Design of a Novel Magnetic Induction Switch with a Permalloy Film and a Trans-Impedance Amplifier Circuit

Abstract

:1. Introduction

2. Materials and Methods

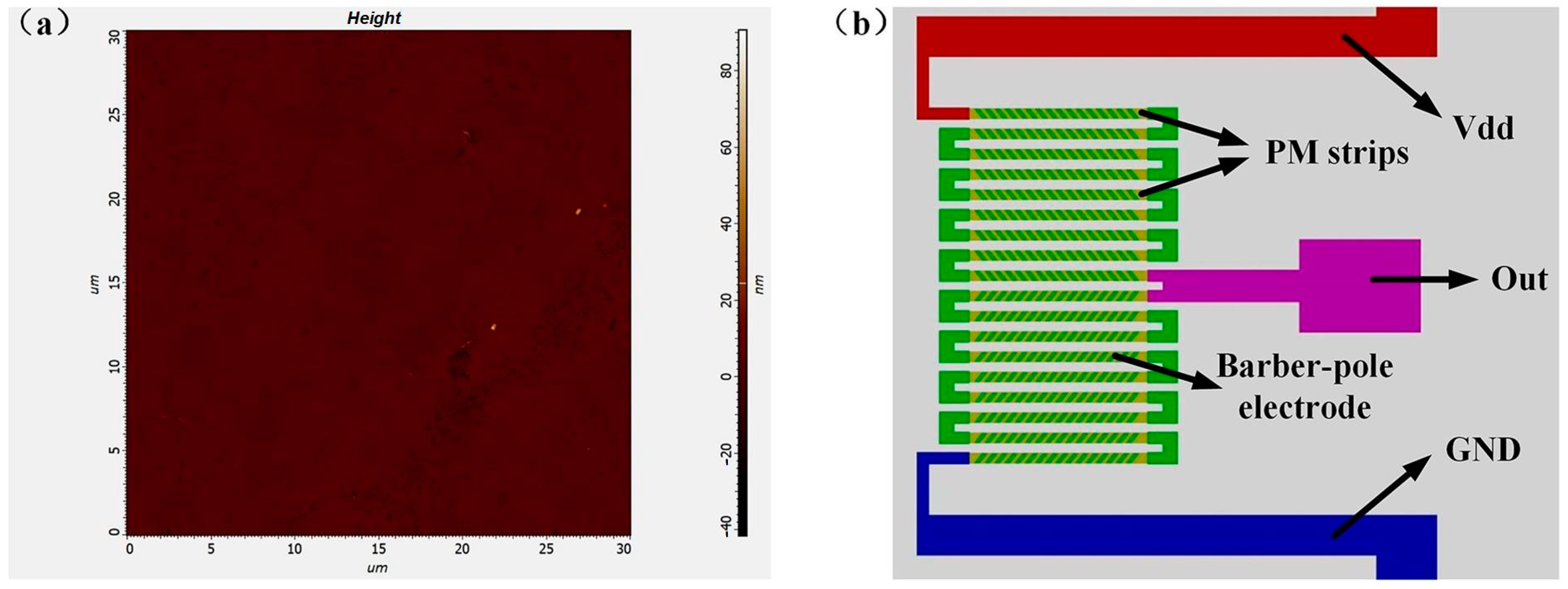

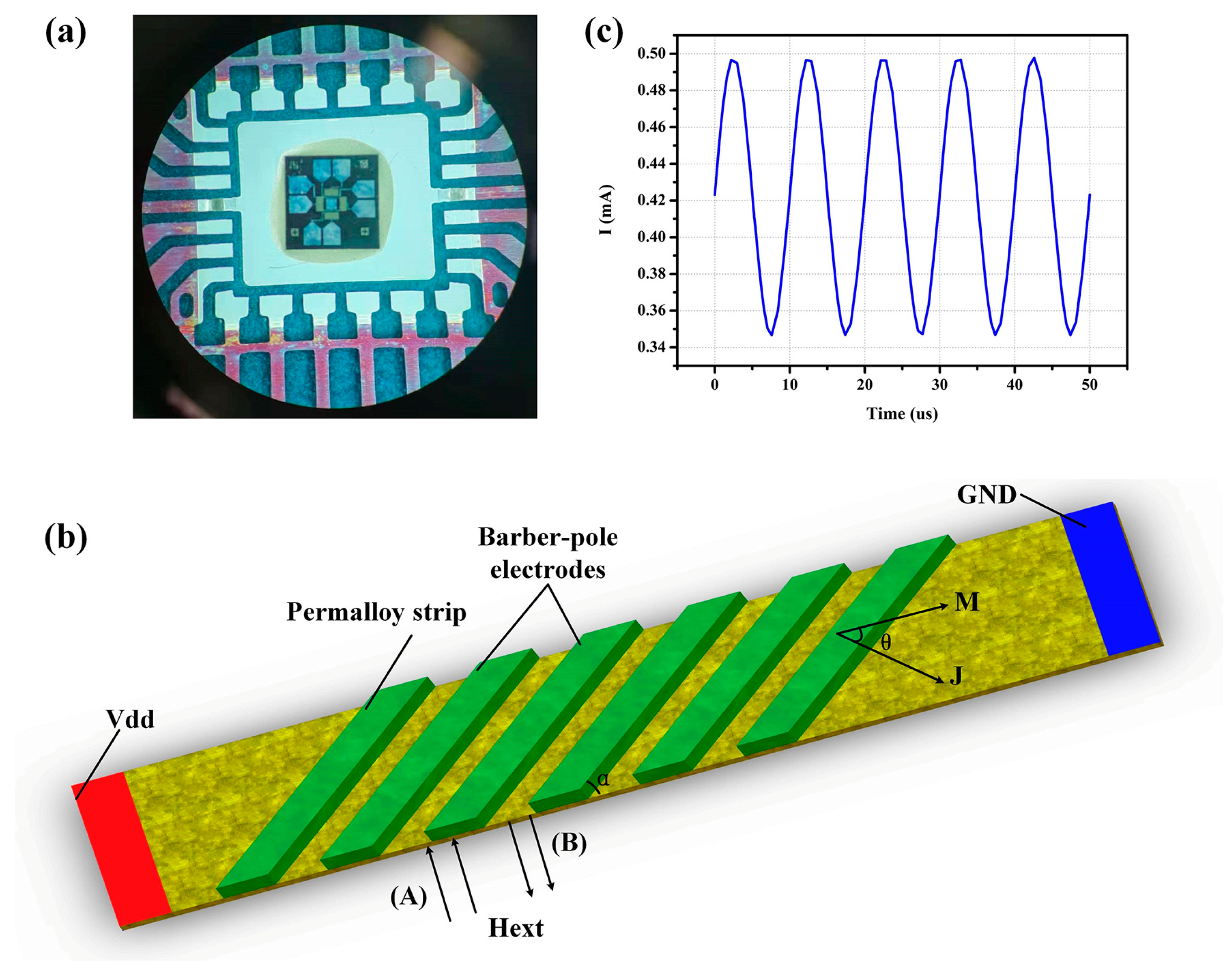

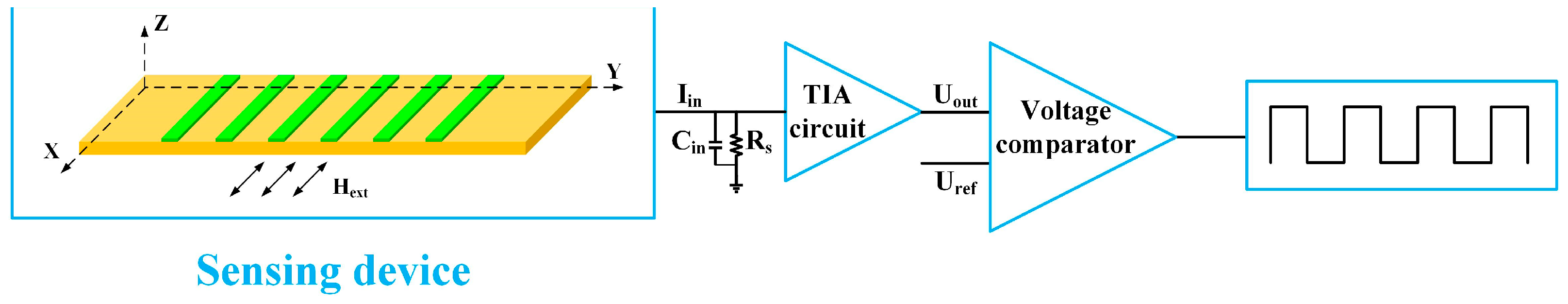

2.1. Sensing Device

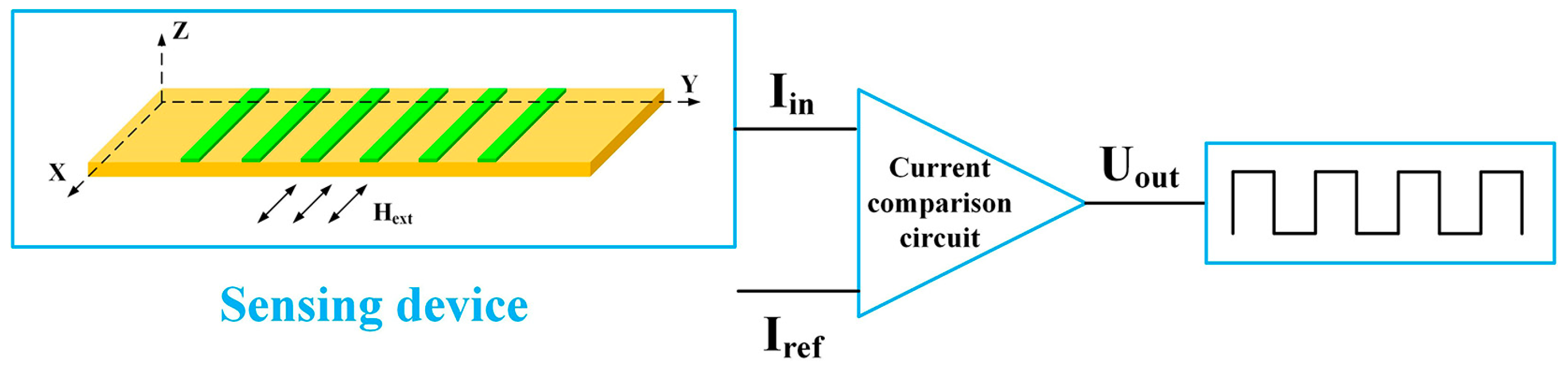

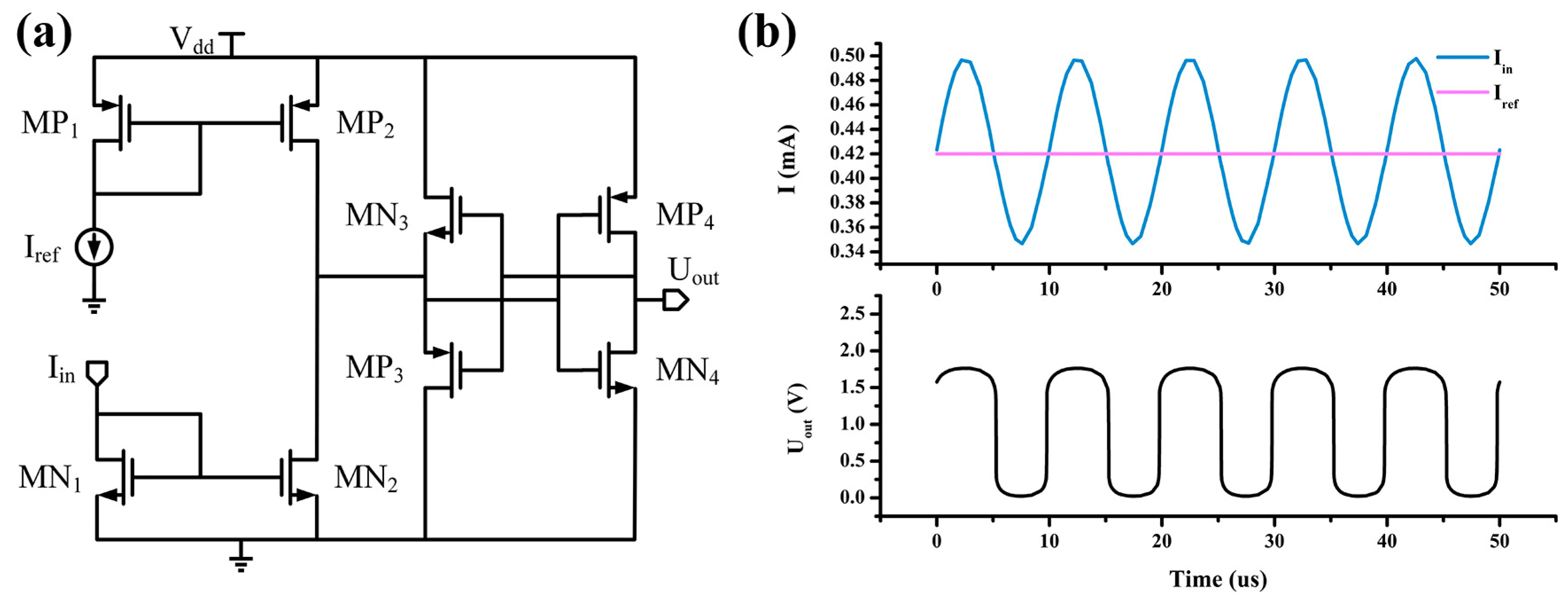

2.2. Current Comparison Circuit

2.3. TIA Circuit

3. Results and Discussions

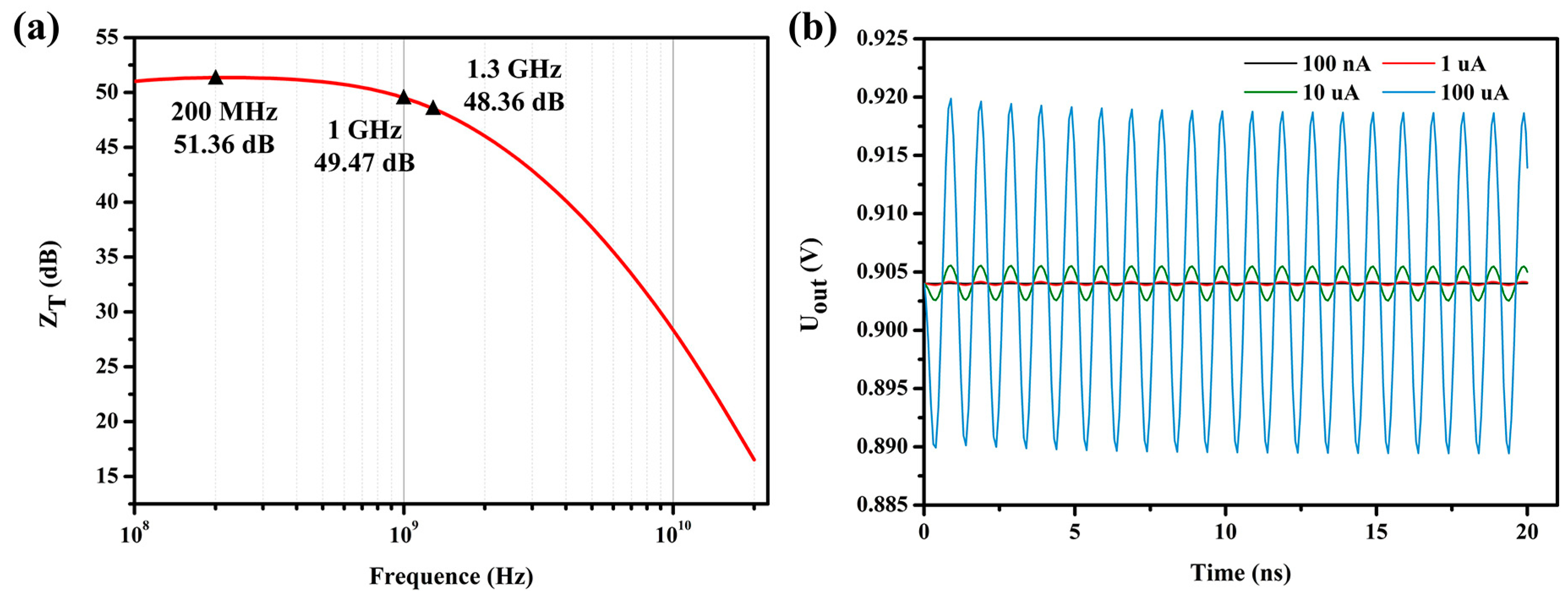

3.1. Circuit Analysis

3.2. Simulation Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mishra, P.K.; Halavath, N.; Bhuktare, S. Strain-mediated voltage controlled magnetic anisotropy based switching for magnetic memory applications. J. Appl. Phys. 2023, 134, 123905. [Google Scholar] [CrossRef]

- Demirci, E. Magnetic and Magnetotransport Properties of Memory Sensors Based on Anisotropic Magnetoresistance. J. Supercond. Nov. Magn. 2020, 33, 3835–3840. [Google Scholar] [CrossRef]

- Liu, S.M.; Li, X.; Wang, Y.Q.; Yang, Y.F.; Meng, L.X.; Cheng, T.H.; Wang, Z.L. Magnetic switch structured triboelectric nanogenerator for continuous and regular harvesting of wind energy. Nano Energy 2021, 83, 105851. [Google Scholar] [CrossRef]

- Komine, T.; Chiba, T. Numerical analysis of voltage-controlled magnetization switching operation in magnetic-topological-insulator-based devices. Appl. Phys. Lett. 2023, 123, 102404. [Google Scholar] [CrossRef]

- Zhang, J.H.; Wang, Z.; Ma, C. A CMOS transimpedance amplifier with broad-band and high gain based on negative Miller capacitance. Integration 2023, 91, 60–66. [Google Scholar] [CrossRef]

- Costanzo, R.; Bowers, S.M. A Current Reuse Regulated Cascode CMOS Transimpedance Amplifier with 11-GHz Bandwidth. IEEE Microw. Wirel. Compon. 2018, 28, 816–818. [Google Scholar] [CrossRef]

- Fina, I.; Fábrega, L.; Martí, X.; Sánchez, F.; Fontcuberta, J. Magnetic switch of polarization in epitaxial orthorhombic YMnO thin films. Appl. Phys. Lett. 2010, 97, 232905. [Google Scholar] [CrossRef]

- Chen, W.Z.; Qian, L.J.; Xiao, G. Deterministic Current Induced Magnetic Switching Without External Field using Giant Spin Hall Effect of β-W. Sci. Rep. 2018, 8, 8144. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Hu, Y.; Wu, Y.F.; Rong, M.Z.; Yi, Q. Investigation of an Active Current Injection DC Circuit Breaker Based on a Magnetic Induction Current Commutation Module. IEEE T Power Deliv. 2018, 33, 1809–1817. [Google Scholar] [CrossRef]

- Wang, T.; Liu, S.; Zhou, Z.X.; Wang, W.Y.; Ren, S.Y.; Liu, B.L.; Gao, Z.X. Dual-responsive amplification strategy for ultrasensitive detection of norovirus in food samples: Combining magnetic relaxation switching and fluorescence assay. Sens. Actuat. B-Chem. 2023, 396, 134573. [Google Scholar] [CrossRef]

- Zhang, X.T.; Huang, H.N. Vehicle Classification Based on Feature Selection with Anisotropic Magnetoresistive Sensor. IEEE Sens. J. 2019, 19, 9976–9982. [Google Scholar] [CrossRef]

- Djuzhev, N.A.; Mazurkin, N.S.; Pozdnyakov, V.S.; Iurov, A.S.; Chinenkov, M.Y. Magnetic-field sensors based on anisotropic magnetoresistive thin-film structures for operation in a wide temperature range. Semicond 2015, 49, 1739–1742. [Google Scholar] [CrossRef]

- Zhang, S.S.L.; Vignale, G.; Zhang, S.F. Anisotropic magnetoresistance driven by surface spin-orbit scattering. Phys. Rev. B 2015, 92, 024412. [Google Scholar] [CrossRef]

- Volmer, M.; Neamtu, J. Magnetic field sensors based on Permalloy multilayers and nanogranular films. J. Magn. Magn. Mater. 2007, 316, E265–E268. [Google Scholar] [CrossRef]

- Belyaev, B.A.; Boev, N.M.; Izotov, A.V.; Skomorokhov, G.V.; Solovev, P.N. Magnetic Properties of Permalloy Thin Film Edges. Russ. Phys. J. 2020, 63, 16–22. [Google Scholar] [CrossRef]

- Wang, C.Y.; Su, W.; Hu, Z.Q.; Pu, J.T.; Guan, M.M.; Peng, B.; Li, L.; Ren, W.; Zhou, Z.Y.; Jiang, Z.D.; et al. Highly Sensitive Magnetic Sensor Based on Anisotropic Magnetoresistance Effect. IEEE Trans. Magn. 2018, 54, 2301103. [Google Scholar] [CrossRef]

- Ueki, R.; Okada, T.; Masuzawa, M.; Tsuchiya, K.; Kawamoto, T.; Utnemori, K.; Kako, E.; Konomi, T.; Sakai, H. Study on Magneto-Resistance Sensors for Low Magnetic Field Measurements. IEEE Trans. Appl. Supercond. 2020, 30, 9001204. [Google Scholar] [CrossRef]

- Romanova, A.; Barzdenas, V. On Noise Modeling of Capacitive Feedback Transimpedance Amplifiers in CMOS. Appl. Sci. 2022, 12, 10186. [Google Scholar] [CrossRef]

- Perelló-Roig, R.; Verd, J.; Bota, S.; Segura, J. A Tunable-Gain Transimpedance Amplifier for CMOS-MEMS Resonators Characterization. Micromachines 2021, 12, 82. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Jiang, Q.; Jiang, Y. Design of a Novel Magnetic Induction Switch with a Permalloy Film and a Trans-Impedance Amplifier Circuit. Inventions 2024, 9, 4. https://doi.org/10.3390/inventions9010004

Zhang S, Jiang Q, Jiang Y. Design of a Novel Magnetic Induction Switch with a Permalloy Film and a Trans-Impedance Amplifier Circuit. Inventions. 2024; 9(1):4. https://doi.org/10.3390/inventions9010004

Chicago/Turabian StyleZhang, Shubin, Qi Jiang, and Yanfeng Jiang. 2024. "Design of a Novel Magnetic Induction Switch with a Permalloy Film and a Trans-Impedance Amplifier Circuit" Inventions 9, no. 1: 4. https://doi.org/10.3390/inventions9010004

APA StyleZhang, S., Jiang, Q., & Jiang, Y. (2024). Design of a Novel Magnetic Induction Switch with a Permalloy Film and a Trans-Impedance Amplifier Circuit. Inventions, 9(1), 4. https://doi.org/10.3390/inventions9010004