Detection of Material Extrusion In-Process Failures via Deep Learning

Abstract

1. Introduction

- When the temperature in the print head is too high for the material being used, the filament becomes too viscous and watery and leaks out of the print nozzle.

- If the nozzle is too far away from the bed, the bottom surface often shows unwanted lines, and/or the first layer does not stick, and if the nozzle is too close, blobs may be the result.

- Ringing (or ripples or shadowing or ghosting or echoing) is a surface finish defect in 3D prints that is created by the sudden acceleration of the printer’s moving parts, and this shaking can become visible as ripples in the surface of the print, which are particularly visible next to a corner or a surface feature.

- Layer shifting is a printing issue, which causes the layers of the printed object to shift from their intended positions, and it is usually associated with improper movement of the X-axis and/or the Y-axis, leading the extruder head to be misaligned mid-printing.

- Warping occurs due to material shrinkage while 3D printing, which causes the corners of the print to lift and detach from the build plate, because the plastics first expands slightly and then contracts during cooldown, and if the material contracts too much, the print bends up from the build plate.

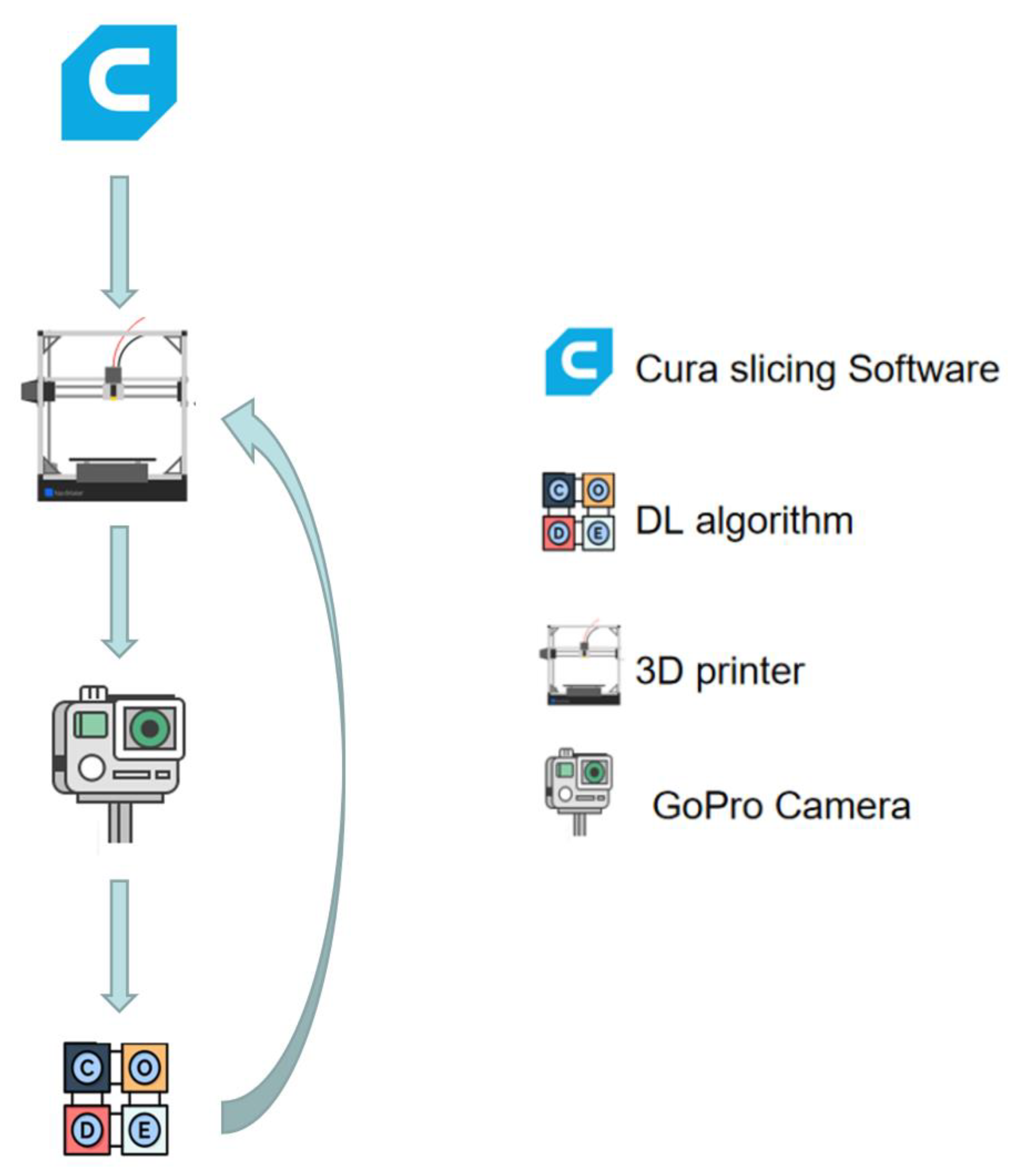

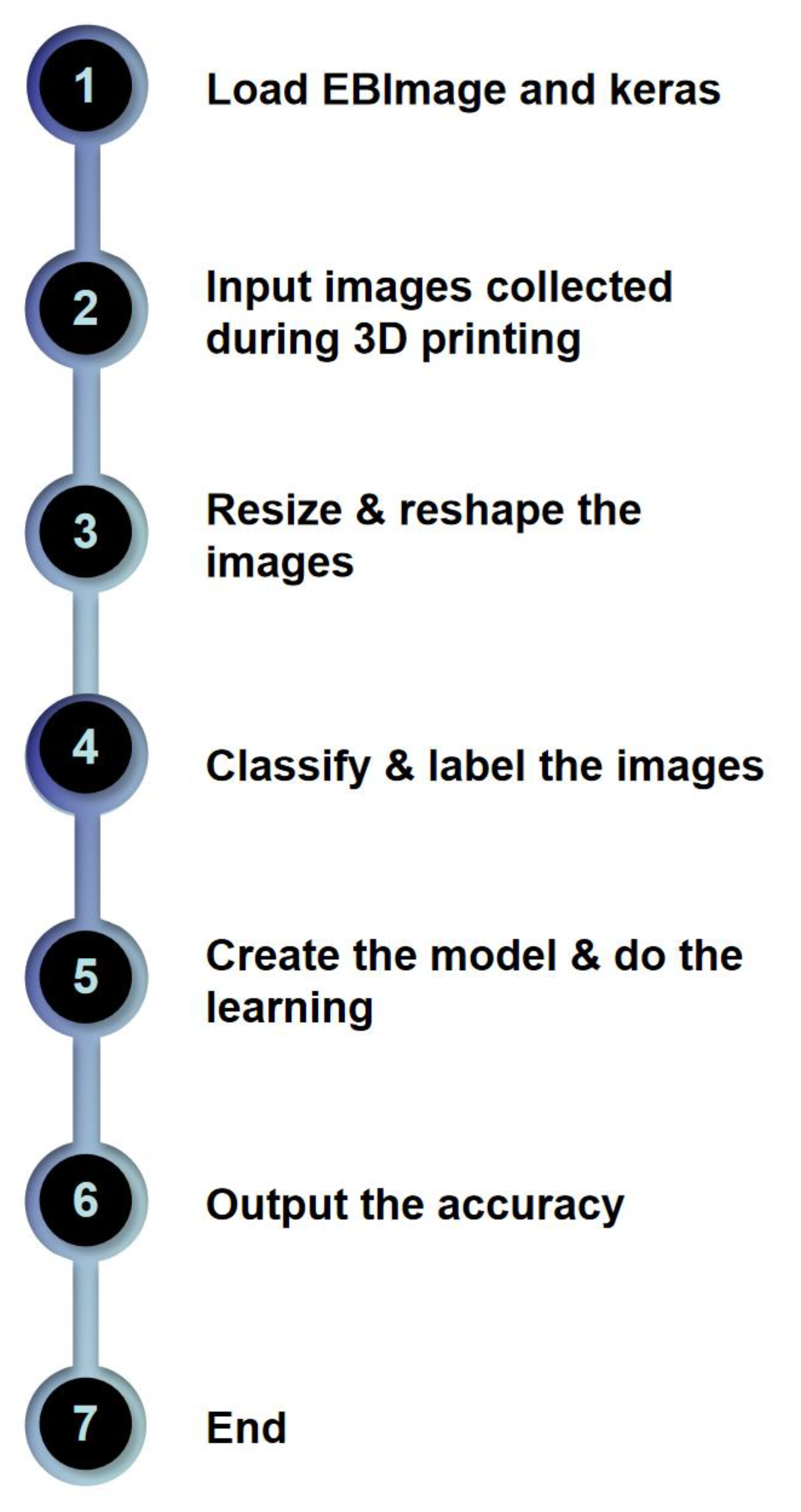

2. Materials and Methods

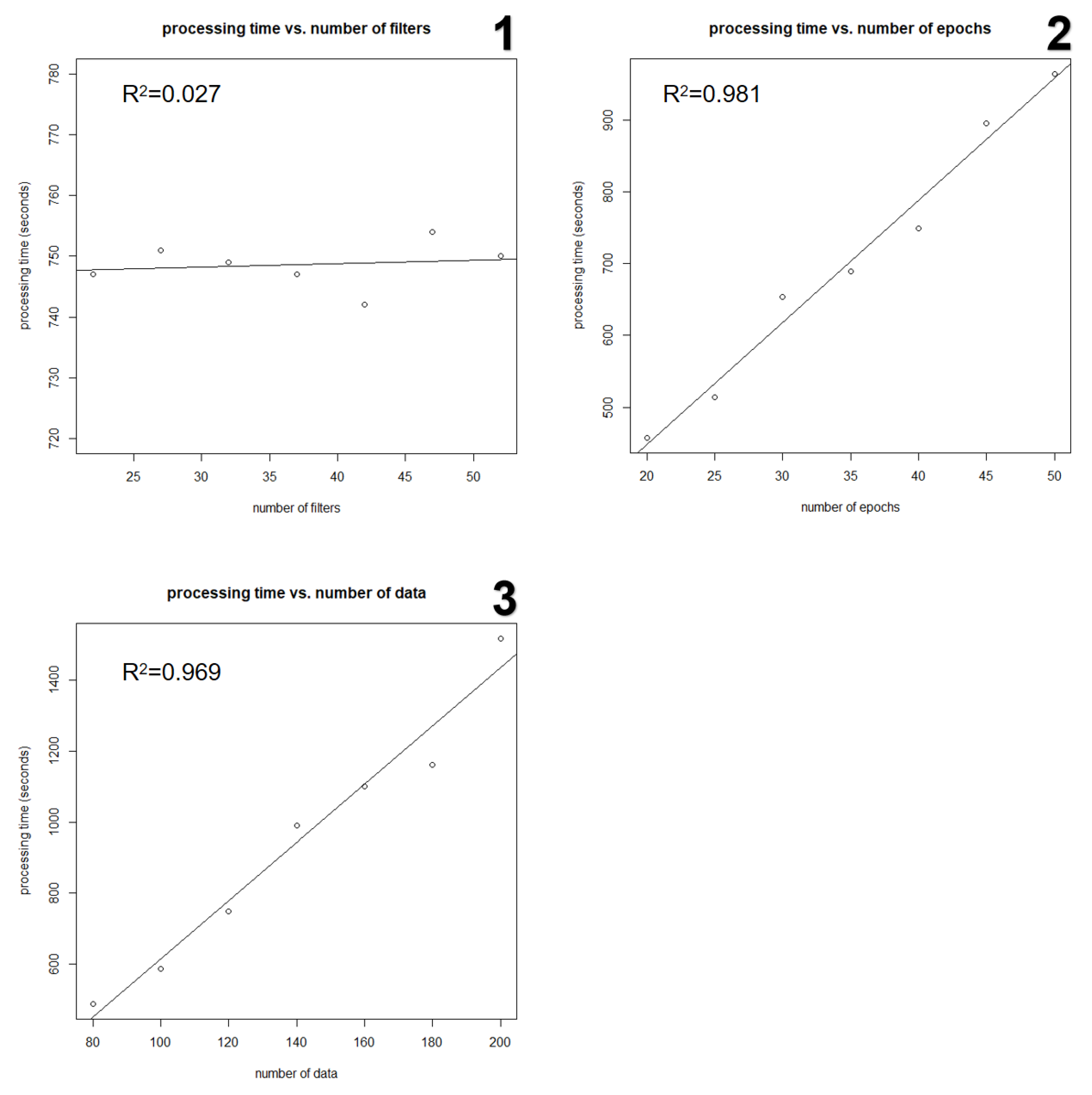

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wong, K.V.; Hernandez, A. A review of additive manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic implications of 3D printing: Market structure models in light of additive manufacturing revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2014; Volume 17. [Google Scholar]

- Redwood, B. Additive Manufacturing Technologies: An Overview. Available online: https://www.3dhubs.com/knowledge-base/additive-manufacturing-technologies-overview. (accessed on 6 May 2020).

- Dehghanghadikolaei, A.; Ibrahim, H.; Amerinatanzi, A.; Hashemi, M.; Moghaddam, N.S.; Elahinia, M. Improving corrosion resistance of additively manufactured nickel–titanium biomedical devices by micro-arc oxidation process. J. Mater. Sci. 2019, 54, 7333–7355. [Google Scholar] [CrossRef]

- Gannarapu, A.; Gozen, B.A. Micro-extrusion-based additive manufacturing with liquid metals and alloys: Flow and deposition driven by oxide skin mechanics. Extreme Mech. Lett. 2019, 33, 100554. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The potential of additive manufacturing in the smart factory industrial 4.0: A review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Terry, S.; Lu, H.; Fidan, I.; Zhang, Y.; Tantawi, K.; Guo, T.; Asiabanpour, B. The Influence of Smart Manufacturing towards Energy Conservation: A Review. Technologies 2020, 8, 31. [Google Scholar] [CrossRef]

- Fidan, I.; Imeri, A.; Gupta, A.; Hasanov, S.; Nasirov, A.; Elliott, A.; Alifui-Segbaya, F.; Nanami, N. The trends and challenges of fiber reinforced additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 102, 1801–1818. [Google Scholar] [CrossRef]

- Mohri, M.; Rostamizadeh, A.; Talwalkar, A. Foundations of Machine Learning; MIT Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Zhang, Z. Detection of the Additive Manufacturing In-Process Failures via Deep Learning. Master’s Thesis, Tennessee Technological University, Cookeville, TN, USA, August 2019. [Google Scholar]

- Ching, T.; Himmelstein, D.S.; Beaulieu-Jones, B.K.; Kalinin, A.A.; Do, B.T.; Way, G.P.; Ferrero, E.; Agapow, P.M.; Zietz, M.; Hoffman, M.M.; et al. Opportunities and obstacles for deep learning in biology and medicine. J. R. Soc. Interf. 2018, 15, 20170387. [Google Scholar] [CrossRef]

- Najafabadi, M.M.; Villanustre, F.; Khoshgoftaar, T.M.; Seliya, N.; Wald, R.; Muharemagic, E. Deep learning applications and challenges in big data analytics. J. Big Data 2015, 2, 1. [Google Scholar] [CrossRef]

- Mamoshina, P.; Vieira, A.; Putin, E.; Zhavoronkove, A. Applications of deep learning in biomedicine. Mol. Pharm. 2016, 13, 1445–1454. [Google Scholar] [CrossRef]

- Deng, L.; Yu, D. Deep learning: Methods and applications. Found. Trends Signal Process. 2014, 7, 197–387. [Google Scholar] [CrossRef]

- Khanzadeh, M.; Rao, P.; Jafari-Marandi, R.; Smith, B.K.; Tschopp, M.A.; Bian, L. Quantifying geometric accuracy with unsupervised machine learning: Using self-organizing map on fused filament fabrication additive manufacturing parts. J. Manuf. Sci. Eng. 2018, 140, 031011. [Google Scholar] [CrossRef]

- Baumann, F.; Roller, D. Vision based error detection for 3D printing processes. MATEC Web Conf. 2016, 591, 1–7. [Google Scholar] [CrossRef]

- Delli, U.; Chang, S. Automated process monitoring in 3D printing using supervised machine learning. Procedia Manuf. 2018, 26, 865–870. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 25, 1097–1105. [Google Scholar] [CrossRef]

- Liu, C.; Law, A.C.C.; Roberson, D.; Kong, Z.J. Image analysis-based closed loop quality control for additive manufacturing with fused filament fabrication. J. Manuf. Syst. 2019, 51, 75–86. [Google Scholar] [CrossRef]

- Gardner, J.M.; Hunt, K.A.; Ebel, A.B.; Rose, E.S.; Zylich, S.C.; Jensen, B.D.; Wise, K.E.; Siochi, E.J.; Sauti, G. Machines as Craftsmen: Localized Parameter Setting Optimization for Fused Filament Fabrication 3D Printing. Adv. Mater. Technol. 2019, 4, 1800653. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, W.; Li, Q.; Wang, T.; Wang, G. In-Situ Monitoring and Diagnosing for Fused Filament Fabrication Process Based on Vibration Sensors. Sensors 2019, 19, 2589. [Google Scholar] [CrossRef] [PubMed]

- Salmi, M.; Ituarte, I.F.; Chekurov, S.; Houtilainen, E. Effect of build orientation in 3D printing production for material extrusion, material jetting, binder jetting, sheet object lamination, vat photopolymerisation, and powder bed fusion. Int. J. Collab. Enterp. 2016, 5, 218–231. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Wayne, W.M.; Rowell, M.; Deason, B.; Eubanks, M. Comparative evaluation of an open-source FDM system. Rapid Prototyp. J. 2014, 20, 205–214. [Google Scholar]

- Zhang, S.; Sun, Z.; Long, J.; Li, C.; Bai, Y. Dynamic condition monitoring for 3D printers by using error fusion of multiple sparse auto-encoders. Comput. Ind. 2019, 105, 164–176. [Google Scholar] [CrossRef]

- He, K.; Yang, Z.; Bai, Y.; Long, J.; Li, C. Intelligent fault diagnosis of delta 3D printers using attitude sensors based on support vector machines. Sensors 2018, 18, 1298. [Google Scholar] [CrossRef]

- Faes, M.; Abbeloos, W.; Vogeler, F.; Valkenaers, H.; Coppens, K.; Goedemé, T.; Ferraris, E. Process monitoring of extrusion based 3D printing via laser scanning. arXiv 2016, arXiv:1612.02219. [Google Scholar]

- Sirinukunwattana, K.; Raza, S.A.; Tsang, Y.-W.; Snead, D.R.J.; Cree, I.A.; Rajpoot, N.M. Locality sensitive deep learning for detection and classification of nuclei in routine colon cancer histology images. IEEE Trans. Med. Imag. 2016, 35, 1196–1206. [Google Scholar] [CrossRef]

- Wu, M.; Song, Z.; Moon, Y.B. Detecting cyber-physical attacks in CyberManufacturing systems with machine learning methods. J. Intell. Manuf. 2019, 30, 1111–1123. [Google Scholar] [CrossRef]

- Ahuja, B.; Karg, M.; Schmidt, M. Additive Manufacturing in Production: Challenges and Opportunities. Laser 3D Manufacturing II. Int. Soc. Optics Photonics 2015, 9353. [Google Scholar] [CrossRef]

- Ultimaker 3 Manual (EN).pdf. Available online: https://ultimaker.com/download/61355/Ultimaker%203%20manual%20%28EN%29.pdf (accessed on 6 May 2020).

- UM_HEROPlus_ENG_REVA_WEB.pdf. Available online: https://gopro.com/content/dam/help/heroplus/manuals/UM_HEROPlus_ENG_REVA_WEB.pdf (accessed on 6 May 2020).

- Surface-Book-User-Guide-EN.pdf. Available online: https://download.microsoft.com/download/7/B/1/7B10C82E-F520-4080-8516-5CF0D803EEE0/surface-book-user-guide-EN.pdf (accessed on 6 May 2020).

- What is R? Available online: https://www.r-project.org/about.html. (accessed on 6 May 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Fidan, I.; Allen, M. Detection of Material Extrusion In-Process Failures via Deep Learning. Inventions 2020, 5, 25. https://doi.org/10.3390/inventions5030025

Zhang Z, Fidan I, Allen M. Detection of Material Extrusion In-Process Failures via Deep Learning. Inventions. 2020; 5(3):25. https://doi.org/10.3390/inventions5030025

Chicago/Turabian StyleZhang, Zhicheng, Ismail Fidan, and Michael Allen. 2020. "Detection of Material Extrusion In-Process Failures via Deep Learning" Inventions 5, no. 3: 25. https://doi.org/10.3390/inventions5030025

APA StyleZhang, Z., Fidan, I., & Allen, M. (2020). Detection of Material Extrusion In-Process Failures via Deep Learning. Inventions, 5(3), 25. https://doi.org/10.3390/inventions5030025