1. Introduction

According to data [

1] for 2010–2019, there has been a steady increase in the production of diesel fuel (DF). At the same time, there has been a particularly intensive growth in the consumption of Winter and Arctic brands in the DF brand structure. This is associated with the use of DF as a fuel for the operation of large-scale machines and technological equipment in actively developed areas with a harsh climate, including the Arctic.

In order to achieve the low-temperature properties specified by the standards [

2,

3,

4] and ensure the uninterrupted operation of the equipment, it is most efficient and cost-effective to use depressants [

4,

5,

6,

7]. It is worth noting that a tiered approach to reducing diesel engine emissions is currently being implemented. By using the right type and ratio of diesel fuel additives, many benefits can be achieved, such as reducing the effect of fuel degradation, increasing the cetane number of the fuel, etc. However, the limited amount of data on both exposure and health effects makes it difficult to predict the risks of additives. In general, the concentrations of fuel additives are low (usually up to 1%), so the exposure over even a long period of time will be low, leading to very minor adverse health effects [

8].

It Is significant that the specific mechanism of interaction of low-temperature (depressant) additives with hydrocarbons included in DF does not exclude cases in which the additives do not work. Again, the reverse is possible, where the presence of certain hydrocarbons in the DF composition enhances the effect of the depressant additive; that is, the effectiveness of the depressant additives largely depends on the DF composition. A change in the fractional composition of the DF may have both positive and negative effects on the performance of the depressants [

9,

10]. Thus, expansion of the fractional composition of DF increases its response to depressants [

11]. A detailed group chemical composition reflecting the molecular-mass distribution of n-paraffins and the ratio of mono-, bi- and polycyclic aromatic hydrocarbons [

12,

13] is also important, since these hydrocarbon groups are the main ones that influence the efficiency of additive action [

14,

15]. A high content of saturated hydrocarbons, primarily medium molecular n-paraffins and aromatic hydrocarbons with a higher substitution ratio, has been found to degrade the low-temperature properties [

16]. The cold filter plugging point can be deteriorated by increasing the share of high-molecular n-paraffins in the fuel composition, which is almost irrelevant to the concentration of the depressant [

17,

18]. The effect is associated with the increased crystallization rates due to an increase in the concentration of high-molecular n-paraffins, resulting in the rapid growth of crystals not modified by the depressant. However, to achieve maximum depression of the DF pour point as the content of high-molecular-weight n-paraffins in it increases, an increase in the concentration of the depressant is required [

19]. It is also worth considering the composition of depressant additives, since the additives can have various effects on the low-temperature properties of DF [

20]. Depressant additives are mainly divided into polymeric, organic non-polymeric and hybrid types; however, the most widely used are polymeric additives based on vinyl acetate and ethylene copolymers, as well as their various modifications [

21]. An additive that is more versatile can be used in fuels with different chemical compositions, while others can effectively reduce the cold filter plugging point of fuels with lower concentrations of high-melt n-paraffins. For fuel with an Increased content of this group of hydrocarbons, the depression of the pour point should be practically comparable to that of the first additive [

12]. In relation to the pour point, regularities in the influence of the n-paraffin concentration in fuel with the addition of a polymer additive have been identified. Thus, with an increase in the paraffin concentration, the depression of PP first increases, followed by a sharp decrease and a deterioration in the efficiency of the additive [

22]. It is also worth considering the molecular weight of the n-paraffins being studied, since the authors [

23] found that the depression of PP is higher in fuel samples with a heavier composition.

In the earlier works by the authors, the influence of the regularities of the fractional [

9] and group composition [

14,

15] of DF on the efficiency of depressant additives were revealed. The revealed regularities are explained based on the concepts of the mechanism of depressant additives’ action. It is shown that the key role in the interaction of substances included in the DF with depressant additives is played by the structure and polarity of the molecules, which can be considered and assessed at the level of individual compounds. Conducting a study on individual hydrocarbons, taking into account the known structure and polarity of the molecules, will allow us to verify the hypotheses put forward earlier, as well as to identify the quantitative patterns of the DF composition’s influence on the depressant additives’ effectiveness.

In order to identify the quantitative patterns of the DF composition’s influence on the depressant additives’ effectiveness, it is necessary to take into account the influence of each individual hydrocarbon in the composition of the DF on the depressant additives’ effectiveness. Carrying out such a study for each individual hydrocarbon in the DF composition is almost impossible, because many hydrocarbons cannot be isolated in their pure form, especially high-molecular-weight hydrocarbons. Despite this, it is feasible to conduct studies on typical representatives of hydrocarbon groups with diverse structures.

In this paper, a detailed study was carried out for two groups of hydrocarbons—aromatics and n-paraffins. The study of model mixtures using pure hydrocarbons, differing in structure and properties, will reveal the patterns of the influence of typical hydrocarbons on the additive effectiveness. This will expand the understanding of the effect of the composition of DF on the efficiency of depressants and allow more efficient use of depressant additives in the production of DF.

The objective of this study is to identify the regularities of individual hydrocarbons, with various groups and structures, in addition to the influence on the depressant additives’ effectiveness.

2. Materials and Methods

The object of this study was a sample of straight-run DF obtained from one of the fields in Western Siberia, a depressant additive (Ad), as well as two groups of individual hydrocarbons: aromatic and n-paraffin. Methylbenzene (toluene, chemical formula C

6N

5-CH

3,

Figure 1d) and bicyclic monoaromatic hydrocarbon 1,2,3,4-tetrahydronephthalene (tetralin, chemical formula C

10H

12,

Figure 1b) were chosen as representatives of aromatic hydrocarbons. Hexadecane (cetane, chemical formula C

16H

34,

Figure 1a), heptadecane (chemical formula C

17H

36,

Figure 1c), geneicosan (chemical formula C

21H

44,

Figure 1e) and docosan (chemical formula C

22H

46,

Figure 1f) were selected as representatives of n-paraffin hydrocarbons. The structure of the individual hydrocarbons is shown in

Figure 1.

The following methods were used to determine the low-temperature properties of the DF sample and the obtained mixtures:

The cloud point (CP) was determined using the liquid low-temperature thermostat CRYO-T-05-01 according to the methods presented in [

24,

25]. The method for determining Tc is as follows: a double-walled test tube filled with the test sample is immersed in a liquid low-temperature thermostat and gradually cooled. Every 1–2 °C, the test tube is removed from the thermostat and compared with a previously prepared test fuel sample at room temperature. If there is visible turbidity of the fuel relative to the standard, the CP is recorded. Repeatability of the method: r = 1 °C, reproducibility of the method: R = 3 °C;

The pour point (PP) was determined using the liquid low-temperature thermostat CRYO-T-05-01 according to the methods presented in [

24,

25]. The method for determining PP is as follows: a double-walled test tube filled with the test sample is immersed in a liquid low-temperature thermostat and gradually cooled. Every 1–2 °C, the test tube is removed from the thermostat. The PP is fixed when the test tube is tilted at 45° and held in this position for 1 min and the meniscus of the sample does not shift. Repeatability of the method: r = 3 °C, reproducibility of the method: R = 6 °C.

The cold filter plugging point (CFPP) were determined using the liquid low-temperature thermostat CRYO-T-05-01 and CFPP determination unit on a cold filter according to the method described in [

26]. The method for determining the CFPP is as follows: in a low-temperature liquid thermostat, using a CFPP determination unit on a cold filter, the sample under study is gradually cooled. At intervals of 1 °C, the test sample is automatically pumped through a standardized wire mesh filter into a glass pipette under a controlled vacuum. If the test sample does not have time to fill the pipette within 60 s, then the experiment is stopped and the CFPP is recorded, because the fuel has lost the ability to pass through the filter. Repeatability of the method: r = 2 °C, reproducibility of the method: R = 0.102 × (25 − x) °C, where x—average of two measurements.

The essence of the methods for determining the CP and PP is the gradual cooling of 50 mL of fuel placed in a test tube with double walls. Moreover, 5 °C before the expected CP, the test tube with the sample is periodically (every 1 °C) removed from the thermostat and compared with the reference sample. If the transparency of the fuel has not changed, then the test tube is again immersed in the thermostat. The sample is cooled to a temperature at which the test sample becomes cloudy when compared with a reference sample. This temperature is the CP. Next, to determine the PP, the fuel is cooled to a temperature at which it will lose mobility when the test tube is tilted at 45° for 1 min.

The essence of the CFPP determination method is to cool 50 mL of fuel under standard conditions and pump a certain volume of fuel through a standardized filter unit. This procedure is repeated every 1 °C until a temperature at which fuel stops passing through the filter unit within 60 s.

Mixtures Preparation

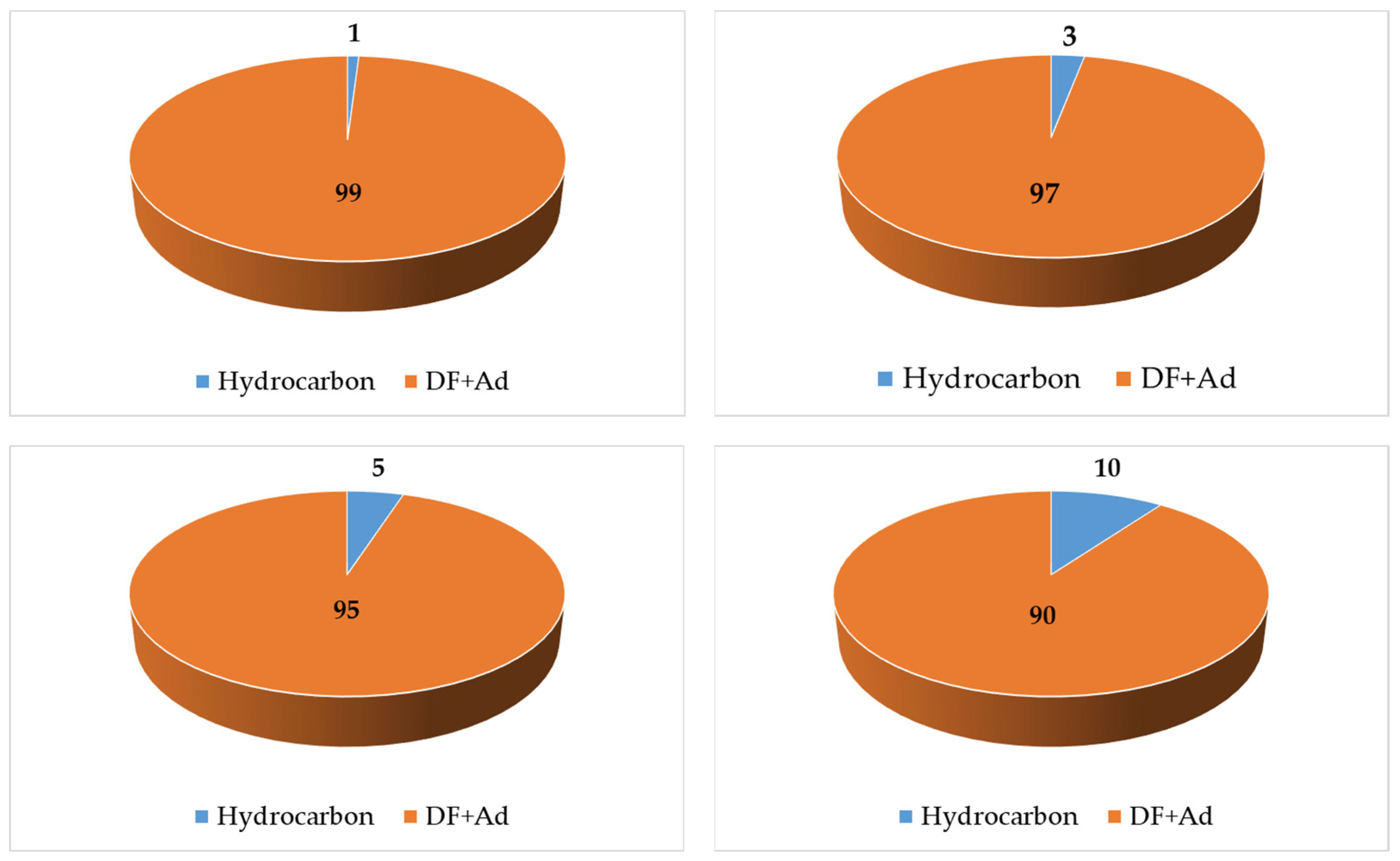

For this research, mixtures of the DF sample and depressant additive with each of the individual hydrocarbons (toluene, tetralin, cetane, heptadecane, geneicosan, docosan) were prepared, the contents of which were 1, 3, 5 and 10% vol. The depressant additive was used in the concentration recommended by the manufacturer (0.6 mL per 100 mL of fuel). The composition of the mixtures is shown in

Figure 2.

To prepare the blend, 100 mL of DF sample was taken using a graduated cylinder. The flask with the test sample was closed with a stopper with a thermometer, so that the thermometer was immersed in the DF and, at the same time, did not touch the bottom and walls of the flask.

Next, the flask was placed in a liquid thermostat and thermostated to a temperature of 25 °C for 30 min, stirring occasionally. Upon reaching the required temperature, a depressant and/or an individual hydrocarbon was introduced into the DF sample.

After that, the blend was stirred for 1 min and placed in a thermostat, thermostatically controlled for 10 min. The resulting blend was left for 1 day in a cold, dark place.

4. Conclusions

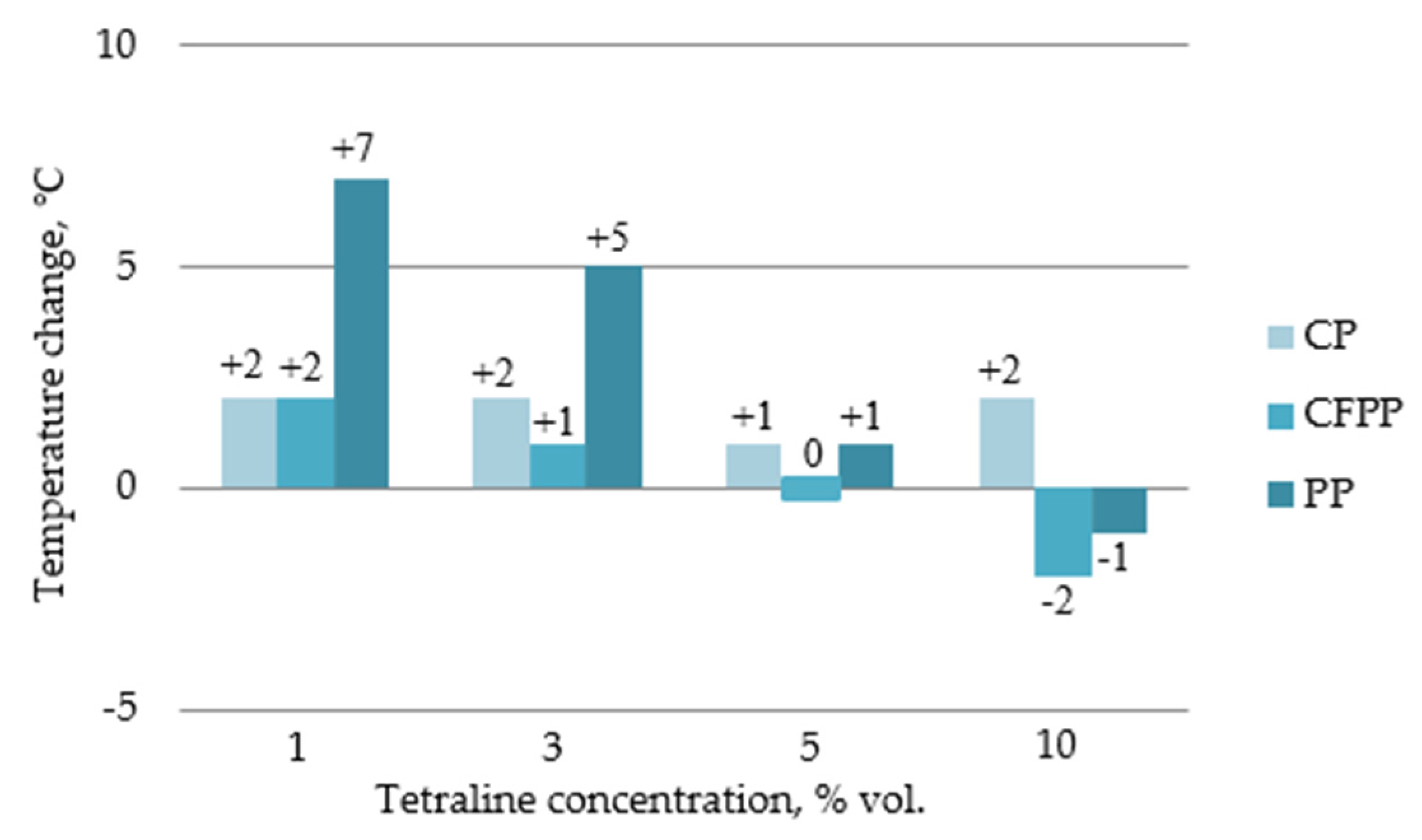

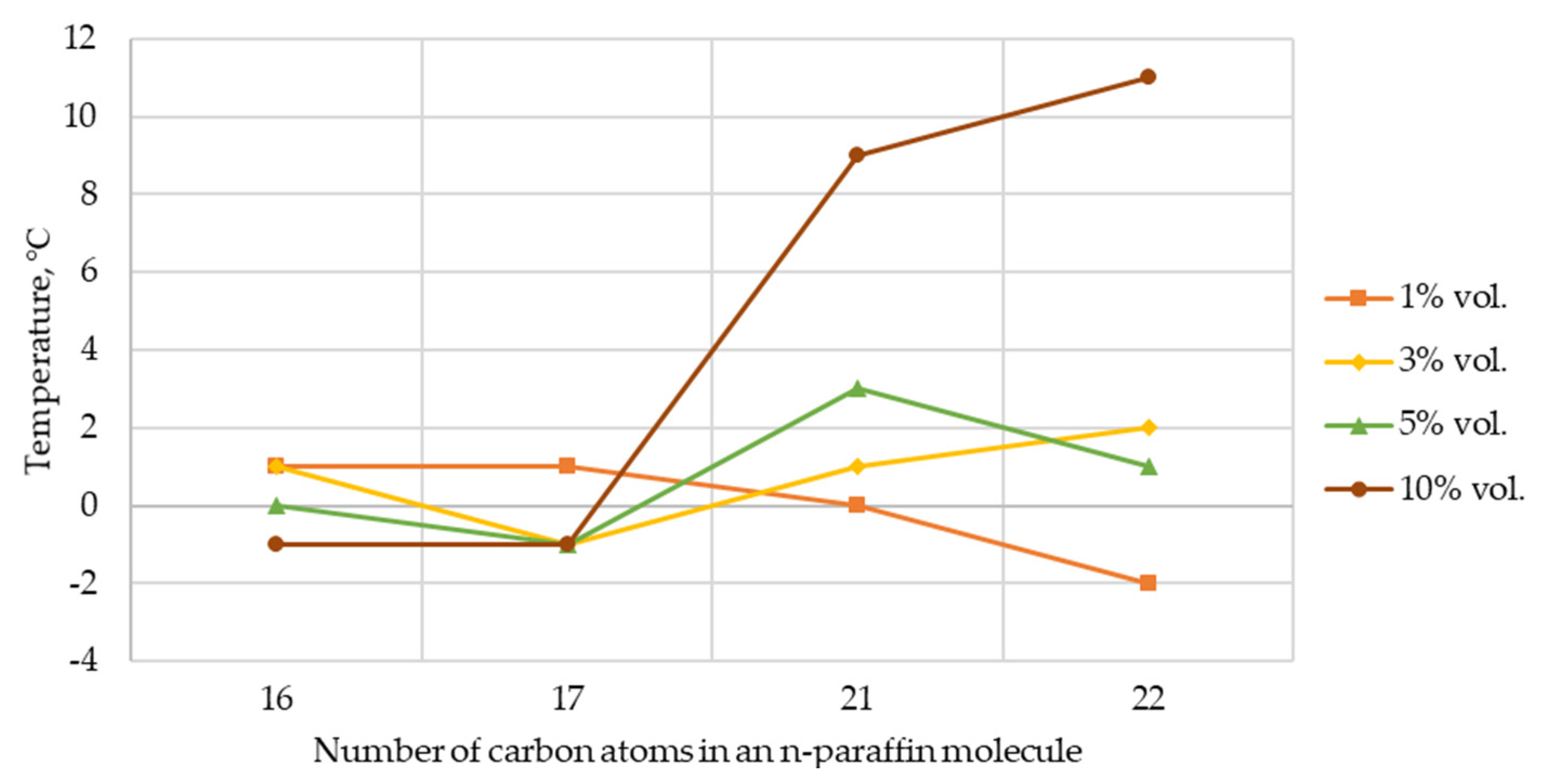

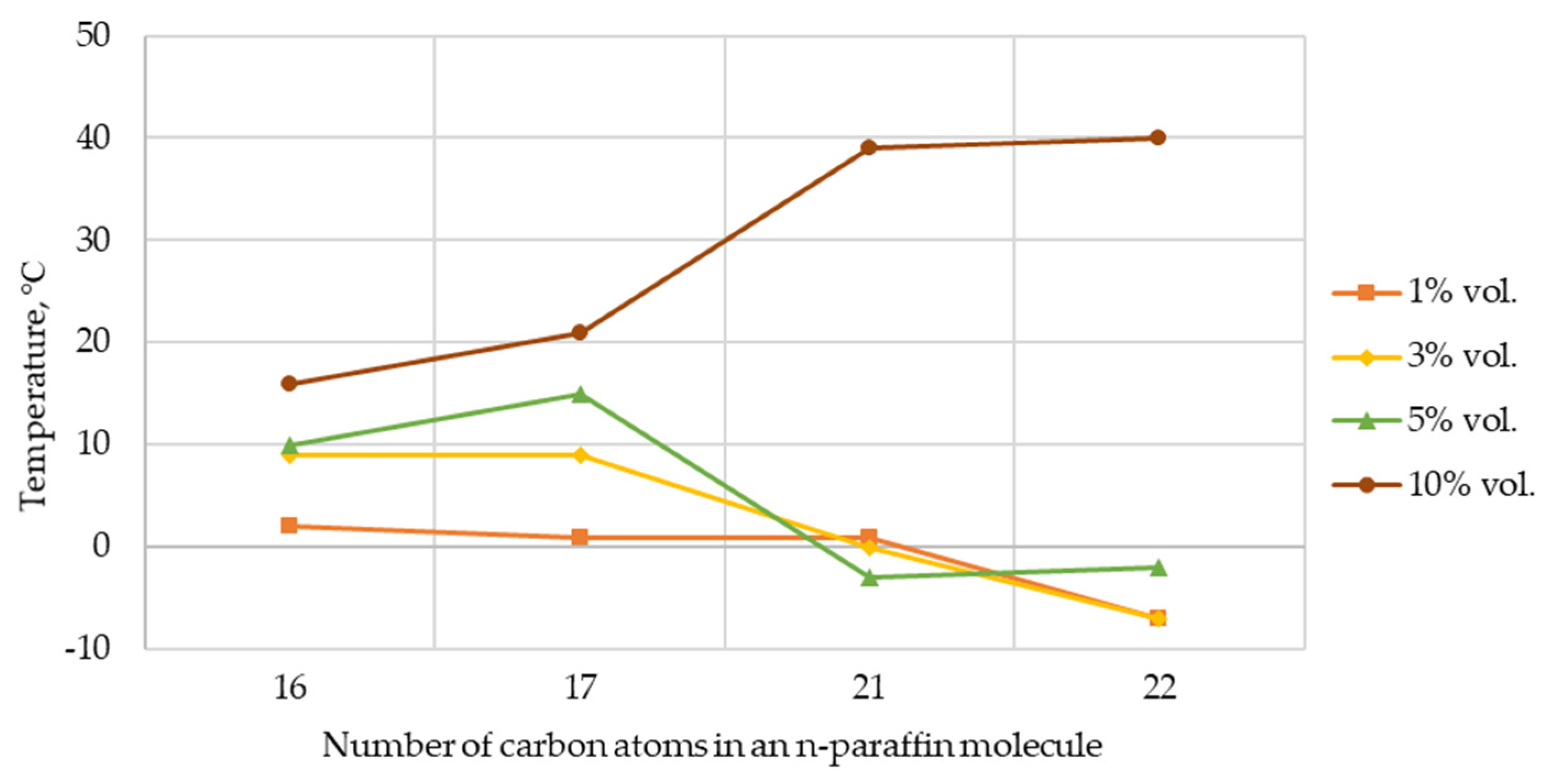

This study found that the efficiency of depressant additives is most negatively affected by the content of the most polar aromatic hydrocarbons (based on the example of tetralin) and light n-paraffins (based on the example of cetane). The most positive effect is caused by the content of small amounts of heavy n-paraffins (for example, heneicosane and docosane).

It has been shown that the addition of toluene reduces the efficiency of the additive in relation to the PP, and the addition of tetralin significantly impairs the additive effectiveness in relation to all the low-temperature properties. It has also been shown that the addition of tetralin has a more pronounced effect on the action of the depressant for all the low-temperature properties than the addition of toluene. In addition, it is shown that the addition to the DF sample/depressant mixtures of 5% vol. of toluene or 5 and 10% vol. of heptadecane or 1 and 3% vol. of heneicosane allows for lowering the CFPP and obtaining a summer brand DF corresponding to the requirements in [

2].

It has been found that for the more effective action of the depressant additive, it is necessary to take into account the content and structure of individual hydrocarbons in the DF composition.

The implementation of this study using individual hydrocarbons as an example made it possible to evaluate the influence of the structure and polarity of hydrocarbons included in DF on the effectiveness of depressant additives, expand the understanding of the mechanism of additives’ action, and verify previously put forward hypotheses.

The revealed quantitative regularities of the influence of the DF composition on the efficiency of depressant additives, especially those that allow for increasing the effect of the additive, will enable the most effective selection of the depressant and its concentration, including obtaining an equal effect with a decrease in the concentration of the additive, which will ultimately reduce the cost of fuel and increase the production volumes of low-freezing DF.