of Thin Plates of Aluminum Alloys 5182 and 5754. Weld. J. 1999, 78, 207s–216s. [Google Scholar]

- Silva, C.L.M.D.; Scotti, A. The Influence of Double Pulse on Porosity Formation in Aluminum GMAW. J. Mater. Process. Technol. 2006, 171, 366–372. [Google Scholar] [CrossRef]

- Chen, C.; Gao, M.; Mu, H.; Zeng, X. Effect of kerf characteristics on weld porosity of laser cutting-welding of AA2219 aluminum alloy. Appl. Surf. Sci. 2019, 494, 1036–1043. [Google Scholar] [CrossRef]

- Chen, G.; Wang, B.; Mao, S.; Zhong, P.; He, J. Research on the “∞”-shaped laser scanning welding process for aluminum alloy. Opt. Laser Technol. 2019, 115, 32–41. [Google Scholar] [CrossRef]

- Cai, C.; He, S.; Chen, H.; Zhang, W. The influences of Ar-He shielding gas mixture on welding characteristics of fiber laser-MIG hybrid welding of aluminum alloy. Opt. Laser Technol. 2019, 113, 37–45. [Google Scholar] [CrossRef]

- Habibi, I.; Triyono, T.; Muhayat, N. A Review on Aluminum Arc Welding and It’s Problems. In Proceedings of the 6th International Conference and Exhibition on Sustainable Energy and Advanced Materials, Surakarta, Indonesia, 16–17 October 2019. [Google Scholar]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Stir Butt Welding. International Patent Application No. PCT/GB92/02203, 24 October 1995. [Google Scholar]

- He, X.; Gu, F.; Ball, A. A review of numerical analysis of friction stir welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef]

- Padhy, G.K.; Wu, C.S.; Gao, S. Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, J.F.; Ma, G.N.; Wu, L.H.; Zhang, X.M.; He, G.Z.; Xue, P.; Ni, D.R.; Xiao, B.L.; Wang, K.S.; et al. Microstructure and mechanical properties of double-side friction stir welded 6082Al ultra-thick plates. J. Mater. Sci. Technol. 2020, 41, 105–116. [Google Scholar] [CrossRef]

- Wernery, J.; Brunner, S.; Weber, B.; Knuth, C.; Koebel, M.M. Superinsulation Materials for Energy-Efficient Train Envelopes. Appl. Surf. Sci. 2021, 11, 2939. [Google Scholar] [CrossRef]

- The Simultaneous Use of Two or More Friction Stir Welding Tools. Available online: https://www.twi-global.com/technical-knowledge/published-papers/the-simultaneous-use-of-two-or-more-friction-stir-welding-tools-january-2005 (accessed on 24 May 2023).

- Smolin, A.Y.; Shilko, E.V.; Astafurov, S.V.; Kolubaev, E.A.; Psakhie, S.G. Understanding the mechanisms of friction stir welding based on computer simulation using particles. Def. Technol. 2018, 14, 643–656. [Google Scholar] [CrossRef]

- Boz, M.; Kurt, A. The influence of stirrer geometry on bonding and mechanical properties in friction stir welding process. Mater. Des. 2004, 25, 343–347. [Google Scholar] [CrossRef]

- Prabha, K.A.; Putha, P.K.; Prasad, B.S. Effect of tool rotational speed on mechanical properties of aluminium alloy 5083 weldments in friction stir welding. Mater. Today Proc. 2018, 5, 18535–18543. [Google Scholar] [CrossRef]

- Palani, K.; Elanchezhian, C.; Ramnathb, B.V.; Bhaskarc, G.B.; Naveen, E. Effect of pin profile and rotational speed on microstructure and tensile strength of dissimilar AA8011 and AA6061-T6 friction stir welded aluminum alloys. Mater. Today Proc. 2018, 5, 24515–24524. [Google Scholar] [CrossRef]

- Mastanaiah, P.; Sharma, A.; Madhusudhan, G. Role of hybrid tool pin profile on enhancing welding speed and mechanical properties of AA2219-T6 friction stir welds. J. Mater. Process. Technol. 2018, 18, 30101–30108. [Google Scholar] [CrossRef]

- Hejazi, I.; Mirsalehi, S.E. Effect of pin penetration depth on double-sided friction stir welded joints of AA6061-T913 alloy. Trans. Nonferrous Met. Soc. China 2016, 26, 676–683. [Google Scholar] [CrossRef]

- Hendrato; Jamasri; Triyono; Puspitasari, P. Mechanical properties and microstructure evolution of double-side friction stir welding AA6061-T6. Key Eng. 2022, 935, 73–81. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Sued, K.; Clucas, D. Development of Metallographic Etchants for the Microstructure Evolution of A6082-T6 BFSW Welds. Metals 2017, 7, 423–439. [Google Scholar] [CrossRef]

- Weng, F.; Liu, Y.; Chew, Y.; Lee, B.Y.; Ng, F.L.; Bi, B. Double-side friction stir welding of thick magnesium alloy: Microstructure and mechanical properties. Sci. Technol. Weld. Join. 2020, 25, 359–368. [Google Scholar] [CrossRef]

- Zhou, M.; Morisada, Y.; Fujii, H. Effect of Ca addition on the microstructure and the mechanical properties of asymmetric double-side friction stir welded AZ61 magnesium alloy. J. Magnes. Alloy. 2020, 8, 91–102. [Google Scholar] [CrossRef]

- Kumar, R.; Varghese, S.; Sivapragash, M. A comparative study of the mechanical properties of single- and double-side friction stir welded aluminium joints. Procedia Eng. 2012, 38, 3951–3961. [Google Scholar] [CrossRef]

- Xu, W.; Wang, H.; Luo, Y.; Li, W.; Fu, M.W. Mechanical behavior of 7085-T7452 Aluminum alloy thick plate joint produced by double-side friction stir welding: Effect of welding parameters and strain rates. J. Manuf. Process. 2018, 35, 261–270. [Google Scholar] [CrossRef]

- Garg, A.; Raturi, M.; Garg, A.; Bhattacharya, A. Microstructure evolution and mechanical properties of double-side friction stir welding between AA6061-T6 and AA7075-T651. CIRP J. Manuf. Sci. Technol. 2020, 31, 431–438. [Google Scholar] [CrossRef]

- Thakur, A.; Sharma, V.; Bhadauria, S.S. Effect of tool tilt angle on weld joint strength and microstructural characterization of double-side friction stir welding of AZ31B magnesium alloy. CIRP J. Manuf. Sci. Technol. 2021, 35, 132–145. [Google Scholar] [CrossRef]

- Mirzaei, M.H.; Asadi, P.; Fazli, A. Effect of Tool Pin Profile on Material Flow in Double Shoulder Friction Stir Welding of AZ91 Magnesium Alloy. Int. J. Mech. Sci. 2020, 183, 105775. [Google Scholar] [CrossRef]

- Ke, W.C.; Oliveira, J.P.; Ao, S.S.; Teshome, F.B.; Chen, L.; Peng, B.; Zeng, Z. Thermal process and material flow during dissimilar double-side friction stir spot welding of AZ31/ZK60 magnesium alloys. J. Mater. Res. Technol. 2022, 17, 1942–1954. [Google Scholar] [CrossRef]

- Nosratia, H.G.; Yazdanib, N.M.; Khoran, M. Double-side friction stir welding of AA 2024-T6 joints: Mathematical modeling and optimization. CIRP J. Manuf. Sci. Technol. 2022, 36, 1–11. [Google Scholar] [CrossRef]

- Longhurst, W.R.; Strauss, A.M.; Cook, G.E.; Cox, C.D.; Hendricks, C.E.; Gibson, B.T.; Dawant, Y.S. Investigation of Force Controlled Friction Stir Welding for Manufacturing and Automation. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2010, 224, 937–949. [Google Scholar] [CrossRef]

- Kumar, S.; Katiyar, J.K.; Kesharwani, G.S.; Roy, B.S. Microstructure, Mechanical, and Force-torque Generation Properties of Friction Stir Welded Third Generation Al/Li Alloy at Higher Traverse Speed. Mater. Today Commun. 2023, 35, 106084–106093. [Google Scholar] [CrossRef]

- Guan, W.; Zhao, Y.; Liu, Y.; Kang, S.; Wang, D.; Cui, L. Force data-driven machine learning for defects in friction stir welding. Scr. Mater. 2022, 217, 114765. [Google Scholar] [CrossRef]

- Eslamia, S.; Mourao, L.; Viriato, N.; Tavares, P.J.; Moreira, P.M.G.P. Multi-axis force measurements of polymer friction stir welding. J. Mater. Process. Technol. 2018, 256, 51–56. [Google Scholar] [CrossRef]

- Guan, W.; Li, D.; Cui, L.; Wang, D.; Wu, S.; Kang, S.; Wang, J.; Mao, L.; Zheng, X. Detection of tunnel defects in friction stir welded aluminum alloy joints based on the in-situ force signal. J. Manuf. Process. 2021, 71, 1–11. [Google Scholar] [CrossRef]

- Franke, D.; Rudraraju, S.; Zinn, M.; Pfefferkorn, F.E. Understanding process force transients with application towards defect detection during friction stir welding of aluminum alloys. J. Manuf. Process. 2020, 54, 251–261. [Google Scholar] [CrossRef]

- Morkhade, S.G.; Gupta, L.M. Effect of load height on buckling resistance of steel beams. Procedia Eng. 2013, 51, 151–158. [Google Scholar] [CrossRef]

- Priyasudana, D.; Crisdion, S.A.; Puspitasari, P.; Triyono; Jamasri; Andoko; Pramono, D.D. Double side friction stir welding effect on mechanical properties and corrosion rate of aluminum alloy AA6061. Heliyon 2023, 9, e13366. [Google Scholar] [CrossRef] [PubMed]

- Muhayat, N.; Harjono, M.S.; Depari, Y.P.D.S.; Prabowo, A.R.; Triyono; Putri, E.D.W.S.; Tuswan, T. Friction stir welded AA5052-H32 under dissimilar pin profile and preheat temperature: Microstructural observations and mechanical properties. Metals 2022, 12, 4. [Google Scholar] [CrossRef]

- Ardika, R.D.; Triyono, T.; Muhayat, N.; Triyono. A review porosity in aluminum welding. Procedia Struct. 2021, 33, 171–180. [Google Scholar] [CrossRef]

- Abnar, B.; Kazeminezhad, M.; Kokab, A.H. Effects of heat input in friction stir welding on microstructure and mechanical properties of AA3003-H18 plates. Trans. Nonferrous Met. Soc. China 2015, 25, 2147–2155. [Google Scholar] [CrossRef]

- Ogunsemi, B.T.; Abioye, T.E.; Ogedengbe, T.I.; Zuhailawati, H. A review of various improvement strategies for joint quality of AA 6061-T6 friction stir weldments. J. Mater. Res. Technol. 2021, 11, 1061–1089. [Google Scholar] [CrossRef]

- Ilman, M.N.; Kusmono; Iswanto, P.T. Fatigue crack growth rate behaviour of friction-stir aluminium alloy AA2024-t3 welds under transient thermal tensioning. Mater. Des. 2013, 50, 235–243. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. C 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Konovalenko, I.; Maruschak, P.; Brezinová, J.; Brezina, J. Morphological Characteristics of Dimples of Ductile Fracture of VT23M Titanium Alloy and Identification of Dimples on Fractograms of Different Scale. Materials 2019, 12, 2051. [Google Scholar] [CrossRef] [PubMed]

| Element | Al | Si | Cu | Fe | Mn | Mg | Ti | Zn |

|---|---|---|---|---|---|---|---|---|

| wt% | 97.19 | 0.63 | 0.24 | 0.52 | 0.08 | 0.94 | 0.06 | 0.04 |

| 900/900 rpm | 1500/1500 rpm |

|---|---|

|  |

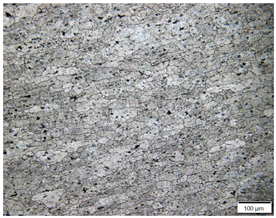

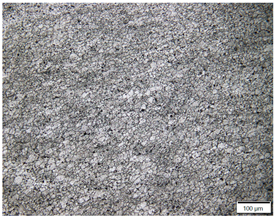

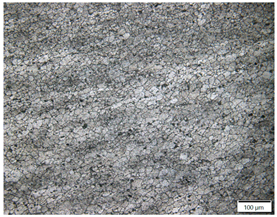

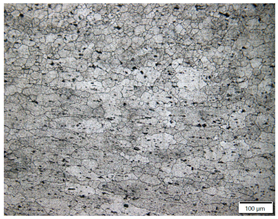

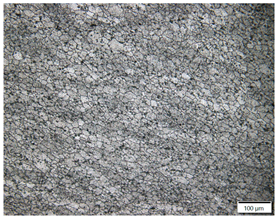

| HAZ (heat-affected zone) | |

|  |

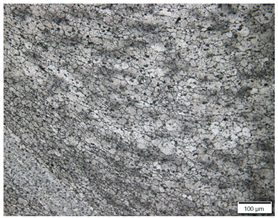

| TMAZ (thermo-mechanically affected zone) | |

|  |

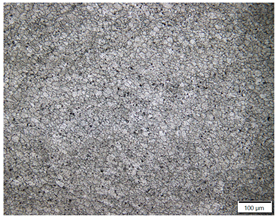

| NZ-U (nugget zone—upper) | |

|  |

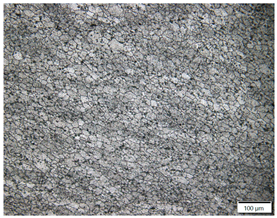

| NZ-L (nugget zone—lower) | |

|  |

| IZ (interaction zone) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhayat, N.; Putri, E.D.W.S.; Hendrato; Depari, Y.P.D.S.; Puspitasari, P.; Jamasri; Prabowo, A.R.; Triyono. Apparatus Design of One-Step Double-Side Friction Stir Welding for Aluminum Plates. Designs 2023, 7, 75. https://doi.org/10.3390/designs7030075

Muhayat N, Putri EDWS, Hendrato, Depari YPDS, Puspitasari P, Jamasri, Prabowo AR, Triyono. Apparatus Design of One-Step Double-Side Friction Stir Welding for Aluminum Plates. Designs. 2023; 7(3):75. https://doi.org/10.3390/designs7030075

Chicago/Turabian StyleMuhayat, Nurul, Ericha Dwi Wahyu Syah Putri, Hendrato, Yohanes Pringeten Dilianto Sembiring Depari, Poppy Puspitasari, Jamasri, Aditya Rio Prabowo, and Triyono. 2023. "Apparatus Design of One-Step Double-Side Friction Stir Welding for Aluminum Plates" Designs 7, no. 3: 75. https://doi.org/10.3390/designs7030075

APA StyleMuhayat, N., Putri, E. D. W. S., Hendrato, Depari, Y. P. D. S., Puspitasari, P., Jamasri, Prabowo, A. R., & Triyono. (2023). Apparatus Design of One-Step Double-Side Friction Stir Welding for Aluminum Plates. Designs, 7(3), 75. https://doi.org/10.3390/designs7030075