1. Introduction

Transportation is responsible for about 22% of CO

2 emissions worldwide, and within this, 74% is produced by road vehicles [

1]. Electrification of transportation has been considered an effective pathway to cut these emissions [

2]. Electric vehicles (EVs) have gained increasing attention over the past years, and large funding has been secured worldwide to improve their marketability [

3]. There have also been political efforts to improve their market share. For instance, the European Commission (EU) has announced an effective ban on the sale of internal combustion engine cars effective from 2035 [

4]. Compared to internal combustion engine (ICE)-based cars that have been driven on roads for decades with technology and reliability that have been proven, the EVs are a new technology; for them, meeting various functional safety requirements is critical. Therefore, it is also important to monitor their performance continuously.

In EV drivetrains, energy/power will be supplied from an energy storage system (ESS), and it will go through several conversion units to transform electric power from DC to AC (motor drive/inverter) and electric power to mechanical power (electric motor), and to adjust the mechanical torque at the wheels through the transmission system [

5]. The drivetrain components work in synergy to propel the vehicle and to ensure road safety; it is worthwhile to monitor them continuously. The performance and capability of drivetrain components can be affected by several factors, e.g., the environmental and driving conditions such as air temperature or driving altitude that could cause lower cooling effectiveness, aging and degradation, and early failures [

6,

7,

8]. The ESS can also be impacted by different charging/discharging rates during EV acceleration and/or braking and by the depth-of-discharge (DoD), e.g., when it is discharged to very low state-of-charge (SoC) levels. At the system level, it is thus important to operate the drivetrain within boundaries that will ensure the safety of all components. The drivetrain loadability should be determined based on the weakest component in the system. This information can be used to determine the maneuverability of the EV on the road, e.g., if the driver needs to adopt a particular driving mode to maintain safety. This paper puts forward the concept of “state-of-function,” or SoF, for the EV drivetrain. Here, the drivetrain SoF is defined as a dynamic limit that, if respected by the electronic control unit (ECU), will ensure the safety of all individual components concurrently. While having this system-level target, in this paper, we consider a bottom-up approach wherein monitoring algorithms based on the state of the art (SotA) and some of the authors’ previous research work are developed for individual components to estimate their state-of-power (SoP). A brief review of the SotA is provided in the following.

Several methods have been proposed in the literature regarding state estimation in individual EV components, e.g., Lithium-ion (Li-ion) batteries, supercapacitors, hybrid battery/supercapacitor systems, and inverters. For each component, the SoP should be estimated within a pre-determined horizon, and the idea is to make sure that with the obtained discharge power limits, the safety-related thresholds of the components such as the voltage, current, or SoC limits will not be violated. Regarding Li-ion battery power prediction, a well-established method has been proposed in [

9], where power limits are calculated based on the voltage, current, and SoC limits, as well as simple battery equivalent circuit models (ECMs). This approach has been used along with other SoC estimation algorithms to improve the prediction accuracy, e.g., by using the Kalman filter [

10], the unscented Kalman filter (UKF) [

11,

12], and the extended Kalman filter (EKF) [

13]. Battery power prediction based on a predictive nonlinear model has been obtained in [

14], wherein the limits on the operating temperature of the battery have been considered in addition to the limits on voltage, current, and SoC. In [

15], an extremum learning algorithm has been used to estimate the SoP based on a first-order RC model. In [

16], a long-term power demand prediction model is established and combined with a two-step state estimation algorithm to estimate the SoP. Similar algorithms have also been applied to predict the SoP in supercapacitor-based ESSs [

1,

17].

Derating electrical motors and motor drives based on power limits has been discussed in various studies in the literature. The existing derating methods are normally applied in two different scenarios: 1—under stressed operating conditions of the converter/motor, e.g., when cooling is insufficient [

18,

19]; 2—under abnormal conditions, e.g., when one/some of the switches in the DC–AC motor drive fails, and the converter has to be operated in a fault-tolerant mode [

20,

21,

22]. These methods include techniques, for example, to directly detect a faulty operation such as an open-switch fault in the motor drive or to estimate the junction temperatures of an insulated gate bipolar transistor (IGBT) or diodes in the converter as a key signature to detect the loadability [

23]. The main aspect with which this paper distinguishes itself is the system-level estimation of the drivetrain cyclability using a new index, herein named the drivetrain’s SoF. The main contributions of this paper are listed in the following:

This paper extends the definition of the SoF for the whole EV drivetrain and estimates it at the system level (traditionally SoF has been used only with electrochemical batteries [

24] and supercapacitors [

25,

26,

27]). The SoF determines the maximum power and torque that can be transmitted to EV wheels such that the safety constraints of individual components are respected.

According to the real-time value of the estimated EV SoF and the real-time road load conditions, two derating schemes are proposed, namely the adaptive cruise control and adaptive pedal sensitivity adjustment. The derating schemes provide safer driving conditions for the system components and the whole EV.

The SoF estimation subroutine and the derating schemes are designed and implemented as part of an efficient online recommender system, which can be embedded into the advanced driver assistant system (ADAS) of the EV to provide better intelligence, autonomy, and flexibility. When necessary, the proposed recommender system interacts with the driver and may recommend a particular performance mode depending on recent state estimation results.

The rest of this paper is structured as follows: In

Section 2, the component-level state estimations and related flowcharts and algorithms are briefly explained. The focused approach of the paper for state estimation at the system level is described in

Section 3,

Section 4 and

Section 5. In

Section 3, the estimation of the SoF of the EV is discussed.

Section 4 deals with the simulation model of the EV and related kinematics for the estimation of the road-load power demand. In

Section 5, the derating schemes are presented, and the design and implementation of the proposed recommender system in the STATEFLOW

© are obtained. The simulation results of the proposed recommender system are provided and discussed in

Section 6. Finally, in

Section 7, the paper is concluded.

2. Component-Level State Estimation

This section discusses the utilized algorithms for state estimation at the component level, and a hybrid battery–supercapacitor ESS was considered as the use case. The usefulness of hybrid storage systems in the automotive context has been demonstrated in a large body of work, e.g., [

28,

29].

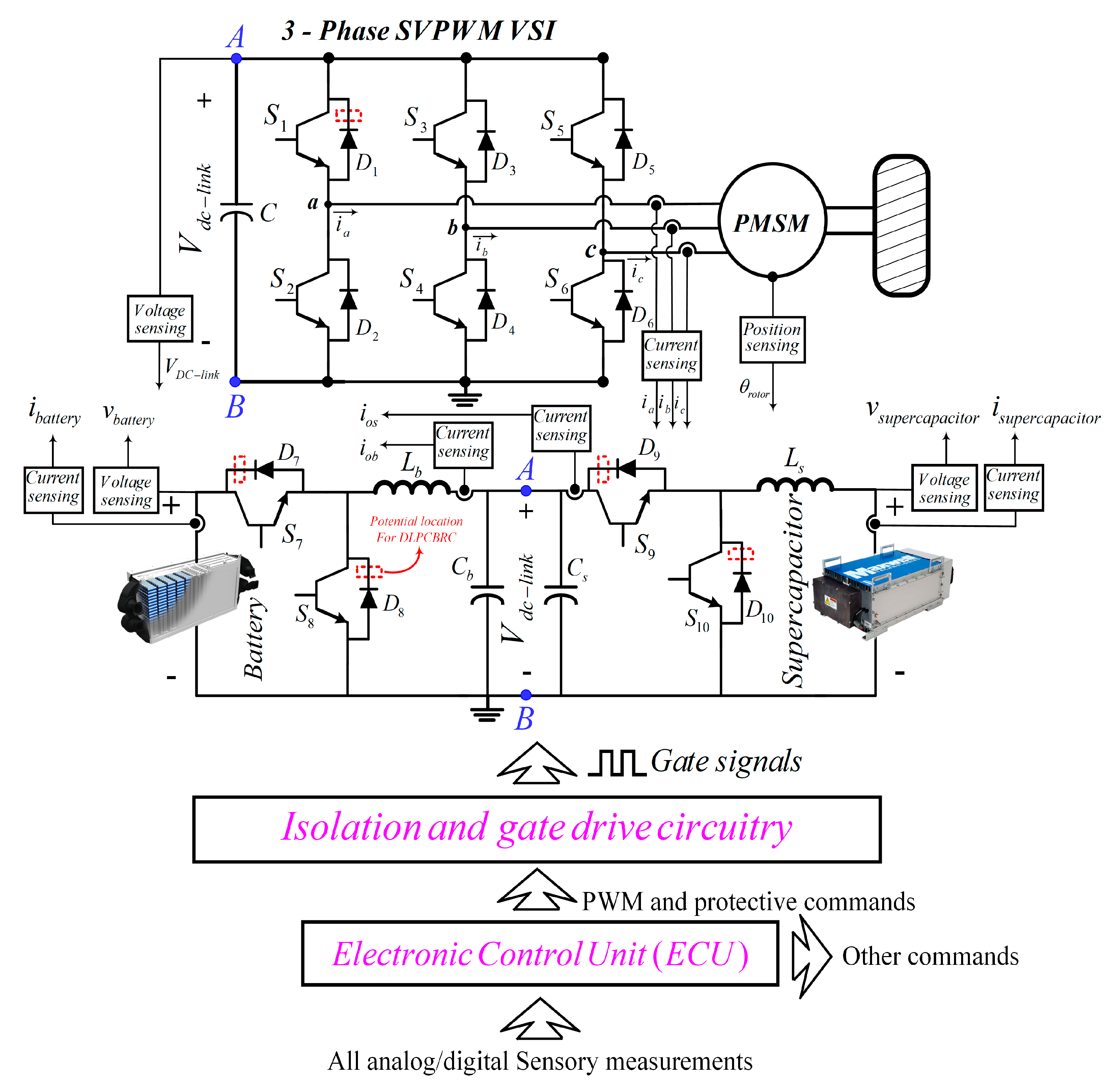

The block diagram of the EV drivetrain, including the ESSs, motor drive, DC–DC converters, electrical motor, ECU, etc., is shown in

Figure 1. As seen, it was assumed that the EV is powered using a hybrid ESS, which is a combination of the battery and supercapacitor, a three-phase two-level inverter, and a permanent-magnet synchronous motor (PMSM). The hybrid ESS usually requires an interfacing power electronics converter to connect the battery and supercapacitor. A complete review of different topologies for hybrid ESSs can be found in the authors’ previous work [

5]. It was also assumed that in the hybrid ESS, the battery and supercapacitor are both connected to the DC link of the motor drive through two different bidirectional DC–DC converters. This structure provides excellent flexibility for sharing power between the individual ESSs during the acceleration or regenerative braking of the EV. This topology was used as an example, but the proposed concept must similarly work for other topologies. For example, an alternative topology can be to directly connect the battery to the DC link, and the supercapacitor bank can be interfaced with the DC link via a DC–DC converter. To build upon our previous work and facilitate the simulation work, we have considered converter monitoring techniques proposed in our earlier papers [

21,

23,

30]. Nevertheless, other SoP estimation algorithms can be used for the component-level estimation phase.

In addition, it was assumed that the battery has a higher voltage profile, and the supercapacitor has a lower voltage profile than the voltage of the DC link. Therefore, the buck-boost converter of the battery is connected such that it works in the buck mode during normal operation mode, and it will be operated in the boost mode when the EV is braking (or coasting) to harvest the regenerative braking energy. On the other hand, the supercapacitor converter operates in the boost mode during normal operating modes and switches to the buck mode during braking (or coasting) occasions.

All estimation algorithms were embedded in the ECU of the EV. The core element of the ECU is a microcomputer with a processing capability reaching 2.5 GHz (an example is Tesla’s AMD Ryzen YE180FC3T4MFG with 2.8 GHz), which enables real-time parallel execution of different sophisticated estimation algorithms. The ECUs are also equipped with Flash, SRAM, and EEPROM memories, which enable downloading bulky codes in the ECU and buffering a large amount of data during the execution of the codes. The ECU also comes with embedded input/output (I/O) digital and analog channels for the supply, reading of the sensory measurements, control commands for the drive and actuators, etc. The sensory measurements in the whole EV drivetrain include the voltage and current of the batteries and supercapacitors, PMSM three-phase currents, voltage and current measurements of the DC–DC converters, rotor position reading by the encoder (or three-phase Hall-effect sensors), DC-link voltage, reference speed and commands from the acceleration and braking pedals, inverter signals, the output voltage of the Rogowski Coils (please refer to [

23] regarding the method for power-loss estimation algorithm), the linear speed of the EV through speed sensor, road angle through gyroscope, etc.

In

Figure 1,

is the DC-link voltage;

ibattery and

vbattery are the current and voltage of the battery ESS;

isupercapacitor and

vsupercapacitor are the current and voltage of the supercapacitor ESS;

ia,

ib, and

ic are the motor phase currents;

ios and

iob are the converter currents; S

1-S

10 and D

1-D

10 are the IGBT switches and diodes in the converters;

C denotes the DC-link capacitance;

Lb and

Ls denote the converter inductances; and

is the rotor position in the PMSM. The voltage-source inverter (VSI) is operated based on the space-vector pulse-width modulation (SVPWM).

The following subsections introduce algorithms that were used to obtain the component-level state estimation.

2.1. Supercapacitor and Battery SoP Estimation and Monitoring

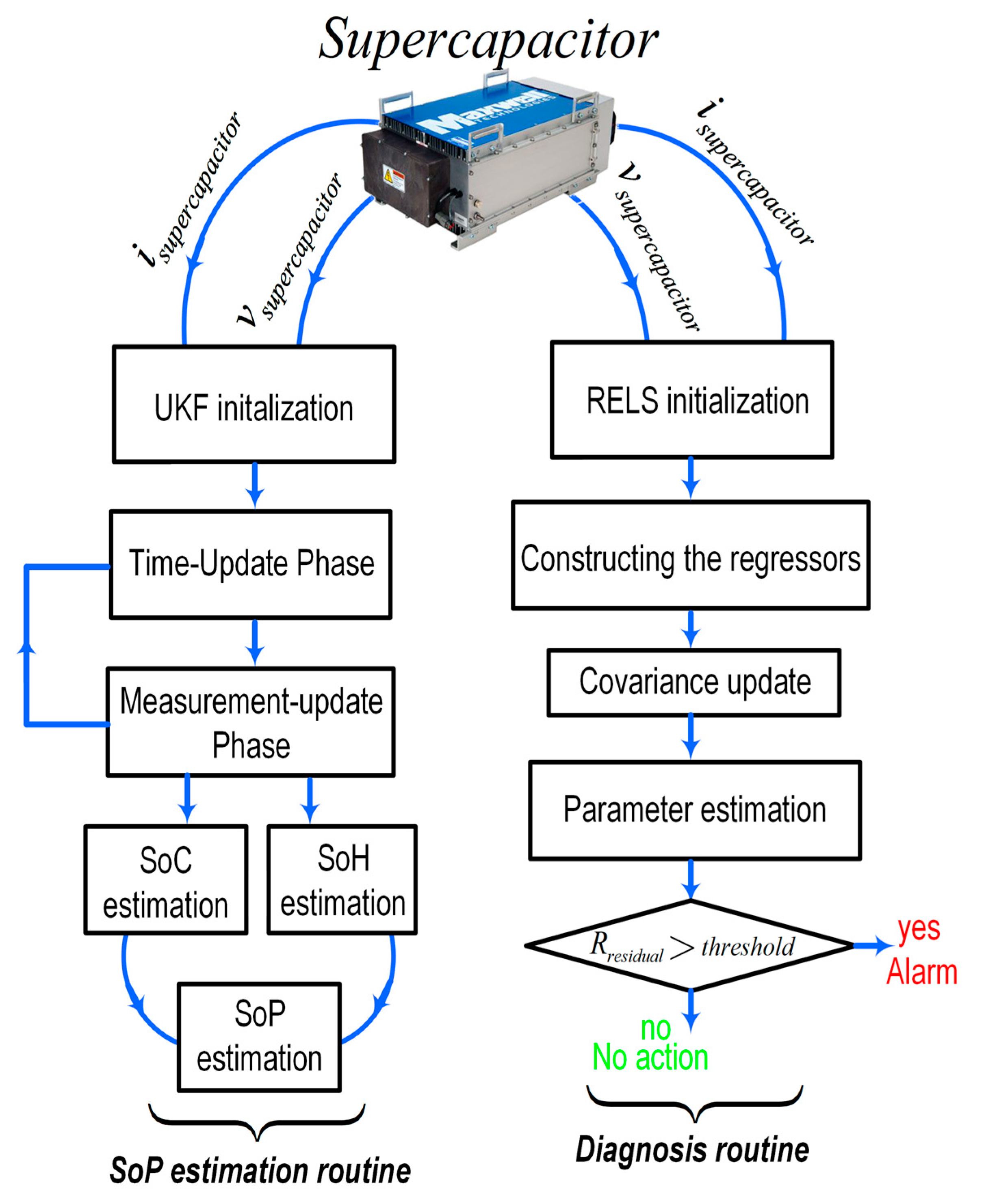

Concerning the supercapacitor ESS, two existing estimation algorithms were used: 1—the method proposed in [

25], wherein a co-estimation algorithm based on the supercapacitor nonlinear model (three-branch RC ECM) and UKF was used for joint accurate estimation of state-of-health (SoH) and SoC, and 2—the method presented in [

27], wherein a linear supercapacitor model and a recursive extended least-squares (RELS) algorithm were used for obtaining an estimation of aging parameters for diagnosis purpose only. As shown in

Figure 2, the two estimation algorithms run in parallel but with different sample times for SoH and SoC estimations. The estimated SoH and SoC are then combined with the SoP estimation method presented in [

17] to estimate the dynamic power limits of the supercapacitor. The SoP of the supercapacitor determines the maximum available discharge power that can be safely released to the drivetrain.

In the case of the battery ESS, the critical states, including the battery SoC, SoH, and SoP were co-estimated using the EKF and RLS algorithms, as described in detail in [

31]. For SoC and SoH estimation, a large number of studies have been done, which can be reused in this context [

32].

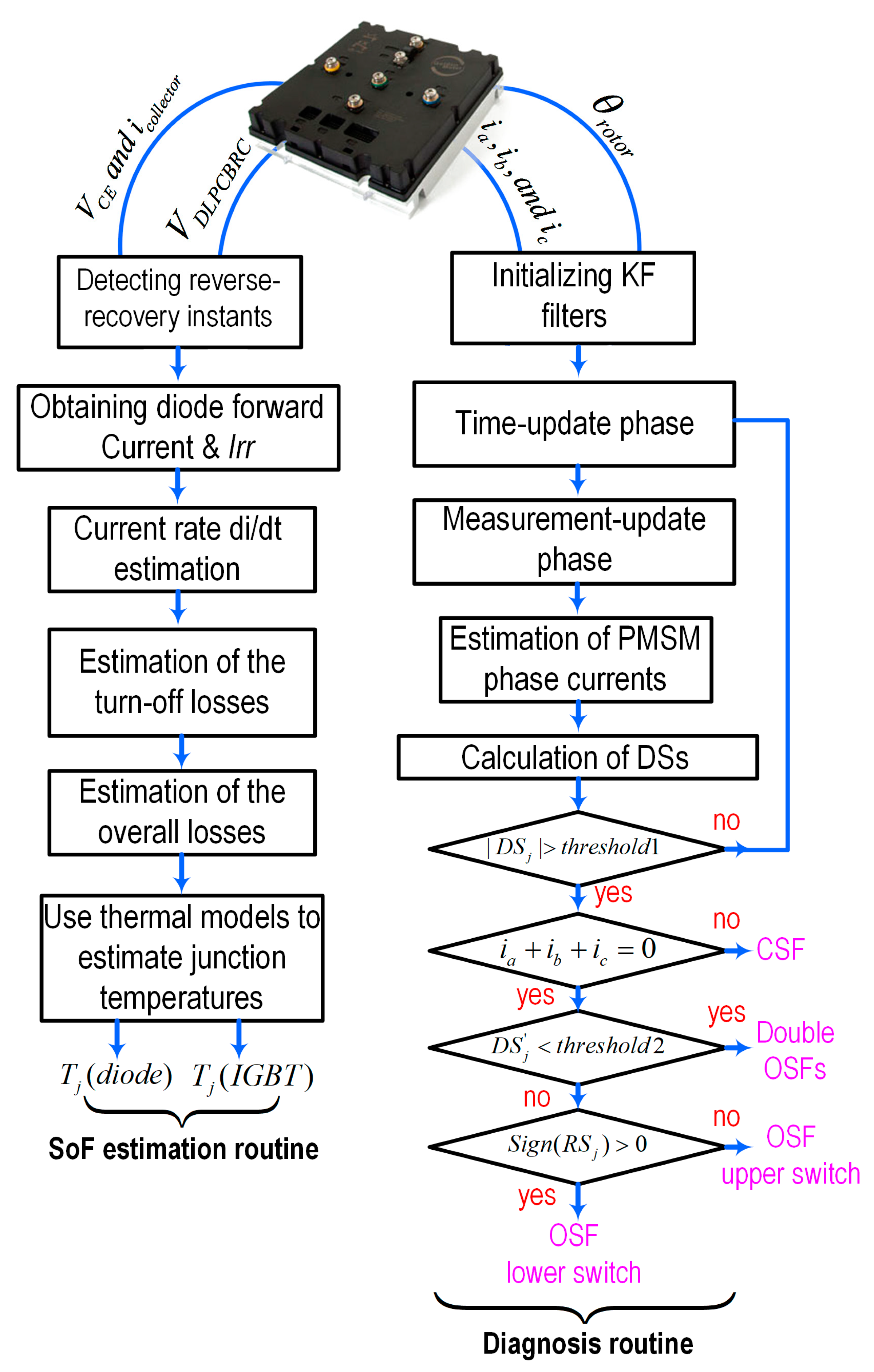

2.2. Performance Monitoring of the Converters

Normally, the DC–DC converters and motor drives in the EV drivetrain are sized according to the maximum power that can be supplied by the ESSs. The systems are usually designed to tolerate a certain level of overload. However, there exist several conditions under which the components might not be able to reach their expected performance characteristics, e.g., due to aging, cooling problems, or failures. For example, in certain driving conditions, such as driving at a high altitude and temperature (where the cooling system becomes less efficient) with maximum road load conditions, the components might not be able to work as they are expected to. Therefore, it is probable that the power electronics circuits cannot handle the maximum available power of the ESSs. In this regard, a determining factor is the junction temperature of the semiconductor switches. When the junction temperature reaches a maximum safety threshold, a protection signal is sent to the motor drive to take immediate safety action (note that this is apart from the short-circuit condition, which requires more sophisticated protection methods). Therefore, the motor drive should be derated according to the estimated junction temperature to keep the power module in a safe operating region (a safety region before the maximum threshold must be usually maintained for safety reasons). The utilized derating scheme determines the SoP of the motor drive, i.e., it determines the maximum power that can be handled by the motor drive for energizing the PMSM. In this paper, it was assumed that the EV is equipped with a PMSM controlled with a SVPWM-field-oriented control (FOC) and a fixed switching frequency. The junction temperature can be reduced by decreasing the power losses of the power modules (to mitigate heating the modules) by either lowering the switching frequency or reducing the load power. In this regard, for example, the active thermal control approach proposed in [

33] can be used. However, since thermal control is not within the scope of this work, we only assumed that the motor drive is 100% functional when its junction temperature is below the derating level. Otherwise, the motor drive would linearly be derated by 1% for each degree Celsius above the derating level (a similar approach has been used by Hyundai Motors

© [

34]). However, it would be worthwhile to take advanced derating schemes into account for the estimation of the motor drive SoF. In addition to junction temperature estimation, an effective open-circuit fault (OCF) or open-switch fault (OSF) diagnosis method, which is based on the authors’ previous contributions, was considered in this paper. The diagnosis algorithm runs in parallel with the temperature estimation subroutine for the monitoring of the power module. The flowchart of the whole algorithm for the power module is depicted in

Figure 3.

2.3. Derating of the PMSM

Contrary to the motor drive and DC–DC converters, which are composed of sensitive IGBT modules with fast temperature rise time, the thermal time constants of the electrical PMSMs are relatively high. Even in overload or harsh conditions, the temperature in the windings of the PMSM will not suddenly increase (the thermal constant of the PMSM depends on the size of the motor and its insulation class). Therefore, the PMSM is not often a limiting component in converting the ESSs’ electrical power to the required mechanical torque. Nonetheless, it is necessary to derate the PMSM under certain circumstances, e.g., when the cooling system is not effective due to aggressive operating conditions such as very high temperatures or high altitudes, which result in low air pressure. Currently, many of the PMSM manufacturers provide the derating information versus the temperature and altitude for different motors sized from 1 to 200 horsepower in their application manuals. For instance,

Table 1 shows the amplitude and ambient reduction factors for SIEMENS

© electrical motors. In our work, this information was simply incorporated as a 3-D lookup table for real-time estimation of the SoP of the PMSM.

3. System-Level Estimation of the SoF

As mentioned before, the main contribution of this work is to extend the definition of the SoF for the whole EV drivetrain by concurrently considering all components. Real-time knowledge of the SoF of the EV helps the driver to understand the overall functionality of the EV and to realize whether the EV can meet certain driver demands and real-time road load requirements. This information can affect drivers’ decisions to provide safer driving conditions. The SoF of the EV depends on the type of energy management strategy used to control the power flow of the individual ESSs, e.g., battery and supercapacitor. To consider the worst-case design boundary, it was assumed that the battery and supercapacitor-related control systems are configured such that they can simultaneously provide their maximum available power to the EV drivetrain. The SoF of the EV can then be estimated taking the estimated SoFs of all system components (as fulfilled in the component-level estimation) into account as follows:

where

is the overall SoF of the EV;

is the maximum available power by the supercapacitor (obtained by estimating the supercapacitor SoP);

is the maximum available power of the battery (obtained by estimating the battery SoP);

is the derating factor of the motor drive;

is the rated power of the motor drive;

is the derating factor of the PMSM; and

is the rated power of the PMSM. In (1), the SoF of the EV is estimated taking into account the ESSs, electrical motor, and motor drive. In addition, the SoF is estimated without considering the power losses associated with the transmission system and electrical motor. In practice, the foregoing factors can also be considered by obtaining and taking into account the efficiency map of these components.

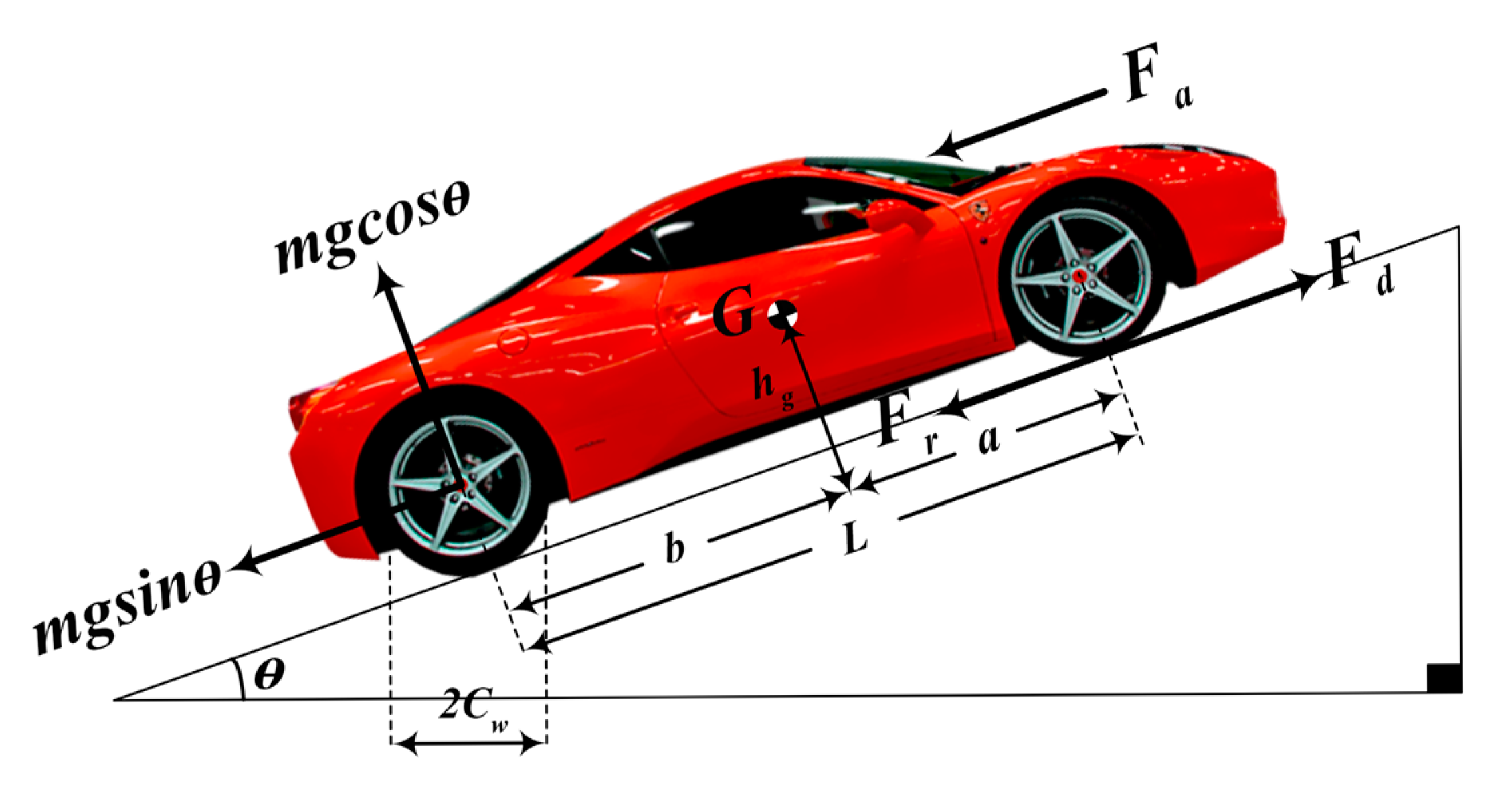

5. Design of the Proposed Recommender System in STATEFLOW©

In the previous section, the road load requirements and dynamic tractive forces of the EV were derived. The output of the accelerator pedal determines the reference speed. In addition, the rate of change of the position of the accelerator pedal, which shows how fast the pedal is depressed, determines the acceleration of the EV. Based on this input and using (2)–(8), the electrical torque () and power () that are needed by the EV can be calculated. On the other hand, the estimated SoF of the EV determines the maximum power that potentially can be supplied by the drivetrain without exceeding any of the safety thresholds of the components. Whenever , the EV can reach the setpoint requested by the driver without any problem. However, when , the EV cannot meet the road load requirements, and the components of the EV will also be subjected to severe overload conditions and may exceed their critical safety thresholds. Two problems may arise here. First, the driver could expect successful EV maneuverability in certain driving conditions (e.g., expecting a certain acceleration level during overtaking), which cannot be fulfilled due to the low drivetrain SoF, and thus, safety can be compromised. Hence, it is necessary to inform the driver of the low drivetrain SoF to avoid an unsuccessful maneuver (e.g., overtaking). Second, components of the drivetrain could exceed their safe operating limits. Therefore, according to the real-time SoF of the EV and the driver commands, the EV should be derated by some means. In this paper, two derating schemes were proposed to achieve the foregoing goals. In the following, first, these derating schemes are explained. The SoF estimation subroutines and the derating schemes were implemented in an online recommender system using STATEFLOW© in MATLAB.

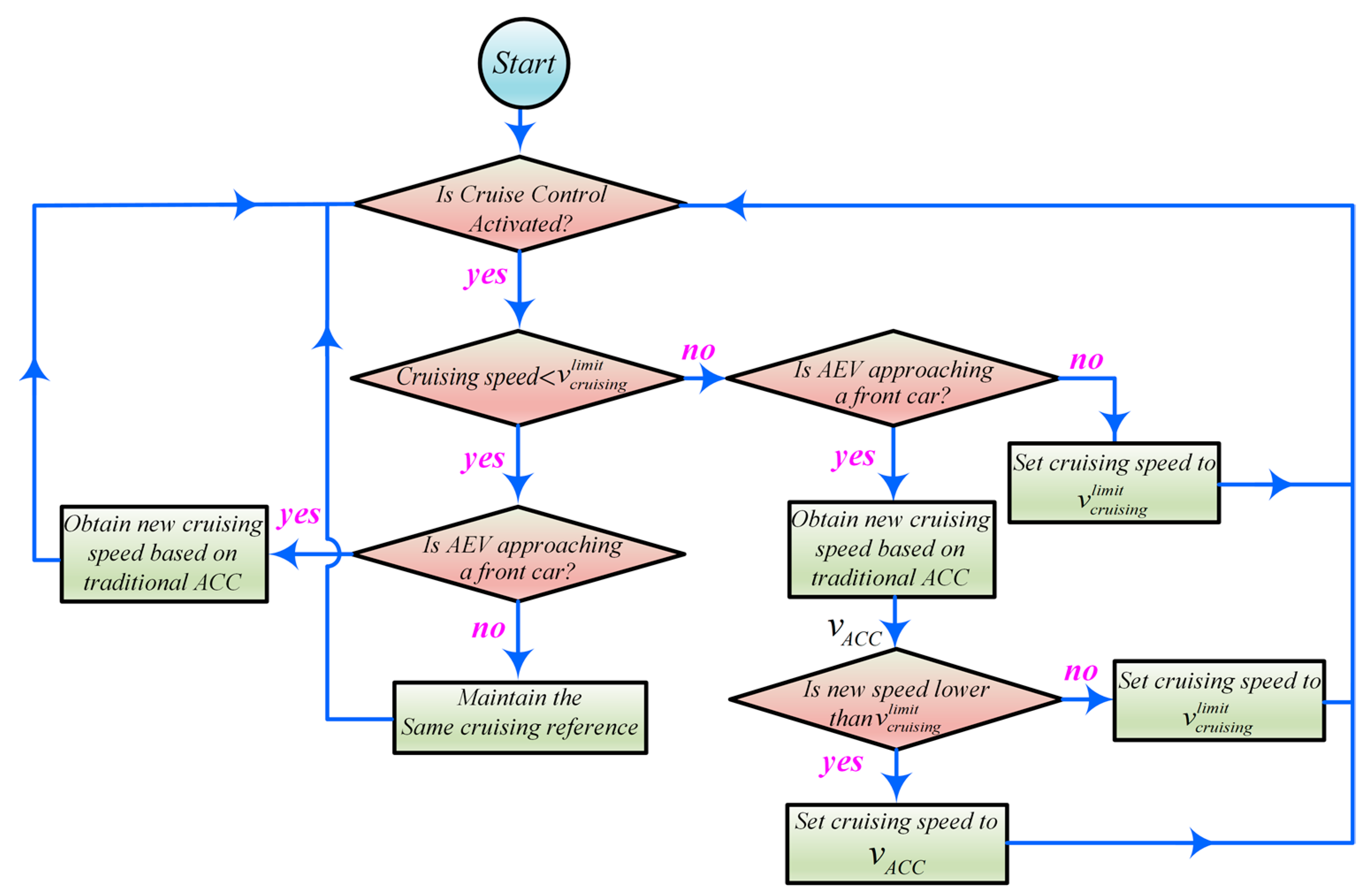

5.1. Derating Scheme 1: Adaptive Cruise Control (ACC)

Adaptive cruise control (ACC) is an already available cruise control system for road vehicles. This system automatically adjusts the vehicle speed for maintaining a safe distance from other vehicles ahead [

36]. In this work, it is suggested to expand the ACC system concept to adjust the cruising speed such that not only the safety distance is maintained (similar to the traditional ACC system), but also the new cruising speed provides a safer operating regime for the EV components. Accordingly, a new ACC system is herein proposed. In the proposed scheme, the new cruising speed is selected by considering the real-time SoF of the EV. In the proposed ACC system, the cruising speed is confined by the maximum achievable cruising speed (

) of the EV, which can be determined using the estimated SoF in

Section 3. The maximum power of the EV drivetrain can be obtained by first subtracting the approximated losses of the motor drive and electric motor from the SoF of the EV, i.e.,

. The power losses of the motor drive were already estimated in the component-level stage. The power losses of the electric motor can be obtained indirectly, by obtaining the PMSM efficiency map with offline experimentations (it is herein skipped for simplicity considering that the PMSM efficiency is >97%). The maximum output power of the EV drivetrain can then be obtained as follows:

where

and

are the power losses of the motor drive and PMSM, respectively. The maximum torque that can be generated at each instant can be calculated using the following formula:

Considering the gear ratio of the transmission system, the value of the torque at the wheels of the EV can be obtained as follows:

Finally, the maximum available tractive force can be calculated as follows:

Based on (7), the maximum achievable cruising speed can be derived as follows:

The flowchart of the proposed ACC system is shown in

Figure 5. This driving mode can be recommended to the driver when the cruise control mode is already activated. When the cruise control mode is not activated, the required tractive force is determined by the driver’s command (through acceleration pedal input). In such conditions, the EV can be derated by defining a virtual pedal position as proposed in the next Section.

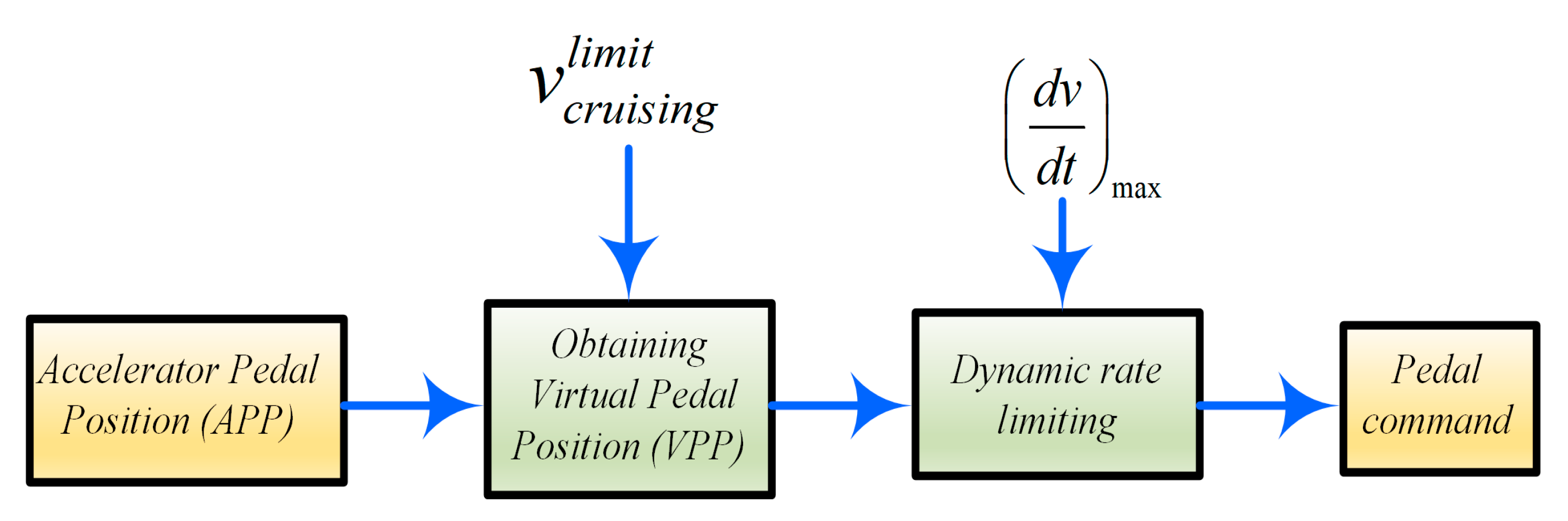

5.2. Derating Scheme 2: Adaptive Pedal Sensitivity Adjustment (APSA)

Peak power transient conditions usually take place during the acceleration of the EV. Therefore, when the estimated

is relatively low, such transient conditions can subject all system components to safety risks. To resolve this issue, in this section, an Adaptive Pedal Sensitivity Adjustment (APSA) mode is proposed. In the proposed design, first, the maximum achievable cruising speed

is obtained using (13). According to the obtained cruising speed, a virtual pedal position filter is defined to confine the speed reference command by the driver. Second, the maximum achievable EV acceleration is calculated, and accordingly, the pedal sensitivity is adaptively limited using a rate limiter filter. Therefore, a new operating mode herein defined as the “safe mode” was designed. Calculation of

was explained in the previous subsection. The maximum achievable acceleration can also be obtained considering (7) as follows:

According to (14), a pedal filter was designed, which obtains a virtual pedal position such that the safety of the EV components based on its real-time

will be guaranteed. The rate-limiting concept is shown in

Figure 6.

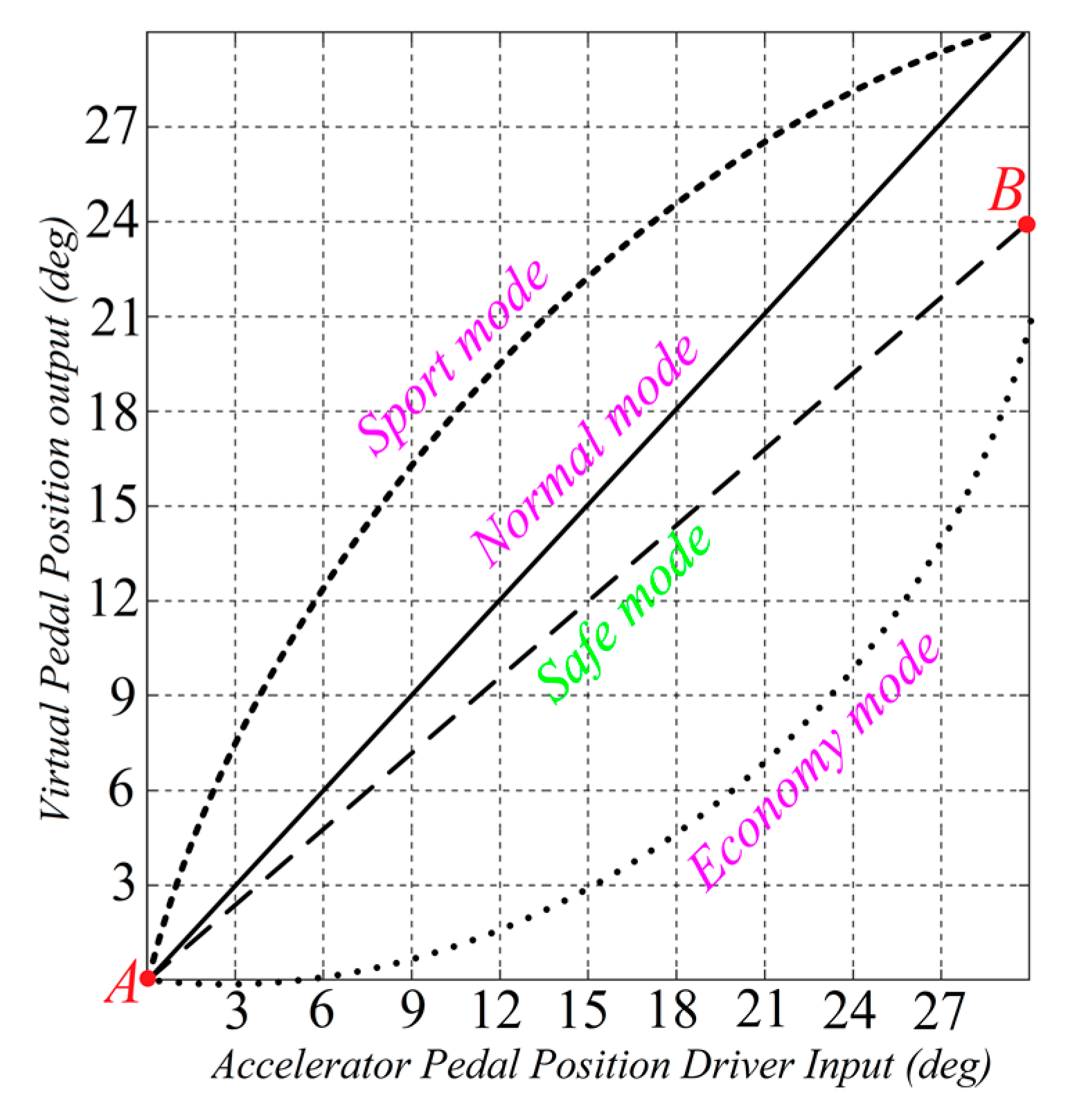

5.2.1. Virtual Pedal Position (VPP)

In the proposed safe mode, the VPP can be obtained by a linear filter considering the maximum achievable cruising speed, as shown in

Figure 7. It is assumed that the accelerator pedal travels 30 degrees at maximum depression. The linear filter can be easily obtained by writing the equation of the straight line AB in

Figure 7.

In practice, the location of point B in

Figure 7 depends on

. The linear filter can then be obtained as follows:

5.2.2. Dynamic Rate Limiting

Based on (14), a dynamic rate limiter was adopted to lower the change rate of the VPP in the proposed safe operating mode. The rate limiter limits the first derivative of the VPP to be no faster than the specified value obtained in (14). The derivative is calculated using the following equation:

where

and

are the current input and time, and

and

are the output and time from the previous step. The output is determined by comparing the signal rate to

. If the rate is lower than

, the same input will be sent to the output. Otherwise, if the rate is larger than

, the output is calculated as follows:

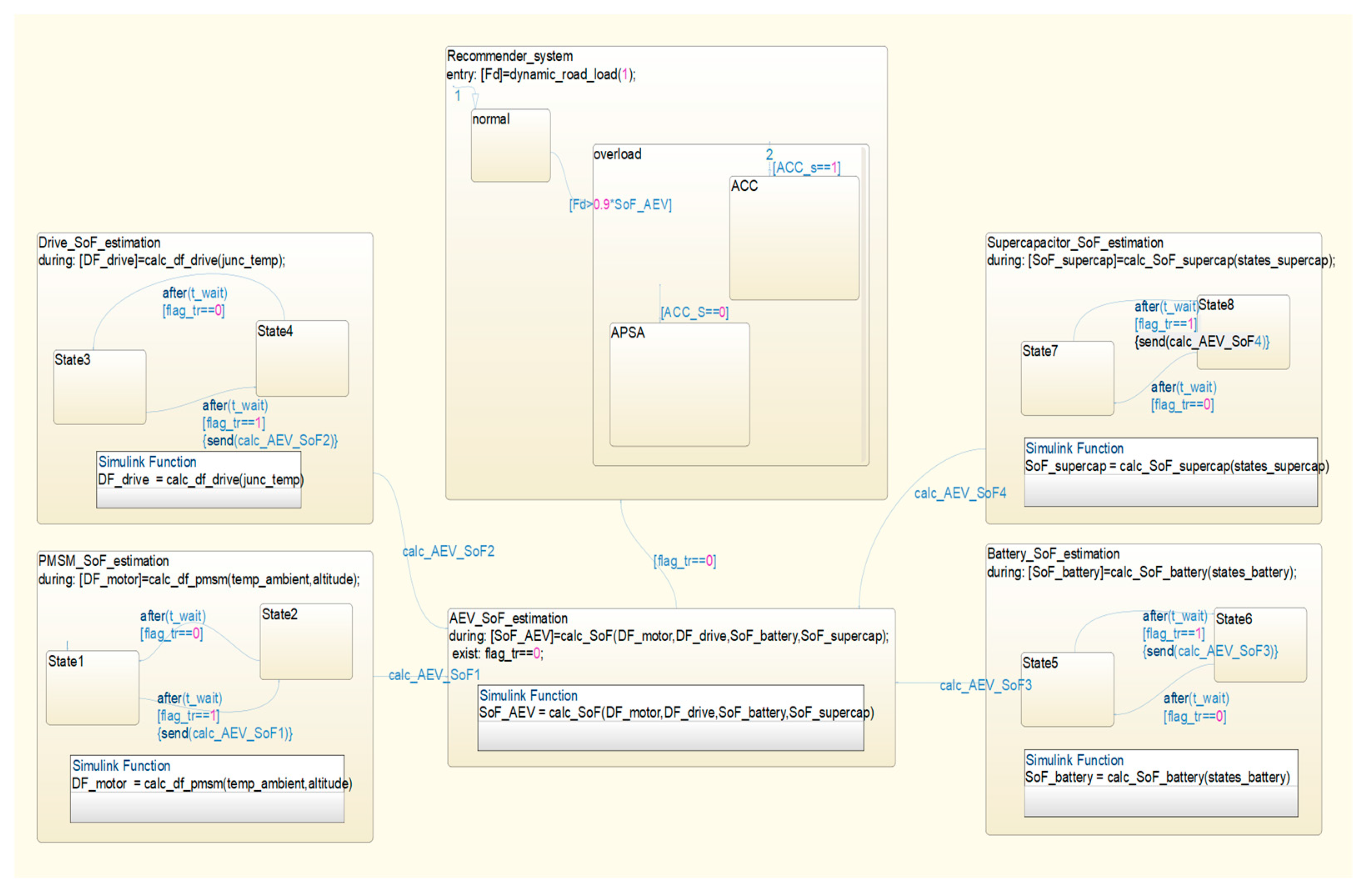

5.3. Implementation of the Proposed Recommender System Using STATEFLOW©

STATEFLOW© is a powerful graphical design and development tool for complex control and supervisory logic problems. Previously, well-known car manufacturers have used STATEFLOW© in the ECU design stage. For instance, Tesla Roadster, Volvo, and Fiat Chrysler Automobiles are among car manufacturers that have used STATEFLOW© in the ECU design stage. Therefore, due to its wide acceptance, in this paper, STATEFLOW© was chosen for the implementation of the proposed schemes and the online recommender system.

The proposed scheme is suggested to be implemented as an add-on or subroutine to the traditional ADASs [

37,

38]. Therefore, similar to other ADASs, the proposed recommender system can take advantage of advanced technologies such as automatic speech recognition (ASR) [

39], text-to-speech (TTS) modules, spoken dialog system (SDS), information filter, and user profile database. The proposed recommender system can communicate with the EV systems via a multiplex network such as a controller area network (CAN).

The proposed recommender system first performs real-time state estimation based on the sensory measurements and techniques explained in the previous sections. Then, it obtains the real-time SoF of the EV and collects supplementary sensory data related to the road and environmental conditions. Based on the estimated SoF of the EV and approximated road load dynamic requirements, the recommender system may change the powertrain performance mode, for instance, between the sport mode, normal mode, fuel economy mode, or the proposed safe mode. The recommender system changes the operating mode based on the preferences of the driver, communicated and confirmed through voice commands, for example. The proposed recommender system has a proactive performance mode advisory function, which recommends either of the foregoing performance modes to the driver according to the observation of recent driver actions. The advisory commands are constructed based on the data collected from the vehicle or non-vehicle sources. The knowledge of the driver’s past actions, behavior, and preferences might also be considered in constructing the advisory commands (though it was not considered here). The proposed safe mode informs the driver that the current SoF of the EV is not sufficient to meet the road load requirements based on the driver’s pedal command. Thus, it suggests switching to safe mode for maintaining the safety of the EV and warns the driver to consider caution in his/her decisions. In the traditional fuel economy mode, the powertrain will be configured to enhance the fuel economy with some potential degradation in the acceleration performance, as seen in

Figure 7. On the other hand, the sport mode increases acceleration and EV responsiveness. In addition, the normal mode is an intermediate mode, which is configured to balance the EV fuel economy and the acceleration performance attributes. The proposed recommender system can use verbal interaction between the driver and the EV to avoid hazards of look-away events, to make the recommender system easy to use, and preferably, to save space on the dashboard. In the proposed safe mode, estimation of the SoF of the EV can be completed in regular intervals, taking into account the required computational load. When the recommended mode differs from the current mode, the proposed recommender system may initiate a verbal exchange with the driver of the car. For instance, if a safe mode or ACC mode is decided by the recommender system, it can create a text string containing the words that the driver should hear, such as, “would you like to switch to the safe mode?” or “would you like to switch to the ACC mode?” The recommender system can continue to explain, “I think the car might work in a safer condition.” The text string can be sent to the TTS module, and the SDS system then waits for a response from the driver. Upon hearing the words, the driver formulates a response, which can be “yes” or “no,” but also can be something more unexpected, such as, “What is the safe mode” or “What is the ACC mode” or “Ask me later,” etc. Upon receiving a confirmation from the driver, the recommender system activates, e.g., the safe mode, and sends a text string containing the sentence, “Safe driving mode activated,” to the TTS module. The information filter ensures that interactions with the driver take place only at appropriate times, e.g., when a driver response is necessary (in critical or fault conditions), when the driver can make a decision (for example recommender avoids interacting with the driver in certain driving conditions, such as passing a cross-road or when the driver is taking a turn). The information filter is responsible for making sure that the recommendations are not made too frequently, causing distraction, frustration, or dissatisfaction with the recommender system. The recommender system can be deactivated by the driver when he/she prefers. In either of the operating modes, when a fault arises in the components of the EV drivetrain, which can be detected by the diagnosis subroutines developed in the previous sections, the recommender system immediately informs the driver to take precautionary actions.

In the previous paragraphs, the concept of the proposed recommender system and some design suggestions and features were provided with details. In the simulation of the recommender system using STATEFLOW, however, some features such as the SDS system were not considered. For the proof of concept, it was assumed that the driver can respond to the recommender by pushing a certain button during the simulation. Nonetheless, in practice, all the aforementioned ideas and subsystems can easily be implemented on the ECU of the car. The voice commands of the recommender system were recorded, imported into the MATLAB workspace as a data file (double), and were played during STATEFLOW simulation using an interpreted MATLAB function block. The implementation view of the STATEFLOW block diagram of the proposed recommender system is shown in

Figure 8. As shown in

Figure 8, the finite state machine included four state blocks that represent different drivetrain components, a state block for the representation of the drivetrain SoF, and a state block for the recommender system. The state machines of the components included a Simulink function that executes the corresponding state estimation algorithms. Every state block had a parent state and offspring states. Transitions were also placed to move from one state to another depending on the drivetrain SoF and the operating conditions.

6. Simulation Results

This section describes the simulations using MATLAB/SIMULINK and STATEFLOW

© conducted to confirm the effectiveness of the proposed recommender system. The drivetrain of the simulated EV consisted of a hybrid ESS with a 96 V, 30 kWh lithium-ion battery pack, and a supercapacitor bank consisting of 90 (24×12) 2.5 V, 2500 F supercapacitor cells (MAXWELL PC2500). The IGBT module was based on the power module from Fuji. The electrical motor model was an MC-PM8 from ADVISOR [

40]. Other simulation parameters of the EV were selected based on VEH_SMCAR from the ADVISOR software. The EV mass with cargo was 1144 kg; the frontal area was 2 m

2; and the radius of the wheels was 0.335 m. Detailed simulation parameters are listed in

Table 2. The PMSM motor drive was controlled with the FOC method, which is the SotA approach for speed control and has been recently considered in many EVs. The FOC decouples torque and flux by using a d-q rotor reference frame. The standard drive cycle output was considered to be the driver request during the simulations.

In

Figure 9,

Figure 10 and

Figure 11, the simulation scenarios and results with and without the utilization of the proposed recommender system are depicted.

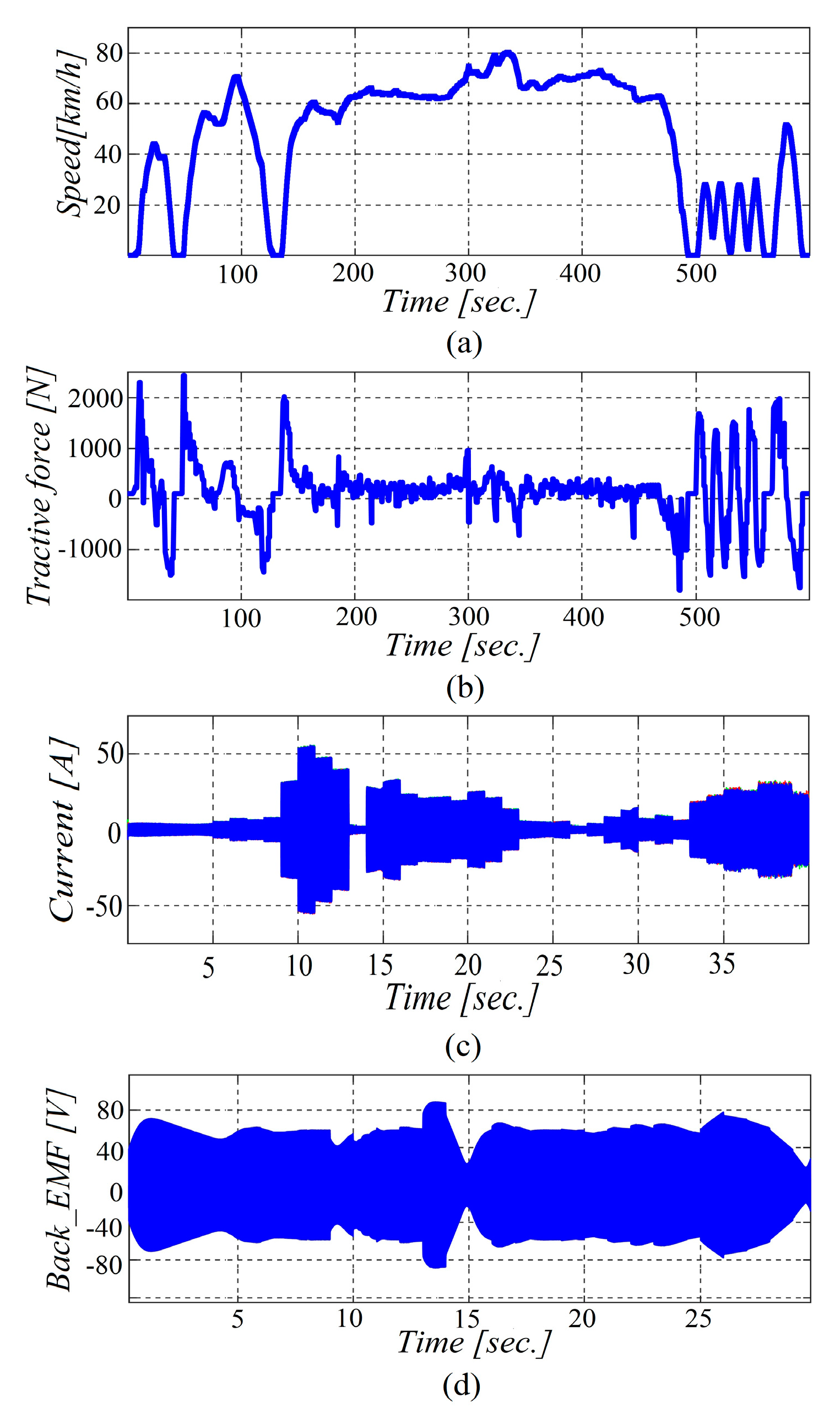

The selected drive cycle was US06, which lasts for

583 s and includes 25.67% cruising events and 36.24% acceleration events. It must be noted that due to the heavy computational burden of the simulation model (since many of the control and estimation algorithms run at the same time), only a small portion of the US06 drive cycle was simulated. The transient force diagram of

Figure 9b shows that the peak power demands occur only during the acceleration events. For instance, while the average required transient force is about 200 N during cruising conditions, e.g., between 200 <

< 300, the required transient force reaches values as large as 2000 N during the acceleration of the EV. Based on

Figure 9c, the current waveform also experiences a large overshoot during the acceleration events. The waveform provided in

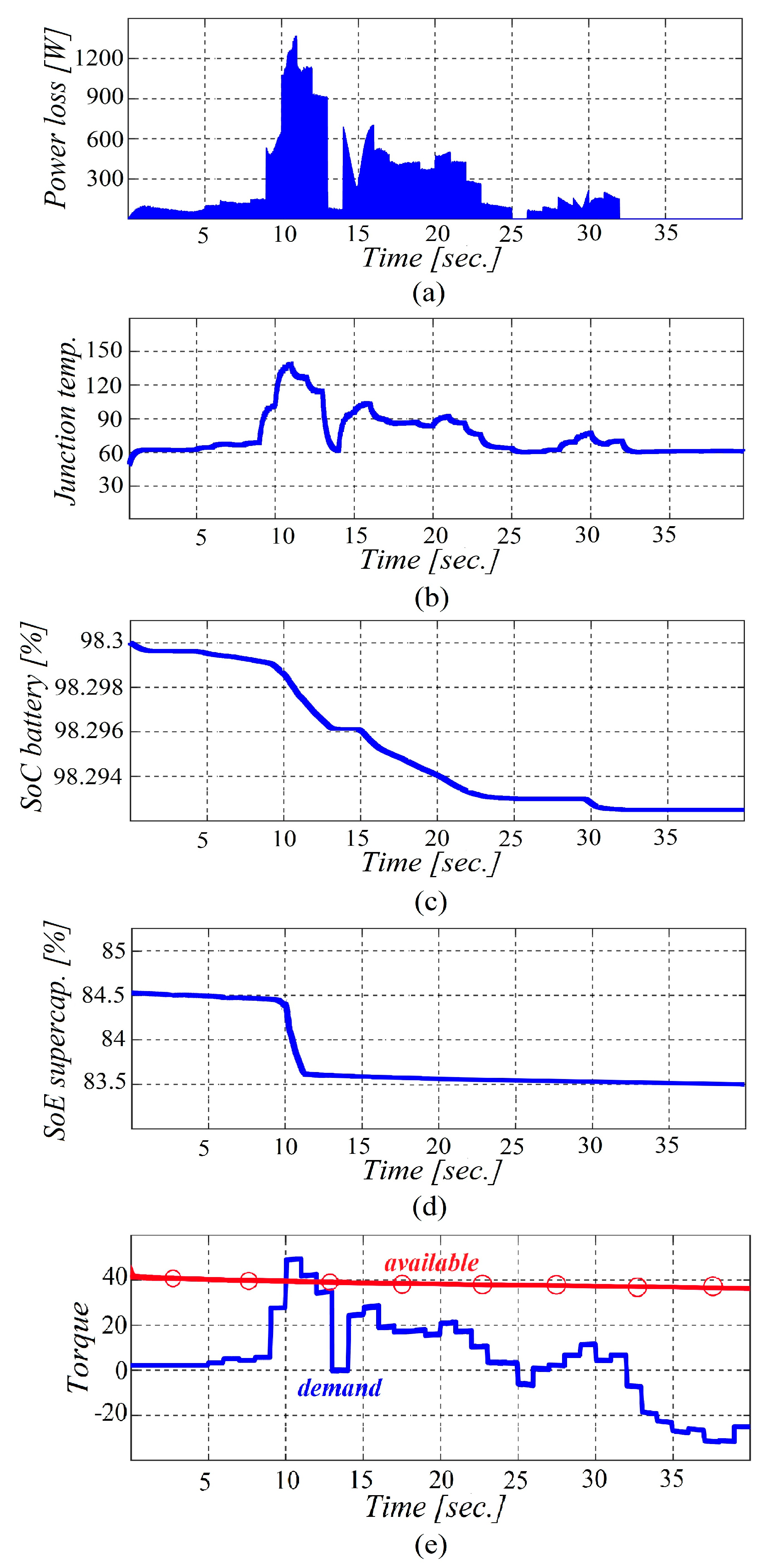

Figure 10b also indicates that the junction temperature of the power module was correctly monitored over the simulation course.

In addition, it is evident that between

= 10 s and

= 12.5 s, the junction temperature had exceeded the critical safety threshold of 120 degrees Celsius. The demanded torque and the available torque (obtained by estimation of the SoF of the EV) are also shown in the last plot in

Figure 10e. It can be seen that between

= 10 s and

= 12.5 s, the demanded torque had exceeded the available torque, and thus, the motor drive junction temperature had exceeded its critical limit. In this scenario, the recommender system successfully issued the recommendation to switch to the safe mode, but the request was rejected by the driver. In

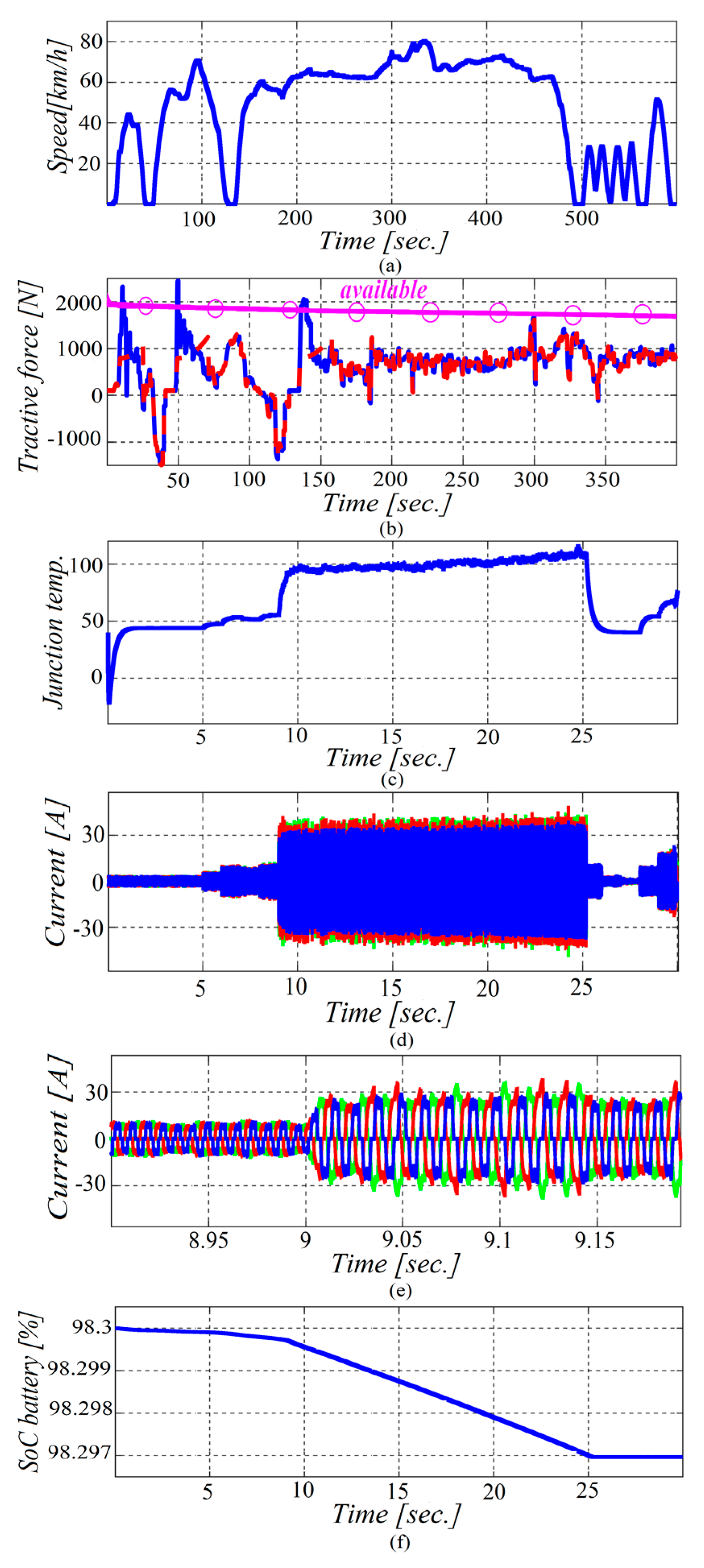

Figure 11, the simulation results are shown for when the safe mode is activated by the driver. As seen in

Figure 11b, due to the activation of the safe mode and the APSA system, the new tractive force (red plot) was reduced during the transient conditions in comparison with the previous tractive force (blue plot). Thus, as can be seen in

Figure 11c, the junction temperature was effectively reduced to under 100 degrees Celsius.