Abstract

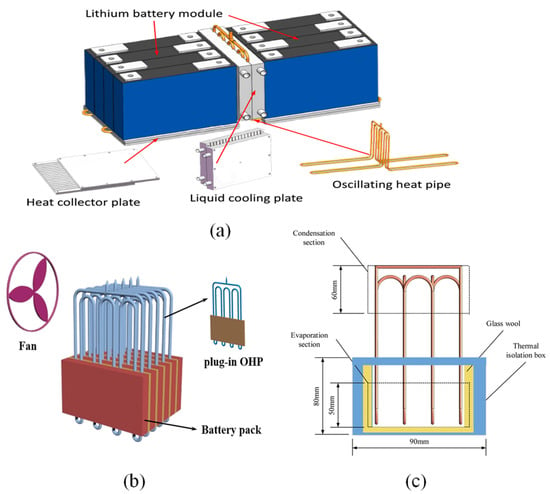

Since their invention by Akachi in 1990s, pulsating heat pipes (PHPs) have attracted widespread interest and application in practice, e.g., grinding, chip cooling, the thermal management of batteries, etc., owing to their notable efficiency in heat transfer and their simplicity and flexibility in structure. Key factors influencing the heat transfer efficacy of pulsating heat pipes are mainly attributed to the thermophysical properties of the working fluid, the structural parameters, and the operating conditions. Research on pulsating heat pipes is conducted through theoretical investigations, numerical simulations, and visual experiments. In this paper, the research on PHPs in recent decades is reviewed with the consideration of the heat transfer performance mechanism and application of pulsating heat pipes, especially research under operation conditions such as with “status with motion” and with “inconsistent heat flux”.

1. Introduction

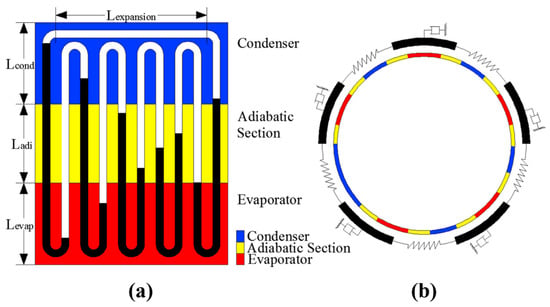

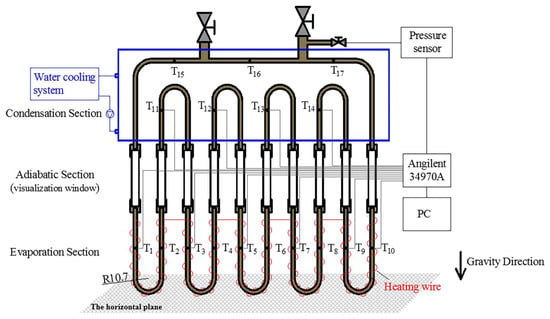

Pulsating heat pipes (PHPs), also referred to as oscillating heat pipes (OHPs) in certain references, represent an innovative heat transfer technology introduced by Akachi from Japan in the 1990s. A pulsating heat pipe consists of three main sections: an evaporator/heating section, a condenser/cooling section, and an adiabatic section [1,2,3,4], as shown in Figure 1. These pipes show a pulsating or oscillating movement of the working fluid within their channels, marking a significant advancement over traditional heat pipes and offering enhanced heat transfer capabilities in specific applications. Additionally, PHPs offer advantages such as high flexibility, rapid thermal response, and excellent heat transfer performance. Therefore, compared to traditional heat pipes, PHPs have a simpler and more compact structure, and are particularly suitable for applications where space is limited or there are cooling load challenges. Pulsating heat pipes find applications in various fields, including rotating machinery cooling [5], battery thermal management systems [6], the cooling of electronics [7], and aerospace [8]. It is noteworthy that pulsating heat pipes exhibit considerable heat transfer efficiency even under microgravity and hypergravity conditions [9].

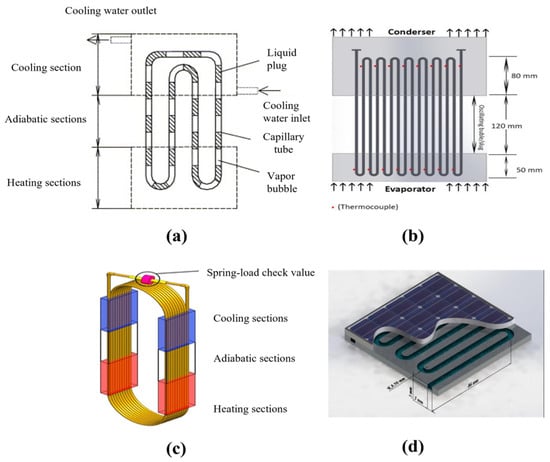

Figure 1.

Types of PHPs. (a) Closed-loop pulsating heat pipes (CLPHPs) [1]; (b) open pulsating heat pipes (OPHPs) [2]; (c) pulsating heat pipe with check valve [3]; (d) flat-plate closed pulsating heat pipes (FPCPHPs) [4].

Pulsating heat pipes consist of one or multiple closed- or open-loop channels, partially filled with a working fluid, i.e., a low-boiling-point liquid such as water or ethanol. That is to say, the working fluid in pulsating heat pipes exhibits a random distribution of liquid and vapor phases and no distinguished channels for liquid or vapor, in contrast to loop heat pipes (LHPs) [10], separate heat pipes (SHPs) [11], and gravity heat pipes (GHPs) [12,13], as shown in Figure 2. The working fluid experiences a phase change from liquid to vapor and back again as it absorbs and releases heat, respectively. The operation of the pulsating heat pipes entails the cyclical movement of the working fluid.

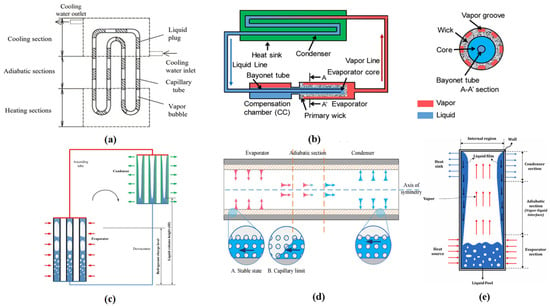

Figure 2.

Structure of different types of heat pipes. (a) Closed-loop pulsating heat pipes (CLPHPs) [1]; (b) loop heat pipes (LHPs) [10]; (c) separate heat pipes (SHPs) [11]; (d,e) gravity heat pipes (GHPs) [12,13].

During operation, heat input at the evaporator sections causes the working fluid to vaporize and form vapor plugs or bubbles. Subsequently, the vapor plugs or bubbles travel along the channel due to pressure difference, reach the condenser section to release heat and condense, and return to the evaporator in the liquid phase through capillary action, gravity, or differential pressure. Because the gas–liquid flow direction in PHPs is random, pulsating motion forms within the channels, continuously scouring the inner walls of the channels, thus achieving continuous and efficient heat transfer. This pulsating motion helps overcome the limitations of traditional heat pipes, including gravitational constraints and large heat dissipation restrictions. Furthermore, the pulsating motion promotes the mixing and agitation of the working fluid, thereby enhancing the heat transfer rate and facilitating the efficient cooling of heat sources.

At present, the review of PHPs is mainly from the aspects of fluid selection, structure influence, operation conditions, mechanism study, and the visualization of pulsating heat pipes in a status without motion [14,15,16]. Han et al. [14] reviewed the research development of PHPs between 1999 and 2014, including geometric parameters, working fluids, operating parameters, operating mechanisms, and new application domains. Bastakoti et al. [15] reviewed the research of PHPs from the perspective of the design of their structure, operating parameters, working mechanisms, and theoretical and numerical modeling. And this review paper mainly focused on the results of experimental and numerical works carried out between 2009 and 2015. Xu et al. [16] summarized the research results of PHPs from the perspective of working fluids, operation mechanisms, and applications between 2001 and 2021. This review highlights the latest research progress in the field of nanofluids and recent advances in the application of nanofluids in PHPs. However, with the advancement of technology, the research on PHP varies from status without motion to status with motion, such as applications in grinding and microgravity conditions, and from continuous heating mode to inconsistent heating mode, such as periodic pulsating heat flux and auxiliary heat flux for BTM (battery thermal management). Therefore, there is a need for an up-to-date summary of conclusions made in recent years.

In this paper, a comprehensive review on the research progress of PHPs in recent decades is conducted, covering the scope of heat transfer performance and mechanisms, based on experimental, theoretical, and numerical analysis. In Section 2, the heat transfer performance of PHPs is summarized with the influence of the working fluid, structure parameters, and operation conditions, especially in status with motion and operation with inconsistent heat flux. Section 3 includes the mechanism of PHPs, with the consideration of theoretical models, numerical simulation, and optical visualization, especially the categories of theoretical models. In the last section, the application of PHPs is introduced.

2. Heat Transfer Performance of PHPs

The heat transfer performance of PHPs refers to the thermal resistance, heat transfer efficiency, starting speed, resistance to drying, etc. It is mainly influenced by the working fluid, structure parameters, and operating conditions.

2.1. Working Fluid

The working fluid is an important choice affecting the heat transfer performance of pulsating heat pipes, and different fluids are suitable for different operating conditions due to the variation in thermophysical parameters. Therefore, it is necessary to study the characteristics of different working fluids to help select suitable working fluids according to different operating conditions. In this section, working fluid is divided into single working fluids, composite working fluids, and mixed working fluids.

2.1.1. Single Working Fluids

The single working fluids commonly used in pulsating heat pipes are water [17,18,19,20,21,22], methanol [17,20,23,24], ethanol [25,26,27,28,29,30,31,32,33], and so on. Table 1 presents the single working fluids in PHPs as well as the effects of the properties of working fluids in cited references. Han et al. [24] investigated the heat transfer performance of closed-loop pulsating heat pipes with four different working fluids (deionized water, ethanol, methanol, and acetone) under different filling ratios and input heat flux. The results showed that PHPs filled with acetone are the easiest to start, while methanol is the most difficult. This is because acetone has the lowest dynamic viscosity, which results in smaller shear forces and correspondingly smaller flow resistances. In this study, dynamic viscosity is considered superior to all other thermal properties, becoming the dominant property for closed-loop PHP oscillation to start up. Hao et al. [34] investigated the heat transfer performance of polytetrafluoroethylene pulsating heat pipes (PHPs) with water, ethanol, and acetone as working fluids. The PHPs were tested in a vertically oriented heating setup. The study indicated that PHPs filled with acetone exhibit the best thermal performance compared to the other two working fluids. This is because acetone has the highest vapor pressure and lowest viscosity, resulting in a high driven force and low shear stress. And pulsating heat pipes with acetone are easier to start up. In addition, acetone has a higher resistance to drying at a low liquid filling ratio because of its lower contact angle on the surface. Bastakoti et al. [35] studied the heat transfer performance of pulsating heat pipes with different filling ratios of methanol, ethanol, and cetyltrimethyl ammonium chloride, C19H42ClN (CTAC), and compared them with that of deionized (DI) water. The results showed that methanol and ethanol have faster start-up speeds due to lower viscosity at 50% filling ratios, but CTAC has lower thermal resistance because of its lower surface tension.

Table 1.

Single working fluids in references.

In recent years, in order to explore the applications of PHPs in the low-temperature domain, an increasing number of scholars have turned their attention to studying the heat transfer performance of low-temperature working fluids, such as hydrogen [36,37,38,39], helium [40,41,42,43,44,45,46], and nitrogen [47,48,49,50,51,52,53]. To understand the heat transfer performance of hydrogen PHPs under different heating modes, Li et al. [39] investigated the heat transfer performance of PHPs under two heating modes (stepwise heating and sudden heating). The results indicated that the sudden heating mode leads to a more stable start-up of hydrogen PHPs due to its instantaneous high thermal load, especially under conditions of lower filling ratio when there is a more uneven distribution of liquid and vapor. This feature is advantageous for the future application of PHPs in heat dissipation for superconducting magnets. Bruce et al. [53] studied the thermal performance of a meter-scale horizontal nitrogen pulsating heat pipe. The study indicated that the maximum equivalent thermal conductivity measured is 85 kW/m·K. It can transfer a maximum heat power of 25 W before reaching its operation limit. Yi et al. [54] investigated the effects of heating power and filling ratios on the oscillation conditions and effective thermal conductivity (ETC) of helium PHPs. The results showed that with the increase in heating power, the ETC of helium-based PHPs first increases and then decreases, and has a maximum value. Moreover, with the increase in the initial liquid filling ratio, the dry-out power increases first and then decreases.

In general, working fluids with low boiling points, low dynamic viscosity, and low surface tension (such as acetone, methanol, and certain refrigerants) have lower start-up power requirements. However, they may experience drying out at high heat inputs. On the other hand, working fluids with high liquid specific heat, high latent heat of vaporization, and high surface tension (such as water) need higher heat power to start up but possess a greater anti-dry-out ability and can make PHPs operate stably under high heat flux. Additionally, choosing mixed working fluids and nanofluids can provide PHPs with low start-up power and a strong anti-dry-out ability. Therefore, it is necessary to select an appropriate working fluid based on the operating conditions.

2.1.2. Composite Working Fluids

Besides single working fluids, it is a common method to add materials to fluids to create composite working fluids for the modification of thermophysical properties and the performance improvement of PHPs [55,56,57,58,59,60]. The most common methods include the addition of nanofluids with high thermal conductivity and the addition of surfactants with low surface tension, as shown in Table 2. Nanoparticles enhance heat transfer due to the enhanced thermophysical properties, especially thermal conductivity, increased nucleation sites because of nanoparticle deposition, and the change in flow regimes in PHPs [16]. In some studies, the enhanced heat transfer capability of nanofluids is also attributed to the Brownian motion of nanoparticles and the mitigation of the thermal boundary layer [61]. Earlier studies found that by dispersing a limited quantity of copper nanoparticles or carbon nanotubes in ethylene glycol or oil, their thermal conductivity could be enhanced by 40% and 150%, respectively [62,63]. This indicated that nanofluids can be used in PHPs to enhance heat transfer capability. Das et al. [64] found that the thermal conductivity of water-based nanofluids is improved by 2–4 times when adding Al2O3 or Cuo to the water. Gonzalez et al. [65] conducted a comparison of the heat transfer performance of water and silver nanofluids in a closed-loop PHP. The results showed that there is decreased thermal resistance in silver nanofluid compared to water. Park et al. [66] dispersed CuNi nanoparticles in high-performance liquid chromatography(HPLC)-grade water, and the resulting fluid was then used to investigate the effect of the nanofluid on heat transfer capability in a well-balanced PHP. The study showed that there is an enhancement of the heat transfer performance of PHP by using CuNi nanofluid. Karthikeyan et al. [67] compared the heat transfer performance of closed-loop pulsating heat pipes with different working fluids (DI water, copper, and silver colloidal nanofluids). The results showed that both nanofluids have lower thermal resistance than DI water. It was also observed that the PHP charged with hybrid nanofluids in the present study obtained lower thermal resistance than the PHP charged with mono-nanofluids. It has also been found that adding magnetic nanofluids to pulsating heat pipes can improve their heat transfer performance to a certain extent when magnetic fields are applied [68,69].

Hybrid nanofluids (HNFs) are also a novel approach to improving the thermal conductivity of pulsating heat pipes. Tanshen et al. [70] observed that the enhancement of heat transfer performance occurs when Al2O3 is combined with multi-walled carbon nanotubes (MWCNTs) as a working fluid. Zufar et al. [71] investigated the heat thermal performance of PHPs with an Al2O3-CuO hybrid nanofluid, a SiO2-CuO hybrid nanofluid, and water. The results showed that the start-up time and thermal resistance of both hybrid nanofluids are lower than water. However, the thermal performance of the Al2O3-CuO hybrid nanofluid exhibited worse performance than the SiO2-CuO hybrid nanofluid due to its high viscosity even the SiO2-CuO hybrid possesses and greater thermal conductivity. It was noticed that there is a slight effect on the start-up time for hybrid nanofluids with the increase in the filling ratio. This is attributed to their high thermal conductivity, which enables them to absorb large amounts of heat in a shorter time. Moreover, the experimental results were compared with other studies which investigate PHP filled with mono-nanofluids, and it showed that hybrid nanofluids have better performance compared to mono-nanofluids. Hashemi et al. [72] compared the thermal performance of three nanofluids (ZrO2 nanofluids, BiFeO3/ZrO2 hybrid nanofluid, and ZrO2/SiO2 hybrid nanofluid) at their respective optimal concentrations in a PHP. The study indicated that both hybrid nanofluids showed lower thermal resistance and larger thermal conductivity and that the ZrO2/SiO2 nanofluid fluid is best. This could be attributed to the better thermal conductivity and higher mixing of ZrO2/SiO2. Smrity et al. [73] study experimentally evaluated the thermal performance of PHPs charged with different working fluids, namely an Al2O3-Cu hybrid nanofluid, an Al2O3 mono-nonfluid, a Cu mono-nanofluid, and water. It was observed that the Al2O3-Cu hybrid nanofluid possessed higher thermal conductivity because of the synergistic thermal effect of the HNF over the mono-nanofluids. In addition, it was found that the Al2O3-Cu hybrid nanofluid exhibited lower thermal resistance, which is attributed to the increase in nucleation sites and enhancement of the generation and displacement of vapor slugs in the base fluid.

In recent years, in addition to nanofluids, surfactants have been employed to enhance the start-up performance of pulsating heat pipes [35,74,75,76,77,78,79,80,81]. The addition of surfactants reduces the surface tension of the fluid, thus facilitating the start-up of the pulsating heat pipe. Bao et al. [75] used sodium stearate as a surfactant to make surfactant solutions. Then, they indicated that the surfactant solutions could start at a lower heat flux. In addition, they showed relatively stable temperature oscillation characteristics and possessed larger dry-out heat fluxes compared to water. Ayel et al. [76] found that surfactants with water cannot improve the thermal performances of flat-plate pulsating heat pipes tested in a horizontal orientation. Nevertheless, excessive addition of surfactants and nanoparticles can increase the fluid’s dynamic viscosity and the probability of particle clustering, thereby increasing flow resistance and the total pressure drop, which leads to a decrease in the heat transfer performance of PHPs. Therefore, it is essential to add an appropriate amount of surfactants and nanoparticles to enhance the heat transfer performance of PHPs.

Table 2.

Composite working fluids in references.

Table 2.

Composite working fluids in references.

| Composite Working Fluids | Effects | Refs. |

|---|---|---|

| Mono-nanofluids | High thermal conductivity; nucleation enhancement | [55,56,57,58,59,60] |

| Hybrid nanofluids | Rheological characteristic enhancement | [70,71,72,73] |

| Surfactant fluids | Surface tension reduction | [35,75,76,77,78,79,80,81] |

2.1.3. Mixed Working Fluids

Some studies have shown that the heat transfer performance of PHPs may be better after mixing working fluids [20,82,83,84,85]. Mixing working fluids alters the thermal properties of the fluid, and the concentration difference between the two fluids drives molecular motion, thereby enhancing the heat transfer performance of PHPs. Han et al. [82] studied the heat transfer performance of pulsating heat pipes filled with water-methanol, water–ethanol, and water–acetone zeotropic mixtures at various volume mixing ratios. The experimental results showed that the anti-dry-out ability of most mixed working fluids is better than that of pure working fluids at low or medium filling rates. This could be attributed to the PCIE (phase-change-inhibition effect) of zeotropic mixtures; i.e., vapor slugs with a lower boiling point and higher saturation pressure suppress the evaporation of water. But the opposite is true for large filling ratios and large input heat; i.e., the heat transfer performance of pure working fluids is better than that of mixed working fluids. Xu et al. [86] compared the heat transfer performance of PHPs in which DI water, ethanol, and ethanol–water mixtures (20, 30, 40, 50, and 75 vol%) were working fluids, and the tests indicated that 30 vol% ethanol–water has the best heat transfer performance. The synergistic effects between ethanol (lower boiling point and lower latent heat of vaporization) and water (higher thermal conductivity and specific heat) increase the velocity of liquid slugs and improve the thermal performance of PHPs. Zamani et al. [87] explored the heat transfer performance of closed-loop pulsating heat pipes which water, ethanol, toluene, acetone, hexane, and their binary mixtures with water as working fluids. The volume mixing ratios for the binary mixtures were 3:1, 1:1, and 1:3 in this study. The results revealed that the heat transfer performance of soluble mixtures (ethanol and acetone) is better than that of insoluble mixtures (toluene and hexane), and the heat transfer performance of the mixture of ethanol–water with a mixing ratio of 1:3 is the best. The enhancement of the heat transfer performance of the PHPs was attributed to the synergistic thermophysical properties of ethanol and water, as well as the transport characteristics induced by temperature and concentration gradients [88].

But some studies indicate that not all mixed working fluids can effectively improve the heat transfer performance of PHPs. Mameli et al. [89] found that pulsating heat pipes filled with pure ethanol (65% v/v) and an azeotropic mixture of ethanol and water (65% v/v) showed no significant difference in heat transfer performance. Cui et al. [90] indicated that adding ethanol and acetone to methanol cannot effectively improve the thermal performance of CLPHPs. Markal et al. [91] observed that increasing the volume fraction of methanol in the pentane–methanol mixture adversely affected the thermal properties of PHPs.

Table 3 shows the characteristics of fluids mixed with different working fluids. The addition of mixed media will increase the fluid’s dynamic viscosity, which raises flow resistance, leading to a decrease in the heat transfer performance of pulsating heat pipes. As a matter of fact, the mechanism behind the enhancement of PHPs by mixed working fluids is not clear. This may be attributed to the PCIE [82], the synergistic thermophysical properties, and the transport characteristics induced by temperature and concentration gradients [88]. Therefore, there is a need to select the appropriate working fluid based on varying operating conditions.

Table 3.

Mixed working fluids in references.

2.2. Structure Parameters

One of the key factors influencing the heat transfer performance of pulsating heat pipes is their structural parameters. These parameters mainly consist of the channel size, cross-sectional configuration, number of turns, the length of each section of the PHPs, and surface characteristics.

2.2.1. Channel Size

In the design of PHPs, the channel size is a crucial parameter for the operation of PHPs. The working fluids in PHPs experience the interaction between gravity, capillary forces, and surface tension, leading to a random distribution of vapor–liquid plugs inside the channels. The channel size, e.g., the diameter of a capillary tube, d, is determined by the bond number, which is the ratio of the buoyancy force to the surface tension force, as depicted in Equation (1).

where σ is surface tension, g represents gravitational acceleration, and ρl and ρv represent the density of the liquid and vapor phases of working fluids, respectively.

The bond number should not exceed two for the successful operation of the PHPs [92]. Otherwise, buoyancy force will dominate surface tension force and liquid will not be able to distribute itself in the capillary tube by the capillary action. Hence, the maximum diameter of the tube (dmax) is calculated as follows:

It can be seen from Equation (2) that the critical diameter is related to the thermal physical properties of the working fluids, i.e., surface tension (σ) and density (ρ). Babu et al. [56] conducted experiments on PHPs with different inner diameters using acetone as the working fluid. They observed that the ideal filling ratio for PHPs is 60%. Additionally, they found that the optimum inner tube circumference is 2 mm, which is closely related to the critical diameter of the PHPs. Under these conditions, PHPs have lower thermal resistance and higher thermal performance.

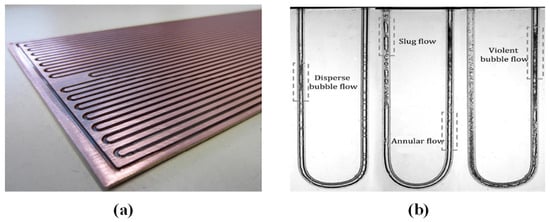

Qu et al. [93] visualized micro-pulsating heat pipes (MPHPs) with varying hydraulic diameters (251 μm, 352 μm, 394 μm) and revealed distinct flow patterns for each size. During the visualization process, they found an intriguing “injection flow” phenomenon in the condenser of 394 μm MPHPs, a previously unreported occurrence, as shown in Figure 3.

Figure 3.

Development of injection flow (β = 70°, φ = 58%, Q = 8.7 W) [93].

Yang et al. [94] conducted simulations to understand the temperature fluctuations in the evaporator and condenser sections of closed-loop pulsating heat pipes with diameters ranging from 1 to 5 mm and water as the working fluid. Their findings revealed that the PHPs with a diameter of 3 mm exhibited a higher heat-carrying capacity and superior heat transfer performance. Wu et al. [95] studied the heat transfer performance of pulsating heat pipes with different inner diameters (1 mm, 1.5 mm, 2 mm) and filling ratios (40–70%). The experimental results showed that when the filling ratio is about 50% and the heating power is 70 W, the thermal resistance of the PHPs with 1.5 mm inner diameter is the lowest, which is 0.1184 °C/W. Lee et al. [96] reported that the operating limit where the thermal performance significantly deteriorates increases with the increase of hydraulic diameter in both cross-sectional shapes (circular or square).

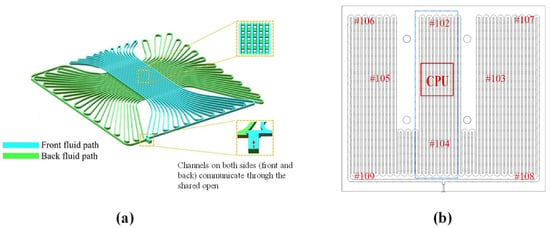

PHPs benefit from an easier start-up in a horizontal orientation due to the pressure imbalance caused by the non-uniform cross-section of the channels. Factors such as surface tension, working fluid properties, vaporization space, and nucleation space contribute to this imbalance between the channels. Yang et al. [97] tested two silicon-based micro-pulsating heat pipes with HFE-7100 as the working fluid, containing uniform channels (0.8 m) and non-uniform channels (0.6 mm or 1.0 mm), respectively, and tested them in both horizontal and vertical orientations with different heating powers. They found that in the horizontal direction, regardless of the channel type, they could not start, mainly due to the lack of gravity assistance in microchannel PHPs at 1–7 W. However, in the vertical direction, with the increase in heating power, they could start, and the junction temperature change of the non-uniform channels was more unstable. Chien et al. [98] compared the heat transfer performance of PHPs with uniform and non-uniform diameters. They found that the PHPs with uniform channels could not start in the horizontal direction; it was only when the filling ratio was at 50% and the heating power was 50 W that the pulsating heat pipes with non-uniform channels could start.

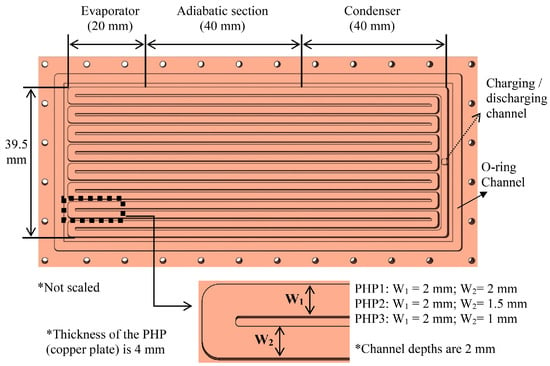

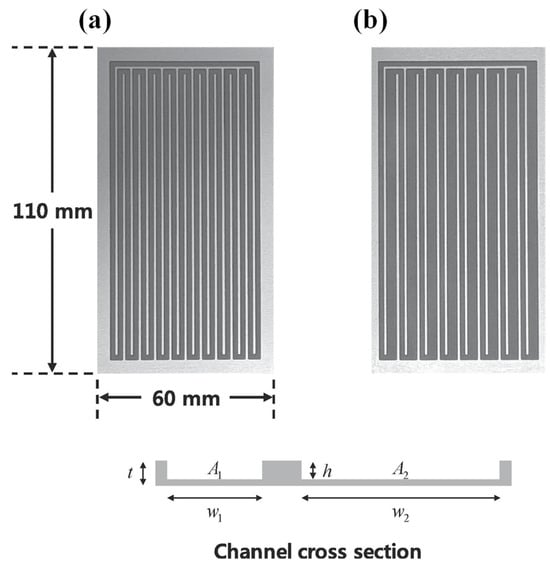

Markal et al. [30] designed plate pulsating heat pipes with channel widths of 2–2 mm, 2–1.5 mm, and 2–1 mm, all having a height of 2 mm, as shown in Figure 4. They observed that in the horizontal orientation, the thermal resistance of the uniform heat pipes remained almost unchanged, whereas the thermal resistance of the two non-uniform heat pipes decreased, indicating better heat transfer performance. This suggests that the non-uniform design can mitigate the influence of gravity. Additionally, reducing the channel diameter increases the evaporative momentum force, which is a crucial factor in enhancing the performance of non-uniform PHPs. In a separate study [31], a PHP with a gradually tapered structure was developed, which promotes fluid circulation and remains less sensitive to variations in inclination angle. This feature is particularly advantageous for ensuring the stable operation of PHPs across different angles of inclination.

Figure 4.

Details of heat pipe geometry [30].

Differences in the cross-section shape also affect the heat transfer performance. Ishida et al. [99] compared the effects of round tubes and square channels on PHPs. They found that the thermal performance of the square channel was worse than that of the circular channel. They attributed this to the presence of dry areas on the flat surface in the square channel, which deteriorated heat transfer. Lee et al. [96] investigated the operating limit of MPHPs for various channel geometries, including cross-sectional shapes and hydraulic diameters. Either circular or square channels with hydraulic diameters of 390 μm, 480 μm, and 570 μm were engraved on a silicon wafer to form a closed loop with five turns. They found that at the same hydraulic diameter, the maximum allowable heat flux of the square pipes was 70% higher than that of the round pipes. Moreover, the liquid film thickness of the square tube was obviously higher than that of the round tube. Another study [100] was conducted involving an experimental investigation of the impact of transverse grooves in channels on the heat transfer efficiency of flat pulsating heat pipes (FPHPs). Their findings revealed that these grooves significantly enhance the heat transfer capabilities of PHPs. Specifically, the thermal resistance was reduced by a substantial 34.6%, and the average thickness of the liquid film decreased by 69.2%, which in turn accelerated the film evaporation heat transfer rate. Different shapes of cross-sections with different capillary effects will result in varying liquid film thicknesses, which will have a certain impact on the flow phenomena and even heat transfer.

2.2.2. Length of Each Section

The relative length of each section in PHPs affects the heat transfer performance. It is certain that PHPs perform better when the amount of heat flux supplied in the evaporator is fully dissipated in the condenser region [95]. Reducing the condenser’s length diminishes the effective area for heat exchange. Therefore, we always want the condenser length to be greater than the evaporator length.

Wang et al. [101] used Computational Fluid Dynamics (CFD)to study the influence of the length ratio of the evaporator to the condenser on the start-up and thermal performance of PHPs. The results showed that increasing the length ratio of the evaporator to the condenser led to accelerated start-up speed of CLPHPs and reduced thermal resistance. However, dry-out easily occurs in CLPHPs at lower filling ratios and higher input powers. Su et al. [102] investigated the effects of heat transfer distance on temperature fluctuations. They monitored temperature variations at three distinct distances (375 mm, 575 mm, and 775 mm) while keeping the inclination angle and filling ratio constant. Their study revealed that as the heat transfer distance increases, thermal resistance also increases. Moreover, shorter distances exhibited higher frequency temperature oscillations with smaller amplitudes, indicating a more efficient heat transfer process. Kim et al. [103] experimentally investigated the effect of the condenser length on the thermal performance of MPHPs at various condenser temperatures. They observed the impact of varying the condenser temperature between 0 °C and 80 °C on a ten-turn MPHP. The study revealed that the ideal length of the condenser in micro-pulsating heat pipes fluctuates with different condenser temperatures. When the condenser temperature was low, the evaporator temperature decreased as the decrease in condenser length. Conversely, when the condenser temperature was high, the evaporator temperature increased as the decrease in condenser length.

2.2.3. Number of Turns

The number of turns is an important geometric parameter of pulsating heat pipes. It is believed that PHPs are more feasible to start up with lower heat input. Sun et al. [38] studied the effect of the number of turns on PHPs by testing two hydrogen closed-loop PHPs with two turns and five turns under different liquid filling ratios and heat flows. They indicated that the effective thermal conductivity of the two-turn PHPs is higher than the five-turn PHPs at each filling ratio. But the thermal resistance of the two-turn PHPs is larger than that of the five-turn PHPs due to the smaller heat transfer area. If the two-turn PHPs are scaled up by 2.5 times to a total of five turns, they will outperform original five-turn PHPs in terms of thermal resistance and effective conductivity. Lyu et al. [40] conducted a similar experiment, comparing serial–parallel 24-turn helium PHPs with 4-turn helium PHPs and serial 24-turn helium PHPs. The results showed that the 24-turn series–parallel helium PHP exhibits the smallest temperature gradient and the smallest thermal resistance. Secondly, the main advantage of the serial–parallel 24-turn helium PHPs is able to transfer very high heat loads under cryogenic operating conditions. Li et al. [45] compared the effect of 8 turns and 48 turns on the heat transfer performance of helium-pulsating heat pipes. They found that increasing the number of turns from 8 to 48 enhances the heat transfer capacity of the PHPs, but the maximum effective thermal conductivity decreases. However, they defined the 48-turn configuration (as shown in Figure 5) and found that the heat transfer capacity and effective thermal conductivity are better in a vertical parallel configuration than in a series configuration.

Figure 5.

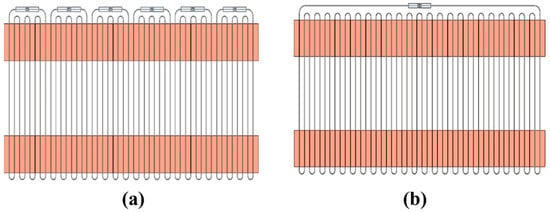

Configurations for PHPs: (a) parallel configuration; (b) series configuration [45].

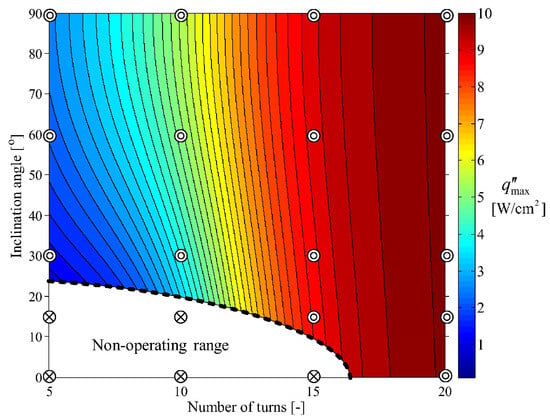

Lee et al. [104] fabricated 5-to-20-turn MPHPs (as shown in Figure 6) with FC-72 as the working fluid and a filling ratio of 50%. They found that the direction dependence of the maximum allowable heat flux weakens as the number of turns increases. The 20-turn MPHP had almost the same maximum allowable heat flux regardless of the inclination angle. Panyoyai et al. [105] studied the effect of the number of bending turns on the performance limit of inclined closed-loop oscillating heat pipes. They found that 5 to 15 turns did not affect the maximum heat flux. Charoensawan et al. [106,107] found that the optimal heat transfer performance of the PHP occurs with 26 turns. They pointed out that pulsating heat pipes are also influenced by factors such as the working fluid, tube diameter, and evaporator temperature. It is noteworthy to mention that the critical number of turns varies in different studies, and there is no common conclusion on the determination of the critical number of turns.

Figure 6.

Contour map of maximum allowable heat flux [104].

2.2.4. Surface Modification

The design of the internal surface of pulsating heat pipes involves a comprehensive consideration of many factors, including hydrophilic, hydrophobic, and surface roughness factors. Aluminum is a low-cost material with high thermal conductivity, widely used in heat dissipation devices. However, when water is used as the working fluid in aluminum heat pipes, it can produce hydrogen, which seriously affects the heat transfer performance of pulsating heat pipes. Xie et al. [108] plated a layer of chromium on the inner surface of aluminum PHPs. The results showed that there is a decrease in the thermal resistance of the aluminum–water PHPs as the heat power and operating temperature increase. However, chromium is too expensive, so it is not suitable for large-scale applications. Kim et al. [109] modified the surface wettability of aluminum pulsating heat pipes using the micro–nano corrosion method to improve the thermal properties and durability of water–aluminum PHPs. Wang et al. [110] obtained the heat transfer performance of three-dimensional closed-loop pulsating heat pipes with different wettability through numerical simulation. They found that the thermal resistance of the hydrophobic surface was lower than that of the hydrophilic surface at low heat load, while the reverse was true at high heat input. Furthermore, due to lower flow resistance and the effect of liquid film, CLPHPs with hydrophilic surfaces can effectively raise the anti-dry-out ability. Hao et al. [111] compared the effects of super hydrophilic and hydrophilic surfaces on the flow behavior and heat transfer performance of PHPs. The results revealed that the hydrophilic surface enhances the interaction between the fluid and the inner wall of the pipes during evaporation, improving the flow efficiency of the liquid inside the heat pipes and facilitating the start-up of pulsating heat pipes. Additionally, the hydrophilic surface increases the maximum displacement and velocity of the liquid slug. Leu et al. [112] compared the effects of different surface properties (unmodified surface, super hydrophilic surface, superhydrophobic surface, mixed hydrophilic and hydrophobic surface) on the internal flow behavior of PHPs. Significant changes in flow behavior were observed in the pulsating heat pipes with a mixed hydrophilic and hydrophobic surface. Specifically, continuous vapor slug flow was formed in the evaporator section, while laminar flow was observed in the unmodified surface PHPs. This maintains a higher vapor pressure in the evaporator section, and the stable flow direction can improve the start-up characteristics of the heat pipes, making them more reliable and efficient during start-up.

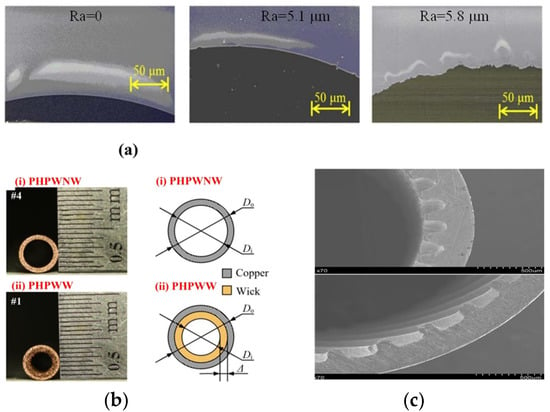

Ishida et al. [99] compared the influence of 1 mm circular tube internal roughness on pulsating heat pipes, as shown in Figure 7a. They found that the effective thermal conductivity values of rough circular tubes are larger than those of smooth circular tubes. They considered that roughness enhances wettability and expands liquid film widely on the inner surface. As a result, thermal performance was enhanced. Wu et al. [113] compared the effects of a sintered core versus an unsintered core on PHPs, as shown in Figure 7b. They found that the addition of a sintered powder core improved nucleation boiling in the evaporator, thereby enhancing the thermal driving force, and provided additional capillary action to facilitate liquid backflow into the evaporator. Qu et al. [114] proposed a micro-slot structure for PHPs, as shown in Figure 7c. This modification led to a reduction in the required starting power for the pulsating heat pipes when oriented vertically.

Figure 7.

(a) Roughness of the surface inside a circular tube (Ra is arithmetic mean roughnes) [99]; (b) physical drawing (left) and size drawing (right) of sintered core; Do, Di, and ∆ are outer diameter, inner diameter, and sintering thickness, respectively [113]; (c) microchannel structure [114].

Structure optimization can involve the inner diameter, cross-sectional structure, length of each section, number of turns, and surface characteristics. When the inner diameter is small, drying out is prone to occur, while with a larger inner diameter, the thermal siphoning effect may occur. Generally, 1–3 mm is chosen. Adding micro-groove structures to the channels can easily generate nucleation sites, enhancing heat transfer performance. Furthermore, PHPs with non-uniform channel designs are easier to start. Appropriately increasing the proportion of the length of the condensation section in PHPs can help improve the heat transfer capability of PHPs. The number of turns does not have a range at present, but there is a critical number of turns in different operating conditions. A superhydrophilic surface design for the evaporation section and a superhydrophobic surface design for the condensation section can reduce the occurrence of drying out.

In the study of structural parameters, researchers have significantly improved the start-up speed and heat transfer efficiency of PHPs by optimizing the inner diameter, inner surface, and number of turns. However, designing and optimizing the inner diameter and surface of PHPs in extreme environments, as well as maintaining low flow resistance and high heat transfer efficiency with a reduced inner diameter, remain challenging issues. Additionally, the long-term durability of different surface modification methods needs further investigation. These are topics worth exploring in future research.

2.3. Operation Conditions

The operation conditions of PHPs may be different and they have great influence on the heat transfer performance of PHPs. In this section, we define two types of operation conditions, i.e., with and without motion, i.e., with and without the consideration of centrifugal force. Moreover, the research on PHPs with different heating modes is also summarized.

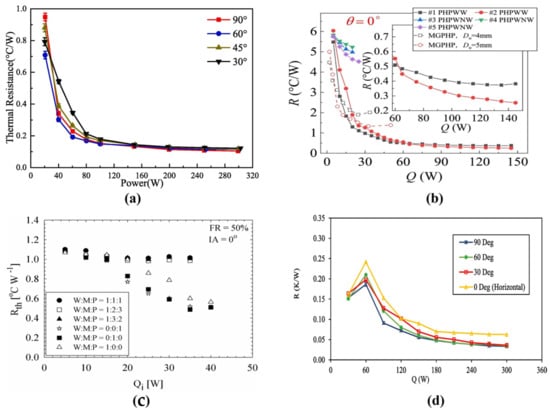

2.3.1. Status without Motion

Although motion and, accordingly, centrifugal force are not involved in the performance investigation of PHPs, recent research has highlighted the significant impact of gravity on the heat transfer efficiency of PHPs. The incline angle of PHPs emerges as a key factor influencing this efficiency, as the gravitational effect varies with the angle. An optimal incline angle is crucial for achieving the best performance. Saha et al. [17] found that closed-loop pulsating heat pipes (CLPHPs) exhibited peak heat transfer performance when inclined at an angle between 50° and 70°, attributed to the higher bubble rise velocity occurring within this range, which enhances the heat transfer rate. As the inclination angle increases, the velocity of bubbles also increases, leading to pointed bubble heads with higher velocities. At 45°, the velocity peaks, and beyond that, as the inclination angle further increases, the bubble heads start to blunt, causing a decrease in bubble velocity. This observation has been experimentally confirmed by Cheng et al. [115] and Bhusan et al. [116]. Qu et al. [117] found that 3D pulsating heat pipes exhibited the best heat transfer performance at an inclination angle of 60°, as shown in Figure 8a. Consequently, when the heat input ranged from 20 W to 100 W, three-dimensional pulsating heat pipes (3D-PHPs) at 60° have minimized thermal resistance. Additionally, the thermal resistance of 3D-PHPs under all working conditions was similar when the heat input exceeded 150 W, indicating that the thermal driven force was strong enough to achieve the annular flow stage. Alizadeh et al. [57] indicated that in other modes, as the input power increases, the thermal resistance decreases, but the lowest thermal resistance is always associated with the vertical mode. Xue et al. [118] studied the relationship between the flow patterns and thermo-hydrodynamics of PHPs. They found that the gravity effect on the flow performance of PHPs is dramatic in a low- power state. However, it decreases rapidly and can be neglected as the flow pattern of PHPs changes into “Annular Flow”.

Figure 8.

(a) Thermal resistance of 3D-PHPs versus heating power with different filling ratios [117]; (b) thermal resistance of PHPs at 0° [113]; (c) thermal resistance of ternary mixture in horizontal direction [119]; (d) the relationship between the thermal resistance 3D-PHPs and input power under different inclination magnetic fields [57].

In the horizontal operation modes, Saha et al. [17] observed that the temperature of the evaporator kept climbing as the inclination angle decreased from 90° to 0° under consistent operating conditions in the horizontal direction. The system could not function properly when the angle reached 5°. When the system is horizontal, the liquid struggles to flow back to the evaporator, causing dry-out. Wu et al. [113] noted that the thermal resistances of PHPs without integral inner-wall sintered powder wicks increased at an inclination angle of 0°. The heat transfer performance worsened because gravity’s positive effect on the unbalanced pressure distribution and liquid flow-back weakened. However, PHPs can be successfully start up at all inclination angles when adding a sintered core, as shown in Figure 8b. Markal et al. [119] found that when heat pipes are placed horizontally, as shown in Figure 8c, the thermal resistance data for the ternary mixture are distributed horizontally. This indicates that FP-CLPHPs equipped with any ternary mixture cannot operate effectively in a horizontal position. Betancur et al. [120] found that the system could only start up with FR 37.5 and 50% in the horizontal position. The oscillations had larger amplitudes in the horizontal position, and a higher heat flux was needed to maintain sustained oscillations. The thermal resistance was more significant compared to devices operated in the vertical position, even when fully activated. Xue et al. [121] found that ammonia CLPHPs can easily start up at a low input power in horizontal operation, but it is difficult to achieve circulation. The capillary in the evaporate section will burn out once the input power increases, leading to higher thermal resistance and a decrease in transfer performance.

However, Qu et al. [114] found that adding micro-groove structures in the horizontal direction can lower the limitations of heat transfer. Qu et al. [93] also investigated the start-up, heat transfer, and flow characteristics of trapezoidal silicon micro-pulsating heat pipes (MPHPs) with three diameters. It was found that the thermal performance tends to decrease when the MPHPs are shifted from the vertical to horizontal direction. Additionally, when R113 or FC-72 is used as the working fluid, the system can start within 200 s. However, when filled with water or ethanol, it cannot start at any angle. Lee et al. [104] found that when the number of turns is 20, the inclination angle from vertical to horizontal does not affect start-up. Alizadeh et al. [57] found that the thermal resistance does not suddenly increase with high input heat flux after applying a magnetic field in the horizontal position. It occurs the dry-out phenomenon, and the magnetic field can compensate for the effect of gravity, as shown in Figure 8d. The major phenomena are listed in Table 4.

Table 4.

Phenomena in status without motion of PHPs.

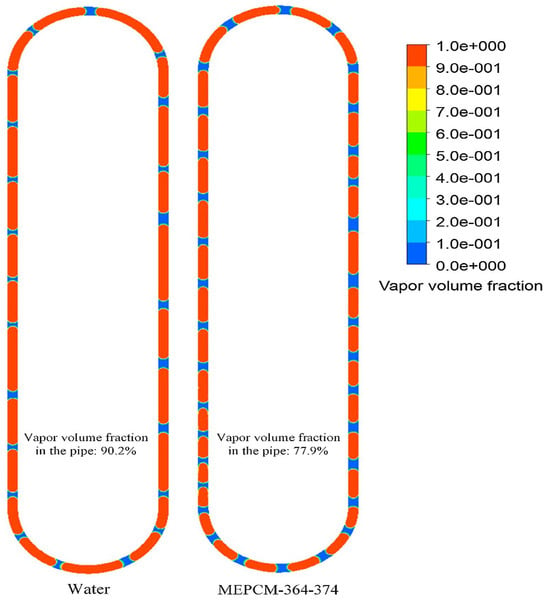

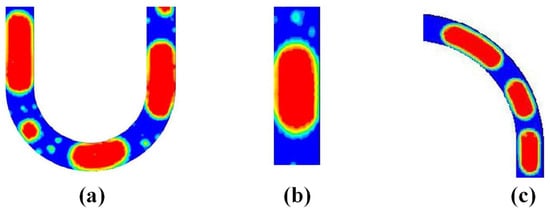

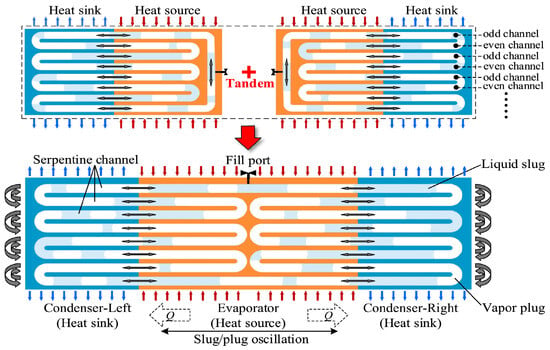

2.3.2. Status with Motion

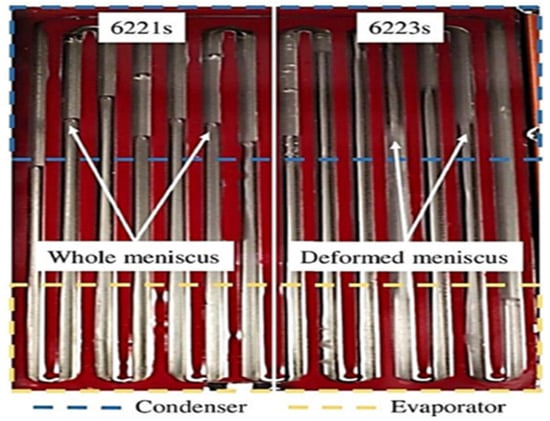

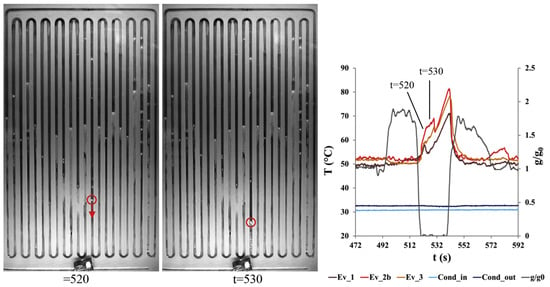

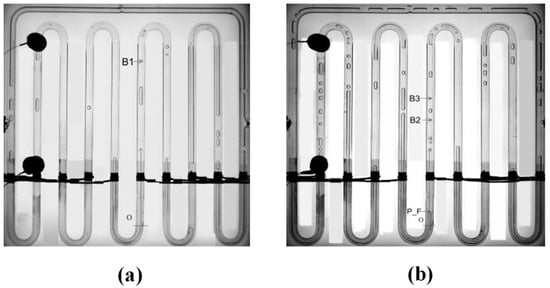

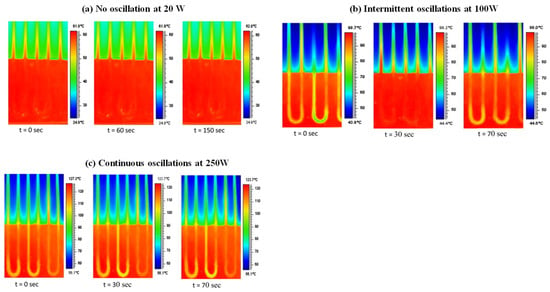

In status with motion, the combination of centrifugal force and gravity affects the performance of PHPs simultaneously. The major phenomena during motion are summarized in Table 5. In space, pulsating heat pipes need to operate effectively in microgravity conditions. Parabolic flight experiments are adopted to conduct experiments with microgravity [9,122,123]. Mameli et al. [9] observed a sudden temperature increase in the evaporator section of pulsating heat pipes during microgravity, but intriguingly, this effect was reversible during the subsequent hypergravity phase. Maksym et al. [124] observed a similar temperature increase in PHPs filled with ethanol under microgravity conditions. This phenomenon was attributed to the transition of the liquid plug’s movement from slug flow to annular or semi-annular flow, known as re-activation phases, triggered by pressure fluctuations or other influences. Interestingly, this transition ultimately restored the heat pipe’s heat transfer capabilities, as shown in Figure 9. Lastly, Mauro et al. [123] investigated the stable operating condition of large-diameter PHPs under microgravity conditions. Their findings revealed that PHPs can maintain stable operation at a thermal input of 185 W. Cecere et al. [22] investigated flat-plate PHPs utilizing water and a self-replenishing wetting mixture (water/n-butanol) as working fluids under variable gravity conditions. They observed that water is unable to operate in low-gravity environments, whereas PHPs filled with the self-replenishing wetting fluid can still operate normally during the microgravity phase, as shown in Figure 10. In addition, Sun et al. [125] discovered that the heat transfer performance of PHPs is less dependent on the diameter and length of the pipe under microgravity, but the temperature has a greater impact than the diameter and length of the pipe.

Figure 9.

Flow patterns one second before (left; slug pattern) and one second after fluid flow reactivation (right; annular pattern) [124].

Figure 10.

View of the FPPHPs’ flow pattern (left) and associated temperature (right) under microgravity conditions with water. Power input: 200 watts [22].

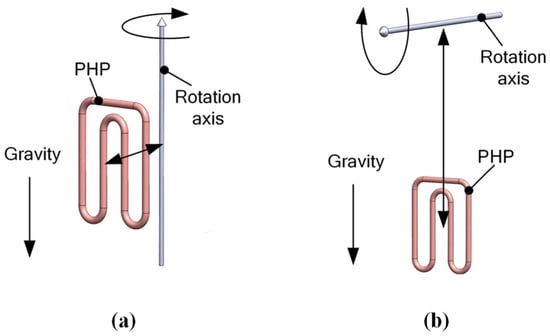

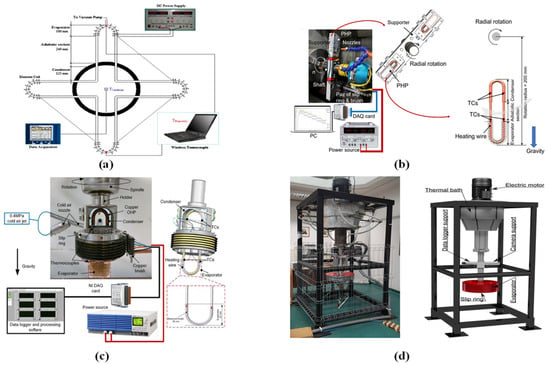

When centrifugal force is unneglectable, the performance of PHPs is influenced comprehensively by centrifugal force and gravity. Categorized by the directions of gravity and centrifugal force, the PHPs with motion status can be divided into two cases: (1) axial rotation and (2) radial rotation [126]. In the first case, centrifugal force is always perpendicular to gravity, and centrifugal force always stays on the surface determined by the directions of gravity and the rotation axis. In the second case, centrifugal force can be at any angle with gravity and the axis is perpendicular to the surface where the centrifugal force and gravity are (as shown in Figure 11).

Figure 11.

Demonstrations of rotating PHPs. (a) Axial rotations and (b) radial rotations [126].

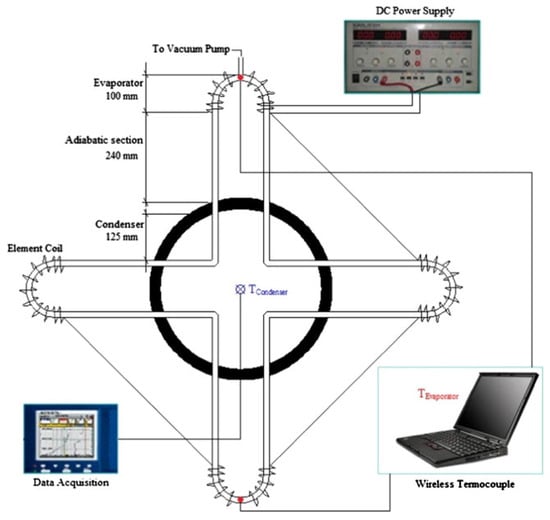

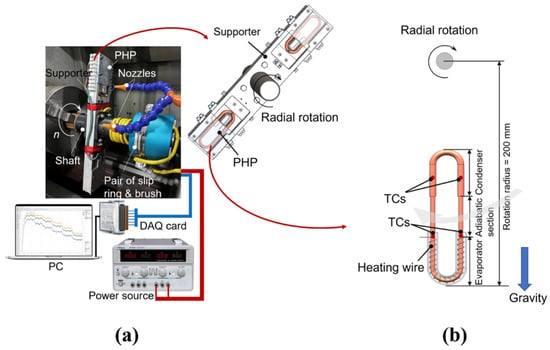

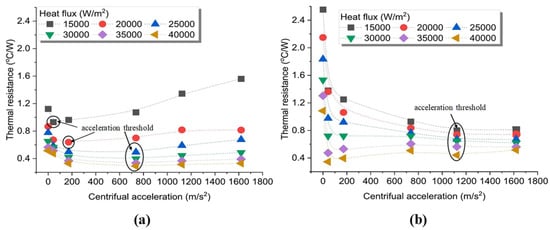

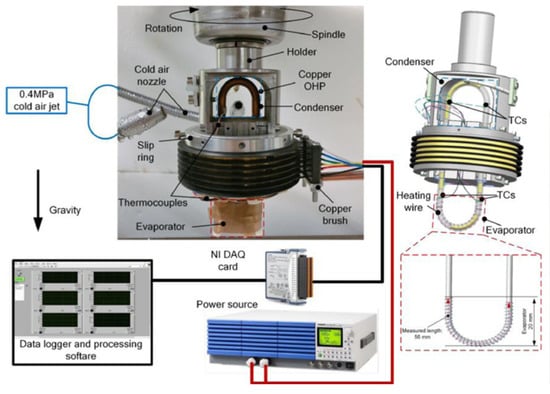

Aboutalebi et al. [127] studied the influence of radial speed on the heat transfer performance of rotating closed-loop pulsating heat pipes (RCLPHPs) in radial mode, as shown in Figure 12. The results indicated that there is a gradual decrease in the thermal resistance of the PHPs as the rotational speed increases because more fluid can return to the evaporator after being condensed, and this not only reduces the possibility of dry-out phenomena but also speeds up the heat transfer rate. In particular, the heat transfer performance of the PHPs is improved significantly at high input powers. Dehshali et al. [5] investigated the heat transfer performance of rotating closed-loop pulsating heat pipes (RCLPHPs) under different radial speeds. The results showed a lower thermal resistance in motion mode compared to stationary mode. Moreover, they indicated that with the increase in radial speed, the liquid could return to the evaporator section faster, and the vapor slug could be pushed to the condenser section faster. So, there is an increase in the thermal resistance as the speed increases. In particular, there is a decrease in the possibility of drying out at the top and bottom positions of the pulsating heat pipe. On-ai et al. [128] evaluated the heat transfer performance of rotating closed-loop pulsating heat pipes (RCLPHPs) by measuring the working fluid temperature amplitude and frequency under different radial accelerations and heat inputs to determine the operating status. The results indicated that with the increase in acceleration, the temperature amplitude decreased and the flow pattern changed from an annular flow to a slug flow, and the flow direction of the working fluid inside the heat pipes transformed from oscillatory flow to stable cyclic flow. When the heat input increases, the temperature amplitude increases, the flow pattern changes from a slug flow to an annular flow with intermittent liquid slug, and the flow direction is always a circulatory flow corresponding to the magnitude of the centrifugal acceleration, thereby enhancing the overall performance of the heat pipes. In addition, the RCLPHP showed a slug-train flow pattern, the same as the ordinary CLPHP, during high centrifugal acceleration. Qian et al. [126] investigated the heat transfer performance of rotating closed-loop pulsating heat pipes (RCLPHPs) containing acetone and deionized water under high radial centrifugal acceleration, as shown in Figure 13. The tests revealed that there is an acceleration threshold with the increase in radial centrifugal acceleration. And the acceleration threshold increases with the increase in heat flux. Below this threshold, the thermal resistance exhibits an inverse relationship with the acceleration; above the threshold, the thermal resistance will remain either constant or inversely proportional to the acceleration. The vapor and liquid phases can be separated to some extent by centrifugal force, and the increase in heat flow can slow down this phenomenon. So, there is a higher acceleration threshold under large heat flux. Acetone with lower surface tension has a lower acceleration threshold, as shown in Figure 14. Moreover, the acceleration threshold for DI water with higher surface tension is significantly larger. Finally, by considering the key parameters including the heat flux, centrifugal accelerations, thermophysical properties of the working fluid, dimensions, and working temperatures, a semi-empirical correlation of dimensionless numbers was built to estimate the heat transport. And the difference between the correlation values and the experimental results was less than 10%.

Figure 12.

RCLPHP experimental setup diagram [127].

Figure 13.

(a) Radial-rotating PHP experimental apparatus; (b) illustration of radial-rotating PHP [126].

Figure 14.

Heat transfer capacity of radial-rotating PHPs filled with (a) acetone and (b) DI water [126].

Table 5.

The phenomena during motion of PHPs.

Table 5.

The phenomena during motion of PHPs.

| Condition | Phenomenon | Refs. |

|---|---|---|

| Microgravity and Hypergravity | Evaporation temperature rises rapidly. Stop-over phenomena occur. Dry-out results in deterioration of heat transfer performance. Reactivation phenomenon leads to enhancement of heat transfer performance. Large inner diameter, self-replenishing wetting, and large temperature difference are essential for stable operation. | [9,22,123,124,125] |

| Centrifugal force | Heat transfer is enhanced with acceleration in rotation less than the threshold value. However, heat transfer performance is deteriorated once the threshold is exceeded. | [5,126,128] |

To the best of our knowledge, there is no clear determination of a threshold value that is valid for common cases, taking into account the variation in structure, accelerator range, working fluid, filling ratio, etc., in experiments.

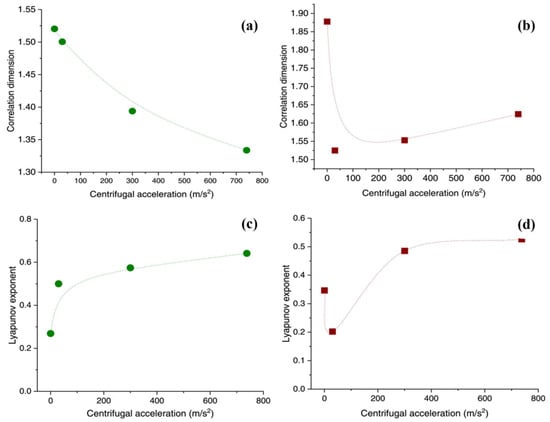

Qian et al. [129] studied the influence of axial rotation on the heat transfer performance of single-loop axial-rotating pulsating heat pipes (ARPHP) filled with ethanol, acetone, and water, as shown in Figure 15. The findings indicated that as centrifugal acceleration increases, the thermal conductivity of ethanol and acetone show a corresponding increase. However, water has high flow friction due to its high dynamic viscosity, causing a deceleration in circulation flow once a specific threshold (a = 30 m/s2) of acceleration is surpassed. Ultimately, the dry-out phenomenon may occur, resulting in a decline in the thermal coefficient. Moreover, the correlation dimension and Lyapunov exponents of the evaporator are proposed to describe the amplitude of oscillation of temperature and determine the degree of chaos, respectively, as shown in Figure 16. A negative Lyapunov exponent corresponds to a stable fixed point, while when the Lyapunov exponent is equal to zero, it indicates a stable limit cycle; when the Lyapunov exponent is positive, it shows a chaos state in the ARPHP. And the correlation dimension changes of the ARPHP with acetone and water showed a consistency with the changes in the thermal performance. Qian et al. [130] discussed the heat transfer performance of single-loop rotating pulsating heat pipes with methanol as the working fluid under different coaxial rotational accelerations. The results showed that with the increase in centrifugal acceleration, there was a noticeable enhancement in the thermal coefficient of PHPs. But it was observed that the rate at which this enhancement occurred gradually diminished with the increasing centrifugal acceleration. And a novel model was developed to simulate and predict the heat transfer coefficient of axial rotating pulsating heat pipes based on experimental data and a grey model. The errors of results from Artificial Neural Network (ANN) models range from 3.36% to 16.6%, exhibiting a high level of accuracy and effectiveness.

Figure 15.

Axial rotation PHP experimental apparatus [129].

Figure 16.

Correlation dimension of the temperature under different centrifugal accelerations: (a) acetone and (b) water. Lyapunov exponents of the evaporator temperature: (c) acetone and (d) water [129].

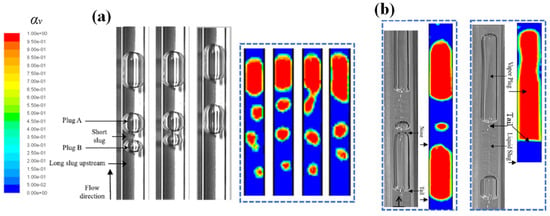

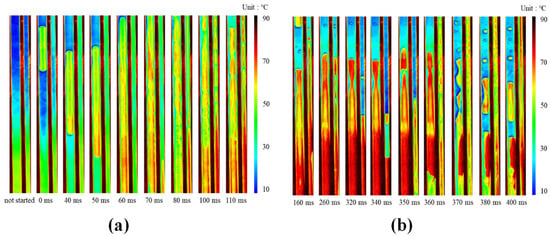

2.3.3. Heat Input Mode

The start-up and operation of PHPs depend on supplying sufficient heating power to generate a steam pressure difference substantial enough to drive the working fluid flow. If this pressure difference is small, under certain operating conditions, PHPs may have difficulty starting. Therefore, the input mode is crucial for the operation and performance of PHPs, especially with the consideration of inconsistent heat flux, such as periodical mode and non-periodical heating mode, as well as non-uniform heating mode. Zhao et al. [131] utilized a mathematical model of PHPs to simulate three distinct heat source modes: non-uniform pulse, uniform pulse, and alternating heat sources. Their study unveiled the dynamics of the internal working fluid and the mechanisms behind enhanced heat transfer. The findings suggest that these heat source modes can boost the heat transfer capabilities of closed-loop pulsating heat pipes under particular circumstances. However, if the configuration conditions are not properly aligned, it can actually diminish the heat transfer performance and potentially destabilize the heat pipe’s operation. Xian et al. [132] indicated that pulse heating can effectively reduce the temperature difference between the evaporation section and the condensation section, thereby improving heat transfer efficiency. In another study [133] conducted by the same research group as ref. [132], they investigated the impact of pulsatile heating on PHPs. They observed a reduction in the liquid film thickness under pulsatile heating compared to continuous heating, indicating increased sensitivity of the vapor slug to temperature fluctuations in the pipe wall. This sensitivity led to a more pronounced oscillatory motion, as depicted in Figure 17. Furthermore, the application of small-pulse heating was found to expand the stable operating range of PHPs.

Figure 17.

The phenomenon of heating power of 50 W in different heating modes: (a) under continuous heating mode; (b) under pulsed heating mode [133].

Wang et al. [134] enhanced the start-up of pulsating heat pipes by assisting heat flow to improve thermal management performance. They demonstrated that this approach effectively enhanced the thermal management performance of the battery by reducing thermal resistance, promoting the regression of local hot spots, and mitigating the risk of thermal runaway. However, selecting appropriate parameters is crucial to prevent excessive evaporator temperature. Li et al. [39] studied the effects of two heating modes (sudden heating and gradual heating) on hydrogen-pulsating heat pipes. The results showed that the pulsating heat pipes exhibited a stable heat transfer performance under both heating modes. Wang et al. [135] discovered that employing two heating modes, non-uniform and uniform, revealed that non-uniform heating pulsating heat pipes can start up quickly, while uniform heating exhibits better heat transfer performance during stable operation. Mameli et al. [122] found that non-uniform heating of the evaporator could enhance the heat pipe’s overall performance, particularly at lower heating powers. The major phenomena are listed in Table 6.

Table 6.

Phenomena in heating modes.

In terms of operating conditions, we mainly discussed conditions without motion, conditions with motion, and heating methods of PHPs. Currently, researchers have made significant progress in the heat transfer performance of PHPs both with and without motion. It has been found that PHPs exhibit optimal heat transfer performance at specific inclination angles, and experiments in microgravity environments have shown that PHPs can operate effectively in space. Additionally, it has been revealed that non-uniform heating methods can enhance the heat transfer performance of PHPs. However, maintaining stable operation of PHPs under extreme conditions remains a research challenge. Different studies have varying opinions on the optimal parameters for inclination angles, acceleration thresholds, and input heat source modes. These are all topics worth discussing in future research.

3. Mechanism of Pulsating Heat Pipes

Theoretical investigations may be useful for the performance estimation and optimization of pulsating heat pipes. By utilizing the physical model, researchers can gain profound insights into the operational principles of PHPs, thereby facilitating optimal design choices and parameter selection. Conducting numerical simulations and visualization experiments on PHPs can validate the accuracy of the physical model, thereby refining and enhancing the theoretical model of PHPs. Therefore, this section will elucidate the mechanism of PHPs through theoretical models, numerical simulation, and visualization experiments [16].

3.1. Theoretical Model of PHPs

Theoretical models play a crucial role in describing the oscillatory motion of PHPs and predicting their heat transfer performance. Several models have been developed for pulsating heat pipes, including spring–mass–damper models, massmomentum–energy equation models, semi-empirical models, and more. The heat absorbed in the evaporation section of pulsating heat pipes is primarily dissipated through the oscillating movements of liquid slugs and vapor slugs. The pressure difference generated within the pulsating heat pipes serves as the driving force for this oscillatory motion. The friction is considered as the resisting force for the motion. The expansion and shrinkage of vapor are also considered in some models.

3.1.1. Spring–Mass–Damper Model

The spring–mass–damping model was first proposed by Ma et al. [136] to predict the oscillating motion of PHPs, as given in Equation (3). It is based on Newton’s law that force is equal to mass times acceleration. The pulsating heat pipes are oriented horizontally, and the model utilizes the temperature differential between the evaporating and condensing sections as the primary driving force behind the oscillatory motion, with frictional and restoring forces considered but the gravitational force neglected.

where hfg, ω, τ, f, μl and μv are latent heat, frequency, times, friction factor, and liquid and vapor viscosity.

Liang et al. [137] presented a mathematical model describing the oscillation characteristics of slug flow in a capillary tube. They demonstrated that the gravitational force affects the frequency and amplitude of the oscillating flow motion in the capillary tube, as given in Equation (4).

where K is the stiff coefficient and Zi is the position of the ith liquid plug in the tube.

Ma et al. [138] proposed a model including the forced convection heat transfer effect caused by oscillating motion; the closed evaporation effect in the evaporation section and the thin film condensation effect in the condensing section are established to predict temperature, as given in Equation (5). The model takes into account the influence of operating temperature and non-linear vapor volume modulus. The results show that the input power and the temperature difference in the evaporating and condensing section are greater than the initial value, the oscillation motion starts, and the heat transfer is enhanced. Compared with the experimental results, it is found that the temperature is basically consistent with the predicted temperature.

Evaporative heat transfer model:

Thin film condensation model:

where S is a suppression factor, Xtt is the Martinelli parameter, and kl is thermal conductivity.

Spinato et al. [139] used the model of Ma et al. [138] to predict the oscillation frequency, but this prediction was inconsistent with the experimental results. This inconsistency arose because they assumed uniform temperature within the system, whereas temperature variations affect the density ratio, which significantly impacts the frequency increase.

A single damping model is used to understand the oscillation behavior of PHPs, but the model loses its effectiveness when the amplitude decreases during stable oscillation. This is not suitable for multi-turn PHPs with multiple liquid plugs.

In these studies, the oscillation characteristics of multi-turn PHPs are theoretically analyzed using the spring–mass–damper model. Gürsel et al. [140] proposed a non-linear spring–mass–damper model to predict the motion of liquid slugs of PHPs with a non-uniform and asymmetric filling, as given in Equation (6). Liquid slugs, vapor plugs, friction, and capillary forces are represented by masses, non-linear springs, and non-linear dampers, as shown in Figure 18. They considered the capillary force and gravity effects. If ignoring these two factors, the model results will match the model of Ma et al. [136]. And they also conducted a comparison with experimental data from Khandekar et al. [141]; the simulation results indicate a high degree of consistency.

where ml,i and ẍi are the mass and acceleration of the ith liquid slug. Fpres,i, Ffric, Fcap,i, and Fgrav,i are the effective pressure force over a liquid slug, the friction force, the effective capillary force, and the gravitational force acting on the ith liquid slug, respectively.

Figure 18.

(a) Schematic diagram of the PHP mechanism; (b) spring–mass–damper model of PHPs [140].

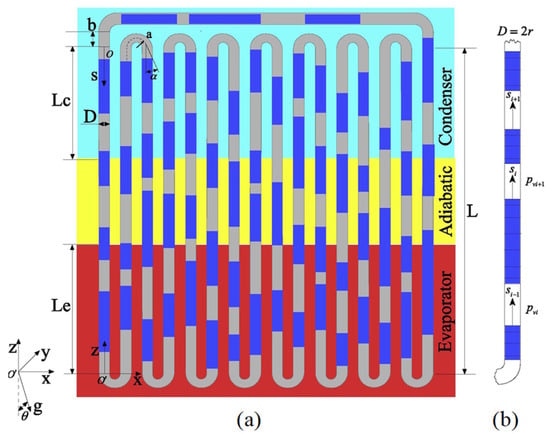

Peng et al. [142] proposed a non-linear model based on the spring–mass–damping model, which accounts for the interphase mass-transferring effect, fluid filling ratio, different heating modes (top or bottom heating), gravity, bending pressure loss, properties of the working fluid, and different random distributions of initial velocities and lengths of fluid slugs. This model was designed to study the influence of the liquid plug length and PHP heat transfer. It can be used to simulate the dynamics and heat transfer of PHPs in detail and accurately, as given in Equation (7). Figure 19 shows the structure of a multi-turn pulsating heat pipe.

where i, Pvi, ∆Pbi, and τp are acceleration, length, pressure, bending pressure loss, and shear stress on the ith liquid slug, respectively. Pvi+1 is pressure on the (i + 1)th liquid slug.

Figure 19.

Structure of multi-turn pulsating heat pipes. (a) coordinate systems, and (b) numbering and finite-element discretization of fluid and vapor slugs [142].

However, the authors cannot quantitatively verify the correlation of oscillation frequency with experimental data. This is mainly because their assumption of an “adiabatic” steam plug is unrealistic for application to real pulsating heat pipes with steam plugs under non-adiabatic conditions with phase change heat transfer.

Yoon et al. [143] proposed a ‘non-adiabatic’ vapor spring liquid mass model, as given in Equation (8). He considered that the vapor plug was in a non-adiabatic state which caused the mass and volume of the vapor plug to change over time. A closed-form correlation of the oscillation frequencies of liquid slugs in MPHPs was proposed and shown to match the experimental data within ±15%.

here ml,n, Ll,n, Dh, μl,n, ρl,n, l,n, fD, Rel,h, g, Av and v,n are the mass, length, hydraulic diameter, viscosity, density, instantaneous displacement variation around the equilibrium position, Darcy friction factor, Reynolds number, gravitational acceleration, the nth vapor plug’s cross-sectional area, and instantaneous pressure variation on the nth liquid slug, respectively.

Overall, the spring–mass–damping model is effective for observing the oscillatory behavior of PHPs; however, it is highly dependent on parameter settings, and improper settings can result in significant deviations from experimental results.

3.1.2. Mass–Momentum–Energy Equation Model

Shafii et al. [144] assumed that each steam slug behaves as an ideal gas and each liquid slug is incompressible, while neglecting pressure loss in bends; the mass, momentum, and energy equations for both phases are solved to predict gas–liquid slug behavior. The study concludes that 95% of heat transfer is due to sensible heat, with latent heat primarily driving oscillation, while gravity has minimal impact on fluid oscillation. This model neglects curve pressure loss only when the number of turns is less. And the mass equation, energy equation, and momentum equation are given in Equation (9)–(11)

where mli, min,li and mout,li are the mass, mass change rate due to condensation, and mass change rate due to evaporation on the ith liquid slug, respectively.

where mvi, min,vi and mout,vi are the mass, mass change rate due to evaporation, and mass change rate due to condensation on the ith vapor slug, respectively; hh, hvsen and hfg are the evaporative heat transfer coefficient, condensation heat transfer coefficient, vapor slug’s sensible heat coefficient, and latent heat coefficient, respectively.

where αl, hvsen, kl, and Tw are the thermal diffusivity of liquid, the liquid slug’s sensible heat transfer coefficient, the thermal conductivity of the vapor plug, and the wall temperature, respectively; Tli is the temperature of the ith liquid slug.

where Cv and A are the specific heat capacity and cross-section of vapor, respectively.

where n, τ and Vli are the tube number, shear stress, and volume of the ith liquid slug, respectively.

Zhang et al. [145] studied the oscillatory flow in a U-shaped mini-tube by simplifying the governing equations to five dimensionless parameters. They established the momentum equation for the layer flow of the liquid slug. In their energy equation, sensible heat is used as the heat input to the vapor plug. They also showed that gravity has no significant effect on fluid oscillations. The momentum equation for the liquid slug and the energy equation of the vapor plugs are given in Equations (12) and (13).

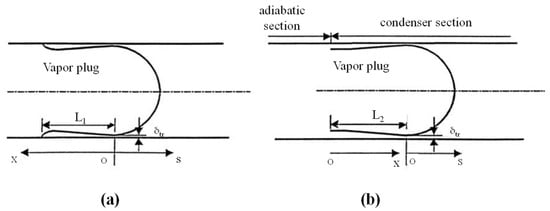

Zhang et al. [146] studied the condensation and evaporation of the film on the walls of PHPs tubes by ignoring gravity, assuming the vapor is in a saturated isothermal state and considering the effect of surface tension on the momentum equation of the liquid slug flow. Their results showed that surface tension has little effect on the frequency and amplitude of oscillation.

Shafii et al. [147] considered the effect of thin film evaporation and proposed a new model based on a previous model [144]. The two newly added models are shown in Equations (14) and (15). The results showed that the heat transfer of PHPs is mainly due to the exchange of sensible heat rather than latent heat. Higher surface tension results in a slight increase in total heat transfer. Figure 20 shows the model building diagram.

where σ, K, Pd, δ, h’fg, Q, μl, and ρl are the surface tension, the curvature of the liquid film, the disjoining pressure, the liquid film thickness, the revised latent heat of evaporation, the heat transfer rate, the dynamic viscosity of the liquid, and the density of the liquid, respectively.

where Tvi and R are the temperature of the ith liquid slug and pipe radius; δ is the liquid film thickness.

Figure 20.

The physical model of film thickness in heating (a) and cooling sections (b) [147].

Yuan et al. [148] investigated the effects of gravity, the initial displacement of the liquid plug, and latent heat on the percentage of total heat transfer in PHPs. They concluded that the amplitude and angular frequency of slug oscillation are mainly determined by the geometry and filling rate of the PHPs. The initial displacement of the liquid plug has no effect on the normal operation of the PHPs. Since sensible heat accounts for a smaller proportion of the total heat transfer at the liquid/gas interface compared to latent heat, latent heat is used as an external heat input in the vapor energy equation, which is the main difference from the model of Zhang et al. [145]. They all assumed the vapor to be isothermal. In reality, the vapor is rarely isothermal, as given in Equation (16).

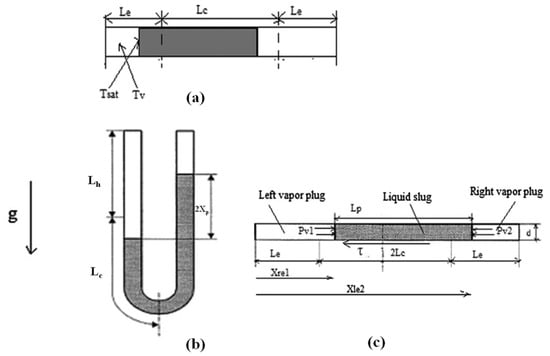

Dilawar et al. [92] proposed a model for non-isothermal vapor mass–momentum–energy equations based on the foundational model of Shafii et al. [144]. The modified liquid momentum equation is given in Equation (17). The modified gas mass equation is given in Equation (18). The actual vapor slug’s mass will cause it to change as it is not isothermal. Therefore, the saturation temperature (Tsat) of the vapor slug at the current pressure is used instead of the Tv calculated by the formula of the ideal gas temperature of the vapor slug, as the temperature of the vapor–liquid interface is used to calculate the rate of mass transferred into the vapor plug due to evaporation or condensation (i.e., in,vi and out,vi), as shown in Figure 21a. Pressure loss at bends and capillary effects at the meniscus are also considered in the numerical model, as shown in Figure 21b,c. The model assumes constant phase change heat transfer coefficients. The evaporator and condenser are maintained at constant temperatures of different magnitudes.

where θ, ∆Pb, σ, vl, and τ are the contact angle, pressure loss at the bend, liquid surface tension, the velocity of the liquid slug, and the wall friction of the liquid slug, respectively.

where Te, Tc, Tsat, and hfg are the evaporator temperature, condenser temperature, evaporator saturation temperature, and latent heat, respectively.

Figure 21.

Theoretical model of U-shaped pulsating heat pipes [92]. (a) The liquid–vapor interface at saturation temperature; (b) U-shaped mini-channel; (c) steady-state position of physical model.

In 2005, Holley et al. [149] developed one of the most comprehensive numerical models for PHP systems. Their 1D lumped parameter model assumed a constant mass flow rate of liquid slugs. The model solved the momentum equation for liquid slugs while considering the energy equations for both phases and the external wall. Although phase changes were not directly accounted for, the model was able to explain the coalescence of liquid elements and the formation of new vapor, as given in Equation (19). Later, Mameli et al. [150,151,152] improved the model of Holley et al. [149] by introducing the effects of tube bends on the dynamics of liquid slugs and calculating the two-phase heat transfer coefficient for the liquid and vapor sections based on the heating regime, as given in Equations (20) and (21). In the study by Manzoni et al. [153], a novel correlation for estimating wall/vapor heat transfer coefficients is introduced to account for the effect of the liquid film on conjugate heat transfer. Through a comparison with experimental data obtained from PHPs tested under normal and hypergravity conditions, the model was validated under various operating conditions and different gravity levels. However, they all ignored the dynamics of the liquid film.

The first and second terms on the left-hand side are pressure differences due to acceleration as a result of mass flow rate change and dilatation (slug elongation or shortening), respectively. The terms on the right-hand side refer to the hydrostatic pressure difference, the difference between pressures at the slug menisci, and pressure difference due to shear.

Nikolayev et al. [154,155] considered the film dynamics in their models with a simplifying assumption of constant and uniform thickness, but with variable length due to evaporation, as given in Equations (22) and (23). Senjaya et al. [156,157] presented a more realistic model of the film dynamics, where the thickness is allowed to vary in space and time. Although these models of the film dynamics can qualitatively describe the self-sustained oscillation of the fluid inside horizontal PHPs, no quantitative validation has yet been provided. Bae et al. [158] proposed a model that directly showed the spatial and temporal changes in liquid film thickness to relax simplifying assumptions about the film dynamics. The results of the numerical simulations were shown to be in good agreement with the experimental data for horizontal and inclined PHPs as well as vertical PHPs with various parameters, including the number of turns, working fluid, fill rate, and operating temperature. The model ignored the local pressure at the bends.

The mass, momentum, and energy equations can provide a thorough analysis of the internal fluid flow and heat transfer processes in a PHP. However, they are highly sensitive to initial and boundary conditions, which are not always easy to define.

3.1.3. Semi-Empirical Model

Semi-empirical models are also proposed for the investigation of the performance of PHPs, based on the collections of experimental results.

Rittidech et al. [159] established empirical equations based on Ku, Pr, Bo, N, Fr, and We values to analyze the influence of these dimensionless numbers on the heat transfer performance of horizontal closed-loop PHPs. The experimental results show that the empirical correlation formula can accurately predict the heat flux, and the obtained correlation accuracy is ±30%. The number of turns, different working fluids, and geometric factors can provide a wide range of applications. However, the inclination angle and filling ratio limit its applicability.

Khandekar et al. [160] established a semi-empirical formula based on Ka, Ja, Pr, N, and β to predict the heat transfer performance of PHPs. They considered a wider range of turns, with the operating temperature determined by the average of the evaporator and condenser temperatures. And the obtained correlation accuracy is ±30%. However, the fixed filling ratio limits its applicability. The formula applies only to open-loop systems. Ka is the Karman number and q is the heat flux, W/m2, as given in Equation (24).

Katpradit et al. [161] proposed two related empirical expressions, one for horizontal and one for vertical configurations, based on Ku, Ja, Di/Le and Bo values. Wa values were added to account for the flooding effect of evaporators drying out; they achieved accuracies of ±18% (Ku0) and ±29% (Ku90). Due to the fixed filling ratio and the disregard for the number of turns, these expressions are not suitable for varying filling ratios, inclination angles, or numbers of turns.

Qu et al. [162] studied the thermal performance of three closed-loop pulsating heat pipes (CLPHPs) in vertical bottom heating mode with heating power. Ku is proposed as a dimensionless measure of thermal performance and refers to the ratio of the input heat flux of PHPs to the critical heat flux, as shown in Equation (25). Based on Bo, Mo, Pr, Ja*, di/Le and Le/Lc, an empirical correlation is proposed to predict the heat transfer performance of CLPHPs. The proposed correlation agreed with the experimental data within a deviation of approximately ±40%; this application is limited by the fixed vertical inclination.

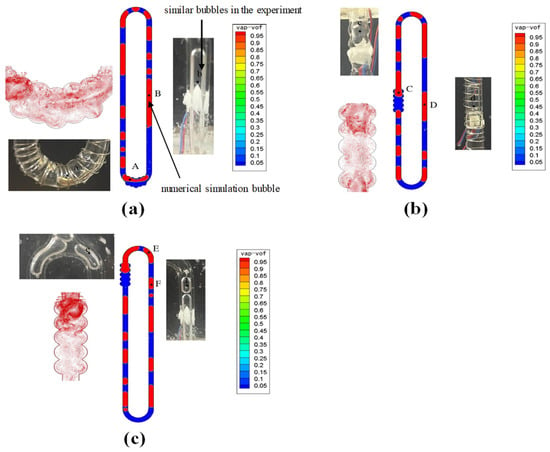

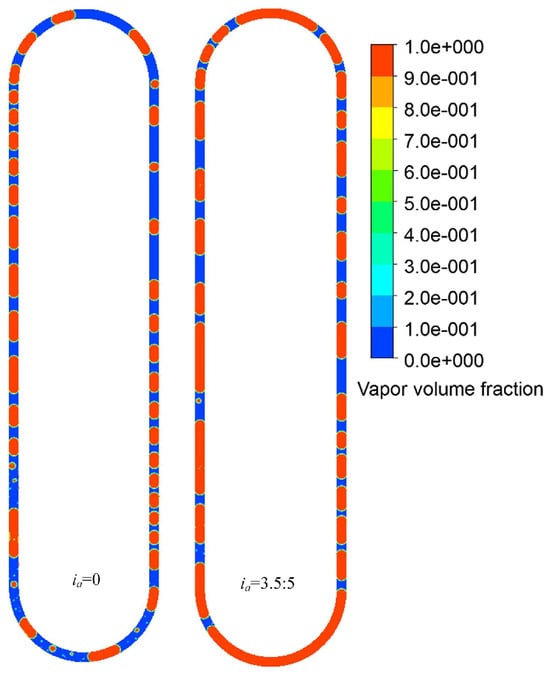

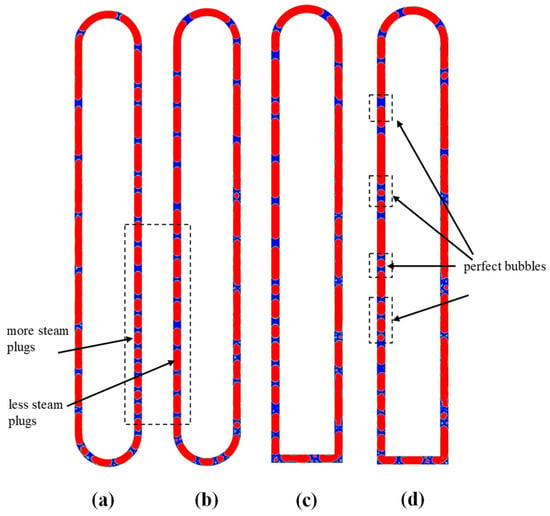

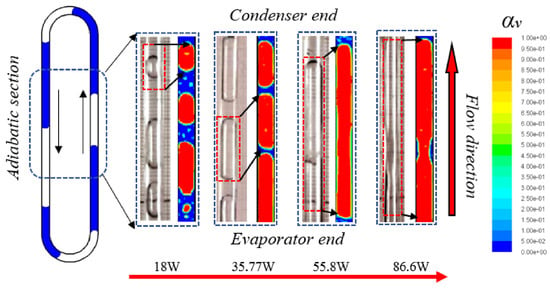

Goshayeshi et al. [163] proposed empirical correlations based on the bond number (Bo), Morton number (Mo), liquid Prandtl number (Pr), modified Jacob number (Ja*), the ratio of to Di/Le to Le/Lc and the number of turns to predict the thermal properties of vertical CLPHPs for Fe3O4/water and γFe2O3/kerosene. The consistency between the experimental data and the empirical correlations is generally good, and the obtained correlation accuracy is ±24%. However, fixed filling ratios and incline angles inhibit variable prediction.