A Modern Ultrasonic Cleaning Tank Developed for the Jewelry Manufacturing Process and Its Cleaning Efficiency

Abstract

1. Introduction

2. Theoretical Background and Methodology

2.1. Computer Simulation

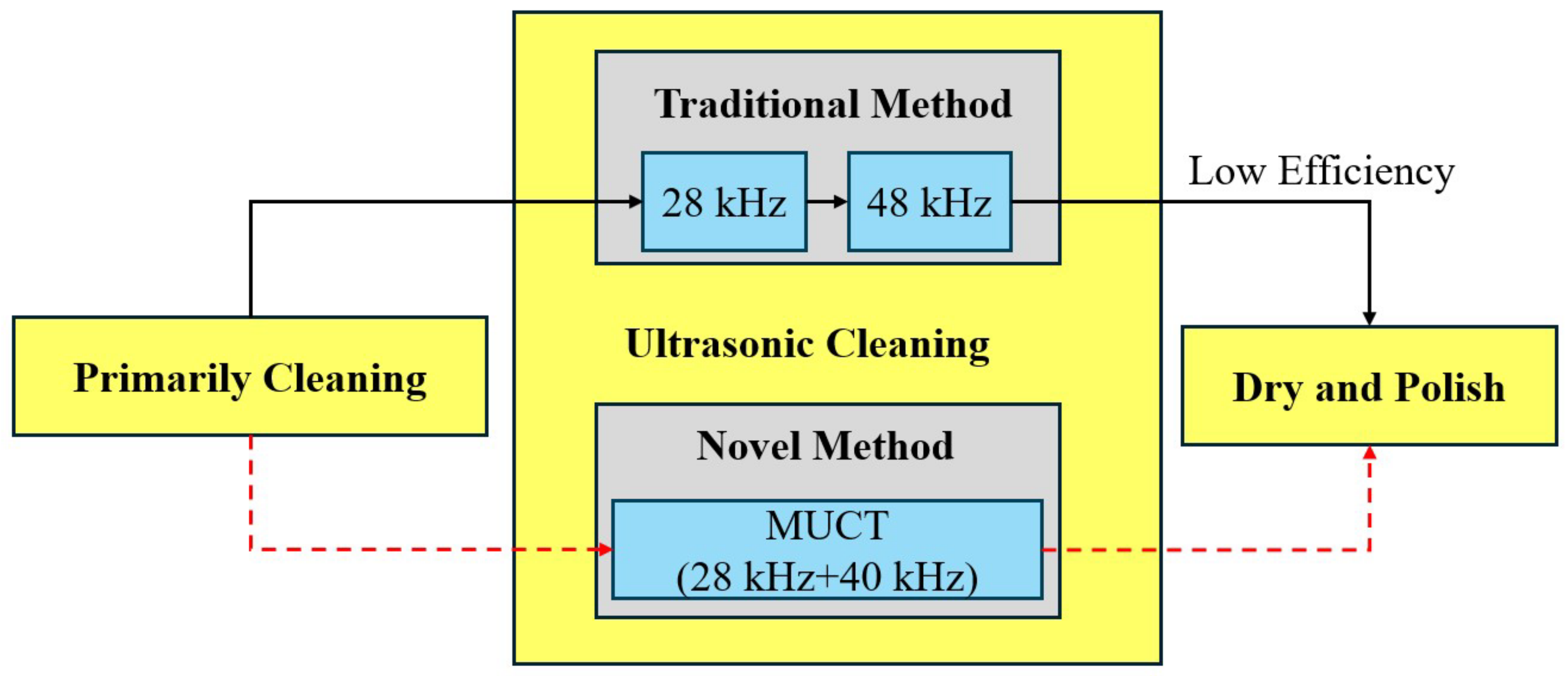

2.2. Jewelry Cleaning Process

2.2.1. Preliminary Cleaning

2.2.2. Ultrasonic Cleaning

2.2.3. Dry and Polish

2.3. Methodology

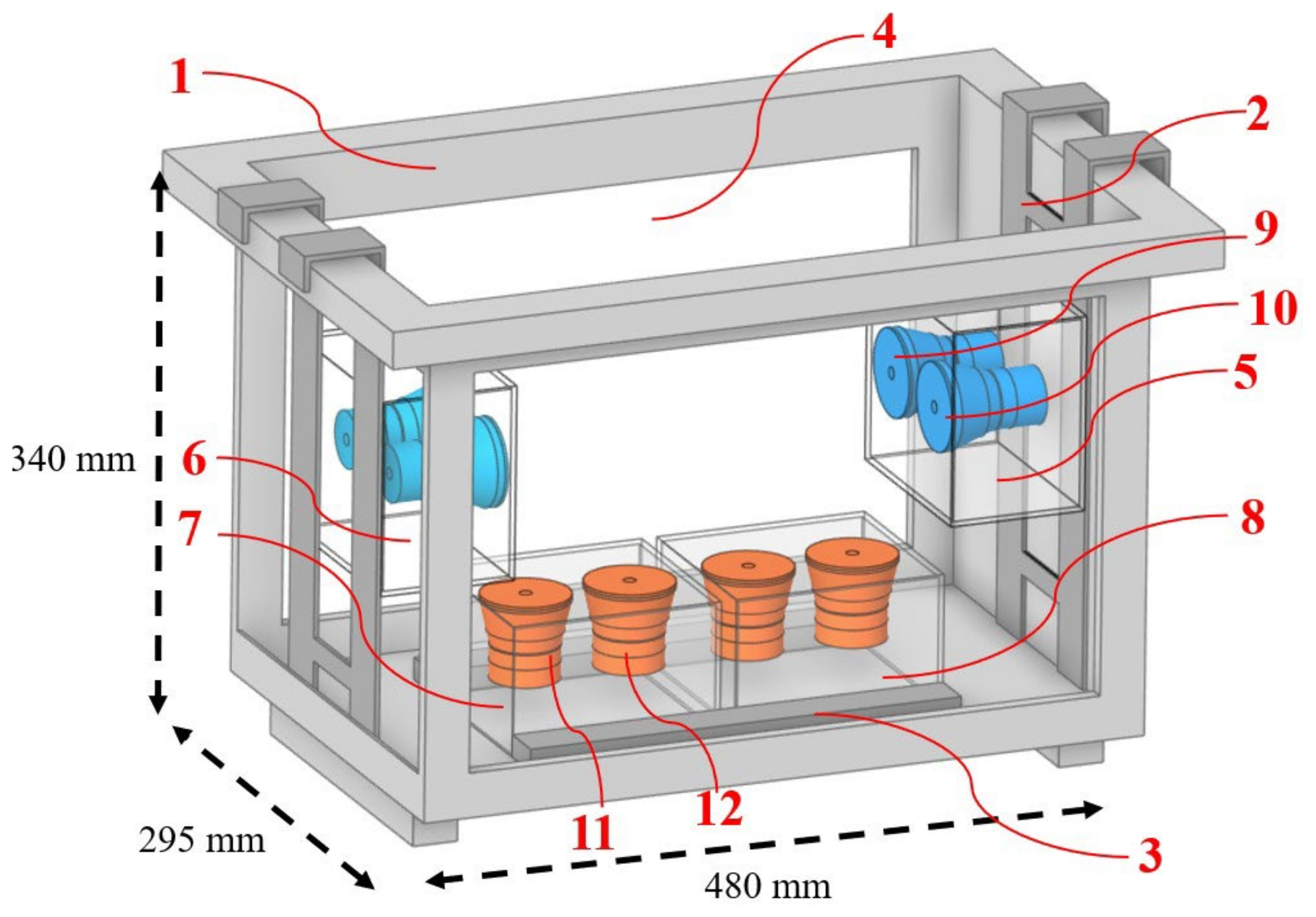

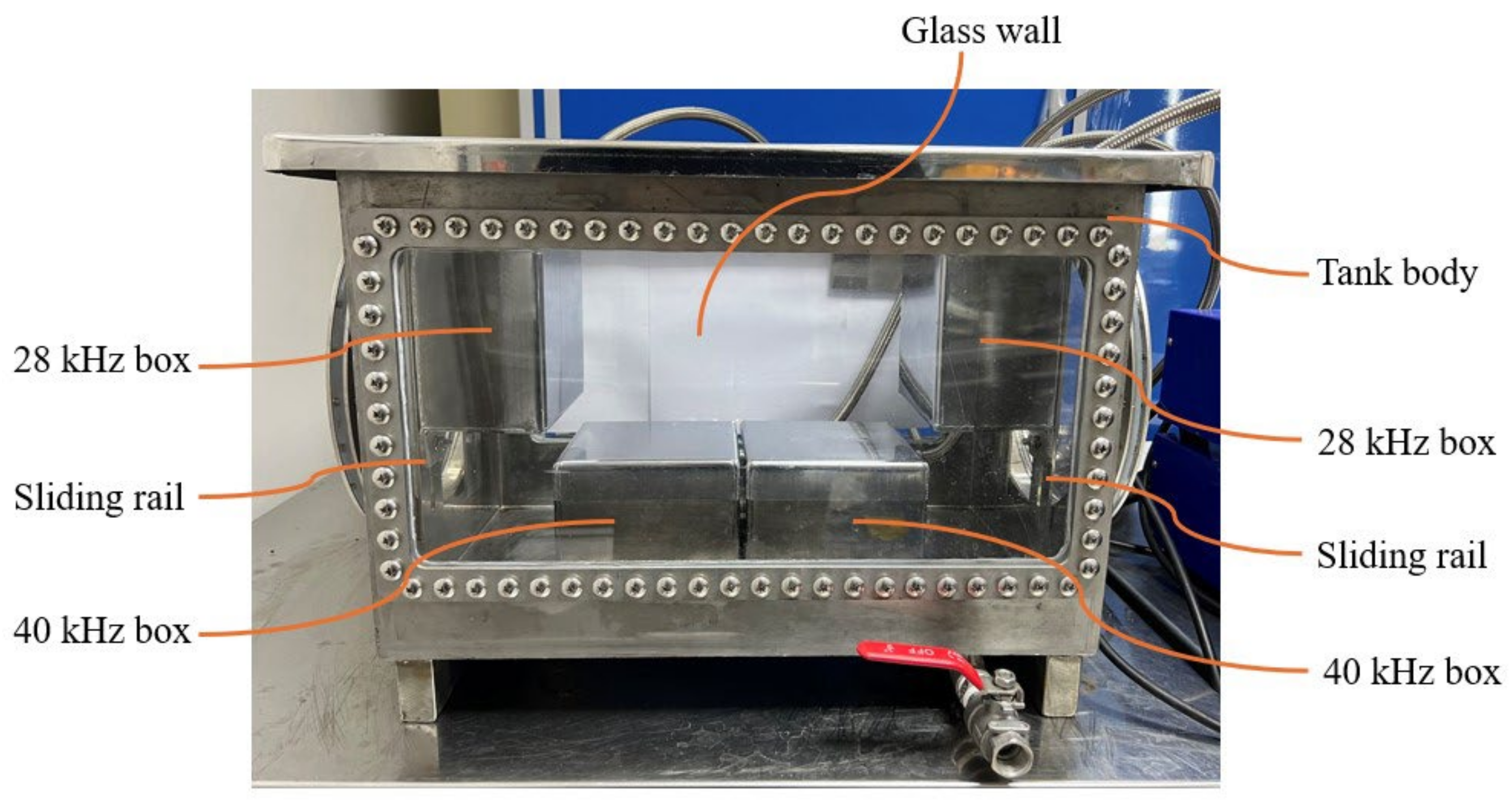

2.3.1. The MUCT Design and Assembly

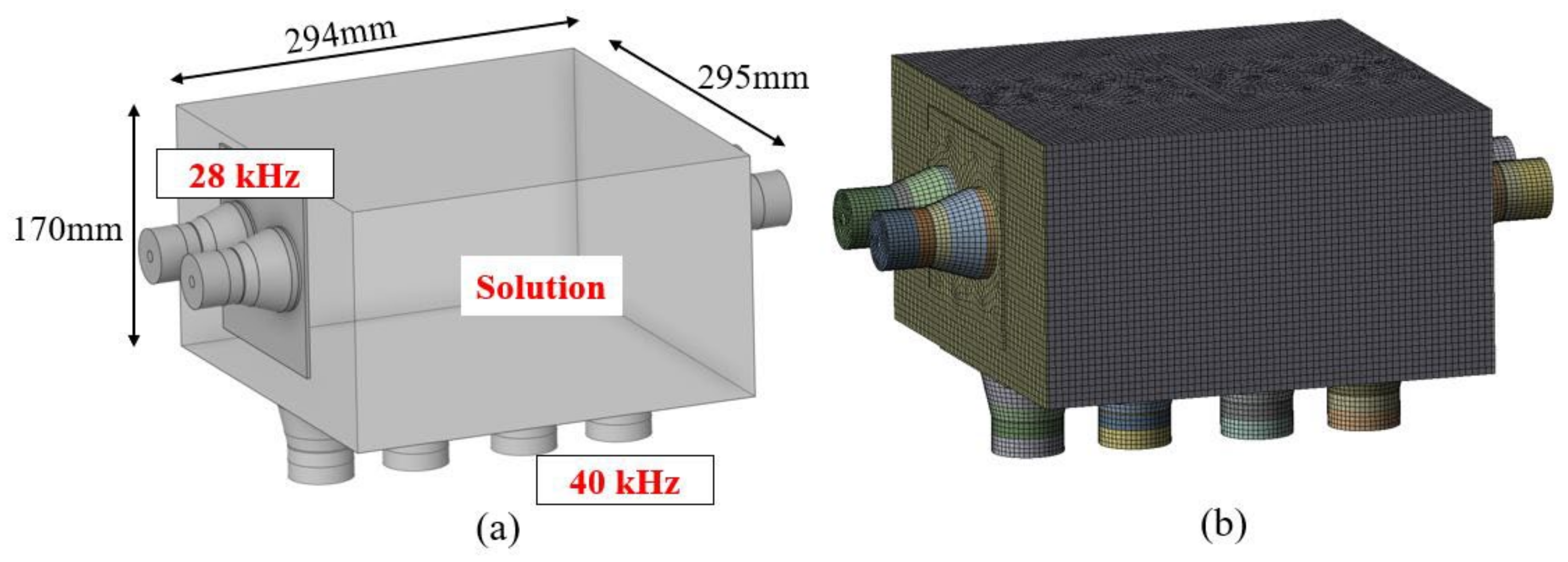

2.3.2. Computer Simulation Process

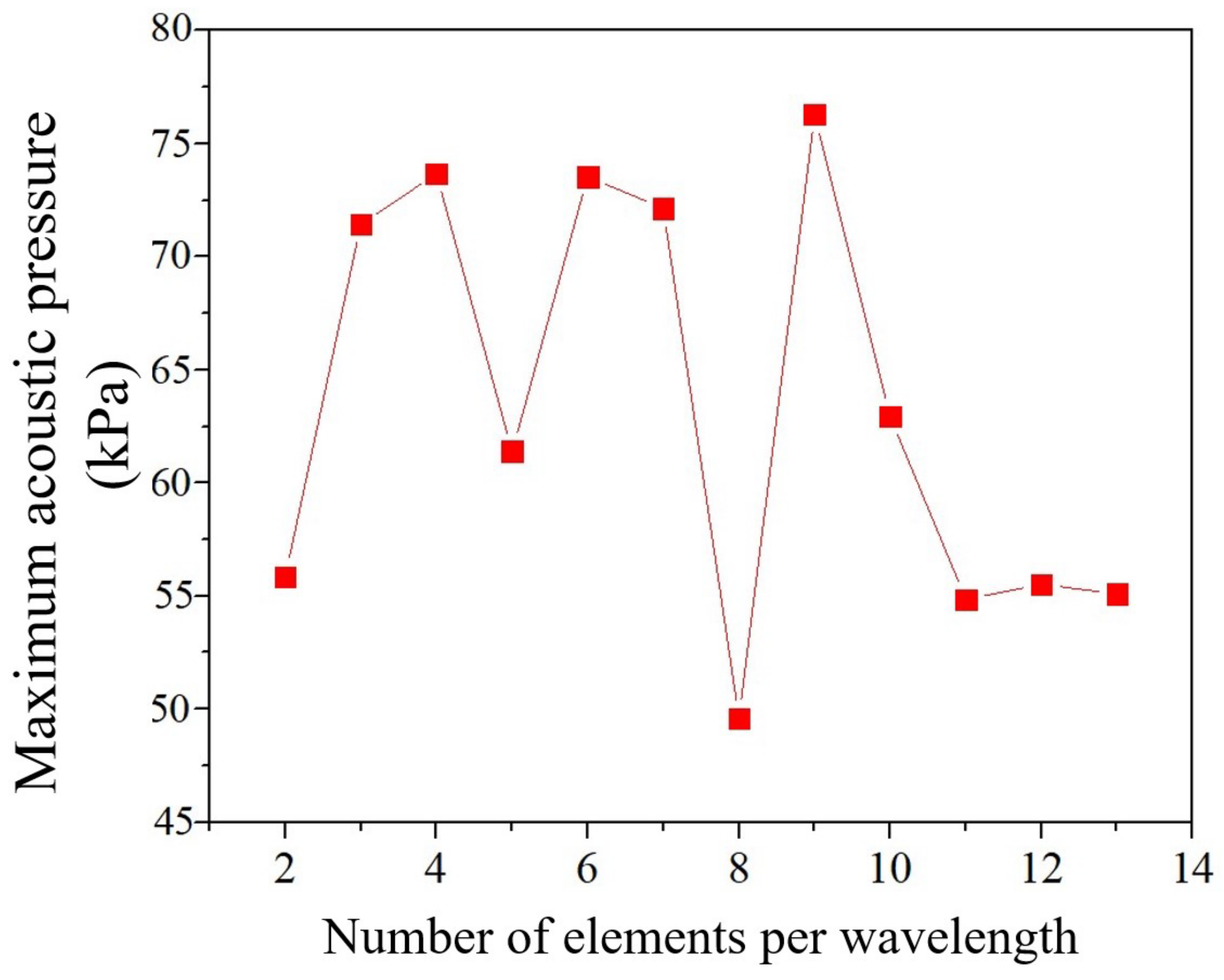

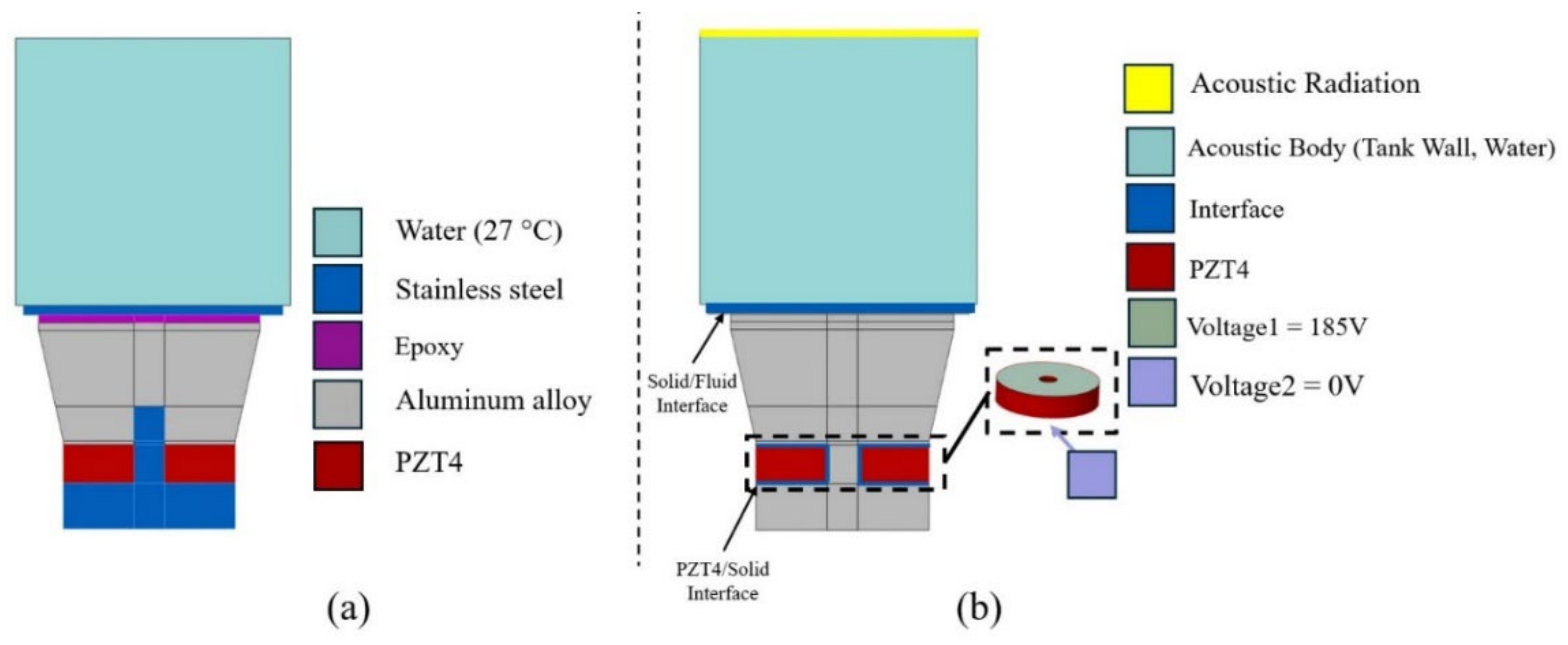

- CAD and Mesh Models

- Material Property, Boundary Condition, and Analysis Settings

2.3.3. Measurements

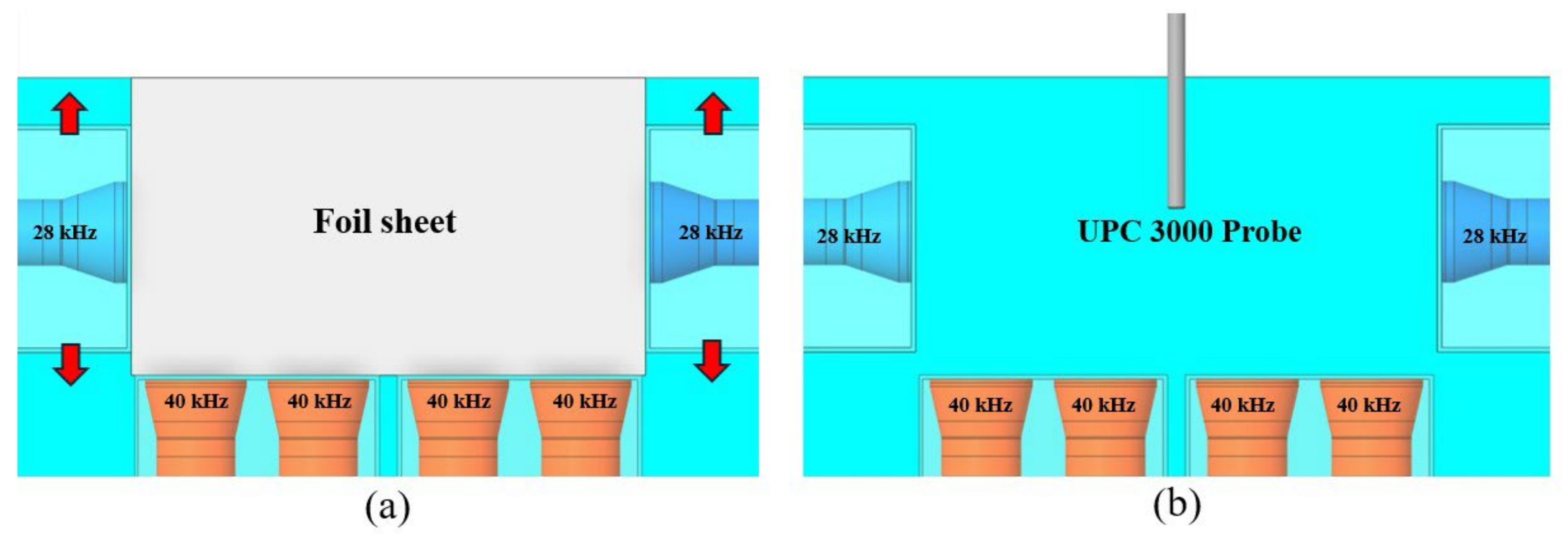

- Foil Corrosion Measurement

- Ultrasonic Power Concentration (UPC) Measurement

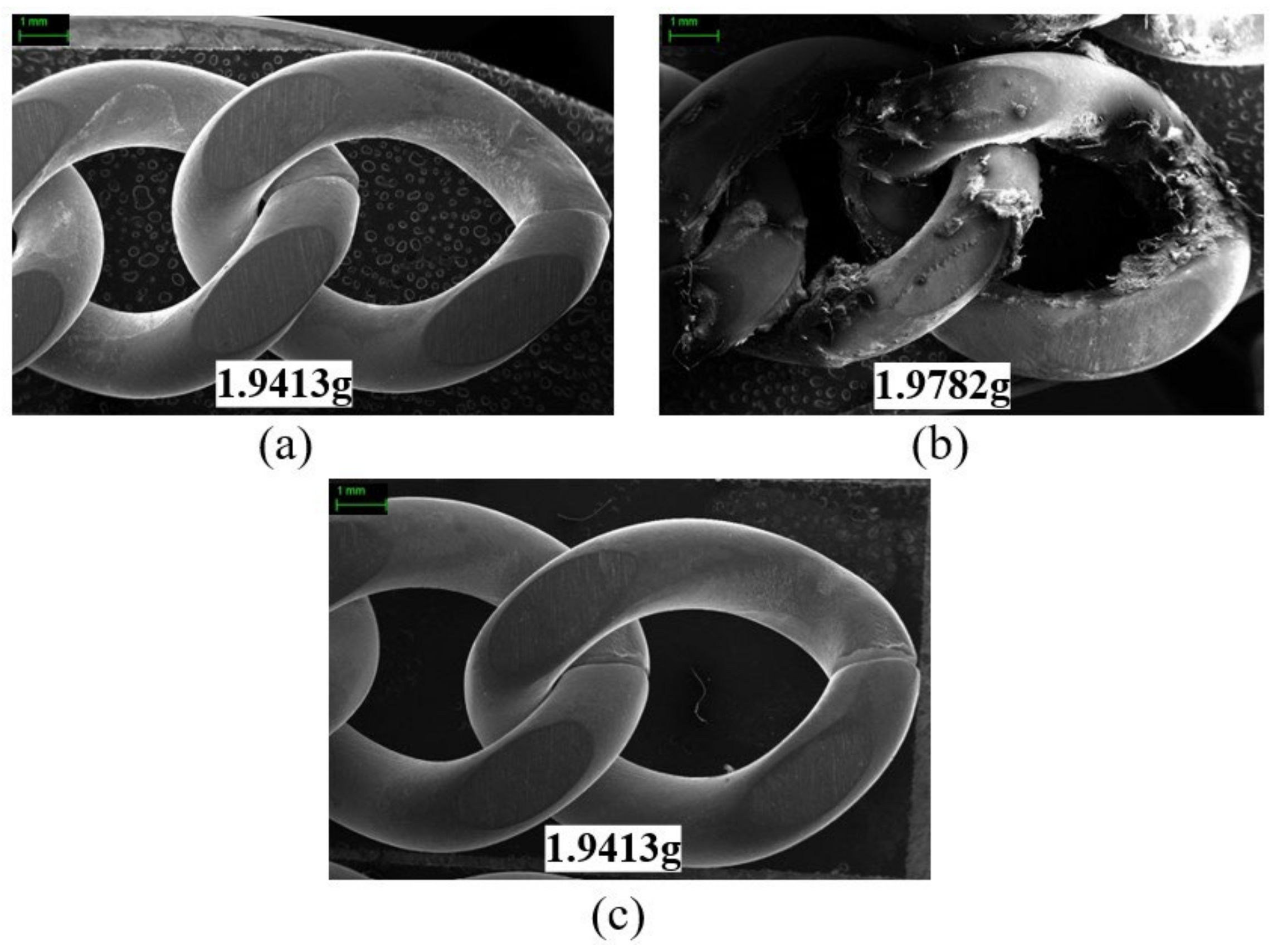

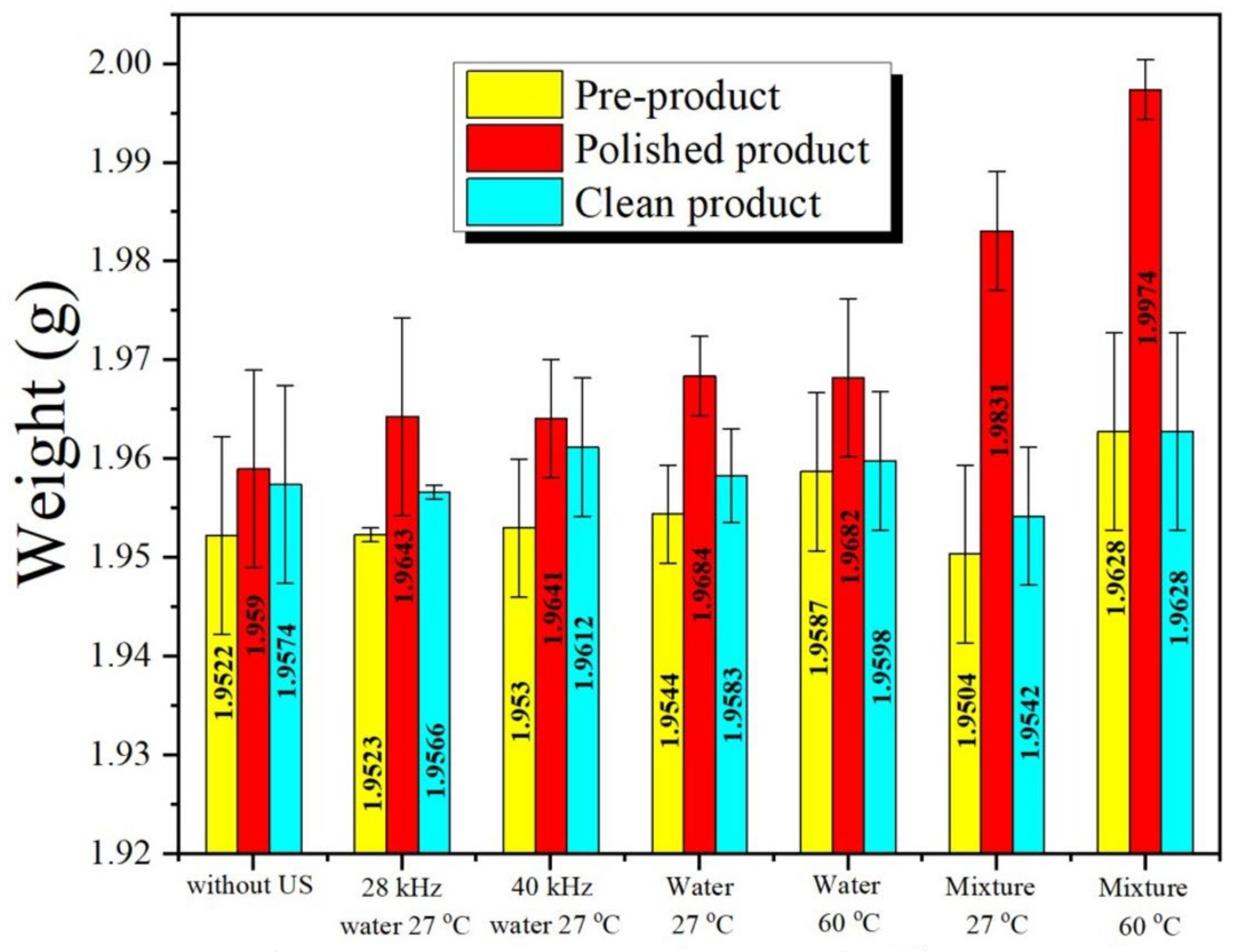

- Product Cleaning

3. Results and Discussion

3.1. The MUCT Operation with Results Credibility

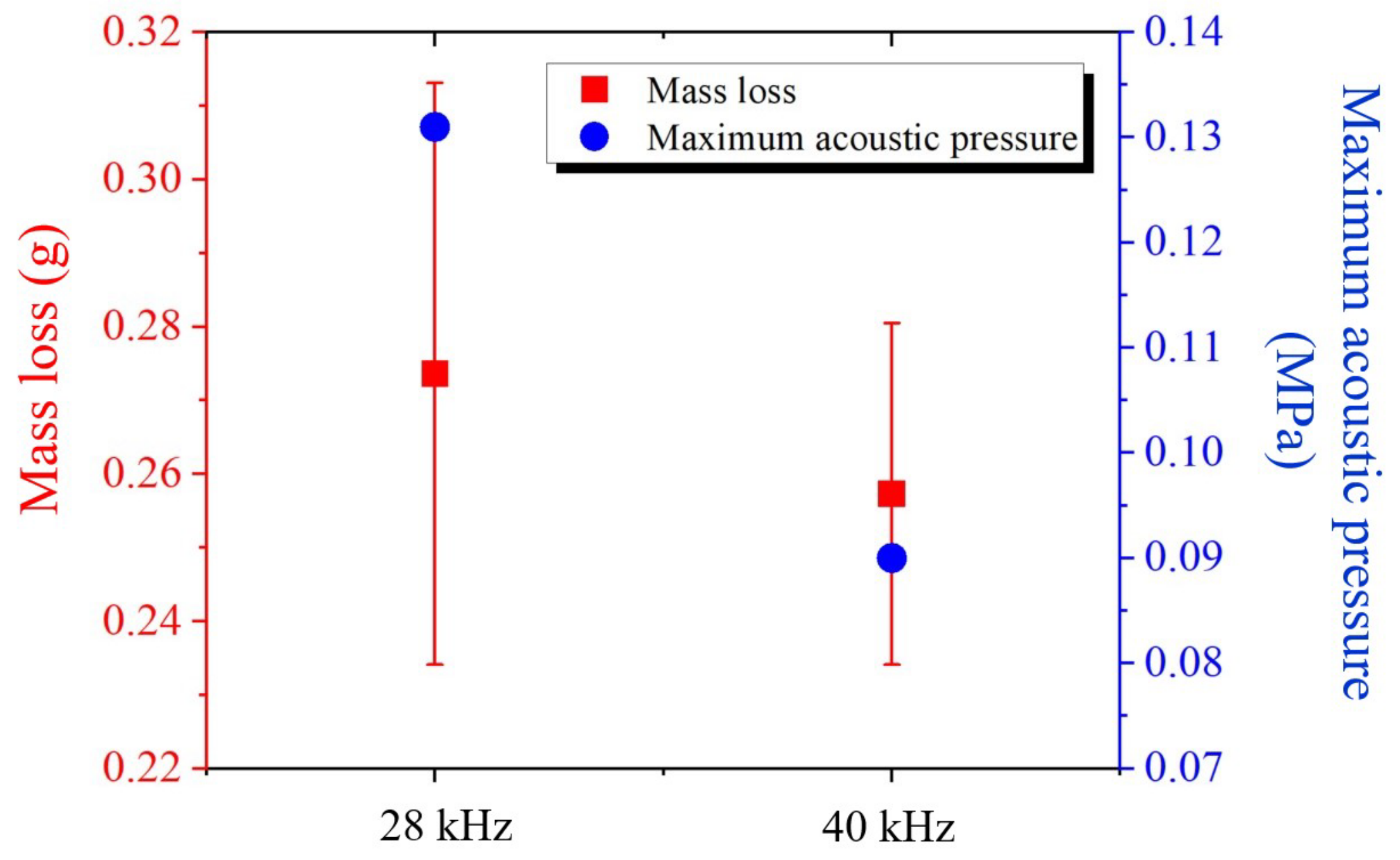

3.1.1. Single Frequency

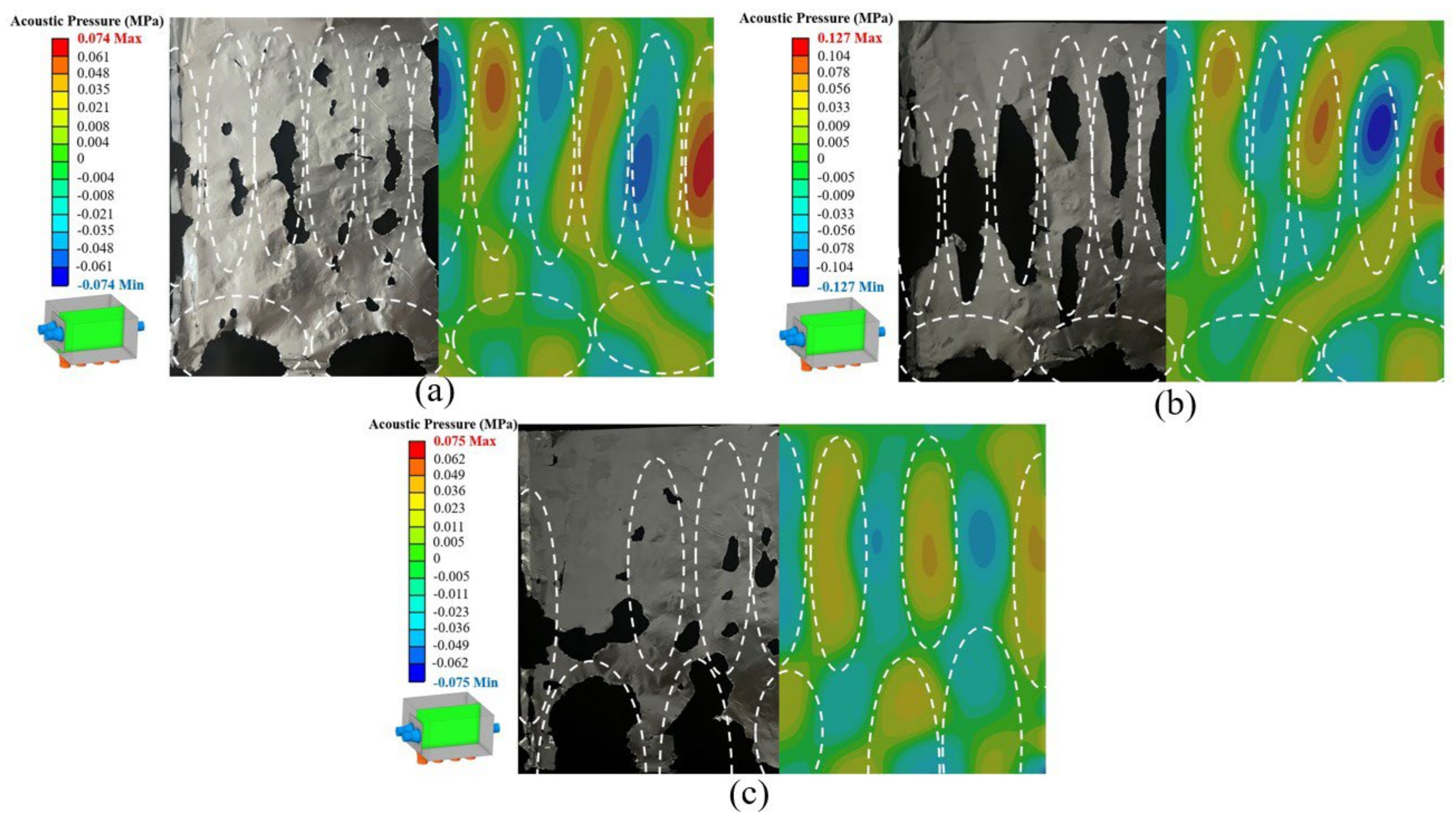

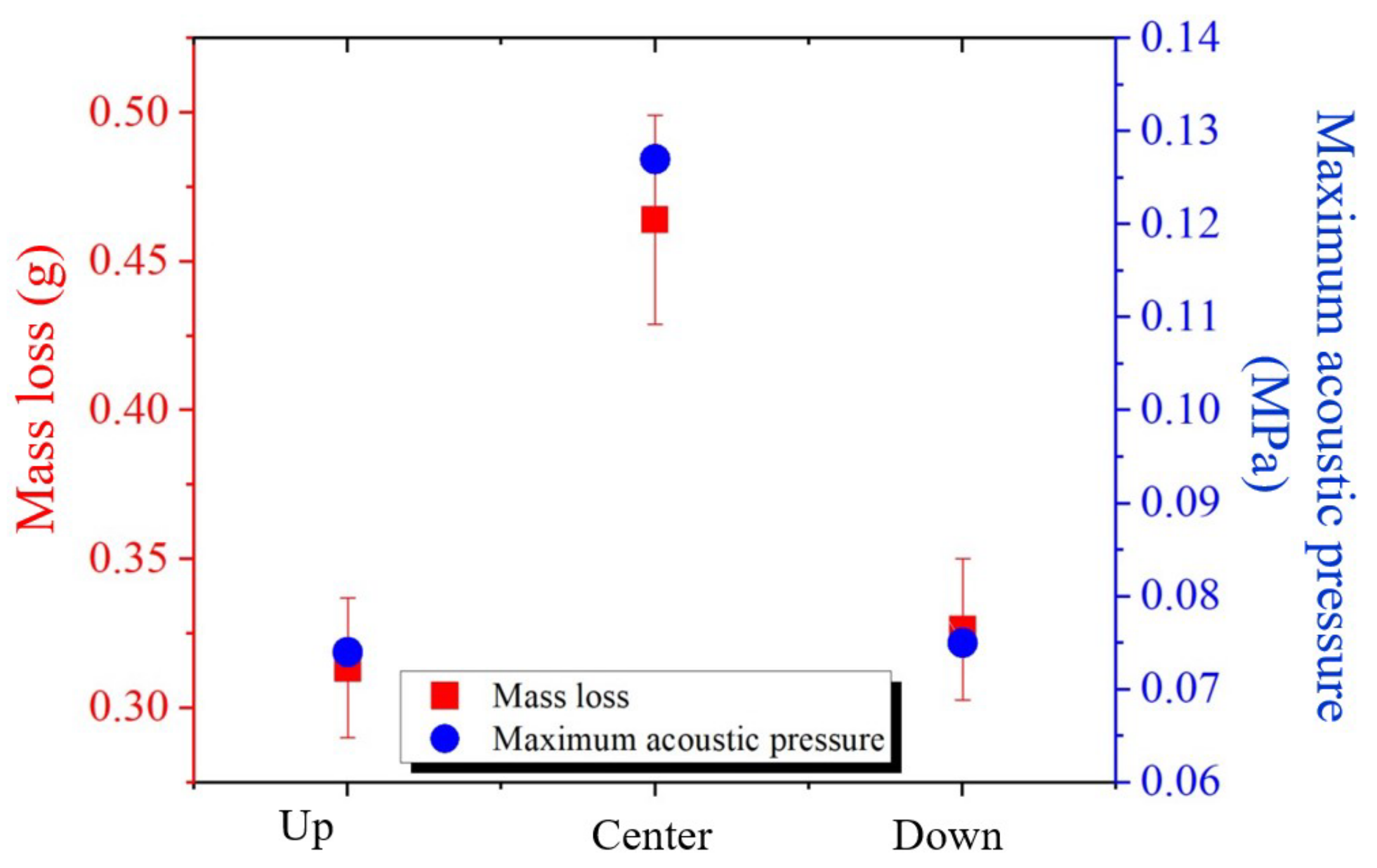

3.1.2. Dual Frequency

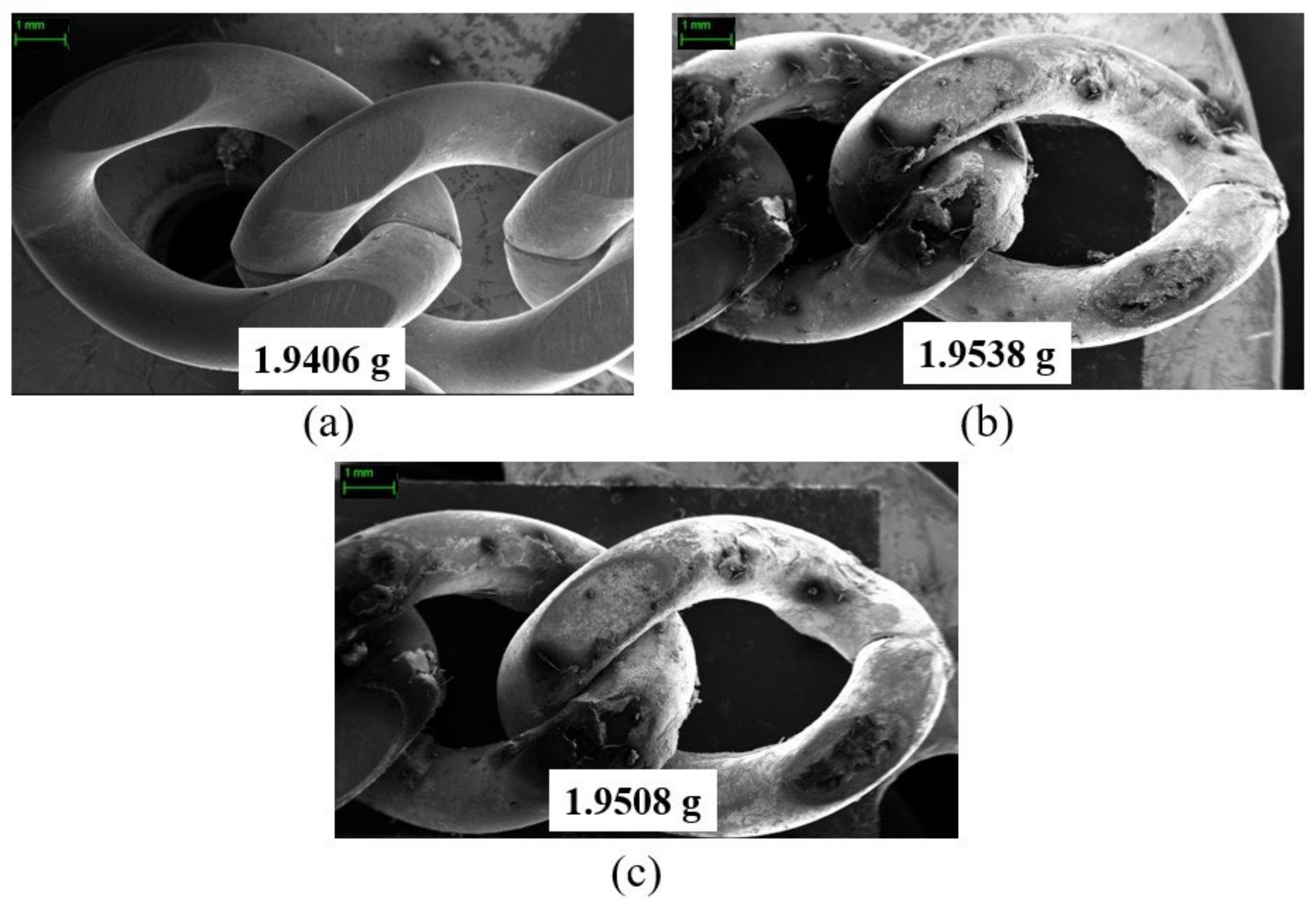

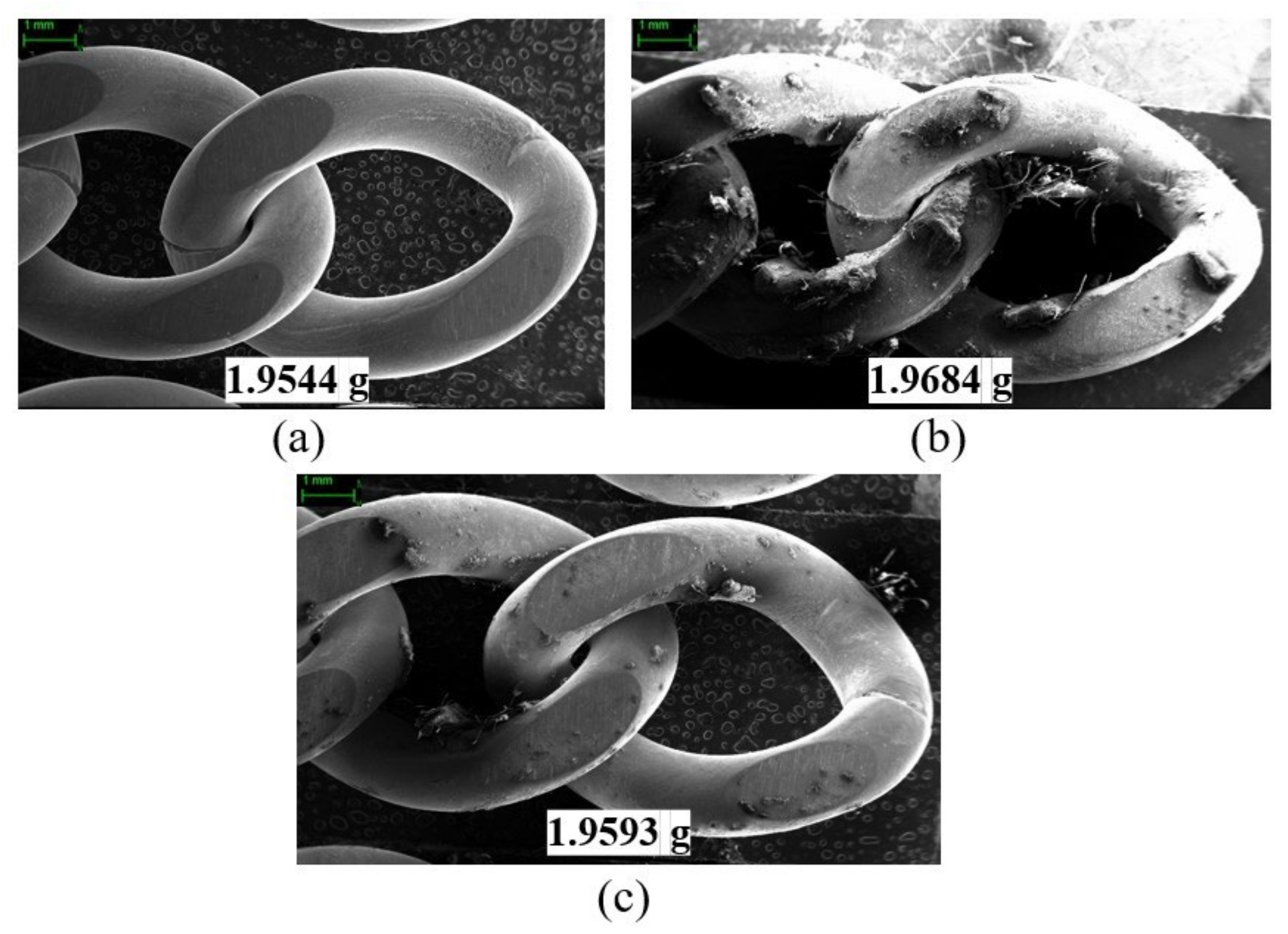

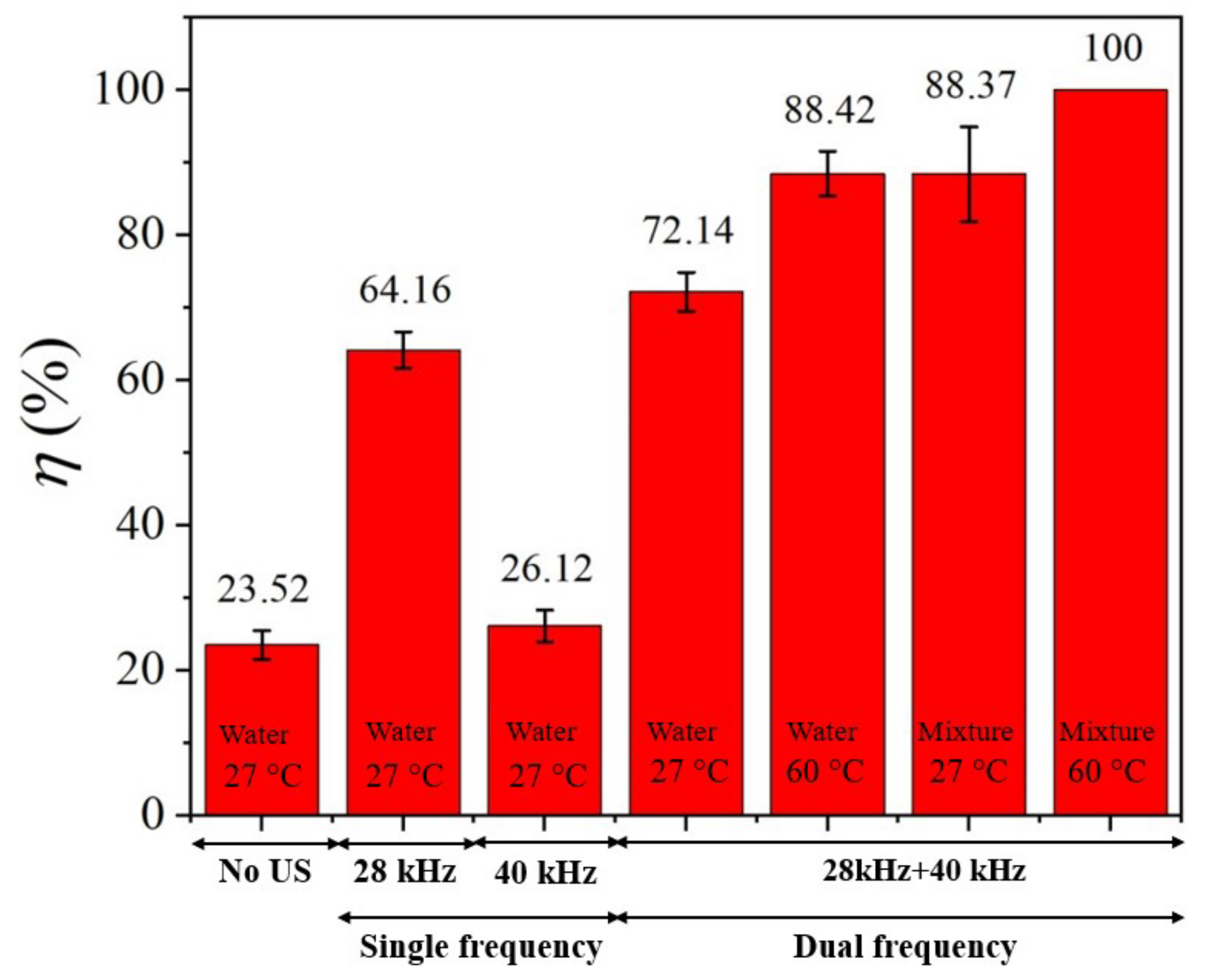

3.2. The MUCT Cleaning Efficiency

3.3. Limitations and Opportunities to Develop the MUCT

4. Conclusions

- A Modern Ultrasonic Cleaning Tank (MUCT) was developed and validated through simulation and experimental testing, proving its effectiveness for jewelry manufacturing.

- The dual-frequency design (28 kHz and 40 kHz) generated cavitation bubbles of varying sizes, enhancing cleaning efficiency compared to single-frequency operation.

- Adjustable transducer positioning enabled users to tailor cavitation intensity for various jewelry types, overcoming the limitations of traditional fixed-position tanks.

- Simulation results (HRA and TDA) aligned with experimental findings (foil corrosion, UPC measurements), confirming the reliability of the design methodology.

- Cleaning tests showed that dual-frequency operation achieved superior efficiency, reaching 100% when combined with hot water and 3% dishwashing liquid at 60 °C.

- The MUCT demonstrated cost-effectiveness by reducing detergent usage and operating time, while also aligning with sustainability goals (SDG 6).

- This research provides a paved foundation for extending ultrasonic cleaning technology beyond silver jewelry to other industrial applications.

5. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- GIT Information Center. Thailand Gem and Jewelry Import-Export Performance January–December 2024. Available online: https://infocenter.git.or.th/en/article/article-20250207 (accessed on 9 February 2025).

- THIT. Thailand Aims to Become the World’s Gem and Jewelry Trading Hub in the Next 5 Years. Available online: https://thaitextile.org/th/insign/detail.590.1.0.html (accessed on 11 February 2025).

- Busnaina, A.; Kashkoush, I. The Effect of Time, Temperature, and Particle Size on Submicron Particle Removal Using Ultrasonic Cleaning. Chem. Eng. Commun. 1993, 125, 47–61. [Google Scholar] [CrossRef]

- Fuchs, F.J. Ultrasonic cleaning and washing of surfaces. In Power Ultrasonics; Woodhead Publishing: Sawston, UK, 2015; pp. 577–609. [Google Scholar]

- Verhaagen, B.; Rivas, D.F. Measuring cavitation and its cleaning effect. Ultrason. Sonochem. 2016, 29, 619–628. [Google Scholar] [CrossRef] [PubMed]

- Awad, S.B.; Nagarajan, R. Chapter 6-Ultrasonic cleaning. In Developments in Surface Contamination and Cleaning; Kohli, R., Mittal, K.L., Eds.; William Andrew Publishing: Oxford, MA, USA, 2010; pp. 225–280. [Google Scholar]

- Mason, T.J. Ultrasonic cleaning: An historical perspective. Ultrason. Sonochem. 2016, 29, 519–523. [Google Scholar] [CrossRef]

- Azam, S.M.; Ma, H.; Xu, B.; Devi, S.; Saddique, M.A.B.; Stanley, S.L.; Bhandari, B.; Zhu, J. Efficacy of ultrasound treatment in the removal of pesticide residues from fresh vegetable: A review. Trends Food Sci. Technol. 2020, 97, 417–432. [Google Scholar] [CrossRef]

- Patel, L.K.; Singh, A.K.; Sharma, V.; Kala, P. Analysis of a hybrid ultrasonic horn profile using finite element analysis. Mater. Today Proc. 2021, 41, 772–779. [Google Scholar] [CrossRef]

- Banerjee, B.; Pradhan, S.; Das, S.; Chakraborty, A.; Dhupal, D. Horn design and analysis in ultrasonic machine process using ANSYS. Adv. Mater. Process. Technol. 2021, 8, 1359–1372. [Google Scholar] [CrossRef]

- Wang, H.; Sun, C. Design and test of a small high frequency ultrasonic cleaning transducer. J. Phys. Conf. Ser. 2023, 2430, 012017. [Google Scholar] [CrossRef]

- Tommiska, O.; Mustonen, J.; Moilanen, P.; Rauhala, T.; Gritsevich, M.; Salmi, A.; Hæggström, E. FEM-based time-reversal technique for an ultrasonic cleaning application. Appl. Acoust. 2022, 193, 108763. [Google Scholar] [CrossRef]

- Zheng, Q.; Xu, J.; Shi, X.; Yu, Y. Design and modeling of a portable ultrasonic cleaner. Int. J. Prod. Sound Qual. 2023, 1, 3–17. [Google Scholar] [CrossRef]

- Lais, H.; Lowe, P.S.; Gan, T.H.; Wrobel, L.C. Numerical modelling of acoustic pressure fields to optimize the ultrasonic cleaning technique for cylinders. Ultrason. Sonochem. 2018, 45, 7–16. [Google Scholar] [CrossRef]

- Tangsopa, W.; Thongsri, J. Development of an industrial ultrasonic cleaning tank based on harmonic response analysis. Ultrasonics 2019, 91, 68–76. [Google Scholar] [CrossRef] [PubMed]

- Srathonghuam, K.; Wonganu, B.; Busayaporn, W.; Thongsri, J. Vibration analysis and development of a submersible ultrasonic transducer for an application in the inhibitory activity of pathogenic bacteria. IEEE Access 2021, 9, 142362–142373. [Google Scholar] [CrossRef]

- Pak, A.; Shirin Abadi Farahani, A.; Shahidi, A. Design, modeling and manufacturing a novel continues ultrasonic cleaning tank by harmonic response analysis. Iran. J. Manuf. Eng. 2022, 9, 21–27. [Google Scholar] [CrossRef]

- Tangsopa, W.; Thongsri, J. A novel ultrasonic cleaning tank developed by harmonic response analysis and computational fluid dynamics. Metals 2020, 10, 335. [Google Scholar] [CrossRef]

- Tang, J.; Cheng, Z.; Zhang, X.; Sun, J.; Liu, Z.; Zhang, H.; Tan, S.; Qiu, F. Continuous ultrasonic ozone coupling technology-assisted control of ceramic membrane fouling coupled enhanced multiphase mixing to treat dye wastewater and CFD flow field simulation. Ultrason. Sonochem. 2024, 104, 106839. [Google Scholar] [CrossRef]

- Tangsopa, W.; Thongsri, J. A dual frequency ultrasonic cleaning tank developed by transient dynamic analysis. Appl. Sci. 2021, 11, 699. [Google Scholar] [CrossRef]

- Liu, C.W.; Wu, C.W. An inventional of multifunction washing ball. IOP Conf. Series Mater. Sci. Eng. 2019, 658, 012019. [Google Scholar] [CrossRef]

- Ashly, K. Sonification as a sample preparation method for elemental analysis. Compr. Anal. Chem. 2003, 41, 353–369. [Google Scholar]

- ANSYS. Introduction to Acoustics; ANSYS Europe: Canonsburg, PA, USA, 2018. [Google Scholar] [CrossRef]

- Fuchs, J. Ultrasonics-Number and Size of Cavitation Bubbles. Available online: https://www.blackstone-ney.com/blog/ultrsonics-number-and-size-of-cavitation-bubbles/ (accessed on 13 February 2025).

- Wu, J. Acoustic streaming and its application. Fluids 2018, 3, 108. [Google Scholar] [CrossRef]

- NGL Cleaning Technology. UPC 3000 Ultrasonic Process Controller. Available online: https://www.ngl-group.com/wp-content/uploads/2024/09/upc-3000-en-pdf.pdf (accessed on 18 February 2025).

- Serway, R.A.; Jewett, J.W. Physics for Scientists and Engineers with Modern Physics, 7th ed.; Cengage Learning: Boston, MA, USA, 2008. [Google Scholar]

- Vetrimurugan, R.; Hooi, B. Study of ultrasonic parameters on removal of contamination from slider surface by using various cleaning chemistry. Int. J. Chem. Environ. Eng. 2012, 3, 392–396. [Google Scholar]

- Vetrimurugan, R.; Goodson, M.; Lim, T.; Nagarajan, S.; Siddharth, J. Experimental investigation of ultrasonic and megasonic frequency on cleaning of various disk drive components. Int. J. Chem. Eng. Appl. 2013, 4, 174–177. [Google Scholar] [CrossRef]

- Gopi, K.R.; Awad, S.B. Ultrasonic cleaning with two frequencies. In Handbook for Critical Cleaning, 2nd ed.; CRC Press: Florida, NW, USA, 2011; pp. 241–246. [Google Scholar]

- Heidari, H.; Karimi, S. Effect of contaminated water (handwashing detergent) on seed germination traits in wheat, mung bean, and chickpea. Tenside Surfactants Deterg. 2024, 61, 189–193. [Google Scholar] [CrossRef]

- Lawson, L.; Chowdhury, A.R. Women in Thailand’s gem and jewelry industry and the sustainable development goals (SDGs): Empowerment or continued inequity. Environ. Sci. Policy 2022, 136, 675–684. [Google Scholar] [CrossRef]

| Material | Type | Value |

|---|---|---|

| Water (27 °C) | Water density Acoustic velocity Dynamic viscosity | 996.45 kg/m3 1499.2 m/s 0.8592 kg/ms |

| Aluminum alloy | Density Young’s modulus Poisson’s ratio Bulk modulus Shear modulus | 2770 kg/m3 7.1 × 1010 Pa 0.33 6.9608 × 1010 Pa 2.6692 × 101 Pa |

| Stainless steel | Density Young’s modulus Poisson’s ratio Bulk modulus Shear modulus | 7750 kg/m3 1.93 × 1011 Pa 0.31 1.693 × 1010 Pa 7.3664 × 101 Pa |

| Piezoelectric (PZT4) | Density Permittivity constant (ε0) Stiffness matrix [cE] Piezoelectric stress [e] Relative permittivity (εr) | 7500 kg/m3 8.854 × 10−12 F/m C11 = C22 = 1.39 × 1011, C21 = 7.78 × 1010, C31 = C32 = 7.43 × 1010, C44 = 3.06 × 1010, C55 = C66 = 2.56 × 1010 Pa e31 = −5.2, e33 = 15.1, e15 = 12.7 C/m2 εr11 = εr22 = 1475, εr33 = 1300 |

| Epoxy | Density Young’s modulus x, y, z direction Poisson’s ratio Shear modulus | 1451 kg/m3 σx, σy = 5.916 × 1010, σz = 7.5 × 109 Pa xy = 0.04, yz, xz = 0.3 xy = 3.3 × 109, yz, xz = 2.7 × 109 Pa |

| Cleaning Condition | Frequency Mode | Detergent | Water Temp (°C) | η (%) | Key findings |

|---|---|---|---|---|---|

| Water (no ultrasonication) | - | - | 27 | 33.33 | - Minimal dubbing removal; mostly due to water solubility, not ultrasonic action. |

| Single frequency | 28 kHz | - | 27 | 64.16 | - Larger cavitation bubbles; better suited for dubbing removal. - Cleaning position: the best at the center, the worst near the transducer [15,20]. |

| 40 kHz | - | 27 | 38.80 | - Small cavitation bubbles; lower removal efficiency for this dirt type compared to 28 kHz. - Adjusting transducer position: affecting cavitation intensity, controlling the cavitation distribution [15,18,20] | |

| Dual frequency | 28 + 40 kHz | - | 27 | 72.14 | - A mix of bubble sizes (7–14 μm) [16,24] improved removal; more cavitation due to higher total power |

| - | 60 | 88.42 | - High cleaning efficiency: heat softened dubbing and reduced water surface tension, enhancing cleaning | ||

| 3% DWL | 27 | 88.37 | -Combination of chemical cleaning and ultrasonic cleaning [4,24] | ||

| 60 | 100 | The highest cleaning efficiency: a mix of bubble sizes; number and stability of bubbles increase; easily forming and expanding bubbles; high-energy exploded bubbles [4,24]; optimal operating conditions; cost saving for jewelry manufacturer. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaiaiad, C.; Borthai, P.; Thongsri, J. A Modern Ultrasonic Cleaning Tank Developed for the Jewelry Manufacturing Process and Its Cleaning Efficiency. Inventions 2025, 10, 90. https://doi.org/10.3390/inventions10050090

Chaiaiad C, Borthai P, Thongsri J. A Modern Ultrasonic Cleaning Tank Developed for the Jewelry Manufacturing Process and Its Cleaning Efficiency. Inventions. 2025; 10(5):90. https://doi.org/10.3390/inventions10050090

Chicago/Turabian StyleChaiaiad, Chatchapat, Pawantree Borthai, and Jatuporn Thongsri. 2025. "A Modern Ultrasonic Cleaning Tank Developed for the Jewelry Manufacturing Process and Its Cleaning Efficiency" Inventions 10, no. 5: 90. https://doi.org/10.3390/inventions10050090

APA StyleChaiaiad, C., Borthai, P., & Thongsri, J. (2025). A Modern Ultrasonic Cleaning Tank Developed for the Jewelry Manufacturing Process and Its Cleaning Efficiency. Inventions, 10(5), 90. https://doi.org/10.3390/inventions10050090