Development of an Approach for Determining the Effectiveness of Inhibition of Paraffin Deposition on the Wax Flow Loop Laboratory Installation

Abstract

:1. Introduction

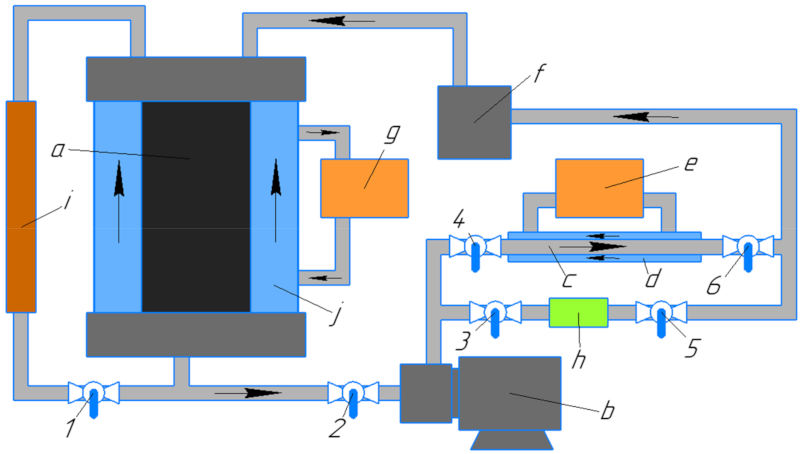

2. Materials and Methods

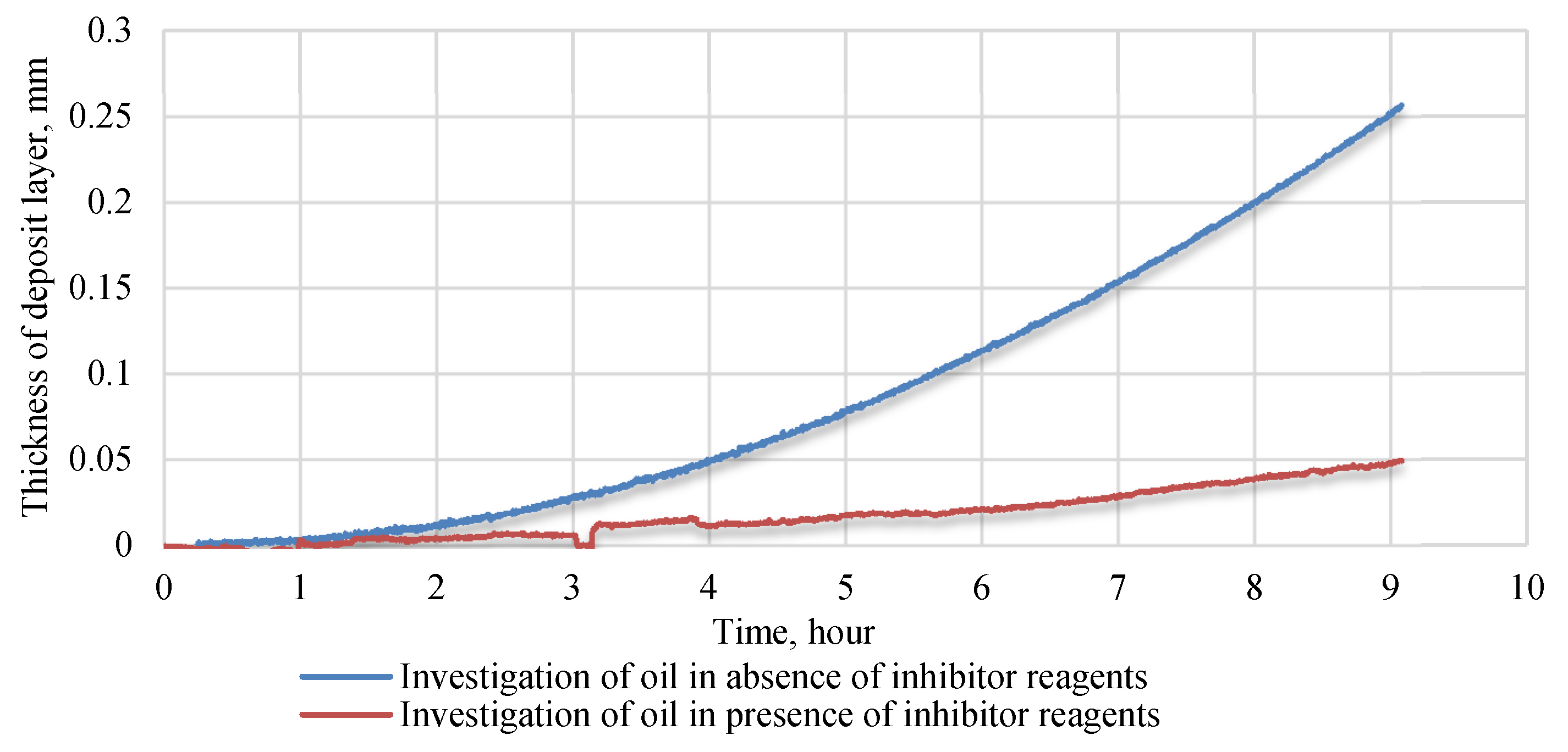

3. Results

4. Discussion

5. Conclusions

- The formation of wax deposits is a complex process that has a significant impact on the operation of an oil production well. One of the most common methods of preventing their formation is the use of inhibitor reagents.

- Evaluation of the effectiveness of the use of these reagents is carried out in laboratory conditions, and the most common method is the “Cold Finger”. This method has a low accuracy, high error, and does not allow reproduction of the field conditions of wax formation. These disadvantages lead to an incorrect carbon number distribution of deposits and create additional errors in determining the effectiveness of inhibitor of wax deposits. The work proposes three methods for assessing the effectiveness of inhibitor reagents using the “WaxFlowLoop” installation.

- In the course of laboratory studies, the method of integrating the paraffin formation curve was found. Comparison of laboratory research results with field data was carried out. The average deviation of the efficiency of wax inhibitors, determined using the «WaxFlowLoop» installation, is only 8.1%, and, for the values obtained on the «Cold Finger» installation, 200%.

- The developed methods for determining the effectiveness of wax inhibitors make it possible to determine this value under conditions of paraffin formation, taking into account the entire volume of data obtained during laboratory research.

- These results confirm the high accuracy of the developed methods and their significant superiority in comparison with the well-known «Cold Finger» method. The data obtained can be used for a more correct selection of the brand of inhibitor reagents, their dosage, and, as a consequence, can increase the efficiency of the production well stock.

Author Contributions

Funding

Conflicts of Interest

References

- Ashmyan, K.D.; Kovaleva, O.V.; Nikitina, I.N. Methodology for assessing the phase state of paraffins in reservoir oils. Vestn. Tskr. Rosnedra 2011, 6, 11–14. [Google Scholar]

- Zlobin, A.A.; Yushkov, I.R. On the question of the mechanism of action of inhibitors to protect against asphalt-resin-paraffin deposits (ARPD). Perm Univ. Bull. Geol. 2011, 3, 78–83. [Google Scholar]

- Towler, B.; Jaripatke, O.; Mokhatab, S. Experimental Investigations of the Mitigation of Paraffin Wax Deposition in Crude Oil Using Chemical Additives. Pet. Sci. Technol. 2011, 29, 468–483. [Google Scholar] [CrossRef]

- Krivoshchekov, S.N.; Vyatkin, K.A.; Kochnev, A.A.; Kozlov, A.V. An approach to estimating the rate of organic deposit formation in a hollow rod string and selection of methods for deposit prevention. Periodico. Tche. Quimica 2021, 18, 164–178. [Google Scholar] [CrossRef]

- Lei, Y.; Han, S.; Zhang, J. Effect of the dispersion degree of asphaltene on wax deposition in crude oil under static conditions. Fuel Process. Technol. 2016, 146, 20–28. [Google Scholar] [CrossRef]

- Safiulina, A.G.; Ibragimova, D.A.; Baibekova, L.R.; Soldatova, R.R.; Petrov, S.M.; Bashkirtseva, N.Y. Modeling of Paraffin Wax Deposition Process in Poorly Extractable Hydrocarbon Stock. Chem. Technol. Fuels Oils 2018, 53, 897–904. [Google Scholar] [CrossRef]

- Lekomtsev, A.V.; Kang, W.; Galkin, S.V.; Ketova, Y.A. Efficiency evaluation of the heat deparafinization of producing well equipped by sub pump with hollow rods. Period. Tche Quim. 2020, 17, 750–765. [Google Scholar] [CrossRef]

- Vyatkin, K.; Mordvinov, V.; Ilushin, P.; Kozlov, A. Influences of the Water Cut of Pumping Oil and the Mineralization of the Associated Water on the Rate of Sludging. Appl. Sci. 2021, 11, 6678. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, X.; Li, J.; Wang, J.; Zhang, L. Investigation on gelation nucleation kinetics of waxy crude oil emulsions by their thermal behavior. J. Pet. Sci. Eng. 2019, 181, 106230. [Google Scholar] [CrossRef]

- Bell, E.; Lu, Y.; Daraboina, N.; Sarica, C. Experimental Investigation of active heating in removal of wax deposits. J. Pet. Sci. Eng. 2021, 200, 108346. [Google Scholar] [CrossRef]

- Jalalnezhad, M.J.; Kamali, V. Development of an intelligent model for wax deposition in oil pipeline. J. Pet. Explor. Prod. Technol. 2016, 6, 129–133. [Google Scholar] [CrossRef] [Green Version]

- Ilushin, P.Y.; Vyatkin, K.A.; Kozlov, A.V. Forecasting the Value of the Linear Pipeline Cleaning Interval Based on the Laboratory Research. International Review of Mechanical Engineering. Int. J. Press. Vessel. Pip. 2021, 15, 294–300. [Google Scholar]

- Dalirsefat, R.; Feyzi, F. A thermodynamic model for wax deposition phenomena. Fuel 2007, 86, 1402–1408. [Google Scholar] [CrossRef]

- Giacchetta, G.; Marchetti, B.; Leporini, M.; Terenzi, A.; Dall’Acqua, D.; Capece, L.; Grifoni, R.C. Pipeline wax deposition modeling: A sensitivity study on two commercial software. Petroleum 2019, 5, 206–213. [Google Scholar] [CrossRef]

- Lepor Leporini, M.; Terenzi, A.; Marchetti, B.; Giacchetta, G.; Corvaro, F. Experiences in numerical simulation of wax deposition in oil and multiphase pipelines: Theory versus reality. J. Pet. Sci. Eng. 2019, 174, 997–1008. [Google Scholar] [CrossRef]

- Banki, R.; Hoteit, H.; Firoozabadi, A. Mathematical formulation and numerical modeling of wax deposition in pipelines from enthalpy–porosity approach and irreversible thermodynamics. Int. J. Heat Mass Transfer. 2008, 51, 3387–3398. [Google Scholar] [CrossRef]

- El-Dalatony, M.M.; Jeon, B.H.; Salama, E.S.; Eraky, M.; Kim, W.B.; Wang, J.; Ahn, T. Occurrence and characterization of paraffin wax formed in developing wells and pipelines. Energies 2019, 12, 967–989. [Google Scholar] [CrossRef] [Green Version]

- Ivanova, L.V.; Vasechkin, A.A.; Koshelev, V.N. Effect of the chemical composition of crude oil and water cut on the amount of asphaltene-resin-paraffin deposits. Pet. Chem. 2011, 51, 395–400. [Google Scholar] [CrossRef]

- Gumerov, R.R.; Rakhimov, M.N.; Sakhibgareev, S.R. Development of an asphaltene-type ARPD inhibitor based on α-olefins. Bull. Bashkir Univ. 2020, 25, 835. [Google Scholar] [CrossRef]

- Bai, J.; Jin, X.; Wu, J.T. Multifunctional anti-wax coatings for paraffin control in oil pipelines. Pet. Sci. 2019, 16, 619–631. [Google Scholar] [CrossRef] [Green Version]

- Sousa, A.L.; Matos, H.; Guerreiro, L.P. Preventing and removing wax deposition inside vertical wells: A review. J. Pet. Explor. Prod. Technol. 2019, 9, 2091–2107. [Google Scholar] [CrossRef]

- Agaev, S.G.; Grebnev, A.N.; Zemlyansky, E.O. Inhibitors of paraffin deposits of binary action. Oilfield Bus. 2008, 9, 46–52. [Google Scholar]

- Yuretskaya, V.o.l.V.; Abdrashitova YuNRepurchase, A.G. Development of compositions of inhibitors of asphalt-resin-paraffin deposits and research of their effectiveness. Oil Ind. 2010, 3, 100. [Google Scholar]

- Wang, Z.; Yu, X.; Li, J.; Wang, J.; Zhang, L. The use of biobased surfactant obtained by enzymatic syntheses for wax deposition inhibition and drag reduction in crude oil pipelines. Catalysts 2016, 6, 61. [Google Scholar] [CrossRef] [Green Version]

- Shadrina, P.N.; Voloshin, A.I.; Lenchenkova, L.E. Methodology for the selection of reagents for the inhibition of highly paraffinic oils. Oil Gas Bus. 2016, 14, 64–68. [Google Scholar]

- Zubova, E.N.; Zhiltsova, S.V.; Bykov, S.E. Study of the process of formation of asphalt-resin-paraffin substances in laboratory conditions. Oilfield Bus. 2021, 1, 46–49. [Google Scholar] [CrossRef]

- Farleeva, A.F.; Garaskina, M.N.; Sidorov, G.M.; Grokhova, E.V.; Gabdulkhakov, R.R. Complex inhibitors for the removal of asphalt-resinous and paraffinic deposits. Basic Res. 2017, 4, 297–304. [Google Scholar]

- Ilushin, P.U.; Vyatkin, K.A.; Kozlov, A.V. Prevention of the formation of asphalt resin paraphic deposits by inner well compauding of oils. Oilfield Bus. 2021, 632, 50–57. [Google Scholar] [CrossRef]

- Mahir, L.H.A.; Vilas Bôas Fávero, C.; Ketjuntiwa, T.; Fogler, H.S.; Larson, R.G. Mechanism of wax deposition on cold surfaces: Gelation and deposit aging. Energy Fuels 2018, 33, 3776–3786. [Google Scholar] [CrossRef]

- Atroshchenko, N.A.; Lisovskiy, N.A. Comparative analysis of research methods for the process of waxing of oil pipelines. Transp. Storage Pet. Prod. 2021, 1. [Google Scholar] [CrossRef]

- Hosseinipour, A.; Japper-Jaafar, A.; Yusup, S.; Ismail, L. Application of the Avrami Theory for Wax Crystallisation of Synthetic Crude Oil. Int. J. Eng. 2019, 32, 18–27. [Google Scholar] [CrossRef]

- Lim, Z.H.; Al Salim, H.S.; Ridzuan, N.; Nguele, R.; Sasaki, K. Effect of surfactants and their blend with silica nanoparticles on wax deposition in a Malaysian crude oil. Petroleum Sci. 2018, 15, 577–590. [Google Scholar] [CrossRef] [Green Version]

- Dos Santos JD, S.; Fernandes, A.C.; Giulietti, M. Study of the paraffin deposit formation using the cold finger methodology for Brazilian crude oils. J. Petroleum Sci. Eng. 2004, 45, 47–60. [Google Scholar] [CrossRef]

- Krivoshchekov, S.; Vyatkin, K.A.; Kozlov, A.V. Modeling of Asphaltene-Resin-Wax Deposits Formation in a String of Hollow Rods During Simultaneous Separate Operation of Two Oil Reservoirs. Chem. Pet. Eng. 2021, 57, 213–219. [Google Scholar] [CrossRef]

- Panacharoensawad, E.; Sarica, C. Experimental study of single-phase and two-phase water-in-crude-oil dispersed flow wax deposition in a mini pilot-scale flow loop. Energy Fuels 2013, 27, 5036–5053. [Google Scholar] [CrossRef]

- Li, R.; Huang, Q.; Zhu, X.; Zhang, D.; Lv, Y.; Larson, R.G. Investigation of delayed formation of wax deposits in polyethylene pipe using a flow-loop. J. Pet. Sci. Eng. 2021, 196, 108104. [Google Scholar] [CrossRef]

- Yang, J.; Lu, Y.; Daraboina, N.; Sarica, C. Wax deposition mechanisms: Is the current description sufficient? Fuel 2020, 275, 117937. [Google Scholar] [CrossRef]

- Fong, N.; Mehrotra, A.K. Deposition under turbulent flow of wax− solvent mixtures in a bench-scale flow-loop apparatus with heat transfer. Energy Fuels 2007, 21, 1263–1276. [Google Scholar] [CrossRef]

- Chi, Y.; Daraboina, N.; Sarica, C. Investigation of inhibitors efficacy in wax deposition mitigation using a laboratory scale flow loop. AIChE J. 2016, 62, 4131–4139. [Google Scholar] [CrossRef]

- Fan, K.; Li, S.; Li, R. Development of wax molecular diffusivity correlation suitable for crude oil in wax deposition: Experiments with a cold-finger apparatus. J. Petroleum Sci. Eng. 2021, 205, 108851. [Google Scholar] [CrossRef]

- Correra, S.; Fasano, A.; Fusi, L.; Primicerio, M. Modelling wax diffusion in crude oils: The cold finger device. Appl. Math. Modell. 2007, 31, 2286–2298. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Huang, Q.; Wang, C.; Li, S.; Qu, W.; Zhao, J.; He, M. Effect of operating conditions on wax deposition in a laboratory flow loop characterized with DSC technique. J. Thermal Anal. Calorim. 2015, 119, 471–485. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, Z.; Hoffmann, R.; Amundsen, L.; Fogler, H.S. Counterintuitive effects of the oil flow rate on wax deposition. Energy Fuels 2012, 26, 4091–4097. [Google Scholar] [CrossRef]

- Ehsani, S.; Mehrotra, A.K. Effects of shear rate and time on deposit composition in the cold flow regime under laminar flow conditions. Fuel 2020, 259, 116238. [Google Scholar] [CrossRef]

- Yaghy, G.; Ali, A.; Charpentier, T.V.; Fusi, L.; Neville, A.; Harbottle, D. Wax deposition using a cold rotating finger: An empirical and theoretical assessment in thermally driven and sloughing regimes. J. Petroleum Sci. Eng. 2021, 200, 108252. [Google Scholar] [CrossRef]

- Chi, Y.; Daraboina, N.; Sarica, C. Effect of the flow field on the wax deposition and performance of wax inhibitors: Cold finger and flow loop testing. Energy Fuels 2017, 31, 4915–4924. [Google Scholar] [CrossRef]

| Oil Field, Object | No. 1 | No. 2 | No. 3 | No. 4 | |

|---|---|---|---|---|---|

| Volume factor, unit fraction | 1.063 | 1.107 | 1.126 | 1.302 | |

| Content% | paraffin | 3.51 | 3.46 | 3.67 | 3.73 |

| Resin and asphaltene | 23.50 | 21.20 | 19.57 | 7.64 | |

| Density ρH, kg/m3 | degassed | 885 | 862 | 850 | 823 |

| reservoir | 865 | 830 | 806 | 740 | |

| Viscosity, mPaс | degassed | 14.73 | 15.53 | 16.42 | 3.37 |

| reservoir | 12.27 | 3.75 | 3.71 | 1.44 | |

| Method | Efficiency, % | ||||

|---|---|---|---|---|---|

| Fluid No. 1 | Fluid No. 2 | Fluid No. 3 | Fluid No. 4 | ||

| «Cold Finger» | 26.68 | 25.51 | 50.51 | 43.77 | |

| «WaxFlowLoop» | Linear approximation | 70.28 | 21.15 | 57.95 | 78.69 |

| Maximum thickness ratio | 70.84 | 27.68 | 59.39 | 82.07 | |

| Integration | 79.54 | 13.17 | 64.74 | 85.37 | |

| Analysis of the dynamics of changes in the inter-treatment period | 78.33 | <15 | 66.66 | 88.10 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilushin, P.; Vyatkin, K.; Kozlov, A. Development of an Approach for Determining the Effectiveness of Inhibition of Paraffin Deposition on the Wax Flow Loop Laboratory Installation. Inventions 2022, 7, 3. https://doi.org/10.3390/inventions7010003

Ilushin P, Vyatkin K, Kozlov A. Development of an Approach for Determining the Effectiveness of Inhibition of Paraffin Deposition on the Wax Flow Loop Laboratory Installation. Inventions. 2022; 7(1):3. https://doi.org/10.3390/inventions7010003

Chicago/Turabian StyleIlushin, Pavel, Kirill Vyatkin, and Anton Kozlov. 2022. "Development of an Approach for Determining the Effectiveness of Inhibition of Paraffin Deposition on the Wax Flow Loop Laboratory Installation" Inventions 7, no. 1: 3. https://doi.org/10.3390/inventions7010003

APA StyleIlushin, P., Vyatkin, K., & Kozlov, A. (2022). Development of an Approach for Determining the Effectiveness of Inhibition of Paraffin Deposition on the Wax Flow Loop Laboratory Installation. Inventions, 7(1), 3. https://doi.org/10.3390/inventions7010003