Parametric Open Source Cold-Frame Agrivoltaic Systems

Abstract

1. Introduction

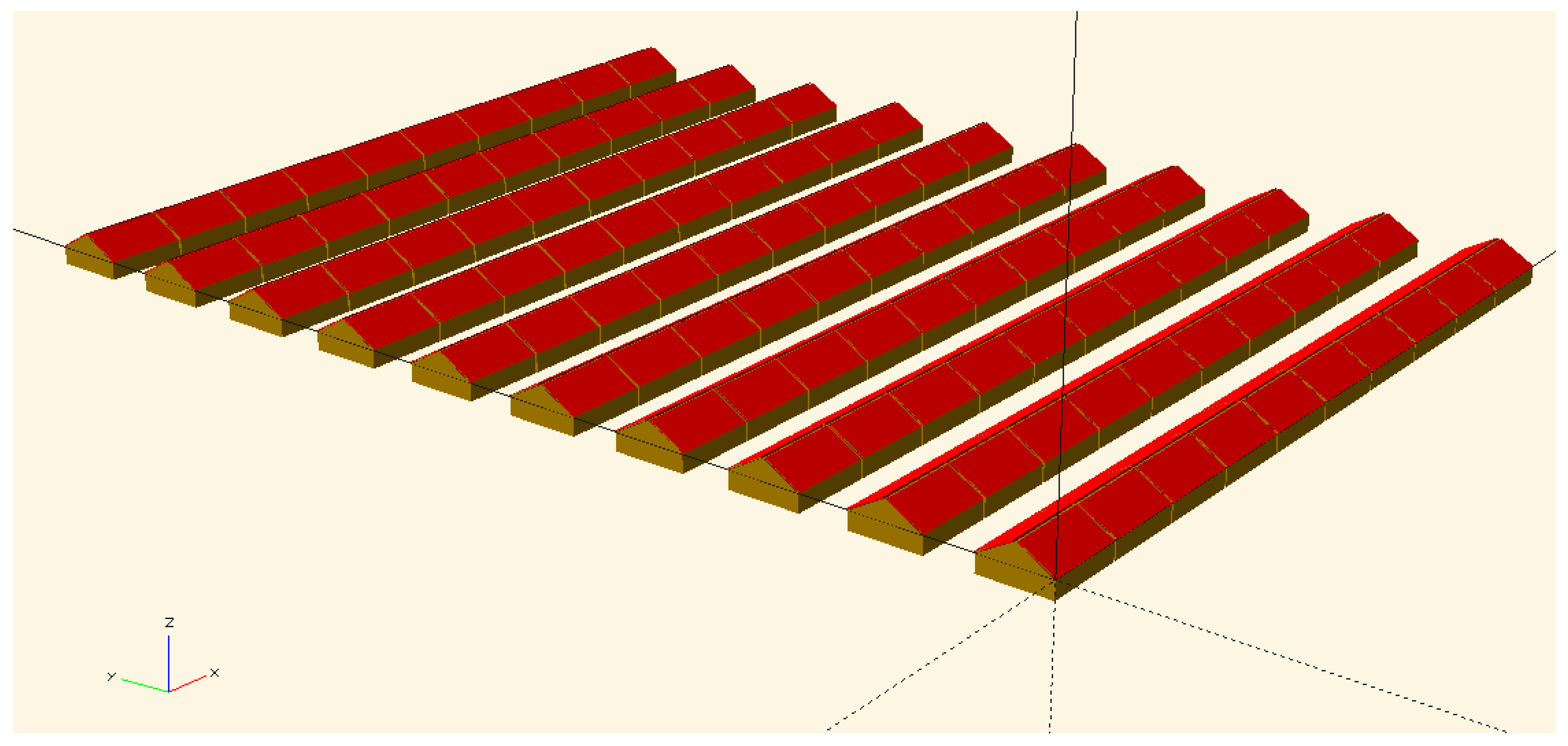

2. Materials and Methods

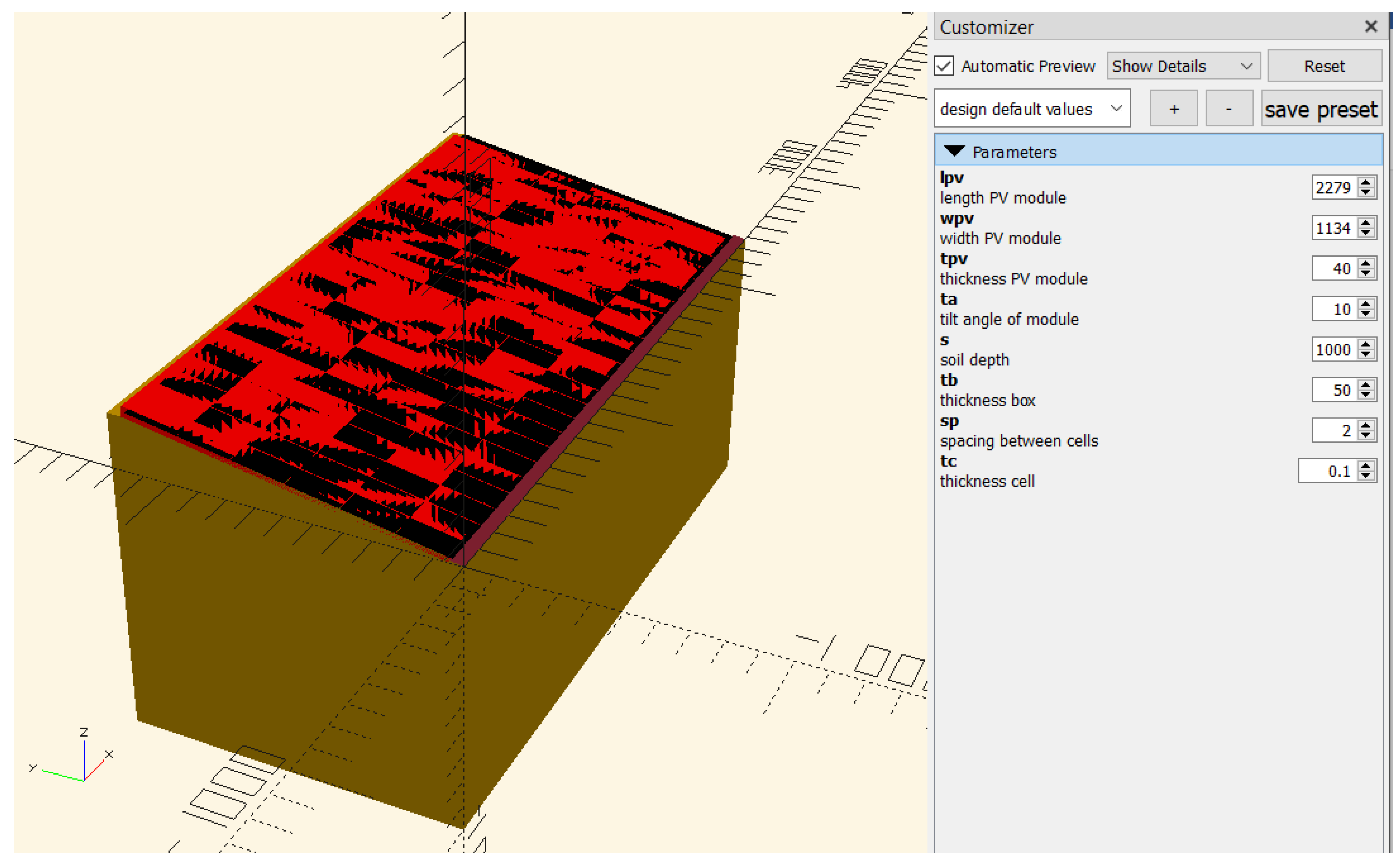

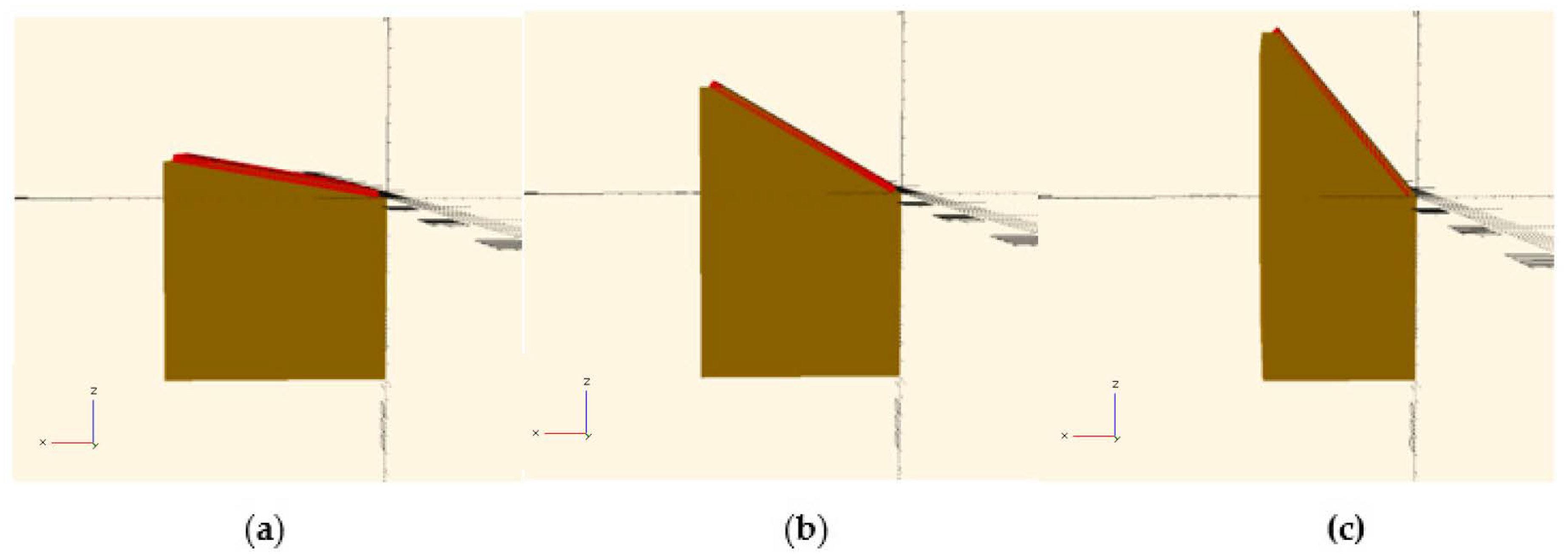

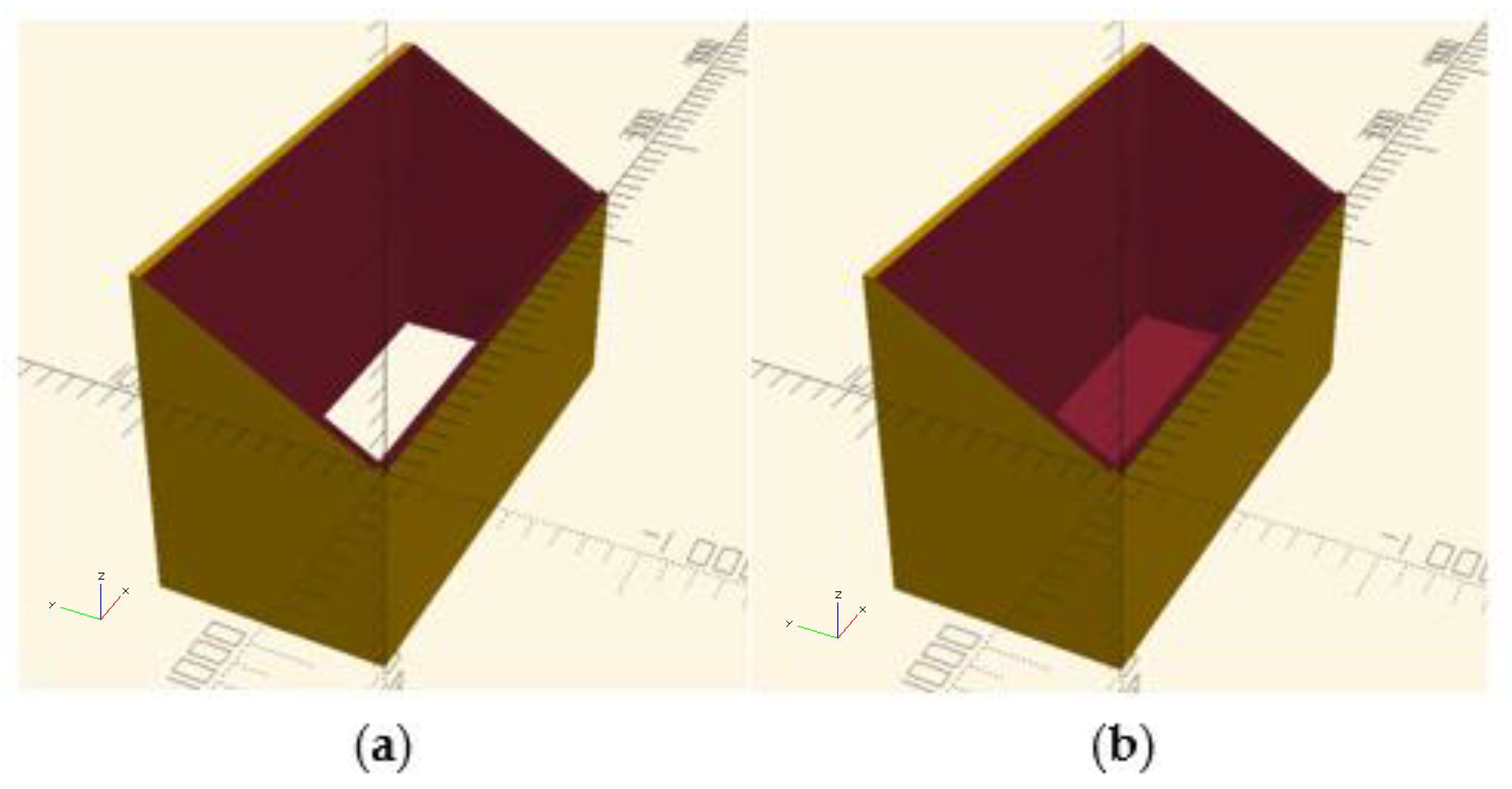

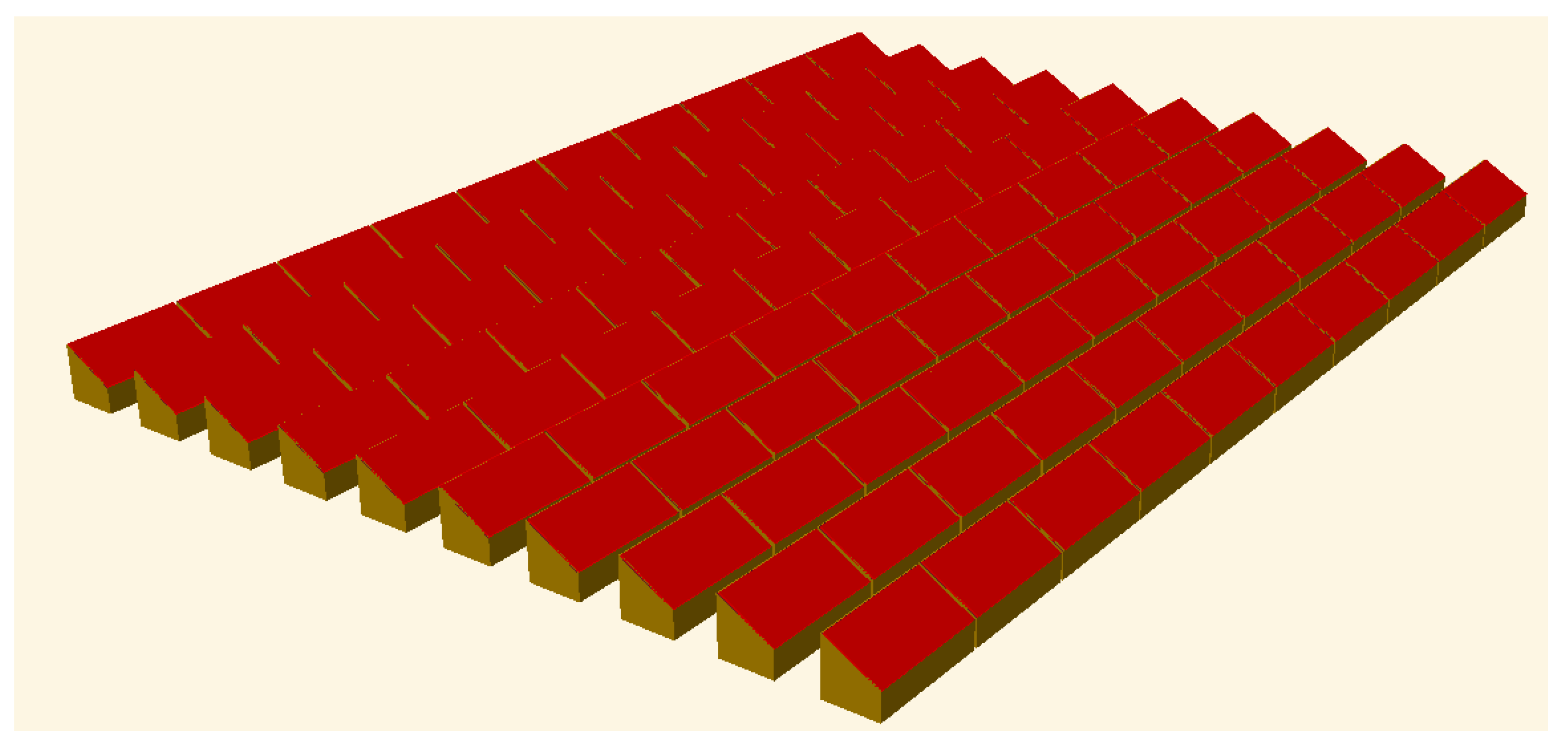

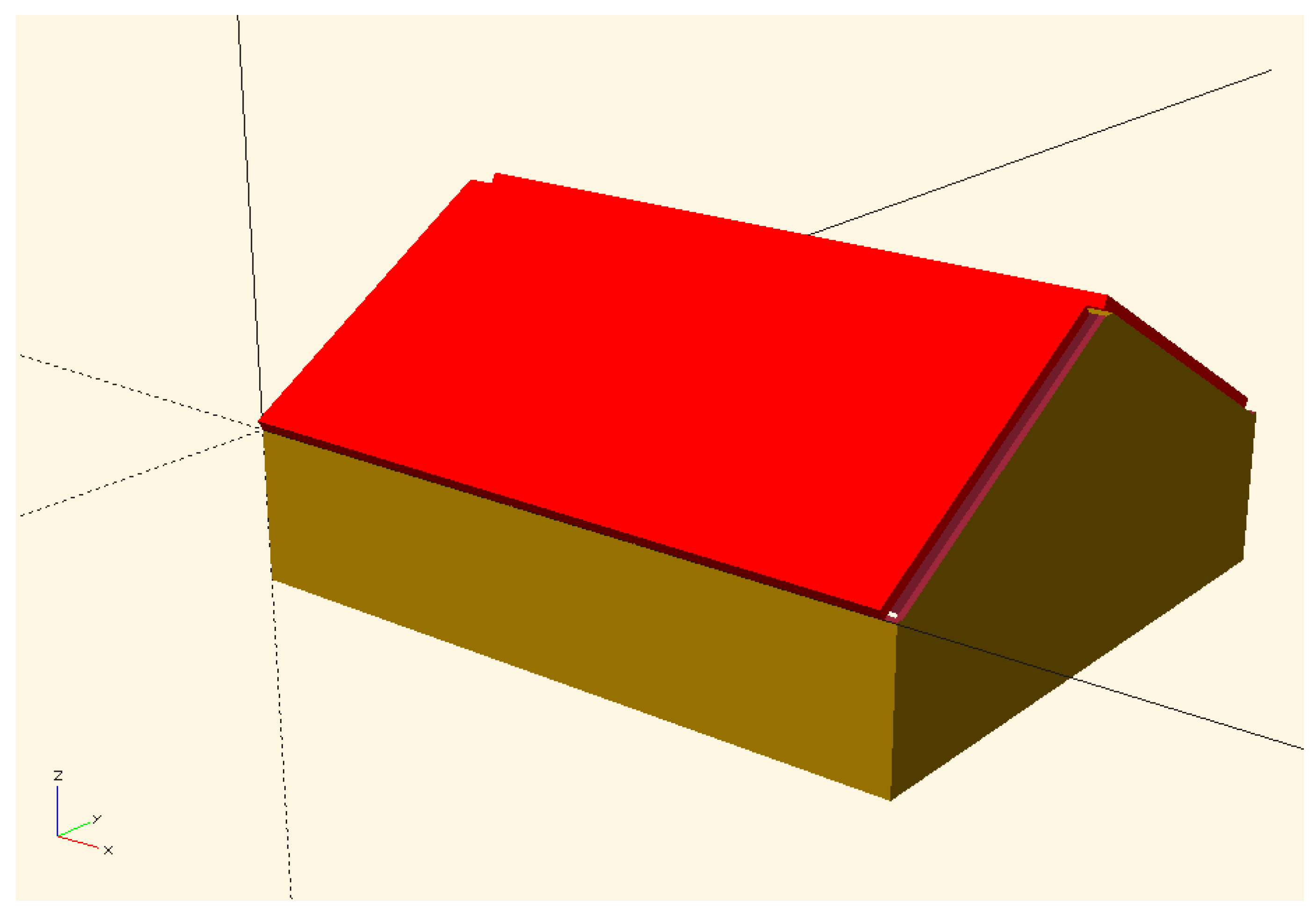

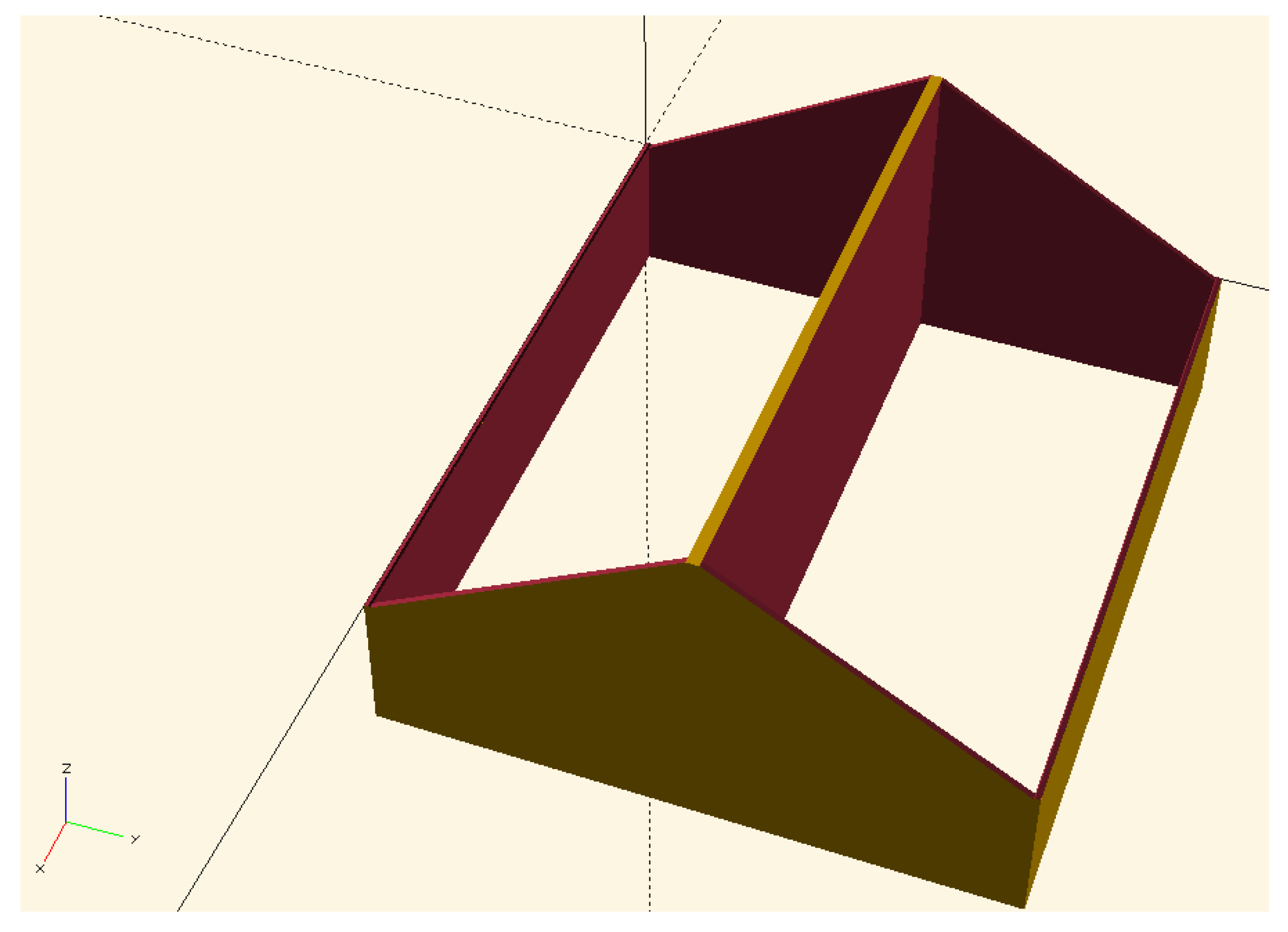

2.1. Parametric Frame Design

2.2. Using DRAM to Fabricate a POSCAS

2.3. Agrivoltaic Module Experimental Design with a POSCAS

3. Results

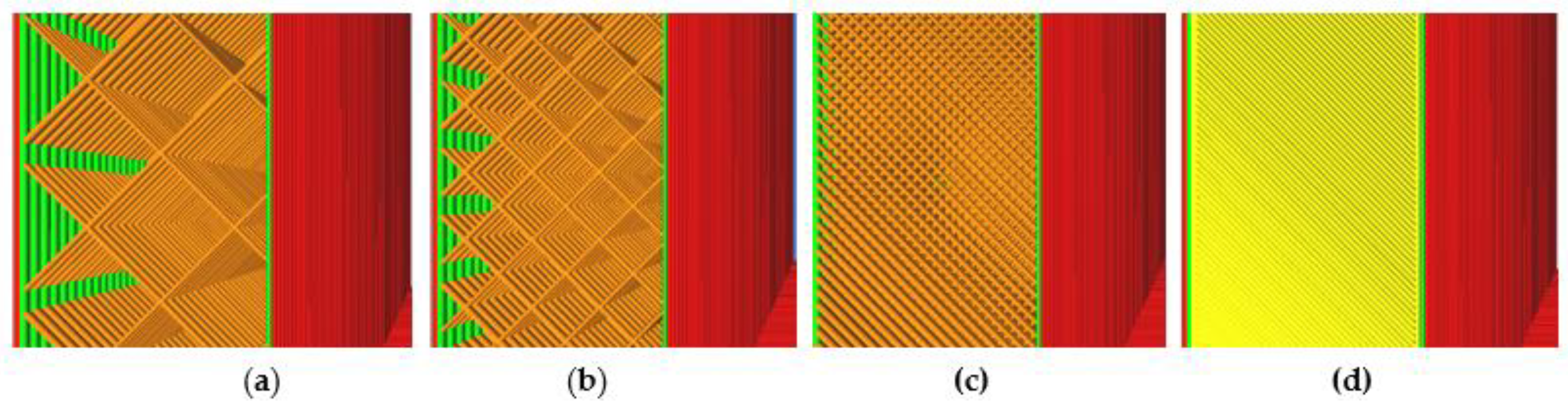

3.1. Parametric Frame Design

3.2. DRAM-Based POSCAS Economics

3.3. Case Study of Red Agrivoltaic Module Experimental Design with a POSCAS

4. Discussion

4.1. Comparison to Cold Frames

4.2. Comparison to Ground-Mounted PV Racks

4.3. POSCAS for Agrivoltaic Research

4.4. Future Work

5. Conclusions

6. Open Source Hardware Certification

Funding

Data Availability Statement

Conflicts of Interest

References

- Feldman, D.; Barbose, G.; Margolis, R.; Wiser, R.; Darghouth, N.; Goodrich, A. Photovoltaic (PV) Pricing Trends: Historical, Recent, and Near-Term Projections; National Renewable Energy Laboratory: Golden, CO, USA, 2012. [Google Scholar]

- Barbose, G.L.; Darghouth, N.R.; Millstein, D.; LaCommare, K.H.; DiSanti, N.; Widiss, R. Tracking the Sun X: The Installed Price of Residential and Non-Residential Photovoltaic Systems in the United States; Lawrence Berkley National Laboratory: Berkeley, CA, USA, 2017. [Google Scholar]

- Yu, C.F.; van Sark, W.G.J.H.M.; Alsema, E.A. Unraveling the photovoltaic technology learning curve by incorporation of input price changes and scale effects. Renew. Sustain. Energy Rev. 2011, 15, 324–337. [Google Scholar] [CrossRef]

- Hong, S.; Chung, Y.; Woo, C. Scenario analysis for estimating the learning rate of photovoltaic power generation based on learning curve theory in South Korea. Energy 2015, 79, 80–89. [Google Scholar] [CrossRef]

- Mauleón, I. Photovoltaic learning rate estimation: Issues and implications. Renew. Sustain. Energy Rev. 2016, 65, 507–524. [Google Scholar] [CrossRef]

- Reuters. Solar Costs to Fall Further, Powering Global Demand—Irena. Reuters. 2017. Available online: https://www.reuters.com/article/singapore-energy-solar-idUSL4N1MY2F8 (accessed on 7 April 2020).

- Lai, C.S.; McCulloch, M.D. Levelized cost of electricity for solar photovoltaic and electrical energy storage. Appl. Energy 2017, 190, 191–203. [Google Scholar] [CrossRef]

- Kang, M.H.; Rohatgi, A. Quantitative analysis of the levelized cost of electricity of commercial scale photovoltaics systems in the US. Sol. Energy Mater. Sol. Cells 2016, 154, 71–77. [Google Scholar] [CrossRef]

- Richard, C. New Wind and Solar Cheaper Than Existing Coal and Gas. 2018. Available online: http://www.windpowermonthly.com/article/1491146 (accessed on 7 April 2020).

- Pearce, J.M.; Sommerfeldt, N. Economics of Grid-Tied Solar Photovoltaic Systems Coupled to Heat Pumps: The Case of Northern Climates of the U.S. and Canada. Energies 2021, 14, 834. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2017; IRENA: Abu Dhabi, United Arab Emirates, 2018. [Google Scholar]

- Dudley, D. Renewable Energy Will Be Consistently Cheaper than Fossil Fuels By 2020, Report Claims. Forbes 2018. Available online: https://www.forbes.com/sites/dominicdudley/2018/01/13/renewable-energy-cost-effective-fossil-fuels-2020/ (accessed on 7 April 2020).

- Kroll, M.; Otto, M.; Käsebier, T.; Füchsel, K.; Wehrspohn, R.; Kley, E.B.; Tünnermann, A.; Pertsch, T. Black silicon for solar cell applications. In Photonics for Solar Energy Systems IV; International Society for Optics and Photonics: Brussels, Belgium, 2012; Volume 8438. [Google Scholar] [CrossRef]

- Modanese, C.; Laine, H.; Pasanen, T.; Savin, H.; Pearce, J. Economic Advantages of Dry-Etched Black Silicon in Passivated Emitter Rear Cell (PERC) Photovoltaic Manufacturing. Energies 2018, 11, 2337. [Google Scholar] [CrossRef]

- Liang, T.S.; Pravettoni, M.; Deline, C.; Stein, J.S.; Kopecek, R.; Singh, J.P.; Luo, W.; Wang, Y.; Aberle, A.G.; Khoo, Y.S. A review of crystalline silicon bifacial photovoltaic performance characterisation and simulation. Energy Environ. Sci. 2019, 12, 116–148. [Google Scholar] [CrossRef]

- Burnham, L.; Riley, D.; Walker, B.; Pearce, J.M. Performance of bifacial photovoltaic modules on a dual-axis tracker in a high-latitude, high-albedo environment. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16 June 2019; pp. 1320–1327. [Google Scholar]

- Barron, A. Cost reduction in the solar industry. Mater. Today 2015, 18, 2–3. [Google Scholar] [CrossRef][Green Version]

- Center for Climate and Energy Solutions (CECS). Renewable Energy. 2019. Available online: https://www.c2es.org/content/renewable-energy/ (accessed on 11 November 2020).

- IEA. Snapshot of Global PV Markets 2020 Report IEA-PVPS T1-37. 2020. Available online: https://iea-pvps.org/wp-content/uploads/2020/04/IEA_PVPS_Snapshot_2020.pdf (accessed on 11 November 2020).

- IEA. Solar PV—Renewables 2020—Analysis. Available online: https://www.iea.org/reports/renewables-2020/solar-pv (accessed on 20 September 2021).

- Pearce, J.; Lau, A. Net Energy Analysis For Sustainable Energy Production From Silicon Based Solar Cells. In Proceedings of the American Society of Mechanical Engineers Solar 2002: Sunrise on the Reliable Energy Economy, Reno, NV, USA, 15–20 June 2002. [Google Scholar]

- NREL. Best Research-Cell Efficiency Chart. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 12 January 2021).

- Bhandari, K.P.; Collier, J.M.; Ellingson, R.J.; Apul, D.S. Energy payback time (EPBT) and energy return on energy invested (EROI) of solar photovoltaic systems: A systematic review and meta-analysis. Renew. Sustain. Energy Rev. 2015, 47, 133–141. [Google Scholar] [CrossRef]

- Engelke, P. Foreign Policy for an Urban World: Global Governance and the Rise of Cities; Atlantic Council: Washington DC, USA, 2013. [Google Scholar]

- Denholm, P.; Margolis, R.M. Land-use requirements and the per-capita solar footprint for photovoltaic generation in the United States. Energy Policy 2008, 36, 3531–3543. [Google Scholar] [CrossRef]

- Wüstenhagen, R.; Wolsink, M.; Bürer, M.J. Social acceptance of renewable energy innovation: An introduction to the concept. Energy Policy 2007, 35, 2683–2691. [Google Scholar] [CrossRef]

- Sovacool, B. Exploring and Contextualizing Public Opposition to Renewable Electricity in the United States. Sustainability 2009, 1, 702–721. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Ratan, P.L. Conceptualizing the acceptance of wind and solar electricity. Renew. Sustain. Energy Rev. 2012, 16, 5268–5279. [Google Scholar] [CrossRef]

- Batel, S.; Devine-Wright, P.; Tangeland, T. Social acceptance of low carbon energy and associated infrastructures: A critical discussion. Energy Policy 2013, 58, 1–5. [Google Scholar] [CrossRef]

- Calvert, K.; Mabee, W. More solar farms or more bioenergy crops? Mapping and assessing potential land-use conflicts among renewable energy technologies in eastern Ontario, Canada. Appl. Geogr. 2015, 56, 209–221. [Google Scholar] [CrossRef]

- Calvert, K.; Pearce, J.M.; Mabee, W.E. Toward renewable energy geo-information infrastructures: Applications of GIScience and remote sensing that build institutional capacity. Renew. Sustain. Energy Rev. 2013, 18, 416–429. [Google Scholar] [CrossRef]

- Nonhebel, S. Renewable energy and food supply: Will there be enough land? Renew. Sustain. Energy Rev. 2005, 9, 191–201. [Google Scholar] [CrossRef]

- Dias, L.; Gouveia, J.P.; Lourenço, P.; Seixas, J. Interplay between the Potential of Photovoltaic Systems and Agricultural Land Use. Land Use Policy 2019, 81, 725–735. [Google Scholar] [CrossRef]

- UN Department of Economic and Social Affairs. Concise Report on the World Population Situation in 2014; UN: New York, NY, USA, 2014.

- FAO. How to Feed the World 2050. 2009; Retrieved 3 December 2020. Available online: http://www.fao.org/fileadmin/templates/wsfs/docs/Issues_papers/HLEF2050_Global_Agriculture.pdf (accessed on 25 October 2021).

- Runge, C.F.; Senauer, B. How Biofuels Could Starve the Poor. Foreign Aff. 2007, 86, 41. [Google Scholar]

- Tomei, J.; Helliwell, R. Food versus Fuel? Going beyond Biofuels. Land Use Policy 2016, 56, 320–326. [Google Scholar] [CrossRef]

- Thompson, P.B. The Agricultural Ethics of Biofuels: The Food vs. Fuel Debate. Agriculture 2012, 2, 339–358. [Google Scholar] [CrossRef]

- Tenenbaum, D.J. Food vs. Fuel: Diversion of Crops Could Cause More Hunger. Environ. Health Perspect. 2008, 116, A254–A257. [Google Scholar] [CrossRef] [PubMed]

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Dinesh, H.; Pearce, J.M. The potential of agrivoltaic systems. Renew. Sustain. Energy Rev. 2016, 54, 299–308. [Google Scholar] [CrossRef]

- Mavani, D.D.; Chauhan, P.M.; Joshi, V. Beauty of Agrivoltaic System regarding double utilization of same piece of land for Generation of Electricity & Food Production. Int. J. Sci. Eng. Res. 2019, 10, 118–148. [Google Scholar]

- Mow, B. Solar Sheep and Voltaic Veggies: Uniting Solar Power and Agriculture. 2018. Available online: https://www.nrel.gov/state-local-tribal/blog/posts/solar-sheep-and-voltaic-veggies-uniting-solar-power-and-agriculture.html (accessed on 2 July 2020).

- Adeh, E.H.; Good, S.P.; Calaf, M. Solar PV Power Potential is Greatest Over Croplands. Sci. Rep. 2019, 9, 11442. [Google Scholar] [CrossRef]

- Ravi, S.; Macknick, J.; Lobell, D.; Field, C.; Ganesan, K.; Jain, R.; Elchinger, M.; Stoltenberg, B. Colocation opportunities for large solar infrastructures and agriculture in drylands. Appl. Energy 2016, 165, 383–392. [Google Scholar] [CrossRef]

- Pringle, A.M.; Handler, R.M.; Pearce, J.M. Aquavoltaics: Synergies for dual use of water area for solar photovoltaic electricity generation and aquaculture. Renew. Sustain. Energy Rev. 2017, 80, 572–584. [Google Scholar] [CrossRef]

- Amaducci, S.; Yin, X.; Colauzzi, M. Agrivoltaic systems to optimize land use for electric energy production. Appl. Energy 2018, 220, 545–561. [Google Scholar] [CrossRef]

- Sekiyama, T.; Nagashima, A. Solar Sharing for Both Food and Clean Energy Production: Performance of Agrivoltaic Systems for Corn, A Typical Shade-Intolerant Crop. Environments 2019, 6, 65. [Google Scholar] [CrossRef]

- Marrou, H.; Wery, J.; Dufour, L.; Dupraz, C. Productivity and radiation use efficiency of lettuces grown in the partial shade of photovoltaic panels. Eur. J. Agron. 2013, 44, 54–66. [Google Scholar] [CrossRef]

- Elamri, Y.; Cheviron, B.; Lopez, J.M.; Dejean, C.; Belaud, G. Water budget and crop modelling for agrivoltaic systems: Application to irrigated lettuces. Agric. Water Manag. 2018, 208, 440–453. [Google Scholar] [CrossRef]

- Malu, P.R.; Sharma, U.S.; Pearce, J.M. Agrivoltaic potential on grape farms in India. Sustain. Energy Technol. Assess. 2017, 23, 104–110. [Google Scholar] [CrossRef]

- Marrou, H.; Guilioni, L.; Dufour, L.; Dupraz, C.; Wéry, J. Microclimate under agrivoltaic systems: Is crop growth rate affected in the partial shade of solar panels? Agric. For. Meteorol. 2013, 177, 117–132. [Google Scholar] [CrossRef]

- Riaz, M.H.; Imran, H.; Alam, H.; Alam, M.A.; Butt, N.Z. Crop-Specific Optimization of Bifacial PV Arrays for Agrivoltaic Food-Energy Production: The Light-Productivity-Factor Approach. arXiv 2021, arXiv:2104.00560. [Google Scholar]

- Santra, P.; Pande, P.C.; Kumar, S.; Mishra, D.; Singh, R.K. Agri-voltaics or Solar farming- the Concept of Integrating Solar PV Based Electricity Generation and Crop Production in a Single Land use System. Int. J. Renew. Energy Res. 2017, 7, 694–699. [Google Scholar]

- Guerin, T.F. Impacts and opportunities from large-scale solar photovoltaic (PV) electricity generation on agricultural production. Environ. Qual. Manag. 2019, 28, 7–14. [Google Scholar] [CrossRef]

- Barron-Gafford, G.A.; Pavao-Zuckerman, M.A.; Minor, R.L.; Sutter, L.F.; Barnett-Moreno, I.; Blackett, D.T.; Thompson, M.; Dimond, K.; Gerlak, A.K.; Nabhan, G.P.; et al. Agrivoltaics provide mutual benefits across the food–energy–water nexus in drylands. Nat. Sustain. 2019, 2, 848–855. [Google Scholar] [CrossRef]

- Pascaris, A.S.; Schelly, C.; Pearce, J.M. A First Investigation of Agriculture Sector Perspectives on the Opportunities and Barriers for Agrivoltaics. Agronomy 2020, 10, 1885. [Google Scholar] [CrossRef]

- Pascaris, A.S.; Schelly, C.; Burnham, L.; Pearce, J.M. Integrating Solar Energy with Agriculture: Industry Perspectives on the Market, Community, and Socio-Political Dimensions of Agrivoltaics. Energy Res. Soc. Sci. 2021, 75, 102023. [Google Scholar] [CrossRef]

- PFAF. Edible Uses. Available online: https://pfaf.org/user/edibleuses.aspx (accessed on 20 September 2021).

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Pearson Education: London, UK, 2014. [Google Scholar]

- Pearce, J.M. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Oberloier, S.; Pearce, J.M. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs 2018, 2, 2. [Google Scholar] [CrossRef]

- Open Source Hardware Association. Definition (English). Available online: https://www.oshwa.org/definition/ (accessed on 20 September 2021).

- The GNU General Public License v3.0—GNU Project—Free Software Foundation. Available online: https://www.gnu.org/licenses/gpl-3.0.en.html (accessed on 20 September 2021).

- Cern OHL Version 2 Wiki·Projects/CERN Open Hardware Licence. Available online: https://ohwr.org/project/cernohl/wikis/Documents/CERN-OHL-version-2 (accessed on 20 September 2021).

- Creative Commons—Attribution 2.0 Generic—CC BY 2.0. Available online: https://creativecommons.org/licenses/by/2.0/ (accessed on 20 September 2021).

- Parametric Open-Source Cold-Frame Agrivoltaic System. 2021. Available online: https://osf.io/k6xwv/ (accessed on 20 September 2021).

- OpenSCAD. Available online: http://openscad.org (accessed on 20 September 2021).

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Pavlo, S.; Fabio, C.; Hakim, B.; Mauricio, C. 3D-Printing Based Distributed Plastic Recycling: A Conceptual Model for Closed-Loop Supply Chain Design. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–8. [Google Scholar]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Woern, A.L.; McCaslin, J.R.; Pringle, A.M.; Pearce, J.M. RepRapable Recyclebot: Open source 3-D prinfigure extruder for converting plastic to 3-D printing filament. HardwareX 2018, 4, e00026. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [PubMed]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific Publishing Company: Singapore, 2009; pp. 568–580. ISBN 978-981-4280-25-9. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Hunt, E.J.; Zhang, C.; Anzalone, N.; Pearce, J.M. Polymer recycling codes for distributed manufacturing with 3-D printers. Resour. Conserv. Recycl. 2015, 97, 24–30. [Google Scholar] [CrossRef]

- Lee, J.H.; Lim, K.S.; Hahm, W.G.; Kim, S.H. Properties of recycled and virgin poly(ethylene terephthalate) blend fibers. J. Appl. Polym. Sci. 2013, 128, 1250–1256. [Google Scholar] [CrossRef]

- Little, H.A.; Tanikella, N.G.; Reich, M.J.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks. Materials 2020, 13, 4273. [Google Scholar] [CrossRef] [PubMed]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Pepi, M.; Zander, N.; Gillan, M. Towards Expeditionary Battlefield Manufacturing Using Recycled, Reclaimed, and Scrap Materials. JOM 2018, 70, 2359–2364. [Google Scholar] [CrossRef]

- Hart, K.R.; Frketic, J.B.; Brown, J.R. Recycling meal-ready-to-eat (MRE) pouches into polymer filament for material extrusion additive manufacturing. Addit. Manuf. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Tang, B.; Wang, J. Investigation of Closed-Loop Manufacturing with Acrylonitrile Butadiene Styrene over Multiple Generations Using Additive Manufacturing. ACS Sustain. Chem. Eng. 2019, 7, 13955–13969. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Vidler, C.; Rosson, L.; Long, J. The Recycling of E-Waste ABS Plastics by Melt Extrusion and 3D Printing Using Solar Powered Devices as a Transformative Tool for Humanitarian Aid. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2018. [Google Scholar]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Rosson, L.; Long, J. EcoPrinting: Investigation of Solar Powered Plastic Recycling and Additive Manufacturing for Enhanced Waste Management and Sustainable Manufacturing. In Proceedings of the 2018 IEEE Conference on Technologies for Sustainability (SusTech), Long Beach, CA, USA, 11–13 November 2018; pp. 1–6. [Google Scholar]

- Boldizar, A.; Möller, K. Degradation of ABS during repeated processing and accelerated ageing. Polym. Degrad. Stab. 2003, 81, 359–366. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef] [PubMed]

- Woern, A.L.; Pearce, J.M. Distributed Manufacturing of Flexible Products: Technical Feasibility and Economic Viability. Technologies 2017, 5, 71. [Google Scholar] [CrossRef]

- Sanchez, F.A.C.; Lanza, S.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. In Annual International Solid Freeform Ffabrication Symposium, ISSF 2015; University of Texas: Austin, TX, USA, 2015; p. 1591. [Google Scholar]

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the Use of Recycled or Biodegradable Filaments for Sustainability of 3D Printing. In Sustainable Design and Manufacturing 2017; Campana, G., Howlett, R.J., Setchi, R., Cimatti, B., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 776–785. [Google Scholar]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Heller, B.P.; Smith, D.E.; Jack, D.A. Planar deposition flow modeling of fiber filled composites in large area additive manufacturing. Addit. Manuf. 2019, 25, 227–238. [Google Scholar] [CrossRef]

- Pringle, A.M.; Rudnicki, M.; Pearce, J.M. Wood Furniture Waste–Based Recycled 3-D Printing Filament. For. Prod. J. 2017, 68, 86–95. [Google Scholar] [CrossRef]

- Zander, N.E. Recycled Polymer Feedstocks for Material Extrusion Additive Manufacturing. In Polymer-Based Additive Manufacturing: Recent Developments; ACS Symposium Series; American Chemical Society: Washington DC, USA, 2019; Volume 1315, pp. 37–51. ISBN 978-0-8412-3426-0. [Google Scholar]

- Meyer, T.K.; Tanikella, N.G.; Reich, M.J.; Pearce, J.M. Potential of distributed recycling from hybrid manufacturing of 3-D printing and injection molding of stamp sand and acrylonitrile styrene acrylate waste composite. Sustain. Mater. Technol. 2020, 25, e00169. [Google Scholar] [CrossRef]

- Gwamuri, J.; Wittbrodt, B.T.; Anzalone, N.C.; Pearce, J.M. Reversing the Trend of Large Scale and Centralization in Manufacturing: The Case of Distributed Manufacturing of Customizable 3-D-Printable Self-Adjustable Glasses; Social Science Research Network: Rochester, NY, USA, 2014. [Google Scholar]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Petersen, E.E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Ultimaker Cura: Powerful, Easy-to-Use 3D Printing Software. Available online: https://ultimaker.com/software/ultimaker-cura (accessed on 20 September 2021).

- Amazon.Com: Polymaker ASA Filament 1.75mm Black ASA 1kg Spool UV Resistant ASA Filament 1.75—PolyLite ASA 3D Printer Filament: Everything Else. Available online: https://www.amazon.com/Polymaker-Printer-Filament-PolyLite-Printing/dp/B07QN4BKMJ/ (accessed on 20 September 2021).

- ASA Pellets for Extruding Your Own Professional 3D Filament. Available online: https://www.3dxtech.com/product/asa-pellets/ (accessed on 20 September 2021).

- Factory Sale High Temperature Resistance And High Impact Asa Plastic Granules Pellets For Lampshade And Radiator Grille—Buy Factory Sale High Temperature Resistance And High Impact Asa Granules Pellets For Lampshade And Radiator Grille, High Temperature Resistant Modified Engineering Plastic, Whether Resistance And Aging Resistance Product on Alibaba.Com. Available online: https://www.alibaba.com/product-detail/Factory-sale-high-temperature-resistance-and_1600179625457.html?spm=a2700.7724857.normal_offer.d_image.5d23e430Y78ODT (accessed on 20 September 2021).

- McKee, G.E.; Kistenmacher, A.; Goerrissen, H.; Breulmann, M. Synthesis, Properties and Applications of Acrylonitrile–Styrene–Acrylate Polymers. In Modern Styrenic Polymers: Polystyrenes and Styrenic Copolymers; John Wiley & Sons, Ltd.: New York, NY, USA, 2003; pp. 341–362. ISBN 978-0-470-86721-1. [Google Scholar]

- Massey, L.K. The Effect of UV Light and Weather: On Plastics and Elastomers; William Andrew: Norwhich, UK, 2006. [Google Scholar]

- Ziptie.com 14-Inch UV Resistant Black Multi-Purpose Cable Ties, 120-Lb Tensile Strength, UL 21S Listed, 100-Pack. Available online: https://ziptie.com/14-in-120-lb-black-heavy-duty-nylon-tie-100-pack.html (accessed on 20 October 2021).

- Hi-MO5. Available online: https://en.longi-solar.com/home/products/Hi_MO5.html (accessed on 20 September 2021).

- Heliene 144 M10. Available online: https://heliene.com/wp-content/uploads/HELIENE_144_M10_BIFACIAL_SPEC_SSM_REV.00.pdf (accessed on 20 September 2021).

- Leite Didoné, E.; Wagner, A. Semi-transparent PV windows: A study for office buildings in Brazil. Energy Build. 2013, 67, 136–142. [Google Scholar] [CrossRef]

- Olivieri, L.; Caamaño-Martín, E.; Moralejo-Vázquez, F.J.; Martín-Chivelet, N.; Olivieri, F.; Neila-Gonzalez, F.J. Energy saving potential of semi-transparent photovoltaic elements for building integration. Energy 2014, 76, 572–583. [Google Scholar] [CrossRef]

- Chae, Y.T.; Kim, J.; Park, H.; Shin, B. Building energy performance evaluation of building integrated photovoltaic (BIPV) window with semi-transparent solar cells. Appl. Energy 2014, 129, 217–227. [Google Scholar] [CrossRef]

- Moralejo-Vázquez, F.J.; Martín-Chivelet, N.; Olivieri, L.; Caamaño-Martín, E. Luminous and solar characterization of PV modules for building integration. Energy Build. 2015, 103, 326–337. [Google Scholar] [CrossRef]

- Martín-Chivelet, N.; Guillén, C.; Trigo, J.F.; Herrero, J.; Pérez, J.J.; Chenlo, F. Comparative Performance of Semi-Transparent PV Modules and Electrochromic Windows for Improving Energy Efficiency in Buildings. Energies 2018, 11, 1526. [Google Scholar] [CrossRef]

- Yano, A.; Onoe, M.; Nakata, J. Prototype Semi-Transparent Photovoltaic Modules for Greenhouse Roof Applications. Biosyst. Eng. 2014, 122, 62–73. [Google Scholar] [CrossRef]

- Yeop Myong, S.; Won Jeon, S. Design of Esthetic Color for Thin-Film Silicon Semi-Transparent Photovoltaic Modules. Solar Energy Mater. Sol. Cells 2015, 143, 442–449. [Google Scholar] [CrossRef]

- Li, Z.; Yano, A.; Cossu, M.; Yoshioka, H.; Kita, I.; Ibaraki, Y. Electrical Energy Producing Greenhouse Shading System with a Semi-Transparent Photovoltaic Blind Based on Micro-Spherical Solar Cells. Energies 2018, 11, 1681. [Google Scholar] [CrossRef]

- Li, Z.; Yano, A.; Cossu, M.; Yoshioka, H.; Kita, I.; Ibaraki, Y. Shading and Electric Performance of a Prototype Greenhouse Blind System Based on Semi-Transparent Photovoltaic Technology. J. Agric. Meteorol. 2018, 74, 114–122. [Google Scholar]

- Li, Z.; Yano, A.; Yoshioka, H. Feasibility Study of a Blind-Type Photovoltaic Roof-Shade System Designed for Simultaneous Production of Crops and Electricity in a Greenhouse. Appl. Energy 2020, 279, 115853. [Google Scholar] [CrossRef]

- Thompson, E.P.; Bombelli, E.L.; Shubham, S.; Watson, H.; Everard, A.; D’Ardes, V.; Schievano, A.; Bocchi, S.; Zand, N.; Howe, C.J.; et al. Tinted Semi-Transparent Solar Panels Allow Concurrent Production of Crops and Electricity on the Same Cropland. Adv. Energy Mater. 2020, 10, 2001189. [Google Scholar] [CrossRef]

- Shen, L.; Lou, R.; Park, Y.; Guo, Y.; Stallknecht, E.J.; Xiao, Y.; Rieder, D.; Yang, R.; Runkle, E.S.; Yin, X. Increasing Greenhouse Production by Spectral-Shifting and Unidirectional Light-Extracting Photonics. Nat Food 2021, 2, 434–441. [Google Scholar] [CrossRef]

- Timmermans, G.H.; Hemming, S.; Baeza, E.; van Thoor, E.A.J.; Schenning, A.P.H.J.; Debije, M.G. Advanced Optical Materials for Sunlight Control in Greenhouses. Adv. Opt. Mater. 2020, 8, 2000738. [Google Scholar] [CrossRef]

- Sánchez-Lanuza, M.B.; Menéndez-Velázquez, A.; Peñas-Sanjuan, A.; Navas-Martos, F.J.; Lillo-Bravo, I.; Delgado-Sánchez, J.-M. Advanced Photonic Thin Films for Solar Irradiation Tuneability Oriented to Greenhouse Applications. Materials 2021, 14, 2357. [Google Scholar] [CrossRef]

- Agricultural Adaptation Council. “Waste” Light Can Lower Greenhouse Production Costs. Greenhouse Canada, 30 December 2019.

- Shen, L.; Yin, X. Increase Greenhouse Production with Spectral-Shifting and Unidirectional Light-Extracting Photonics. In Proceedings of the New Concepts in Solar and Thermal Radiation Conversion IV, SPIE, San Diego, CA, USA, 1–5 August 2021; Volume 11824, p. 1182402. [Google Scholar]

- Growing Trial for Greenhouse Solar Panels—Research & Innovation|Niagara College. Research & Innovation 2019. Available online: https://www.ncinnovation.ca/blog/research-innovation/growing-trial-for-greenhouse-solar-panels (accessed on 25 October 2021).

- Chiu, G. Dual Use for Solar Modules. Greenhouse Canada 2019. Available online: https://www.greenhousecanada.com/technology-issues-dual-use-for-solar-modules-32902/ (accessed on 25 October 2021).

- El-Bashir, S.M.; Al-Harbi, F.F.; Elburaih, H.; Al-Faifi, F.; Yahia, I.S. Red Photoluminescent PMMA Nanohybrid Films for Modifying the Spectral Distribution of Solar Radiation inside Greenhouses. Renew. Energy 2016, 85, 928–938. [Google Scholar] [CrossRef]

- Parrish, C.H.; Hebert, D.; Jackson, A.; Ramasamy, K.; McDaniel, H.; Giacomelli, G.A.; Bergren, M.R. Optimizing Spectral Quality with Quantum Dots to Enhance Crop Yield in Controlled Environments. Commun. Biol. 2021, 4, 124. [Google Scholar] [CrossRef]

- UbiGro A Layer of Light. Available online: https://ubigro.com/case-studies (accessed on 22 September 2021).

- Kerle Makerspace. Diy Greenhouse by KMS. Download Free STL Model|PrusaPrinters. CC-BY-SA-NC. Available online: https://www.prusaprinters.org/prints/62627-diy-greenhouse-by-kms (accessed on 23 September 2021).

- CivicSolar, How Does Heat Affect Solar Panel Efficiencies? Available online: https://www.civicsolar.com/article/how-does-heat-affect-solar-panel-efficiencies (accessed on 4 October 2021).

- Wald, M.L. Why More Solar Panels Should Be Facing West, Not South. The New York Times, 1 December 2014. [Google Scholar]

- Azzouz, L.; Chen, Y.; Zarrelli, M.; Pearce, J.M.; Mitchell, L.; Ren, G.; Grasso, M. Mechanical Properties of 3-D Printed Truss-like Lattice Biopolymer Non-Stochastic Structures for Sandwich Panels with Natural Fibre Composite Skins. Compos. Struct. 2019, 213, 220–230. [Google Scholar] [CrossRef]

- Mnati, M.J.; Van den Bossche, A.; Chisab, R.F. A Smart Voltage and Current Monitoring System for Three Phase Inverters Using an Android Smartphone Application. Sensors 2017, 17, 872. [Google Scholar] [CrossRef] [PubMed]

- Anand, R.; Pachauri, R.K.; Gupta, A.; Chauhan, Y.K. Design and analysis of a low cost PV analyzer using Arduino UNO. In Proceedings of the 2016 IEEE 1st International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 4–6 July 2016; pp. 1–4. [Google Scholar]

- De Anchieta Marques, W.; Ferreira, V.H.; Sotelo, G.G. Design of a real-time, low-cost monitoring system for hybrid solar-wind power generation system. In Proceedings of the 2018 Simposio Brasileiro de Sistemas Eletricos (SBSE), Niteroi, Brazil, 12–16 May 2018; pp. 1–6. [Google Scholar]

- Oberloier, S.; Pearce, J.M. Open Source Low-Cost Power Monitoring System. HardwareX 2018, 4, e00044. [Google Scholar] [CrossRef]

- Chen, F.; Wittkopf, S.K.; Khai Ng, P.; Du, H. Solar Heat Gain Coefficient Measurement of Semi-Transparent Photovoltaic Modules with Indoor Calorimetric Hot Box and Solar Simulator. Energy Build. 2012, 53, 74–84. [Google Scholar] [CrossRef]

- Colantoni, A.; Monarca, D.; Marucci, A.; Cecchini, M.; Zambon, I.; Di Battista, F.; Maccario, D.; Saporito, M.G.; Beruto, M. Solar Radiation Distribution inside a Greenhouse Prototypal with Photovoltaic Mobile Plant and Effects on Flower Growth. Sustainability 2018, 10, 855. [Google Scholar] [CrossRef]

- Enokela, J.A.; Othoigbe, T.O. An automated greenhouse control system using Arduino prototyping platform. Aust. J. Eng. Res. 2015, 1, 64–73. Available online: http://www.mecs-press.org/ijieeb/ijieeb-v9-n3/v9n3-1.html (accessed on 23 September 2021).

- Vimal, P.V.; Shivaprakasha, K.S. IOT based greenhouse environment monitoring and controlling system using Arduino platform. In Proceedings of the 2017 International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT), Kerala, India, 6–7 July 2017; pp. 1514–1519. [Google Scholar]

- Saha, T.; Jewel, M.K.; Mostakim, M.N.; Bhuiyan, N.H.; Ali, M.S.; Rahman, M.K.; Ghosh, H.K.; Hossain, M.K. Construction and development of an automated greenhouse system using Arduino Uno. Int. J. Inf. Eng. Electron. Bus. 2017, 9, 1. [Google Scholar] [CrossRef]

- Siddiqui, M.F.; Kanwal, N.; Mehdi, H.; Noor, A.; Khan, M.A. Automation and monitoring of greenhouse. In Proceedings of the 2017 International Conference on Information and Communication Technologies (ICICT), Karachi, Pakistan, 30–31 December 2017; pp. 197–201. [Google Scholar]

- Bedell, R.; Hassan, A.; Tinet, A.-J.; Arrieta-Escobar, J.; Derrien, D.; Dignac, M.-F.; Boly, V.; Ouvrard, S.; Pearce, J.M. Open-Source Script for Design and 3D Printing of Porous Structures for Soil Science. Technologies 2021, 9, 67. [Google Scholar] [CrossRef]

- Jaiganesh, S.; Gunaseelan, K.; Ellappan, V. IOT Agriculture to Improve Food and Farming Technology. In Proceedings of the 2017 Conference on Emerging Devices and Smart Systems (ICEDSS), Mallasamudram, India, 3–4 March 2017; pp. 260–266. [Google Scholar]

- Kassim, M.R.M. IoT Applications in Smart Agriculture: Issues and Challenges. In Proceedings of the 2020 IEEE Conference on Open Systems (ICOS), Kota Kinabalu, Malaysia, 17–19 November 2020; pp. 19–24. [Google Scholar]

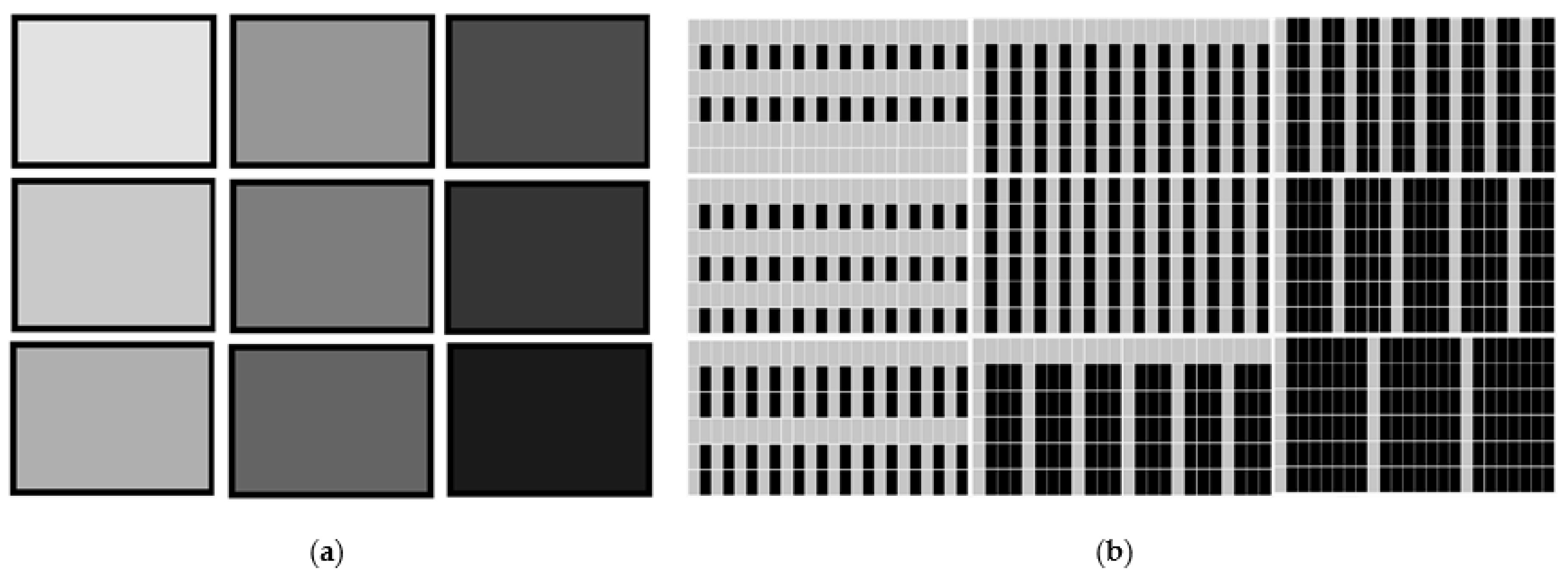

| Approximate Percent PV | a | b |

|---|---|---|

| 10 * | 2 | 2 * |

| 20 | 2 | 2 |

| 30 | 2/3 | 3/2 |

| 40 | 2 | 6 |

| 50 | 2 | 0 |

| 60 | 4 | 6 |

| 70 | 6 | 6 |

| 80 | 5 | 0 |

| 90 | 8 | 0 |

| Variable | Unit | Explanation |

|---|---|---|

| lpv | mm | Length of the PV module to be adjusted for PV based on specification sheet from PV manufacturer. |

| wpv | mm | Width of the PV module to be adjusted for PV based on specification sheet from PV manufacturer. |

| tpv | mm | Thickness of the PV to be adjusted for PV based on specification sheet from PV manufacturer. |

| ta | ° | Tilt angle of the modules measured from the ground surface. This can be optimized for solar electric yield based on latitude. |

| s | mm | This determines the height of the walls of the POSCAS, which provides the maximum soil depth for a raised bed growing system. |

| tb | mm | Box wall thickness will depend on the loads expected and the materials used to fabricate the POSCAS. |

| Polymer Type | Feedstock Cost ($/kg) | Frame Mass Bottomless (kg) | Frame Cost Bottomless POSCAS ($) | Total Cost Bottomless POSCAS ($) | Percentage Difference Base POSCAS |

|---|---|---|---|---|---|

| Commercial Filament | 30 | 30.5 | 915.00 | 915.56 | 196% |

| Commercial Pellets | 8 | 30.5 | 244.00 | 244.56 | 187% |

| Recycled Pellets | 2.5 | 30.5 | 76.25 | 76.81 | 161% |

| DRAM | 0.25 | 30.5 | 7.63 | 8.19 | 0% |

| Tilt Angle (degrees) | |||||

| 10 | 0.25 | 24.2 | 6.05 | 6.61 | 21% |

| 30 | 0.25 | 30.5 | 7.63 | 8.19 | 0% |

| 50 | 0.25 | 33.5 | 8.38 | 8.94 | 9% |

| Soil Depth (mm) | |||||

| 1000 | 0.25 | 49.7 | 12.43 | 12.99 | 45% |

| 500 | 0.25 | 30.5 | 7.63 | 8.19 | 0% |

| 250 | 0.25 | 20.8 | 5.20 | 5.76 | 35% |

| Infill (%) | |||||

| 0 | 0.25 | 9.5 | 2.38 | 2.94 | 94% |

| 10 | 0.25 | 20.0 | 5.00 | 5.56 | 38% |

| 20 | 0.25 | 30.5 | 7.63 | 8.19 | 0% |

| 50 | 0.25 | 62.0 | 15.50 | 16.06 | 65% |

| 100 | 0.25 | 114.3 | 28.58 | 29.14 | 112% |

| Wall thickness (mm) | |||||

| 10 | 0.25 | 18.8 | 4.70 | 5.26 | 44% |

| 20 | 0.25 | 30.5 | 7.63 | 8.19 | 0% |

| 50 | 0.25 | 66.5 | 16.63 | 17.19 | 71% |

| Box Type | |||||

| Bottomless | 0.25 | 30.5 | 7.63 | 8.19 | 0% |

| Bottom | 0.25 | 44.9 | 11.23 | 11.79 | 36% |

| Module hole type | Cost of zip ties | Percent Cost | |||

| 4 | 0.36 | 4.4% | |||

| 6 | 0.54 | 6.6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pearce, J.M. Parametric Open Source Cold-Frame Agrivoltaic Systems. Inventions 2021, 6, 71. https://doi.org/10.3390/inventions6040071

Pearce JM. Parametric Open Source Cold-Frame Agrivoltaic Systems. Inventions. 2021; 6(4):71. https://doi.org/10.3390/inventions6040071

Chicago/Turabian StylePearce, Joshua M. 2021. "Parametric Open Source Cold-Frame Agrivoltaic Systems" Inventions 6, no. 4: 71. https://doi.org/10.3390/inventions6040071

APA StylePearce, J. M. (2021). Parametric Open Source Cold-Frame Agrivoltaic Systems. Inventions, 6(4), 71. https://doi.org/10.3390/inventions6040071