Impact of Digital Twins on Real Practices in Manufacturing Industries

Abstract

1. Introduction

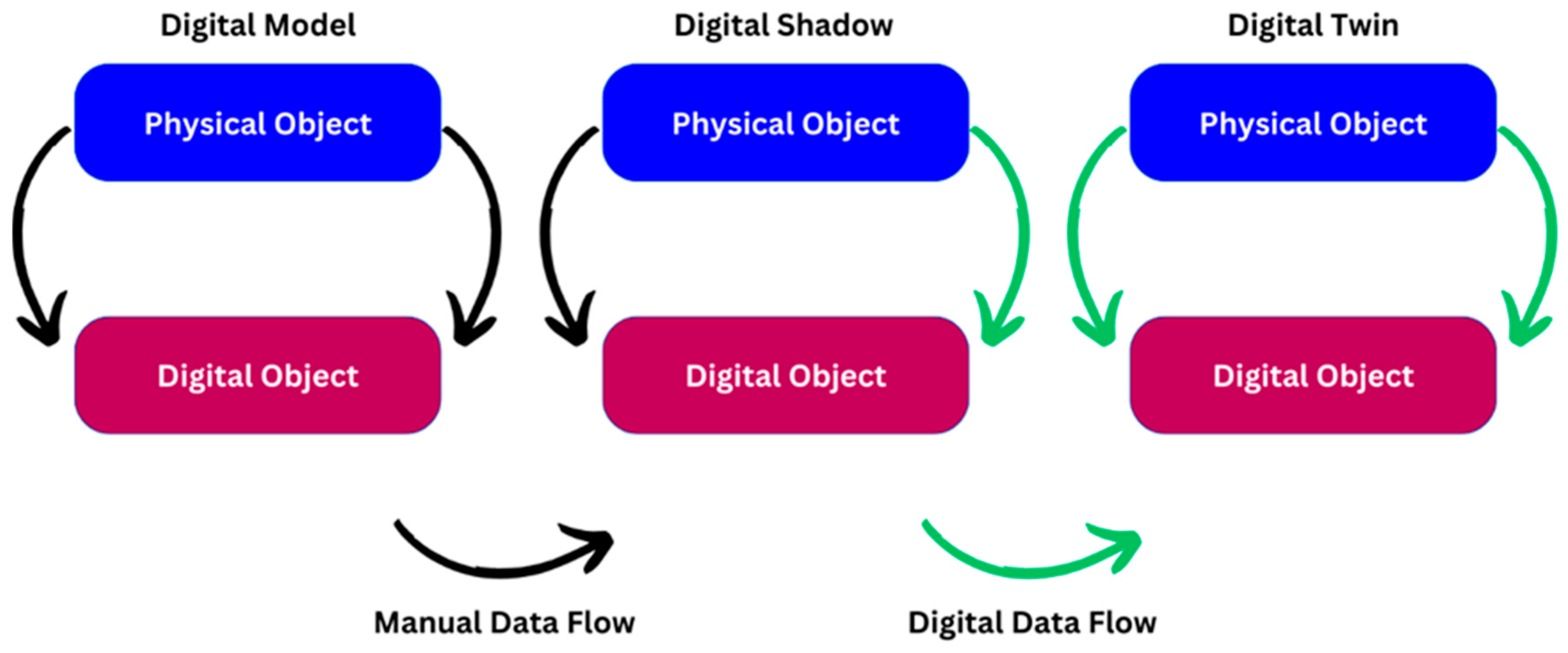

1.1. Digital Model

1.2. Digital Shadow

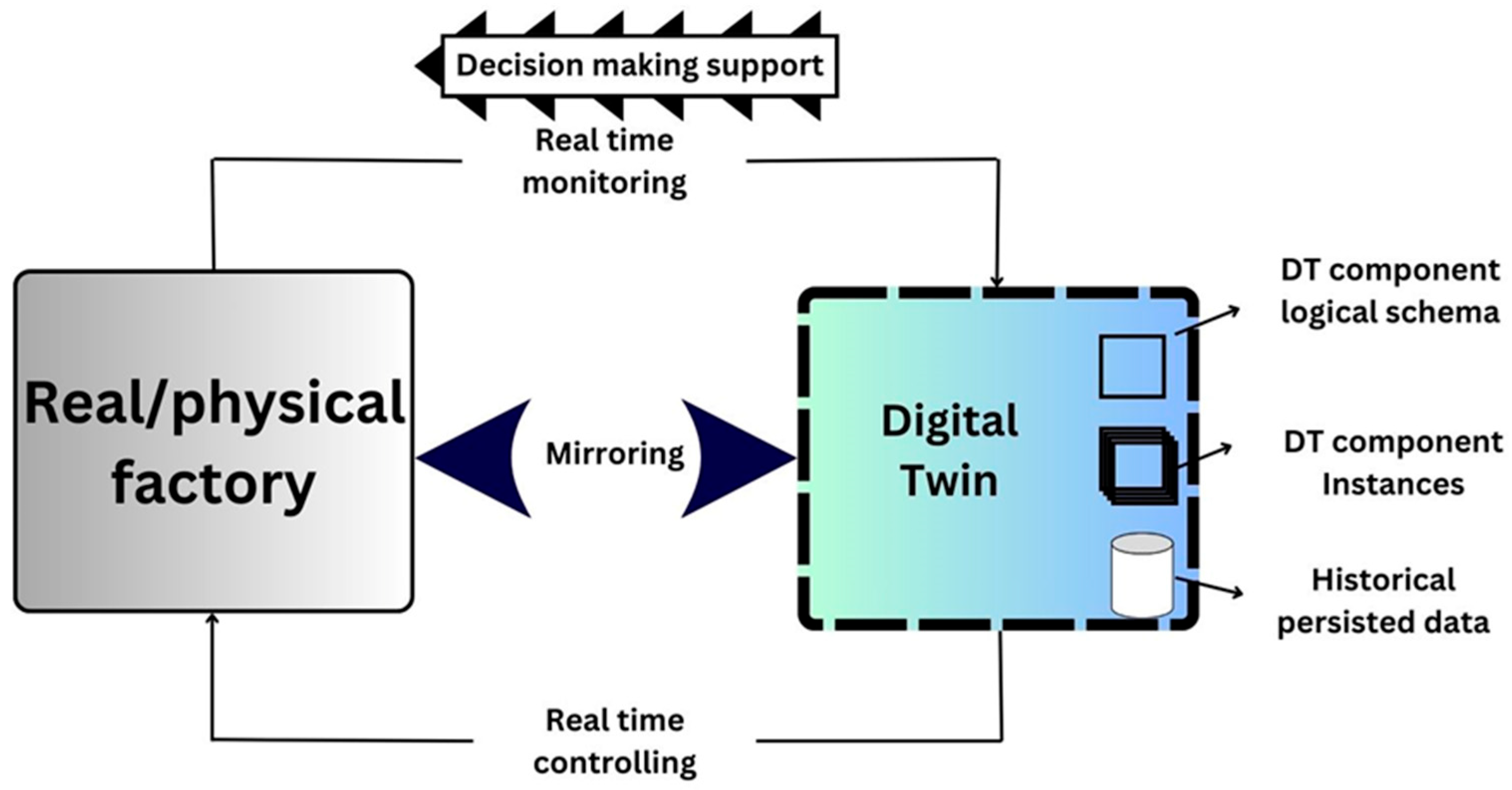

1.3. Digital Twin

Meta-Analysis and Proposed Unified Taxonomy

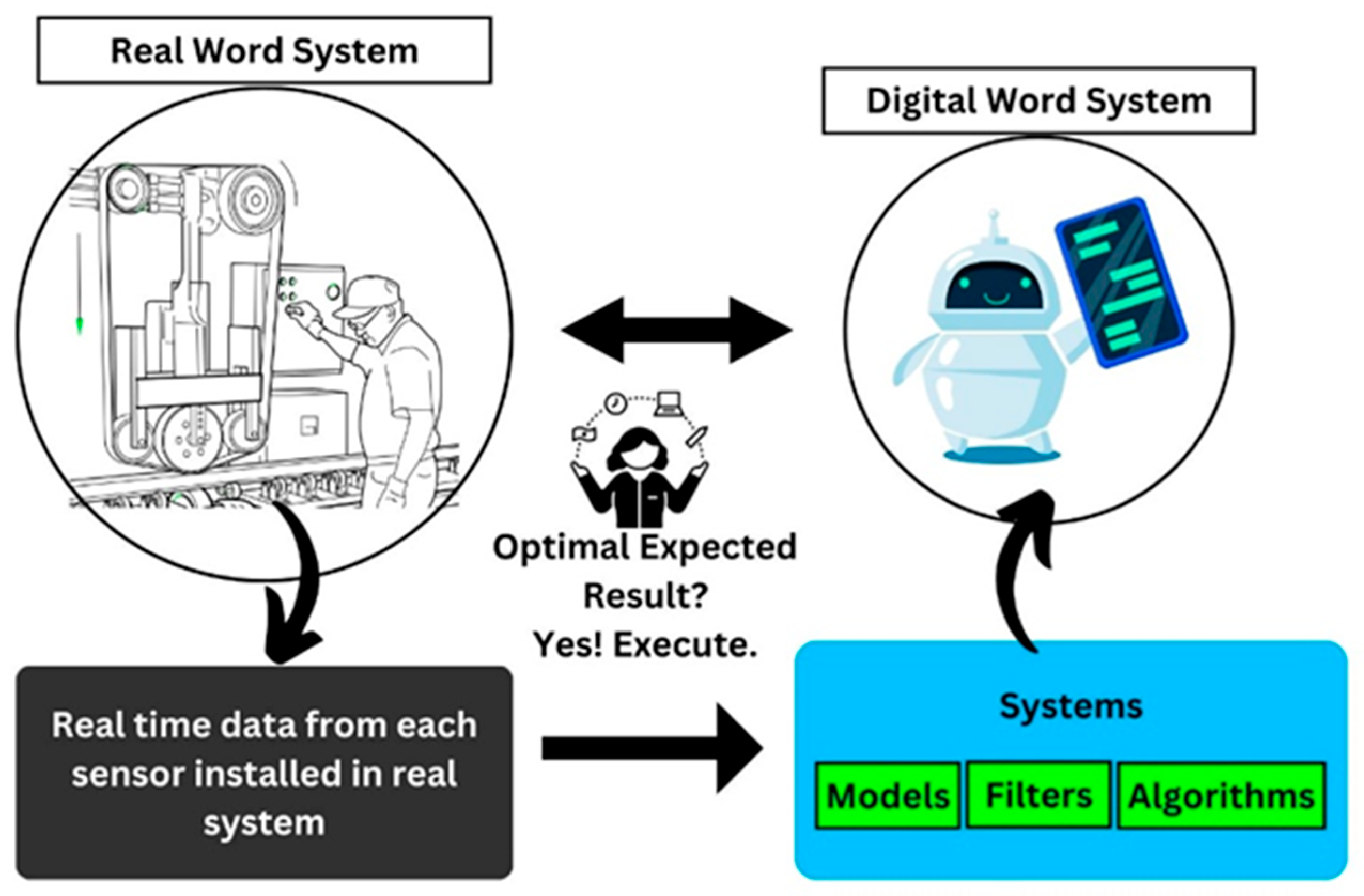

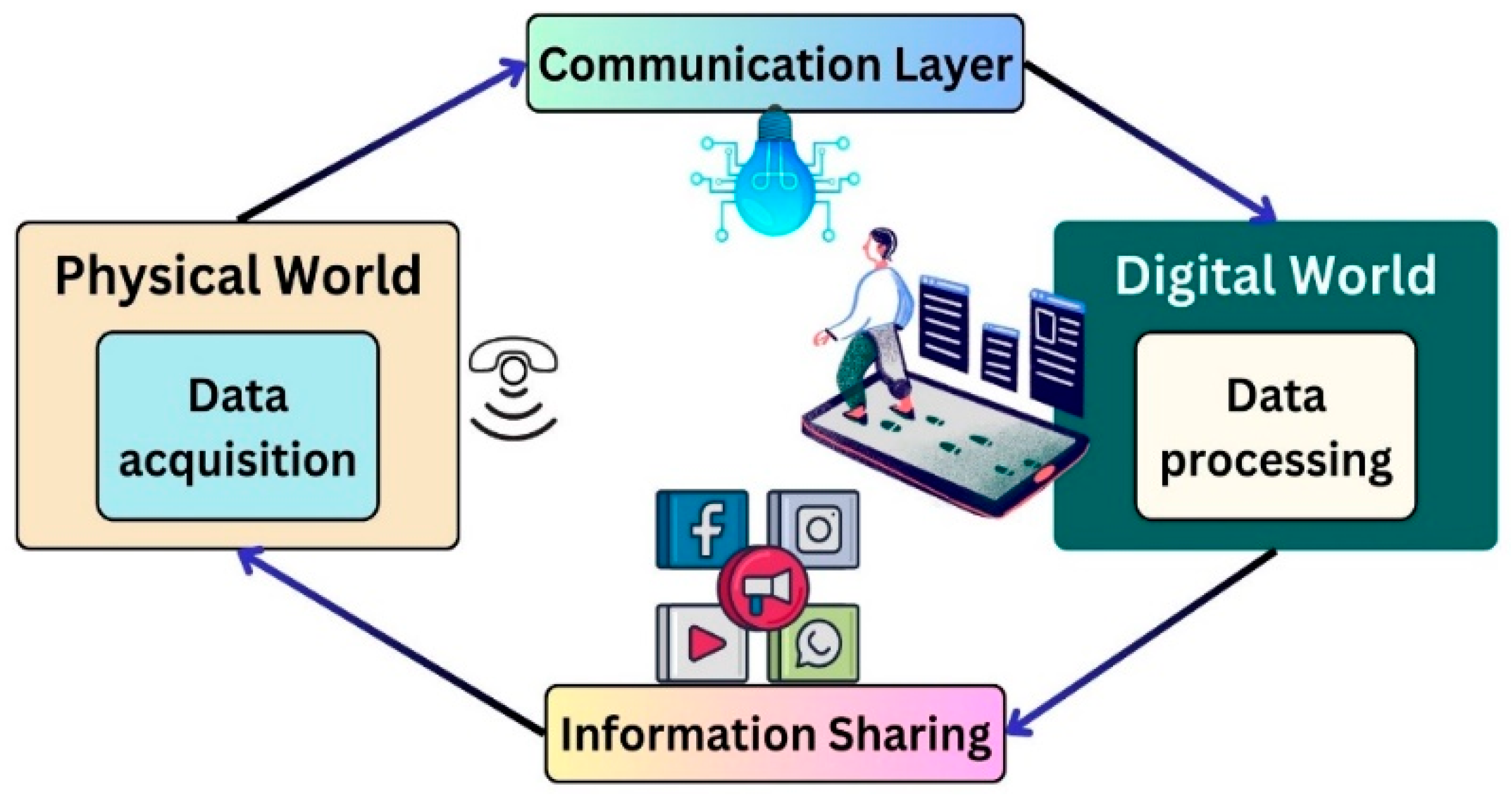

2. Digital Twins and Cyber-Physical Systems

3. Digital Twins: Practice, Challenges, and Open Research

3.1. Improving Design-Led Sustainable and Hybrid Retail Experiences via Digital Twins

3.2. Cloud-Based Framework for the Elderly Healthcare Services

3.3. Digital Twin Framework: Specification and Opportunities

3.4. A Survey on Digital Twin: Applications, and Design

- Phase 1: Design and Modeling

- Phase 2: Data Integration and Connectivity

- Phase 3: Simulation and Analysis

- Phase 4: Optimization and Control

- Phase 5: Evolution and Decommissioning

3.5. An Optimization Tool for Production Planning

4. Digital Twin: Origin to Future

- Comparative Analysis of DT Implementation Types

4.1. Implementation of Digital Twins in the Food Supply Chain

4.2. Digital Twin: Challenges and Open Research

4.3. Digital Twin: Enablers from a Modeling Perspective

4.4. Digital Twin: Vision, Benefits and Boundaries

4.5. Digital Twins-Based Smart Manufacturing System

4.6. Industrial Applications of Digital Twins

4.7. Construction with Digital Twin Information Systems

5. Opportunities for Supply Chains, and Business Models

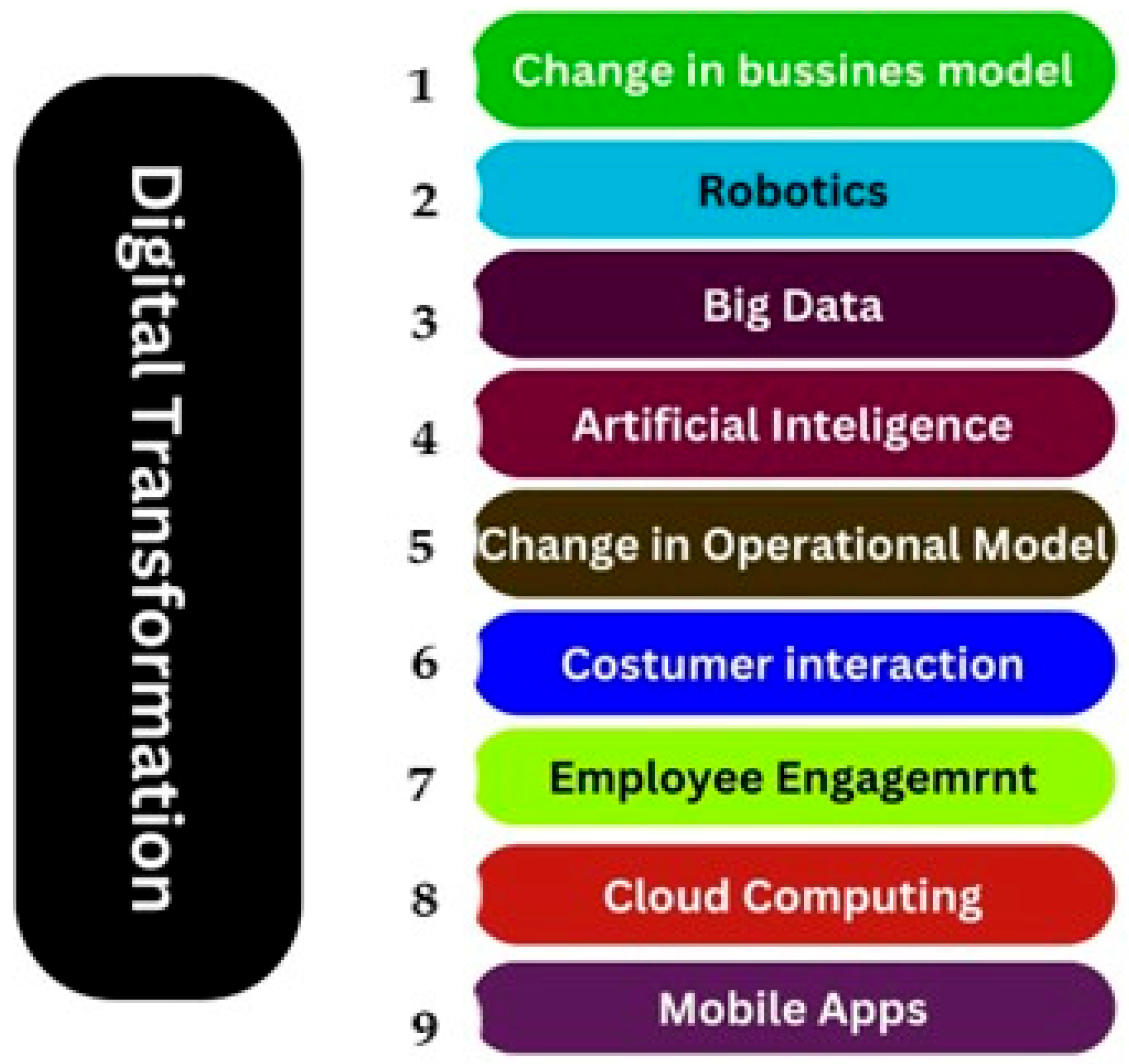

5.1. Industry 4.0 and Digital Twins

5.2. Application of Digital Twins in Multiple Fields

5.3. Digital Twin in Manufacturing

5.4. The Digital Twin in Industry 4.0

5.5. Digital Twins in Industry 5.0

5.6. Digital Twin-Based Sustainable Intelligent Manufacturing

- Recent Developments in Intelligent Process Monitoring

- Adaptive Remaining Useful Life (RUL) Prediction Models

- Integration with Digital Twin-Based Intelligent Systems

- Implications for Future Research

5.7. The Use of Digital Twin for Predictive Maintenance in Manufacturing

5.8. Digital Twins and Various Technologies in Museums/Cultural Heritage

6. The Dual Strategy for Textile and Fashion Production Using Clothing Waste

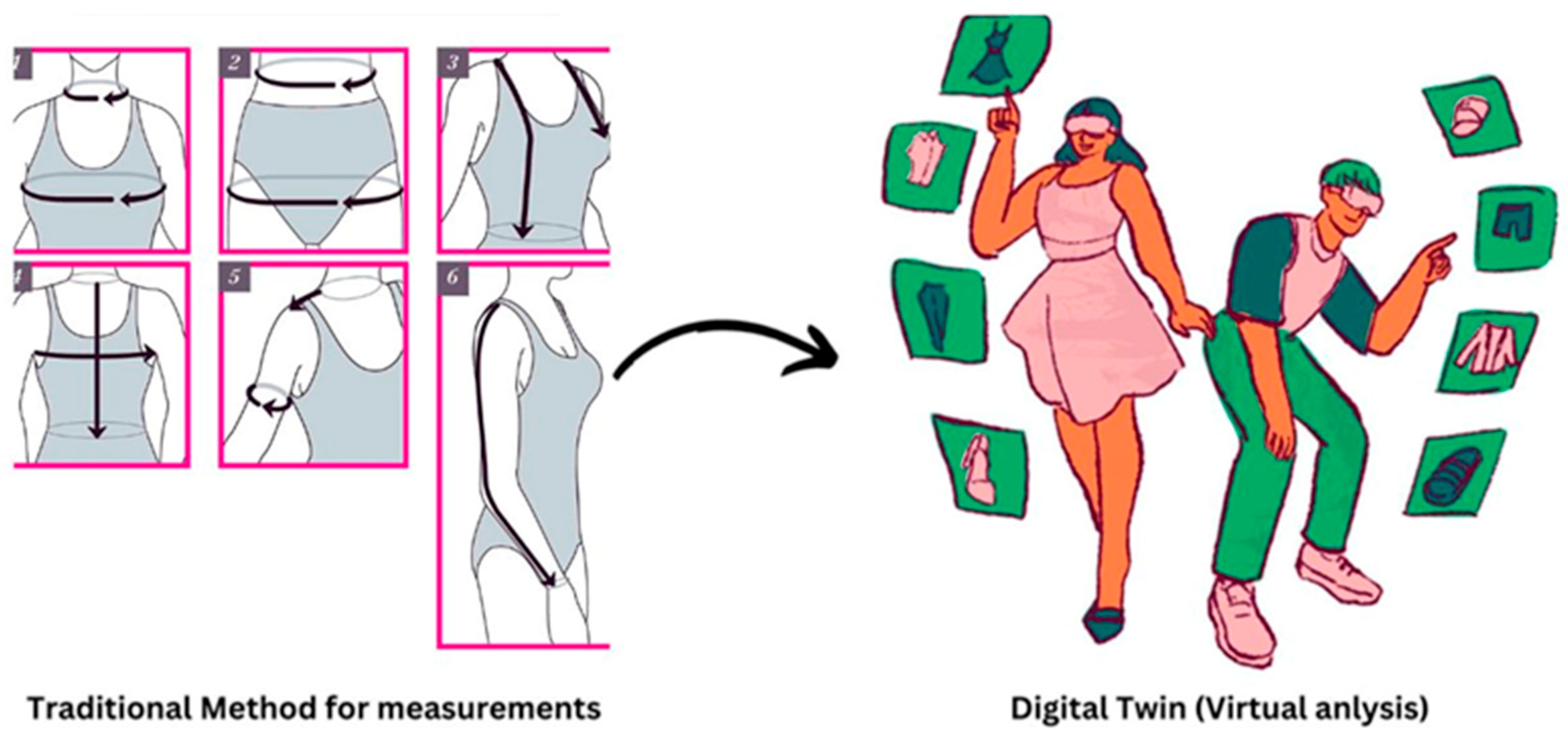

7. Revolutionizing the Garment Industry 5.0

8. Sustainable Value in the Fashion Industry

9. Digital Twin-Driven Product Design and Manufacturing

- Insufficient studies examining two-way, real-time interactions between Digital Twins and physical assets. Insufficient investigation of spatiotemporal dynamics, security obstacles, and interpretability problems in the context of Digital Twins.

- Lack of all-inclusive solutions for creating synchronized, identical Digital Twins in a variety of businesses. Minimal attention is paid to how physical assets change over time and how Digital Twin models maintain backward compatibility.

- Inadequate consideration of the imperatives of safety and security, which call for more interpretability and transparency in decision-making based on Digital Twins. Insufficient investigation into Digital Twin user interface design impedes smooth integration and user-friendly functioning. All things considered, there is a research vacuum when it comes to tackling the complex issues involved in optimizing the capabilities of Digital Twin technologies in diverse fields.

10. Future Innovations and Development Trends in Digital Twin Technology

- High-performance simulation, quantum computing:

- Interaction with the Metaverse to Immersive Visualization and Collaboration:

- Autonomous Digital Twins that run on AI:

11. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Aivaliotis, P.; Georgoulias, K.; Chryssolouris, G. The use of Digital Twin for predictive maintenance in manufacturing. Int. J. Comput. Integr. Manuf. 2019, 32, 1067–1080. [Google Scholar] [CrossRef]

- Aivaliotis, P.; Georgoulias, K.; Arkouli, Z.; Makris, S. Methodology for enabling digital twin using advanced physics-based modelling in predictive maintenance. Procedia CIRP 2019, 81, 417–422. [Google Scholar] [CrossRef]

- Jacoby, M.; Usländer, T. Digital twin and internet of things-Current standards landscape. Appl. Sci. 2020, 10, 6519. [Google Scholar] [CrossRef]

- He, B.; Bai, K.J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2021, 9, 1–21. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Mourtzis, D. Towards the 5th industrial revolution: A literature review and a framework for process optimization based on big data analytics and semantics. J. Mach. Eng. 2021, 21, 5–39. [Google Scholar] [CrossRef]

- Brunheroto, P.H.; Tomanek, D.P.; Deschamps, F. Implications of industry 4.0 to companies’ performance: A comparison between brazil and germany1. Braz. J. Oper. Prod. Manag. 2021, 18, 1–10. [Google Scholar] [CrossRef]

- Kenett, R.S.; Bortman, J. The digital twin in Industry 4.0: A wide-angle perspective. Qual. Reliab. Eng. Int. 2022, 38, 1357–1366. [Google Scholar] [CrossRef]

- Chinesta, F.; Cueto, E.; Abisset-Chavanne, E.; Duval, J.L.; Khaldi, F.E. Virtual, Digital and Hybrid Twins A new paradigm in data-based engineering and engineered data. Arch. Comput. Methods Eng. 2018, 27, 105–134. [Google Scholar] [CrossRef]

- Glaessgen, E.H.; Stargel, D.S. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, Hl, USA, 23–26 April 2012. [Google Scholar]

- Bottani, E.; Cammardella, A.; Murino, T.; Vespoli, S. From the Cyber-Physical System to the Digital Twin: The process development for behaviour modelling of a Cyber Guided Vehicle in M2M logic. In Proceedings of the XXII Summer School “Francesco Turco”—Industrial Systems Engineering, Palermo, Italy, 13–15 September 2017. [Google Scholar]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-Pap. 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Cai, Y.; Starly, B.; Cohen, P.; Lee, Y.S. Sensor Data and Information Fusion to Construct Digital-twins Virtual Machine Tools for Cyber-physical Manufacturing. Procedia Manuf. 2017, 10, 1031–1042. [Google Scholar] [CrossRef]

- Ahmadi-Assalemi, G.; Al-Khateeb, H.; Maple, C.; Epiphaniou, G.; Alhaboby, Z.A.; Alkaabi, S.; Alhaboby, D. Digital twins for precision healthcare. In Advanced Sciences and Technologies for Security Applications; Springer: Berlin/Heidelberg, Germany, 2020; pp. 133–158. [Google Scholar] [CrossRef]

- Björnsson, B.; Borrebaeck, C.; Elander, N.; Gasslander, T.; Gawel, D.R.; Gustafsson, M.; Jörnsten, R.; Lee, E.J.; Li, X.; Lilja, S. Digital twins to personalize medicine. Genome Med. 2020, 12, 4. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Lv, Z. Application of Digital Twins in multiple fields. Multimed. Tools Appl. 2022, 81, 26941–26967. [Google Scholar] [CrossRef] [PubMed]

- Agalianos, K.; Ponis, S.T.; Aretoulaki, E.; Plakas, G.; Efthymiou, O. Discrete event simulation and digital twins: Review and challenges for logistics. Procedia Manuf. 2020, 51, 1636–1641. [Google Scholar] [CrossRef]

- Rubio, E.M.; Dionísio, R.P.; Miguel, P.; Torres, B. Predictive Maintenance of Induction Motors in the Context of Industry 4.0. Int. J. Mechatron. Appl. Mech. 2018, 4, 238–242. [Google Scholar] [CrossRef]

- Casciani, D.; Chkanikova, O.; Pal, R. Exploring the nature of digital transformation in the fashion industry: Opportunities for supply chains, business models, and sustainability-oriented innovations. Sustain. Sci. Pract. Policy 2022, 18, 773–795. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, Y.; Liu, X.; Zheng, Y. A Digital-Twin-Assisted Fault Diagnosis Using Deep Transfer Learning. IEEE Access 2019, 7, 19990–19999. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmstrom, J. Digital Twin: Vision, benefits, boundaries, and creation for buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer International Publishing: Cham, Switzerland, 2016; pp. 85–113. [Google Scholar] [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital twin: Values, challenges and enablers from a modeling perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital Twin: Values, Challenges and Enablers. arXiv 2019, arXiv:1910.01719. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Chen, Y. Integrated and Intelligent Manufacturing: Perspectives and Enablers. Engineering 2017, 3, 588–595. [Google Scholar] [CrossRef]

- Liu, Z.; Meyendorf, N.; Mrad, N. The role of data fusion in predictive maintenance using digital twin. AIP Conf. Proc. 2018, 1949, 020023. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Vrabič, R.; Erkoyuncu, J.A.; Butala, P.; Roy, R. Digital twins: Understanding the added value of integrated models for through-life engineering services. Procedia Manuf. 2018, 16, 139–146. [Google Scholar] [CrossRef]

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging digital twin technology in model-based systems engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT driven service-oriented smart manufacturing: Framework and characteristics. IEEE Trans. Syst. Man. Cybern. Syst. 2019, 49, 81–91. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward New-Generation Intelligent Manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Picone, M.; Mamei, M.; Zambonelli, F. A Flexible and Modular Architecture for Edge Digital Twin: Implementation and Evaluation. ACM Trans. Internet Things 2023, 4, 8. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann.-Manuf. Technol. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the art theory and practice, challenges, and open research questions. J. Ind. Inf. Integr. 2022, 30, 100383. [Google Scholar] [CrossRef]

- Claudia, M.; Dieck, T.; Jung, T. Progress in IS Augmented Reality and Virtual Reality the Power of AR and VR for Business. Available online: http://www.springer.com/series/10440 (accessed on 31 August 2025).

- Ceschin, F.; Gaziulusoy, I. Evolution of design for sustainability: From product design to design for system innovations and transitions. Des. Stud. 2016, 47, 118–163. [Google Scholar] [CrossRef]

- Arnette, A.N.; Brewer, B.L.; Choal, T. Design for sustainability (DFS): The intersection of supply chain and environment. J. Clean. Prod. 2014, 83, 374–390. [Google Scholar] [CrossRef]

- Bertola, P.; Teunissen, J. Fashion 4.0. Innovating Fashion Industry Through Digital Transformation. Res. J. Text. Appar. 2018, 22, 352–369. [Google Scholar] [CrossRef]

- Spagnoli, A.; Cardoso, G.F. Dematerializing fashion. Improving design-led sustainable and hybrid retail experiences via digital twins. In Proceedings of the Cumulus Conference: Connectivity and Creativity in Times of Conflict, Online, 12–15 April 2023; p. 372. [Google Scholar]

- Liu, Y.; Zhang, L.; Yang, Y.; Zhou, L.; Ren, L.; Wang, F.; Liu, R.; Pang, Z.; Deen, M.J. A Novel Cloud-Based Framework for the Elderly Healthcare Services Using Digital Twin. IEEE Access 2019, 7, 49088–49101. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, Y.; Tao, F.; Li, B.H.; Ren, L.; Zhang, X.; Guo, H.; Cheng, Y.; Hu, A.; Liu, Y. Cloud manufacturing: A new manufacturing paradigm. Enterp. Inf. Syst. 2014, 8, 167–187. [Google Scholar] [CrossRef]

- Majumder, S.; Aghayi, E.; Noferesti, M.; Memarzadeh-Tehran, H.; Mondal, T.; Pang, Z.; Deen, M.J. Smart homes for elderly healthcare—Recent advances and research challenges. Sensors 2017, 17, 2496. [Google Scholar] [CrossRef] [PubMed]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A survey on digital twin: Definitions, characteristics, applications, and design implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Moyne, J.; Qamsane, Y.; Balta, E.C.; Kovalenko, I.; Faris, J.; Barton, K.; Tilbury, D.M. A Requirements Driven Digital Twin Framework: Specification and Opportunities. IEEE Access 2020, 8, 107781–107801. [Google Scholar] [CrossRef]

- Ding, K.; Chan, F.T.S.; Zhang, X.; Zhou, G.; Zhang, F. Defining a Digital Twin-based Cyber-Physical Production System for autonomous manufacturing in smart shop floors. Int. J. Prod. Res. 2019, 57, 6315–6334. [Google Scholar] [CrossRef]

- Batty, M. Digital twins. Environ. Plan. B Urban Anal. City Sci. 2018, 45, 817–820. [Google Scholar] [CrossRef]

- Bostrom, N. Are we living in a computer simulation? Philos. Q. 2003, 53, 243–255. [Google Scholar] [CrossRef]

- Schrotter, G.; Hürzeler, C. The Digital Twin of the City of Zurich for Urban Planning. PFG—J. Photogramm. Remote Sens. Geoinf. Sci. 2020, 88, 99–112. [Google Scholar] [CrossRef]

- Dawkins, O.; Dennett, A.; Hudson-Smith, A. Living with a Digital Twin: Operational management and engagement using IoT and Mixed Realities at UCL’s Here East Campus on the Queen Elizabeth Olympic Park. In Proceedings of the 26th Annual GIScience Research UK Conference: GISRUK 2018, Leicester, UK, 17–20 April 2018. [Google Scholar]

- Ferro, R.; Cordeiro, G.A.; Ordóñez, R.E.C.; Beydoun, G.; Shukla, N. An optimization tool for production planning: A case study in a textile industry. Appl. Sci. 2021, 11, 8312. [Google Scholar] [CrossRef]

- Efendioglu, N.; Woitsch, R. A modelling method for digital service design and intellectual property management towards industry 4.0: CAxMan case. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Cham, Switzerland, 2017; Volume 10371, pp. 153–163. [Google Scholar] [CrossRef]

- Zhou, J.; Yao, X.; Zhang, J. Big Data in Wisdom Manufacturing for Industry 4.0. In Proceedings—2017 5th International Conference on Enterprise Systems: Industrial Digitalization by Enterprise Systems, ES, Beijing, China, 22–24 September 2017; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2017; pp. 107–112. [Google Scholar] [CrossRef]

- Magomadov, V.S. The digital twin technology and its role in manufacturing. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2020. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital twin: Origin to future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Leiva, B.C.; Strategy, V.P. Demystifying the Digital Thread and Digital Twin Concepts. Industry Week, 1 August 2016. [Google Scholar]

- Agrawal, T.K.; Kumar, V.; Pal, R.; Wang, L.; Chen, Y. Blockchain-based framework for supply chain traceability: A case example of textile and clothing industry. Comput. Ind. Eng. 2021, 154, 107130. [Google Scholar] [CrossRef]

- Bhandal, R.; Meriton, R.; Kavanagh, R.E.; Brown, A. The application of digital twin technology in operations and supply chain management: A bibliometric review. Supply Chain. Manag. Int. J. 2022, 27, 182–206. [Google Scholar] [CrossRef]

- Ghadge, A.; Yates, N.M.; Huang, Y.; Yates, N. Implementation of Digital Twins in the Food Supply Chain: A Review and Conceptual Framework. J. Prod. Res. 2024, 62, 6400–6426. Available online: https://www.researchgate.net/publication/376229142 (accessed on 31 August 2025). [CrossRef]

- Barykin, S.Y.; Bochkarev, A.A.; Kalinina, O.V.; Yadykin, V.K. Concept for a supply chain digital twin. Int. J. Math. Eng. Manag. Sci. 2020, 5, 1498–1515. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital twin driven human–robot collaborative assembly. CIRP Ann. 2019, 68, 499–502. [Google Scholar] [CrossRef]

- Bruynseels, K.; de Sio, F.S.; van den Hoven, J. Digital Twins in health care: Ethical implications of an emerging engineering paradigm. Front. Genet. 2018, 9, 31. [Google Scholar] [CrossRef]

- Laaki, H.; Miche, Y.; Tammi, K. Prototyping a Digital Twin for Real Time Remote Control over Mobile Networks: Application of Remote Surgery. IEEE Access 2019, 7, 20235–20336. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Q.; Chen, X.; Zhang, D.; Leng, J. A Digital Twin-Based Approach for Designing and Multi-Objective Optimization of Hollow Glass Production Line. IEEE Access 2017, 5, 26901–26911. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, C.; Xu, X. Visualisation of the digital twin data in manufacturing by using augmented reality. Procedia CIRP 2019, 81, 898–903. [Google Scholar] [CrossRef]

- Jiang, Y.; Yin, S.; Li, K.; Luo, H.; Kaynak, O. Industrial applications of digital twins. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2021, 379, 20200360. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Melesse, T.Y.; Di Pasquale, V.; Riemma, S. Digital twin models in industrial operations: A systematic literature review. Procedia Manuf. 2020, 42, 267–272. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with digital twin information systems. Data-Centric Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Han, K.K.; Golparvar-Fard, M. Potential of Big Visual Data and Building Information Modeling for Construction Performance Analytics: An Exploratory Study. Autom. Constr. 2017, 73, 184–198. [Google Scholar] [CrossRef]

- Dijkman, R.M.; Sprenkels, B.; Peeters, T.; Janssen, A. Business models for the Internet of Things. Int. J. Inf. Manag. 2015, 35, 672–678. [Google Scholar] [CrossRef]

- Naqvi, S.M.R.; Ghufran, M.; Meraghni, S.; Varnier, C.; Nicod, J.-M.; Zerhouni, N. Human Knowledge Centered Maintenance Decision Support in Digital Twin Environment. J. Manuf. Syst. 2022, 65, 528–537. [Google Scholar] [CrossRef]

- Speicher, T.L.; Defranco, J.F. Industry 4.0 and Digital Twins. Computer 2023, 56, 84–88. [Google Scholar] [CrossRef]

- Hussain, A.; Sajid, M.; Iqbal, D.; Sarwar, M.I.; Farooq, A.; Siddique, A.; Khan, M.Q.; Kim, I.-S. Impact of Novel Varietal and Regional Differences on Cotton Fiber Quality Characteristics. Materials 2022, 15, 3242. [Google Scholar] [CrossRef]

- Khan, M.Q.; Kharaghani, D.; Sanaullah; Shahzad, A.; Duy, N.P.; Hasegawa, Y.; Azeemullah; Lee, J.; Kim, I.S. Fabrication of Antibacterial Nanofibers Composites by Functionalizing the Surface of Cellulose Acetate Nanofibers. ChemistrySelect 2020, 5, 1315–1321. [Google Scholar] [CrossRef]

- Kharaghani, D.; Kurniwan, E.B.; Khan, M.Q.; Yoshiko, Y. MiRNA-nanofiber, the next generation of bioactive scaffolds for bone regeneration: A review. Micromachines 2021, 12, 1472. [Google Scholar] [CrossRef]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Tichy, M.; Muller, M. Factors Affecting Acoustic Properties of Natural-Fiber-Based Materials and Composites: A Review. Textiles 2021, 1, 55–85. [Google Scholar] [CrossRef]

- Bakhsh, N.; Khan, M.Q.; Ahmad, A.; Hassan, T. Recent Advancements in Cotton Spinning. In Cotton Science and Processing Technology; Springer: Singapore, 2020; pp. 143–164. [Google Scholar] [CrossRef]

- Shafiq, F.; Siddique, A.; Pervez, N.; Hassan, M.M.; Naddeo, V.; Cai, Y.; Hou, A.; Xie, K.; Khan, M.Q.; Kim, I.-S. Extraction of natural dye from aerial parts of argy wormwood based on optimized taguchi approach and functional finishing of cotton fabric. Materials 2021, 14, 5850. [Google Scholar] [CrossRef]

- Javed, Z.; Rafiq, L.; Nazeer, M.A.; Siddiqui, S.; Ramzan, M.B.; Khan, M.Q. Piezoelectric nanogenerator for bio-mechanical strain measurement. Beilstein J. Nanotechnol. 2022, 13, 192–200. [Google Scholar] [CrossRef]

- Bie, X.; Khan, M.Q.; Ullah, A.; Ullah, S.; Kharaghani, D.; Phan, D.-N.; Tamada, Y.; Kim, I.S. Fabrication and characterization of wound dressings containing gentamicin/silver for wounds in diabetes mellitus patients. Mater. Res. Express 2020, 7, 045004. [Google Scholar] [CrossRef]

- Ullah, S.; Hashmi, M.; Khan, M.Q.; Kharaghani, D.; Saito, Y.; Yamamoto, T.; Kim, I.S. Silver sulfadiazine loaded zein nanofiber mats as a novel wound dressing. RSC Adv. 2019, 9, 268–277. [Google Scholar] [CrossRef]

- Mandolla, C.; Petruzzelli, A.M.; Percoco, G.; Urbinati, A. Building a digital twin for additive manufacturing through the exploitation of blockchain: A case analysis of the aircraft industry. Comput. Ind. 2019, 109, 134–152. [Google Scholar] [CrossRef]

- Chhetri, S.R.; Faezi, S.; Canedo, A.; Al Faruque, M.A. QUILT: Quality inference from living digital twins in IoT-enabled manufacturing systems. In IoTDI 2019, Proceedings of the 2019 Internet of Things Design and Implementation, Montreal, QC, Canada, 15–18 April 2019; Association for Computing Machinery, Inc.: New York, NY, USA, 2019; pp. 237–248. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Jain, P.; Poon, J.; Singh, J.P.; Spanos, C.; Sanders, S.R.; Panda, S.K. A Digital Twin Approach for Fault Diagnosis in Distributed Photovoltaic Systems. IEEE Trans. Power Electron. 2019, 35, 940–956. [Google Scholar] [CrossRef]

- Karadeniz, A.M.; Arif, I.; Kanak, A.; Ergun, S. Digital Twin of eGastronomic Things: A Case Study for Ice Cream Machines. In Proceedings of the 2019 IEEE International Symposium on Circuits and Systems (ISCAS), Sapporo, Japan, 26–29 May 2019; IEEE: New York, NY, USA, 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine learning based digital twin framework for production optimization in petrochemical industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.; Zheng, X. From Surveillance to Digital Twin: Challenges and Recent Advances of Signal Processing for Industrial Internet of Things. IEEE Signal Process. Mag. 2018, 35, 120–129. [Google Scholar] [CrossRef]

- Howard, D. The Digital Twin: Virtual Validation in Electronics Development And Design. In Proceedings of the 2019 Pan Pacific Microelectronics Symposium (Pan Pacific), Kauai, HI, USA, 11–14 February 2019; IEEE: New York, NY, USA, 2019; pp. 1–9. [Google Scholar] [CrossRef]

- Kuehn, W. Simulation in digital enterprises. In ACM International Conference Proceeding Series; Association for Computing Machinery: New York, NY, USA, 2019; pp. 55–59. [Google Scholar] [CrossRef]

- Lu, Y.; Peng, T.; Xu, X. Energy-efficient cyber-physical production network: Architecture and technologies. Comput. Ind. Eng. 2019, 129, 56–66. [Google Scholar] [CrossRef]

- Shangguan, D.; Chen, L.; Ding, J. A hierarchical digital twin model framework for dynamic cyber-physical system design. In Proceedings of the ICMRE’19: The 5th International Conference on Mechatronics and Robotics Engineering, Rome, Italy, 16–19 February 2019; pp. 123–129. [Google Scholar] [CrossRef]

- Sivalingam, K.; Sepulveda, M.; Spring, M.; Davies, P. A Review and Methodology Development for Remaining Useful Life Prediction of Offshore Fixed and Floating Wind turbine Power Converter with Digital Twin Technology Perspective. In Proceedings of the 2018 2nd International Conference on Green Energy and Applications, ICGEA 2018, Singapore, 24–26 March 2018; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2018; pp. 197–204. [Google Scholar] [CrossRef]

- Lv, Z. Digital Twins in Industry 5.0. Research 2023, 6, 0071. [Google Scholar] [CrossRef] [PubMed]

- Beier, G.; Matthess, M.; Guan, T.; de Oliveira Pereira Grudzien, D.I.; Xue, B.; de Lima, E.P.; Chen, L. Impact of Industry 4.0 on corporate environmental sustainability: Comparing practitioners’ perceptions from China, Brazil and Germany. Sustain. Prod. Consum. 2022, 31, 287–300. [Google Scholar] [CrossRef]

- Li, B.H.; Hou, B.C.; Yu, W.T.; Lu, X.B.; Yang, C.W. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Mavrikios, D.; Papakostas, N.; Mourtzis, D.; Michalos, G.; Georgoulias, K. Digital manufacturing: History, perspectives, and outlook. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 451–462. [Google Scholar] [CrossRef]

- Semeraro, C.; Lezoche, M.; Panetto, H.; Dassisti, M. Digital Twin Paradigm: A Systematic Literature Review. Comput. Ind. 2021, 130, 103469. [Google Scholar] [CrossRef]

- Luther, W.; Baloian, N.; Biella, D.; Sacher, D. Digital Twins and Enabling Technologies in Museums and Cultural Heritage: An Overview. Sensors 2023, 23, 1583. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Bottani, E.; Ciarapica, F.E.; Costantino, F.; Di Donato, L.; Ferraro, A.; Mazzuto, G.; Monteriù, A.; Nardini, G.; Ortenzi, M.; et al. Digital twin reference model development to prevent operators’ risk in process plants. Sustainability 2020, 12, 1088. [Google Scholar] [CrossRef]

- Cuc, S.; Vidovic, M. Environmental Sustainability through Clothing Recycling. Oper. Supply Chain. Manag. 2011, 4, 108–115. [Google Scholar] [CrossRef]

- Rotimi, E.O.O.; Topple, C.; Hopkins, J. Towards a conceptual framework of sustainable practices of post-consumer textile waste at garment end of lifecycle: A systematic literature review approach. Sustainability 2021, 13, 2965. [Google Scholar] [CrossRef]

- Lee, H. The Dual Strategy for Textile and Fashion Production Using Clothing Waste. Sustainability 2023, 15, 11509. [Google Scholar] [CrossRef]

- Wagg, D.J.; Worden, K.; Barthorpe, R.J.; Gardner, P. Digital Twins: State-of-The-Art and Future Directions for Modeling and Simulation in Engineering Dynamics Applications. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part B Mech. Eng. 2020, 6, 030901. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Donmezer, S.; Demircioglu, P.; Bogrekci, I.; Bas, G.; Durakbasa, M.N. Revolutionizing the Garment Industry 5.0: Embracing Closed-Loop Design, E-Libraries, and Digital Twins. Sustainability 2023, 15, 15839. [Google Scholar] [CrossRef]

- dos Santos Durão, L.F.C.; de Senzi Zancul, E.; Schützer, K. Digital twin: A concept in evolution. Prod. Manag. Dev. 2021, 19, e20210001. [Google Scholar] [CrossRef]

- Wagner, R.; Kabalska, A. Sustainable value in the fashion industry: A case study of value construction/destruction using digital twins. Sustain. Dev. 2023, 31, 1652–1667. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Angin, P.; Anisi, M.H.; Göksel, F.; Gürsoy, C.; Büyükgülcü, A. Agrilora: A digital twin framework for smart agriculture. J. Wirel. Mob. Netw. Ubiquitous Comput. Dependable Appl. 2020, 11, 77–96. [Google Scholar] [CrossRef]

- Tuegel, E.J. The airframe digital twin: Some challenges to realization. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, Hl, USA, 23–26 April 2012; American Institute of Aeronautics and Astronautics Inc.: Reston, VA, USA, 2012. [Google Scholar] [CrossRef]

- Hochhalter, J.D.; Leser, W.P.; Newman, J.A.; Gupta, V.K.; Yamakov, V.; Cornell, S.R.; Scott, A.W.; Gerd, H. Coupling Damage-Sensing Particles to the Digitial Twin Concept. 2014. Available online: http://www.sti.nasa.gov (accessed on 31 August 2025).

- Le, P. An Ontology-Based Approach for Closed-Loop Product Lifecycle Management. Ph.D. Thesis, ÉCOLE POLYTECHNIQUE FÉDÉRALE DE LAUSANNE, Lausanne, Switzerland, 2010. [Google Scholar]

- Lu, Q.; Shen, X.; Zhou, J.; Li, M. MBD-Enhanced Asset Administration Shell for Generic Production Line Design. IEEE Trans. Syst. Man. Cybern. Syst. 2024, 54, 5593–5605. [Google Scholar] [CrossRef]

- Iranshahi, K.; Brun, J.; Arnold, T.; Sergi, T.; Müller, U.C. Digital twins: Recent advances and future directions in engineering fields. Intell. Syst. Appl. 2025, 26, 200516. [Google Scholar] [CrossRef]

| Sr | Author | Definition | Reference | Key Limitations |

|---|---|---|---|---|

| 1 | Nasa 2012 | A Digital Twin is a comprehensive Multiphysics, multiscale, statistical simulation of an auto or system as built that utilizes the best physical models currently on the market, sensor updates, fleet history, etc., to mimic the life of its corresponding flying twin. | [10] | Highly domain-specific (aerospace focus); limited generalization to other industries at the time. |

| 2 | Chen 2017 | A computerized representation of a physical system or equipment that interfaces with the operational components and reflects all functional attributes is called a “Digital Twin.” | [27] | Emphasizes data representation but lacks clarity on lifecycle integration and scalability. |

| 3 | Liu et al., 2018 | The Digital Twin is essentially a living, breathing copy of the corresponding physical asset or system. It is able to anticipate events in real time and adapts to changes in operations on a constant basis by using data collected from the internet. | [28] | Conceptually broad; lacks specification on data standards, model structure, and implementation frameworks. |

| 4 | Zheng et al., 2019 | A Digital Twin is a collection of virtual data that, from the micro-atomic to the macro geometrical levels, completely characterizes a possible or real physical output. | [29] | Focused on data characterization; omits feedback mechanisms and real-time synchronization aspects. |

| 5 | Vrabič et al., 2018 | A Digital Twin is an integrated simulation and service data-based digital model of a real object or assembly. Throughout the product life cycle, data from many sources is stored in the digital representation. This data, which forecasts future conditions in the design and operating contexts, is updated often and presented in multiple ways to enhance decision-making. | [30] | Requires extensive and continuous data input; implementation complexity and cost are high. |

| 6 | Madni 2019 | A Digital Twin is a virtual image of its physical counterpart that is updated with details on overall health, performance, and maintenance throughout the physical system’s life cycle. | [31] | Focuses on monitoring; offers limited discussion of predictive or adaptive capabilities. |

| Sr | Author (Year) | Core Definition Focus | Physical Link (P) (Required) | Simulation/Modeling (S) (Variable) | Real-Time Data (R) (Required) | Lifecycle Scope (L) (Variable) |

|---|---|---|---|---|---|---|

| 1 | NASA [10] | Comprehensive multiphysics, multiscale statistical simulation to mimic the life of its corresponding flying twin. | ✓ | ✓ | ✓ | ✓ |

| 2 | Chen [27] | Computerized representation that interfaces with operational components and reflects all functional attributes. | ✓ | × | ✓ | × |

| 3 | Liu et al. [28] | Living, breathing copy able to anticipate events in real time and adapt to changes using data collected from the internet. | ✓ | ✓ | ✓ | ✓ |

| 4 | Zheng et al. [29] | Collection of virtual data that completely characterizes a possible or real physical output. | ✓ | × | × | × |

| 5 | Vrabič et al. [30] | Integrated simulation and service data-based digital model that forecasts future conditions throughout the product life cycle. | ✓ | ✓ | ✓ | ✓ |

| 6 | Madni [31] | Virtual image updated with details on overall health, performance, and maintenance throughout the physical system’s life cycle. | ✓ | × | ✓ | ✓ |

| DT Application Type | Average ROI (3-Year Period) | Reduction in Equipment Downtime (%) | Process Efficiency Gain (%) |

|---|---|---|---|

| Predictive Maintenance | 15–25% | 18–30% | 5–8% |

| Production Line Optimization | 10–15% | 5–10% | 12–22% |

| Product Lifecycle Management | 8–12% | N/A (Focus on Design) | 15–25% |

| Implementation Type | Technical Complexity | Required Data Velocity | Primary Business Value |

|---|---|---|---|

| Predictive Maintenance DT | Medium–High | Real-Time Streaming | Cost Savings (reduced failures) |

| Process Optimization DT | High | Near Real-Time/Streaming | Output Maximization (increased yield) |

| Design Simulation DT | Low–Medium | Static/Batch Uploads | Reduced R&D Costs and Time-to-Market |

| Sr | Author | Type | Linked to | Specific Area | Tools and Techniques | Reference |

|---|---|---|---|---|---|---|

| 1 | Mandolla et al. (2019) | Case investigation | Manufacturing | The aircraft | Blockchain, Visualization | [89] |

| 2 | Chhetri et al. (2019) | Case investigation | Manufacturing | Assembly Line | AI, Sensors, | [90] |

| 3 | Tao et al. (2018) | Review | Manufacturing | Assembly Line | CPS, Industry 4.0, AI | [91] |

| 5 | Jain et al. (2019) | Concept | Manufacturing | Fault Diagnosis | Industry 4.0 | [92] |

| 6 | Karadeniz et al. (2019) | Case investigation | Manufacturing | Ice Cream Machines | AR, VR, Industry 4.0, AI, CPS | [93] |

| 7 | Min et al. (2019) | Case Study | Manufacturing | Petrochemical factory | AI, Optimization | [94] |

| 8 | He et al. (2018) | Review | Manufacturing | Power station | Simulation, AI, Analytics | [95] |

| 9 | Howard (2019) | Concept | Manufacturing | Product Development | EDA visualization | [96] |

| 10 | Kuehn (2019) | Concept | Manufacturing | Smart Industry | Simulation | [97] |

| 11 | Lu (2019) | Review | Manufacturing | Smart Industry | Cloud, CPS, Industry 4.0 | [98] |

| 12 | Shangguan et al. (2019) | Case investigation | Manufacturing | Wind Turbine | CPS | [99] |

| 13 | Sivalingam et al. (2018) | Review | Manufacturing | Wind Turbine | CPS, Simulation | [100] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.Q.; Alvi, M.A.H.; Nawaz, H.H.; Umar, M. Impact of Digital Twins on Real Practices in Manufacturing Industries. Inventions 2025, 10, 106. https://doi.org/10.3390/inventions10060106

Khan MQ, Alvi MAH, Nawaz HH, Umar M. Impact of Digital Twins on Real Practices in Manufacturing Industries. Inventions. 2025; 10(6):106. https://doi.org/10.3390/inventions10060106

Chicago/Turabian StyleKhan, Muhammad Qamar, Muhammad Abbas Haider Alvi, Hafiza Hifza Nawaz, and Muhammad Umar. 2025. "Impact of Digital Twins on Real Practices in Manufacturing Industries" Inventions 10, no. 6: 106. https://doi.org/10.3390/inventions10060106

APA StyleKhan, M. Q., Alvi, M. A. H., Nawaz, H. H., & Umar, M. (2025). Impact of Digital Twins on Real Practices in Manufacturing Industries. Inventions, 10(6), 106. https://doi.org/10.3390/inventions10060106