Gait Cycle Monitoring System Based on Flexiforce Sensors

Abstract

1. Introduction

2. Materials and Methods

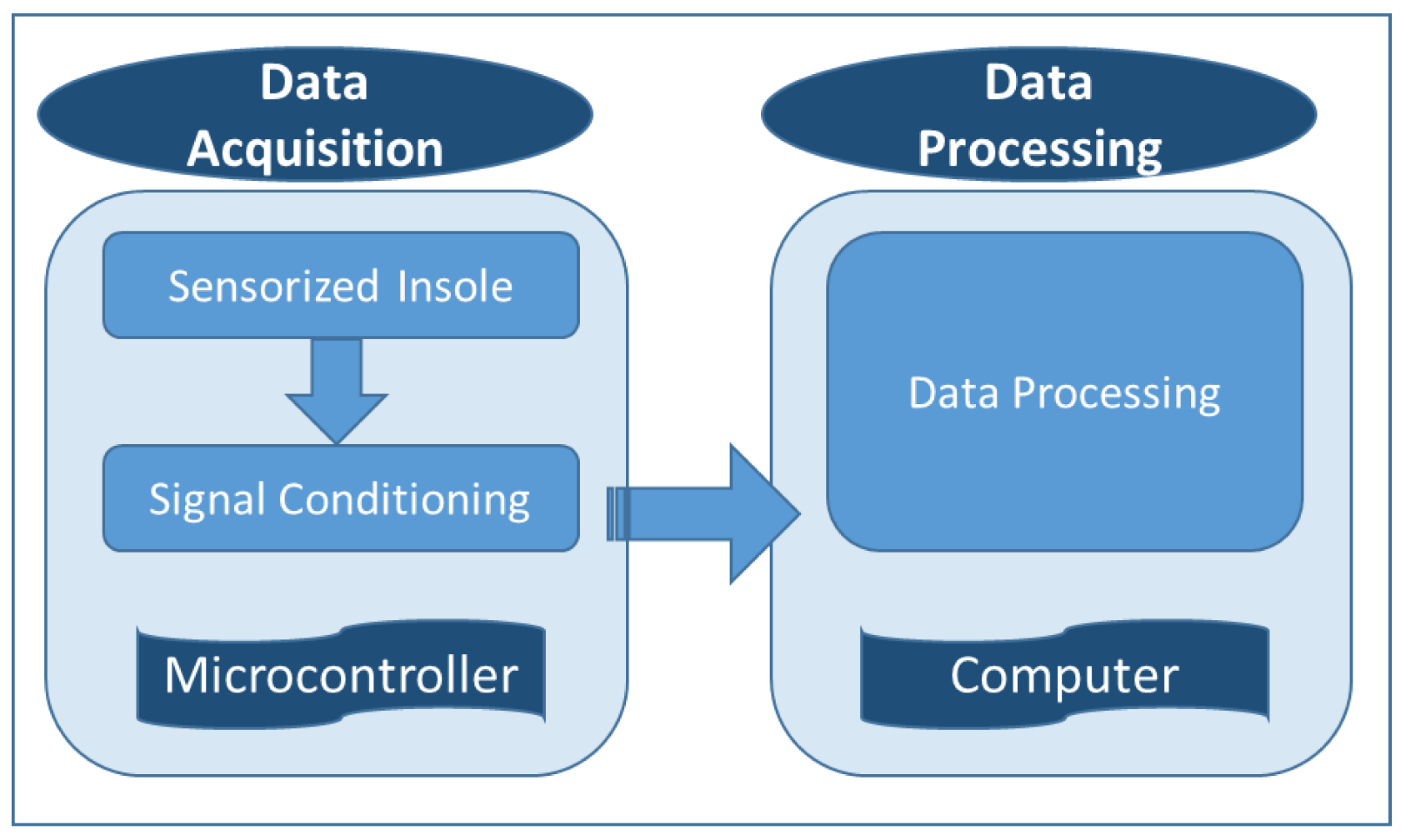

2.1. System Overview

2.2. Data Acquisition

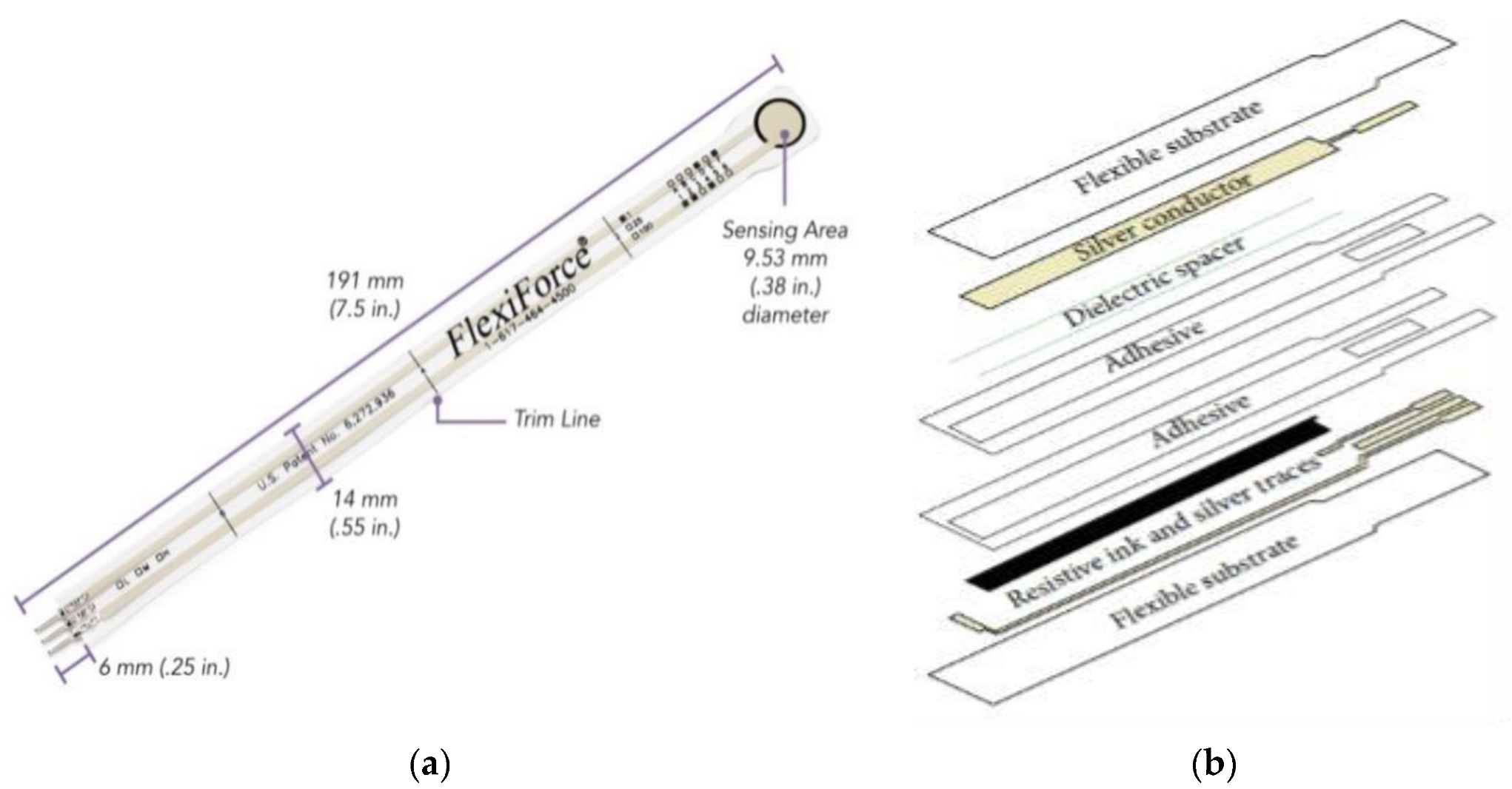

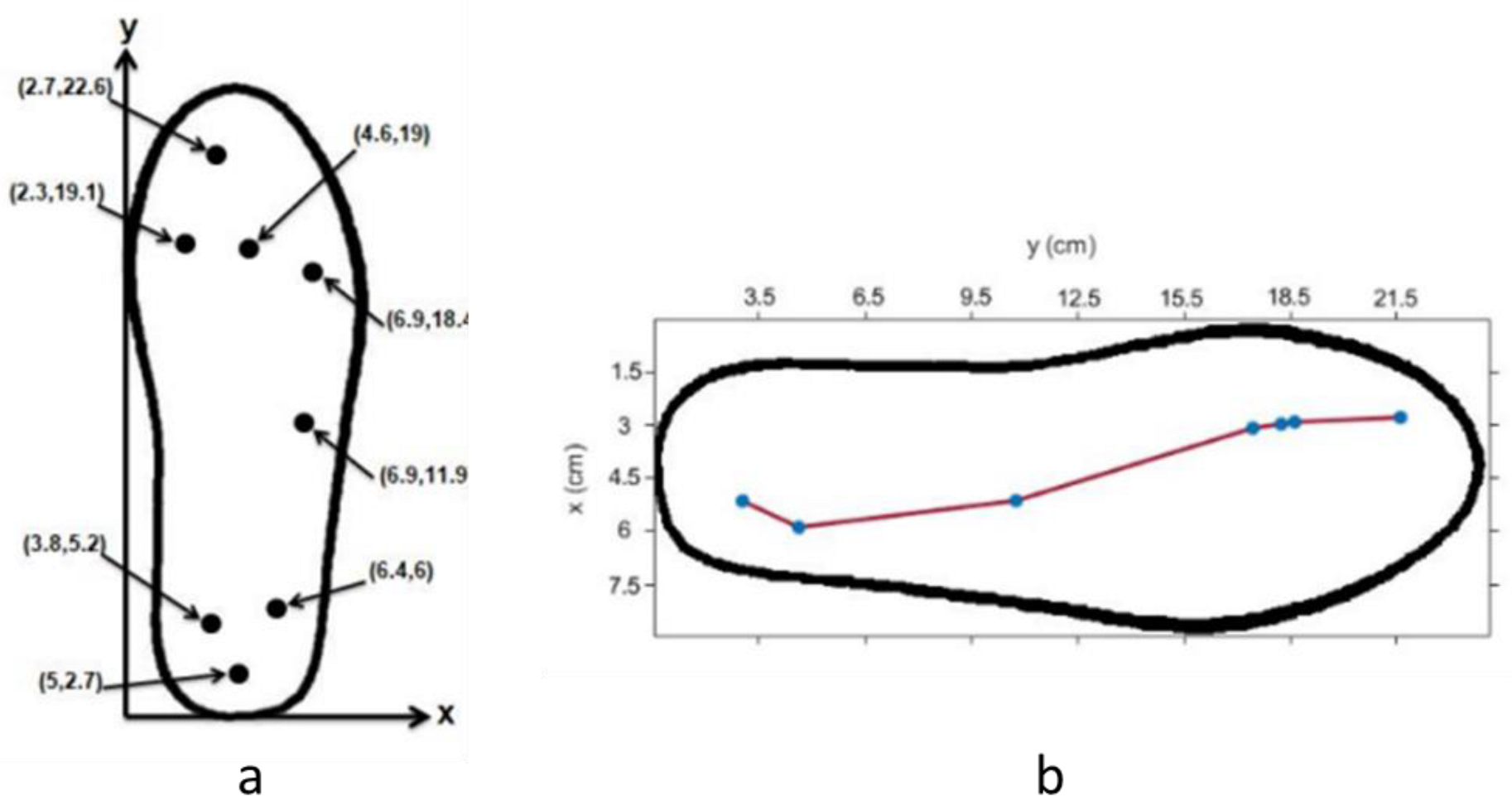

2.2.1. Sensorized Insole

- The sensitivity range of the applied force had to be suitable. During normal walking activity for most people, the plantars’ maximum bearing force would be around 100 kg and the contact area would be 2 cm × 1 cm [15]. The maximum bearing force should be greater while conducting heavy exercises or working with high-heeled shoes.

- The selected sensor should be small in size, flexible and have very small thickness, to ensure the comfort of the insole wearer.

- Finally, the sensor should be able to withstand high temperatures and humidity due to its location inside the shoe.

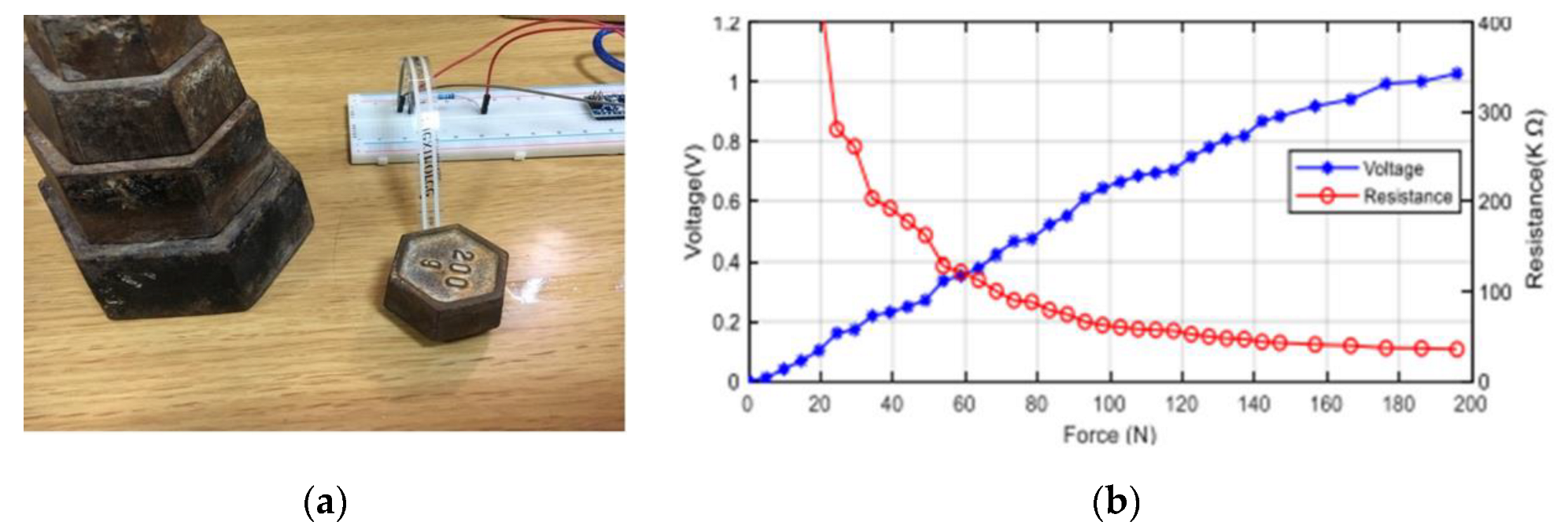

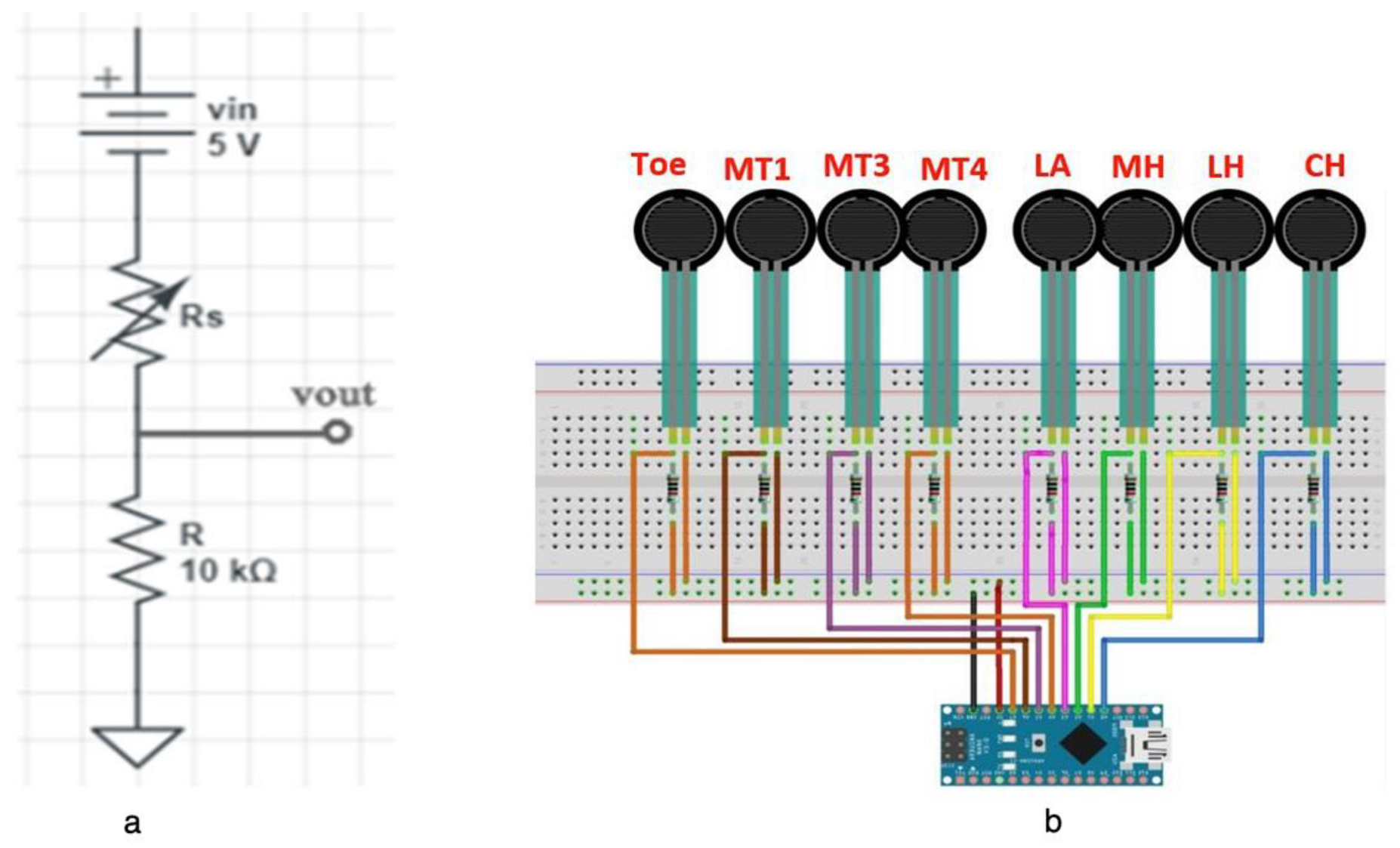

2.2.2. Signal Conditioning

2.3. Data Processing

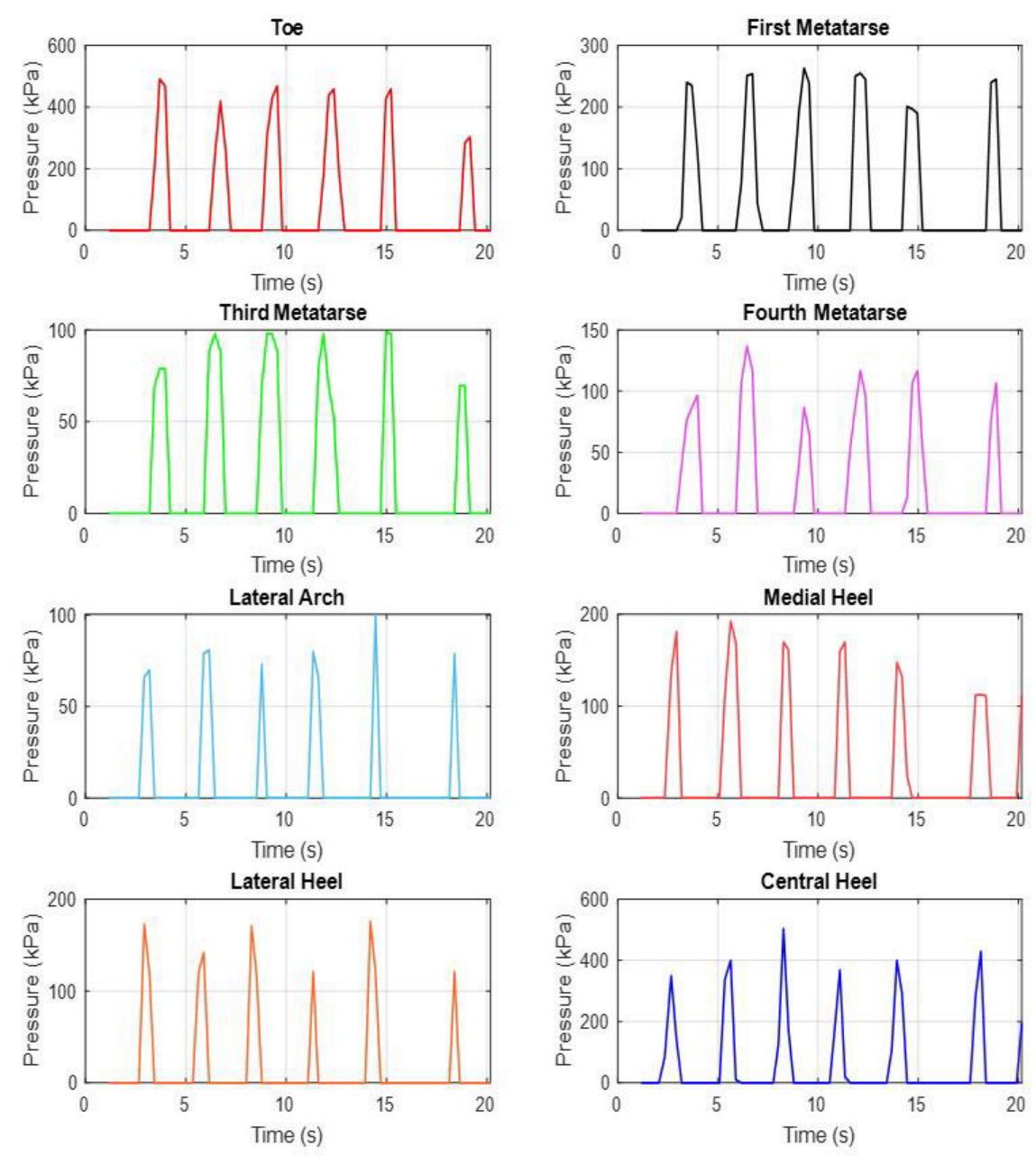

3. Results

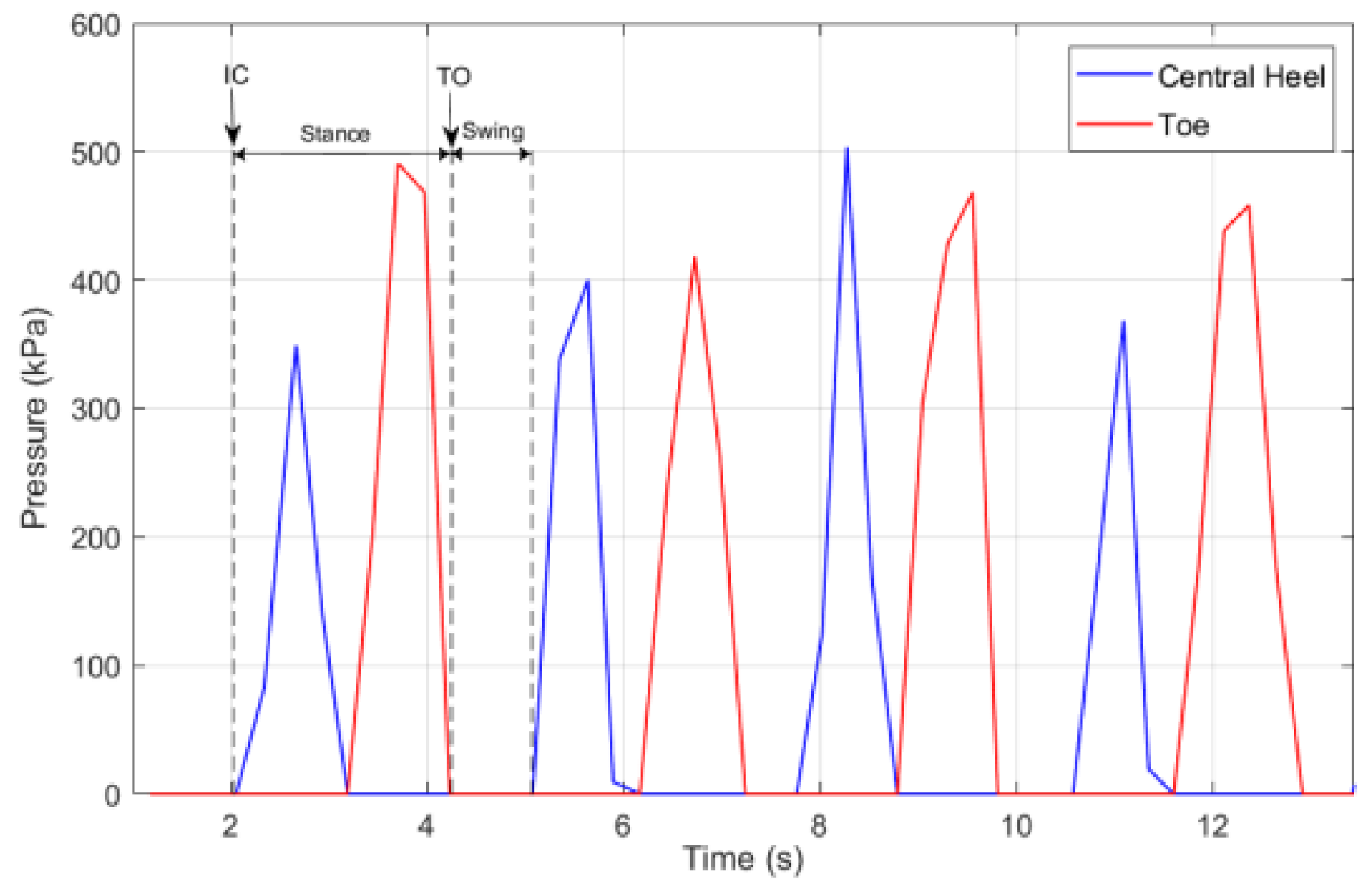

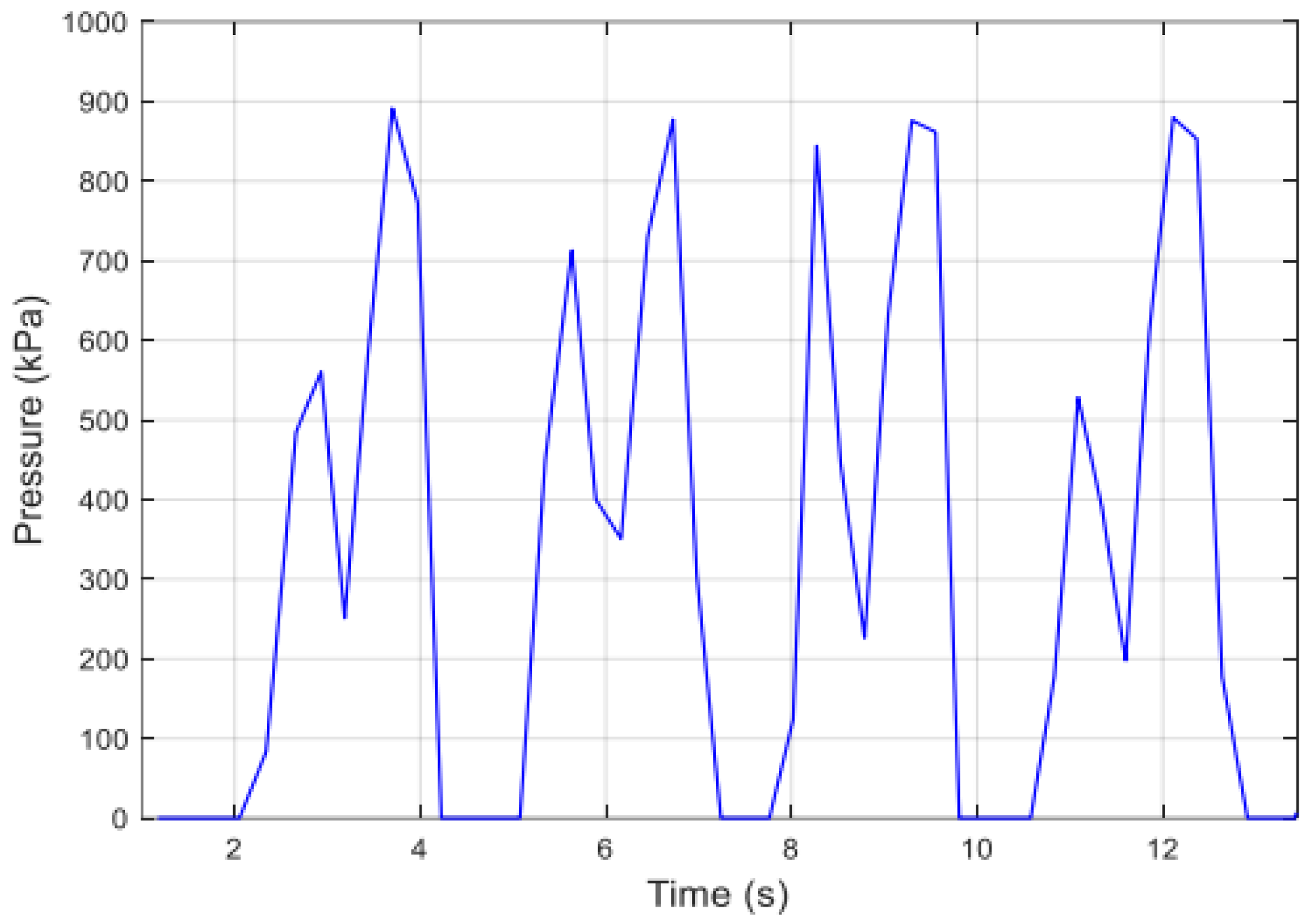

3.1. Gait Analysis Parameter Calculation

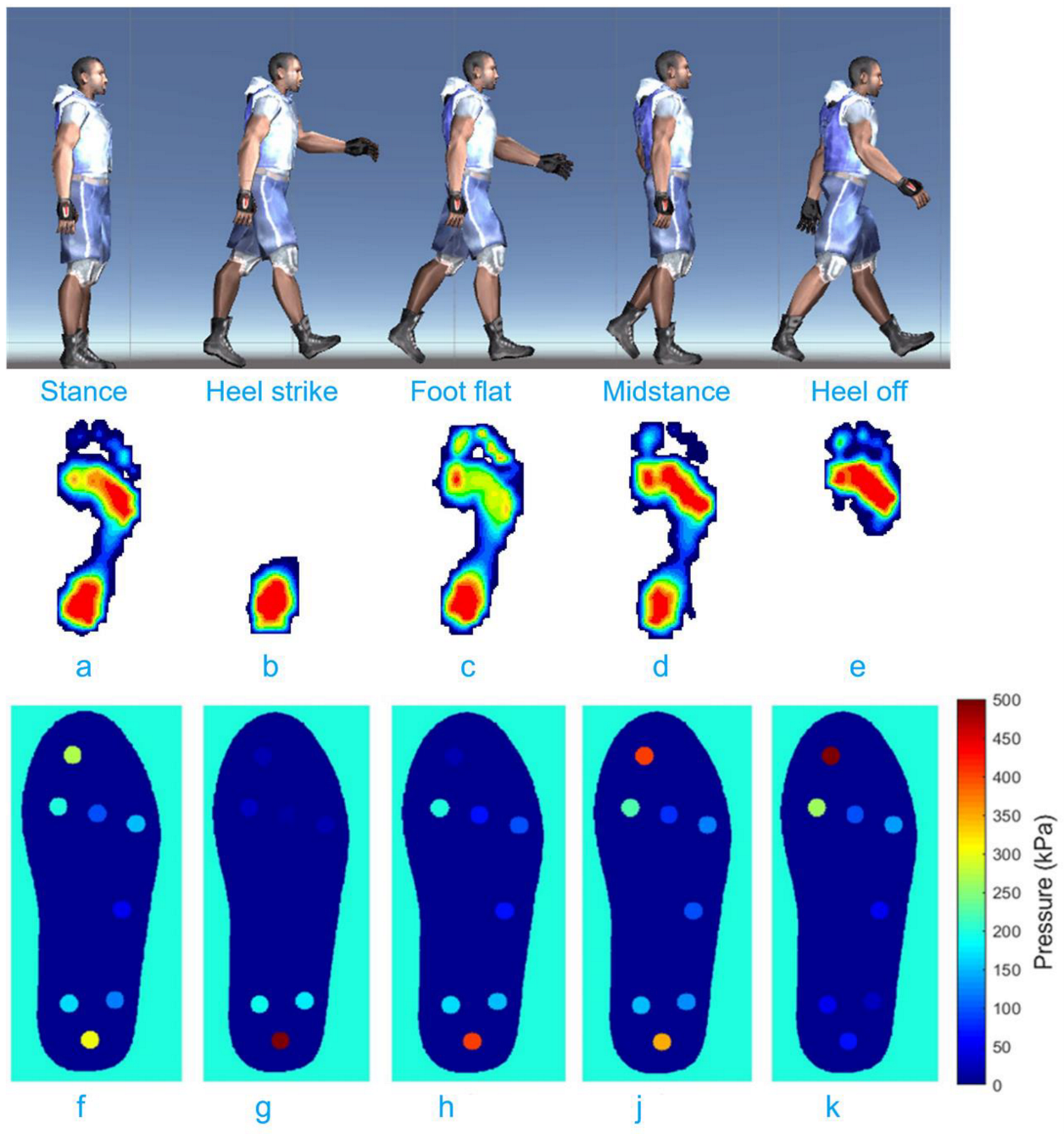

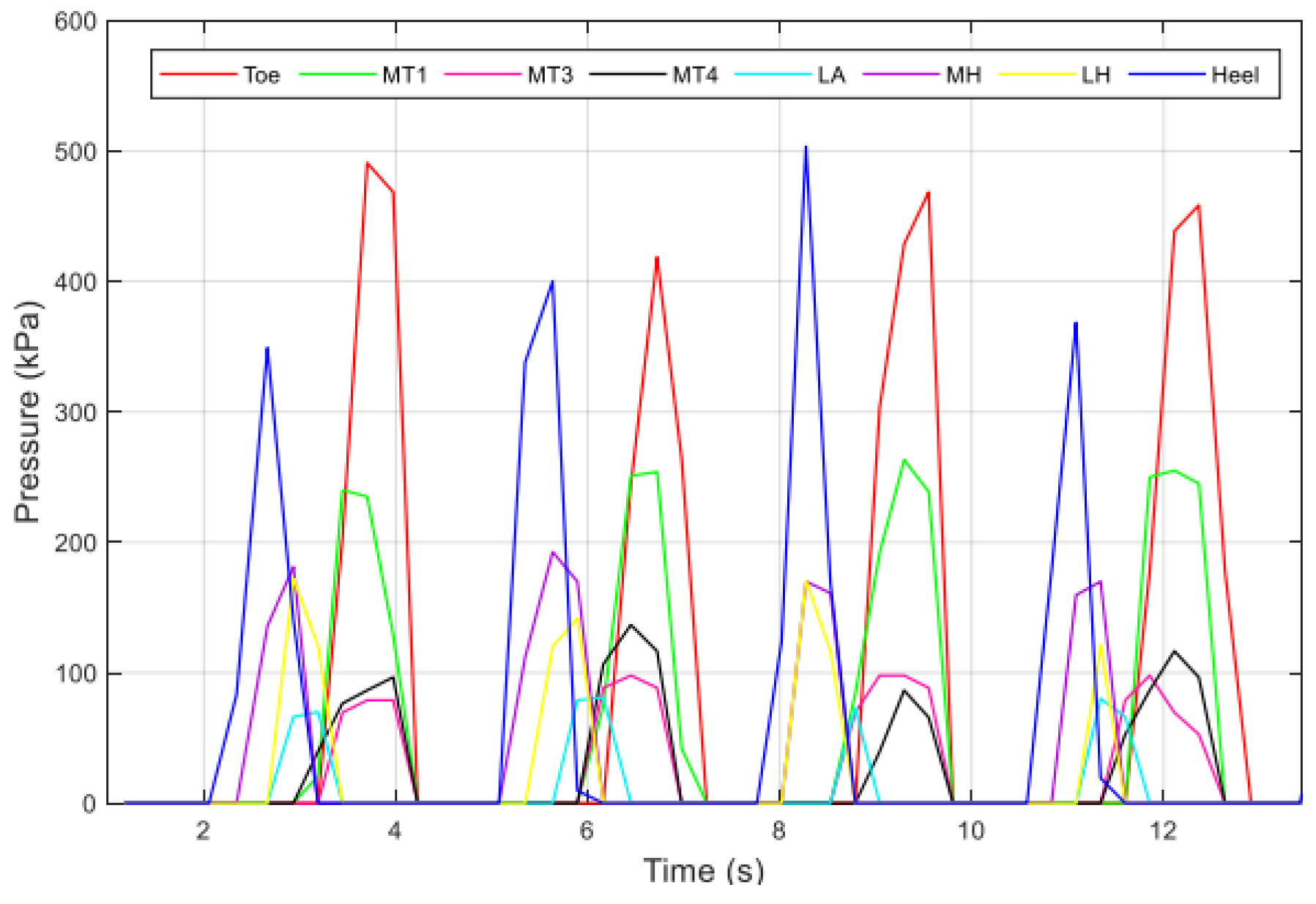

3.2. The Plantar Pressure Distribution Pattern

3.3. COP Trajectory Calculation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, H.-T.; Zhang, X.-R.; Wang, Z.-Y.; Wen, D.-L.; Ba, Y.-Y.; Kim, B.; Han, M.-D.; Zhang, H.-X.; Zhang, X.-S. Super-Stretchable Multi-Sensing Triboelectric Nanogenerator Based on Liquid Conductive Composite. Nano Energy 2021, 83, 105823. [Google Scholar] [CrossRef]

- Ba, Y.-Y.; Bao, J.-F.; Wang, Z.-Y.; Deng, H.-T.; Wen, D.-L.; Zhang, X.-R.; Tu, C.; Zhang, X.-S. Self-Powered Trajectory-Tracking Microsystem Based on Electrode-Miniaturized Triboelectric Nanogenerator. Nano Energy 2021, 82, 105730. [Google Scholar] [CrossRef]

- Liu, Y.; Khanbareh, H.; Halim, M.A.; Feeney, A.; Zhang, X.; Heidari, H.; Ghannam, R. Piezoelectric Energy Harvesting for Self-Powered Wearable Upper Limb Applications. Nano Sel. 2021, 2, 1459–1479. [Google Scholar] [CrossRef]

- Wen, D.-L.; Sun, D.-H.; Huang, P.; Huang, W.; Su, M.; Wang, Y.; Han, M.-D.; Kim, B.; Brugger, J.; Zhang, H.-X.; et al. Recent Progress in Silk Fibroin-Based Flexible Electronics. Microsyst. Nanoeng. 2021, 7, 35. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Li, H.; Xiao, J.; Song, H.; Li, B.; Cai, S.; Chen, Y.; Ma, Y.; Feng, X. Ultralow-Cost, Highly Sensitive, and Flexible Pressure Sensors Based on Carbon Black and Airlaid Paper for Wearable Electronics. ACS Appl. Mater. Interfaces 2019, 11, 33370–33379. [Google Scholar] [CrossRef] [PubMed]

- Wen, D.-L.; Deng, H.-T.; Liu, X.; Li, G.-K.; Zhang, X.-R.; Zhang, X.-S. Wearable Multi-Sensing Double-Chain Thermoelectric Generator. Microsyst. Nanoeng. 2020, 6, 68. [Google Scholar] [CrossRef] [PubMed]

- Albensi, R.J.; Nyland, J.; Caborn, D.N. The Relationship of Body Weight and Clinical Foot and Ankle Measurements to the Heel Forces of Forward and Backward Walking. J. Athl. Train. 1999, 34, 328–333. [Google Scholar] [PubMed]

- Hausdorff, J.M.; Ladin, Z.; Wei, J.Y. Footswitch System for Measurement of the Temporal Parameters of Gait. J. Biomech. 1995, 28, 347–351. [Google Scholar] [CrossRef]

- Lawrence, T.L.; Schmidt, R.N. Wireless In-Shoe Force System [for Motor Prosthesis]. In Proceedings of the 19th Annual International Conference of the IEEE Engineering in Medicine and Biology Society. “Magnificent Milestones and Emerging Opportunities in Medical Engineering” (Cat. No.97CH36136), Chicago, IL, USA, 30 October–2 November 1997; IEEE: Piscataway, NJ, USA, 2002; Volume 5, pp. 2238–2241. [Google Scholar]

- Shu, L.; Hua, T.; Wang, Y.; Li, Q.; Feng, D.D.; Tao, X. In-Shoe Plantar Pressure Measurement and Analysis System Based on Fabric Pressure Sensing Array. IEEE Trans. Inf. Technol. Biomed. 2010, 14, 767–775. [Google Scholar] [CrossRef] [PubMed]

- Imaizumi, K.; Iwakami, Y.; Yamashita, K. Analysis of Foot Pressure Distribution Data for the Evaluation of Foot Arch Type. In Proceedings of the 2011 Annual International Conference of the IEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; Volume 2011, pp. 7388–7392. [Google Scholar] [CrossRef]

- Meier, R.; Kelly, N.; Almog, O.; Chiang, P. A Piezoelectric Energy-Harvesting Shoe System for Podiatric Sensing. In Proceedings of the 2014 36th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Chicago, IL, USA, 26–30 August 2014; Volume 2014, pp. 622–625. [Google Scholar] [CrossRef]

- Malvade, P.S.; Joshi, A.K.; Madhe, S.P. IoT Based Monitoring of Foot Pressure Using FSR Sensor. In Proceedings of the 2017 International Conference on Communication and Signal Processing (ICCSP), Melmaruvathur, India, 6–8 April 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 0635–0639. [Google Scholar]

- Bencheikh, M.A.; Boukhenous, S. A Low Cost Smart Insole for Diabetic Foot Prevention. In Proceedings of the 2018 International Conference on Applied Smart Systems (ICASS), Médéa, Algeria, 24–25 November 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar]

- Qihang, W.; Wenlian, L.; Zuyun, F. A new system for foot pressure measurement and gait analysis. Chin. J. Biomed. Eng. 2000, 19, 32–40. [Google Scholar]

- FlexiForce A201 Sensor. Tekscan. Available online: https://www.tekscan.com/products-solutions/force-sensors/a201 (accessed on 12 June 2022).

- Almassri, A.M.; Wan Hasan, W.Z.; Ahmad, S.A.; Ishak, A.J.; Ghazali, A.M.; Talib, D.N.; Wada, C. Pressure Sensor: State of the Art, Design, and Application for Robotic Hand. J. Sens. 2015, 2015, 846487. [Google Scholar] [CrossRef]

- Tiberio, D. Pathomechanics of Structural Foot Deformities. Phys. Ther. 1988, 68, 1840–1849. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Arduino Nano. Arduino Online Shop. Available online: https://store-usa.arduino.cc/products/arduino-nano?selectedStore=us (accessed on 12 June 2022).

- Lou, C.; Wang, S.; Liang, T.; Pang, C.; Huang, L.; Run, M.; Liu, X. A Graphene-Based Flexible Pressure Sensor with Applications to Plantar Pressure Measurement and Gait Analysis. Materials 2017, 10, 1068. [Google Scholar] [CrossRef] [PubMed]

- Van Deursen, R. Mechanical Loading and Off-Loading of the Plantar Surface of the Diabetic Foot. Clin. Infect. Dis. 2004, 39 (Suppl. 2), S87–S91. [Google Scholar] [CrossRef] [PubMed]

- Razak, A.H.A.; Zayegh, A.; Begg, R.K.; Wahab, Y. Foot Plantar Pressure Measurement System: A Review. Sensors 2012, 12, 9884–9912. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Mashagbeh, M.; Alzaben, H.; Abutair, R.; Farrag, R.; Sarhan, L.; Alyaman, M. Gait Cycle Monitoring System Based on Flexiforce Sensors. Inventions 2022, 7, 51. https://doi.org/10.3390/inventions7030051

Al Mashagbeh M, Alzaben H, Abutair R, Farrag R, Sarhan L, Alyaman M. Gait Cycle Monitoring System Based on Flexiforce Sensors. Inventions. 2022; 7(3):51. https://doi.org/10.3390/inventions7030051

Chicago/Turabian StyleAl Mashagbeh, Mohammad, Heba Alzaben, Raheeq Abutair, Reem Farrag, Leena Sarhan, and Musa Alyaman. 2022. "Gait Cycle Monitoring System Based on Flexiforce Sensors" Inventions 7, no. 3: 51. https://doi.org/10.3390/inventions7030051

APA StyleAl Mashagbeh, M., Alzaben, H., Abutair, R., Farrag, R., Sarhan, L., & Alyaman, M. (2022). Gait Cycle Monitoring System Based on Flexiforce Sensors. Inventions, 7(3), 51. https://doi.org/10.3390/inventions7030051