Operational Excellence in a Biogas Plant through Integration of Lean Six Sigma Methodology

Abstract

:1. Introduction

2. Materials and Methods

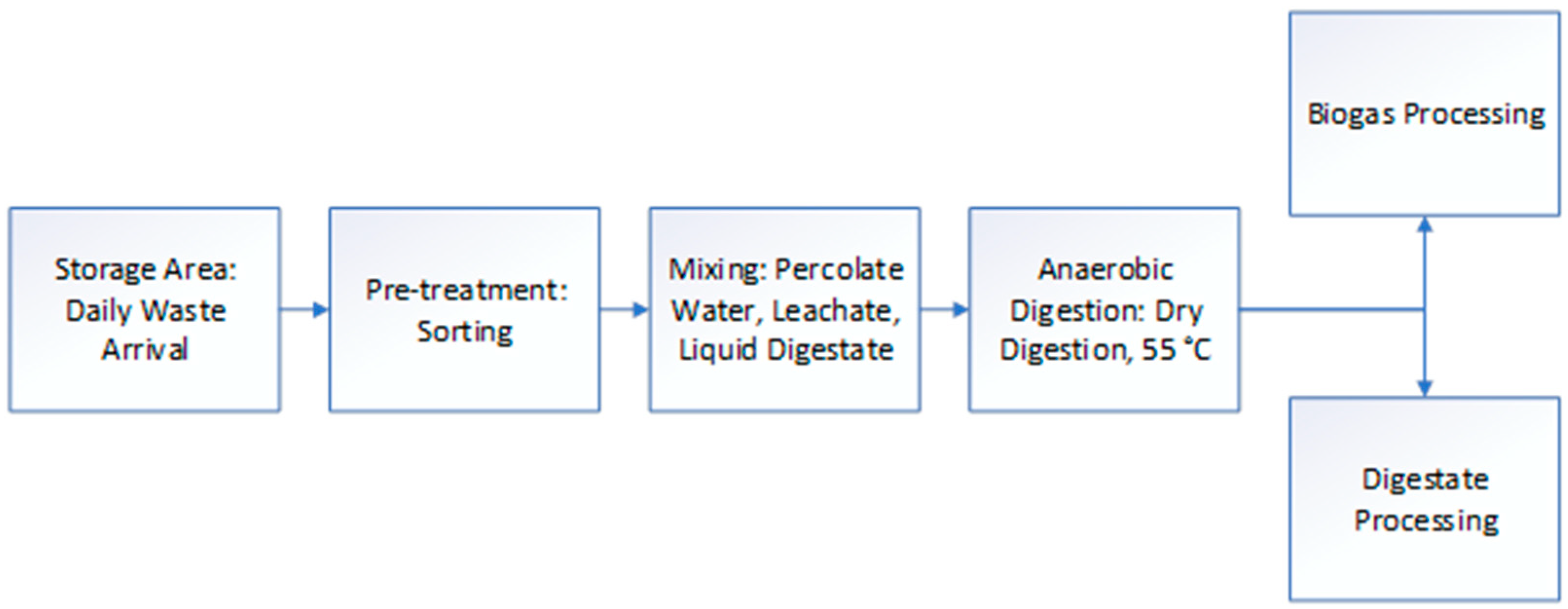

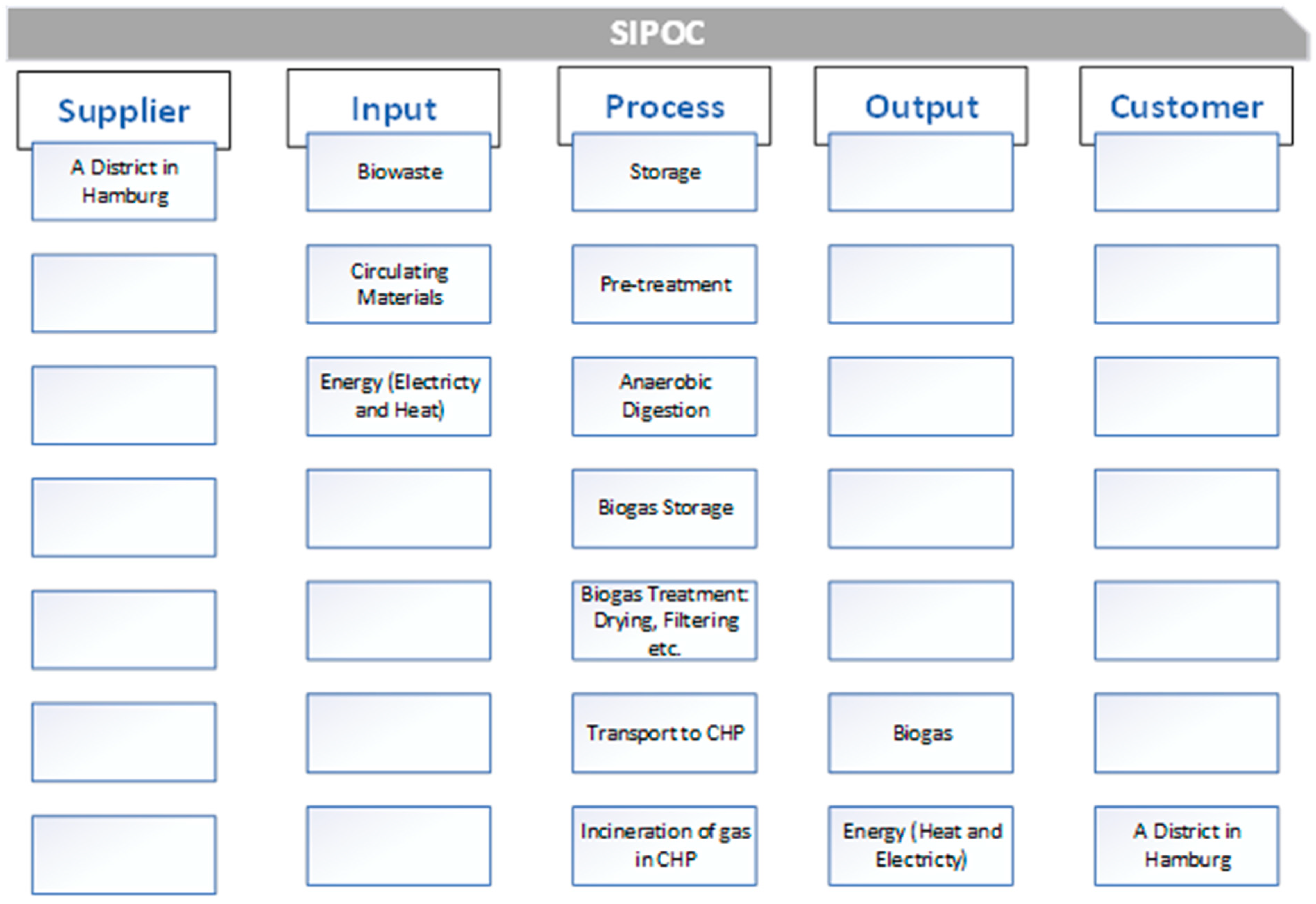

2.1. Studied Industrial-Scale Biogas Plant

2.2. Lean Six Sigma Methodology

2.2.1. Define

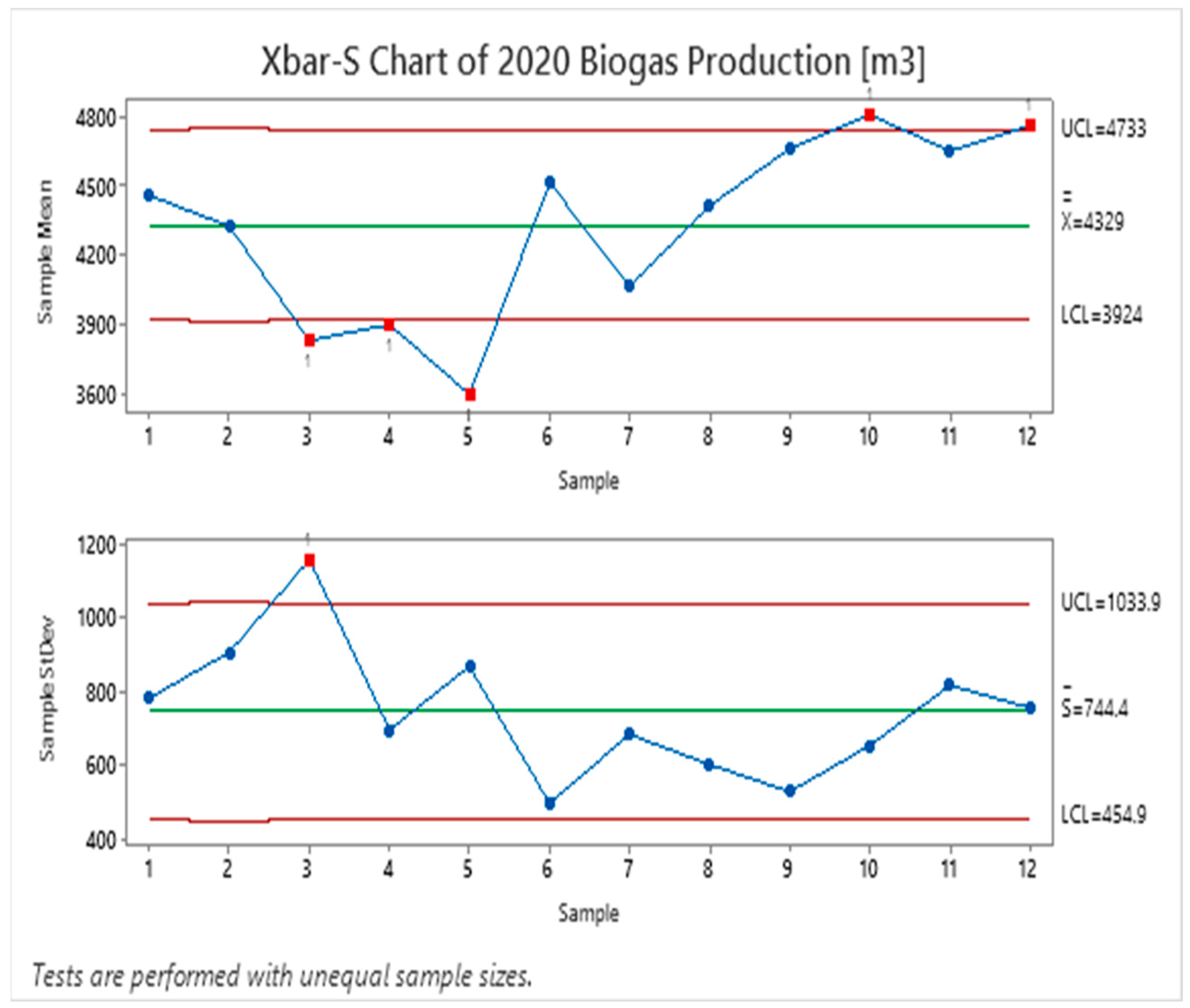

2.2.2. Measure

2.2.3. Analyze

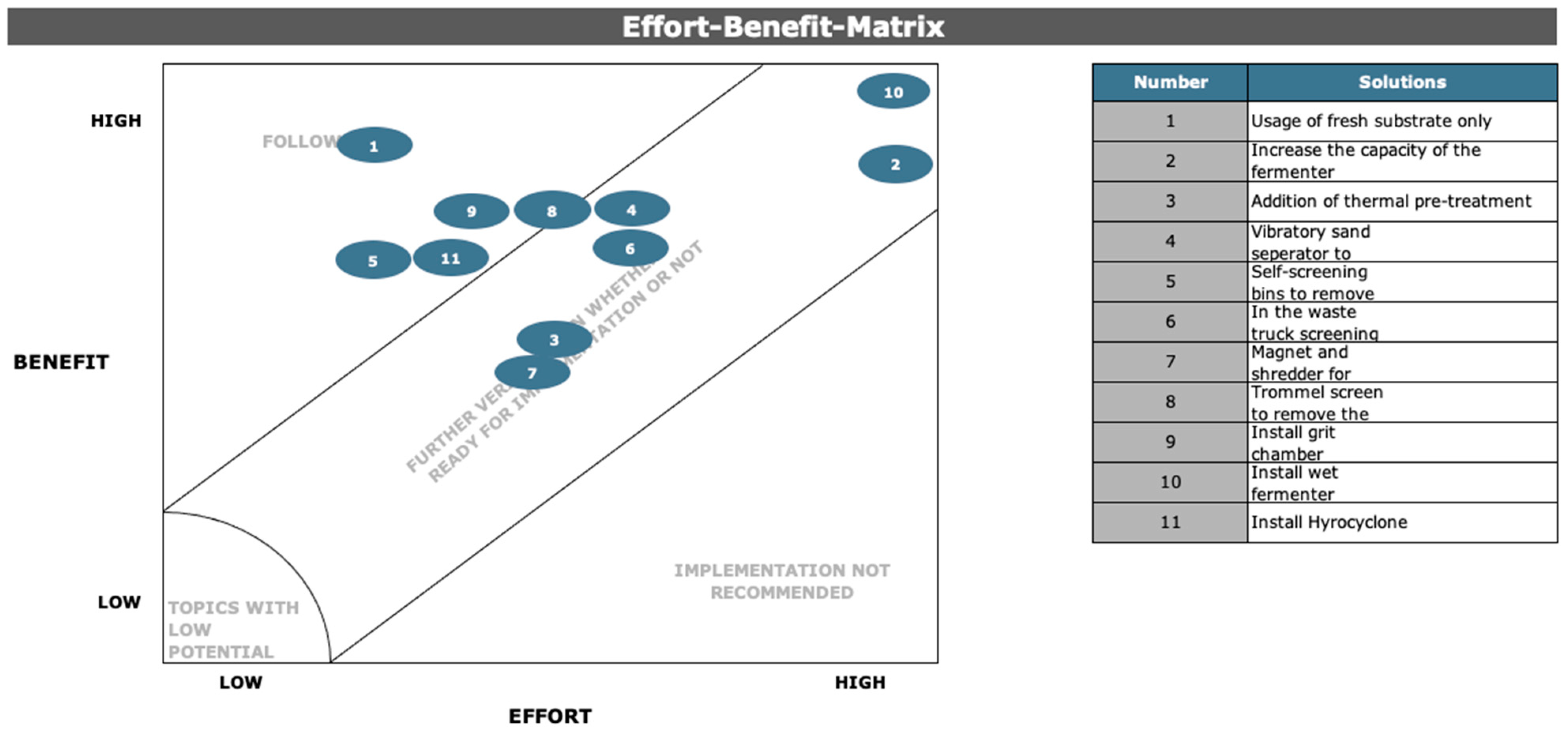

2.2.4. Improve

- Usage of fresh substrate only;

- Increasing the capacity of fermenter;

- Addition of the thermal pre-treatment;

- Vibratory sand separator to remove sand;

- Self-screening bins to remove sand;

- In the waste truck screening to remove sand;

- Magnet and shredder for particle size reduction;

- Trommel screen to remove sand content;

- Install grid chamber;

- Install wet fermentation;

- Install hydrocyclone.

2.2.5. Control

3. Results and Discussion

- Improvements at the quality of input material;

- Improvements at the implemented pre-treatment and digestion technologies.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vögeli, Y.; Lohri, C.R.; Gallardo, A.; Diener, S.; Zurbrügg, C. Anaerobic Digestion of Biowaste in Developing Countries: Practical Information and Case Studies; Eawag—Swiss Federal Institute of Aquatic Science and Technology: Dübendorf, Switzerland, 2014. [Google Scholar]

- Birol, F. Germany 2020, Energy Policy Review; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Da Gomez, C.C. Biogas as an energy option: An overview. In The Biogas Handbook; Woodhead Publishing: Sawston, UK, 2013; pp. 1–16. [Google Scholar]

- Fachagentur Nachwachsende Rohstoffe e.V. Guide to Biogas; Agency for Renewable Resources: Gulzow, Germany, 2012. [Google Scholar]

- Tabatabaei, M.; Ghanavati, H. Biogas; Springer: Cham, Switzerland, 2018; ISBN 978-3-319-77334-6. [Google Scholar]

- Treichel, H.; Fongaro, G. Improving Biogas Production; Springer: Cham, Switzerland, 2019; ISBN 978-3-030-10515-0. [Google Scholar]

- Deng, L.; Liu, Y.; Wang, W. Biogas Technology; Springer: Singapore, 2020; ISBN 978-981-15-4939-7. [Google Scholar]

- Nsair, A.; Cinar, S.O.; Alassali, A.; Abu Qdais, H.; Kuchta, K. Operational Parameters of Biogas Plants: A Review and Evaluation Study. Energies 2020, 13, 3761. [Google Scholar] [CrossRef]

- Rocamora, I.; Wagland, S.T.; Villa, R.; Simpson, E.W.; Fernández, O.; Bajón-Fernández, Y. Dry anaerobic digestion of organic waste: A review of operational parameters and their impact on process performance. Bioresour. Technol. 2020, 299, 122681. [Google Scholar] [CrossRef] [PubMed]

- Nsair, A.; Cinar, S.Ö.; Qdais, H.A.; Kuchta, K. Optimizing the performance of a large scale biogas plant by controlling stirring process: A case study. Energy Convers. Manag. 2019, 198, 111931. [Google Scholar] [CrossRef]

- Cinar, S.; Cinar, S.O.; Wieczorek, N.; Sohoo, I.; Kuchta, K. Integration of artificial intelligence into biogas plant operation. Processes 2021, 9, 85. [Google Scholar] [CrossRef]

- Önen, S.; Nsair, A.; Kuchta, K. Innovative operational strategies for biogas plant including temperature and stirring management. Waste Manag. Res. 2019, 37, 237–246. [Google Scholar] [CrossRef] [PubMed]

- Önen, S.; Kuchta, K. Evaluation of temperature changes in anaerobic digestion process. Detritus 2020, 10, 11–18. [Google Scholar] [CrossRef]

- Cinar, S.O.; Nsair, A.; Wieczorek, N.; Kuchta, K. Long-Term Assessment of Temperature Management in an Industrial Scale Biogas Plant. Sustainability 2022, 14, 612. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, R.; El-Mashad, H.M.; Dong, R. Effect of feed to inoculum ratios on biogas yields of food and green wastes. Bioresour. Technol. 2009, 100, 5103–5108. [Google Scholar] [CrossRef]

- Seno, J.; Nyoman, I. The effect of feed to inoculums ratio on biogas production rate from cattle manure using rumen fluid as inoculums. Int. J. Sci. Eng. 2010, 1, 41–45. [Google Scholar]

- Pham, C.H.; Saggar, S.; Vu, C.C.; Tate, K.R.; Tran, T.T.T.; Luu, T.T.; Ha, H.T.; Nguyen, H.L.T.; Sommer, S.G. Biogas production from steer manures in Vietnam: Effects of feed supplements and tannin contents. Waste Manag. 2017, 69, 492–497. [Google Scholar] [CrossRef]

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Effect of substrate pretreatment on biogas production through anaerobic digestion of food waste. Int. J. Hydrog. Energy 2017, 42, 26522–26528. [Google Scholar] [CrossRef]

- Ma, X.; Jiang, T.; Chang, J.; Tang, Q.; Luo, T.; Cui, Z. Effect of substrate to inoculum ratio on biogas production and microbial community during hemi-solid-state batch anaerobic co-digestion of rape straw and dairy manure. Appl. Biochem. Biotechnol. 2019, 189, 884–902. [Google Scholar] [CrossRef] [PubMed]

- Begum, S.; Anupoju, G.R.; Sridhar, S.; Bhargava, S.K.; Jegatheesan, V.; Eshtiaghi, N. Evaluation of single and two stage anaerobic digestion of landfill leachate: Effect of pH and initial organic loading rate on volatile fatty acid (VFA) and biogas production. Bioresour. Technol. 2018, 251, 364–373. [Google Scholar] [CrossRef] [PubMed]

- Orhorhoro, E.K.; Ebunilo, P.O.; Sadjere, G.E. Effect of organic loading rate (OLR) on biogas yield using a single and three-stages continuous anaerobic digestion reactors. Int. J. Eng. Res. Afr. 2018, 39, 147–155. [Google Scholar] [CrossRef]

- Haryanto, A. Effect of hydraulic retention time on biogas production from cow dung in a semi continuous anaerobic digester. Int. J. Renew. Energy Dev. 2018, 7, 93–100. [Google Scholar] [CrossRef]

- Santos, F.S.; Ricci, B.C.; Neta, L.S.F.; Amaral, M.C.S. Sugarcane vinasse treatment by two-stage anaerobic membrane bioreactor: Effect of hydraulic retention time on changes in efficiency, biogas production and membrane fouling. Bioresour. Technol. 2017, 245, 342–350. [Google Scholar] [CrossRef]

- Musa, M.A.; Idrus, S. Effect of Hydraulic Retention Time on the Treatment of Real Cattle Slaughterhouse Wastewater and Biogas Production from HUASB Reactor. Water 2020, 12, 490. [Google Scholar] [CrossRef] [Green Version]

- Sukpancharoen, S.; Phetyim, N. Green hydrogen and electrical power production through the integration of CO2 capturing from biogas: Process optimization and dynamic control. Energy Rep. 2021, 7, 293–307. [Google Scholar] [CrossRef]

- Chen, L.; Cong, R.-G.; Shu, B.; Mi, Z.-F. A sustainable biogas model in China: The case study of Beijing Deqingyuan biogas project. Renew. Sustain. Energy Rev. 2017, 78, 773–779. [Google Scholar] [CrossRef] [Green Version]

- Mustafa, M.Y.; Calay, R.K.; Román, E. Biogas from organic waste-a case study. Procedia Eng. 2016, 146, 310–317. [Google Scholar] [CrossRef] [Green Version]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Wahmkow, C.; Knape, M.; Konnerth, E. Biogas Intelligence-operate biogas plants using Neural Network and Fuzzy logic. In Proceedings of the 2013 Joint IFSA World Congress and NAFIPS Annual Meeting (IFSA/NAFIPS), Edmonton, AB, Canada, 24–28 June 2013; IEEE: Piscataway, NJ, USA, 2013. [Google Scholar]

- Meran, R.; John, A.; Roenpage, O.; Staudter, C.; Lunau, S. Six Sigma + Lean Toolset: Mindset for Successful Implementation of Improvement Projects; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 3642358829. [Google Scholar]

- Singh, M.; Rathi, R. A structured review of Lean Six Sigma in various industrial sectors. Int. J. Lean Six Sigma 2019, 10, 622–664. [Google Scholar] [CrossRef]

- Töpfer, A. Lean Six Sigma: Erfolgreiche Kombination von Lean Management, Six Sigma und Design for Six Sigma; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 3540850600. [Google Scholar]

- Kaswan, M.S.; Rathi, R. Analysis and modeling the enablers of green lean six sigma implementation using interpretive structural modeling. J. Clean. Prod. 2019, 231, 1182–1191. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R. Green Lean Six Sigma for sustainable development: Integration and framework. Environ. Impact Assess. Rev. 2020, 83, 106396. [Google Scholar] [CrossRef]

- Gupta, S.; Modgil, S.; Gunasekaran, A. Big data in lean six sigma: A review and further research directions. Int. J. Prod. Res. 2020, 58, 947–969. [Google Scholar] [CrossRef]

- De Clercq, D.; Jalota, D.; Shang, R.; Ni, K.; Zhang, Z.; Khan, A.; Wen, Z.; Caicedo, L.; Yuan, K. Machine learning powered software for accurate prediction of biogas production: A case study on industrial-scale Chinese production data. J. Clean. Prod. 2019, 218, 390–399. [Google Scholar] [CrossRef]

- Cinar, S.Ö.; Cinar, S.; Kuchta, K. Machine Learning Algorithms for Temperature Management in the Anaerobic Digestion Process. Fermentation 2022, 8, 65. [Google Scholar] [CrossRef]

- Taghizadegan, S. Essentials of Lean Six Sigma; Elsevier: Amsterdam, The Netherlands, 2010; ISBN 0080462324. [Google Scholar]

| CTC | Quantity Gas Fermenter (m3 h−1) | Pressure of Biogas in Central Storage (mbar) | CHP 1 Gas Quantity (m3 h−1) | CHP 2 Gas Quantity (m3 h−1) | Total Digestate for Dewatering (L) |

|---|---|---|---|---|---|

| Average biogas generated should reach the target goal of 250 m3 h−1 | 9–Strong Correlation | 3–Medium Correlation | 3–Medium Correlation | 3–Medium Correlation | 1–Weak Correlation |

| Metric(s) | Measuring Device | Measurement Method(s) | Decision Criteria |

|---|---|---|---|

| Biogas in m3 | Sensor | The volume of biogas produced from anaerobic digestion in the fermenter every second is detected by sensor. However, the volume of biogas produced would be summed up by a computing system automatically at the end of the day. Therefore, volume flow of biogas produced per day is registered and recorded. | Volume of biogas produced per day by fermenter is given consideration. Volume of biogas produced per second by fermenter is considered. One day is from 00:00:00 to 23:59:59. |

| Variable | Art der Variable | Type (C/D) | Responsible | Method | Date/Time/Frequency | Data Source | Target |

|---|---|---|---|---|---|---|---|

| Biogas produced by Fermenter | Output | C | Employee at the company | Volume of biogas produced per day would be recorded later in an excel file | Start: 1 January 2020 00:00:00 Stop: 31 December 2020 23:59:59Total samples: 366 measurements. | Directly after the Fermenter | 5500 m3 d−1 |

| At a Time | Over Time | |

|---|---|---|

| Discrete | Pareto–Diagram Bar Chart Pie Chart | Run Chart Control Charts (p–Chart, np–Chart, c–Chart, U–Chart) |

| Continuous | Histogram Boxplot Dot Plot Multi-Variation Chart | Run Chart Control Charts (I/MR Chart, X-bar R Chart, X-bar S Chart) |

| Potential Cause | Definition |

|---|---|

| Hydraulic Retention Time | HRT is too short and is non-ideal for current process |

| Low Biogas Potential | Input waste substrate has low biogas potential |

| Size of substrate | The size of input substrate is big for the process |

| Leachate | Addition of leachate and percolate water with acidic pH |

| Pre-treatment | Inhomogeneous pre-mixing of input substrate at mixer |

| Lack of digestion | Waste substrate is not entirely anaerobically digested within fermenter |

| Impurities | High sand content (impurities) in input waste substrate |

| Quality of Input | Changing quality of the input waste material along the year |

| Quantity of Input | Low biowaste quantity delivered |

| Experiment | Covered Potential Cause |

|---|---|

| AMPTS II–BMP for different particle sizes | Quality of the input |

| AMPTS II–BMP for different freshness of the substrate | Quality and quantity of the input |

| AMPTS II–BMP through the output of fermentation residues | Hydraulic Retention time |

| AMPTS II–Importance of pre-treatment for sand content | Impurities, pre-treatment |

| BMP in climate room–BMP for different leachate contents | Leachate |

| Determination of sand content from different points | Impurities and quality of the input |

| TS & vs.–TS and vs. of the substrate and digestate samples | Quality of the input |

| Experiment |

|---|

| AMPTS II–BMP for different particle sizes |

| AMPTS II–BMP for different freshness of the substrate |

| AMPTS II–BMP through the output of fermentation residues |

| AMPTS II–Importance of pre-treatment for sand content |

| GB21–Leachate content |

| Determination of sand content from different points |

| TS & OTS–TS and vs. of the substrate |

| Possible Cause(s) | p-Value | Explanation |

|---|---|---|

| Particle size of the substrate | p < 0.001 | Null hypothesis rejected |

| Freshness of the substrate | p < 0.001 | Null hypothesis rejected |

| Hydraulic Retention Time | p > 0.05 | Null hypothesis is not rejected |

| Amount of Leachate | p > 0.05 | Null hypothesis is not rejected |

| Sand Content | p < 0.001 | Null hypothesis rejected |

| No. | Root Cause(s) |

|---|---|

| 1 | Particle size of the substrate |

| 2 | Freshness of the substrate |

| 3 | Hydraulic Retention Time |

| 4 | Sand Content |

| No. | Idea | No. of Root Cause |

|---|---|---|

| 1 | Usage of fresh substrate only | 2, 3 |

| 2 | Increase the capacity of the fermenter | 2, 3 |

| 3 | Addition of thermal pre-treatment | 1, 2, 4 |

| 4 | Vibratory sand separator to remove the sand | 1 |

| 5 | Self-screening bins to remove the sand | 1 |

| 6 | In the waste truck screening to remove the sand | 4 |

| 7 | Magnet and shredder for particle reduction | 4 |

| 8 | Trommel screen to remove the sand | 4 |

| 9 | Install grit chamber | 4 |

| 10 | Install wet fermenter | 3 |

| 11 | Install Hyrocyclone | 4 |

| S 1 | S 2 | S 3 | S 4 | S 5 | S 6 | S 7 | S 8 | S 9 | S 10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Particle size of the substrate | 0 | 0 | 2 | 0 | 1 | 1 | 1 | 0 | 0 | 2 |

| Freshness of the substrate | 2 | 1 | 2 | −1 | 1 | 1 | 0 | −1 | 0 | −1 |

| HRT | 2 | 2 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | −1 |

| Sand Content | 0 | 0 | 2 | 2 | 2 | 1 | 2 | 2 | 1 | 2 |

| Total | 4 | 3 | 6 | 1 | 5 | 5 | 3 | 1 | 1 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cinar, S.; Önen Cinar, S.; Staudter, C.; Kuchta, K. Operational Excellence in a Biogas Plant through Integration of Lean Six Sigma Methodology. Designs 2022, 6, 61. https://doi.org/10.3390/designs6040061

Cinar S, Önen Cinar S, Staudter C, Kuchta K. Operational Excellence in a Biogas Plant through Integration of Lean Six Sigma Methodology. Designs. 2022; 6(4):61. https://doi.org/10.3390/designs6040061

Chicago/Turabian StyleCinar, Samet, Senem Önen Cinar, Christian Staudter, and Kerstin Kuchta. 2022. "Operational Excellence in a Biogas Plant through Integration of Lean Six Sigma Methodology" Designs 6, no. 4: 61. https://doi.org/10.3390/designs6040061

APA StyleCinar, S., Önen Cinar, S., Staudter, C., & Kuchta, K. (2022). Operational Excellence in a Biogas Plant through Integration of Lean Six Sigma Methodology. Designs, 6(4), 61. https://doi.org/10.3390/designs6040061