Abstract

A sugarcane harvester prototype was fabricated and evaluated to save time, labor, and harvesting expenses, which are included in production costs. The single-row harvester prototype fits the functional needs of the physical qualities of sugarcane and was designed to be installed on a tractor. One serrated edge cutter disc, three forward speeds, and three cutter disc speeds were used to evaluate the performance of the fabricated sugarcane harvester. The results of the technical evaluation showed that the average forward speed was 5 km h−1, and the average cutter disc speed was 2000 rpm by a cutter disc with a serrated edge produced the ideal sugarcane harvesting parameters. The actual field capacity, the power required and the specific energy requirements, were determined. Despite that economic evaluation empathies that the combination of 3.5 km h−1 forward speed and a 1000 rpm cutting speed also achieved the highest benefits ($115.12/ha).

1. Introduction

One of the most important sugar crops is sugarcane worldwide on which many industries depend. Manual harvesting of sugarcane is one of the most traditional methods in many regions of the world. Sugarcane production in the world was amounted about 1949.31 million metric tons [1], the cultivated area of sugarcane in Egypt is about 136,915 hectares producing 15,242,687 tons [2]. Usually, the sugarcane crop cultivation period is about four to five years and throughout the planting cycle, it is harvested more than once, increased yield and output are primarily dependent on the crop’s service and fertilization. In cutting techniques, different types of stalks have different mechanical properties, and the same kind of stalks have different mechanical qualities owing to crop ripeness, moisture content, and planting site. Manual harvesting of sugarcane is the commonly used method. Sugarcane mechanization is an unavoidable alternative for lowering production costs, increasing worker productivity, and reducing the high demand for farmers’ labor. Cultivation quality, particularly in rows spacing 1–1.2 meters irrespective, is ordinarily up to required standards [3].

The sugarcane harvester type 4GZ-9 was chosen as the test prototype for both theory and field tests. The parameters for the base-cutter were adjusted, and the broken rootstock in proportion ratooning sugarcane decreased to 2.11% [4]. Experiments were conducted to determine the mechanical properties and failure of sugarcane stalks under bending force. At bending loads, sugarcane stalks exhibited four types of damage: cracking in the neutral layer, transverse cracking, bottom longitudinal cracking, and irregular cracking, according to the findings. These results are relevant in terms of sugarcane cutting research and blade design [5]. The sugarcane harvester’s advancing speed and the base-rotation cutter’s speed must be matched [6].

The effects of the influencing parameters on the cracked biennial root rate were taken into consideration. The optimization of the cracked rate at the condition of the minimum frequency and amplitude, as well as two soil bases, was performed. The results showed that the frequency and amplitude have a notable impact on the cracked biennial root rate. At the optimal condition, the broken rate is less than 11% [7]. Mechanized production, in most cases, necessitates a row spacing of more than 1.2 meters [8].

The influence of sugarcane size, and the dynamic response of the hydraulic system [9]. As well as the influence on the number of broken roots caused by vibration, speed ratio, blade numbers, and inclination angle of the base-cutter [10]. The tiny sugarcane harvesting system’s economic efficiency was studied. In China, it was discovered that the small, chopped sugarcane harvesting technology may be used in the current situation [11].

Energy consumption was correlated to rotating speeds (R Speed) and cane stool diameters (S diameter); however, tilt angles (T angle) and cane feeding rates (F rate) had negative associations. Furthermore, it was determined that R Speed, S diameter, and F rate had a substantial impact on energy consumption in the process of sugarcane base cutting at a 95% level, but the T angle had no impact. In addition, the four above mentioned factors influenced base cutting energy in the following order: S diameter > F rate > R Speed > T angle (18.45 >18.39 > 12.91 > 9.06). R Speed2, T angle4, S diameter1, and F rate3 (200 rpm disc rotating speed, 20° disc tilt angle, 60 mm S diameter, and 1.0 m s−1 Frate), were found to be the best factor-level combination. Comprehending the relationship between energy consumption and the four factors mentioned above can help researchers improve the design of a contra-rotating base cutter, which may increase energy efficiency and lower the energy required during sugarcane harvesting [12].

Designed a sugarcane base cutter with a revolving knife and identified the operational conditions that will save energy inputs. A blade peripheral velocity of 13.8 m s−1, an oblique angle of 35°, and a tilt angle of 27.8° were found to be suitable [13]. A 6-kW gasoline engine was used to construct a self-propelled single axle moving sugarcane harvester walking type. It was developed for farmers in impoverished nations who could not afford to purchase expensive sugarcane harvesters. The number of workers needed to cut and windrow sugarcane stems was reduced due to harvesting by this machine [14].

Sugarcane harvesting is among the most expensive field operations in production. To lower total harvest costs and increase sugarcane output, sugarcane harvesters must be improved in terms of cane stalk recovery percentage and field efficiency [15].

The base cutter that rotates in the opposite direction has a lesser stubble damage rate than the traditional base cutter and can increase cutting quality. The results also showed that a disc rotational speed of 550 rpm, a cane stalk feed rate of 0.5 m s−1, 5 blades, and a disc tilt angle of 0° are the optimum parameters for the contra-rotating base cutter. The stubble damage rate of the contra-rotating base cutter was 15% once these optimal parameters were established, which was significantly lower than that of the traditional base cutter (25%) [16].

When cane yield increases from 56 to 78-ton ha−1, harvesting rates for single-row and two-row whole stalk harvesters will drop by 33% and 14%, respectively. A single-row harvester costs 35% less per hour than a double-row harvester for a full stalk harvester. Nevertheless, the cost per acre was 69% more expensive because a single row harvester’s field capacity was 61% lower than a double row harvester’s [17]. A serrated-edge blade has better cutting ability than a smooth-edge blade [18]. For a serrated-edge blade, the ones with a shorter pitch consume less energy [19].

The main research problem is that in many agricultural areas, there are no machines that are suitable for all types of sugarcane harvesting, no standard size for the distance between sugarcane rows therefore manual harvesting has become a commonly used method which is very expensive in comparison to mechanical harvesting. The cultivated areas are restricted and need to have suitable size harvesters for limited holdings. In developed countries, used to harvest sugarcane manually and did not accept or could use mechanical harvesters cause of believing that mechanical harvester is very expensive cost, need import machines from other industrialized countries and lost big amount of crop during mechanical harvester.

As a result, the main goal of this research was to fabricate a sugarcane harvester prototype attached on a tractor that farmers would find it suitable for all cultivation distances while also being simple to disassemble, install, adjust, maintain, and works in small farming holdings to reduce harvesting costs, which is important because the sugar business is a strategic product with high costs. The optimum operating conditions, engineering characteristics, economic evaluation of the fabricated harvester are investigated. Moreover, the research aimed to minimize cost, labor, and stipulated power requirements when using the prototype.

2. Materials and Methods

In El-Ibrahimia city, Sharkia Gov., Egypt, at a private workshop, the prototype of the sugarcane machine was assembled. Field experiments were conducted during the growing seasons of 2020 and 2021 at a private farm in Santimay Village, El-Dakahlia Gov. the soil at this experimental site was classified as clay soil. The experiments were laid out as factorial with two factors in a randomized complete block design (RCBD) with three replicates.

2.1. Sugarcane

Sugarcane (variety; C 9) physical and mechanical properties having stalks average moisture content of 80%. Shown in Table 1.

Table 1.

Physical and mechanical properties of sugarcane (variety; C 9).

2.2. Tractor

For the field experiments, a tractor was made in China, super master AS400X model, having a diesel engine with 1000 rpm maximum output and extreme power of 29.43 kW was utilized.

2.3. Fabricated Sugarcane Harvester Prototype Specification

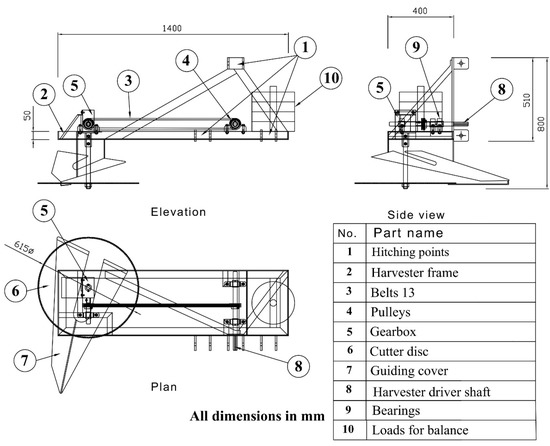

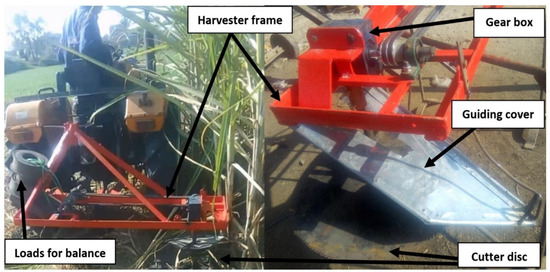

As depicted in Figure 1 and Figure 2, the mounted harvester prototype for sugarcane harvesting comprised of four basic parts: the mainframe, unit for cutting, gearbox, and transmission of power.

Figure 1.

Fabricated sugarcane harvester prototype.

Figure 2.

Fabricated sugarcane harvester prototype mounted on a tractor.

The prototype sugarcane harvester’s mainframe was made of iron, with dimensions of (50 × 50 × 5 mm3), it’s in the shape of L. The mainframe had a length of 1400 mm, a width of 400 mm, and a height of 800 mm.

To boost stability throughout the operation process, 75 kg loads have been put to the left side of the frame, as indicated in (Figure 2). There are two primary parts to the cutter unit. The sharp-toothed edged disc is the initial component. It has a diameter of 615 mm and is made of 3 mm thickness of iron sheet. The second component is a steel shaft with respective diameter and length of 25 and 320 mm. The gearbox was mounted on the prototype frame, and movement was conveyed from the gearbox to another steel shaft connect to the cutter disc’s shaft end to alter the power source’s transmission direction (PTO) by a factor of 1:2.

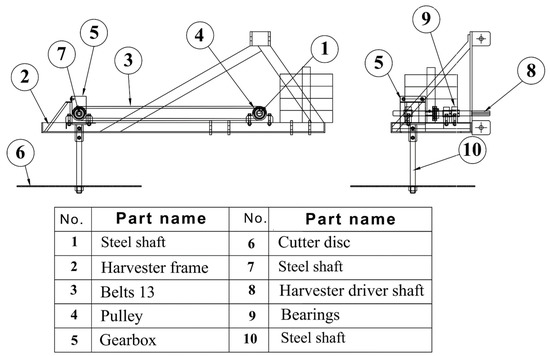

The power generated on the PTO shaft is transferred to the steel shaft on the prototype frame through the transmission system, which is supported by two bearings. The movement is then transferred to another steel shaft through two pulleys and two belts. On one side, it was fixed to the gearbox, and on the other side, it was fixed to the prior steel shaft by bearing (Figure 3).

Figure 3.

Power transmission system.

2.4. Experimental Conditions

Three forward speeds of 2, 3.5, and 5 km h−1, as well as three cutter disc speeds of 1000, 1500, and 2000 rpm, were used to test the sugarcane harvester prototype’s performance.

2.5. Instruments

The sugarcane samples were massed using a digital scale balance (OHAUS-USA). The balance’s highest mass was 2610 g, with a 0.1 g precision. Cutting force, for example, was measured using a digital force gauge. The FGN-5 type was manufactured in Japan and has a measuring range of 1000 N, an accuracy of 0.2% at 23 °C, and a weight of around 450 g.

The rotational speed of pulleys, cutting discs, and shafts was measured using a laser tachometer with an accuracy of 0.05%. This tachometer measures rotational speed from 0.05 to 19,999 revolutions per minute. The moisture content of sugarcane stalks was determined according to [20].

A fuel consumption gadget was used to estimate the fuel consumption during the pulling operation. It has a capacity of approximately 750 mL. A reading ruler (calibrated tube) is positioned vertically beside the tractor fuel tank and is split into 15 sections. Each division reads 50 mL. The calibrated tube is connected to the tank at the bottom end, and diesel can flow via the tube from the tank. As a result, the same amount of fuel in the tank will be the same amount in the tube. Each decrease of fuel in the tank’s will result in a drop in the tube level. The tube level was measured so that the amount of fuel utilised could be determined.

A 10-meter tap is used to assess several physical parameters of sugarcane as well as the trip distance to calculate tractor advance speeds. During the harvesting procedure, a timer with a precision of 0.01 s was employed to record the time spent on each treatment as well as the tractor forward speed. The diameter of sugarcane stalks was measured by using a digital vernier calibre with a precision of 0.01 mm.

2.6. Measurements

The following equation was used to calculate the actual field capacity:

where Ttotal is the total real time in (h ha−1) and Afc is the actual field capacity in (ha h−1).

Afc = (Ttotal)−1

The following equation was used to calculate field efficiency:

where Tfc is the theoretical field capacity in (ha h−1); Afc is the actual field capacity in (ha h−1), and η is the field efficiency in (%)

η = Afc/Tfc

According to [21], the following equation was used to calculate power (P).

where Po is the required power in (kilowatt); HV is the fuel heating value in (kJ kg−1); ηth is the thermal efficiency in (%); c is constant (3600) and FC is consumption of fuel in (kg h−1)

Po = (FC × c−1) × [(ηth × (100)−1] × HV

The following equation was used to determine the specific energy requirement:

where Speng is the specific energy requirements in (kW h ha−1); Afc actual field capacity in (ha h−1); and Po is the required power in (kilowatt).

Speng= P × Afc−1

The data were analyzed using R software version 3.6.1. The least significant difference (LSD) at p ≤ 0.05 was calculated to display the significant differences among evaluated treatments.

2.7. Economic Evaluation

This section of the research aims to assess the feasibility of using a locally fabricated cutting machine for harvesting sugarcane crops and compare its performance to the prevailing manual method; In order to achieve this goal, the research mainly based on estimating the percentage of benefits to the costs achieved from using the fabricated machine in cutting sugarcane crop.

The first; Operating costs items: they express all direct and indirect costs. The direct costs include the following items:

- The wage paid for the forces driving the machine (tractor and driver): It is represented by the hourly rental price of the tractor at the price prevailing in the experimental area, which is $9.54/h.

- Depreciation of the machine. Although the annual installment for depreciation of the machines is considered fixed costs, converting them to a share of the operating hour cost from the depreciation installment is considered as a variable cost.

Annual depreciation premium = the price of the machine/the life expectancy of the machine

The share of the operating hour from the depreciation installment of the machine = Annual depreciation premium/(number of days in the operating season × 8 operating hours per day)

Assumingly the cost of the fabricated machine $267.18, the life expectancy of the machine 10 years, the average harvest season for sugarcane three and a half months and compensate in the previous equation, the average share of the operating hour from the annual depreciation premium is $0.32/h.

As for the indirect costs, they are represented in two main items:

- 1

- The cost of UCSS (un cutting sugarcane stalks): It is represented by the cost of manual cutting of sugarcane stalks that were not cut mechanically due to several reasons. Among these reasons, the land was not prepared properly for cultivation to suit the mechanical cutting and/or not carrying out the lashing process for the sugarcane stalks, which was carried out at least twice so that the stalks remain standing and do not fall on the ground which obstacle the mechanical cutting process. Therefore, workers are essential to cut the sugarcane stalks that were not cut mechanically, and the cost of manual cutting is calculated as follows:Average hourly wage ($0.95) × The number of operating hours for the mechanical cutting process

- 2

- The value of losses: It is the value of the remaining part of the land from the sugarcane stalks without cutting compared to the manual cutting that is directly cut at the ground level. The losses value can be estimated as follows:Losses value = The amount of losses in tons × Average price per ton ($52.99/t)The amount of wastage in tons = 1 The average remaining length of each stalk in cm × The average number of stalks in hectare × 2 Average weight of 1 cm per ton1 The average remaining length of sugarcane stalk after cutting was about 4 cm at 2.5 km h−1 forward speed and about 5 cm at 3.5 km h−1 forward speed, while it was 7 cm for 5 km h−1 forward speed.2 It was calculated by dividing the average weight of stalks in tons/the average length of stalks in cm

The second; The benefits achieved from the use of mechanical cutting of sugarcane, expressed as the difference between the cost of mechanical cutting and the cost of manual cutting, as well as the time and effort it saves in the cutting process.

The Relative Importance of the Operating Cost Items of the Sugarcane Cutting Machine

Table 2 shows the relative importance of the cost items at various machine forward speeds and different cutting speeds. It was obvious, that the value of losses represents the largest part of the operating costs, followed by the cost of the driving forces to pull the machine, followed by the cost of UCSS and finally the cost of depreciating the machine. The table data also indicates that the lowest operating cost was recorded at 3.5 km h−1 forward speed and 1000 rpm cutting speed, with total operating costs estimated at $152.06/ha. Where [22] agreed that the lower costs in mechanical harvesting than in manual harvesting as a result of reducing labor.

Table 2.

The relative importance of the cost items for different forward and cutting speeds.

The data of the following (Table 3) shows that all transactions of various forward and cutting speeds achieved positive (profitable) benefits and that the combination of 3.5 km h−1 forward speed and a 1000 rpm cutting speed also achieved the highest benefits ($115.12/ha), representing the highest rate of return (benefits) for costs estimated at 75.7% of the total operating costs for the same transaction.

Table 3.

Cost-benefit ratio for different forward speeds and cutting speeds.

These results agree with the findings of [23], who analysed the costs of sugarcane production utilising machines with human labour. The automated system cost 14.19% less than the manual system, according to their findings. Harvesting is the most expensive of any other mechanical system operation, but planting might save more money than any other activity. They also recommended that planting and harvesting were the two most important processes for early mechanization.

According to our results, manual harvesting of one hectare area is quite costly, which has a considerable beneficial impact on the price of sugar and black honey. To lower sugar production costs, it is critical to reduce labours costs and time. In this context manufacturing small scale machines such as the prototype under investigation would be cost-effective in harvesting sugarcane.

3. Results and Discussion

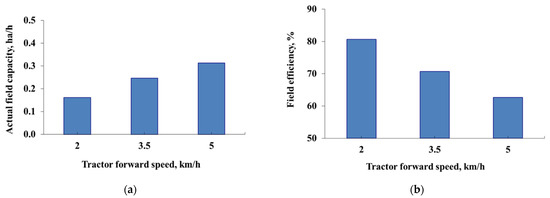

3.1. Actual Field Capacity and Field Efficiency

The prototype was evaluated by calculating the actual field capacity and field efficiency from the rated width of prototype and their relationship to the forward speed of the tractor, where the forward speeds were 2, 3.5 and 5 km h−1. Where the results showed in Figure 4a,b that by increasing the forward speeds of the tractor from 2 to 5 km h−1, the field capacity increased from 0.161 to 0.313 ha h−1, respectively. While we found a reverse proportion in the relationship between the forward speeds of the tractor and the field efficiency, where the field efficiency decreased from 80.67 to 62.69%, respectively, as the decrease in field efficiency was about 22.3%, under the different speeds of the cutter disc. The ratio between lost time and total operational time was greater at high speed than at slow speed, which resulted in a drop in field efficiency by increasing forward speed.

Figure 4.

The effect of the tractor forward speed on (a) Actual field capacity and (b) field efficiency.

The results of our research correspond with those obtained by [14], who reported that in field tests, the machine’s average field capacity was 0.13 ha h−1, with a 71% average field efficiency. These findings are reinforced by the findings of [8], who assessed the Guangxi Institute of Agricultural Machinery’s by evaluate 4GZ-9 full stalk harvester, installed on 11–14.7 kW small hand tractor. Following cutting, the sugarcane stalks were laid down on the ground beside the machine. When the sugarcane is not severely lodged, it can be used. It has a field capacity ranged from 0.1 to 0.15 ha h−1 and can handle row spacing of 1.0 m or more.

Table 4 showed that when forward speed 5 km h−1 was the highest significant value for each of 0.31 and 0.5 ha h−1 of actual field capacity and theoretical field capacity, while when forward speed 2 km h−1 was the best significant value in cutting efficiency of 80.67%, while at speed 5 km h−1 was the lowest value.

Table 4.

Relationship between the different forward speeds on actual field capacity, theoretical field capacity and field efficiency.

3.2. Power Required and Specific Energy Requirement

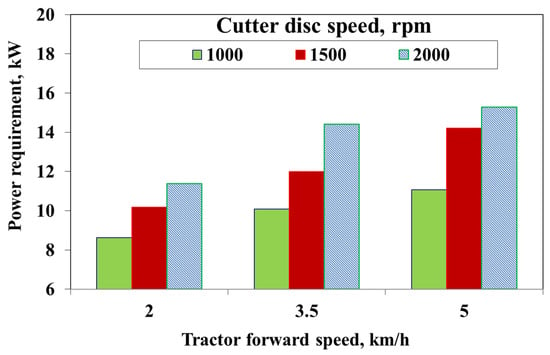

Figure 5 shows the relationship between the power requirements and the tractor forward speed during the harvesting process. The average results were shown at a tractor forward speed of 2 km h−1, the power requirements increased by 8.62, 10.18 and 11.37 kW when increasing the speed of the cutter disc from 1000, 1500 and 2000 rpm, respectively. When the tractor forward speed was increased to 3.5 km h−1, the power requirements increased more and became 10.07, 12 and 14.41 kW when the speed of the cutter disc increased from 1000, 1500 and 2000 rpm, respectively. When increasing the tractor forward speed was increased to 5 km h−1, we find an increase in power requirements from 11.07, 14.21, and 15.28 kW, under the speed of the cutter disc increased from 1000, 1500 and 2000 rpm, respectively, and from the results, it became clear that the power requirements for the harvest process increases as a result of the increase in the number of sugarcane stalks corresponding to the cutting disc with an increase in cutter disc speeds and forward tractor speeds

Figure 5.

The power requirement as affected by tractor forward speed and cutting disc speed.

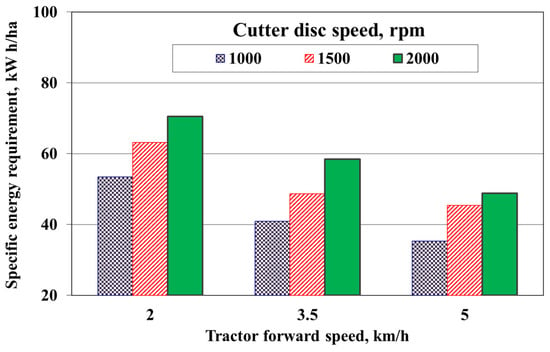

Figure 6 shows the relationship between specific energy requirements and the tractor forward speed during the harvesting process.

Figure 6.

The tractor forward speed and cutter disc speed have an influence on specific energy requirement.

The average results were a decrease in specific energy requirements from 53.44, 40.87 and 35.33 kW h ha−1, with an increase in tractor forward speeds from 2, 3.5 and 5 km h−1, respectively, at a cutter disc speed of 1000 rpm. The cutting disc speed at 1500 rpm, we found a decrease in specific energy requirements of 63.15, 48.67 and 45.34 kW h ha−1 under tractor forward speeds of 2, 3.5 and 5 km h−1, respectively.

At a cutter disc speed of 2000 rpm, the average results showed a decrease in specific energy requirements of 70.52, 58.46 and 48.8 kW h ha−1 under tractor forward speeds of 2, 3.5 and 5 km h−1, respectively.

These statistics show that at different cutter disc speeds, there is a significant relation between power requirements and forward speed. These results are consistent with the findings of [24] during the experimental extractor of a sugarcane chopper harvester, who claimed that the average power consumption was higher at higher feeding rates than at lower feeding rates.

4. Conclusions

The present study aimed to fabricate a small sugarcane harvester suitable for small size farms. The fabricated sugarcane harvester prototype is recommended by technical evaluation to harvest sugarcane with one serrated edge cutter disc was used at a forward speed of 5 km h−1 and a rotational speed of 2000 rpm. The greatest actual field capacity of 0.313 ha h−1, a specific energy requirement of 48.76 kW h ha−1 and power required of 15.28 kW. Despite that economic evaluation empathies that the lowest operating cost was recorded at 3.5 km h−1 forward speed and 1000 rpm cutting speed, with total operating costs estimated at $152.06/ha. The combination of 3.5 km h−1 forward speed and a 1000 rpm cutting speed also achieved the highest benefits ($115.12 /ha), representing the highest rate of return (benefits) for costs estimated at 75.7% of the total operating costs for the same transaction. The fabricated prototype for harvesting sugarcane saved labour, time, energy, and cost and therefore the final net income. This research study showed effectively improve the efficiency sugarcane harvesting process.

Author Contributions

Conceptualization, A.M.E.S. and M.I.E.D.; methodology and investigation, A.M.E.S. and M.I.E.D.; writing-original draft preparation, A.M.E.S., Y.S.M. and M.I.E.D.; primitive and final field experiments, A.M.E.S. and M.I.E.D.; writing-review and editing, A.M.E.S.; Y.S.M. and M.I.E.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We thank Mohamed El Shal, Adel H. Elmetwalli and El Sayed mansour for their cooperation in editing and reviewing this manuscript, and we thank our family members.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Statista. Statista 2019. Available online: https://www.statista.com/ (accessed on 23 January 2021).

- FAO. Production Crops All Data. FAOSTAT; FAO: Rome, Italy, 2018. [Google Scholar]

- Lai, C.Q. Mechanization of inter-tillage is the primary breakthrough link in sugarcane industry. Guang Xi Agric. Mech. 2003, 6, 33. [Google Scholar]

- Wang, R.F.; Yang, J.; Liang, Z.X.; Mo, J.L.; Gu, H.Y. Experimental optimization study on working parameters of sugarcane harvester cutter. J. Agric. Mech. Res. 2004, 4, 144–147. [Google Scholar]

- Liu, Q.T.; Ou, Y.G.; Yuan, N.X. Bending load induced failure forms of sugarcane stalks. Trans. Chin. Soc. Agric. Eng. 2004, 20, 6–9. [Google Scholar]

- Zheng, D.K.; Ou, Y.G.; Li, Z.W.; Qing, S.L.; Liu, Q.T. The parameters matching of sugarcane harvester moving rate and base cutter rev. J. Agric. Mech. Res. 2010, 6, 35–38. [Google Scholar]

- Yang, J.; Chen, G.J.; Liang, Z.X.; Mo, J.L.; Li, M. Experimental study on influencing factors of broken biennial root rate for a single base cutter of sugarcane harvester. Trans. Chin. Soc. Agric. Mach. 2007, 38, 69–74. [Google Scholar]

- Ou, Y.; Malcolm, W.; Yang, D.; Liu, Q.; Zheng, D.; Wang, M.; Liu, H. Mechanization technology: The key to sugarcane production in China. Int. J. Agric. Biol. Eng. 2013, 6, 1–27. [Google Scholar]

- Song, C.H.; Ou, Y.G. Screw and sugarcane mechanism for sugar cane up effect. J. Hunan Agric. Univ. 2004, 21, 569–571. [Google Scholar]

- Lu, Y.; Yang, J.; Liang, Z.; Mo, J.; Qiao, Y. Simulative kinematics analysis on the affecting factors of rate of broken biennial root of single base cutter of sugarcane harvester. Trans. Chin. Soc. Agric. Mach. 2008, 39, 50–55. [Google Scholar]

- Wang, X.M.; Mo, J.L. Economical efficiency analysis of the application of the sectional type sugarcane harvesting system. J. Agric. Mech. Res. 2011, 9, 49–52. [Google Scholar]

- Wang, F.; Ma, S.; Xing, H.; Bai, J.; Ma, J.; Ke, W. Basecutting energy consumption of sugarcane stools using contra-rotating basecutters. In Proceedings of the ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019. Code 151393. [Google Scholar]

- Gupta, C.P.; Oduori, M.F. Design of the revolving knife-type sugarcane basecutter. Trans. ASAE 1992, 35, 1747–1752. [Google Scholar] [CrossRef]

- Gupta, C.P.; Lwin, L.; Kiatiwat, T. Development of a self-propelled single-axle sugarcane harvester. Appl. Eng. Agric. 1996, 12, 427–434. [Google Scholar] [CrossRef]

- Ma, S.; Scharf, P.A.; Karkee, M.; Zhang, Q. Performance Evaluation of a Chopper Harvester in Hawaii Sugarcane Fields. 2014. Available online: https://elibrary.asabe.org/abstract.asp?aid=44613 (accessed on 3 March 2022).

- Wang, F.; Zhang, W.; Di, M.; Wu, X.; Song, Z.; Xie, B.; Yang, G.; Ma, S. Sugarcane cutting quality using contra-rotating basecutters. Trans. ASABE 2019, 62, 737–747. [Google Scholar] [CrossRef]

- Salassi, M.E.; Champagne, L.P. Estimated costs of soldier and combine sugarcane harvesting systems in Louisiana. Dept of Agriculture and Agribusiness, Louisiana State University. Baton Rouge. Research Report, 1996. Available online: https://ageconsearch.umn.edu/record/31660/ (accessed on 3 March 2022).

- Mello, R.D.C.; Harris, H. Performance of basecutter of sugarcane harvester with angled and serrated blades. Rev. Bras. Eng. Agrícola Ambient. 2003, 7, 355–358. [Google Scholar] [CrossRef]

- Mello, R.D.C.; Harris, H. Cane Damage and Mass Losses for Conventional and Serrated Basecutter Blades. 2000. Available online: https://www.cabdirect.org/cabdirect/abstract/20002402092# (accessed on 3 March 2022).

- ASAE Standards, 2012. S358.2; Moisture Measurement—Forages. ASAE: St. Joseph, MI, USA, 2012.

- Hunt, D. Farm Power and Machinery Management, 8th ed.; Ames Iowa State University Press: Iowa City, IA, USA, 1983; p. 29. [Google Scholar]

- Ahmed, A.E.; Alam-Eldin, A.O.M. An assessment of mechanical vs manual harvesting of the sugarcane in Sudan–The case of Sennar sugar factory. J. Saudi Soc. Agric. Sci. 2015, 14, 160–166. [Google Scholar] [CrossRef]

- Zhang, H.; Luo, J.; Liao, P.W. Sugarcane mechanization cost analysis and the establishment of a profit evaluation model. Chin. J. Trop. Crops 2010, 10, 1669–1673. [Google Scholar]

- Bai, J.; Ma, S.; Yang, G.; Wang, F.; Xing, H.; Ke, W. Testing and analysis of the extractor of a sugarcane chopper harvester. Trans. ASABE 2020, 63, 251–257. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).