Building Model-Driven Decision Support System in Product Redesign Plan

Abstract

1. Introduction

2. Literature Review

2.1. Critical-to-Reprocess Operations

2.2. Product Disposition Decision

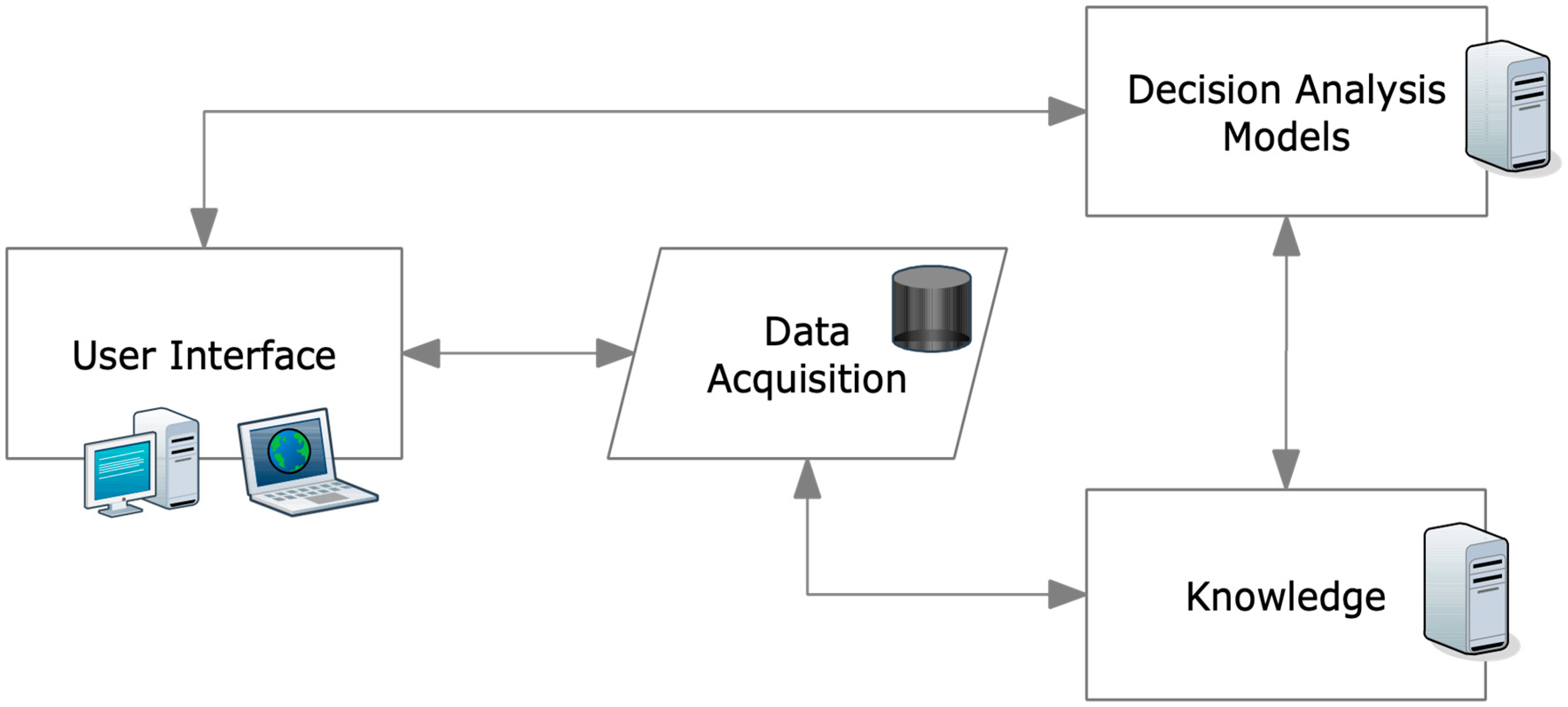

3. System Architecture: A Model-Driven DSS

3.1. Model Formulation

3.2. Model Application

- (a)

- The economic indicator of this case application is represented as a ratio of the performance benchmark that is more than or equal to one. Then, and for proposed recovery configuration option of ‘RA’ and ‘RB’ are written as follows in Equations (30)–(33):

- (b)

- The environmental indicator of this case application is represented as a ratio of the performance benchmark that is approximately close or equal to one. Then, and for proposed product configuration of ‘RA’ and ‘RB’ are written as follows in Equations (34)–(37):

- (c)

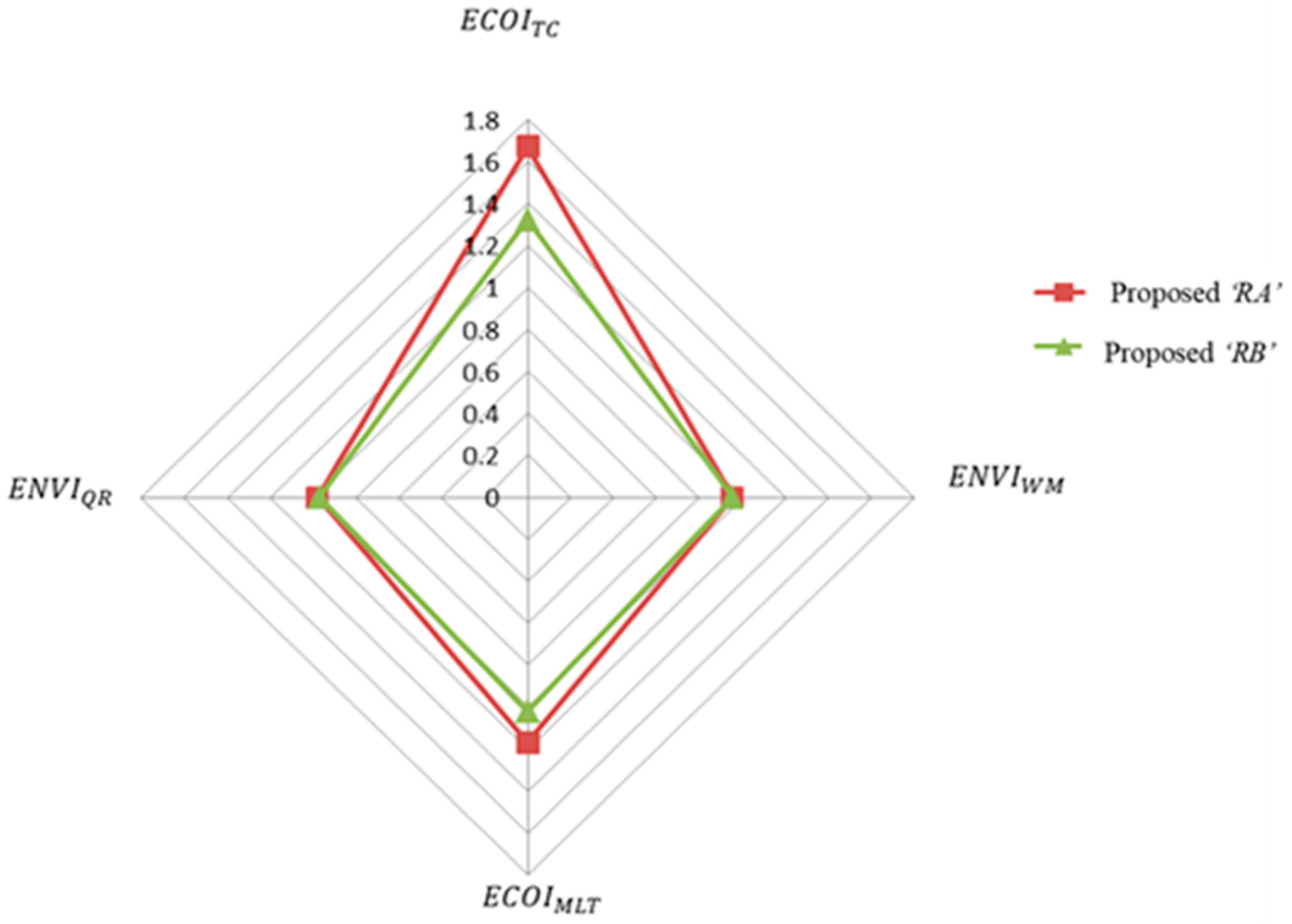

- In existing literature, there are many researchers and industry practitioners, who have successfully applied and have then recommended the use of the trade-off preference diagram in practical case assessment for manufacturing industries [4,12,14,15,19,69]. In this case application, a trade-off preference diagram for analysing recovery configurations of ‘RA’ and ‘RB’ was modified to suit the company, and then applied for assessing economic benefits and environmental impacts when producing a manufactured product with different recovery configuration options. An overall quantitative value of , for this case application as shown in Equation (38) was formulated to evaluate the utilisation value of recoverable content of a manufactured product in terms of the economic and environmental indicators. Equation (38) is calculated as the summation of each of the areas under a right angled triangle for the trade-off preference diagram as follows:

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Notations and Parameters

| Decision variables: | |

| Maximum number of modules for a manufactured product | |

| n | Maximum number of components of the mth module for a manufactured product |

| r | Decision Index of virgin, r = 1, reuse, r = 2, remanufacture, r = 3 and recycle, r = 4 |

| m | is the mth module of the manufactured product, |

| i | is the ith component of the module, where each component comprises a single material only, |

| is the ith component of the mth module, otherwise, = 0 | |

| Cost parameters: | |

| The cost margin of the operational processes, of the ith component | |

| The total cost of new acquisition material of the ith component | |

| The cost for procurement activity of the ith component | |

| Inventory holding cost of the ith component (procurement) | |

| The total cost of manufacturing of the ith component | |

| The cost of manufacturing of the ith component | |

| Inspection cost of the ith component after manufacturing | |

| Testing cost of the ith component after manufacturing | |

| Inventory holding cost of the ith component (manufacturing) | |

| The total cost for assembly of the ith component | |

| The cost for mechanical joint assembly of the ith component (i.e., welding, brazing, adhesive, bonding, etc.) | |

| The cost of assembly of the ith component (i.e., threaded fasteners, rivets, etc.) | |

| The cost of direct reuse of the ith component | |

| The cost of cleaning of the ith component | |

| Inspection cost of the ith component after cleaning | |

| Testing cost of the ith component after cleaning | |

| Inventory holding cost of the ith component (reuse) | |

| The total cost for disassembly of the ith component | |

| The cost for mechanical joint disassembly of the ith component (i.e., welding, brazing, adhesive, bonding, etc.) | |

| The cost of disassembly of the ith component (i.e., threaded fasteners, rivets, etc.) | |

| Total cost of remanufacturing of the ith component | |

| The cost of repairing of the ith component | |

| The cost of replacing of the ith component | |

| Inspection cost of the ith component after remanufacturing | |

| Testing cost of the ith component after cleaning | |

| Inventory holding cost of the ith component (remanufacturing | |

| =1 the ith component can be repaired, otherwise, =0 | |

| =1 the ith component can be replaced, otherwise, =0 | |

| The total cost of recycling of the ith component including shredding, separation and handling, etc., with or without disassembly. | |

| The cost of shredding, separation and handling, etc. without disassembly of the ith component | |

| The cost of shredding, separation and handling, etc. with disassembly of the ith component | |

| =1 the ith component needs to be disassembled for recycling, otherwise, =0 | |

| =1 the ith component needs not to be disassembled for recycling, otherwise, =0 | |

| Inventory holding cost of the ith component (recycling) | |

| The total cost of disposal and treatment of the ith component that is the incineration or landfill for hazardous or non-hazardous contents | |

| The disposal cost with hazardous content of the ith component | |

| The disposal cost without hazardous content of the ith component | |

| = 1 if the ith component with hazardous content, otherwise, =0 | |

| = 1 if the ith component with non-hazardous content, otherwise, =0 | |

| The total cost of the returns activity, c of the returned item, incurred by the manufacturer | |

| The cost of general administration of the item | |

| The cost of sorting of the item | |

| The cost of shipping and transporting of the item | |

| Time parameters: | |

| The lead-time for the operational process, of the ith component | |

| The total lead-time of manufacturing of the ith component | |

| The time required of manufacturing setup job of the ith component | |

| The time required of manufacturing of the ith component | |

| The time required of test activity of the ith component (manufacturing) | |

| The time required of inspection activity of the ith component (manufacturing) | |

| The total lead-time for assembly of the ith component | |

| The time required of assembly setup job of the ith component | |

| The time required of mechanical joint job of the ith component | |

| The time required of subassembly job of the ith component | |

| The time required of test activity of the ith component (assembly) | |

| The time required of inspection activity of the ith component (assembly) | |

| The total lead-time of direct reuse of the ith component | |

| The time required of direct reuse setup job of the ith component | |

| The time required cleaning/processing job of the ith component | |

| The time required of test activity of the ith component (reuse) | |

| The time required of inspection activity of the ith component (reuse) | |

| The total lead-time for disassembly of the ith component | |

| The time required of disassembly setup job of the ith component | |

| The time required of mechanical disjoint job of the ith component | |

| The time required of sub-disassembly job of the ith component | |

| The time required of test activity of the ith component (disassembly) | |

| The time required of inspection activity of the ith component (disassembly) | |

| The total lead-time of remanufacturing of the ith component | |

| The time required of remanufacturing setup job of the ith component | |

| The time required of repairing of the ith component | |

| The time required of replacing of the ith component | |

| =1, if the ith component is to be repaired, otherwise, =0 | |

| =1, if the ith component is to be replaced, otherwise, =0 | |

| The time required of test activity of the ith component (remanufacture) | |

| The time required of inspection activity of the ith component (remanufacture) | |

| The total lead-time of recycling of the ith component | |

| The time required of recycling setup job of the ith component | |

| The time required of recycling with disassembly of the ith component | |

| The time required of recycling without disassembly of the ith component | |

| =1, if the ith component is for recycling with disassembly, otherwise =0 | |

| =1, if the ith component is for recycling without disassembly, otherwise =0 | |

| The time required of test activity of the ith component (recycle) | |

| The time required of inspection activity of the ith component (recycle) | |

| Total lead-time of disposal and treatment of the ith component | |

| The time required of disposal setup job of the ith component | |

| The time required to dispose the ith component with hazardous content | |

| The time required to dispose the ith component without hazardous content | |

| =1 if the ith component has hazardous content, otherwise, =0 | |

| =1 if the ith component has non-hazardous content, otherwise =0 | |

| The time required of test activity of the ith component (disposal) | |

| The time required of inspection activity of the ith component (disposal) | |

| Waste parameters: | |

| Total mass of a manufactured product | |

| Total mass of the recovery proportion of a manufactured product | |

| The mass proportion of the ith component | |

| Quality parameters: | |

| The Weibull shape parameter of the ith component | |

| The characteristic life for the ith component | |

| The average operating hours before the ith component is taken back | |

References

- Jacobs, B.W.; Subramanian, R. Sharing responsibility for product recovery across the Supply Chain. Prod. Oper. Manag. 2012, 21, 85–100. [Google Scholar] [CrossRef]

- Johnson, D.; Srivastava, R. Design for sustainability: Product development tools and life cycle economics. In Proceedings of the 39th Annual Meeting of the Decision Sciences Institue, Baltimore, MD, USA, 22–25 November 2008; pp. 1711–1716. [Google Scholar]

- Khor, K.S.; Hazen, B.T. Remanufactured products purchase intentions and behaviour: Evidence from Malaysia. Int. J. Prod. Res. 2017, 55, 2149–2162. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef] [PubMed]

- Johnson, M.R.; McCarthy, I.P. Product recovery decisions within the context of Extended Producer Responsibility. J. Eng. Technol. Manag. 2014, 34, 9–28. [Google Scholar] [CrossRef]

- Ng, Y.T.; Lu, W.F.; Song, B. Quantification of End-of-life Product Condition to Support Product Recovery Decision. Procedia CIRP 2014, 15, 257–262. [Google Scholar] [CrossRef]

- Parlikad, A.K.; McFarlane, D.C.; Kulkarni, A.G. Improving product recovery decisions through product information. In Innovation in Life Cycle Engineering and Sustainable Development; Brissaud, D., Tichkiewitch, S., Zwolinski, P., Eds.; Springer: Dordrecht, The Netherlands, 2006; pp. 153–172. [Google Scholar] [CrossRef]

- Reuter, M.A.; van Schaik, A.; Ignatenko, O.; de Haan, G.J. Fundamental limits for the recycling of end-of-life vehicles. Miner. Eng. 2006, 19, 433–449. [Google Scholar] [CrossRef]

- Fleischmann, M.; Bloemhof-Ruwaard, J.M.; Dekker, R.; van der Laan, E.; van Nunen, J.A.E.E.; Van Wassenhove, L.N. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef]

- Das, D.; Dutta, P. A system dynamics framework for integrated reverse supply chain with three way recovery and product exchange policy. Comput. Ind. Eng. 2013, 66, 720–733. [Google Scholar] [CrossRef]

- Wan, H.-D.; Krishna Gonnuru, V. Disassembly planning and sequencing for end-of-life products with RFID enriched information. Robot. Comput. Integr. Manuf. 2013, 29, 112–118. [Google Scholar] [CrossRef]

- Ziout, A.; Azab, A.; Atwan, M. A holistic approach for decision on selection of end-of-life products recovery options. J. Clean. Prod. 2014, 65, 497–516. [Google Scholar] [CrossRef]

- Kuik, S.S.; Nagalingam, S.; Amer, Y. Sustainable supply chain for collaborative manufacturing. J. Manuf. Technol. Manag. 2011, 22, 984–1001. [Google Scholar] [CrossRef]

- Meng, K.; Lou, P.; Peng, X.; Prybutok, V. Quality-driven recovery decisions for used components in reverse logistics. Int. J. Prod. Res. 2017, 55, 4712–4728. [Google Scholar] [CrossRef]

- Steeneck, D.W.; Sarin, S.C. Determining end-of-life policy for recoverable products. Int. J. Prod. Res. 2017, 55, 5782–5800. [Google Scholar] [CrossRef]

- Gavidel, S.Z.; Rickli, J.L. Quality assessment of used-products under uncertain age and usage conditions. Int. J. Prod. Res. 2017, 55, 7153–7167. [Google Scholar] [CrossRef]

- BCG. Sustainbility nears a tipping point. In MIT Sloan Management Review; BCG: Boston, MA, USA, 2012; pp. 2–6. [Google Scholar]

- Zhang, H.C.; Kuo, T.C.; Lu, H.; Huang, S.H. Environmentally conscious design and manufacturing: A state-of-the-art survey. J. Manuf. Syst. 1997, 16, 352–371. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. Issues in environmentally conscious manufacturing and product recovery: A survey. Comput. Ind. Eng. 1999, 36, 811–853. [Google Scholar] [CrossRef]

- Goggin, K.; Browne, J. The resource recovery level decision for end-of-life products. Prod. Plan. Control 2000, 11, 628–640. [Google Scholar] [CrossRef]

- Erdos, G.; Kis, T.; Xirouchakis, P. Modelling and evaluating product end-of-life options. Int. J. Prod. Res. 2001, 39, 1203–1220. [Google Scholar] [CrossRef]

- Bufardi, A.; Sakara, D.; Gheorghe, R.; Kiritsis, D.; Xirouchakis, P. Multiple criteria decision aid for selecting the best product end of life scenario. Int. J. Comput. Integr. Manuf. 2003, 16, 526–534. [Google Scholar] [CrossRef]

- Shih, L.-H.; Chang, Y.-S.; Lin, Y.-T. Intelligent evaluation approach for electronic product recycling via case-based reasoning. Adv. Eng. Inform. 2006, 20, 137–145. [Google Scholar] [CrossRef]

- Kobayashi, H. A systematic approach to eco-innovative product design based on life cycle planning. Adv. Eng. Inform. 2006, 20, 113–125. [Google Scholar] [CrossRef]

- Staikos, T.; Rahimifard, S. An end-of-life decision support tool for product recovery considerations in the footwear industry. Int. J. Comput. Integr. Manuf. 2007, 20, 602–615. [Google Scholar] [CrossRef]

- Jin, K.; Zhang, H. A decision support model based on a reference point method for end-of-life electronic product management. Int. J. Adv. Manuf. Technol. 2007, 31, 1251–1259. [Google Scholar] [CrossRef]

- Jayal, A.D.; Badurdeen, F.; Dillon, O.W., Jr.; Jawahir, I.S. Sustainable manufacturing: Modeling and optimization challenges at the product, process and system levels. CIRP J. Manuf. Sci. Technol. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- Heller, J.E.; Löwer, M.; Feldhusen, J. Requirement based Future Product Cost Estimation using Lifecycle Assessment Data. Procedia CIRP 2014, 15, 520–525. [Google Scholar] [CrossRef]

- Borsato, M. Bridging the gap between product lifecycle management and sustainability in manufacturing through ontology building. Comput. Ind. 2014, 65, 258–269. [Google Scholar] [CrossRef]

- Ghadimi, P.; Azadnia, A.H.; Mohd Yusof, N.; Mat Saman, M.Z. A weighted fuzzy approach for product sustainability assessment: A case study in automotive industry. J. Clean. Prod. 2012, 33, 10–21. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, J.; Yu, J.-Y.; Noori, H. A new methodology for evaluating sustainable product design performance with two-stage network data envelopment analysis. Eur. J. Oper. Res. 2012, 221, 348–359. [Google Scholar] [CrossRef]

- Ondemir, O.; Gupta, S.M. Quality management in product recovery using the Internet of Things: An optimization approach. Comput. Ind. 2014, 65, 491–504. [Google Scholar] [CrossRef]

- Behdad, S.; Williams, A.S.; Thurston, D. End-of-Life Decision Making With Uncertain Product Return Quantity. J. Mech. Des. 2012, 134, 100902. [Google Scholar] [CrossRef]

- Chang, W.L.; Lin, J.-H. Optimal maintenance policy and length of extended warranty within the life cycle of products. Comput. Math. Appl. 2012, 63, 144–150. [Google Scholar] [CrossRef]

- Subramanian, R.; Talbot, B.; Gupta, S. An Approach to Integrating Environmental Considerations Within Managerial Decision-Making. J. Ind. Ecol. 2010, 14, 378–398. [Google Scholar] [CrossRef]

- Iakovou, E.; Moussiopoulos, N.; Xanthopoulos, A.; Achillas, C.; Michailidis, N.; Chatzipanagioti, M.; Koroneos, C.; Bouzakis, K.D.; Kikis, V. A methodological framework for end-of-life management of electronic products. Resour. Conserv. Recycl. 2009, 53, 329–339. [Google Scholar] [CrossRef]

- Yang, Q.; Yu, S.; Jiang, D. A modular method of developing an eco-product family considering the reusability and recyclability of customer products. J. Clean. Prod. 2014, 64, 254–265. [Google Scholar] [CrossRef]

- Kwak, M.; Kim, H. Design for life-cycle profit with simultaneous consideration of initial manufacturing and end-of-life remanufacturing. Eng. Optim. 2013, 1–18. [Google Scholar] [CrossRef]

- Madaan, J.; Kumar, P.; Chan, F.T.S. Decision and information interoperability for improving performance of product recovery systems. Decis. Support Syst. 2012, 53, 448–457. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamentals of Modern Manufacturing; John Wiley and Sons, Inc.: New York, NY, USA, 2010. [Google Scholar]

- Zhao, Y.; Pandey, V.; Kim, H.; Thurston, D. Varying Lifecycle Lengths Within a Product Take-Back Portfolio. J. Mech. Des. 2010, 132, 091012. [Google Scholar] [CrossRef]

- Diaz, R.; Marsillac, E. Evaluating strategic remanufacturing supply chain decisions. Int. J. Prod. Res. 2017, 55, 2522–2539. [Google Scholar] [CrossRef]

- Zikopoulos, C. Remanufacturing lotsizing with stochastic lead-time resulting from stochastic quality of returns. Int. J. Prod. Res. 2017, 55, 1565–1587. [Google Scholar] [CrossRef]

- Mangla, S.; Madaan, J.; Chan, F.S. Analysis of Performance Focused Variables for Multi-Objective Flexible Decision Modeling Approach of Product Recovery Systems. Glob. J. Flex. Syst. Manag. 2012, 13, 77–86. [Google Scholar] [CrossRef]

- Das, K.; Chowdhury, A.H. Designing a reverse logistics network for optimal collection, recovery and quality-based product-mix planning. Int. J. Prod. Econ. 2012, 135, 209–221. [Google Scholar] [CrossRef]

- Shaharudin, M.R.; Zailani, S.; Tan, K.C. Barriers to product returns and recovery management in a developing country: Investigation using multiple methods. J. Clean. Prod. 2014. [Google Scholar] [CrossRef]

- Lee, H.M.; Lu, W.F.; Song, B. A framework for assessing product End-Of-Life performance: Reviewing the state of the art and proposing an innovative approach using an End-of-Life Index. J. Clean. Prod. 2014, 66, 355–371. [Google Scholar] [CrossRef]

- Souza, G.C. Closed-Loop Supply Chains: A Critical Review, and Future Research. Decis. Sci. 2013, 44, 7–38. [Google Scholar] [CrossRef]

- Umeda, Y.; Takata, S.; Kimura, F.; Tomiyama, T.; Sutherland, J.W.; Kara, S.; Herrmann, C.; Duflou, J.R. Toward integrated product and process life cycle planning—An environmental perspective. CIRP Ann. Manuf. Technol. 2012, 61, 681–702. [Google Scholar] [CrossRef]

- Yu, S.; Yang, Q.; Tao, J.; Tian, X.; Yin, F. Product modular design incorporating life cycle issues—Group Genetic Algorithm (GGA) based method. J. Clean. Prod. 2011, 19, 1016–1032. [Google Scholar] [CrossRef]

- Yamada, T.; Ohta, N. Modeling and Design for Reuse Inverse Manufacturing Systems with Product Recovery Values. In Advances in Sustainable Manufacturing; Seliger, G., Khraisheh, M.M.K., Jawahir, I.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 197–202. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Guo, S.; Aydin, G.; Souza, G.C. Dismantle or remanufacture? Eur. J. Oper. Res. 2014, 233, 580–583. [Google Scholar] [CrossRef]

- Lifset, R.; Atasu, A.; Tojo, N. Extended Producer Responsibility. J. Ind. Ecol. 2013, 17, 162–166. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Hu, G.; Bidanda, B. Modeling sustainable product lifecycle decision support systems. Int. J. Prod. Econ. 2009, 122, 366–375. [Google Scholar] [CrossRef]

- Thabrew, L.; Ries, R. Application of life cycle thinking in multidisciplinary multistakeholder contexts for cross-sectoral planning and implementation of sustainable development projects. Integr. Environ. Assess. Manag. 2009, 5, 445–460. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.F.R.; Lai, J.-H. Decision support for environmental impact assessment: A hydrid approach using fuzzy logic and fuzzy analytic network process. Expert Syst. Appl. 2009, 36, 5119–5136. [Google Scholar] [CrossRef]

- Godichaud, M.; Tchangani, A.; Pérès, F.; Iung, B. Sustainable management of end-of-life systems. Prod. Plan. Control 2011, 23, 216–236. [Google Scholar] [CrossRef]

- Sebnem Ahiska, S.; King, R.E. Inventory optimization in a one product recoverable manufacturing system. Int. J. Prod. Econ. 2010, 124, 11–19. [Google Scholar] [CrossRef]

- Huang, Y.-S.; Gau, W.-Y.; Ho, J.-W. Cost analysis of two-dimensional warranty for products with periodic preventive maintenance. Reliab. Eng. Syst. Saf. 2015, 134, 51–58. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Wang, Y. Customized warranty offering for configurable products. Reliab. Eng. Syst. Saf. 2013, 118, 1–7. [Google Scholar] [CrossRef]

- Kleyner, A.; Sandborn, P. Minimizing life cycle cost by managing product reliability via validation plan and warranty return cost. Int. J. Prod. Econ. 2008, 112, 796–807. [Google Scholar] [CrossRef]

- Saleh, J.H.; Marais, K. Reliability: How much is it worth? Beyond its estimation or prediction, the (net) present value of reliability. Reliab. Eng. Syst. Saf. 2006, 91, 665–673. [Google Scholar] [CrossRef]

- Yadav, O.P.; Singh, N.; Chinnam, R.B.; Goel, P.S. A fuzzy logic based approach to reliability improvement estimation during product development. Reliab. Eng. Syst. Saf. 2003, 80, 63–74. [Google Scholar] [CrossRef]

- Shu, L.H.; Flowers, W.C. Reliability Modeling in Design for Remanufacture. Trans. ASME J. Mech. Des 1998, 120, 620–627. [Google Scholar] [CrossRef]

- Merkhofer, M.W.; Conway, R.; Anderson, R.G. Multiattribute Utility Analysis as a Framework for Public Participation in Siting a Hazardous Waste Management Facility. Environ. Manag. 1997, 21, 831–839. [Google Scholar] [CrossRef]

- Sandborn, P.A.; Murphy, C.F. A model for optimizing the assembly and disassembly of electronic systems. IEEE Trans. Electron. Packag. Manuf. 1999, 22, 105–117. [Google Scholar] [CrossRef]

- Xing, K.; Belusko, M.; Luong, L.; Abhary, K. An evaluation model of product upgradeability for remanufacture. Int. J. Adv. Manuf. Technol. 2007, 35, 1–14. [Google Scholar] [CrossRef]

| CTR Operations | Description |

|---|---|

| (1) Material Flows | Arrangement for supplying raw materials and assembly parts and/or component from direct or indirect vendors and/or suppliers [4,7,25,26,39,44] |

| (2) Assembly/Dis-assembly related activity | Production facilities needed for assembly/disassembly (i.e., manual/semi-automated/automated processes) associated activities [5,6,12,28,45,46,47] |

| (3) Reuse related activity | Manufacturing infrastructure and facilities needed for cleaning, handling, sorting, inspecting and testing activities [5,12,27,30,47,48,49] |

| (4) Remanufacture related activity | Manufacturing infrastructure and facilities needed for rectifying, repairing and replacing parts and/or components [5,12,27,30,31,47,48,49] |

| (5) Recycle related activity | Manufacturing infrastructure and reprocessing facilities needed for shredding, separating, sorting, inspecting and testing [5,11,12,27,30,32,33,37,38,47,48,49] |

| (6) Disposal Treatment | Manufacturing infrastructure and treatment facilities needed for segregating non-hazardous or hazardous portions in product or component [4,8,19,20,24,50,51] |

| (7) Returned arrangement activity | End-of-life arrangement for sorting activities, returns authorisation and administration works, and rebate whenever needed [4,5,10,11,33,35,36,38,41,49] |

| Operational Improvement Aspects | Description |

|---|---|

| Recovery cost | Recovery cost for producing a manufactured product, includes costs of acquiring materials, parts and/or components for assembly and/or disassembly related activities for the purpose of reusing, remanufacturing, and recycling [4,5,10,11,12,33,37,38,41,51,55] |

| Manufacturing lead-time | Lead-time for recovery operations include various operational and/or non-operational related activities, such as machine setup, testing, inspection, control, sorting, etc. when reusing, remanufacturing and recycling parts and/or component for producing a manufactured product [4,5,10,11,12,33,35,36,37,38,41,51,55,56,57,58] |

| Waste minimisation | Weight recovery proportion for producing a manufactured product, includes various combinations of reused, rebuilt, recycled or virgin parts and/or components [4,5,11,12,31,32,37,38,39,49,50,55,59,60] |

| Quality performance | Reliability describes the ability of a manufactured product to perform well under stated operating condition for a specified period of time. This is one of the important aspects if the product fails during post-use stage or within warranty period. A trade-off decision disposition may be a compromise option for manufacturers and consumers [61,62,63,64,65,66] |

| No. Component per Module, Qty. | Proposed ‘RA’ | Proposed ‘RB’ |

|---|---|---|

| ZA/module AA | 3 | |

| ZB/module BB | 2 | |

| ZC/module CC | 3 | |

| ZD/module DD | 5 | |

| ZE/module EE | 3 | |

| No. Component per Module, Qty. | ‘Exist’—Manufacturer | Proposed Recovery Configuration Option ‘RA’ | Proposed Recovery Configuration Option ‘RB’ |

|---|---|---|---|

| ZA/module AA | 1 Recycle and 2 Virgin | 3 Reuse. | 1 Reuse and 2 Reman. |

| ZB/module BB | 1 Recycle and 1 Virgin | 2 Virgin. | 2 Virgin. |

| ZC/module CC | 2 Recycle and 1 Virgin | 2 Reuse and 1 Recycle; | 2 Reman and 1 Reuse. |

| ZD/module DD | 3 Recycle and 2 Virgin | 1 Reuse; 2 Reman and 2 Virgin. | 2 Reman; 2 Recycle and 1 Reuse. |

| ZE/module EE | 1 Recycle and 2 Virgin | 2 Reuse and 1 Recycle. | 3 Recycle. |

| Product | Component/Module | ||||||||

| ZA/module AA | 0.58 | 1.37 | 0.25 | 1.15 | 0.13 | 1.88 | 0.48 | 1.32 | |

| ZB/module BB | 1.72 | 5.87 | 0.45 | 1.53 | 0.25 | 1.23 | 0.54 | 2.24 | |

| ZC/module CC | 0.55 | 3.94 | 0.32 | 1.36 | 0.32 | 0.98 | 0.48 | 2.24 | |

| ZD/module DD | 0.75 | 4.56 | 0.68 | 1.47 | 0.68 | 1.23 | 0.24 | 2.85 | |

| ZE/module EE | 0.25 | 3.98 | 0.21 | 1.85 | 0.21 | 1.01 | 0.17 | 2.12 |

| Collection Activity Costs per Product | ||||

|---|---|---|---|---|

| ‘Exist’ | 0.05 | 0.125 | 0.251 | 0.137 |

| Proposed ‘RA’/‘RB’ | 0.25 | 0.214 | 0.362 | 0.325 |

| Product | Component per Module in Minutes | |||||||

| ZA/module AA | 0.81 | 1.17 | 0.68 | 1.23 | 2.21 | 0.56 | 5.58 | |

| ZB/module BB | 0.74 | 1.85 | 1.01 | 1.13 | 2.12 | 0.41 | 2.74 | |

| ZC/module CC | 0.56 | 1.62 | 1.01 | 1.47 | 1.56 | 0.21 | 3.22 | |

| ZD/module DD | 0.72 | 1.36 | 0.74 | 1.71 | 2.14 | 0.12 | 4.12 | |

| ZE/module EE | 0.35 | 1.25 | 0.65 | 1.12 | 3.48 | 0.14 | 3.21 |

| Product | Module Level | Module AA | Module BB | Module CC | Module DD | Module EE |

| ‘Exist’ | 0.9781 | 0.9924 | 0.9812 | 0.9801 | 0.9751 | |

| ‘RA’ | 0.9753 | 0.9834 | 0.9835 | 0.9723 | 0.9723 | |

| ‘RB’ | 0.9753 | 0.9834 | 0.9835 | 0.9723 | 0.9623 |

| Configuration | ‘Exist’ | Proposed ‘RA’ | Proposed ‘RB’ |

|---|---|---|---|

| Cost (TC) | $110.41 | $66.19 | $83.88 |

| Time (MLT) | 85.19 min | 72.81 min | 83.25 min |

| Waste (WM) | 0.4958 | 0.6203 | 0.6203 |

| Quality (QR) | 0.9102 | 0.8918 | 0.8826 |

| Product Configuration | |

|---|---|

| Proposed ‘RA’ | 2.746 |

| Proposed ‘RB’ | 2.251 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuik, S.; Diong, L. Building Model-Driven Decision Support System in Product Redesign Plan. Designs 2019, 3, 18. https://doi.org/10.3390/designs3010018

Kuik S, Diong L. Building Model-Driven Decision Support System in Product Redesign Plan. Designs. 2019; 3(1):18. https://doi.org/10.3390/designs3010018

Chicago/Turabian StyleKuik, Swee, and Li Diong. 2019. "Building Model-Driven Decision Support System in Product Redesign Plan" Designs 3, no. 1: 18. https://doi.org/10.3390/designs3010018

APA StyleKuik, S., & Diong, L. (2019). Building Model-Driven Decision Support System in Product Redesign Plan. Designs, 3(1), 18. https://doi.org/10.3390/designs3010018