A Finger Exoskeleton Robot for Finger Movement Rehabilitation

Abstract

:1. Introduction

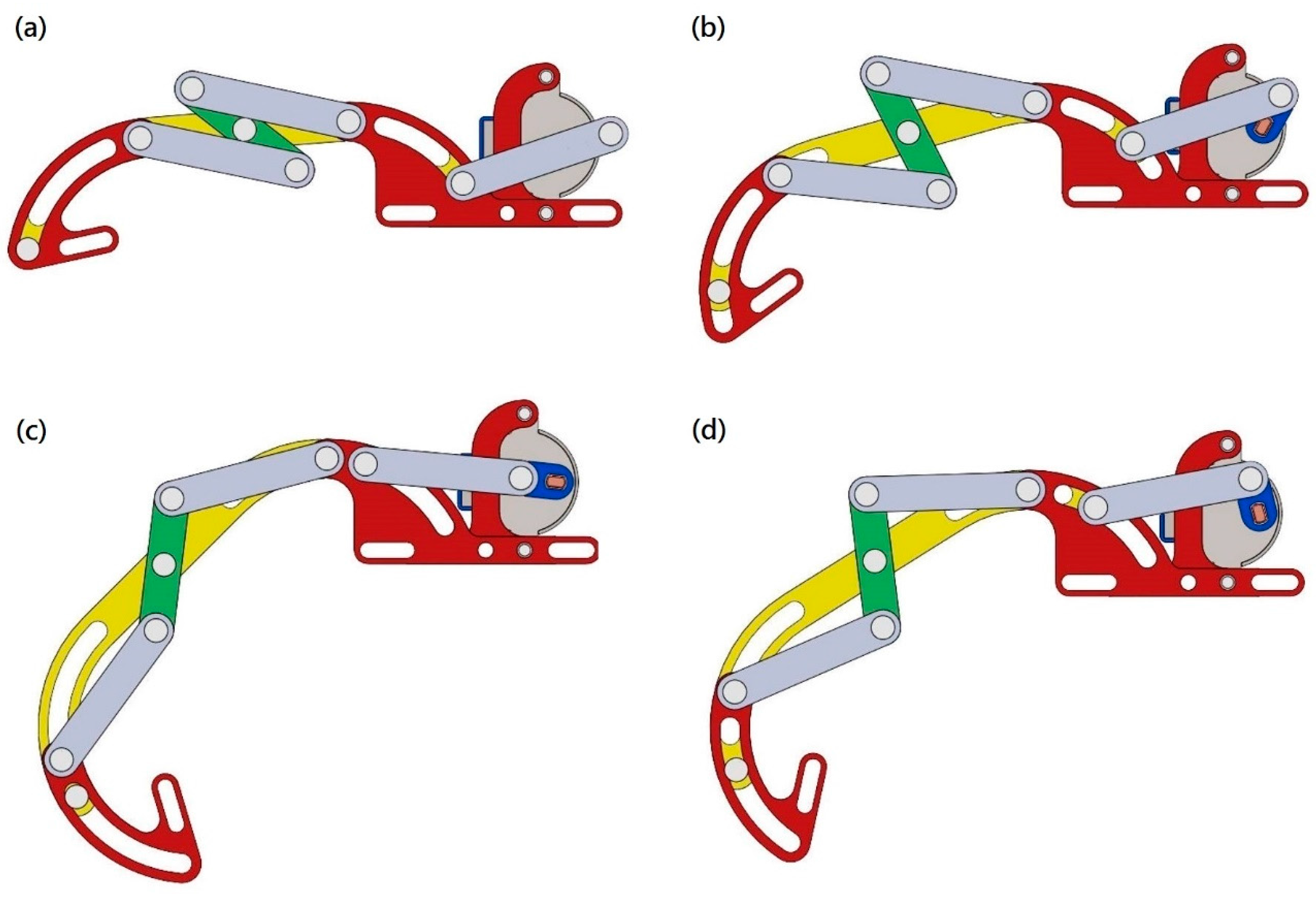

2. Design and Simulation

2.1. Design

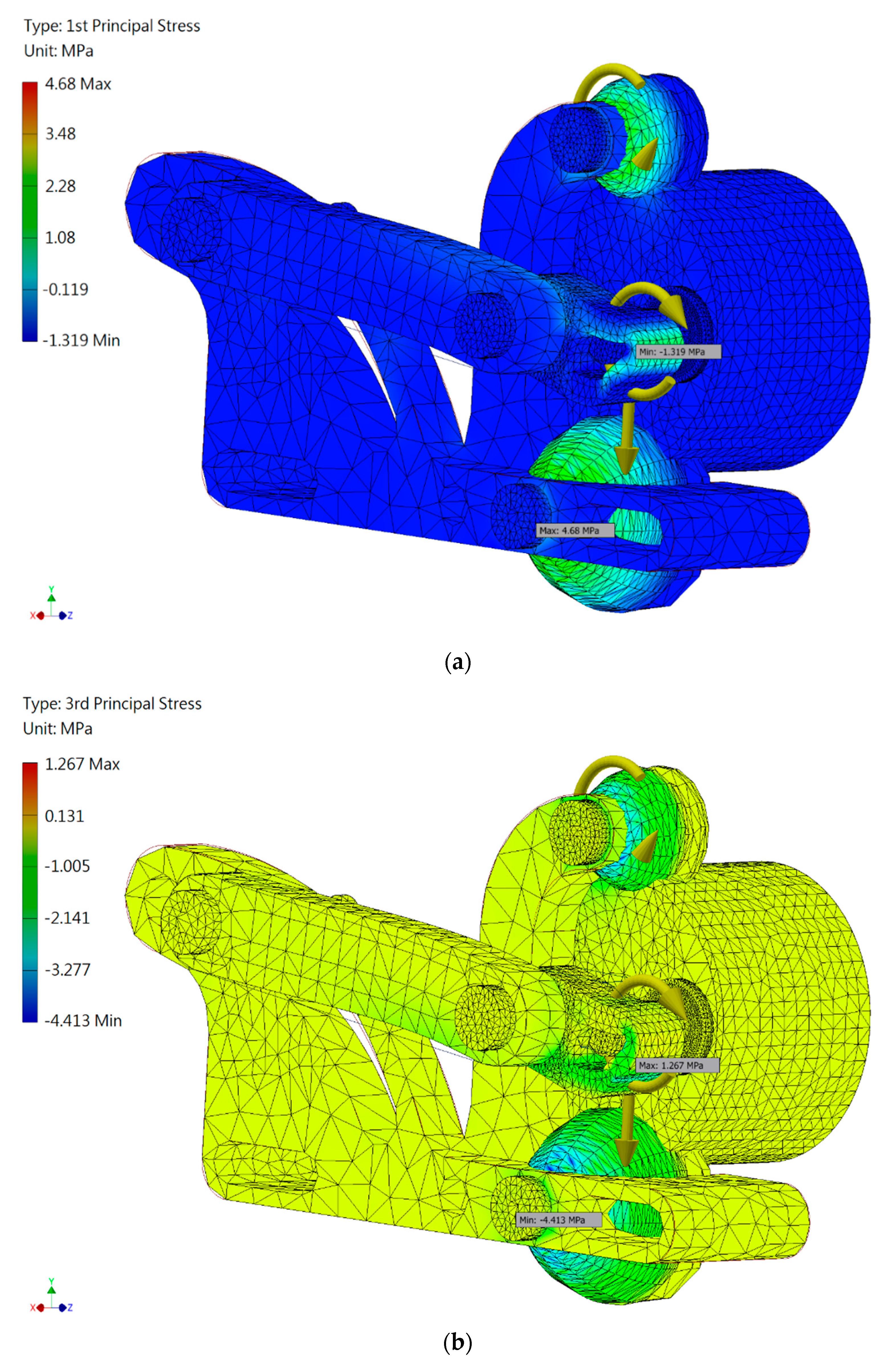

2.2. Simulation

3. Experiment

3.1. Control

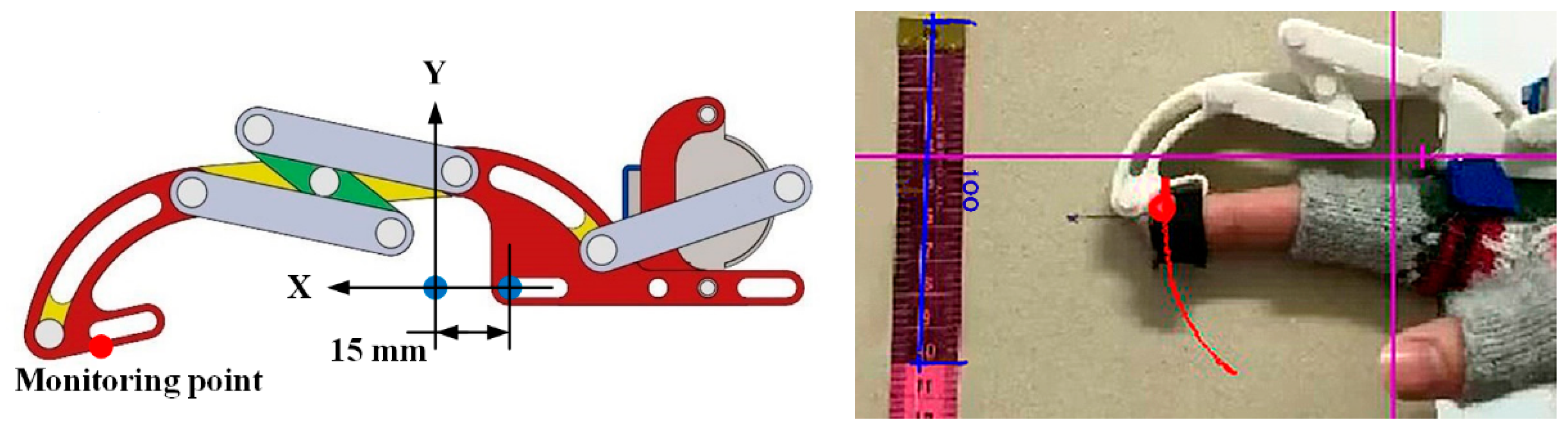

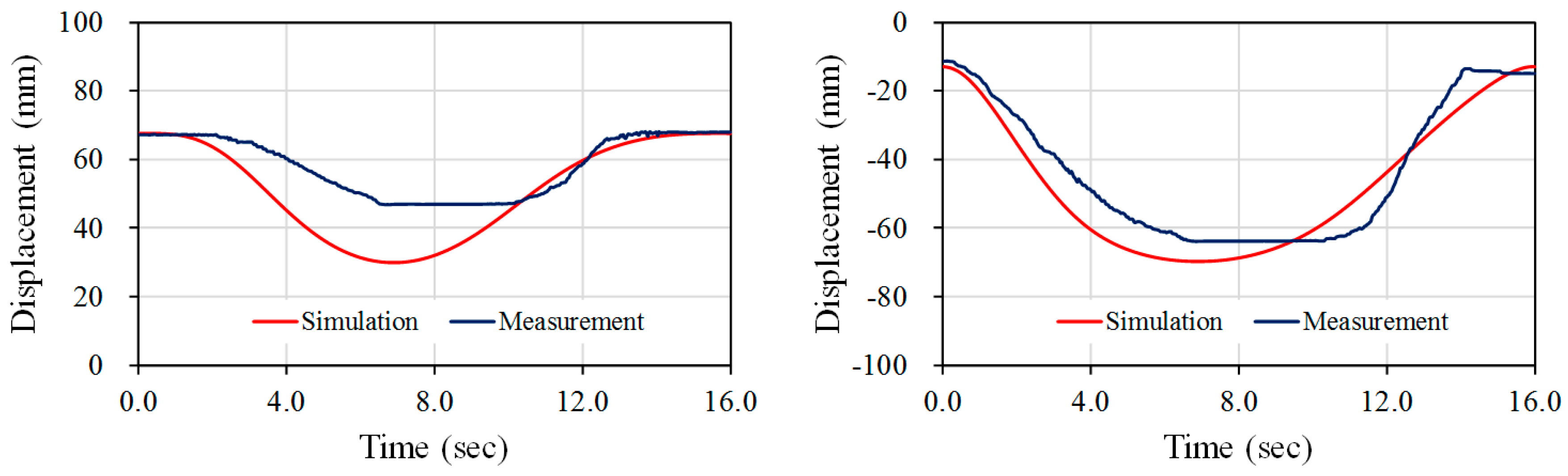

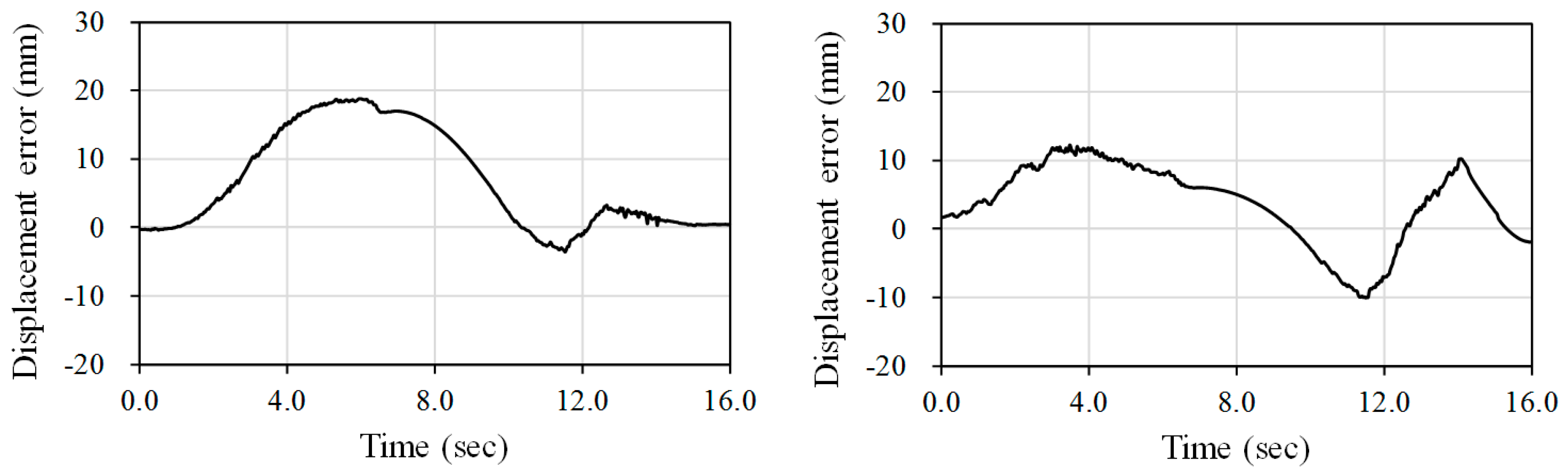

3.2. Motion Analysis

4. Discussion

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Seshadri, S.; Wolf, P.A. Lifetime risk of stroke and dementia: Current concepts, and estimates from the Framingham study. Lancet Neurol. 2007, 6, 1106–1114. [Google Scholar] [CrossRef]

- Huang, H.C.; Siao, C.J.; Chen, Y.G. The rehabilitation system of finger joints. In Proceedings of the International Conference on Control Automation and Systems, Gwangju, South Korea, 20–23 October 2013; pp. 1055–1060. [Google Scholar]

- Krebs, H.I.; Hogan, N.; Aisen, M.L.; Volpe, B.T. Robot-aided neurorehabilitation. IEEE Trans. Rehabil. Eng. 1998, 6, 75–87. [Google Scholar] [CrossRef] [PubMed]

- Reinkensmeyer, D.J.; Kahn, L.E.; Averbuch, M.; McKenna-Cole, A.; Schmit, B.D.; Rymer, W.Z. Understanding and treating arm movement impairment after chronic brain injury, progress with the ARM guide. J. Rehabil. Res. Dev. 2000, 37, 653–662. [Google Scholar] [PubMed]

- Burgar, C.G.; Lum, P.S.; Shor, P.C.; Machiel Van Der Loos, H.F. Development of robots for rehabilitation therapy, the Palo Alto VA/Stanford’s experience. J. Rehabil. Res. Dev. 2000, 37, 663–673. [Google Scholar] [PubMed]

- Ito, S.; Kawasaki, H.; Ishigure, Y.; Natsume, M.; Mouri, T.; Nishimoto, Y. A design of fine motion assist equipment for disabled hand in robotic rehabilitation system. J. Frankl. Inst. 2011, 348, 79–89. [Google Scholar] [CrossRef]

- Li, J.; Wang, S.; Wang, J.; Zheng, R.; Zhang, Y.; Chen, Z. Development of a hand exoskeleton system for index finger rehabilitation. Chin. J. Mech. Eng. 2011, 25, 223–233. [Google Scholar] [CrossRef]

- Kyberd, P.J.; Light, C.; Chappell, P.H.; Nightingale, J.M.; Whatley, D.; Evans, M. The design of anthropomorphic prosthetic hands: A study of the Southampton Hand. Robotica 2001, 19, 593–600. [Google Scholar] [CrossRef]

- Pons, J.L.; Ceres, R.; Pfeiffer, F. Multifingered dextrous robotics hand design and control: A review. Robotica 1999, 17, 661–674. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Li, B.; Zhou, W. The underactuation and motion-coupling in robotic fingers and two new 1-DOF motion-coupling anthropomorphic fingers. In Proceedings of the IEEE International Conference on Robotics and Biomimetics (ROBIO 2008), Bangkok, Thailand, 21–26 February 2009. [Google Scholar]

- Toda, H.; Kobayakawa, T.; Sankai, Y. A multi-link system control strategy based on biological reaching movement. Adv. Robot. 2006, 20, 661–679. [Google Scholar] [CrossRef]

- Heo, P.; Gu, M.G.; Lee, S.; Rhee, K.; Kim, J. Current hand exoskeleton technologies for rehabilitation and assistive engineering. Int. J. Precis. Eng. Manuf. 2012, 13, 807–824. [Google Scholar] [CrossRef]

- Allotta, B.; Conti, R.; Governi, L.; Meli, E.; Ridolfi, A.; Volpe, Y. Development and experimental testing of a portable hand exoskeleton. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015. [Google Scholar]

- Polygerinos, P.; Lyne, S.; Wang, Z.; Nicolini, L.F.; Mosadegh, B.; Whitesides, G.M.; Walsh, C.J. Towards a soft pneumatic glove for hand rehabilitation. In Proceedings of the International Conference on Intelligent Robots and Systems (IROS), IEEE/RSJ, Tokyo, Japan, 3–7 November 2013. [Google Scholar]

- Pfeiffer, F. Grasping with hydraulic fingers—An example of mechatronics. IEEE/ASME Trans. Mechatron. 1996, 1, 158–167. [Google Scholar] [CrossRef]

- Zardoshti-Kermani, M.; Wheeler, B.C.; Badie, K.; Hashemi, R.M. EMG feature evaluation for movement control of upper extremity prostheses. IEEE Trans. Rehabil. Eng. 1995, 3, 324–333. [Google Scholar] [CrossRef]

- Wolpaw, J.R.; Birbaumer, N.; McFarland, D.J.; Pfurtscheller, G.; Vaughan, T.M. Brain–computer interfaces for communication and control. Clin. Neurophysiol. 2002, 113, 767–791. [Google Scholar] [CrossRef]

- Pires, J.N.; Bugmann, G. Robot-by-voice: Experiments on commanding an industrial robot using the human voice. Ind. Robot. 2005, 32, 505–511. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Zhang, Y.; Wan, S. Design of an exoskeleton for index finger rehabilitation. In Proceedings of the IEEE EMBS conference, Minneapolis, MN, USA, 2–6 September 2009. [Google Scholar]

- Kawasaki, H.; Kimura, H.; Nishimoto, Y.; Hayashi, H.; Sakaeda, H. Hand rehabilitation support system based on self-motion control, with a clinical case report. In Proceedings of the Automation Congress, Budapest, Hungary, 24–26 July 2006. [Google Scholar]

- Wege, A.; Hommel, G.; Kondak, K. Development and control of a hand exoskeleton for rehabilitation of hand injuries. In Proceedings of the International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005. [Google Scholar]

| Value | First Principal Stress | Third Principal Stress | Safety Factor | Displacement |

|---|---|---|---|---|

| Maximum | 4.68 MPa | 1.27 MPa | 15 | 0.02 mm |

| Minimum | −1.32 MPa | −4.41 MPa | 3.07 | 0 mm |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, T.-H.; Chiang, Y.-C.; Chan, W.-T.; Chen, S.-J. A Finger Exoskeleton Robot for Finger Movement Rehabilitation. Inventions 2017, 2, 12. https://doi.org/10.3390/inventions2030012

Hsu T-H, Chiang Y-C, Chan W-T, Chen S-J. A Finger Exoskeleton Robot for Finger Movement Rehabilitation. Inventions. 2017; 2(3):12. https://doi.org/10.3390/inventions2030012

Chicago/Turabian StyleHsu, Tzu-Heng, Yen-Cheng Chiang, Wei-Tun Chan, and Shih-Jui Chen. 2017. "A Finger Exoskeleton Robot for Finger Movement Rehabilitation" Inventions 2, no. 3: 12. https://doi.org/10.3390/inventions2030012

APA StyleHsu, T.-H., Chiang, Y.-C., Chan, W.-T., & Chen, S.-J. (2017). A Finger Exoskeleton Robot for Finger Movement Rehabilitation. Inventions, 2(3), 12. https://doi.org/10.3390/inventions2030012