Abstract

With Tangible User Interfaces, the computer user is able to interact in a fundamentally different and more intuitive way than with usual 2D displays. By grasping real physical objects, information can also be conveyed haptically, i.e., the user not only sees information on a 2D display, but can also grasp physical representations. To recognize such objects (“tangibles”) it is skillful to use capacitive sensing, as it happens in most touch screens. Thus, real objects can be located and identified by the touch screen display automatically. Recent work already addressed such capacitive markers, but focused on their coding scheme and automated fabrication by 3D printing. This paper goes beyond the fabrication by 3D printers and, for the first time, applies the concept of capacitive codes to laser cutting and another immediate prototyping approach using modeling clay. Beside the evaluation of additional properties, we adapt recent research results regarding the optimized detection of tangible objects on capacitive screens. As a result of our comprehensive study, the detection performance is affected by the type of capacitive signal processing (respectively the device) and the geometry of the marker. 3D printing revealed to be the most reliable technique, though laser cutting and immediate prototyping of markers showed promising results. Based on our findings, we discuss individual strengths of each capacitive marker type.

Keywords:

tangible user interface; capacitive; marker; 3D printing; multi-touch; laser cutting; prototyping 1. Introduction

Tangible User Interfaces (TUI) offer a considerable advantage over conventional 2D screens. Instead of visualizing information only on a 2D display, users can grab real 3D objects (so-called “tangibles”), which represent digital information. Their position and type are automatically detected and processed by the computer. This detection process can be realized with different methods, usually optical methods, such as QR (Quick response) codes. However, such procedures usually require additional effort (i.e., camera and image processing) to identify and process the objects. In addition, this method suffers from problems such as occlusion and does not work without sufficient illumination. Today, however, capacitive touch displays are most commonly used in tablets and smartphones, which makes it particularly useful to look at tangible objects, that make use of this interaction method. Similar to a real human finger, tangibles are detected capacitively on the surface of the screen and their position and type can be processed in the software. There are no problems as with optical tracking, since the objects are detected via the integrated capacitive interface of the device. Capacitive sensing also enables users to interact with more than one finger (or contact points). In contrast to resistive touch screens, one or more touches are detected without the necessity to apply force to the screen. This allows interactive applications which are intuitive and tailor-made for mobile devices. Due to these advantages, we will introduce capacitive markers, their use in a TUI and our contribution in more detail below. The first approach of Rekimoto [1] dates back over a decade and describes the basics by electrically mimicking a real human finger with respect to a capacitive display. More precisely, a grid of electrodes continuously measures capacitances between each electrode in x and y direction, the capacitance of an approaching human finger changes the electrodes’ capacitance at a specific x-y location. Thus, Kratz et al. [2] determined the position and rotation of touch points on the display simulated by an aluminum knob. Following work extended this concept to a low-cost prototyping environment, i.e., Wiethoff et al. used cardboard and conductive ink [3]. Shemelya et al. described the manual assembly of conductive parts [4], Schneider and Götzelmann integrated this into an automatic 3D printing process [5]. To identify the respective tangible, they optimized the spatial arrangement of touch points for encoding information, while Yu et al. [6] employed active modulation of the touch points. Gonzales et al. [7] exploited the fact that the fingers touch the display when grasping an object on it and could identify the object and its position.

Furthermore, identification and tracking of tangibles can be achieved by computer vision methods, which requires explicit hardware (i.e., optical markers and cameras) and suffers from multiple limitations like occlusion and costs [8,9]. The tracking of tangibles is possible via microcontrollers [10], RFID (Radio Frequency Identification) [11] or magnetic sensors [12,13], too, but needs a much higher level of assembly effort and complexity compared to a low-cost prototyping environment. Regarding the potential and limitations for future dissemination, those approaches seem more realistic. Unfortunately, all so far mentioned low-cost approaches [3,4,5] rely on either a human finger touch or an additional electrical contact to be functional. Voelker et al. addressed this problem by making use of the capacitive touch screen’s structure itself in order to detect untouched tangibles by capacitive bridging [14]. Most recently, Thoresen and Hanke carried out finite-element simulations and real experiments, proving the detection of ungrounded objects with capacitive touch screens and proposing an optimized setup of the screen [15].

However, the combination of those results regarding ungrounded touch with capacitive markers in a low-cost prototyping environment has not yet been investigated. Moreover, there has been no comparison of different manufacturing methods for capacitive markers in the context of TUI, which is an important factor for its dissemination potential. Hence, this paper expands a previous short paper about 3D printed capacitive markers (“CapCodes”) [5], which introduced a coding scheme for capacitive markers and their automated fabrication by 3D printers. This paper applies capacitive codes to other fabrication processes including laser cutting and a modelling clay based approach, which can be used for prototyping tangible user interfaces immediately. Several additional properties are tested in this paper and we adapted the recent research results of Thoresen and Hanke [15] who propose optimizations for the detection of tangible objects on capacitive screens. Each of these techniques is evaluated in a comprehensive study. Concisely, we want to investigate the following questions:

- How do capacitive markers fabricated by laser cutting, prototyping and 3D printing perform compared to each other?

- How do side effects (e.g., type of device, type of interaction) affect the detection performance?

- Does a certain layer of insulation (between the pad and the touch screen) possibly enhance the untouched detection performance?

- Can capacitive markers in our study be detected untouched?

Section 2 contains detailed information on components and knowledge used to examine these questions. Afterwards, experimental results are presented and discussed in-depth in Section 3. In Section 4, a short summary recapitulates important results, underlines main findings of this paper and points out possible future improvements.

2. Materials and Methods

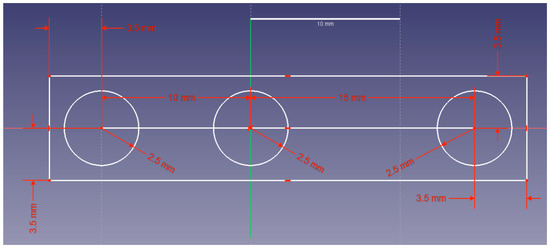

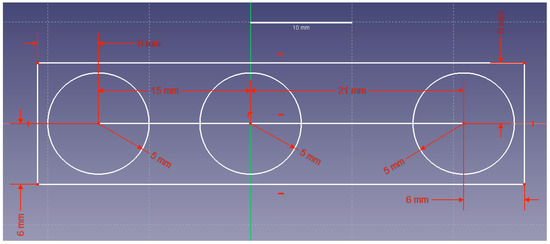

Our study verifies the applicability of capacitive codes by three different methods. In this section, we describe the fabrication processes, the materials used in our study and the methods applied for the actual verification. To answer the raised questions thoroughly, we fabricated capacitive markers using 3D printing, laser cutting and prototyping using clay. In addition, we also examined characteristic parameters of each fabrication technique. To compare the different marker types, we used two common geometries for the markers, i.e., with 5 mm and 10 mm pad diameter. These are shown in a two-dimensional drawing in Figure 1 and Figure 2. We also varied the insulating layer of each marker type (wherever possible) to identify a possible improvement in detection performance. Finally, we list all variables and their values in our study.

Figure 1.

Drawing of the bearing surface for 5 mm pad diameter markers, the circles represent conductive material and are connected in 1 mm height.

Figure 2.

Drawing of the bearing surface for 10 mm pad diameter markers, the circles represent conductive material and are connected in 1 mm height.

The following Section 2.1 and Section 2.2 provide a more detailed insight into each step of our procedure to answer the previously presented questions.

2.1. Apparatus and Materials

Identification of objects is crucial for tangible user interaction to couple physical objects with digital information [6]. Conductive material can be used to integrate markers into individual objects for user interaction. To ensure optimal comparability between the three fabrication methods, a common geometry for the capacitive markers was defined.

2.1.1. Capacitive Markers and Touch Screen Displays in General

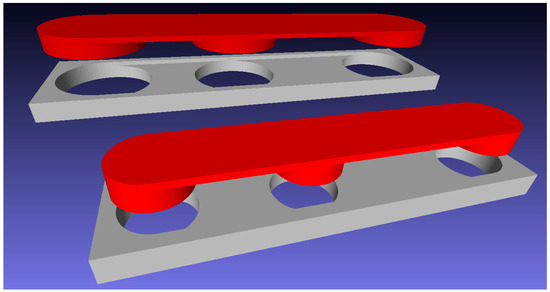

As explained in the introduction, touch screens detect a human finger touch by capacitive sensing. A grid of electrodes continuously measures capacitances between each electrode in x and y direction, the capacitance of a human finger changes the electrodes’ capacitance at a specific x-y location. Thus, the position of the finger is localized. To locate tangible objects on such touch screens, they have to involve a conductive area on the contact surface to the touch screen (analogous to a human finger). Moreover, those conductive parts can be connected, as is the case when a person touches the surface with more than one finger. This forms a so-called “capacitive bridge” (see Figure 3 and Figure 4). When touching this bridge, the “bridge piers” (so-called pads) trigger several simultaneous touches on the touch screen, just as multiple fingers are detected at once. The locations of these concurrent touch positions can be used to encode information [5]. Depending on the specific setup, those bridges can be even detected passively, i.e., without the need for a human finger touch [14]. In order to increase the untouched detection performance, recent results also suggested integrating a certain insulating layer between the conductive pad and the touch screen surface [15].

Figure 3.

Exploded view of 3D printer capacitive markers with no insulation layer, i.e., the pads (or “bridge piers”) have direct contact to the touch screen surface below. The 5 mm pad diameter is shown in front and 10 mm pad diameter in the back. In this CAD view, the insulating parts are colored grey, conductive ones (“bridges”) red.

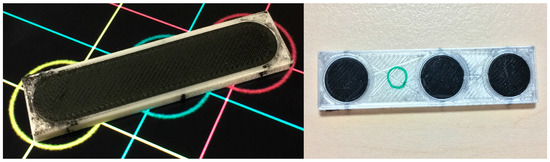

Figure 4.

Left: Real 3D printed marker being detected untouched on capacitive touch screen, visualized by colored circles and hair crosses on the display. The black material is conductive PLA (polylactide), the white one is insulating PLA. Right: Bottom view of this capacitive marker (with no insulating layer as the pads rest directly on the touch screen.).

2.1.2. Consistent Geometry of Used Capacitive Markers

Based on earlier results on a capacitive coding scheme [5], the authors exemplarily derived a geometry for conductive pads’ diameter of 5 mm and 10 mm (see Figure 1 and Figure 2). The centers of each pad were located 10 and 15 mm (5 mm diameter) and 15 and 21 mm (10 mm diameter) apart. The total height of the marker (using 3D printing) was 2 mm, whereas the conductive part bridging the pads began 1 mm above the lowest point. With non-3D-printing fabrication techniques, this was achieved by a (cardboard panel or acrylic glass) material thickness of 1 mm. To realize an insulating layer between the pads and the touch screen, we limited the process of cutting when using a laser cutter so that a rest of insulating material in the pad’s area remains. When using a 3D printer, we replaced conductive material on the lowest parts of the capacitive ‘bridge piers’ (see Figure 3) with insulating one.

2.1.3. 3D Printing

Capacitive markers can be fabricated by 3D printing [4,5]. In this paper, a script-based solid modelling framework OpenSCAD (Version 2015.03, available online: http://www.openscad.org/about.html) was used to procedurally construct the individual 3D models for each capacitive marker’s size and insulating layer (see exemplary Figure 3 and Figure 4). 3D printing is an additive manufacturing technique (AM) which generally comprises different methods to create a real-world 3D object in a layer based production process. The deposition process of these layers depicts the main difference between individual AM techniques. Especially in the low-cost segment being relevant to hobbyists and consumer devices, FDM (fused deposition modeling) is the method of choice. Here, the real-world object emerges from many discrete layers, whereas each layer is generated by the deposition of molten plastic. Thus, printing material (referred to as filament) is heated and extruded through a nozzle, which moves along the printing plane. There, the extruded filament solidifies and serves as a subsoil for the next layer. Most filament materials, like polylactide (PLA) or acrylonitrile butadiene styrene (ABS) are insulating, but there exist conductive ones as well. To fabricate the intended capacitive markers, an off-the-shelf printer Ultimaker 3 (Ultimaker, Geldermalsen, the Netherlands) was used. This device is equipped with a twin extruder fed by insulating and conductive PLA with a diameter of 2.85 mm to realize the corresponding parts of the marker in one printing process. More precisely, insulating Innofil3D PLA pearl white (Innofil3D BV, Emmen, the Netherlands) and Proto-Pasta conductive PLA (ProtoPlant INC, Vancouver, WA, USA) with a specific resistance of were used; PLA per se was chosen since it is one of the most common types of filament for consumer-grade printers and features less warping than ABS. The translation of the digital 3D model to the printer’s machine language (so called slicing) was done by a popular slicing software CURA (Version 2.7.0, available online: https://ultimaker.com/en/products/ultimaker-cura-software). Using default settings, the smaller capacitive markers (5 mm pad diameter) took each 10–15 min and overall approx. 10 cm of filament to print, the bigger ones (10 mm pad diameter) took each about 30 min and 15–20 cm of filament. By utilizing a dual extruder, the fabrication (respectively printing) process runs fully automatically and no post-processing is necessary.

2.1.4. Laser Cutting (Used with Acrylic Glass and Cardboard Panel)

For the fabrication of the markers by laser cutting we utilized the widely used carbon dioxide laser (CO2 laser) [16]. By producing laser beams up to 60 watts, this laser offers a broad spectrum for cutting and engraving different materials such as acrylic glass or cardboard panels. Essential for the manufacturing of markers with a varying insulating layer is the ability to modify the transversal speed along the cutting plane and the power of the beam. Over the course of our study, we used an air-cooled Epilog Zing 24 laser (Epilog Laser, Golden, CO, USA) with a maximum power of 40 Watt. It allows manually percentage control of speed and power (i.e., each from 1% to 100%). The patterns for engraving and cutting were created in the vector graphics editor Inkscape (Version 0.48.3, available online: https://inkscape.org/en/about/), the laser cutter was controlled with the software VisiCut (Version 1.7-310, available online: https://github.com/t-oster/VisiCut). For the engraving and cutting process of the acrylic glass and cardboard markers, we used the parameters listed in Table 1. The engraving process was used to create the indentations in acrylic glass, where conductive silver can be accumulated. As shown in Figure 1, Figure 2 and Figure 5, these pads are located in a defined position relative to each other and are electrically connected. With acrylic glass and cardboard panel, the cutting process was used to cut the rectangular contour of each marker from a larger workpiece. In the latter case, the circles were also cut out (see Figure 1 and Figure 2), through which the clay comes into direct contact with the touch screen panel (see Figure 6). Since the conductive silver is liquid before being applied to the laser prepared acrylic glass, there is always a small layer of insulation, because the silver needs a surface to dry.

Table 1.

Device parameters for fabrication of capacitive markers, the power and speed of the laser can only be controlled in relative percentages. In order to be able to reproduce and assess the results, the device parameters and the processing times are specified.

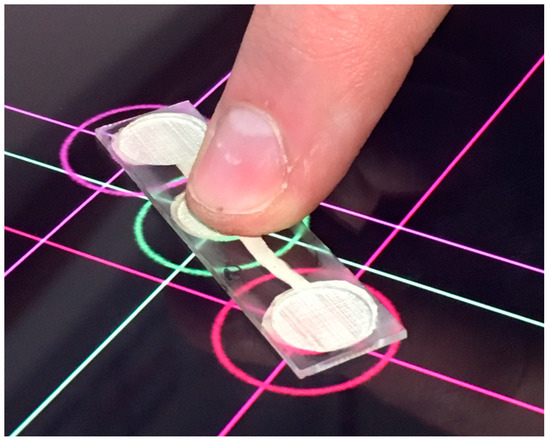

Figure 5.

Capacitive marker (10 mm pad diameter) fabricated by laser cutting in use on capacitive touch screen. The colored rings and hair crosses indicate that each individual pad has been recognized as separate touch point by the touch screen. The microstructure resulting from the engraving process and the conductive silver varnish are also well visible.

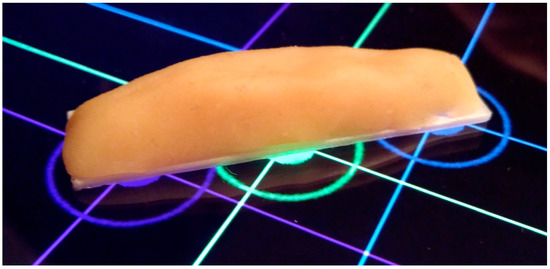

Figure 6.

Detection of untouched marker consisting of conductive modeling clay, as insulating part cardboard panel was used. The colored circles and hair crosses indicate, that each pad was recognized by the touch screen.

Generally, the utilized laser supports 28 different materials for cutting and engraving. Our focus was on acrylic glass panels, because they are durable and available at comparatively low costs supporting the dissemination potential of such capacitive markers. Furthermore, the cardboard panel of a rapid prototyping environment is not intended to be used with a laser cutter, but for our study and its evaluation with ideally geometrically identical markers, we yet considered this combination. Both materials have a thickness of 1 mm. Preliminary tests with a material thickness below 1 mm showed that the conductive bridge between the engraved touch points was too close to the display resulting in markers being only recognized as a single touch point.

In contrast to the proposed 3D printing technique, the process of manufacturing capacitive markers by laser cutters could not be completely automated. After the initial creation (i.e., firstly to cut the contour of the marker and secondly to engrave the area of the pads), the pad areas still contain residues of the engraving process, which have to be removed. Moreover, the marker itself is not yet capacitive. Therefore, we used conductive silver Kemo L 100 (Kemo Electronic GmbH, Geestland, Germany) with a specific resistance of (typically used for repairing electrical circuits) to fill and connect the engraved touch points (see Figure 5). The applied varnish contains 1 g of pure silver in a package size of 2 g and dries within a few minutes. The complete application process of creating one marker with three touch points (10 mm pad diameter) takes approximately 5 min. Markers with a pad diameter of 5 mm take about 3 min. The pure processing time by the laser is between 30 s and 2 min, depending on the device settings and the size of the capacitive marker. Compared to the creation of capacitive markers by 3D printing, this approach is just as fast, even though extra effort in form of manual post-processing has to be taken into account.

2.1.5. Prototyping by Modeling Clay

There are certain areas of application, where a rapid fabrication technique is crucial. For example in an educational environment, students in the classroom should be able to fabricate individual capacitive markers to interact and learn with their tablet computer quick and easy. This kind of interaction is thinkable in a business or academic environment, too. Here, one might think of a meeting situation, where the teamwork is supported by a tangible user interface consisting of rapidly fabricated capacitive markers. A simple but effective means for prototyping capacitive markers is to attach conductive modeling clay to perforated cardboard (see Figure 1, Figure 2 and Figure 6). This conductive clay can be easily made out of usual ingredients. In public forums of the maker community there are multiple recipes for producing conductive modeling clay. For our paper, we used the following procedure for producing suitable modeling clay: First of all, 180 mL water, 100 mL lemon juice, 100 g flour and 50 g salt have to be mixed in a heatable container. When it is has been thoroughly mixed, the mixture has to be heated up 80–120 °C until it agglomerates to a single chunk. After cooling down the sticky material has to be manually kneaded by adding up to 50 g flour until its surfaces gets non-adhesive. The resulting material can be used for several hundreds of markers and should be stored in an air-tight container. An inherent problem of this rapid prototyping approach is that when the clay is continually exposed to air dries after a couple of days (depending on the air moisture) and thus, loses its conductivity. This effect can be reduced by adding glycerol or vegetable oil. Nevertheless, the advantages of rapid application and functionality outweigh this drawback.

2.1.6. Comparison of Fabrication Techniques

Table 2 provides a comparison of the strengths and drawbacks for each of the presented techniques. This table compares 3D printing, laser cutting and prototyping for production and function parameters. In concrete terms, this involves the time, costs and manual effort required to produce capacitive markers. The functionality over time (respectively lifetime) of the markers is also differentiated.

Table 2.

Tabellaric line-up of fabrication techniques characteristics.

2.2. Methods and Measurements

The following three sections show how and with which variables the fabricated markers were evaluated in our study.

2.2.1. Variables

We introduced the following variables to answer the questions presented above (see introduction) in defined conditions: Type of device, type of fabrication, marker geometry, thickness of insulation layer and method of interaction with the marker. Table 3 lists values for each variable; the exact values were specified from preliminary testing. For the sake of clarity, the exact thickness of each insulating layer is listed in Table 4. For the best possible comparability between the three fabrication methods, we tried to match the values of each thickness, but this was only feasible within the limits of each fabrication technique. Regarding the interaction method, “Untouched” stands for putting the capacitive marker on the screen without touching the conductive parts, whereas “Touched” includes continuous touching the marker laying static on the touch screen. “Touched and moved” expands this approach to randomly moving the touched marker for approximately one second on the screen.

Table 3.

Compilation of study variables and their values.

Table 4.

Measured thickness of insulating layer for each marker type. An insulation layer of 0 mm indicates that there is no insulation layer and that the conductive pads are directly on the touch screen display. The values for Laser cutting and rapid prototyping are listed on the left side, the ones for 3D printing on the right.

2.2.2. Metrics for Detection Quality

To evaluate the particular detection performance for each combination of above presented variables, the following metrics was introduced: Given the current situation, the marker is tested ten times; when at a time all three desired touch points are detected, this trial is assessed successful, else not. This procedure seems in the authors’ view most reasonable, since this detection of three points can be easily further improved by proper processing of the touch signals.

Thus, the measure for each combination of variables ranges from 0 (zero detections in ten trials) to 10 (ten detections in ten trials). In this study, the exact x and y locations of the detected touches are neglected, because the focus in our study is placed on the practicability of different fabrication techniques per se. An even more exact measure of quality would certainly produce even more precise results. However, as this study is a basic test of the different marker types, this quality standard is assumed to be sufficiently accurate.

2.2.3. Measurement of Insulating Layer

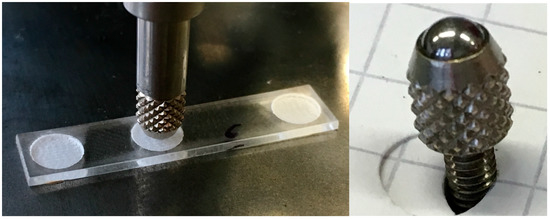

As the real geometry of fabricated capacitive markers deviates from the theoretically designed model, it is necessary to measure the real-world condition. Hence, the insulating layer (representing a variable in our study) of every marker was measured with a tactile dial gauge (see Figure 7). For this purpose, an equivalent duplicate for each capacitive marker was fabricated, which lacked the conductive part. Consequently, the authentic thickness of each insulation layer was manually measurable using a Mitutoyo ID-C112B (Mitutoyo Deutschland GmbH, Neuss, Germany) dial gauge with an appropriate probe head.

Figure 7.

Determination of insulating layer’s thickness using a tactile measurement. Left: Measuring engraved acrylic glass, here an insulation layer is necessary on which the conductive silver can dry. Right: probe head in detail, the ball on the top has a diameter of approx. 3 mm.

3. Results and Discussion

The following section presents essential results of our study. The detailed interpretation of those data also takes place in this section. In the following figures, a “Rating” is used as a metric for the detection performance of each capacitive marker (previously introduced in Section 2.2.2). This rating ranges from 0 to 10 and indicates how often a marker has been correctly detected in 10 attempts in the respective situation. An overview of possible variables describing such a situation in our study is shown in Table 3.

3.1. Overall Effects of Device, Interaction Method, Fabrication and Size of Marker on Detection Performance

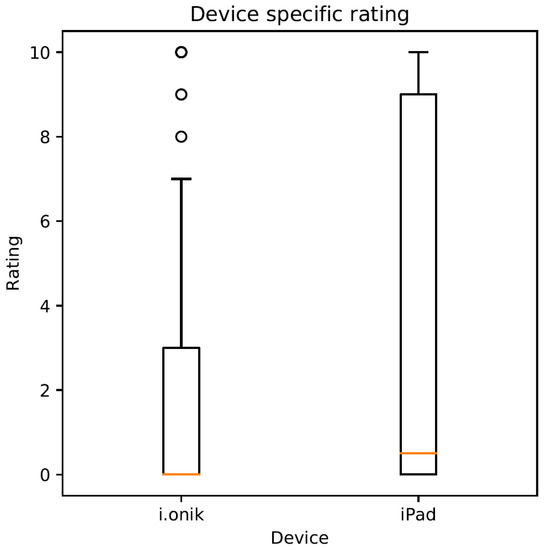

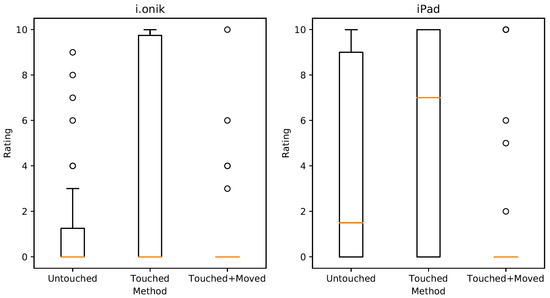

First, the device specific rating was measured to identify, how each tablet performs (Figure 8). Initially, it can be observed that the detection performance of markers between both devices is differing. It is clearly visible, that the iPad’s interquartile range is bigger and no outliers are present across the range of the quality measure for the detection performance. The median value, in contrast to the i.onik device, is non-zero, too. In general, using the iPad the results of all variables regarding each of the marker types exceeded the performance on the i.onik device. An applied Wilcoxon signed rank test with W = 178.5, n = 42, p < 0.001 and an effect size of 0.53 confirms this thesis. Furthermore, the comparison of detection performance regarding different interaction methods on both devices (Figure 9) again suggests a device-specific difference. Whereas in both cases the “Touched” interaction method appears superior to “Untouched” and “Touched and Moved”, as its interquartile range is obviously bigger within the rating measure. The iPad achieves two non-zero median values, merely the “Touched and Moved” method exhibits only outliers above the zero median. Especially the “Touched” interaction method at the iPad shows a median value of 7 indicating this situation to be the best overall condition for the detection of capacitive markers in our study. The “Untouched” interaction method also has a non-zero median value, but its interquartile range does not completely span over the complete range of the detection performance measure. With “Touched and moved” on the iPad and “Untouched” and “Touched and moved” on the i.onik tablet, only outliers are located in higher ranking scores.

Figure 8.

Device specific rating of detection performance (“Rating”) regarding both tablets.

Figure 9.

Comparison of detection performance (“Rating”) regarding different interaction methods on both devices.

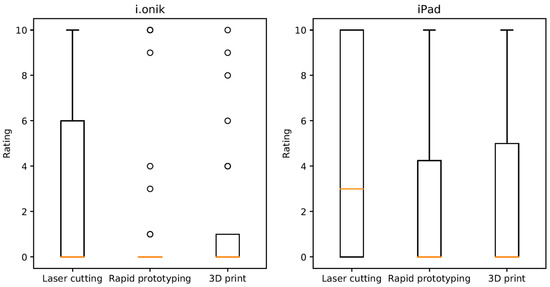

Figure 10 depicts the variable “Fabrication” with respect to detection performance on each device; here, the only non-zero median was measured with the iPad and laser cutting. All three fabrication techniques at the iPad cover the complete range of the rating scale with no visible outliers; at the i.onik device this is only achieved with laser cutting. This suggests that in this specific scenario laser cutted capacitive markers on the iPad would deliver the best detection performance. Using rapid prototyping and 3D printing, higher rating scores (i.e., better detection performance) can only be achieved in few cases, i.e., for the iPad above the upper quartile and for the i.onik device as outliers. Looking at the complete rating scale and all fabrication methods, laser cutting appears as first choice on both devices.

Figure 10.

Differentiating the detection performance (“Rating”) regarding the fabrication techniques on each tablet.

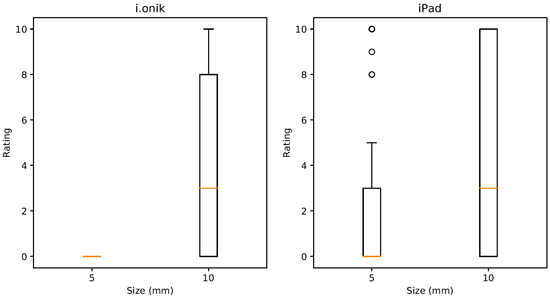

This observation can be justified by the fact that the interquartile range in the iPad or the minimum to maximum distance regarding the i.onik device with laser cutting is maximized. The size of the capacitive marker (respectively the pad diameter) has not been considered. Therefore, Figure 11 isolates this variable and relates it to each device.

Figure 11.

Comparing the two sizes of the capacitive markers regarding the overall detection performance (“Rating”).

In both cases, the 10 mm diameter scores a non-zero mean and the rating range is covered by the interquartile (iPad) or minimum to maximum distance (i.onik), respectively. Markers with 5 mm diameter scatter clearly less than the 10 mm ones; ratings above chance level (i.e., 5) are only achieved by outliers at the iPad. The i.onik tablet detected no 5 mm markers at all. Performing a Wilcoxon rank test confirms the superiority of 10 mm markers by W = 65.5, n = 57, p < 0.001 and an effect size of 0.80.

3.2. Untouched Detection and Possible Detection Enhancement by an Insulating Layer

Looking at the results table with all possible combinations of variables, one can find different lines, at which the untouched detection of capacitive markers was successful. Generally, only markers with 10 mm pad diameter were detected. With the iPad, markers fabricated by rapid prototyping and no insulating layer were always detected (see Figure 6), otherwise 3D printed markers of the same size were detected (see Figure 4). Here, no insulating layer led to a 100% detection rate (rating of 10), while with increasing thickness the rate almost linearly dropped to 20% (rating of 2) (at 0.56 mm of insulation). The i.onik tablet detected markers fabricated by rapid prototyping with no insulating layer, too, but at a 40% success rate. As with the iPad, the i.onik device detected 3D printer markers untouched from no insulating layer (100% success rate) to 0.47 mm of insulation (30% success rate). As mentioned earlier in this paper, Thorensen and Hanke [15] attained an optimized detection of untouched objects by expanding the distance between the conductive pad of the capacitive marker and the electrodes of the touch screen display (i.e., below the glass of the screen). We approximated this extension in our study by introducing an insulating layer between the touch screen surface and the pad of the marker. However, the results of the study conducted in this paper suggest, that with an increasing insulating layer the untouched detection performance decreases, which most probably results from the prototyping conditions that do not exactly fit Thorensen’s and Hanke’s environment.

3.3. Assessment of Fabrication Techniques Regarding Their Production Characteristic and Marker Detection

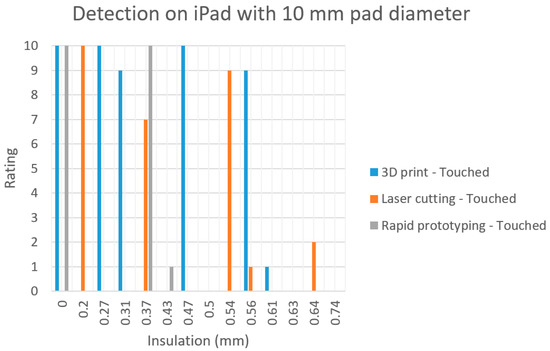

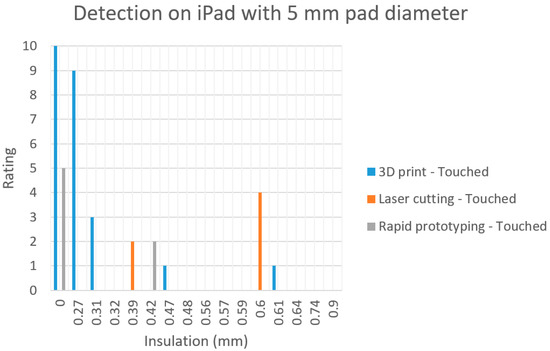

In order to compare the three fabrication techniques in a preferably most ideal situation (i.e., best detection performance with most non-zero ratings), the situation when detecting 10 mm pad radius capacitive markers by “Touched” interaction method on the iPad was chosen. Using the iPad (the boxplot in Figure 8 assigns a superior detection performance) and touched Interaction (Figure 9 assigned this method the highest median), 10 mm pad size capacitive markers were detected (in Figure 11 this size has the only non-zero median and suggests a better detection performance compared to 5 mm). Figure 12 indicates, that with no insulating layer (i.e., 0 mm), the markers fabricated by 3D printing and rapid prototyping (i.e., applying modeling clay) were always detected.

Figure 12.

Detection performance (“Rating”) of different marker types with varying insulation layer using the large markers on the iPad.

Laser cutting (acrylic glass with conductive silver) was equally successful, though it is necessary that there is (conditional of manufacturing) always a small insulation layer coated with the silver. With an increasing insulation layer, the detection performance generally decreases; at a rough estimate above 0.5 mm there is no longer a reasonable detection possible. Nevertheless, until there capacitive markers fabricated by 3D printing, laser cutting and rapid prototyping offer a decent detection performance. The same situation with 5 mm pad diameter (see Figure 13) unveils that 3D printed markers of this size and no insulation layer were successfully detected as well, if they were fabricated by 3D printing. Here, rapid prototyping and laser cutting are far behind.

Figure 13.

Detection performance (“Rating”) of different marker types with varying insulation layer using the small markers on the iPad.

The detection performance of all three fabrication techniques drops much faster with an increasing insulation layer, too. With more than 0.3 mm of insulation, the detection rate of any marker is clearly below the chance level. Interestingly, in this specific situation the performance of markers fabricated by laser cutting could be uniquely boosted with an increasing insulation layer. This behavior might origin from the coarse fabrication environment, in which the amount and geometry of conductive silver varies due to handmade production.

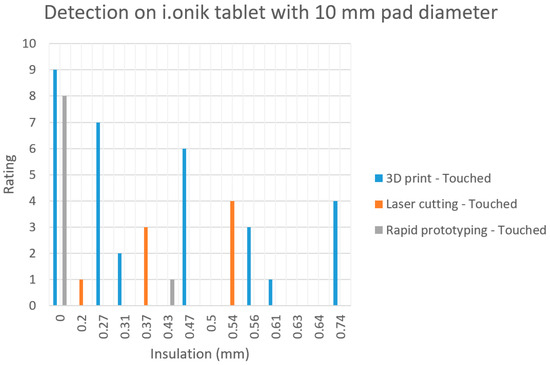

Regarding the i.onik tablet, only 10 mm pad diameter markers were detected at all. Figure 14 compares the detection performance of all fabrication methods using the “Touched” interaction method.

Figure 14.

Detection performance (“Rating”) of different marker types with varying insulation layer using the large markers on the i.onik tablet.

One can see, that non-insulated markers produced by 3D printing and rapid prototyping were detected well, beyond that the detection of 3D printed markers up to 0.5 mm of insulation layer is above chance level. The results of laser cutting and rapid prototyping are always located below chance level (i.e., rating of 5). However, the detection performance of markers fabricated by laser cutting continuously increases with an increasing thickness of an insulation layer. In this specific situation, the effect described by Thorensen and Hanke [15] might take place, but at this point the fabrication-oriented design of our study does not allow a more precise investigation.

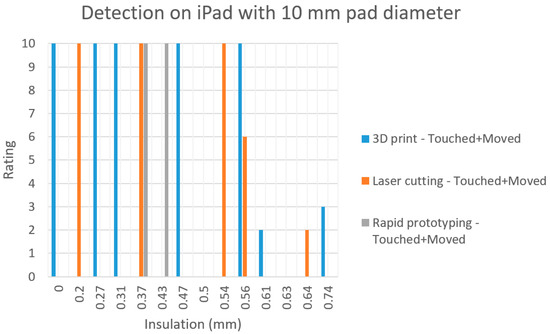

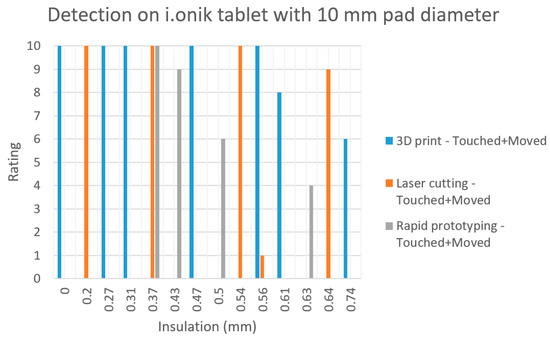

Furthermore, switching the interaction method variable from “Touched” to “Touched and moved” has an impact on the detection performance on both devices. When comparing the bar charts in Figure 12 and Figure 14, Figure 15 and Figure 16, one can see that the quantity of always detected markers (i.e., rating of 10) is obviously increased. Apart from rapid prototyping, laser cutting and 3D printing yield up to an insulation layer of approx. 0.5 mm markers that are always detected. Rapid prototyping with no insulation layer is not represented, since the stickiness of the modeling clay prohibited a free-moving marker on the touch screen panel.

Figure 15.

Detection performance (“Rating”) of different marker types with varying insulation layer using the large markers on the iPad. Contrary to the previous figures, these results show the interaction “Touched and Moved”.

Figure 16.

Detection performance (“Rating”) of different marker types with varying insulation layer using the large markers on the i.onik tablet. Contrary to the previous figures, these results show the interaction “Touched and Moved”.

Looking at these results while involving each fabrication techniques’ characteristics (as listed in Table 3), the below presented application scenarios for each fabrication technique can be identified. 3D printing offers the best overall detection performance and durable capacitive markers. Though there is no need for manual post processing, the 3D model must be previously constructed and processed to be automatically manufactured by the 3D printer. A certain time for the printing process and financial resources to purchase such a device has to be existing, too. A real-life example might be the preparation of several identical capacitive markers for a group of colleagues or students, each being supported by interacting with such a tangible object.

Laser cutting is advantageous when the total production time and lot size of a capacitive markers comes to focus. Hereby, a big amount of even large-scale probes can be quickly produced. However, for each capacitive marker a minimal amount of post processing (i.e., applying conductive silver) is necessary and the asset costs are not negligible. The manual application of conductive material might affect the function of the capacitive marker. An application for laser cut markers is the direct integration of capacitive codes into engraved relief images which can be explored in combination with an interactive device such as a tablet computer. In particular, this scenario is of interest for the tactile exploration of relief images by blind people.

Finally, rapid prototyping with conductive modeling clay sticks out with remarkable low fabrication costs and immediate application for prototyping tangible objects. Though an insulating part is necessary, in the simplest case an ordinary hole punch and cardboard can be used. An inherent problem of this rapid prototyping approach is the non-persistence and possible variability in function, because the individual production and application of the modeling clay cannot be objectively monitored like in the other fabrication techniques. Nevertheless, there are application scenarios, where the capacitive marker’s immediate availability justifies those downsides. For example concerning school matters, children or students could improve the learning effect by interacting with objects on a tangible user interface, that they only just build themselves.

3.4. Future Work

Based on this initial study, further enhancements should address the finer monitoring of fabrication parameters while conducting a study with a distinct bigger quantity of devices. At the same time, a more precise formulation of the detection performance by explicitly evaluating each of the capacitive marker’s touch points seems worth achieving. The information gained in this paper can be used as a basis for these further developments.

4. Conclusions

In this paper, we went beyond the fabrication of capacitive markers by 3D printing and transferred this concept to laser cutting and an immediately applicable prototyping approach. We compared the three fabrication techniques in a comprehensive study, for which current research results concerning the optimized untouched detection of capacitive markers were included. Beside the already known 3D printing process, laser cutting was utilized to cut and engrave acrylic glass in conjunction with the manual application of conductive silver, producing capacitive markers. Immediate prototyping with cardboard panel and conductive modeling clay generated markers as well. Our study generally confirmed the functionality of markers produced by all three fabrication techniques and identified a setting (markers with biggest and closest to screen conductive area being touched and moved), in which all three marker types performed very well. Furthermore, a significant effect of the capacitive markers’ geometry and the used device on the detection performance was proven. In addition, 3D printed and prototyped markers could be detected untouched, tough the detection performance of touched (and moved) ones is in general drastically improved. Concerning an increasing insulation layer between the touch screen panel and the pads of the capacitive marker, we deduced a general decrease in detection performance. Based on our findings, we also characterized each fabrication technique stating appropriate use cases and discussed individual strengths of each capacitive marker type. Thus, we identified favorites regarding consistent and automatic fabrication (3D printing), large-scale and fast fabrication (Laser cutting) and immediate and experimental fabrication (clay prototyping).

Our study generally demonstrated, that all three fabrication techniques are applicable to fabricate well-functioning capacitive markers, while future research might widen the spread of variables and narrow the scales for its evaluation, so that the utilization of capacitive markers in everyday use comes closer to reality.

Beside 3D printing, the new fabrication techniques laser cutting and prototyping increase the possibilities to produce capacitive markers, which might contribute to dissemination for tangible approaches in general.

Author Contributions

Timo Götzelmann introduced the idea to transfer capacitive codes of the foundational paper to other fabrication techniques. Thomas Bielmeier took over the manufacturing process with the laser cutter and Julian Kreimeier the process with 3D printing. Timo Götzelmann worked on the prototyping approach using the conductive clay. The study was mainly carried out by Julian Kreimeier, who was supported by Thomas Bielmeier and Timo Götzelmann in carrying out the experiments and evaluating the data. The paper was finally written mainly by Julian Kreimeier, with Timo Götzelmann providing helpful comments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rekimoto, J. SmartSkin: An Infrastructure for Freehand Manipulation on Interactive Surfaces. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems (CHI ’02), Minneapolis, MN, USA, 20–25 April 2002; ACM: New York, NY, USA, 2002; pp. 113–120. [Google Scholar]

- Kratz, S.; Westermann, T.; Rohs, M.; Essl, G. CapWidgets: Tangile Widgets Versus Multi-touch Controls on Mobile Devices. In Proceedings of the CHI ’11 Extended Abstracts on Human Factors in Computing Systems, Vancouver, BC, Canada, 7–12 May 2011; ACM: New York, NY, USA, 2011; pp. 1351–1356. [Google Scholar]

- Wiethoff, A.; Schneider, H.; Rohs, M.; Butz, A.; Greenberg, S. Sketch-a-TUI: Low Cost Prototyping of Tangible Interactions Using Cardboard and Conductive Ink. In Proceedings of the Sixth International Conference on Tangible, Embedded and Embodied Interaction (TEI ’12), Kingston, ON, Canada, 19–22 February 2012; ACM: New York, NY, USA, 2012; pp. 309–312. [Google Scholar]

- Shemelya, C.; Cedillos, F.; Aguilera, E.; Maestas, E.; Ramos, J.; Espalin, D.; Muse, D.; Wicker, R.; MacDonald, E. 3D printed capacitive sensors. In Proceedings of the 2013 IEEE SENSORS, Baltimore, MD, USA, 3–6 November 2013; pp. 1–4. [Google Scholar]

- Götzelmann, T.; Schneider, D. CapCodes: Capacitive 3D Printable Identification and On-screen Tracking for Tangible Interaction. In Proceedings of the 9th Nordic Conference on Human-Computer Interaction (NordiCHI ’16), Gothenburg, Sweden, 23–27 October 2016; ACM: New York, NY, USA, 2016; pp. 32:1–32:4. [Google Scholar]

- Yu, N.-H.; Chan, L.-W.; Lau, S.Y.; Tsai, S.-S.; Hsiao, I.-C.; Tsai, D.-J.; Hsiao, F.-I.; Cheng, L.-P.; Chen, M.; Huang, P.; et al. TUIC: Enabling Tangible Interaction on Capacitive Multi-touch Displays. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems (CHI ’11), Vancouver, BC, Canada, 7–12 May 2011; ACM: New York, NY, USA, 2011; pp. 2995–3004. [Google Scholar]

- Morales González, R.; Appert, C.; Bailly, G.; Pietriga, E. TouchTokens: Guiding Touch Patterns with Passive Tokens. In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems (CHI ’16), San Jose, CA, USA, 7–12 May 2016; ACM: New York, NY, USA, 2016; pp. 4189–4202. [Google Scholar]

- Jordà, S.; Geiger, G.; Alonso, M.; Kaltenbrunner, M. The reacTable: Exploring the Synergy between Live Music Performance and Tabletop Tangible Interfaces. In Proceedings of the 1st International Conference on Tangible and Embedded Interaction (TEI ’07), Baton Rouge, LA, USA, 15–17 February 2007; ACM: New York, NY, USA, 2007; pp. 139–146. [Google Scholar]

- Ikeda, K.; Tsukada, K. CapacitiveMarker: Novel Interaction Method Using Visual Marker Integrated with Conductive Pattern. In Proceedings of the 6th Augmented Human International Conference (AH ’15), Singapore, 9–11 March 2015; ACM: New York, NY, USA, 2015; pp. 225–226. [Google Scholar]

- Voelker, S.; Cherek, C.; Thar, J.; Karrer, T.; Thoresen, C.; Øvergard, K.I.; Borchers, J. PERCs: Persistently Trackable Tangibles on Capacitive Multi-Touch Displays. In Proceedings of the 28th Annual ACM Symposium on User Interface Software & Technology (UIST ’15), Charlotte, NC, USA, 11–15 November 2015; ACM: New York, NY, USA, 2015; pp. 351–356. [Google Scholar]

- Olwal, A.; Wilson, A.D. SurfaceFusion: Unobtrusive Tracking of Everyday Objects in Tangible User Interfaces. In Proceedings of the Graphics Interface 2008 (GI ’08), Windsor, ON, Canada, 28–30 May 2008; Canadian Information Processing Society: Toronto, ON, Canada, 2008; pp. 235–242. [Google Scholar]

- Liang, R.-H.; Chan, L.; Tseng, H.-Y.; Kuo, H.-C.; Huang, D.-Y.; Yang, D.-N.; Chen, B.-Y. GaussBricks: Magnetic Building Blocks for Constructive Tangible Interactions on Portable Displays. In Proceedings of the 32nd Annual ACM Conference on Human Factors in Computing Systems (CHI ’14), Toronto, ON, Canada, 26 April–1 May 2014; ACM: New York, NY, USA, 2014; pp. 3153–3162. [Google Scholar]

- Hwang, S.; Ahn, M.; Wohn, K. MagGetz: Customizable Passive Tangible Controllers on and Around Conventional Mobile Devices. In Proceedings of the 26th Annual ACM Symposium on User Interface Software and Technology (UIST ’13), St. Andrews, UK, 8–11 October 2013; ACM: New York, NY, USA, 2013; pp. 411–416. [Google Scholar]

- Voelker, S.; Nakajima, K.; Thoresen, C.; Itoh, Y.; Øvergard, K.I.; Borchers, J. PUCs: Detecting Transparent, Passive Untouched Capacitive Widgets on Unmodified Multi-touch Displays. In Proceedings of the 2013 ACM International Conference on Interactive Tabletops and Surfaces (ITS ’13), St. Andrews, UK, 6–9 October 2013; ACM: New York, NY, USA, 2013; pp. 101–104. [Google Scholar]

- Thoresen, C.B.; Hanke, U. Numerical Simulation of Mutual Capacitance Touch Screens for Ungrounded Objects. IEEE Sens. J. 2017, 17, 5143–5152. [Google Scholar] [CrossRef]

- Patel, C.K.N. Continuous-Wave Laser Action on Vibrational-Rotational Transitions of CO2. Phys. Rev. 1964, 136, A1187–A1193. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).