Virtual Mannequin Simulation for Customized Electromagnetic Shielding Maternity Garment Manufacturing

Abstract

1. Introduction

2. Literature Review

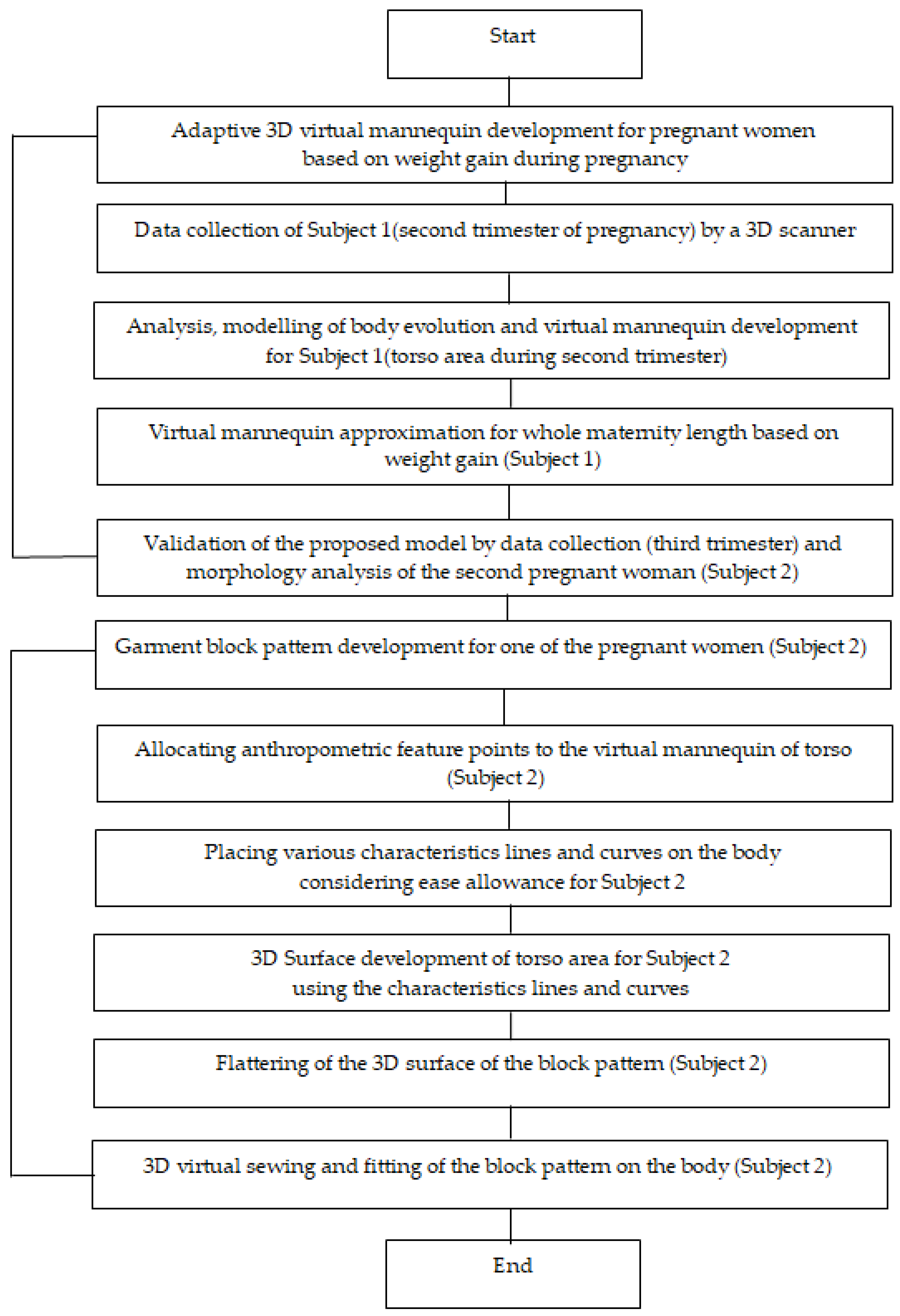

3. Materials and Methods

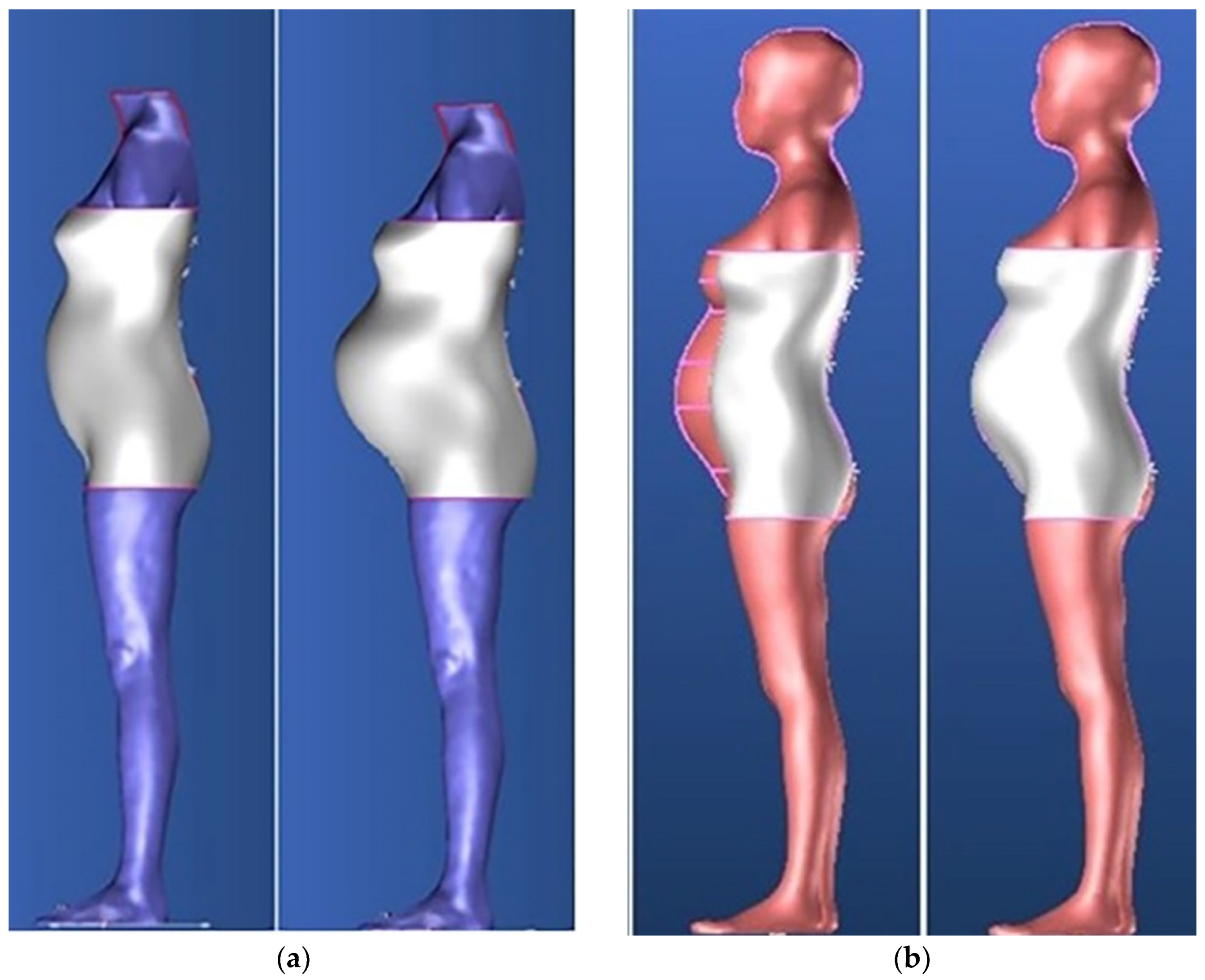

3.1. Three-Dimensional (3D) Virtual Mannequin for Pregnant Women

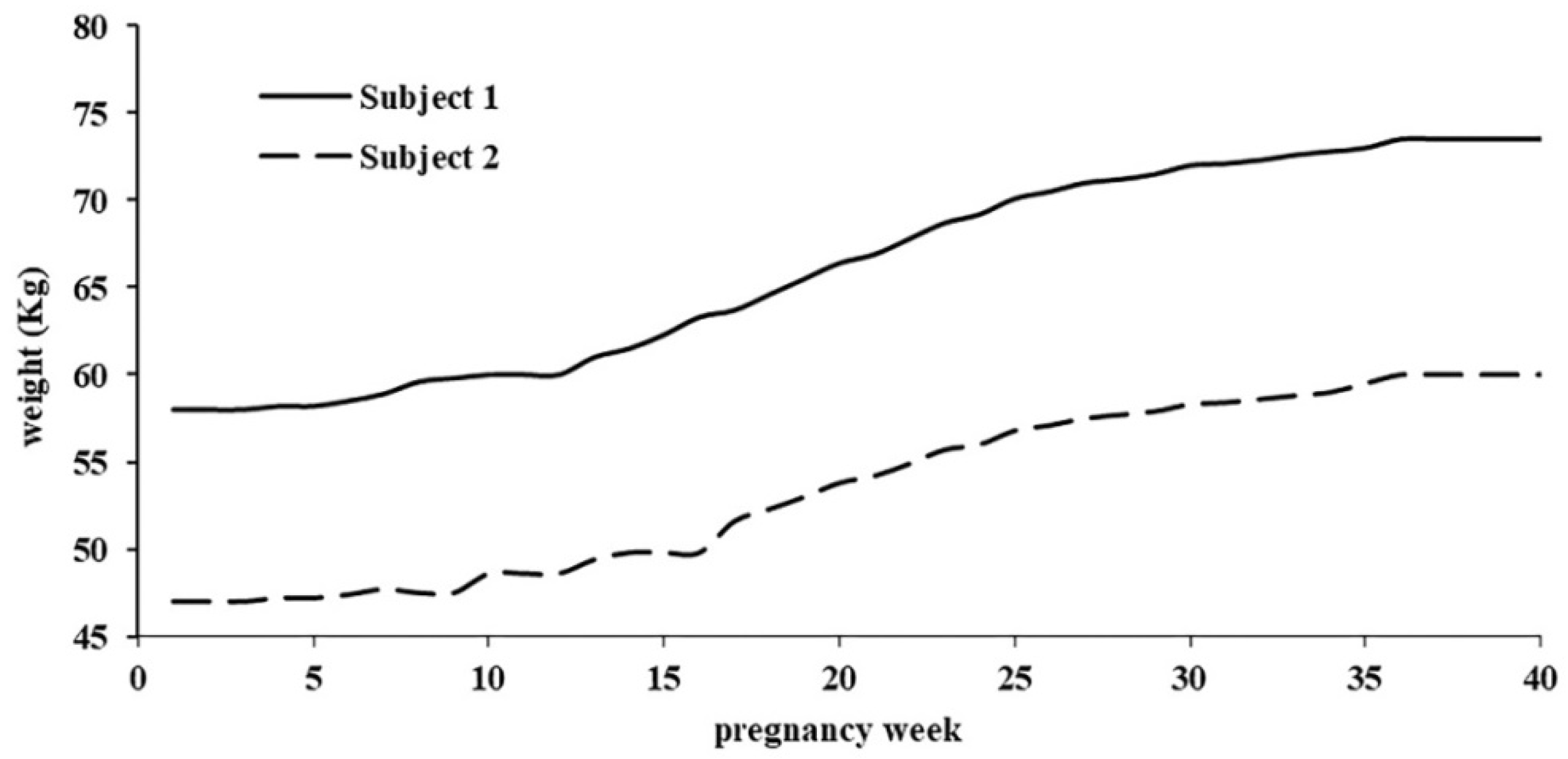

3.1.1. Data Collection

3.1.2. Analysis and Modeling of Body Evolution

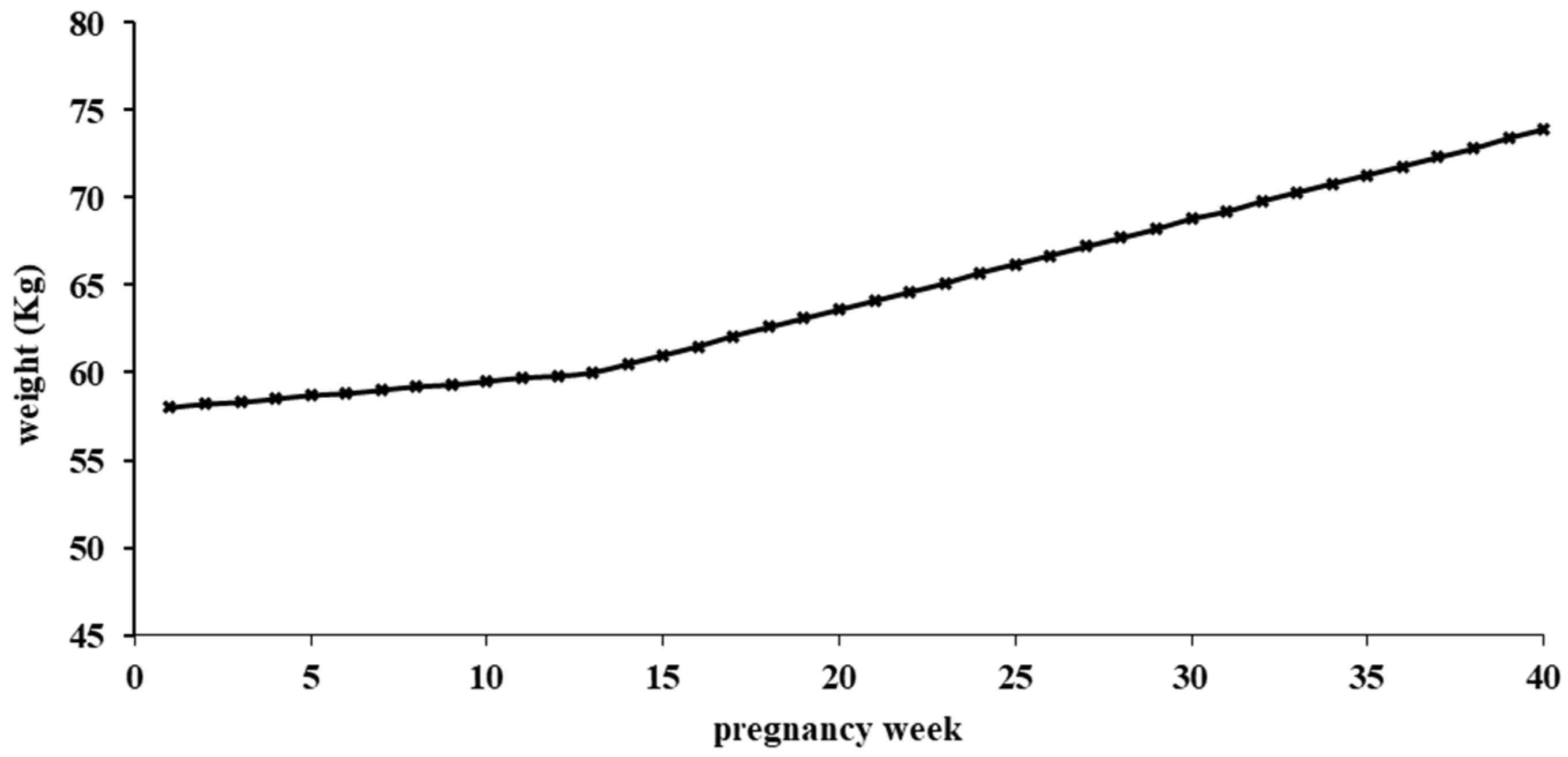

3.1.3. Virtual Mannequin Estimation for Whole Maternity Length based on Weight Gain

3.1.4. Validation of the Proposed Model

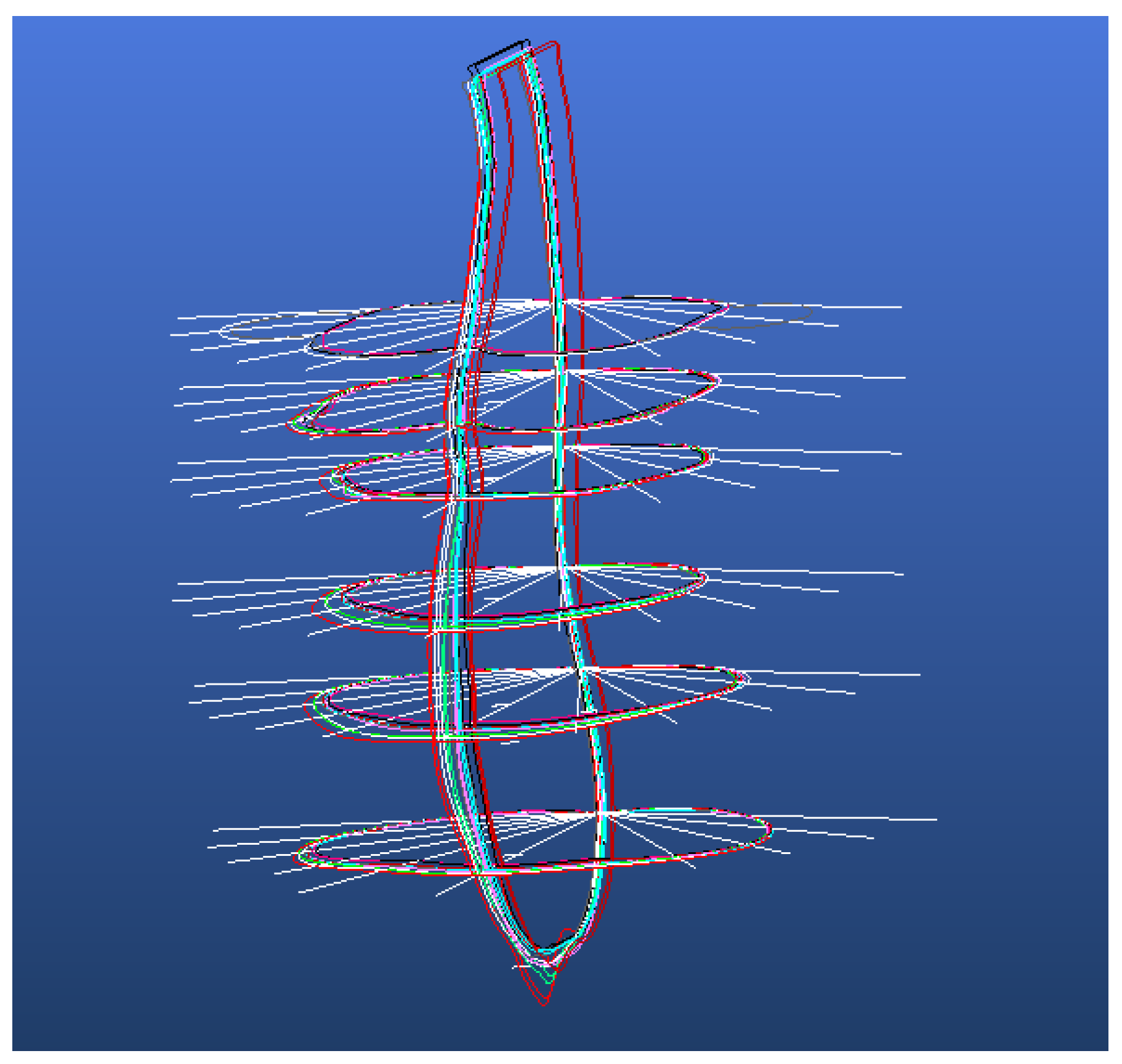

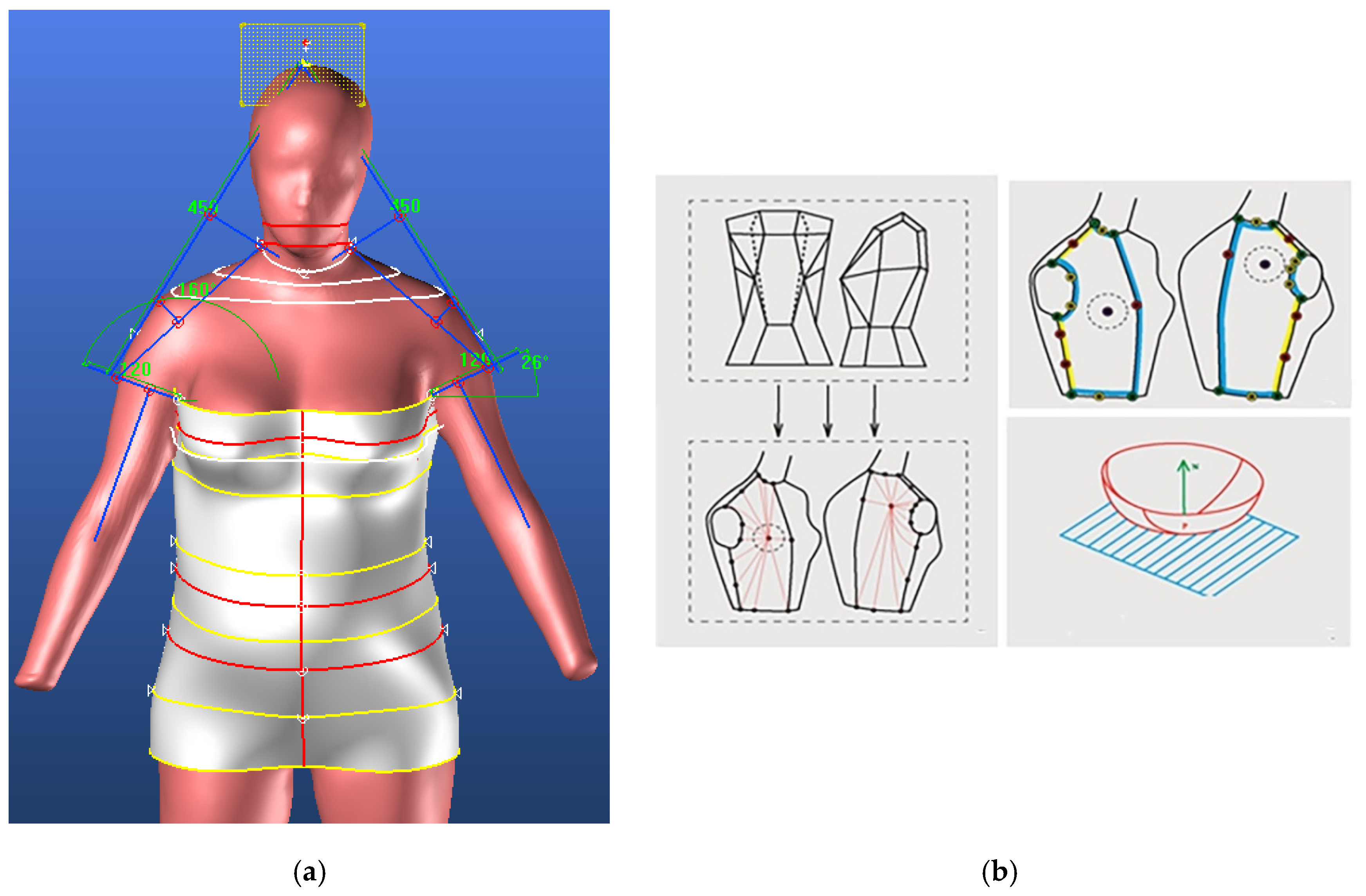

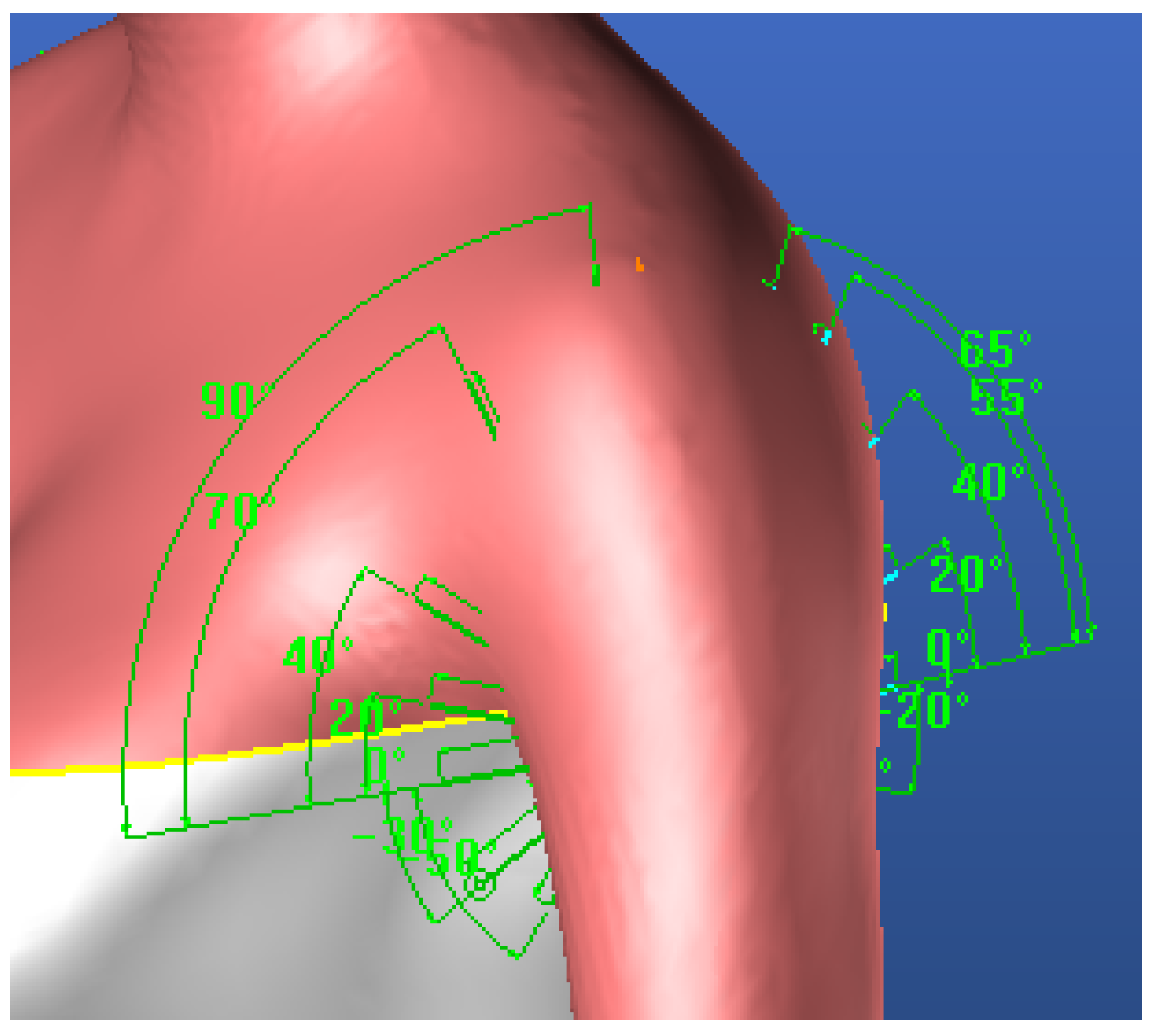

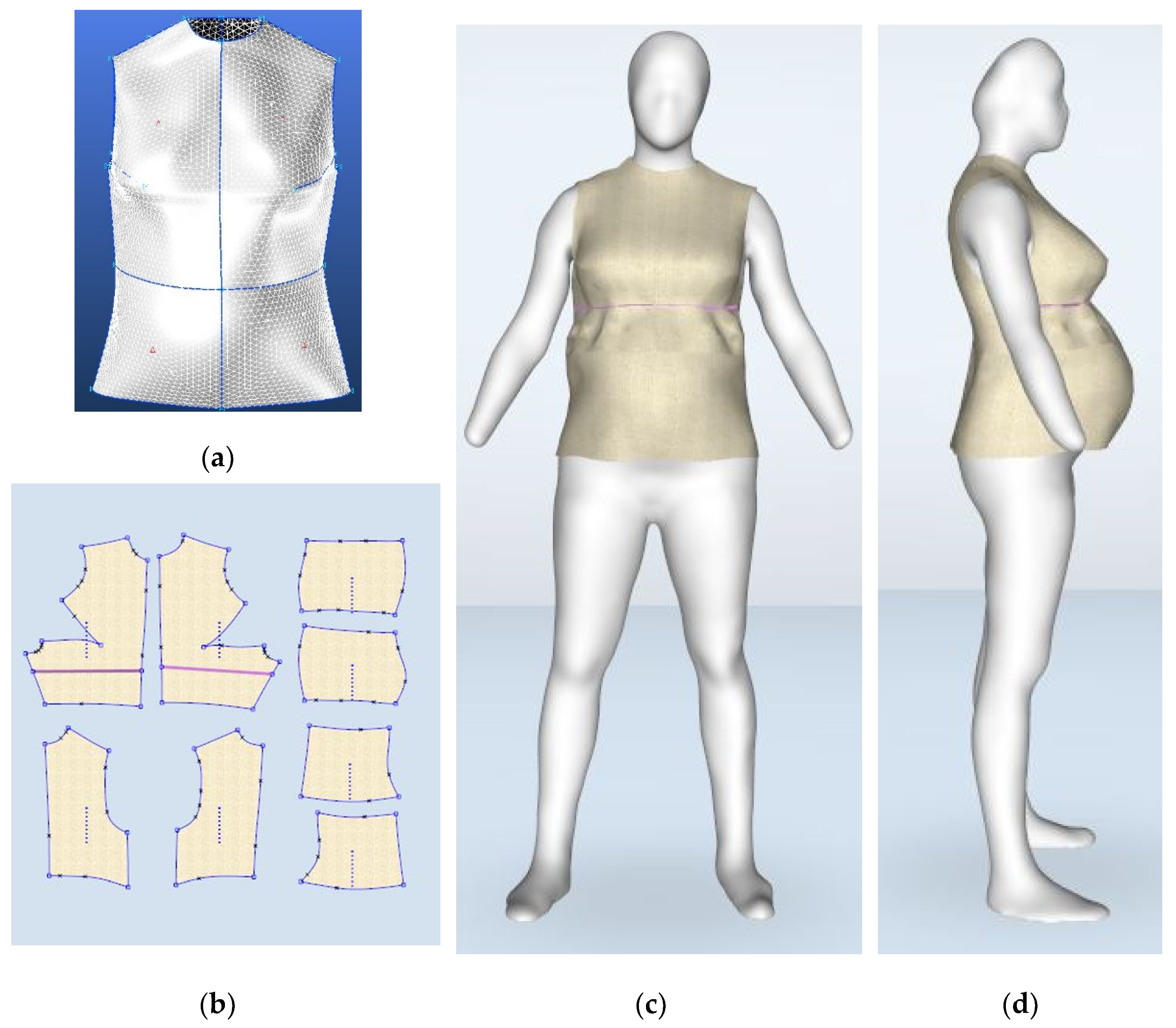

3.1.5. Garment Block Pattern Development

4. Results and Discussion

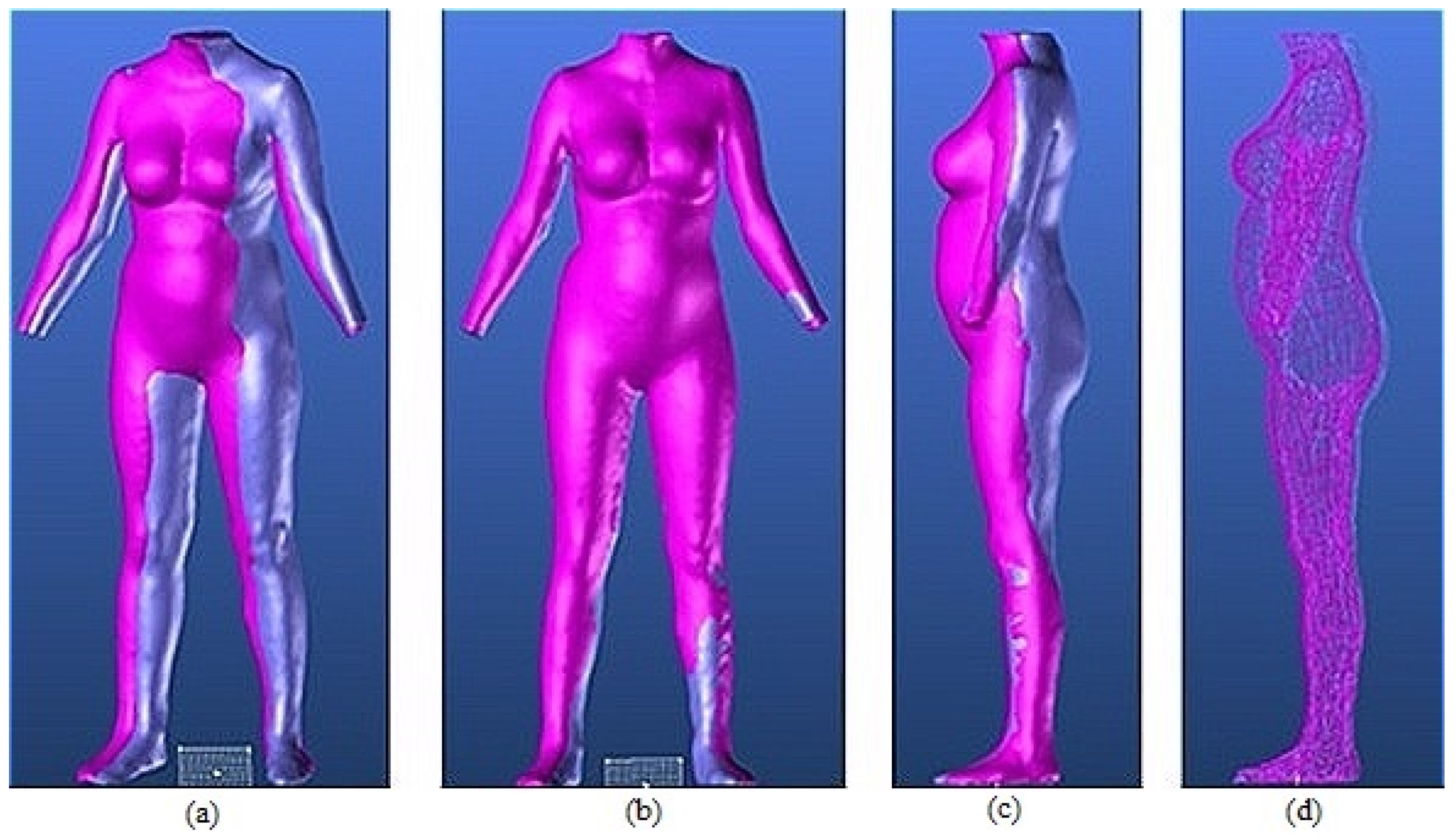

4.1. Three-Dimensional (3D) Virtual Mannequin Generation

4.2. Validation of the Proposed Model

4.3. Garment Block Pattern Development

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Toghchi, M.J.; Campagne, C.; Cayla, A.; Bruniaux, P.; Loghin, C.; Cristian, I.; Burgnies, L.; Chen, Y. Electrical Conductivity Enhancement of Hybrid PA6,6 Composite Containing Multiwall Carbon Nanotube and Carbon Black for Shielding Effectiveness Application in textiles. Synth. Met. 2019, 251, 75–84. [Google Scholar] [CrossRef]

- Pheasant, S.; Haslegrave, C.M. Bodyspace: Anthropometry, Ergonomics, and Design of Work; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Wang, C.C.L.; Wang, Y.; Yuen, M.M.F. Design automation for customized apparel products. CAD Comput. Aided Des. 2005, 37, 675–691. [Google Scholar] [CrossRef]

- Nkambule, M.T. Apparel Sizing and Fit Preferences and Problems of Plus-Size. Swazi Working Women. Ph.D. Thesis, University of Pretoria, Pretoria, South Africa, 2010. [Google Scholar]

- Wang, C.C.L.; Yuen, M.M.F. Editorial: CAD methods in garment design. CAD Comput. Aided Des. 2005, 37, 583–584. [Google Scholar] [CrossRef]

- Cichocka, A.; Bruniaux, P.; Frydrych, I. 3D Garment Modelling—Creation of a virtual mannequin of the human body. Fibres Text. East. Eur. 2014, 22, 123–131. [Google Scholar]

- McCartney, J.; Hinds, B.K.; Seow, B.L.; Gong, D. Dedicated 3D CAD for garment modelling. J. Mater. Process. Technol. 2000, 107, 31–36. [Google Scholar] [CrossRef]

- Wang, J.; Lu, G.; Li, W.; Chen, L.; Sakaguti, Y. Computer-Aided Design Interactive 3D garment design with constrained contour curves and style curves. Comput. Des. 2009, 41, 614–625. [Google Scholar]

- Duan, L.; Yueqi, Z.; Ge, W.; Pengpeng, H. Automatic three-dimensional-scanned garment fitting based on virtual tailoring and geometric sewing. J. Eng. Fibers Fabr. 2019, 14. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, D.; Yuen, M.M. Computers in Industry A survey on CAD methods in 3D garment design. Comput. Ind. 2010, 61, 576–593. [Google Scholar] [CrossRef]

- LaBat, K.L.; Ryan, K.S. Human Body: A Wearable Product Designer’s Guide, 1st ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Li, J.; Wang, Y. Automatically Constructing Skeletons and Parametric Structures for Polygonal Human Bodies; Digital. Interactive Media Lab, Institute of Automation, Academy of Chinese Sciences: Beijing, China, 2007. [Google Scholar]

- Wang, C.C.L. Parameterization and parametric design of mannequins. CAD Comput. Aided Des. 2005, 37, 83–98. [Google Scholar] [CrossRef]

- Allen, B.; Curless, B.; Popović, Z. The space of human body shapes. ACM Trans. Graph. 2003, 22, 587. [Google Scholar] [CrossRef]

- Abtew, M.A.; Bruniaux, P.; Boussu, F.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Female seamless soft body armor pattern design system with innovative reverse engineering approaches. Int. J. Adv. Manuf. Technol. 2018, 98, 2271–2285. [Google Scholar] [CrossRef]

- Hamad, M.; Thomassey, S.; Bruniaux, P. A new sizing system based on 3D shape descriptor for morphology clustering. Comput. Ind. Eng. 2017, 113, 683–692. [Google Scholar] [CrossRef]

- Hong, Y.; Zeng, X.; Bruniaux, P.; Liu, K. Interactive virtual try-on based three-dimensional garment block. Text. Res. J. 2017, 87, 1261–1274. [Google Scholar] [CrossRef]

- Rudolf, A.; Cupar, A.; Kozar, T.; Stjepanović, Z. Study Regarding the Virtual Prototyping of Garments for Paraplegics. Fibers Polym. 2015, 16, 1177–1192. [Google Scholar] [CrossRef]

- Cupar, A.; Rudolf, A. Construction of adapted garments for people with scoliosis using virtual prototyping and CASP method. Ind. Text. 2016, 67, 141–149. [Google Scholar]

- Furferi, R.; Mussi, E.; Servi, M.; Uccheddu, F.; Volpe, Y.; Facchini, F. 3D Acquisition of the Ear Anatomy: A Low-Cost Set up Suitable for the Clinical Practice. In XV Mediterranean Conference on Medical and Biological Engineering and Computing—MEDICON 2019, Proceedings of the Mediterranean Conference on Medical and Biological Engineering and Computing, Coimbra, Portugal, 26–28 September 2019; Magjarevic, R., Henriques, J., Neves, N., de Carvalho, P., Eds.; Springer Nature Switzerland AG: Cham, Switzerland, 2019; Volume 76, pp. 669–678. [Google Scholar]

- Uccheddu, F.; Ghionzoli, M.; Volpe, Y.; Servi, M.; Furferi, R.; Governi, L.; Facchini, F.; Piccolo, R.L.; McGreevy, K.S.; Martin, A.; et al. A Novel Objective Approach to the External Measurement of Pectus Excavatum Severity By Means of an Optical Device. Ann. Thorocic Surg. 2018, 106, 221–227. [Google Scholar] [CrossRef] [PubMed]

- Thomassey, S.; Bruniaux, P. A template of ease allowance for garments based on a 3D reverse methodology. Int. J. Ind. Ergon. 2013, 43, 406–416. [Google Scholar] [CrossRef]

- Cordier, F.; Seo, H.; Magnenat-Thalmann, N. Made-to-measure technologies for an online clothing store. IEEE Comput. Graph. Appl. 2003, 23, 38–48. [Google Scholar] [CrossRef]

- Groß, C.; Fuhrmann, A.; Luckas, V. Automatic pre-positioning of virtual clothing. In Proceedings of the 19th Spring Conference on Computer Graphics, New York, NY, USA, 24–26 April 2003. [Google Scholar]

- Ho, S.S.M.; Yu, W.W.M.; Lao, T.T.; Chow, D.H.K.; Chung, J.W.Y.; Li, Y. Garment needs of pregnant women based on content analysis of in-depth interviews. J. Clin. Nurs. 2009, 18, 2426–2435. [Google Scholar] [CrossRef]

- Lederman, S.A.; Paxton, A.; Heymsfield, S.B.; Wang, J.; Thornton, J.; Pierson, R.N., Jr. Body fat and water changes during pregnancy in women with different body weight and weight gain. Obstet. Gynecol. 1997, 90, 483–488. [Google Scholar] [CrossRef]

- Calvo, E.B.; López, L.B.; Balmaceda, Y.D.V.; Poy, M.S.; González, C.; Quintana, L.; Cámera, K.; Barrientos, E.; Berlingueres, S.; Garciarena, S. Reference charts for weight gain and body mass index during pregnancy obtained from a healthy cohort. J. Matern. Neonatal Med. 2009, 22, 36–42. [Google Scholar] [CrossRef] [PubMed]

- Georgeta, P.; Alexandra, M.; Sabina, O. Innovative clothing design for women during pregnancy. Ann. Univ. Oradea Fascicle Text. Innov. 2015, 16, 67–72. [Google Scholar]

- Rodriguez, C.Q.; Anisimova, A.; Ryan, S.; Troynikov, O. Critical design aspects of maternity support-garments and its contemporary perspective. KnE Eng. 2017, 2, 91. [Google Scholar] [CrossRef]

- Sohn, M.; Bye, E. Visual analysis of body shape changes during pregnancy. Int. J. Fash. Des. Technol. Educ. 2012, 5, 117–128. [Google Scholar] [CrossRef]

- Wu, G.; Liu, S.; Wu, X.; Ding, X. International Journal of Industrial Ergonomics Research on lower body shape of late pregnant women in Shanghai area of China. Int. J. Ind. Ergon. 2015, 46, 69–75. [Google Scholar] [CrossRef]

- FTTS-FA-003. Test Method of Specified Requirements of Electromagnetic Shielding Textiles. In Committee for Conformity Assessment on Accreditation and Certification of Functional and Technical Textiles; TTRI: Taipei, Taiwan, 2003. [Google Scholar]

- Zamanian, A.; Hardiman, C. Electromagnetic radiation and human health: A review of sources and effects. EMR Hum. Heal. 2005, 16, 16–26. [Google Scholar]

- Hossmann, K.A.; Hermann, D.M. Effects of electromagnetic radiation of mobile phones on the central nervous system. Bioelectromagnetics 2003, 24, 49–62. [Google Scholar] [CrossRef]

- Erogul, O.; Oztas, E.; Yildirim, I.; Kir, T.; Aydur, E.; Komesli, G.; Irkilata, C.H.; Irmak, K.M.; Peker, F.A. Effects of electromagnetic radiation from a cellular phone on human sperm motility: An in vitro study. Arch. Med. Res. 2006, 37, 840–843. [Google Scholar] [CrossRef]

- Sohlstr, A.; Forsum, E. Changes in adipose tissue volume and distribution during reproduction in Swedish women as assessed by magnetic resonance imaging13. Am. J. Clin. Nutr. 1995, 61, 287–295. [Google Scholar] [CrossRef]

- de Onis, M.; Garza, C.; Onyango, A.W.; Borghi, E. Comparison of the WHO Child Growth Standards and the CDC 2000 Growth Charts 1. J. Nutr. 2007, 137, 144–148. [Google Scholar] [CrossRef]

- Ölin, A.; Rössner, S. Factors Related to Body Weight Changes During and After Pregnancy: The Stockholm Pregnancy and Weight Development Study. Obes. Res. 1996, 4, 271–276. [Google Scholar] [CrossRef] [PubMed]

- Brenner, W.E.; Edelman, D.A.; Hendricks, C.H. A standard of fetal growth for the united states of America. Am. J. Obstet. Gynecol. 1976, 126, 555–564. [Google Scholar] [CrossRef]

- Barbara, A.F.; Laros, R.K., Jr. Prepregnancy weight, weight gain, and birth weight. Am. J. Obstet. Gynecol. 1986, 154, 503–509. [Google Scholar]

- Efrat, S. The Development of a Method for Generating Patterns for Garments that Conform to the Shape of the Human Body. Ph.D. Thesis, De Montfort University, Leicester, UK, 1982. [Google Scholar]

- Chen, Y.; Zeng, X.; Happiette, M.; Bruniaux, P.; Ng, R.; Yu, W. A new method of ease allowance generation for personalization of garment design. Int. J. Cloth. Sci. Technol. 2008, 20, 161–173. [Google Scholar] [CrossRef]

| Trimester | Month | Week |

|---|---|---|

| 1 | 1 | 1–4 |

| 2 | 5–8 | |

| 3 | 9–13 | |

| 2 | 4 | 14–17 |

| 5 | 18–21 | |

| 6 | 22–26 | |

| 3 | 7 | 27–30 |

| 8 | 31–35 | |

| 9 | 36–40 |

| Parameter | Formula |

|---|---|

| Height (H) | 1649 |

| Armpit | 0.751 × H |

| Breast | 0.7186 × H |

| Underbust | 0.685 × H |

| Waist | 0.63 × H |

| Belly | 0.58 × H |

| Hip | 0.51 × H |

| Crotch | 0.458 × H |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Javadi Toghchi, M.; Bruniaux, P.; Campagne, C.; Cayla, A.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Virtual Mannequin Simulation for Customized Electromagnetic Shielding Maternity Garment Manufacturing. Designs 2019, 3, 53. https://doi.org/10.3390/designs3040053

Javadi Toghchi M, Bruniaux P, Campagne C, Cayla A, Loghin C, Cristian I, Chen Y, Wang L. Virtual Mannequin Simulation for Customized Electromagnetic Shielding Maternity Garment Manufacturing. Designs. 2019; 3(4):53. https://doi.org/10.3390/designs3040053

Chicago/Turabian StyleJavadi Toghchi, Marzieh, Pascal Bruniaux, Christine Campagne, Aurélie Cayla, Carmen Loghin, Irina Cristian, Yan Chen, and Lichuan Wang. 2019. "Virtual Mannequin Simulation for Customized Electromagnetic Shielding Maternity Garment Manufacturing" Designs 3, no. 4: 53. https://doi.org/10.3390/designs3040053

APA StyleJavadi Toghchi, M., Bruniaux, P., Campagne, C., Cayla, A., Loghin, C., Cristian, I., Chen, Y., & Wang, L. (2019). Virtual Mannequin Simulation for Customized Electromagnetic Shielding Maternity Garment Manufacturing. Designs, 3(4), 53. https://doi.org/10.3390/designs3040053