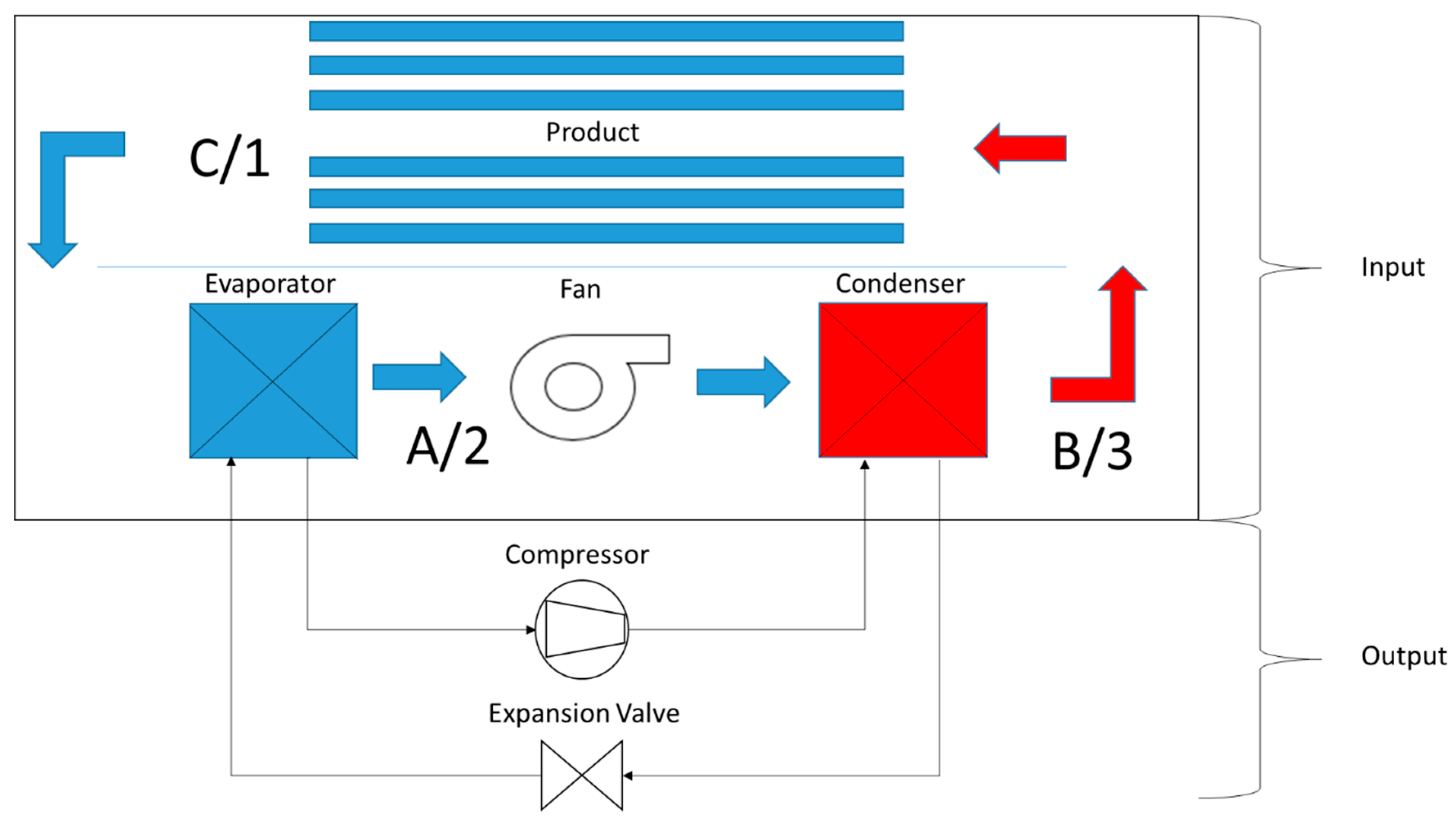

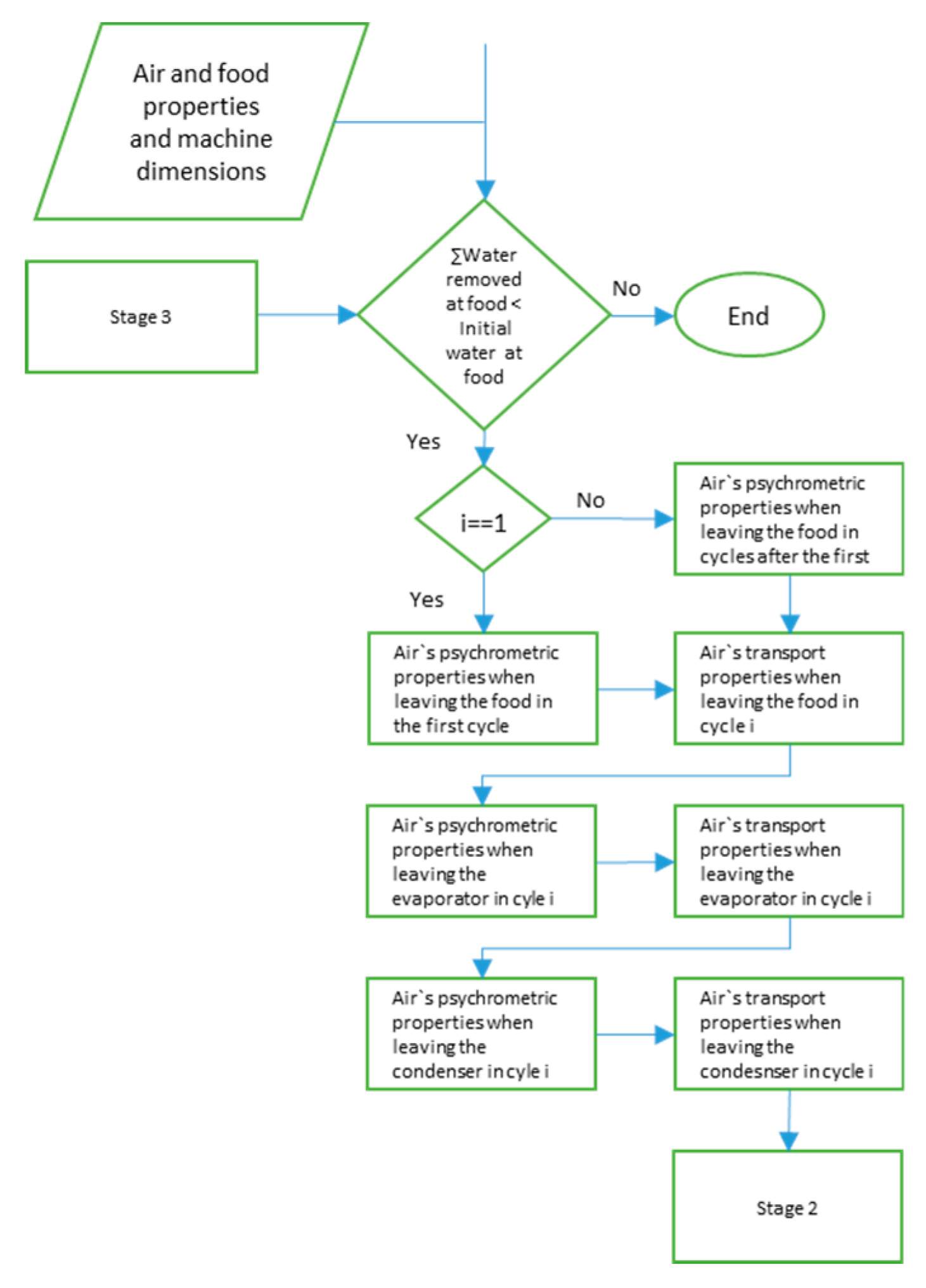

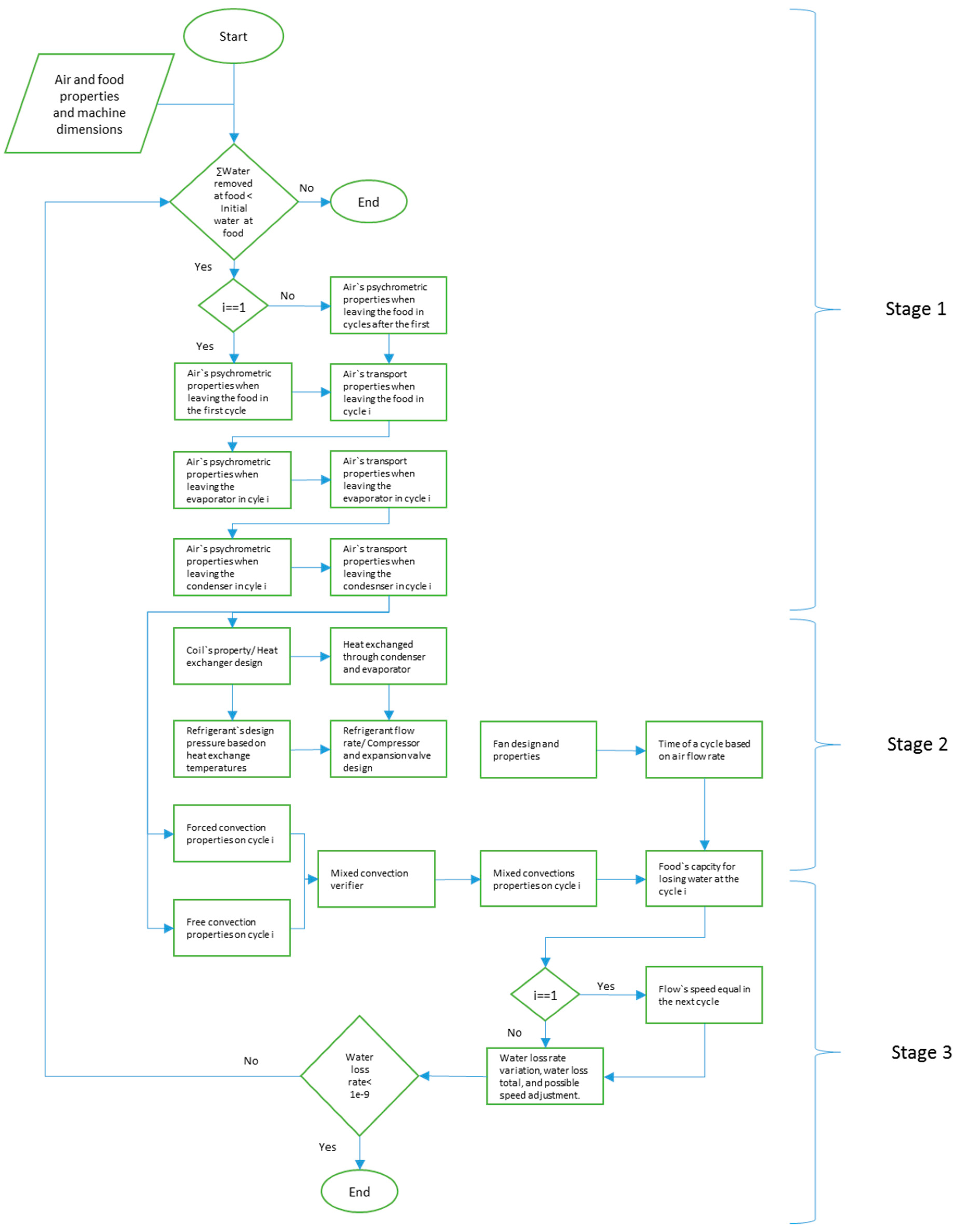

The design algorithm is a logic map of the efficient design of food-drying heat pump air-based machines. The algorithm inputs are the type of food, the air properties and the dimensions of the food container, as well as the dryer component properties. To guarantee the temperature control throughout the drying process, the working temperature of the air to which the food is being exposed to is used as input. Therefore, it is possible to ascertain the final product quality, since over-heating could cause damage to the product. Meanwhile, the algorithm outputs the mass flow of refrigerant fluid from which the compressor and expansion valve can be selected. The difference of the algorithm inputs and outputs, and their relation to the machine design are depicted in

Figure 1. In this figure within the circulating air volume there are 2 different nomenclatures aiming the description of different things: A, B and C are related only to the air properties; and 1, 2 and 3 represent the 3 stages of the algorithm, with different transport and energy equations:

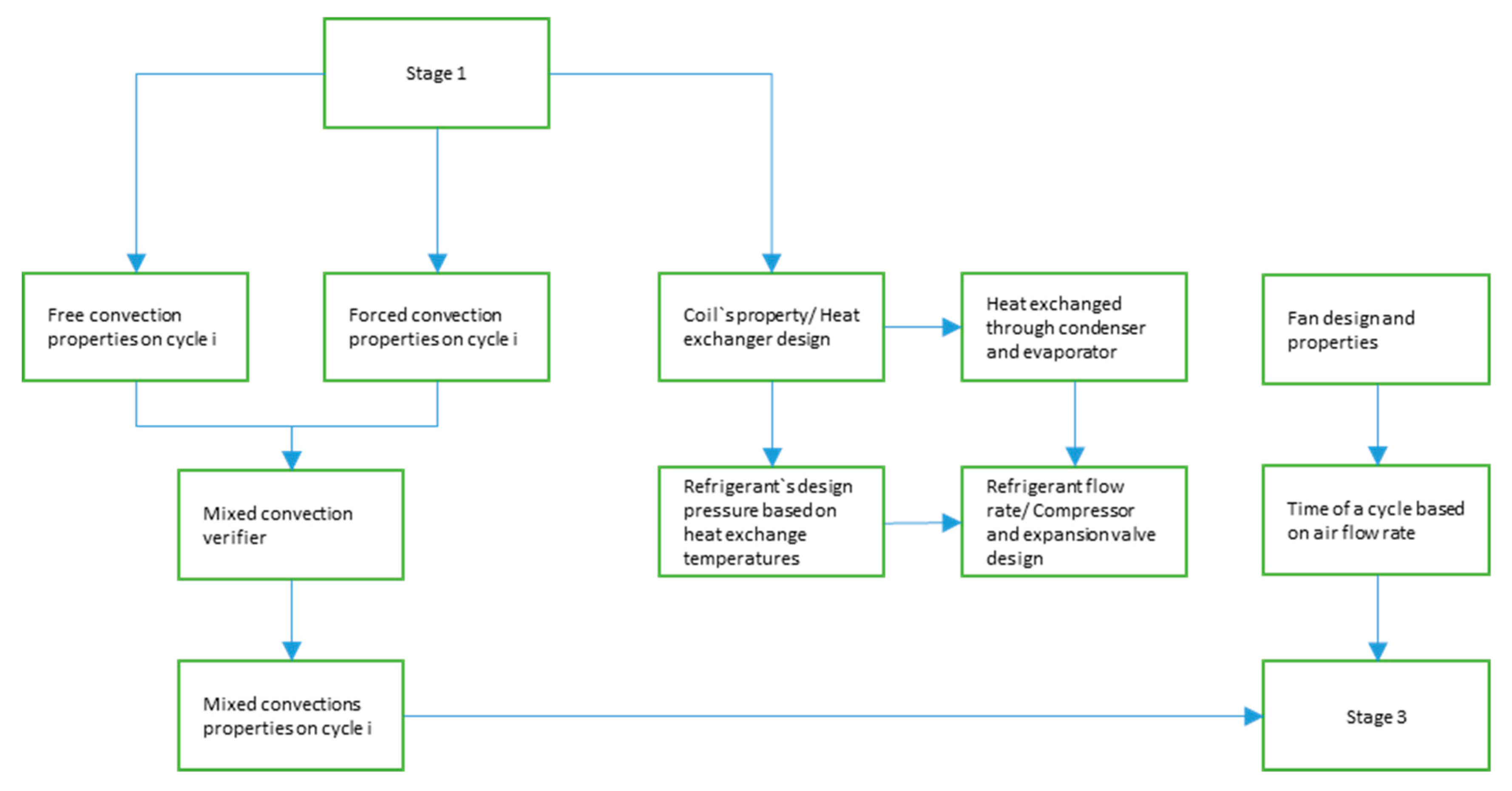

2.1. Stage 1 of the Algorithm

The first stage of the algorithm determines the psychrometric and dynamic states of the air. The literature recommends temperatures for drying each food, and by using them in the following psychrometric and transport equations, one obtains every property necessary to the characterization of the process and posterior steps [

5,

6,

7].

The calculus of the air properties are given by Equations (1)–(17). The specific psychrometry Equations (1)–(8) are recommended by [

6]. The psychrometric equations utilized at this stage describe the humid air based on its temperature, amount of water as vapor and the air’s occupied volume [

8,

9,

10].

To provide the readers less clutter information on the variables of the equations, a list of variables and units is shown at the end of the article.

At first it is necessary to obtain the vapor saturation pressure

and the absolute humidity

. The air humidity after the contact with the food in the first iteration and after the air leaves the evaporator, corresponding to air process C and A in

Figure 1, are calculated by Equations (1) and (2):

In the following iterations, the absolute humidity is obtained by adding the total humidity lost by the food to the air humidity after it left the condenser, process B to C in

Figure 1. The air humidity when it leaves the condenser is equal to the one when it left the evaporator. Therefore, the next step are the calculations of the air’s vapor pressure

, and its enthalpy

, from the absolute humidity Equations (3) and (4):

With the air’s vapor pressure and the vapor saturation pressure, the relative humidity

and the dew point

are then calculated for this pressure, Equations (5) and (6).

Additionally, with the vapor’s pressure and the absolute humidity, the algorithm calculates the specific volume

and the vapor molar fraction

relative to the mixture and molar mass.

The determination of the transport properties, Equations (11)–(17) as stated by [

7], require the non-dimensional dry air/water vapor proportion parameters

and

, Equations (9) and (10) also recommended by [

7].

The acronyms and respectively represent the molar masses of the vapor and dry air while the and represent their dynamic viscosity. Therefore, with the proportion parameters and defined, the mean thermophysical properties are calculated.

Firstly, the thermal conductivity of the humid air

is given by Equation (11):

The specific heat

of this air is obtained with Equation (12).

These properties are used to obtain the thermal diffusivity α, which is expressed by Equation (13):

Additionally, the mixture density

for incompressible gases are calculated according to Equation (14):

The transport properties that govern the fluid’s movement are calculated from the equations pointed by [

7]. The dynamic viscosity

of the mixture results from Equation (15):

With

and

, the cinematic viscosity

then is obtained with Equation (16):

The Prandl number

, which is used to determine the water loss, is calculated from Equation (17):

2.2. Stage 2 of the Algorithm

The second stage of the algorithm relates to the heat flow analysis and component design, it uses the data calculated in Stage 1, the pre-determined dimensions and construction parameters of components to calculate results that are essential to the final design of the product.

To reduce the time from client order to the actual manufacturing of the novel compact food-drying machine, a supplier component database is created from which off-the-shelf products such as heat exchangers and fans will be selected. Their physical dimensions and operating parameters are used in the algorithm. As a heat pump system can be defined by the compressor and the heat exchangers [

9], the heat output of this stage will be used to calculate the mass flow rate of refrigerant required to select a fitting compressor.

The reasoning behind this is that controlled temperatures are a main focus of the algorithm to assure product quality. Additionally, the heat exchangers and fans are parts that affect the final product dimension if changed, and so, by selecting products that are available in the market, the cost of production is expected to drop and the final product construction can be streamlined. Any machine designed through this method will have its power output controlled through the variation of the compressor’s cycle rate.

At this stage, the fan’s diameter is used with previously calculated air speed and density to obtain the air mass flow rate, which will be used in the third stage for controlling the removed water.

With the combined data from Stage 1 and the dimensions of components, the heat which will flow to the air is calculated. That heat is the same that is removed from the refrigerant fluid, and since the temperatures have been set, the enthalpy variation of the refrigerant expected is known and so its mass flow rate is achieved.

To do so, the equations used were the ones that relate to the heat exchangers, such as logarithmic mean temperature difference, Nusselt and Reynolds dimensionless numbers, global heat conductivity and heat flow equation at heat exchangers. These equations are pointed out in [

10,

11,

12,

13].

The logarithmic mean temperature difference

is a variable that accounts for the logarithmic nature of the heat transfer properties and converts the temperatures and the exchanger’s entry and exit, jointly with the external’s fluid temperature to obtain a mean value that can be used in heat transfer equations.

These equations also require a mean global heat flux coefficient

. This has the same principle of the previous Equation (18), making a mean value that accounts for every heat transfer process. However, unlike the logarithmic mean temperature difference, this equation results in a heat transfer factor.

where

represents the thickness of the heat exchanger’s walls.

Therefore, the required data to calculate such a factor are the conduction heat transfer coefficient for the heat exchanger’s material

, and the convection heat transfer coefficient for the operating air flow

.

where D equals to the heat exchanger’s cylinder diameter

is the air’s heat conductivity and

is a dimensionless number obtained through the following equation:

In this equation, the

and

variables are constants obtained based on the heat exchanger’s dimensions and layout. The

is another number obtained by:

The

in the equation is the air’s speed. Finally, the final exchanged heat value

, equals to:

where

is the total exposed heat exchanger area. The heat can be used, as previously mentioned, together with the variation of enthalpy

, to obtain the refrigerant mass flow rate

.

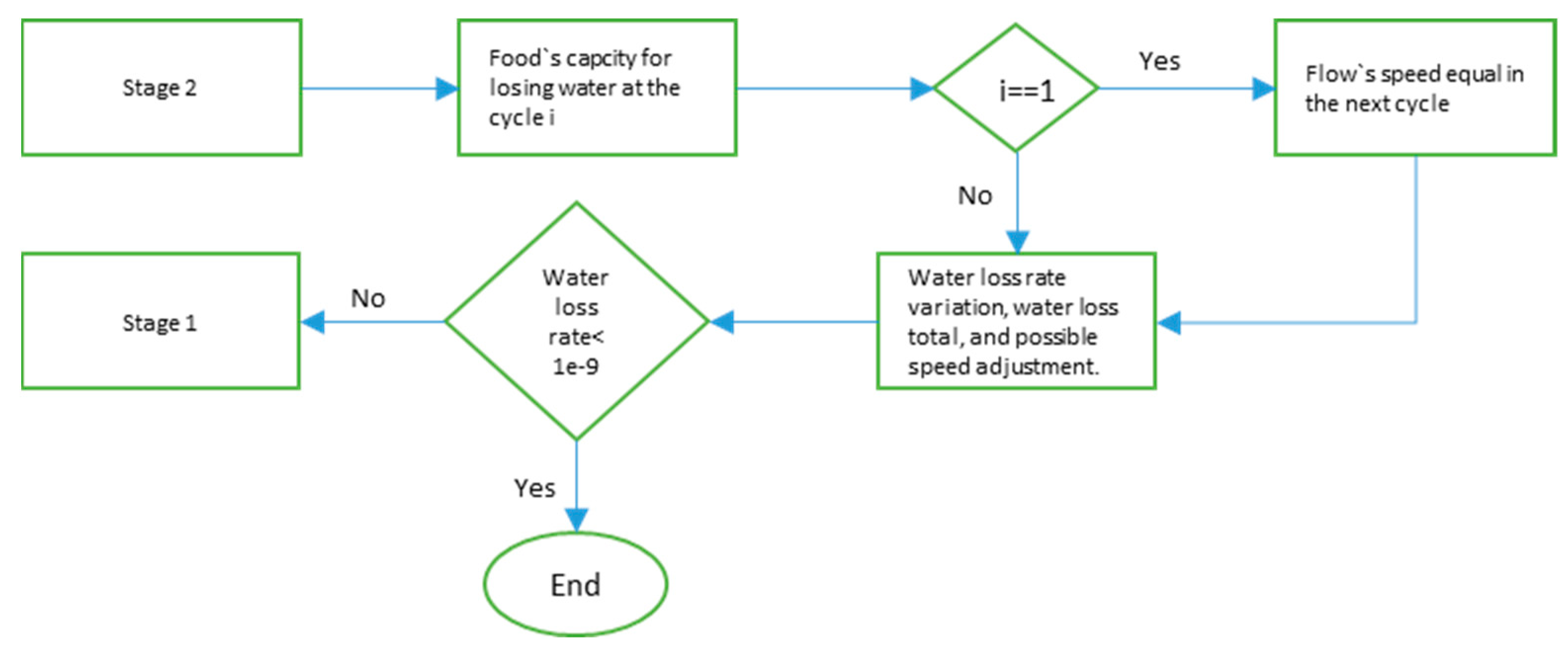

2.3. Stage 3 of the Algorithm

The third stage, the food analysis, is a control stage. This means that in it the algorithm has its control variables calculated to provide the iterative results that make the calculating cycles continue or stop. For this case, the control variable is food’s moisture level, and it is calculated through the use of well-known food-drying models. The Modified Henderson model was selected for its recurring appearance in the literature and consequent versatility. It requires the air’s humidity level, temperature and speed to calculate the water loss variation [

4,

5].

For the calculus of the water mass transfer and consequently, total moisture left in the product, the air diffusion coefficient is used as cited at [

11,

14]. This coefficient is presented in Equation (25):

This equation will lead to an underestimation of the drying time for it does not consider the biological properties of internal moisture diffusion and surface diffusion. However, the algorithm structure is built to incorporate further published knowledge in this particular field.

With the air diffusion coefficient calculated, the Graschof

and Schimdt

numbers can be obtained:

where

is the characteristic dimension, which in the case of the drying machine are the spaces between the plaques that hold the food. With both Graschof and Schimdt, the Rayleigh

and Sherwood numbers can be obtained, for both natural

and forced

convections:

If Reynolds is less than 200.000,

However for value greater than that,

With Sherwood defined, the mass transfer coefficient is obtained with Equation (32).

The

value is the food containing plaque’s height. The total water mass removed

is calculated by:

In Equation (33), is the plaque’s area, is the number of plaques and is the difference between density of water in the air and food.

The next step of the algorithm compares the value obtained with the mass transfer equation and the Modified Henderson model, and select the most conservative value. This value is removed from the food’s total humidity and accounted for in the control function, restarting the cycle if necessary.