Effect of Load Changes on Hybrid Shipboard Power Systems and Energy Storage as a Potential Solution: A Review

Abstract

1. Introduction

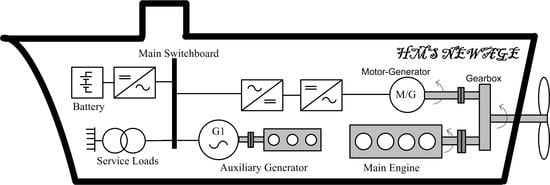

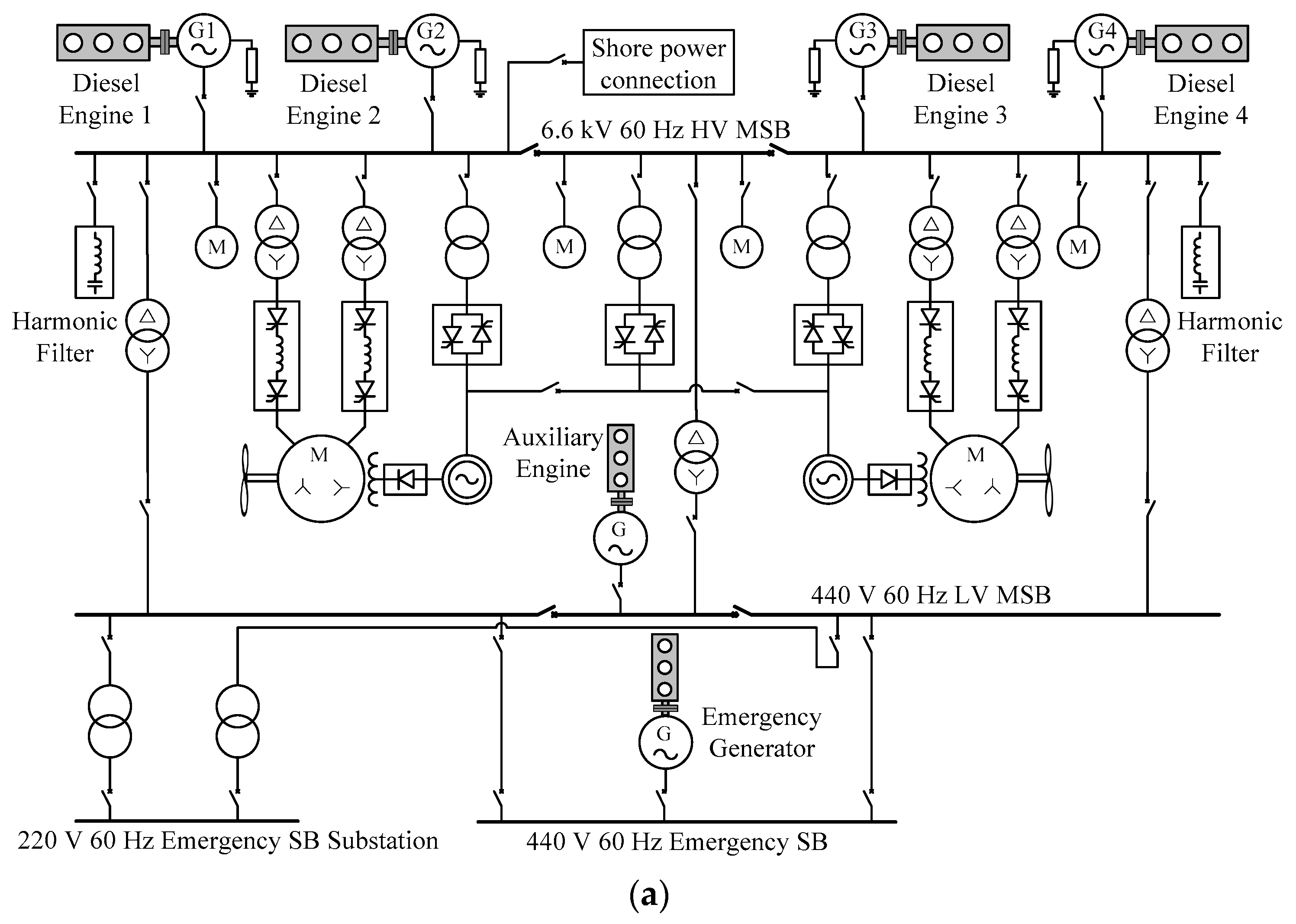

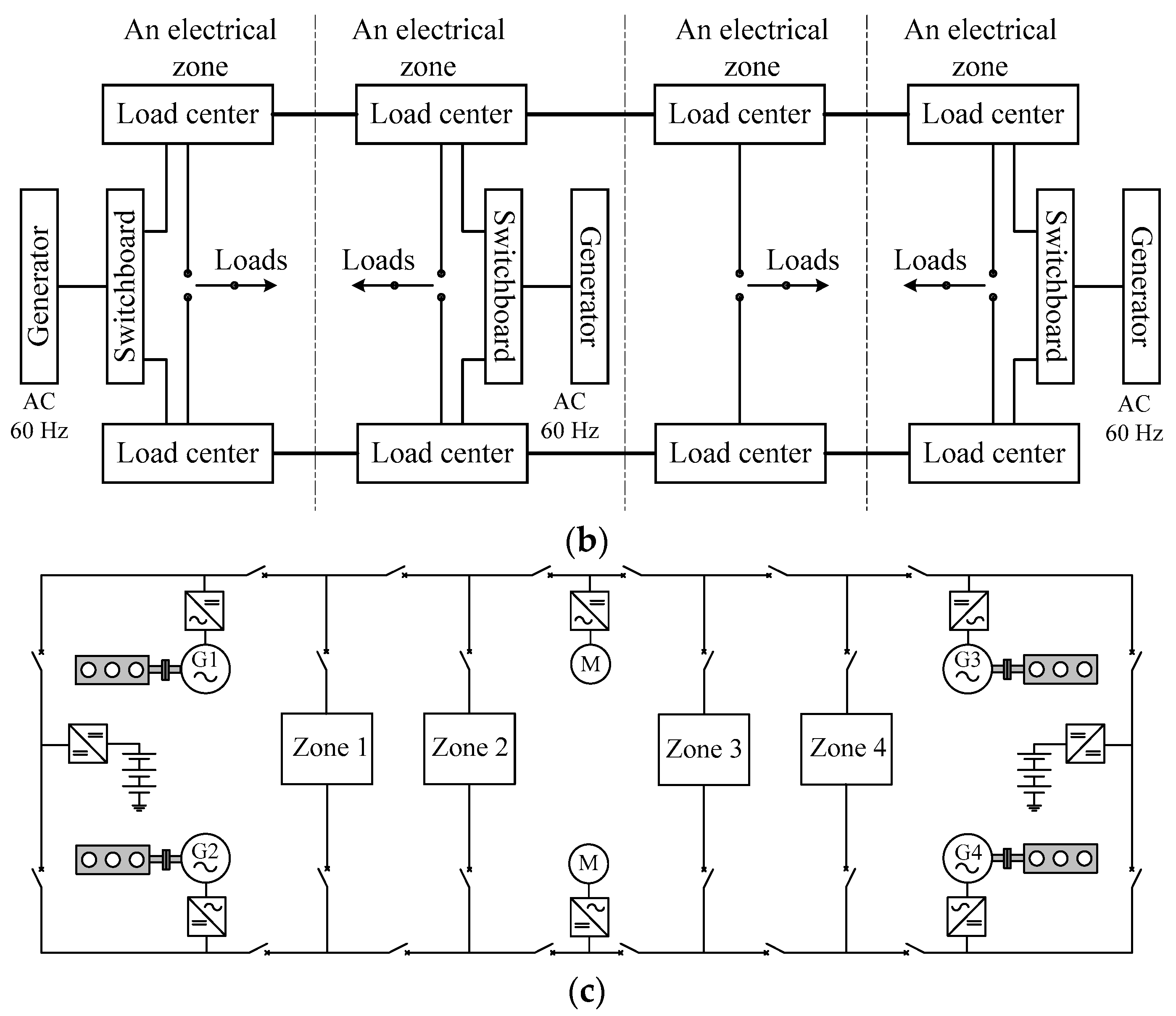

2. Shipboard Power Systems Overview

- Boost or Power Take In (PTI) Mode—Main Engine and Auxiliary Generators supply power to hotel and propulsion loads. Shaft machine acts as a motor to drive the propellers.

- Parallel Mode—Power demand is more than that of the capacity of auxiliary generators but less than that of the main engine. The main engine thus runs at partial load and supplies power for hotel loads and propulsion with one auxiliary generator also supplying power to hotel loads. Shaft machine acts as an alternator and supplies electrical energy.

- Transit Mode or Power Take Out (PTO) Mode—Only the main engine supplies power to propulsion and hotel loads. Shaft machine acts as an alternator.

- Shore Connection or Cold Ironing Mode—Only port supply satisfies ship’s power demand.

- Power Take Home (PTH) Mode—Main Engine fails. Auxiliary Generators supply power for hotel and propulsion loads. Shaft machine acts as a motor.

- Hybrid Mode or PTO/PTI Mode—Shaft machine acts as an alternator or motor in order to maintain shaft machine and main engine RPM in the range of 70–100% of full load to increase their efficiencies.

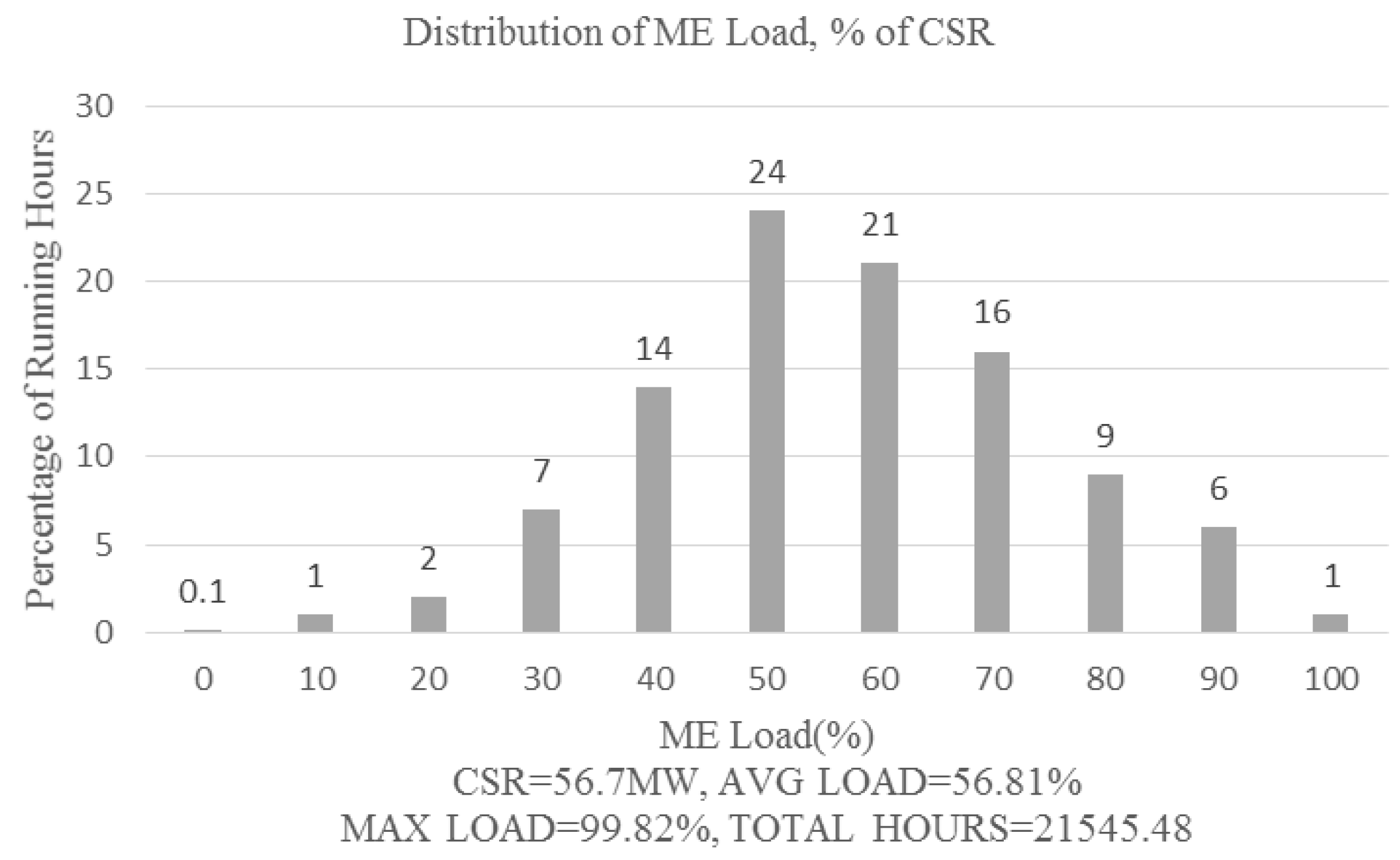

3. Loading Conditions and Its Effects on the Shipboard Power System

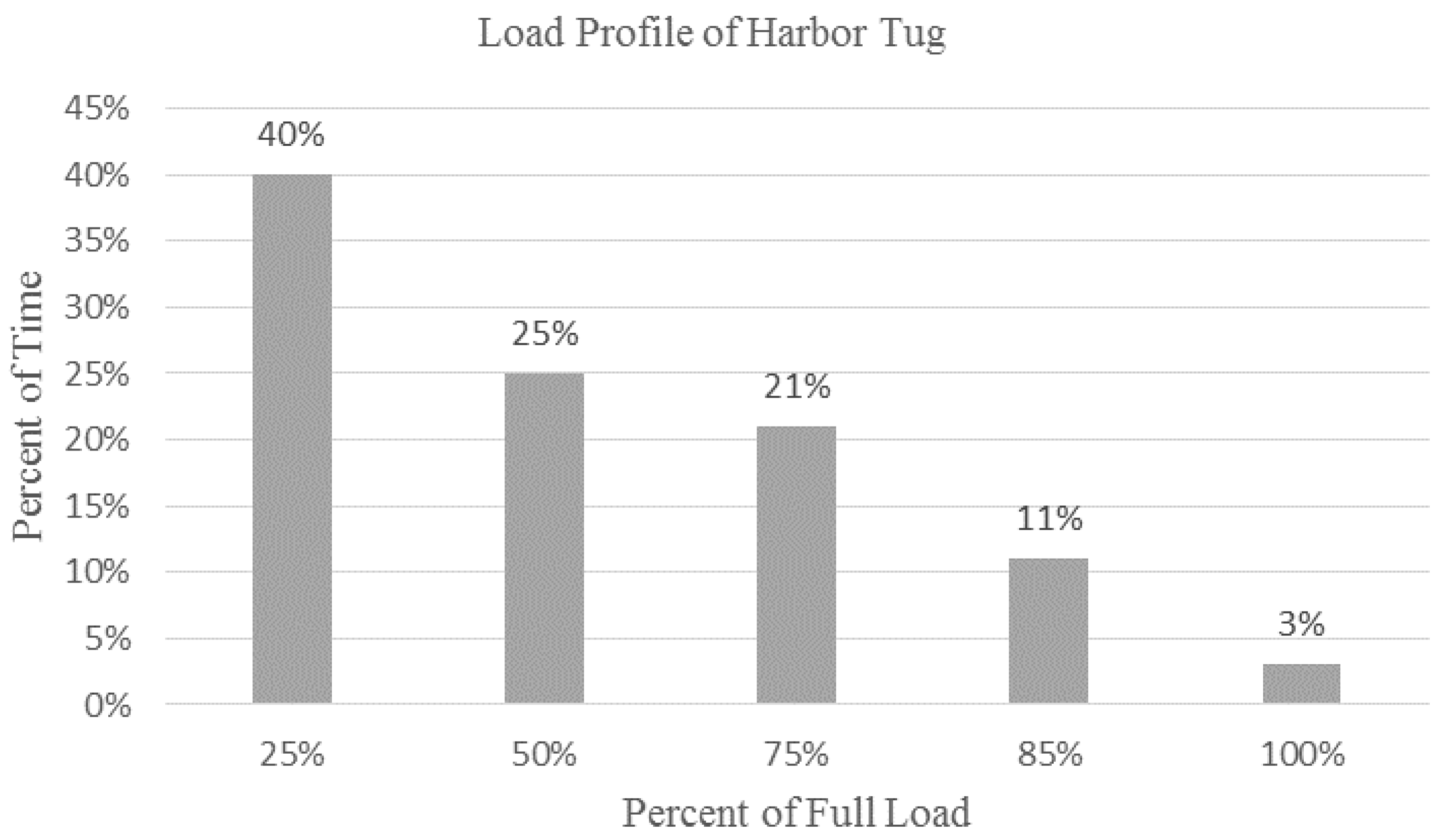

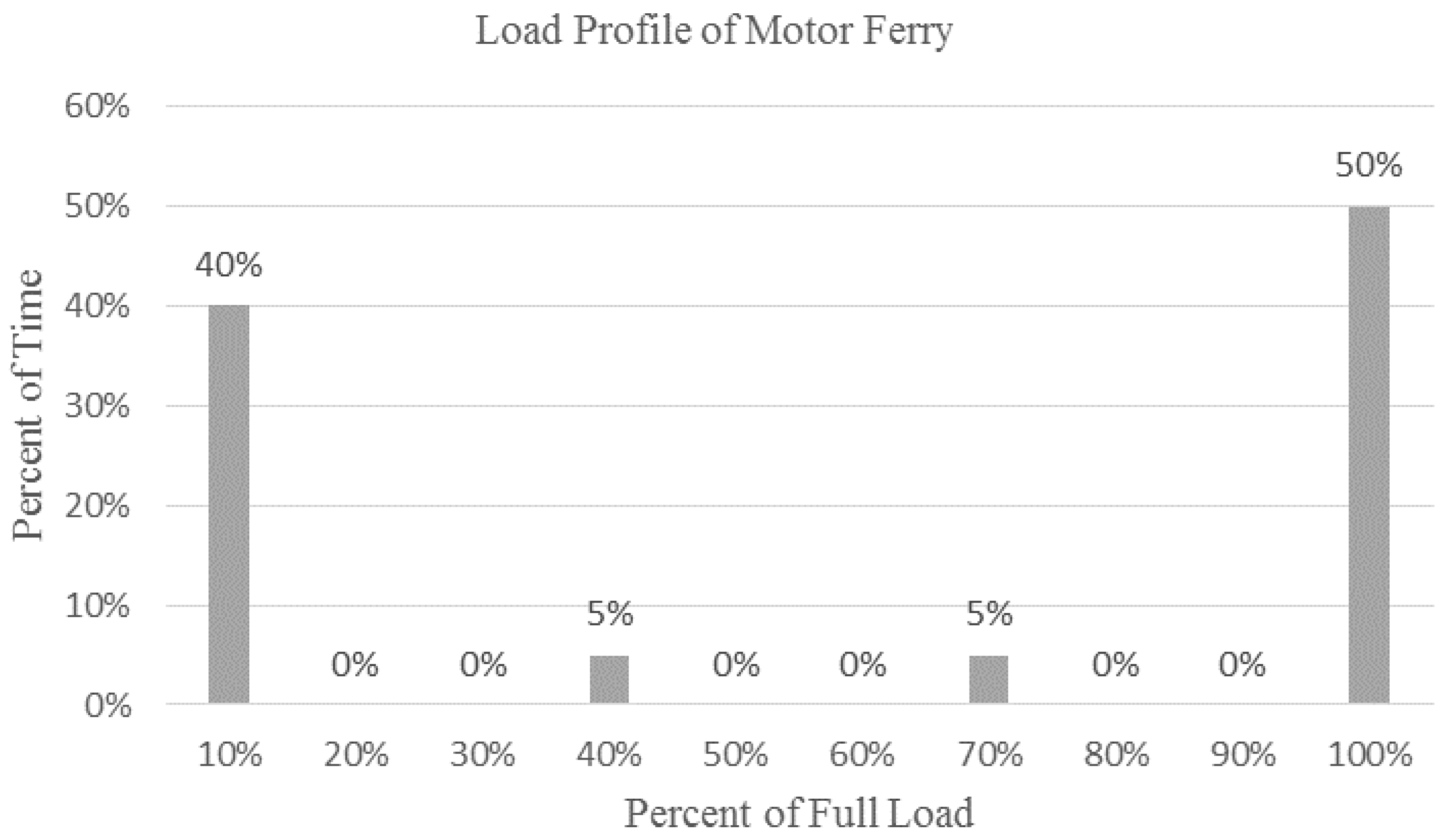

3.1. Loading Conditions of Ships

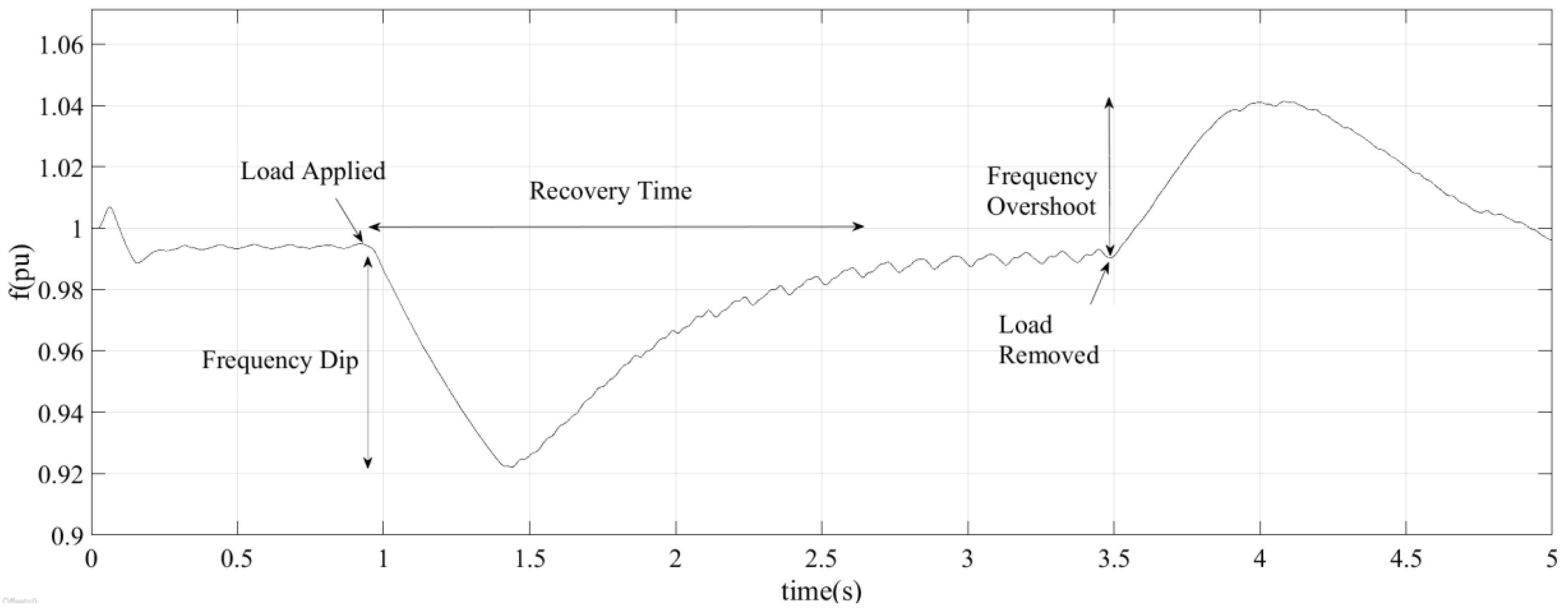

3.2. Load Changes and Its Effects for the Shipboard Power System

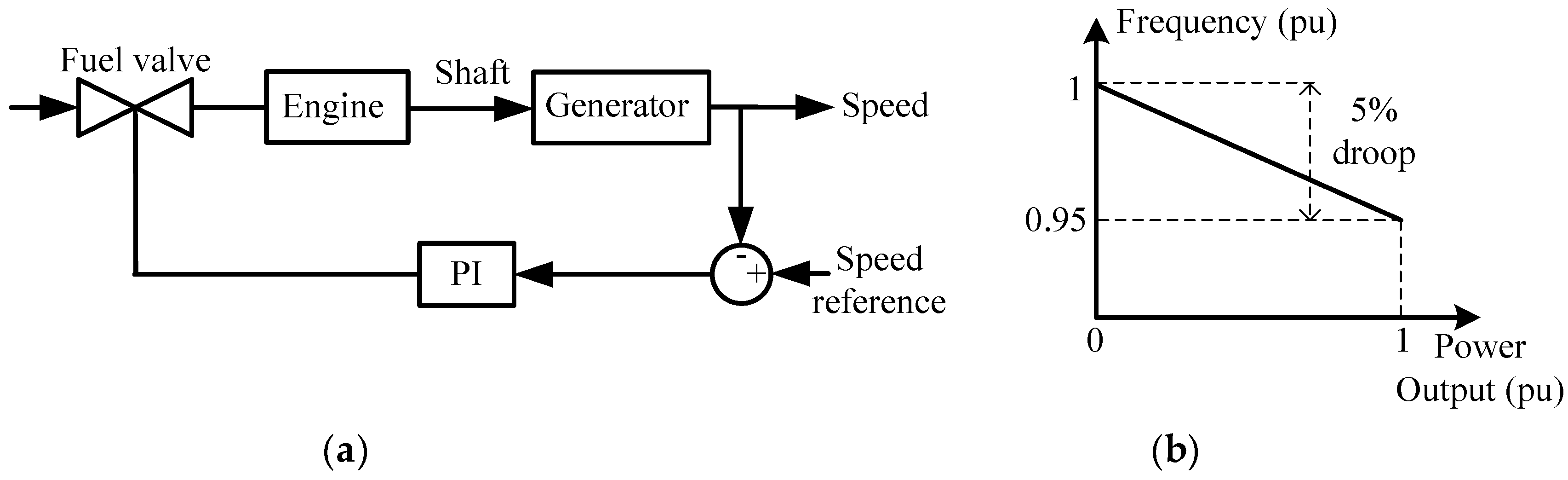

3.3. Conventional Shipboard Voltage and Frequency Control

3.4. Energy Storage Systems

3.4.1. Energy Storage Devices

3.4.2. Energy Storage Control Systems

4. Challenges of Implementing Energy Storage in Shipboard Power Systems to Reduce Load Change Transients

5. Conclusions

Conflicts of Interest

References

- McCoy, T.J. Electric ships past, present, and future [Technology Leaders]. Electr. Mag. IEEE 2015, 3, 4–11. [Google Scholar] [CrossRef]

- Radan, D.; Sorensen, A.J.; Adanes, A.K.; Johansen, T.A. Reducing power load fluctuations on ships using power redistribution Control. Mar. Technol. 2008, 45, 162–174. [Google Scholar]

- Mindykowski, J.; Szweda, M.; Tomasz, T. Voltage and frequency deviations in exemplary ship’s network—Research for ship owner. Electri. Power Qual. Util. Mag. 2005, 1, 61–68. Available online: http://www.leonardo-energy.org/sites/leonardo-energy/files/root/EPQU/MVol1No2/mindy.pdf (accessed on 19 July 2017).

- Mirošević, M.; Maljković, Z. Effect of sudden change load on isolated electrical grid. In Proceedings of the 2015 International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles (ESARS), Aachen, Germany, 3–5 March 2015; IEEE: Piscataway, NJ, USA, 2014; pp. 1–4. [Google Scholar]

- Prousalidis, J.; Hatzilau, I.K.; Michalopoulos, P.; Pavlou, I.; Muthumuni, D. Studying Ship Electric Energy Systems with Shaft Generator. In Proceedings of the IEEE Electric Ship Technologies Symposium, Philadelphia, PA, USA, 17–25 July 2005; pp. 156–162. [Google Scholar]

- Hou, J.; Sun, J.; Hofmann, H. Mitigating power fluctuations in electrical ship propulsion using model predictive control with hybrid energy storage system. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014; pp. 4366–4371. [Google Scholar]

- Arani, M.F.M.; El-Saadany, E.F. Implementing virtual inertia in DFIG-based wind power generation. IEEE Trans. Power Syst. 2013, 28, 1373–1384. [Google Scholar] [CrossRef]

- Wenjie, C.; Ådnanses, A.K.; Hansen, J.F.; Lindtjørn, J.O.; Tang, T. Super-capacitors based hybrid converter in marine electric propulsion system. In Proceedings of the Electrical Machines (ICEM), 2010 XIX International Conference, Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar]

- Lopes, J.A.P.; Moreira, C.L.; Madureira, A.G. Defining control strategies for MicroGrids islanded operation. IEEE Trans. Power Syst. 2006, 21, 916–924. [Google Scholar] [CrossRef]

- Al-Barazanchi, S.A.M.; Vural, A.M. Modeling and intelligent control of a stand-alone PV-Wind-Diesel-Battery hybrid system. In Proceedings of the 2015 International Conference on Control, Instrumentation, Communication and Computational Technologies (ICCICCT), Kumaracoil, India, 18–19 December 2015; pp. 423–430. [Google Scholar]

- Bø, T.I.; Johansen, T.A. Battery power smoothing control in a marine electric power plant using nonlinear model predictive control. IEEE Trans. Control Syst. Technol. 2017, 25, 1449–1456. [Google Scholar] [CrossRef]

- Butler, K.L.; Sarma, N.D.R. General reconfiguration methodology for AC radial shipboard power systems. In Proceedings of the Power Engineering Society Winter Meeting, Piscataway, NJ, USA, 23–27 January 2000; Volume 2, pp. 1226–1230. [Google Scholar]

- Shen, Q.; Ramachandran, B.; Srivastava, S.K.; Andrus, M.; Cartes, D.A. Power and Energy Management in Integrated Power System. In Proceedings of the Electric Ship Technologies Symposium (ESTS), Piscataway, NJ, USA, 10–13 April 2011; pp. 414–419. [Google Scholar]

- Bennabi, N.; Charpentier, J.F.; Menana, H.; Billard, J.Y.; Genet, P. Hybrid propulsion systems for small ships: Context and challenges. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; pp. 2948–2954. [Google Scholar]

- Hybrid Propulsion—Flexibility and Maximum Efficiency Optimally Combined, MAN Diesel & Turbo. Available online: https://marine.man.eu/docs/librariesprovider6/4-Stroke-Engines/hybrid-propulsion.pdf?sfvrsn=6 (accessed on 19 July 2017).

- Nielson, B.O. 8500 TEU Container Ship Concept Study; Project: 4-4383; Odense Steel Shipyard Ltd.: Mukenbo, Denmark, 2009. [Google Scholar]

- Kim, S.O.; Ock, Y.B.; Heo, J.K.; Park, J.C.; Shin, H.S.; Lee, S.K. CFD simulation of added resistance of ships in head sea for estimating energy efficiency design index. In Proceedings of the OCEANS 2014–TAIPEI, Taipei, Taiwan, 7–10 April 2014; pp. 1–5, 7–10. [Google Scholar]

- Journee, J.M.J. Prediction of Speed and Behaviour of a Ship in a Seaway. Available online: http://shipmotions.nl/DUT/PapersReports/0427-ISP-76.pdf (accessed on 19 July 2017).

- Kristensen, H.O.; Marie, L. Prediction of Resistance and Propulsion Power of Ships. Project no. 2010-56; Emissionsbeslutningsstøttesystem Work Package 2, Report no. 04. Available online: https://www.academia.edu/32052238/Prediction_of_Resistance_and_Propulsion_Power_of_Ships (accessed on 19 July 2017).

- Völker, T. Hybrid Propulsion Concepts on Ships. Available online: zeszyty.am.gdynia.pl/.../Hybrid%20propulsion%20concepts%20on%20ships_200.pdf (accessed on 19 July 2017).

- Jayasinghe, S.G.; Meegahapola, L.; Fernando, H.; Jin, Z.; Guerrero, J.M. Review of Ship Microgrids: System Architectures, Storage Technologies and Power Quality Aspects. Inventions 2017, 2, 4. [Google Scholar] [CrossRef]

- Tetra Tech Inc. Use of Shore Side Power for Ocean Going Vessels; American Association of Port Authorities: Alexandria, VA, USA; Available online: http://wpci.iaphworldports.org/data/docs/onshore-power-supply/library/1264151248_2007aapauseofshore-sidepowerforocean-goingvessels.pdf (accessed on 19 July 2017).

- Rolls Royce Power Electric Systems. Hybrid Shaft Generator Propulsion System Upgrade—Making Fixed Engine Speed History. 2010. Available online: http://www.rolls-royce.com/~/media/Files/R/Rolls-Royce/documents/customers/marine/hsg-brochure.pdf (accessed on 19 July 2017).

- Hall, T.D. Practical Marine Electrical Knowledge, 2nd ed.; Witherby Publishers: Livingston, UK, 1999; p. 2. [Google Scholar]

- Prabha, K. Power System Stability and Control, 1st ed.; McGraw-Hill: New York, NY, USA, 1993. [Google Scholar]

- Srivatchan, N.S.; Rangarajan, P.; Rajalakshmi, S. Control Scheme for Power Quality Improvement in Islanded Microgrid Operation. Procedia Technol. 2015, 21, 212–215. [Google Scholar] [CrossRef]

- Gayatri, M.T.L.; Parimi, A.M.; Kumar, A.V.P. Utilization of Unified Power Quality Conditioner for voltage sag/swell mitigation in microgrid. In Proceedings of the 2016 Biennial International Conference on Power and Energy Systems: Towards Sustainable Energy (PESTSE), Bangalore, India, 21–23 January 2016; pp. 1–6. [Google Scholar]

- Jayawardena, A.V.; Meegahapola, L.G.; Robinson, D.A.; Perera, S. Low-voltage ride-through characteristics of microgrids with distribution static synchronous compensator (DSTATCOM). In Proceedings of the 2015 Australasian Universities Power Engineering Conference (AUPEC), Wollongong, Australia, 27–30 September 2015; pp. 1–6. [Google Scholar]

- Sun, Z.; Wang, J.; Dai, Y. Modeling and control system design of a marine electric power generating system. In Proceedings of the 2011 6th IEEE Conference on Industrial Electronics and Applications, Beijing, China, 21–23 June 2011; pp. 1916–1921. [Google Scholar]

- Cupelli, M.; Ponci, F.; Sulligoi, G.; Vicenzutti, A.; Edrington, C.S.; El-Mezyani, T.; Monti, A. Power Flow Control and Network Stability in an All-Electric Ship. Proc. IEEE 2015, 103, 2355–2380. [Google Scholar] [CrossRef]

- Kanellos, F.D.; Tsekouras, G.J.; Prousalidis, J.; Hatzilau, I.K. An effort to formulate frequency modulation constraints in ship-electrical systems with pulsed loads. IET Electr. Syst. Transp. 2011, 1, 11–23. [Google Scholar] [CrossRef]

- Kanellos, F.D.; Tsekouras, G.J.; Prousalidis, J.; Hatzilau, I.K. Effort to formulate voltage modulation constraints in ship-electrical systems with pulsed loads. IET Electr. Syst. Transp. 2012, 2, 18–28. [Google Scholar] [CrossRef]

- Hou, J.; Sun, J.; Hofmann, H.G. Mitigating Power Fluctuations in Electric Ship Propulsion with Hybrid Energy Storage System: Design and Analysis. IEEE J. Ocean. Eng. 2017, PP, 1–15. [Google Scholar] [CrossRef]

- IEEE. IEEE Recommended Practice for Electrical Installations on Shipboard—Electrical Testing. Available online: http://ieeexplore.ieee.org/document/7865875/ (accessed on 19 July 2017).

- Roa, M. ABS Rules for Integrated Power Systems (IPS). In Proceedings of the 2009 IEEE Electric Ship Technologies Symposium, Baltimore, MD, USA, 20–22 April 2009; pp. 1–17. [Google Scholar]

- Zarghami, M.; Vaziri, M.Y.; Rahimi, A.; Vadhva, S. Applications of Battery Storage to Improve Performance of Distribution Systems. In Proceedings of the Green Technologies Conference, Denver, CO, USA, 4–5 April 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 345–350. [Google Scholar]

- Mercier, P.; Cherkaoui, R.; Oudalov, A. Optimizing a Battery Energy Storage System for Frequency Control Application in an Isolated Power System. IEEE Trans. Power Syst. 2009, 24, 1469–1477. [Google Scholar] [CrossRef]

- Hou, J.; Sun, J.; Hofmann, H. Interaction analysis and integrated control of hybrid energy storage and generator control system for electric ship propulsion. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015; pp. 4988–4993. [Google Scholar]

- Das, D.C.; Roy, A.K.; Sinha, N. PSO based frequency controller for wind-solar-diesel hybrid energy generation/energy storage system. In Proceedings of the 2011 International Conference of Energy, Automation, and Signal (ICEAS), Bhubaneswar, India, 28–30 December 2011; pp. 1–6. [Google Scholar]

- Zhang, J.; Li, Q.; Cong, W.; Zhang, L. Restraining integrated electric propulsion system power fluctuation using hybrid energy storage system. In Proceedings of the 2015 IEEE International Conference on Mechatronics and Automation (ICMA), Beijing, China, 2–5 August 2015; pp. 336–340. [Google Scholar]

- Mufti, M.D.; Iqbal, S.J.; Lone, S.A.; Ain, Q.U. Supervisory Adaptive Predictive Control Scheme for Supercapacitor Energy Storage System. IEEE Syst. J. 2015, 9, 1020–1030. [Google Scholar] [CrossRef]

| Type of Ship | S-Value Calculation |

|---|---|

| Bulk carriers and tankers | |

| Container vessels (single screw) | |

| Twin screw ships (Ro-Ro ships) with open shaft lines (and twin rudders) | |

| Twin screw ships (Ro-Ro ships with twin rudders) | |

| Double ended ferries |

| Ship Service | Electrical Loading Value |

|---|---|

| Normal service at sea, excluding shaft motor and reefers | 1820 KW |

| Normal service at sea, including shaft motor and excl. reefers | up to 8590 KW |

| Normal service at sea, excluding shaft motor and incl. 50% reefers | 4100 KW |

| Normal service at sea, including shaft motor and 50% reefers | up to 10,650 KW |

| Normal service at sea, including shaft motor and 100% reefers | up to 12,870 KW |

| Sea going average, excluding shaft motor, incl.25% reefer loading | 2960 KW |

| Vessel Type | Port Call Frequency (days) | Port Calls per Year | Average Hours in Port | Estimated Annual Hours | Average Electric Load (MW-h/year) |

|---|---|---|---|---|---|

| Container ship | 45 | 8 | 43 | 347 | 339 |

| Tanker ship | 15 | 24 | 30 | 734 | 976 |

| Cruise ship | 14 | 26 | 10 | 273 | 1911 |

| Quantity in Operation | Permanent Variation | Temporary Variation |

|---|---|---|

| Frequency | ±5% | ±10% (5 s) |

| Voltage | +6% to −10% | ±20% (1.5 s) |

| Types of Control | Advantages | Disadvantages |

|---|---|---|

| Battery energy storage system with Kalman filters tuned by Model Predictive Control (MPC) [18] |

|

|

| Coordinated supercapaciter-battery energy storage with MPC power tracking [6] |

|

|

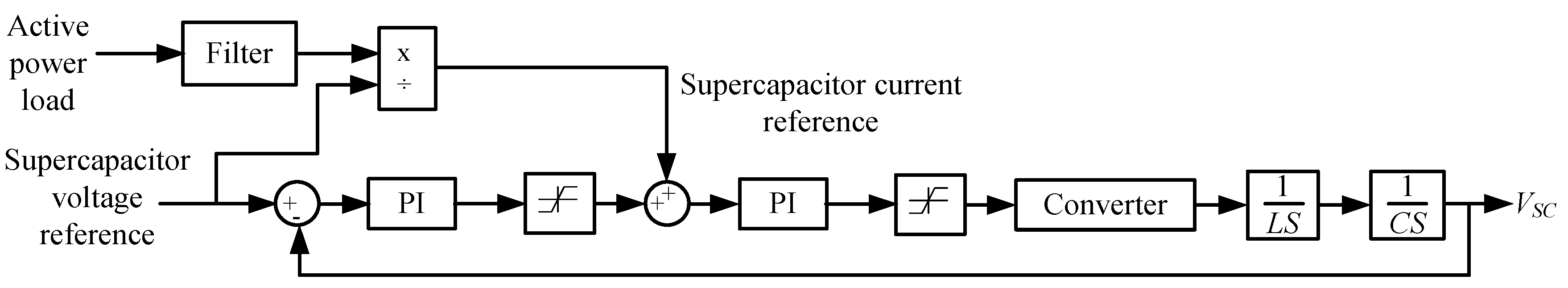

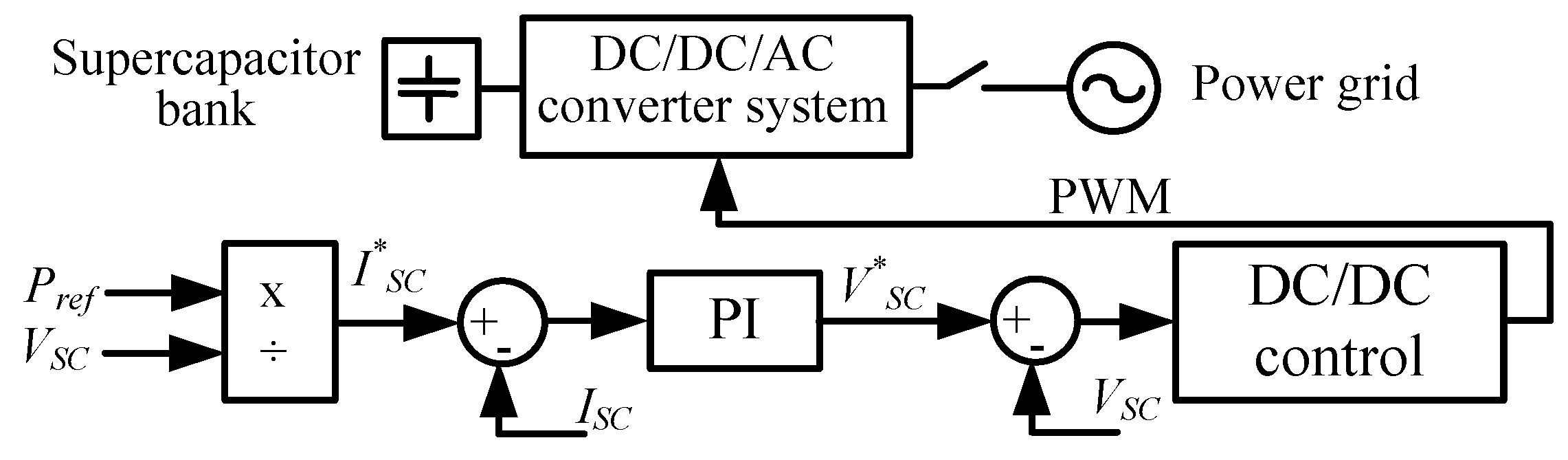

| Supercapacitor-based hybrid converter with Proportional-Integral (PI) control [8] |

|

|

| Battery Energy Storage System for frequency control using load frequency control dynamic simulator [37] |

|

|

| Battery and supercapacitor hybrid energy storage system with motor load following for torque and power fluctuation reduction [38] |

|

|

| Battery and supercapacitor hybrid energy storage system with bus voltage regulation for torque and power fluctuation reduction [38] |

|

|

| Battery and supercapacitor hybrid energy storage system with integrated energy management system for torque and power fluctuation reduction [38] |

|

|

| Photovoltaic (PV)-Wind-Diesel battery hybrid system with PI and fuzzy logic control [9] |

|

|

| Wind-Solar-Diesel hybrid energy storage system with PSO-based frequency controller [39] |

|

|

| Active parallel hybrid energy storage system with Particle Swarm Optimization (PSO) control of battery and supercapacitor to decrease power fluctuations [40] |

|

|

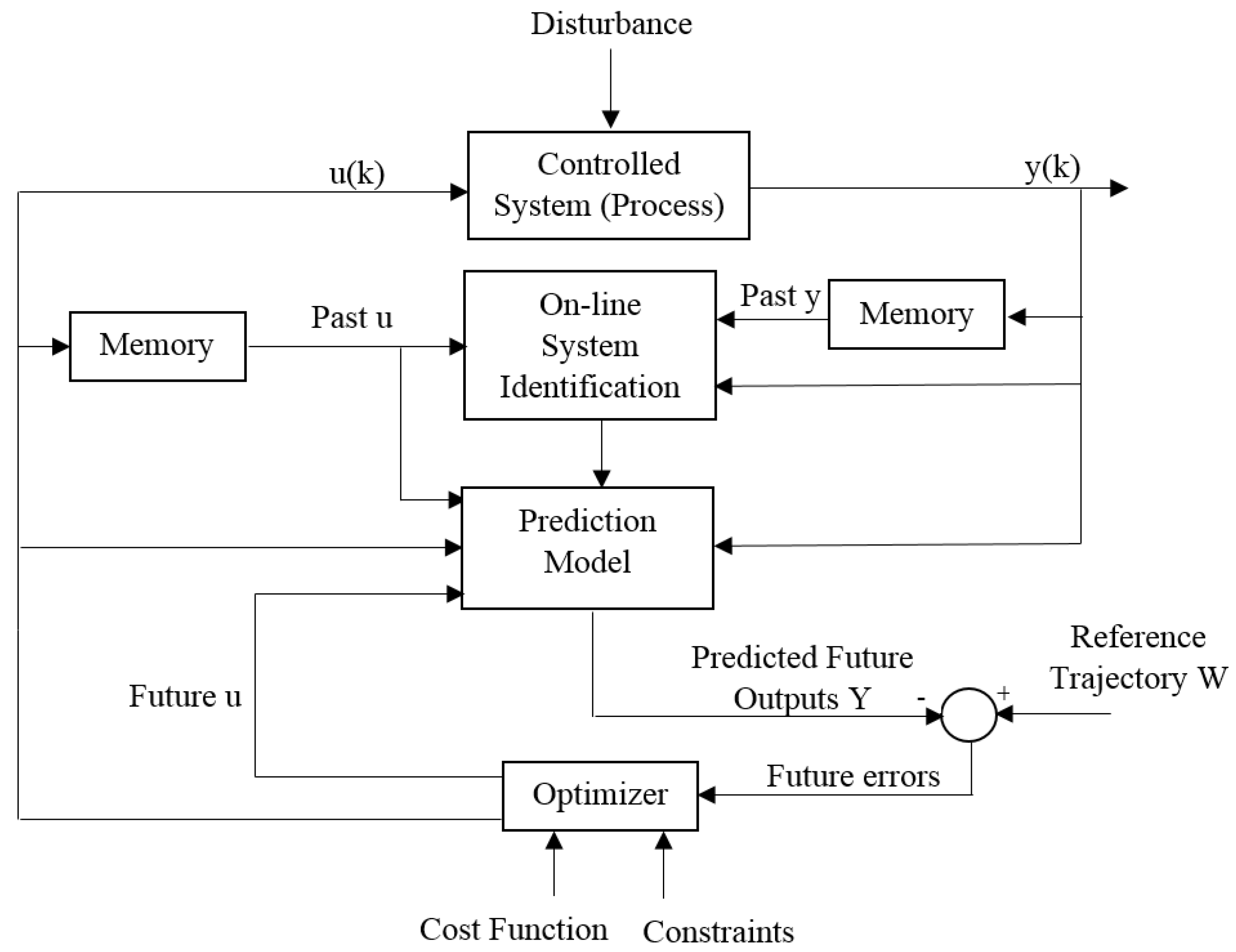

| Adaptive general predictive control used for supercapacitor energy storage system in multi-area network [41] |

|

|

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shagar, V.; Jayasinghe, S.G.; Enshaei, H. Effect of Load Changes on Hybrid Shipboard Power Systems and Energy Storage as a Potential Solution: A Review. Inventions 2017, 2, 21. https://doi.org/10.3390/inventions2030021

Shagar V, Jayasinghe SG, Enshaei H. Effect of Load Changes on Hybrid Shipboard Power Systems and Energy Storage as a Potential Solution: A Review. Inventions. 2017; 2(3):21. https://doi.org/10.3390/inventions2030021

Chicago/Turabian StyleShagar, Viknash, Shantha Gamini Jayasinghe, and Hossein Enshaei. 2017. "Effect of Load Changes on Hybrid Shipboard Power Systems and Energy Storage as a Potential Solution: A Review" Inventions 2, no. 3: 21. https://doi.org/10.3390/inventions2030021

APA StyleShagar, V., Jayasinghe, S. G., & Enshaei, H. (2017). Effect of Load Changes on Hybrid Shipboard Power Systems and Energy Storage as a Potential Solution: A Review. Inventions, 2(3), 21. https://doi.org/10.3390/inventions2030021