1. Introduction

As widely known [

1], Liquid Crystal Elastomers (LCEs) are polymeric materials characterized by both the elastic behavior of rubbers and the anisotropic self-organization of liquid crystals [

2,

3,

4]. Consequently, they can be subjected to reversible deformation when exposed to different external stimuli such as heat, light, or electric fields. Some key properties of LCEs, for instance semi-soft elasticity, auxetic behavior, and their ability to actuate comes from the interaction between the material inherent liquid-crystal alignment and the arrangement of the polymer backbone [

5]. LCEs have drawn interest in several engineering fields with particular reference to soft robotics and biomedicine. Earlier studies demonstrated their potential for mimicking biological structures such as intervertebral disks [

6] or muscle tissue [

7]. Recently, the REPAIR Project, funded under the European Union’s Horizon 2020 program, demonstrated that specifically designed LCEs, when stimulated by light, can generate peak stresses in the order of 400 mN/mm

2, comparable to those produced by fully calcium-activated muscle fibers [

8]. These results can be considered groundwork for the creation of artificial cardiac muscles and for producing implantable contractile devices to support cardiac function in patients suffering from heart failure.

Synthesis strategies for LCEs are commonly grouped into two approaches [

1], among which the one-step cross-linking method directly polymerizes low-molecular-weight monomers. This technique is particularly suitable for fabricating LCEs via capillary infiltration between two substrates, due to the relatively low viscosity of the prepolymer mixture. Polymerization is subsequently triggered, typically through ultraviolet (UV) irradiation or thermal curing, to permanently fix the mesogen orientation within the cross-linked network.

Several alignment mechanisms have been reported in the literature [

2,

3,

4], including mechanical deformation, externally applied fields, and surface-induced orientation. The latter is widely employed in liquid-crystal display (LCD) manufacturing due to its high spatial resolution. Surface alignment layers guide mesogen orientation through either (1) intermolecular interactions between the monomers and the coated substrate or (2) micro/nano-scale grooves that require a preferred direction. These grooves are commonly produced via rubbing, in which a velvet-like cloth is drawn across the coated slide to generate microscopic unidirectional tracks [

9,

10].

Once the alignment layer is prepared, an infiltration cell is assembled, typically using borosilicate microspheres as spacers to define thickness [

11]. Therefore, the LCE precursor is driven into the gap by capillary action at its isotropic transition temperature. The infiltrated system is then photopolymerized. Because the rubbing process and the construction of the infiltration cell directly determine the film’s orientation quality and thickness uniformity, these steps are critical.

Unfortunately, this process is characterized by inconsistent rubbing, non-uniform thickness, mostly due to the borosilicate microspheres used as spacers that do not guarantee a uniform distance between the slides and may result in the beads remaining embedded in the final film, and adhesive issues since the adhesive (cyanoacrylate) may shrink during drying, leading to uneven film thickness. To partially address these issues, Profili et al. [

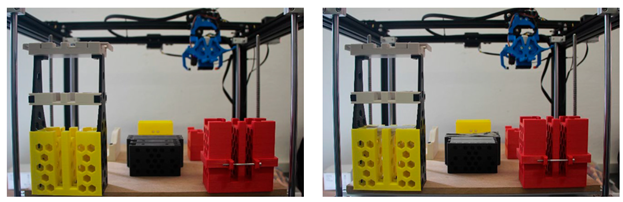

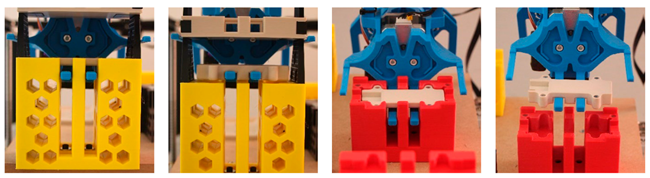

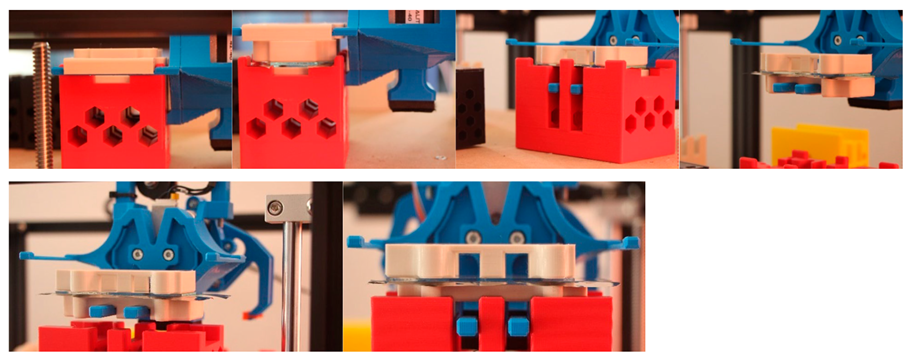

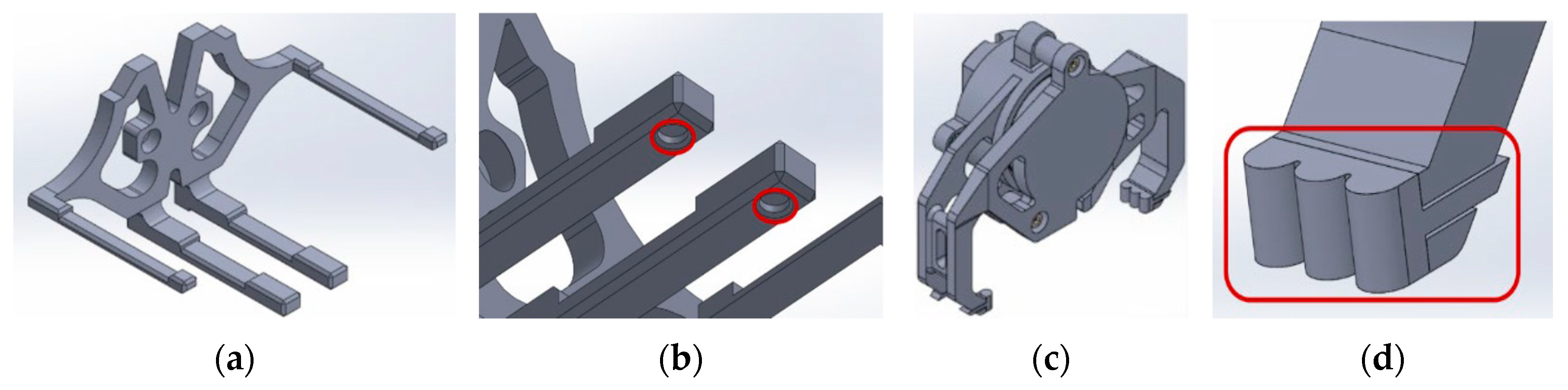

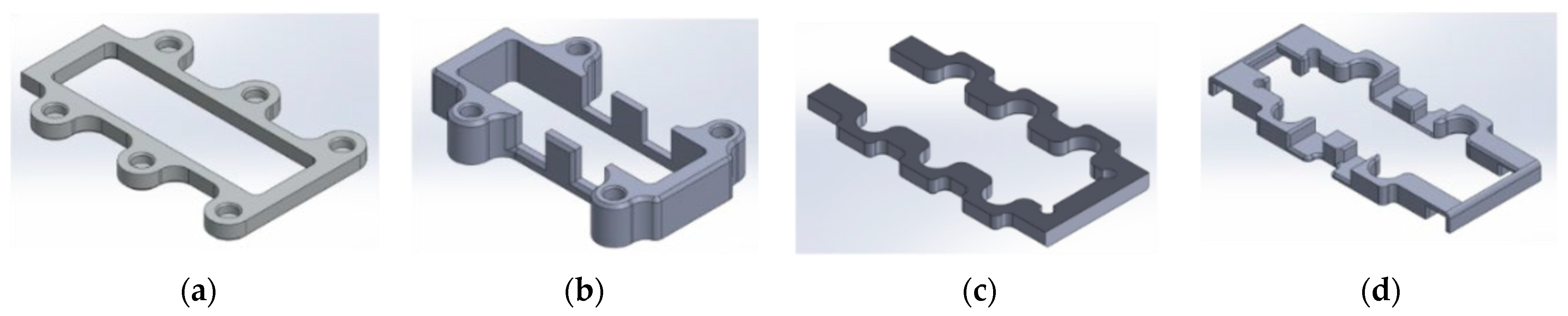

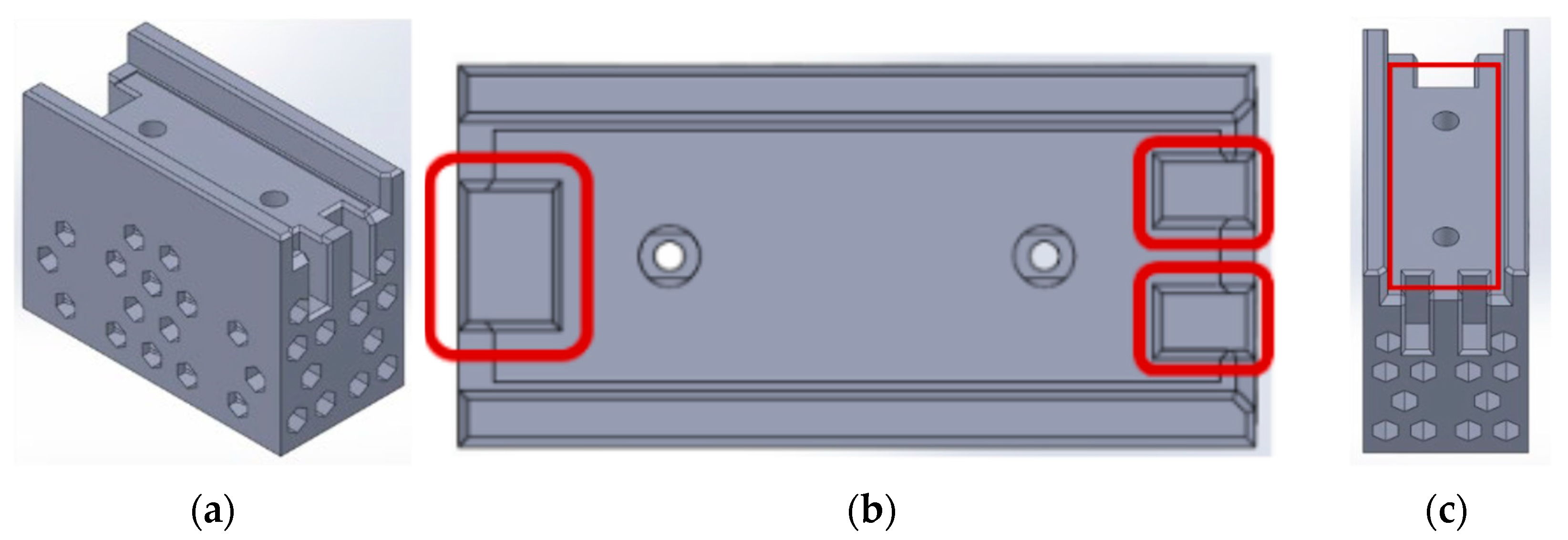

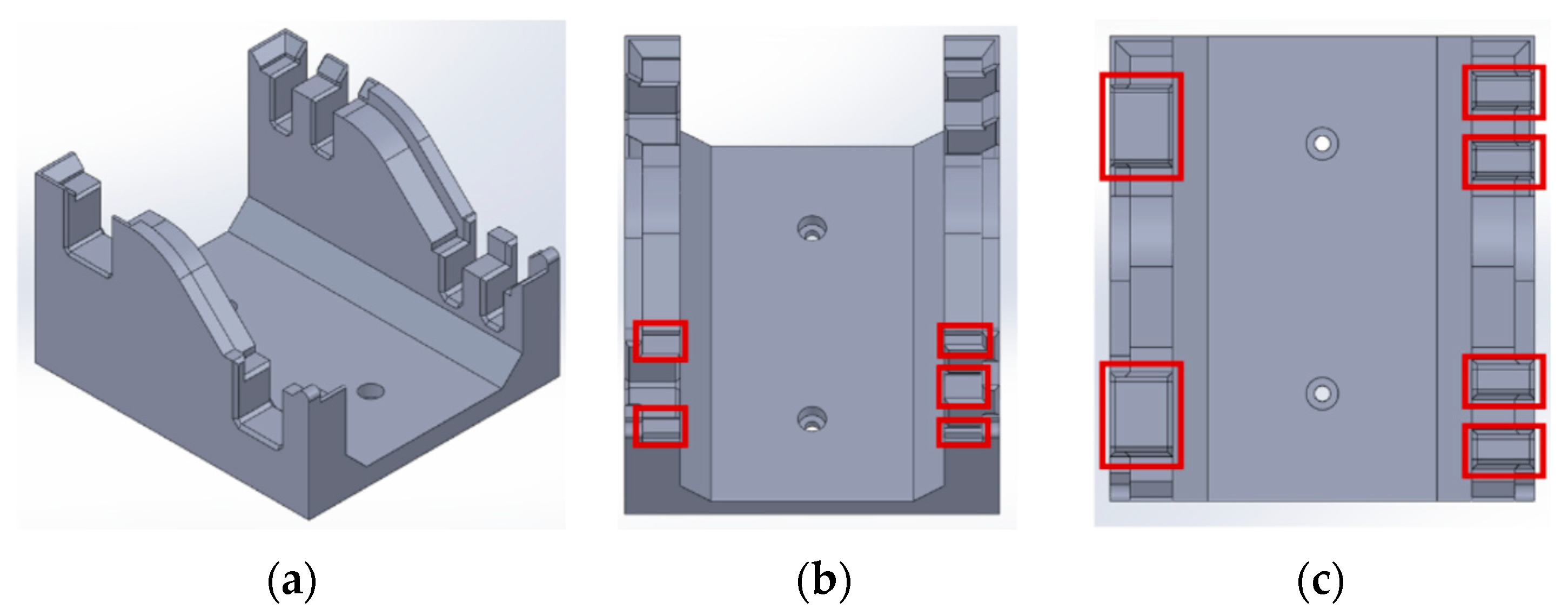

12] introduced an improved fabrication methodology based on the development of two mechanical systems using 3D-printed components combined with aluminum substrates for thermal stability. The first system standardizes the rubbing process, which is crucial for inducing mesogen orientation in LCEs. A 3D-printed base with a recessed slide holder constrains the glass substrate and ensures a constant rubbing direction, eliminating the slippage commonly occurring in vacuum-based setups. This structure (see

Figure 1a) exposes only the PVA-coated region while allowing controlled handling after rubbing. The second system consists of a modular infiltration cell assembly incorporating calibrated metal strips as precise spacers and magnets embedded in aluminum supports (i.e., a slide holder) to maintain stable alignment between the two slides (see

Figure 1).

This replaces the conventional use of microspheres and adhesives, thereby preventing thickness variability and mechanical distortions caused by shrinkage during glue curing. Using this method, it is possible to obtain capillary infiltration of an LCE precursor mixture at its isotropic transition temperature, followed by UV-initiated photopolymerization and thermal post-curing [

13].

This method still requires manual handling during rubbing, slide positioning, spacer placement, and film extraction phases. This reliance on operator skill introduces potential variability and, most importantly, limits overall reproducibility. Furthermore, the system is designed to manufacture one film at a time, which is adequate for prototyping but not for applications needing fast and multiple creation of LCE films. Automating rubbing direction, sliding motion, alignment pressure, and infiltration timing would ensure higher quality, precise slide spacing, and uniform infiltration independently from the operator’s skill [

14].

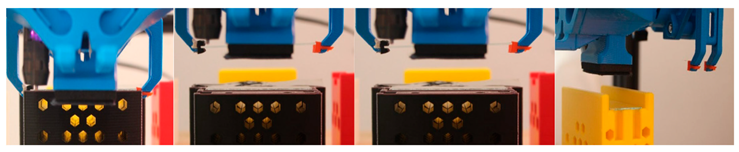

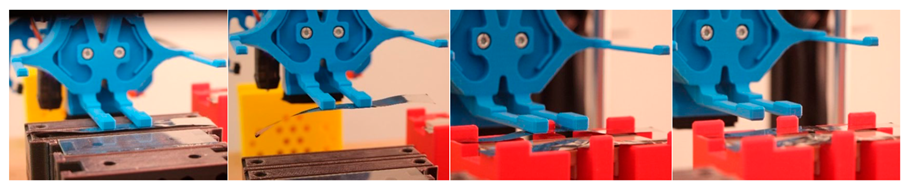

To address this issue, the present work aims to automate the mechanical alignment steps to manufacture LCE films. Instead of attempting to automate the entire chemical fabrication workflow, the system targets the operations most prone to operator error: rubbing, slide manipulation, spacer positioning, and infiltration cell assembly. These steps are mechanized through a dedicated low-cost prototype obtained by customizing a Cartesian robot derived from a 3D printer. By replacing microspheres and adhesive bonding with calibrated metal spacers and magnetic coupling, the framework ensures more controlled and repeatable film geometry. Furthermore, the limited cost of the equipment enables parallel deployment of multiple units, significantly increasing production throughput. It is important to remark that the main intent here is to automate only the mechanical assembly steps (rubbing, spacer placement, slide alignment), while infiltration and polymerization remain semi-manual due to the chemical sensitivity of LCE precursors.

To the best of the authors’ knowledge, there is only one comparable automated system for LCE fabrication reported in the literature, namely the RoboLEC workstation, presented in [

15]. Although both approaches rely on modifying the hardware of a commercial 3D printer to automate repetitive laboratory tasks, the objectives, alignment strategies, and levels of mechanical redesign largely differ. RoboLEC is designed to automate photoaligned LCE fabrication, leveraging azopolyimide-coated slides and a laser projector to generate arbitrary director patterns, while also integrating automated glue dispensing, heating, and UV polymerization. In contrast, the system proposed in this work focuses on the mechanical assembly of the infiltration cell, automating the critical steps. Furthermore, whereas RoboLEC aims at producing patterned molecular orientations for micromechanics and soft robotics, the present system targets scalable and low-cost production of uniformly aligned LCE films with controlled thickness. As a result, the two hardware systems address different aspects of the fabrication workflow and respond to distinct material and application requirements.

To contextualize the contribution of the system provided in this paper,

Table 1 provides a quantitative comparison with the RoboLEC workstation [

15]. In particular, a comparison between the two systems across cost, throughput, alignment quality, and film-thickness consistency is provided in a qualitative manner.

More in detail, the proposed system is not devoted to the automation of the infiltration and polymerization stages, which are still partially manual due to the sensitivity of LCE chemistry to both temperature and curing conditions. Rather, the present work concentrates on the phases where mechanical repeatability has the largest impact on film quality. By stabilizing these steps, the proposed framework lays the groundwork for full automation in LCEs manufacturing.

2. Workflow for the Design of the Automated System

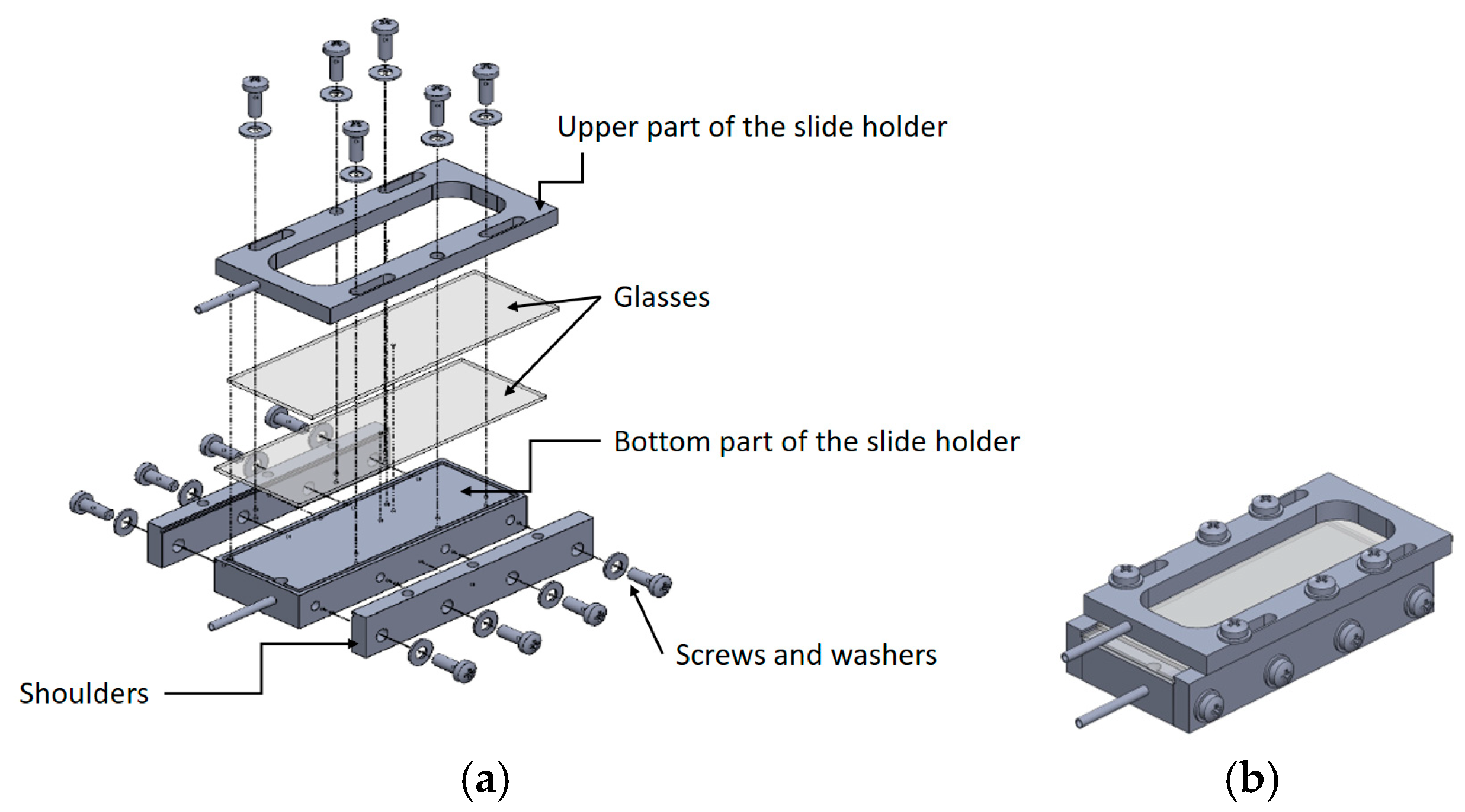

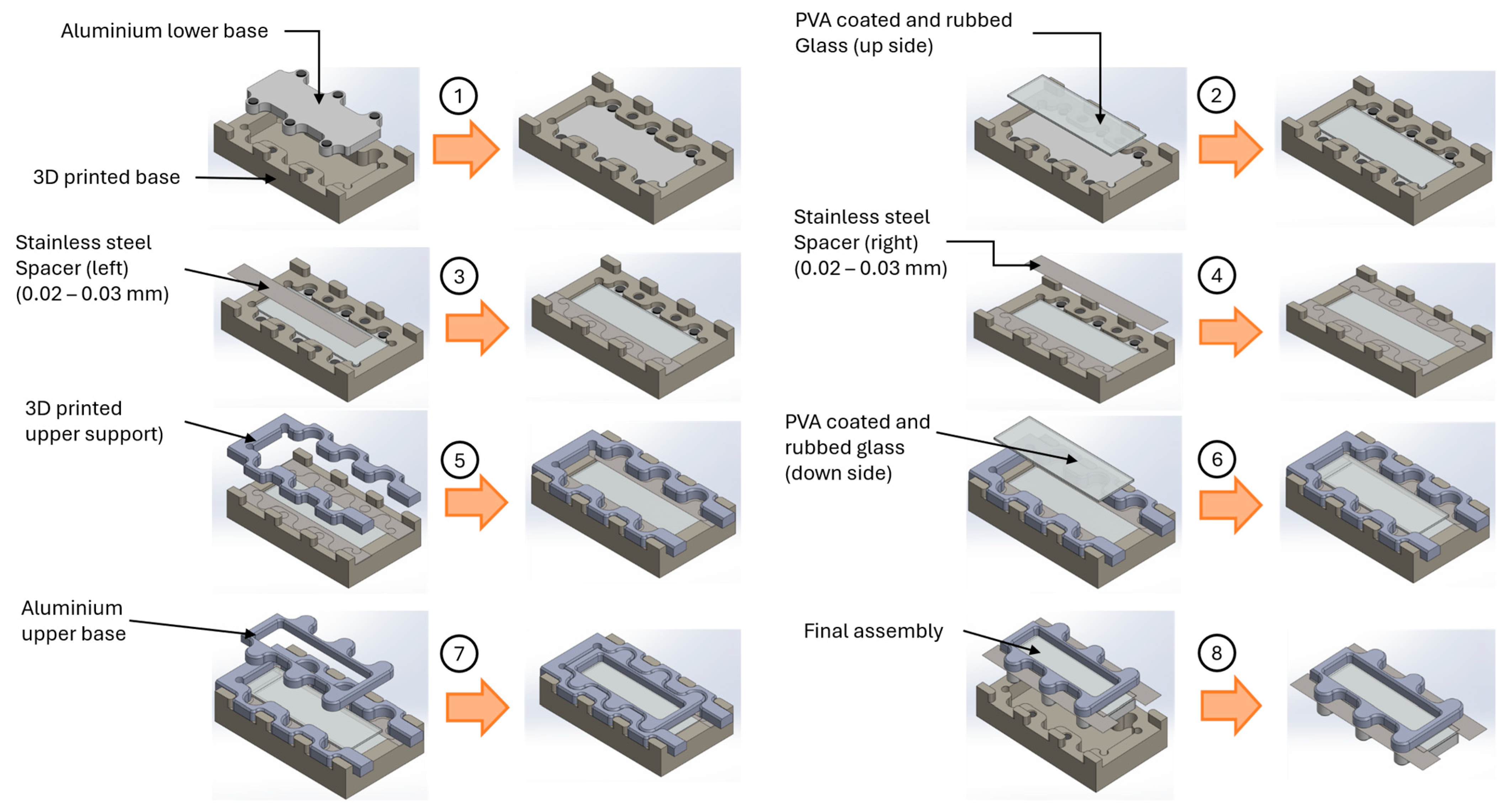

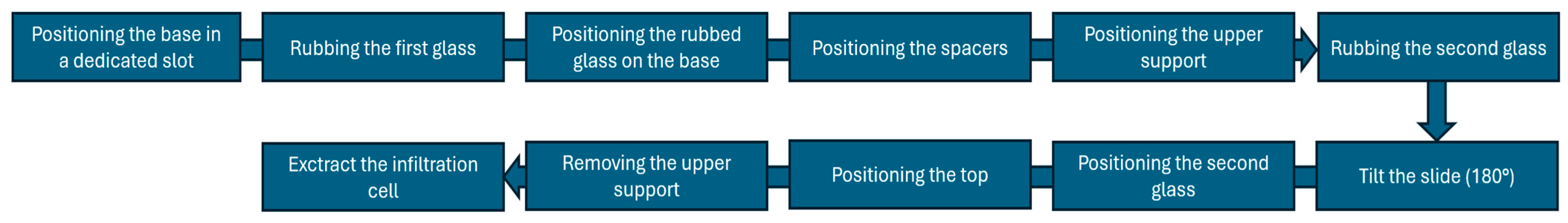

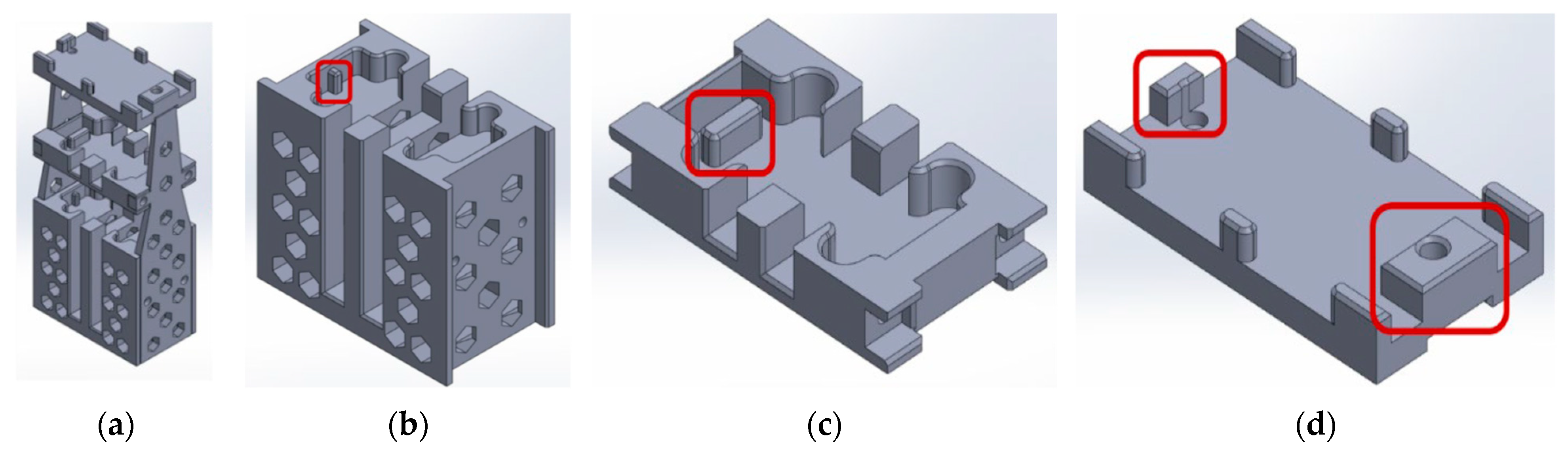

The typical manual manufacturing process of LCE samples consists of six steps [

12] (see

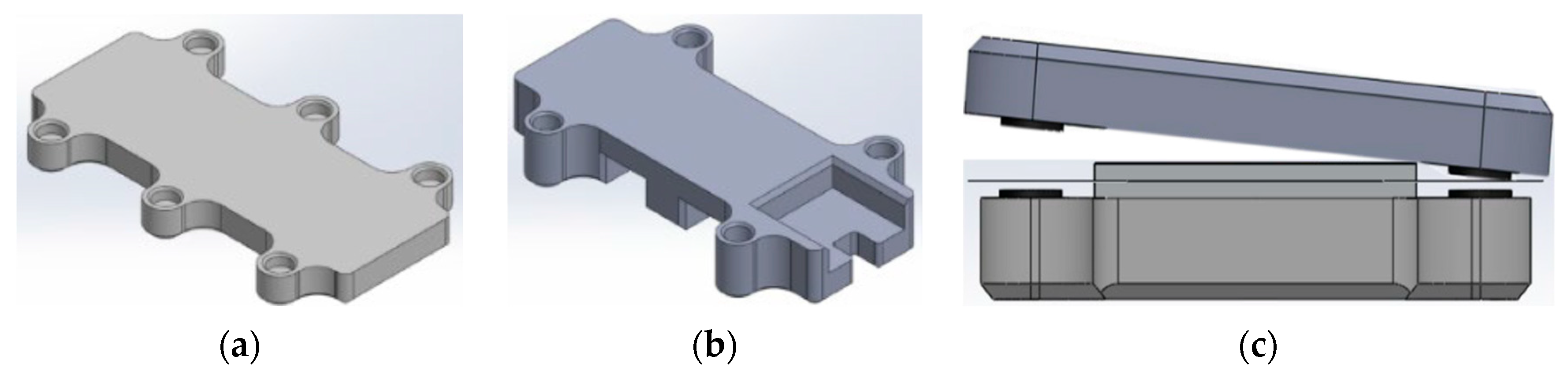

Figure 2). First, the lower aluminum base is inserted into the 3D-printed support base, which provides a maximum clearance of 0.4 mm and therefore allows only vertical movement. Next, the first slide, previously rubbed and coated with PVA, is placed on the base with the coated side facing upward. The metal spacers are then positioned externally and held in place by the magnets embedded in the metal base, after which the upper support is inserted to guide the positioning of the second slide. The second slide is subsequently placed with the PVA-coated side facing downward. Finally, the upper metal part is installed and magnetically coupled to the lower metal part, bringing the two slides together at the distance defined by the spacers. At this point, the assembled infiltration cell can be removed and transferred onto the heating plate for infiltration followed by UV photopolymerization.

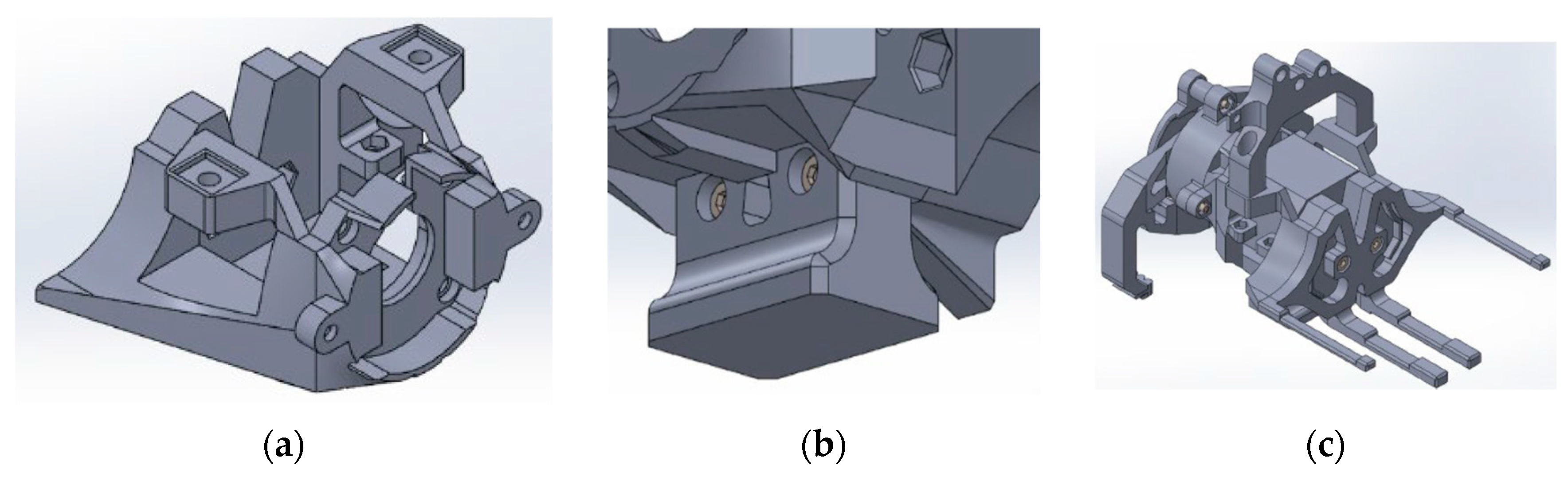

Each phase requires precise hand coordination to avoid damaging the sacrificial PVA layer, misplacing the spacers, or introducing slight angular deviations that could compromise the uniformity of film thickness and the quality of mesogen alignment. To automate this process a dedicated hardware system is here developed to replicate the process carried out manually by the operator but with more precision. In detail, the required movements allowing to correctly assemble an LCE are the ones depicted in

Figure 3.

A Cartesian robot was therefore selected to meet the need for high precision and repeatability. As widely recognized, the kinematic structure of this class of robots is typically described as “PPP,” indicating three prismatic joints that provide linear motion along the X, Y, and Z axes through mutually orthogonal slides.

This configuration is widely employed in commercial FDM 3D printers. In this work, the Creality Ender 5 Plus (Creality Inc., Shenzen, China) was chosen as the baseline platform for developing the customized Cartesian system, although other platforms can be adopted as well. Because the purpose of this system is to accelerate the development of multiple LCEs within a limited time frame, it is essential to keep the cost of each manufacturing unit as low as possible to allow parallel operation of many machines. For this reason, a modified 3D printer provides an effective and economical hardware basis that can be readily adapted to the specific production workflow and automated for assembling the infiltration device.

5. Results

To assess the repeatability of the developed system, ten fabrication cycles under identical conditions and evaluated variability in both geometric and optical outputs were tested. The primary goal of these trials was not to perform a complete statistical analysis but rather to provide functional validation; accordingly, this small dataset allows us to quantify repeatability across the automated sequence.

For the tests, once the cell has been constructed by the Cartesian robot, it is placed on a temperature-controlled plate at 65 °C, together with the flask containing the mixture.

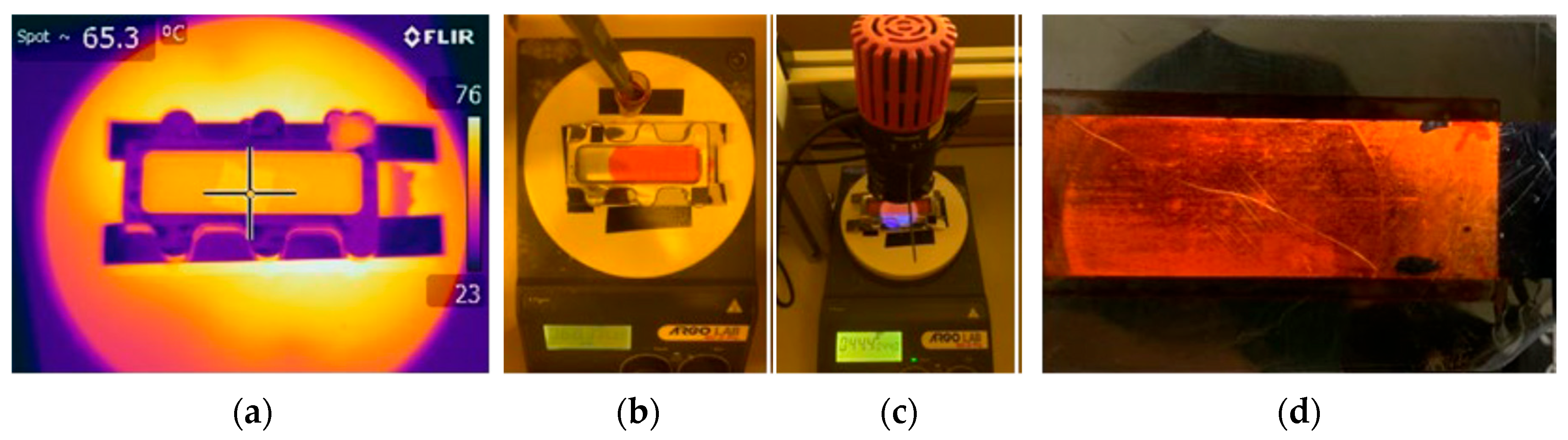

After checking the actual temperature of the cell with the thermal imaging camera in

Figure 16a, small amounts of the mixture are collected with a metal rod and placed in the infiltration site of the cell. Infiltration front progresses through 25% of channel length every ~7 min (

Figure 16b). After about half an hour, the cell is completely infiltrated and the cooling phase begins to bring the cell to a temperature of 40 °C, which is necessary for the first treatment with ultraviolet light. After 20 min, the temperature is checked with the same camera and the correct value is verified, and the UV lamp is switched on for 10 min (

Figure 16c). Next, the cell is brought to a temperature of 65 °C for the second ultraviolet light polymerization treatment, for a further 10 min. The first exposure to the lamp is the most important one: in fact, the temperature at which polymerization of the film takes place must be kept under control [

18]. At the end of the second exposure to the lamp, the cell is allowed to cool for 5 min, after which the film is removed from the cell and evaluated for crystal linearity and birefringence (

Figure 16d).

It is important to highlight that none of the PLA structural components of the automated workstation are exposed to temperatures approaching their glass transition temperature (typically around 55–60 °C). During the LCE curing process, only the infiltration cell is transferred to the external heating plate and UV-curing station, while the robot and its PLA-printed fixtures remain thermally isolated from the heated environment. As a result, the PLA parts experience only ambient-temperature operation, ensuring dimensional stability and mechanical integrity throughout repeated manufacturing cycles. For LCE chemistries requiring higher curing temperatures (e.g., up to 80 °C), the heating occurs entirely off-board, and the robot does not undergo thermal loading.

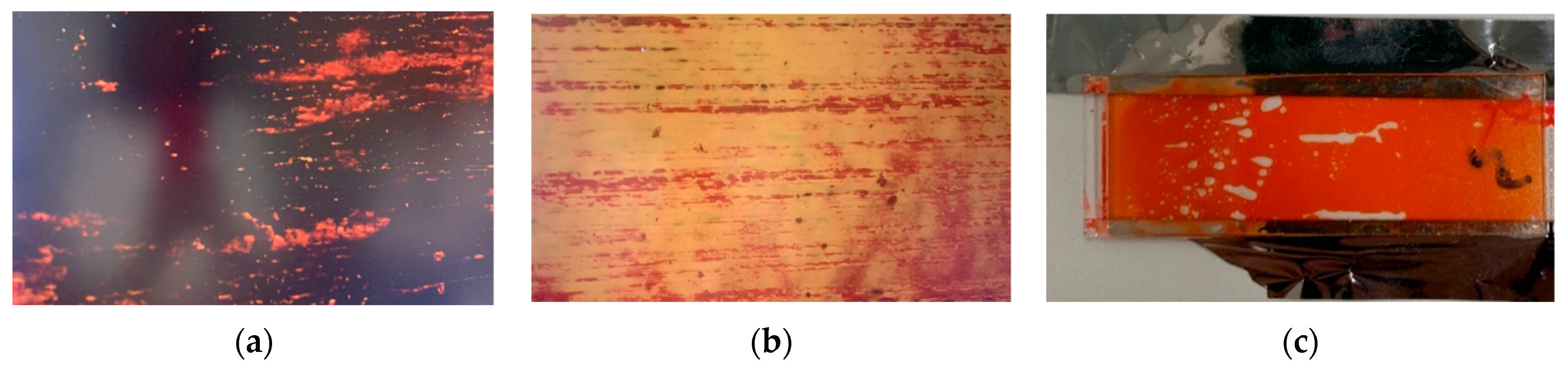

In the initial LCE production trials, the films were misaligned and showed inconsistencies in transparency and final color, as shown in

Figure 17. The causes can be attributed to two main factors:

The rubbing step with the Cartesian robot was not performed correctly, creating microchannels that were not aligned with respect to the liquid crystal alignment plane, or applying insufficient pressure.

The temperatures set on the thermal plate did not match the actual temperatures, significantly altering the temperatures required for the UV curing steps. The use of the thermal imaging camera revealed a temperature difference between the hot plate temperature and the actual temperature of approximately T = +5 °C, which resulted in the first polymerization step being performed at a cell temperature too close to the transition temperature.

In particular, the first has little effect on color, unlike the second, which affects the refraction of light. In some cases, there is no refraction at all, while in others it occurs in random areas of the elastomer. During the infiltration phase, another potential defect can occur: the formation of air bubbles in the LCE film. These bubbles form as a result of the uneven distribution of the compound in the alignment plane and cannot be filled once formed.

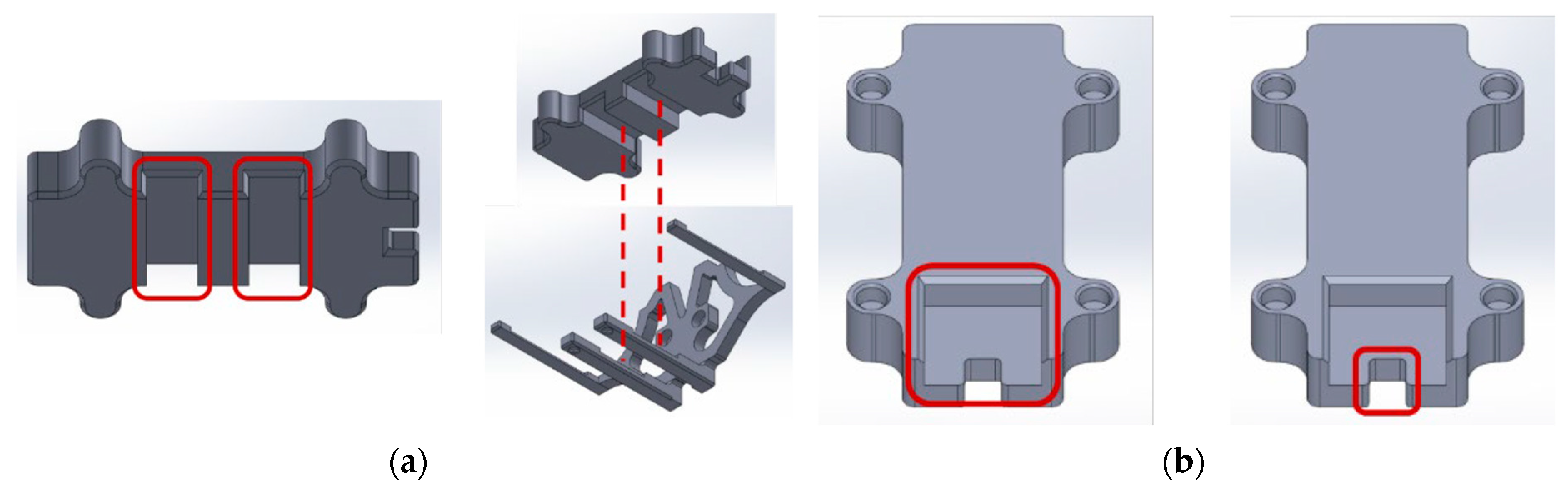

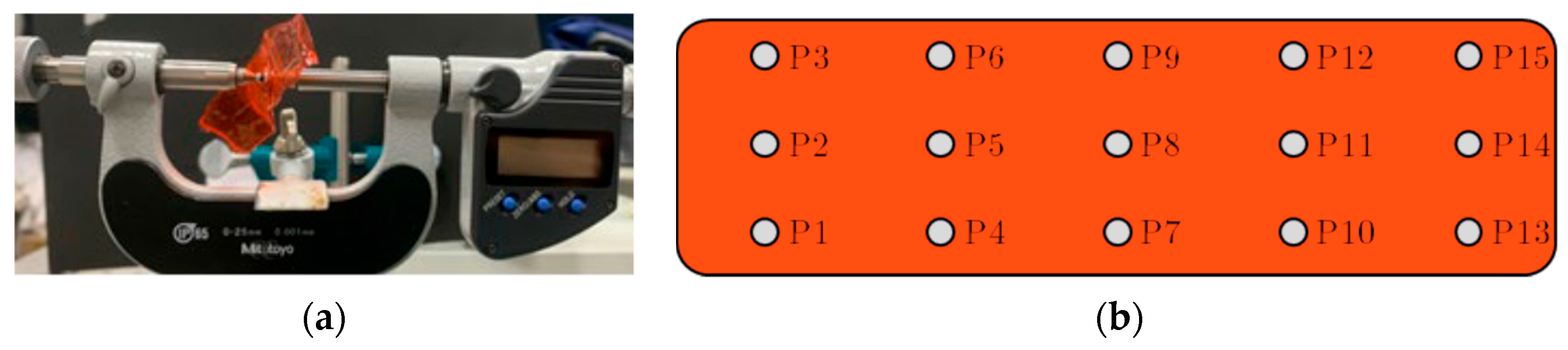

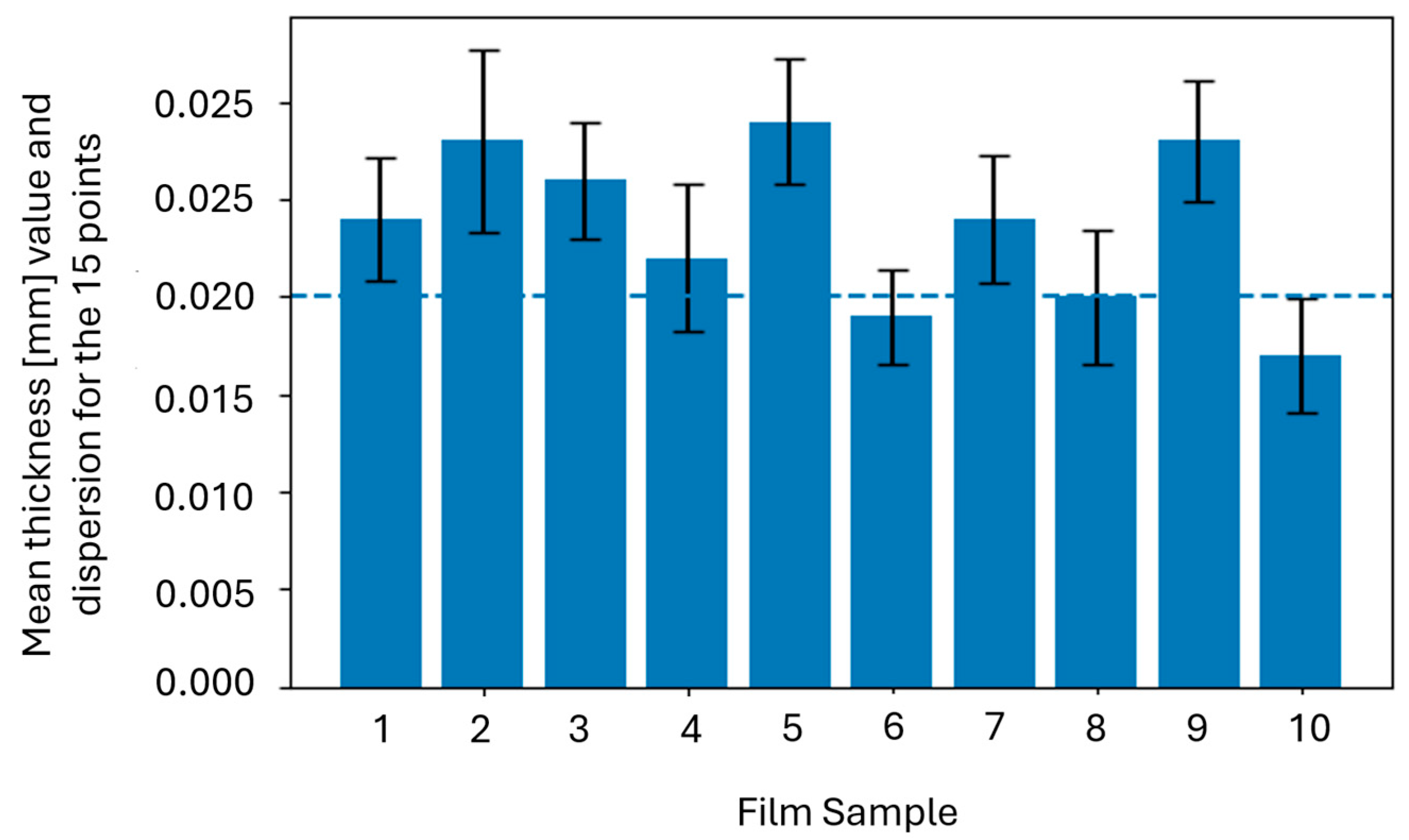

To avoid the possible formation of bubbles within the film, a stirring rod is used to stimulate the points where a difference in the flow of the mixture is observed on the infiltration plane. Modifications were then made to the Cartesian robot for the rubbing phase and temperatures were corrected. To test the repeatability of the apparatus, ten infiltration cells were made (i.e., ten films were produced). The thickness of each film was measured at fifteen different positions (P1–P15) as shown in

Figure 18, using a micrometer with a measurement sensitivity of 0.001 mm. The film is placed between two disks to ensure its stability. Each measurement was repeated three times, and the average was calculated. Knowing the thickness of each disk, the thickness of the film is obtained by a simple difference between the two, with an uncertainty corresponding to the sensitivity of the instrument. The results of the measurements of the films produced by the spacer with a nominal thickness of 0.020 mm are shown in

Table 3. To provide a clearer statistical representation of the thickness data reported in

Table 3,

Figure 19 shows the mean thickness of each of the ten fabricated LCE films together with their corresponding standard deviations. Each bar represents the average value obtained in the fifteen measurement points per sample, while the error bars denote the standard deviation obtained from the three repeated measurements at each point. This visualization highlights the intra-sample variability (standard deviations in the range of 0.0024–0.0047 mm), confirming that the automated assembly process produces geometrically consistent films. The bar chart also makes evident that inter-sample differences arise primarily from the systematic offset between the nominal spacer thickness (0.020 mm) and the actual substrate-defined gap, rather than from stochastic variation in the robotic assembly.

It is important to highlight that the deviation between spacer thickness and final film thickness does not occur because of the automated assembly but, rather, from substrate variability that the automated system is not able to compensate. Therefore, the results in

Table 3 also emphasize how the available commercial slides are affected by error.

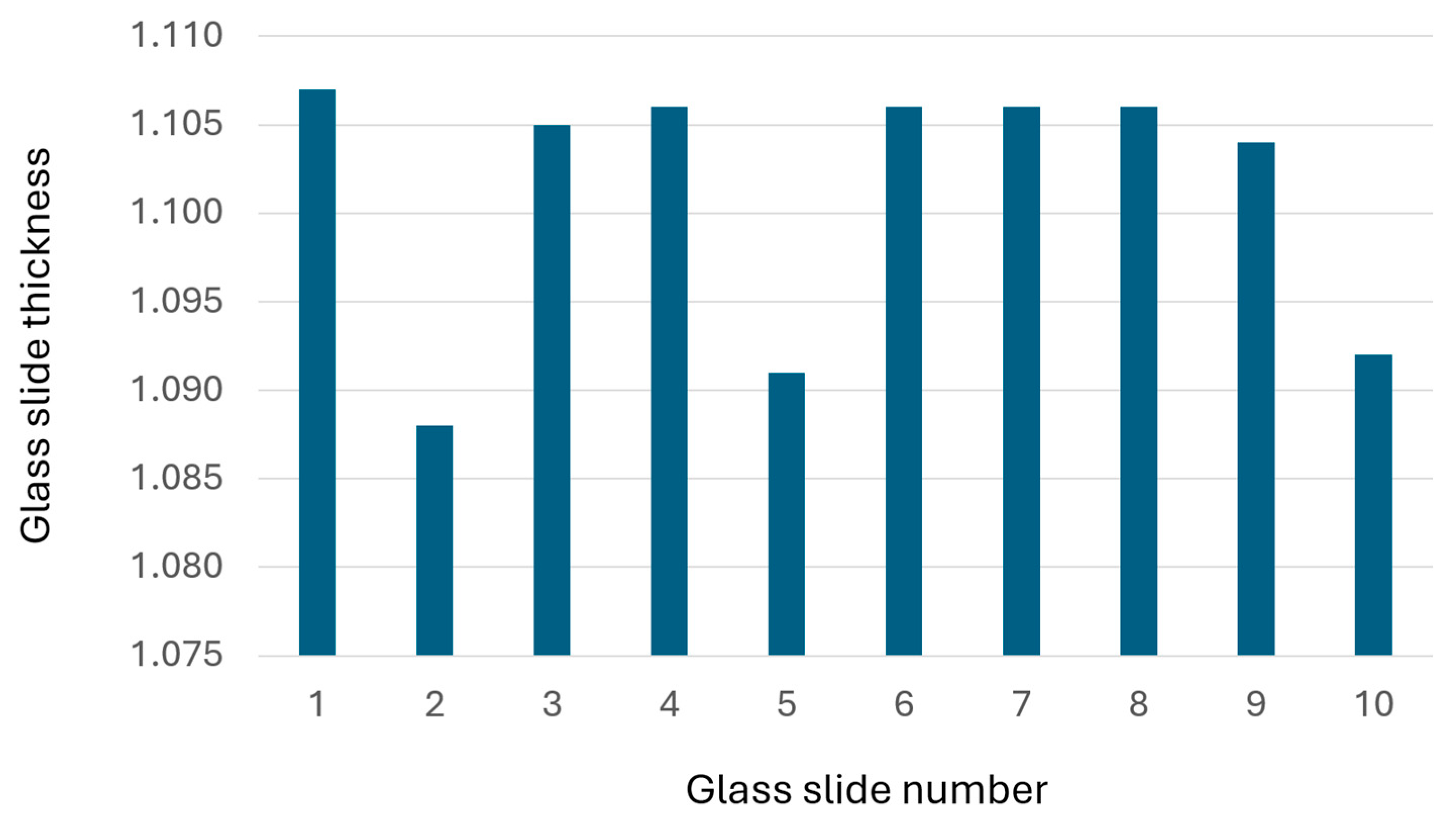

In fact, the correlation between local slide thickness and film thickness confirms that the developed machine is able to preserve the geometry imposed by the substrates reliably. It can also be seen that the average thickness of the films differs from the nominal thickness of the spacers. Therefore, it was decided to investigate the causes of this phenomenon by measuring the thickness of the laboratory slides after PVA coating. As with the films, the glass was measured at fifteen points, as shown in

Figure 18. The measurements were repeated three times, and the average was then calculated and shown in

Table 4.

From the measurements shown in

Table 4, the laboratory slides have average dimensions and deviations in line with the desired film thickness.

Figure 20 highlights how each slide’s mean thickness differs from the nominal value equal. This shows that small slide-to-slide deviations (on the order of a few micrometers) are sufficient to influence the final LCE film thickness despite the high repeatability of the automated assembly process.

To further validate the performance of the automated manufacturing framework and to distinguish robot-induced variability from substrate-induced effects, three additional quantitative analyses were carried out: (1) statistical correlation between slide thickness and final film thickness, (2) assessment of positional repeatability of the Cartesian manipulator, and (3) quantification of rubbing-induced microgroove uniformity.

As shown in

Table 3 and

Table 4, both the PVA-coated slides and the resulting LCE films exhibit spatial thickness variations. To assess whether the film-thickness deviations originate from substrate geometry rather than from robotic assembly, a Pearson correlation analysis [

19] was carried out. The evaluated correlation coefficient was found to be equal to r = 0.78, indicating a positive relationship between local slide thickness and local film thickness, and comparable with scientific literature values [

20,

21].

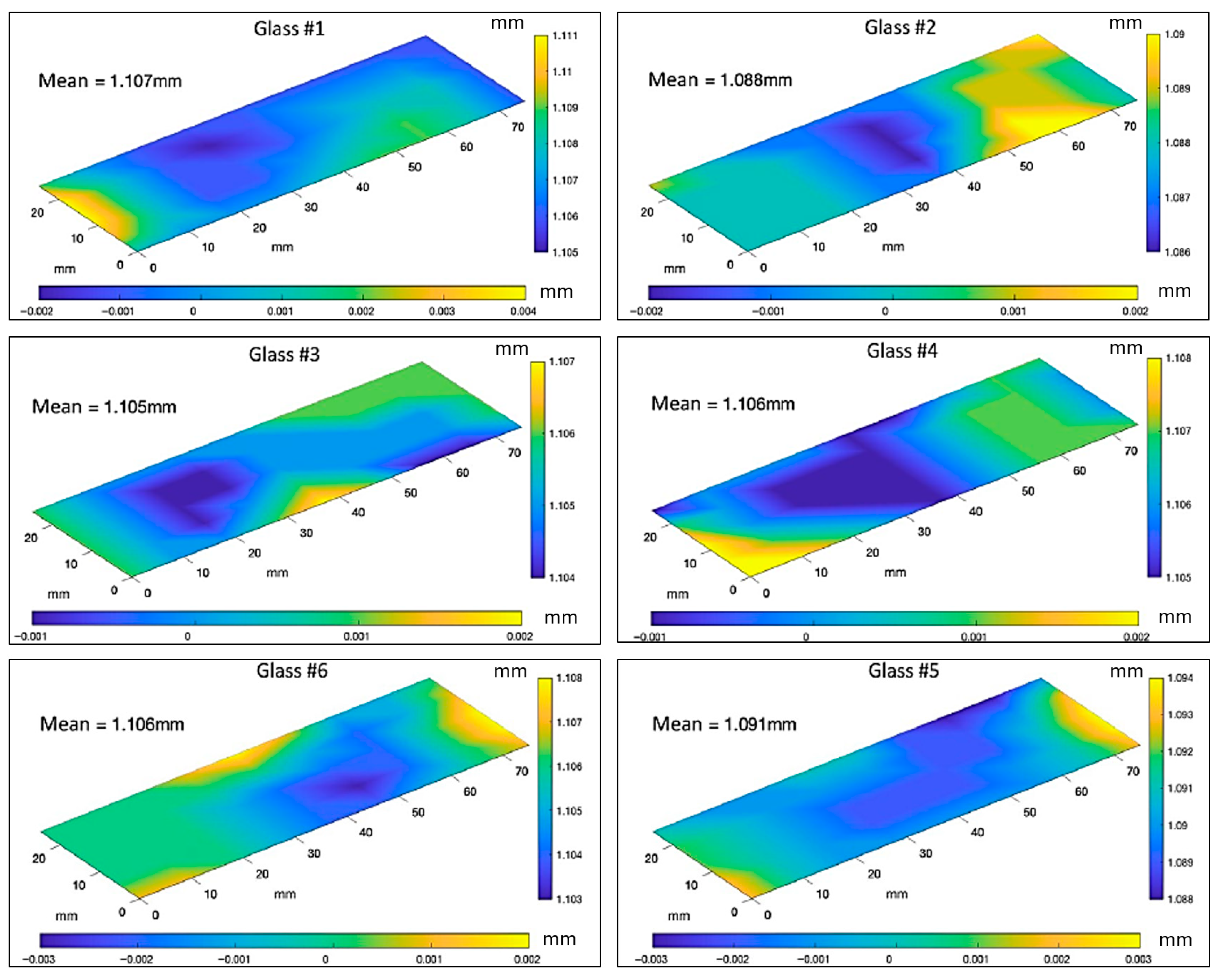

This is sufficiently in accordance with the maps presented in

Figure 21, which show, as an illustrative example, thickness gradients for 6 out of 10 glasses. Values, for the whole set of 10 samples, are in the order of 10–15 µm across a single slide. In the figure, the color bar on the right-hand side refers to thickness value, while the bottom color bar refers to the deviation from the average value.

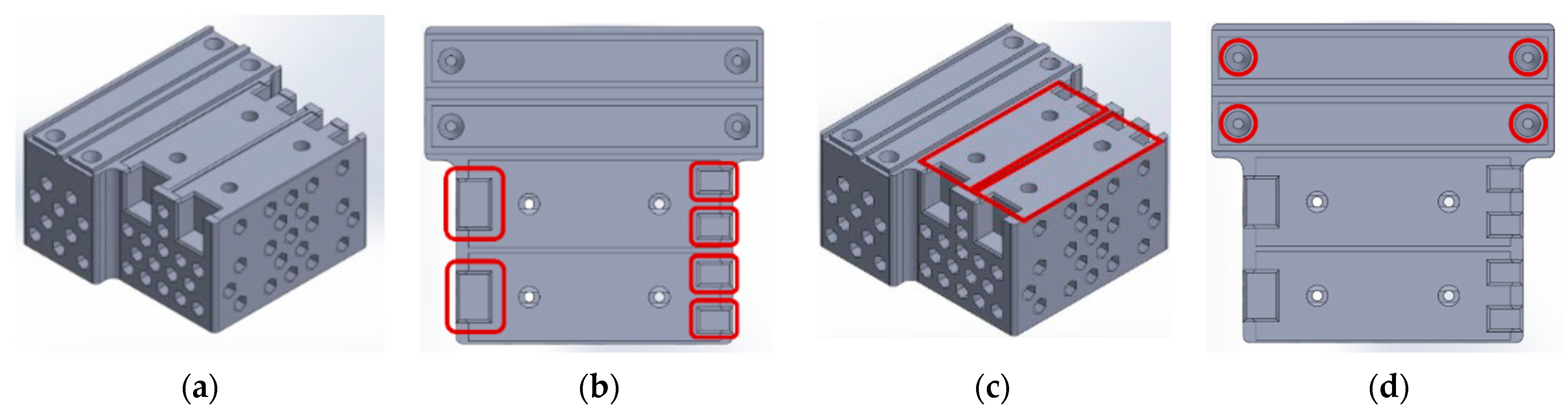

With the corrected setup, quantitative measurements were then carried out to distinguish the contributions of substrate variability from those introduced by the robotic assembly. The repeatability of the machine was evaluated by recording the end effector position at different stages: slide gripping, spacer placement, rubbing engagement, and final cell closure. In particular 20 cycles were tested; infiltration was not performed during the tests. The higher positional variation in the machine resulted equal to ±0.08 mm in the XY plane and ±0.05 mm in Z. These values are quite consistent with the mechanical tolerances of the Ender 5 Plus platform [

22] and are lower than the thickness variation listed in

Table 4. The standard deviation of slide seating position within the lower holder was approximately equal to 0.07 mm, confirming that the system introduces low drift over time.

To assess the uniformity of surface microgrooves generated by the automated rubbing system, coated slides were analyzed using polarized optical microscopy. For each slide, intensity profiles were extracted along the rubbing direction. For each pixel, the transmitted intensity varies according to the well-known relation

, where

is the angle between the LC director and the polarizer axis [

23]. By acquiring two intensity fields

and

, the director angle can be estimated through the ratio of the two measurements.

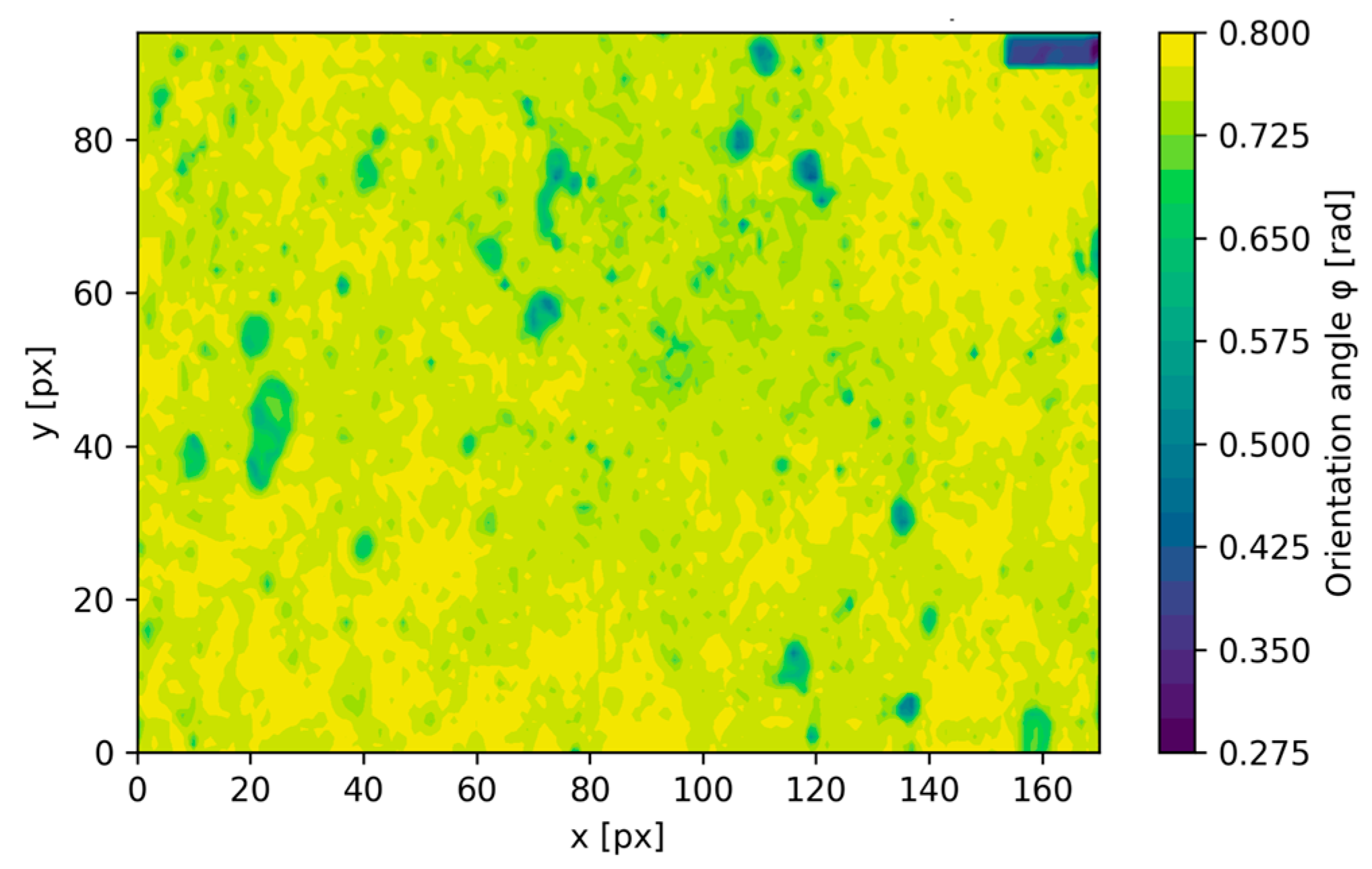

Figure 22 shows contour map of the local LC director orientation [

24] extracted from polarized optical microscopy images acquired at 0° and 45° between crossed polarizers. The color scale represents the orientation angle

, showing a nearly uniform director field with small, localized deviations.

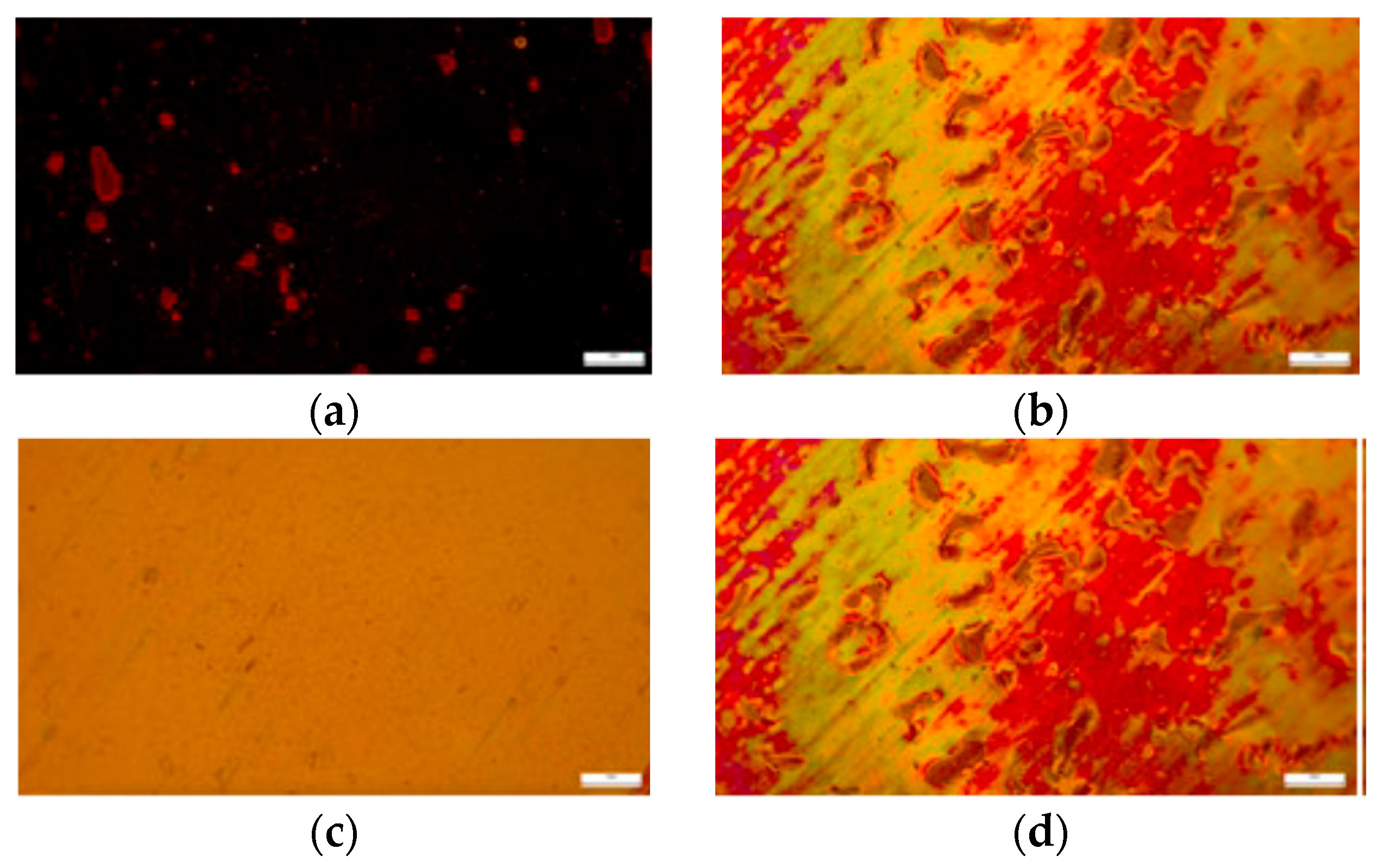

Automated rubbing produced patterns with a coefficient of variation consistently below 7%, indicating stable groove orientation and depth across the entire rubbed region. These results can also be visually evaluated as demonstrated in

Figure 23a,b, where films remain substantially dark at 0° and bright at 45°, demonstrating appropriate mesogen orientation throughout the sample. In comparison, manually rubbed slides typically exhibited intensity variation higher than 12%, mostly due to inconsistent pressure and stroke orientation (see

Figure 23c,d).

Even though the substrate variability remains a limiting factor, the automated system reduces operator-dependent sources of error, including rubbing pressure, alignment angle, slide overlap, and spacer placement. These are significant contributors to misalignment and film defects in manual fabrication.

It is important to remark that the dataset of ten fabricated films is intended as a functional validation of the automated workflow rather than a full statistical demonstration of scalability. In fact, the limited sample size does not permit high-confidence inferential statistics, but the collected measurements highlight that the dominant source of thickness variation originates from substrate irregularity rather than from robot-induced errors. This interpretation is supported by the strong correlation between local slide thickness and final film thickness as well as by the measured positional repeatability of the Cartesian system, whose variability remains below the magnitude of the substrate-driven deviations. To further strengthen the repeatability analysis, as already mentioned, 20 more assembly cycles were run to quantify robotic positioning variability. Measured values for position remained in the range ±0.08 mm in the plane XY and ±0.05 mm in Z. Rubbing uniformity analysis, again assessed by using polarized optical microscopy demonstrated a coefficient of variation below 7% thus confirming stable microgroove geometry. These metrics further confirm thickness non-uniformity, rather than robotic misalignment, as the dominant factor affecting final film thickness.

6. Conclusions

This study introduced an automated manufacturing framework for Liquid Crystal Elastomer films, aimed at overcoming the reproducibility, precision, and scalability limitations inherent to traditional manual fabrication.

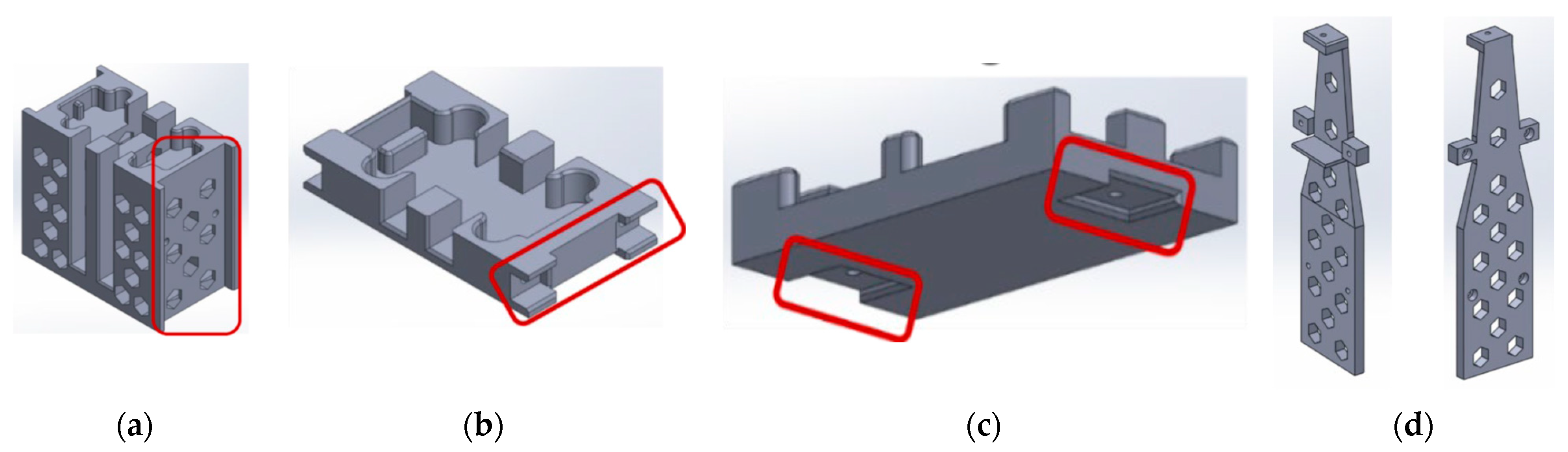

By analyzing each phase of the manual process, i.e., rubbing, slide handling, spacer positioning, infiltration cell assembly, and post-processing, a comprehensive redesign of the infiltration device components is provided. Moreover, this work described the integration of these redesigned elements into a customized Cartesian robotic platform derived from a modified Creality Ender 5 Plus system. The developed system incorporates dedicated mechanical subsystems, including fork-based end-effectors for base, top, spacer manipulation, mechanical gripper for glass slide engagement, a redesigned set of magnetic slide holders optimized for robotic interfacing, a modular alignment shelf for initial component arrangement, a dedicated rubbing station for consistent microgroove generation, and a servo-free flipping mechanism enabling automatic inversion of the upper slide.

These components allow executing all assembly operations with reduced operator involvement and high spatial repeatability. The modifications also limit several issues typically raised from manual fabrication, such as uneven spacer adhesion, misalignment during placement, and the presence of borosilicate microspheres embedded in the final film. Experimental validation confirms that the automated platform correctly automates the mechanical alignment steps crucial for LCE fabrication and supports thermally controlled infiltration and UV-initiated polymerization steps. When coupled with corrected thermal plate calibration, the system produces films exhibiting good-quality nematic alignment, as evidenced by polarized optical microscopy: films remain dark at 0° and bright at 45°, indicating proper mesogen orientation across the entire sample [

25]. Ten fabricated films were analyzed to assess manufacturing repeatability. Results show that while the alignment quality is consistent, the final film thickness deviates from the nominal spacer dimension. Subsequent metrological inspection revealed that these deviations are primarily attributable to thickness non-uniformity of the PVA-coated glass slides, which directly impacts the achievable precision of the LCE layer, despite the mechanical accuracy of the robot.

Overall, the automated system demonstrates improvements in reliability, geometrical repeatability, contamination avoidance, and quality of liquid-crystal alignment compared to manual fabrication. Beyond improving fabrication accuracy, the possibility to operate multiple low-cost units in parallel expands the practical availability of LCE films for research laboratories. This scalability is relevant for fields where iterative testing, device integration, or characterization of LCEs is required, enabling experimental workflows that are currently impractical with manual fabrication.

Although automation improves geometric repeatability, results in

Table 3 and

Table 4 demonstrate that substrate thickness variations persist as the principal source of error. This issue can be mitigated by pre-screening slides through automated micrometer or interferometric mapping and by implementing an adaptive Z-compensation mechanism in the spacer region. Future versions of the framework will incorporate these solutions to reduce film thickness variability.

In detail, the analysis of the film thickness data (

Table 3) in combination with the slide-thickness maps (

Table 4 and

Figure 21) demonstrates that the principal limitation to thickness uniformity is the intrinsic geometric variability of commercially available glass slides, which often exhibit local deviations of 10–15 µm. These values are comparable to or larger than the nominal film thickness itself. Since the automated assembly produces highly repeatable positioning (as already stated, varying in the range ±0.08 mm in XY, ±0.05 mm in Z), the dominant error clearly arises from substrate irregularity rather than from the robotics workflow. To improve the precision of the final LCE films, several substrate-oriented interventions can be implemented. By way of example, a preliminary characterization and sorting step can be integrated into the workflow, wherein the robot (or a low-cost profilometer) measures thickness at multiple points- Slides exceeding a predefined tolerance threshold are automatically rejected or assigned to applications requiring lower precision.

For more advanced automation, the system could incorporate adaptive Z-axis compensation, in which the robot adjusts the spacer offset or introduces micro-shimming based on a thickness map computed during slide loading.

Future works will also be devoted to the mitigation of external causes of thickness variability, in further improving thermal compensation during polymerization, and extending automation to post-curing, cutting, and mechanical-electrical characterization of the films. These enhancements could be useful to advance the system toward a fully autonomous, high-throughput manufacturing platform capable of supporting emerging applications such as artificial muscles, adaptive optics, and soft actuator arrays.

Eventually, the integration of systematic mechanical testing to assess the tensile response and stress director coupling of the films produced by the automated framework will also be planned for the future. In fact, the present study focuses on automating the assembly steps that most strongly influence geometric uniformity and molecular alignment; therefore, a rigorous evaluation of mechanical performance requires additional process refinements, including standardized specimen preparation, controlled cutting along the director, and fully calibrated thermal curing protocols. As these elements are currently being optimized and incorporated into the workflow, tensile characterization will be conducted in a subsequent phase to verify the consistency of modulus, ultimate stress, strain at break, and viscoelastic behavior across different batches.