Digital Triplet Approach for Real-Time Monitoring and Control of an Elevator Security System

Abstract

1. Introduction

2. Literature Review

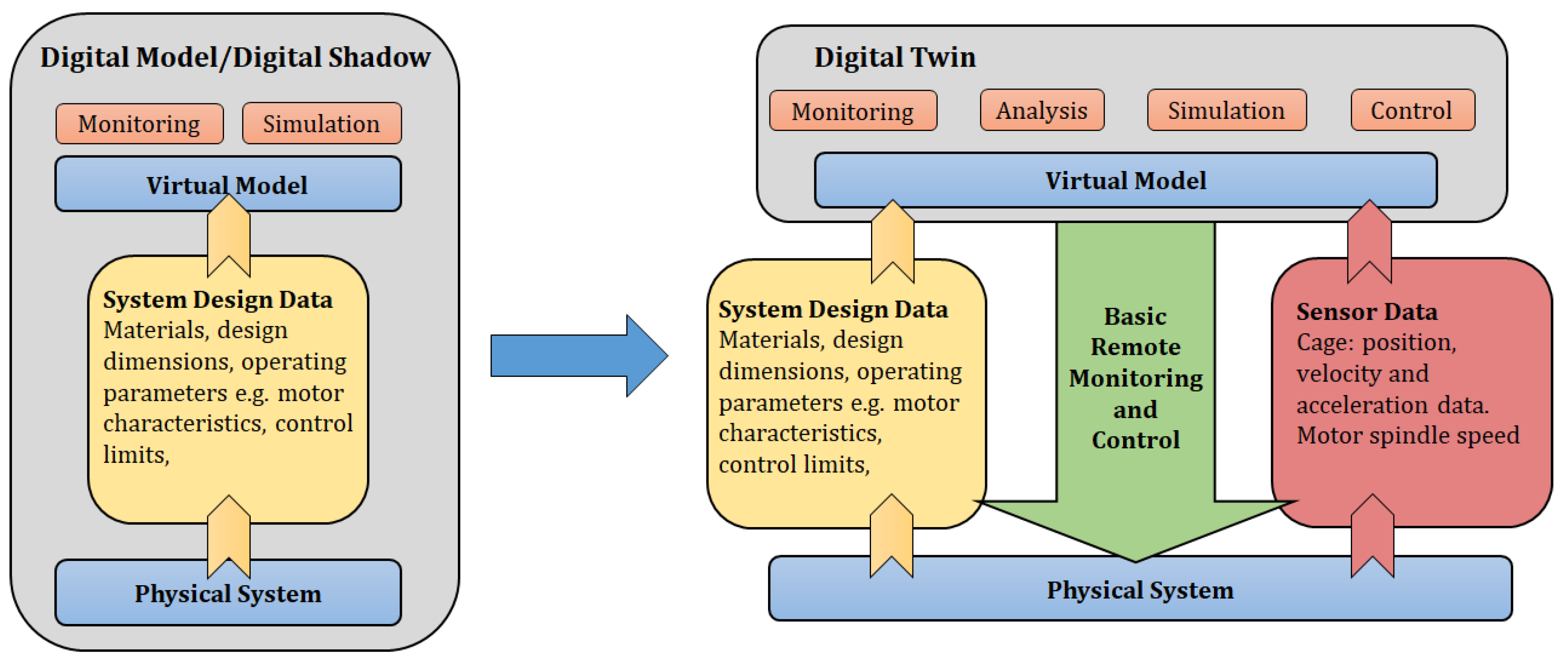

2.1. From Digital Twin to Digital Triplet

2.1.1. Development of Digital Twin Technology

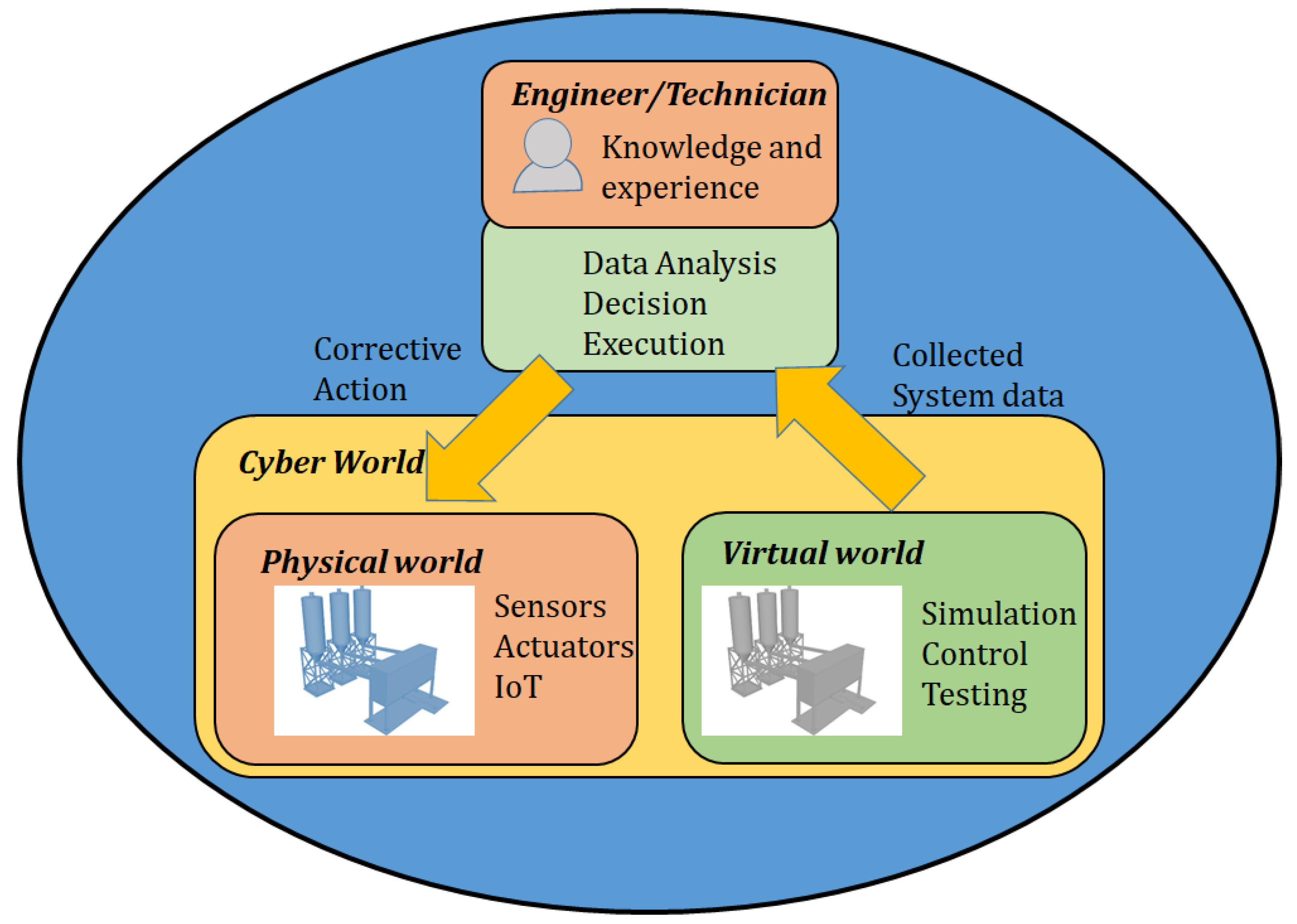

2.1.2. Digital Triplet

- i.

- The adoption of digitisation in Japanese manufacturing industries might not fit the prevailing Japanese engineering philosophy and might extinguish its strengths.

- ii.

- Engineers/technicians found it difficult to adopt digitisation due to the need to apply their knowledge and experience to effect changes not only to the physical system but also to their virtual counterparts.

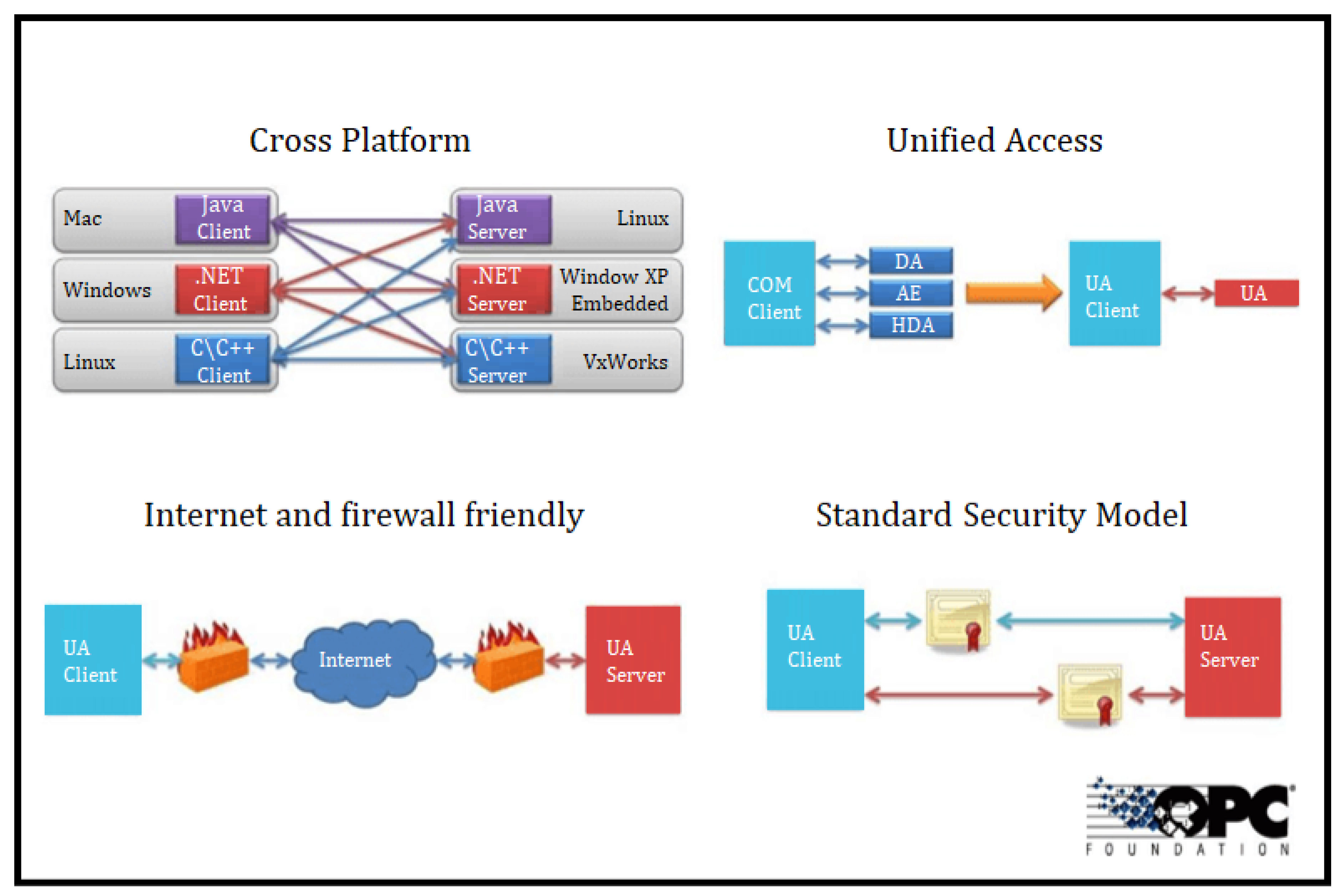

2.2. OPC-UA in Industrie 4.0

- i.

- Restricted use to only Windows operating system;

- ii.

- Difficulty in handling and integrating different OPC services, i.e.OPC-AE, OPC-DA, OPC-HDA;

- iii.

- Incompatibilities with internet firewalls protocols;

- iv.

- Emergent security issues since initially access and data security was not a concern.

2.3. Integration of Machine learning in Digital Twins and OPC-UA

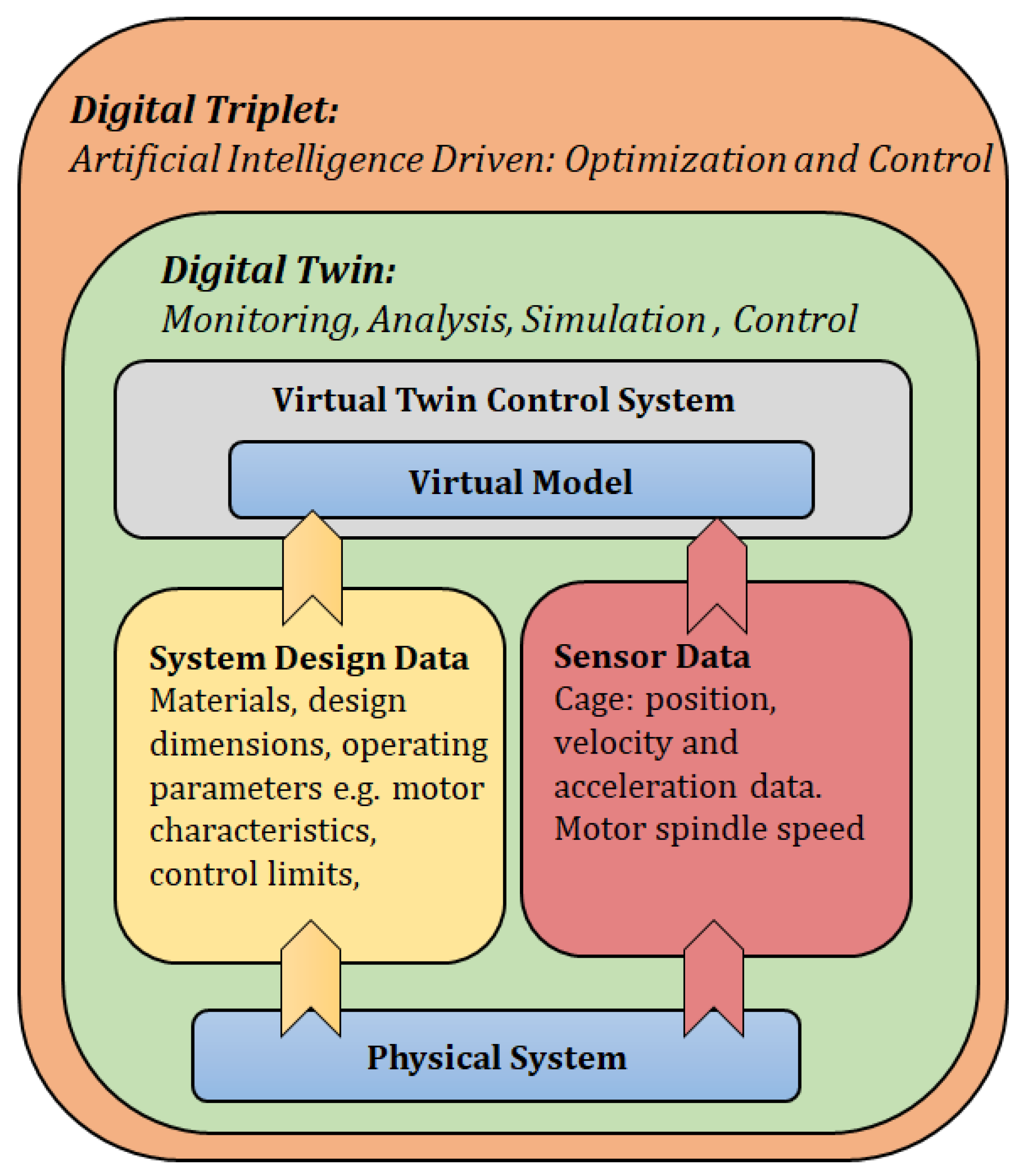

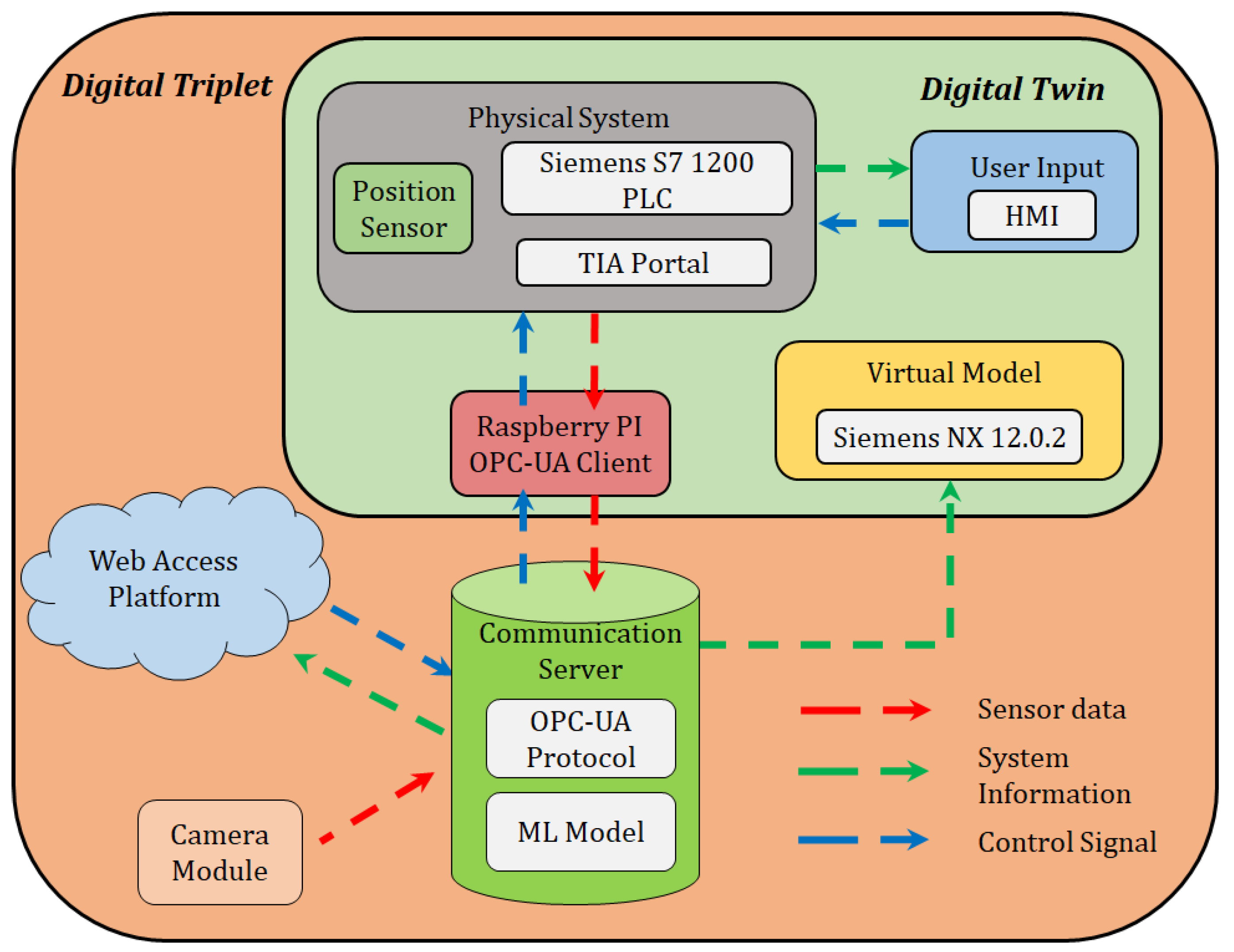

3. Design of the Digital Triplet for the Three-Floor Model Elevator System

- i.

- Physical System—Consisted of the three-floor elevator model controlled by a Siemens S7 1200 PLC, an ultrasonic distance sensor and an HMI;

- ii.

- Virtual Model—A digital model of the elevator system was generated using Siemens NX 12.0.2 modelling and simulation software. It receives sensor data from the Raspberry Pi and updates the position of the model in line with the position of the elevator cage;

- iii.

- Raspberry Pi—This served as an OPC-UA client and acted as an intermediary between the PLC and OPC server since PLC S7-1200 cannot function independently as an OPC-UA Client;

- iv.

- OPC Communication Server—An information server that enabled communication between the physical system and the web access platform. It also contained a trained object recognition module able to detect objects from a camera feed;

- v.

- Web Access Platform—An internet enabled means of controlling and monitoring the elevator model remotely;

- vi.

- Camera—A security feature, akin to common surveillance systems in elevators with a connection to the OPC server. Image frames from the camera are captured and sent to the object recognition algorithm housed in the OPC server.

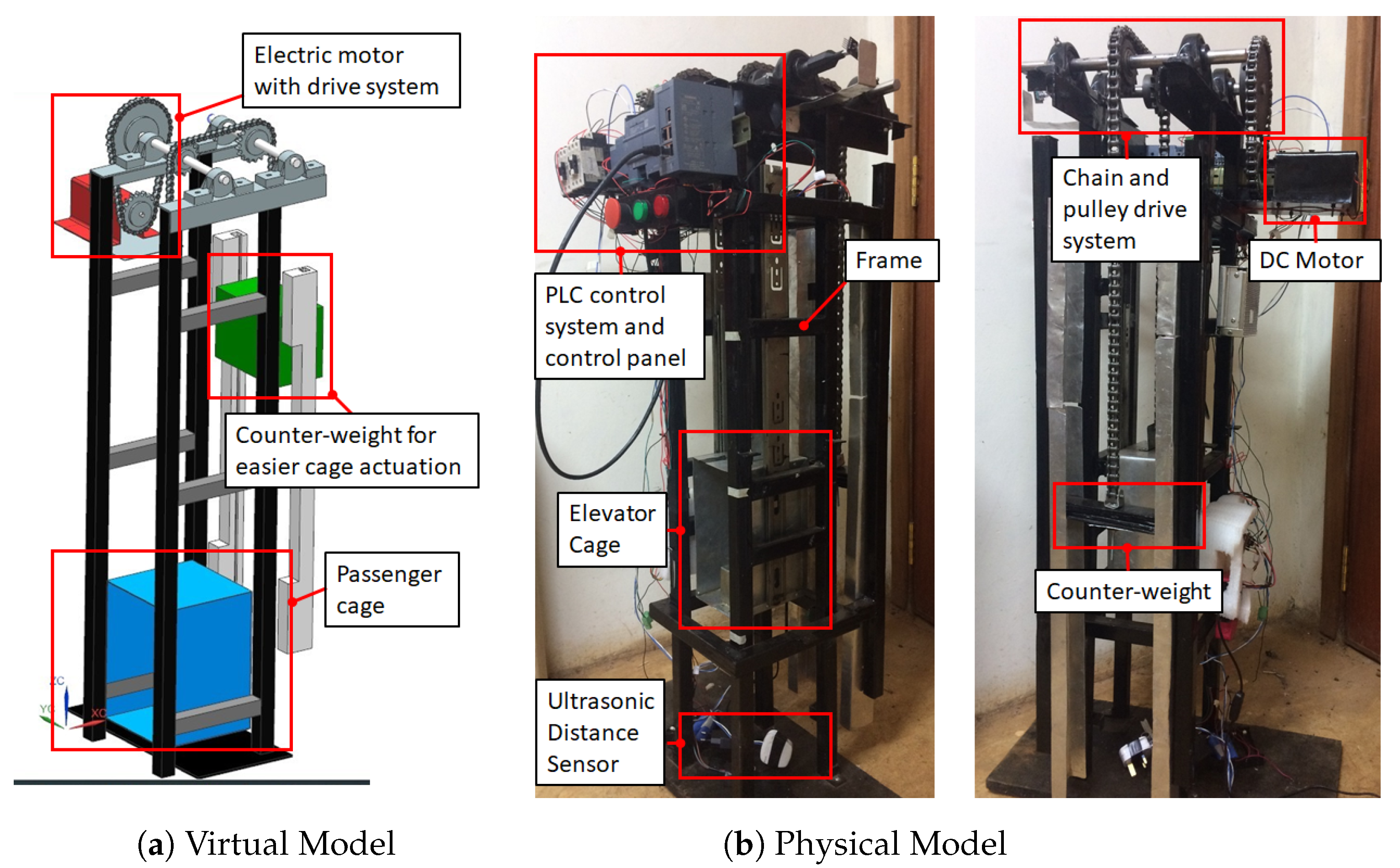

3.1. Virtual and Physical Model Implementation

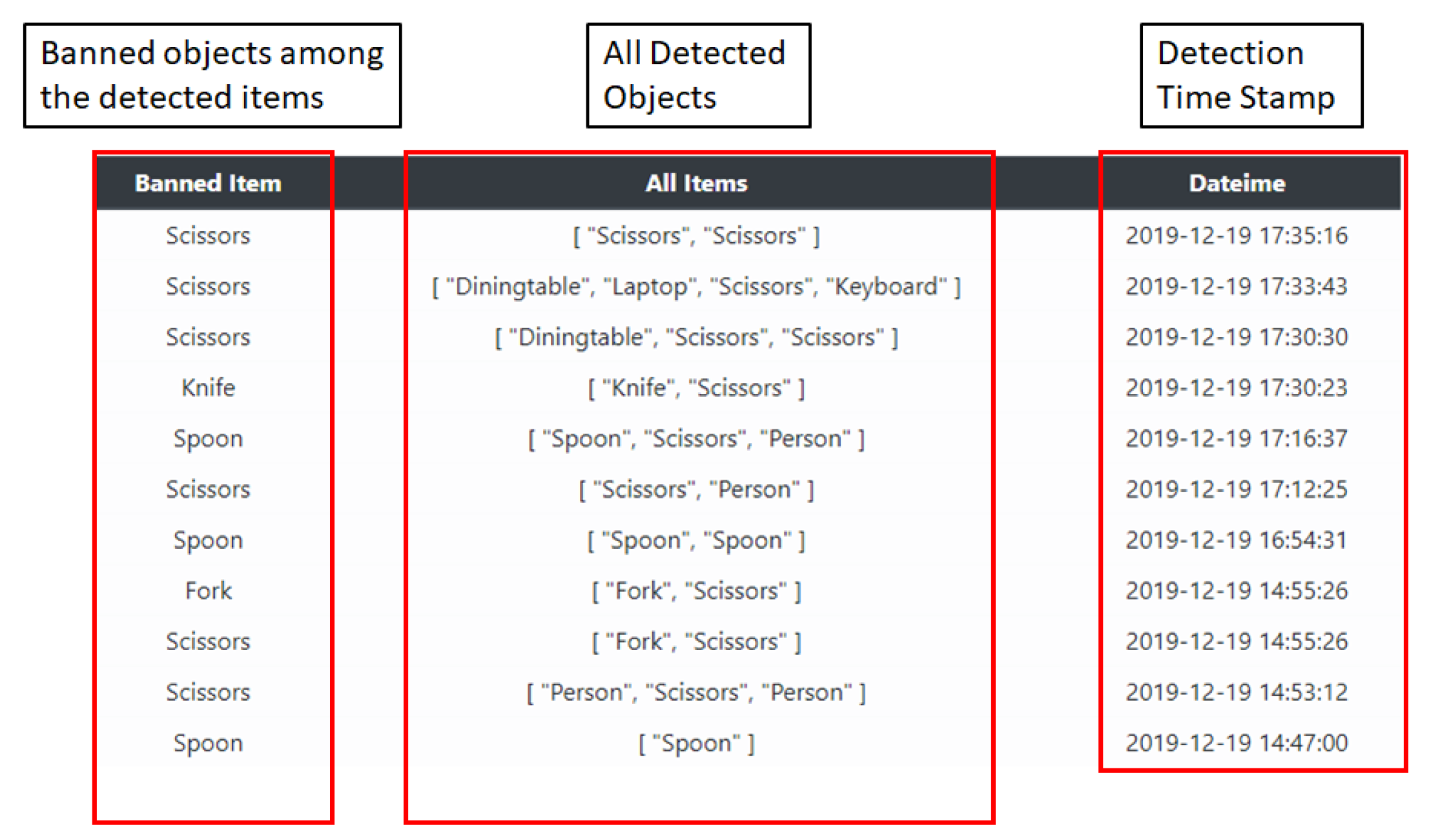

3.1.1. OPC Server and Object Recognition Module

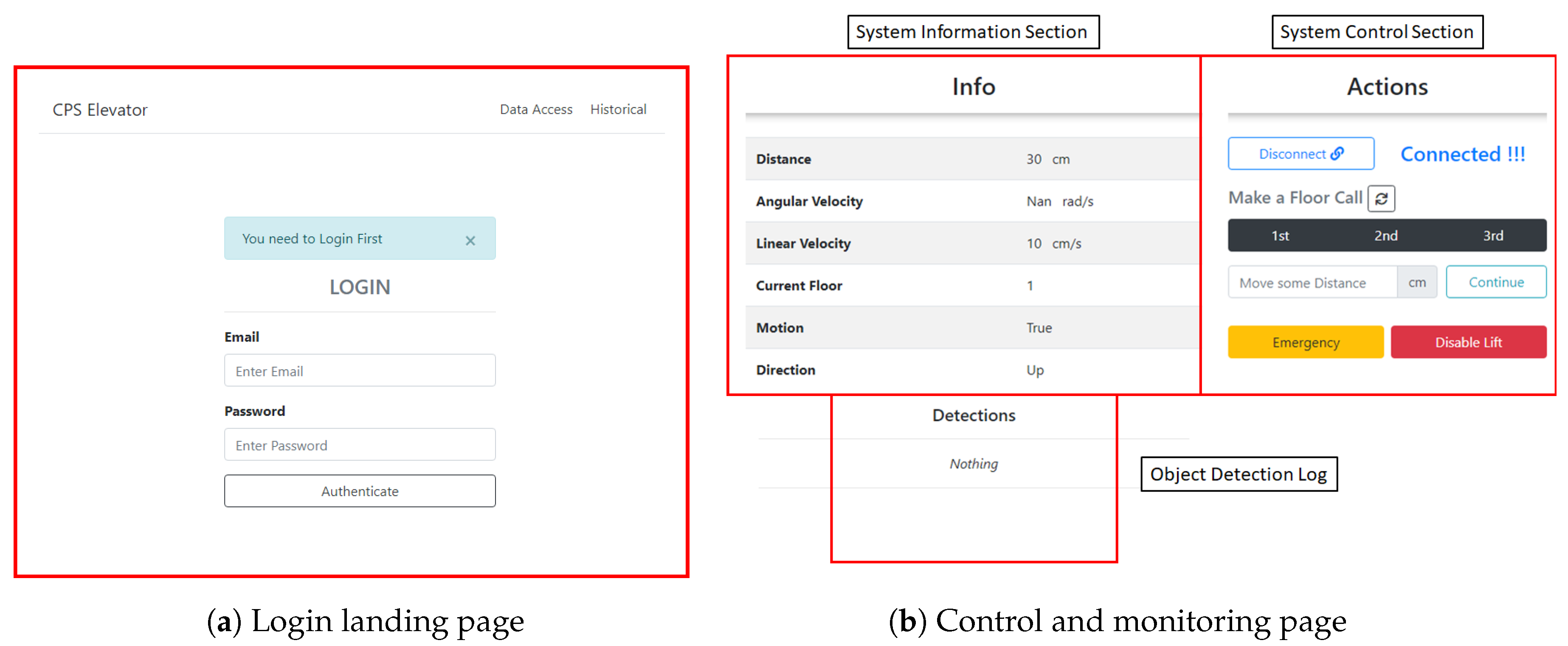

3.1.2. Web Access Platform (WAP)

3.2. Elevator Control Sequence

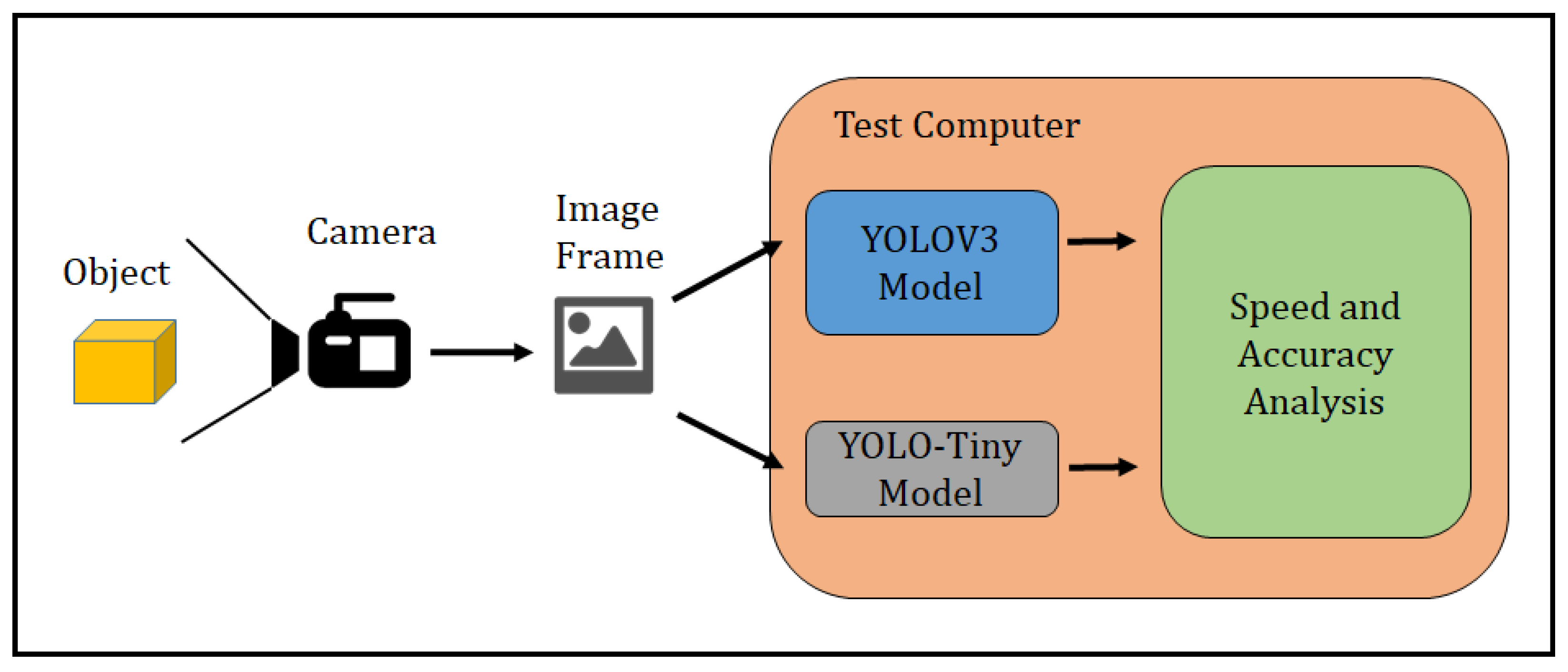

4. Performance Testing: Preliminary Accuracy and Speed Testing of Object Detection Models

4.1. Model Accuracy and Speed Experiment

4.2. System Interstitial Time Experiments

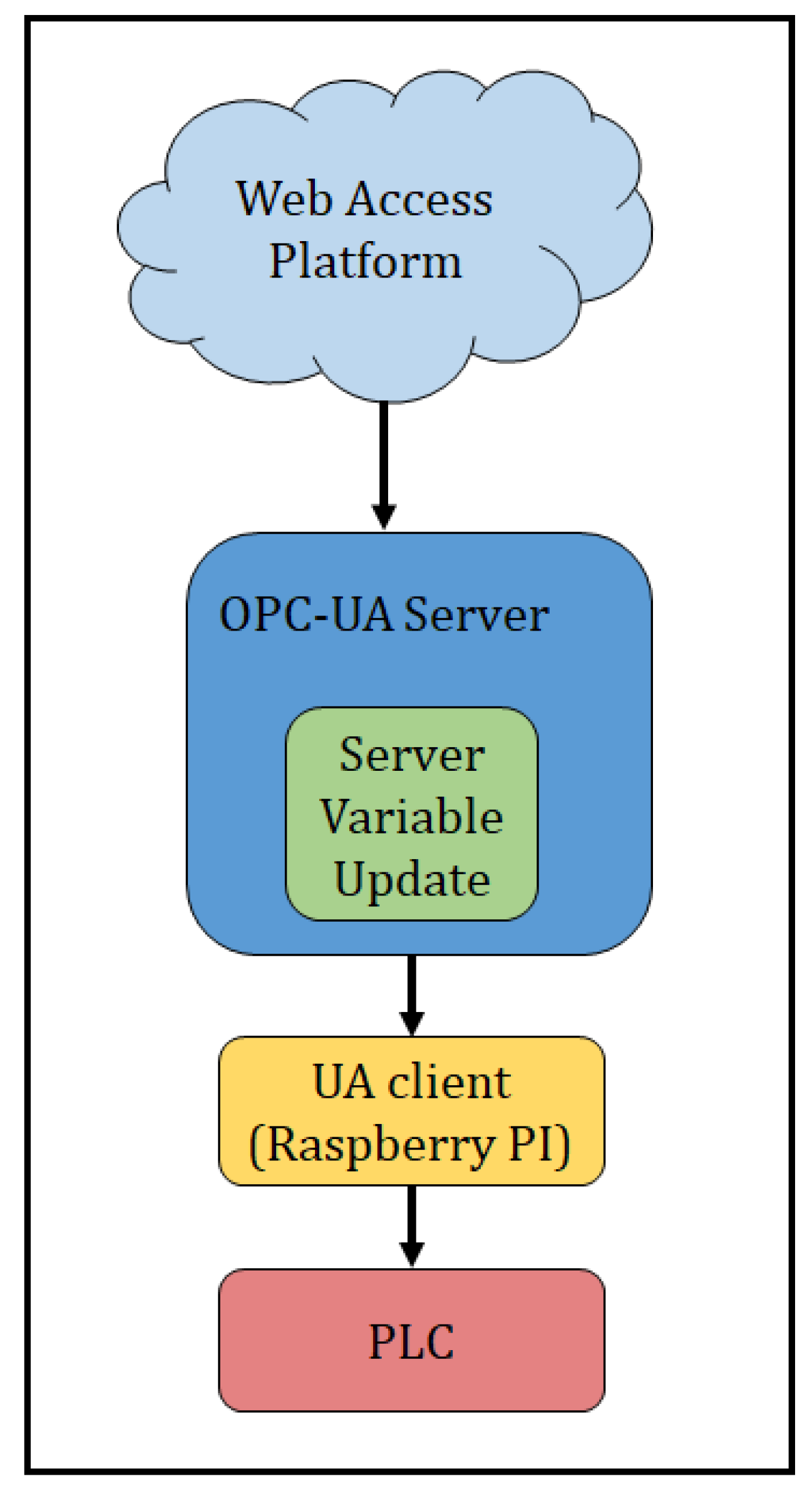

4.2.1. Time Response between WAP and PLC Experiment

- i.

- Sending of user command from WAP to OPC-UA server;

- ii.

- Update of relevant variables within the OPC-UA server;

- iii.

- Query and update of server variable by UA client (Raspberry Pi);

- iv.

- Relay of variable from UA client to PLC.

4.2.2. Time Response between Camera, ML Model and PLC Experiment

- i.

- Sending of camera frame;

- ii.

- Pre-processing of frame to be fed into the YOLOV3 model;

- iii.

- Classification of object within frame;

- iv.

- Update of relevant variables within the OPC-UA server;

- v.

- Query and update of server variable by UA client (Raspberry Pi);

- vi.

- Relay of variable from UA client to PLC.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Neugebauer, R.; Hippmann, S.; Leis, M.; Lherr, M. Industrie 4.0-From the perspective of applied research. In Proceedings of the 49th CIRP-CMS 2016, Stuttgart, Germany, 25–27 May 2016; pp. 2–7. [Google Scholar]

- Mrugalska, B.; Wyrwicka, M. Towards lean production in industry 4.0. Procedia Eng. 2017, 182, 466–473. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 363–369. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Diez-Olivan, A.; Del Ser, J.; Galar, D.; Sierra, B. Data fusion and machine learning for industrial prognosis: Trends and perspectives towards Industry 4.0. Inf. Fusion 2019, 50, 92–111. [Google Scholar] [CrossRef]

- Umeda, Y.; Ota, J.; Kojima, F.; Saito, M.; Matsuzawa, H.; Sukekawa, T.; Takeuchi, A.; Makida, K.; Shirafuji, S. Development of an education program for digital manufacturing system engineers based on ‘Digital Triplet’concept. Procedia Manuf. 2019, 31, 3563–3576. [Google Scholar]

- Uhlemann, T.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. In Proceedings of the 24th CIRP Conference on Life Cycle Engineering, Kamakura, Japan, 8–10 March 2017; pp. 335–340. [Google Scholar]

- Negri, E.; Fumagall, L.; Macchi, M. A review of the roles of Digital Twin in CPS-based production systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Um, J.; Weyer, S.; Quint, F. Plug-and-Simulate with Modular Assembly Line enabled by Digital Twins and the use of AutomationML. IFAC PapersOnLine 2017, 50, 15904–15909. [Google Scholar] [CrossRef]

- Weyer, S.; Meyer, T.; Ohmer, M.; Gorecky, D.; Zuhlke, D. Future Modeling and Simulation of CPS-based Factories and Example from the Automotive Industry. IFAC PapersOnLine 2016, 49, 97–102. [Google Scholar] [CrossRef]

- OPC Foundation. “What is OPC?”. Available online: https://opcfoundation.org/about/what-is-opc/ (accessed on 17 March 2020).

- Silva, M. “OPC UA support for Beremiz softPLC”. Available online: https://hdl.handle.net/10216/115498 (accessed on 17 March 2020).

- OPC Foundation. “History - OPC Foundation”. Available online: https://opcfoundation.org/about/opc-foundation/history/ (accessed on 20 March 2020).

- Schwarz, M.; Borcsok, J. A survey on OPC and OPC-UA: About the standard, developments and investigations. In Proceedings of the 2013 XXIV International Conference on Information, Communication and Automation Technologies (ICAT), Sarajevo, Bosnia and Herzegovina, 30 October–1 November 2013. [Google Scholar]

- Soderberg, R.; Warmefjord, K.; Carlson, J.; Lindkvist, L. Toward a Digital twin for real-time geometry assurance in individualized production: 360 Degree Comparison. CIRP Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Bao, J.; Guo, D.; Li, J.; Zhang, J. The modelling and operations for the digital twin in the context of manufacturing. Enterp. Inf. Syst. 2018, 13, 534–556. [Google Scholar]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Zhu, W.; Tao, F. Digital twin modelling method for CNC machine tool. In Proceedings of the 2018 IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), Zhuhai, China, 27–29 March 2018. [Google Scholar]

- Osinde, N.; Byiringiro, J.; Gichane, M.; Smajic, H. Process Modelling of Geothermal Drilling System Using Digital Twin for Real-Time Monitoring and Control. Designs 2019, 3, 45. [Google Scholar] [CrossRef]

| Pretrained Model- YOLOV3 (COCO Dataset) | Trained Model-YOLO Tiny (Custom Dataset) | |||||

|---|---|---|---|---|---|---|

| No. | Bottle | Knife | Time | Bottle | Knife | Time |

| 1 | 0.563078 | 1.436954 | 0.538134 | 0.293176 | ||

| 2 | 0.518505 | 1.097018 | 0.26874 | 0.115766 | ||

| 3 | 0.712644 | 1.147794 | 0.238605 | 0.122837 | ||

| 4 | 0.604001 | 1.115672 | 0.35785 | 0.11534 | ||

| 5 | 0.617293 | 1.095899 | 0.236708 | 0.11451 | ||

| 6 | 0.768312 | 1.098382 | 0.20796 | 0.118993 | ||

| 7 | 0.847213 | 1.087484 | 0.299728 | 0.115685 | ||

| 8 | 0.83869 | 1.101691 | 0.246914 | 0.117492 | ||

| 9 | 0.461898 | 1.085279 | 0.202363 | 0.114799 | ||

| 10 | 0.878751 | 1.086199 | 0.222235 | 0.114908 | ||

| 11 | 0.855653 | 1.085588 | 0.38596 | 0.115583 | ||

| 12 | 0.67897 | 1.089047 | 0.267305 | 0.120144 | ||

| 13 | 0.431009 | 1.236007 | 0.352158 | 0.12096 | ||

| 14 | 0.62166 | 1.235347 | 0.394833 | 0.121908 | ||

| 15 | 0.977759 | 1.227963 | 0.923965 | 0.115066 | ||

| 16 | 0.982802 | 1.251054 | 0.717396 | 0.122392 | ||

| 17 | 0.943187 | 1.232909 | 0.877083 | 0.115504 | ||

| 18 | 0.888342 | 1.236449 | 0.757118 | 0.117676 | ||

| 19 | 0.945846 | 1.489872 | 0.974552 | 0.113529 | ||

| 20 | 0.679464 | 1.338581 | 0.728801 | 0.124169 | ||

| 21 | 0.932162 | 1.26507 | 0.411357 | 0.120918 | ||

| 22 | 0.950707 | 1.278451 | 0.239319 | 0.11672 | ||

| 23 | 0.988292 | 1.322283 | 0.208433 | 0.11777 | ||

| 24 | 0.995962 | 1.21862 | 0.523656 | 0.119485 | ||

| 25 | 0.999116 | 1.222793 | 0.365052 | 0.122549 | ||

| 26 | 0.999661 | 1.216217 | 0.834931 | 0.115162 | ||

| 27 | 0.996282 | 1.222553 | 0.654359 | 0.119391 | ||

| 28 | 0.457893 | 1.217895 | 0.342688 | 0.150091 | ||

| 29 | 0.984947 | 1.576505 | 0.24305 | 0.115937 | ||

| 30 | 0.978729 | 1.203016 | 0.208724 | 0.128472 | ||

| AVG | 0.833396 | 0.7513 | 1.217286 | 0.339926 | 0.615581 | 0.125231 |

| Camera Frame Send Time | Frame Pre- Processing Time | Model Classification Time | Variable Update Time | Raspberry Pi Response Time | Raspberry Pi to PLC Write Time | Total Signal Travel Time | |

|---|---|---|---|---|---|---|---|

| Average time in Sec | 0.025 | 0.003 | 1.026 | 0.050 | 0.202 | 0.033 | 1.338099 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gichane, M.M.; Byiringiro, J.B.; Chesang, A.K.; Nyaga, P.M.; Langat, R.K.; Smajic, H.; Kiiru, C.W. Digital Triplet Approach for Real-Time Monitoring and Control of an Elevator Security System. Designs 2020, 4, 9. https://doi.org/10.3390/designs4020009

Gichane MM, Byiringiro JB, Chesang AK, Nyaga PM, Langat RK, Smajic H, Kiiru CW. Digital Triplet Approach for Real-Time Monitoring and Control of an Elevator Security System. Designs. 2020; 4(2):9. https://doi.org/10.3390/designs4020009

Chicago/Turabian StyleGichane, Michael M., Jean B. Byiringiro, Andrew K. Chesang, Peterson M. Nyaga, Rogers K. Langat, Hasan Smajic, and Consolata W. Kiiru. 2020. "Digital Triplet Approach for Real-Time Monitoring and Control of an Elevator Security System" Designs 4, no. 2: 9. https://doi.org/10.3390/designs4020009

APA StyleGichane, M. M., Byiringiro, J. B., Chesang, A. K., Nyaga, P. M., Langat, R. K., Smajic, H., & Kiiru, C. W. (2020). Digital Triplet Approach for Real-Time Monitoring and Control of an Elevator Security System. Designs, 4(2), 9. https://doi.org/10.3390/designs4020009