Manual Resin Gear Drive for Fine Adjustment of Schlieren Optical Elements

Abstract

1. Introduction

2. Models and Materials

2.1. Influence of the Parabolic Mirror Tilt Angle on the Sensitivity of the Schlieren System

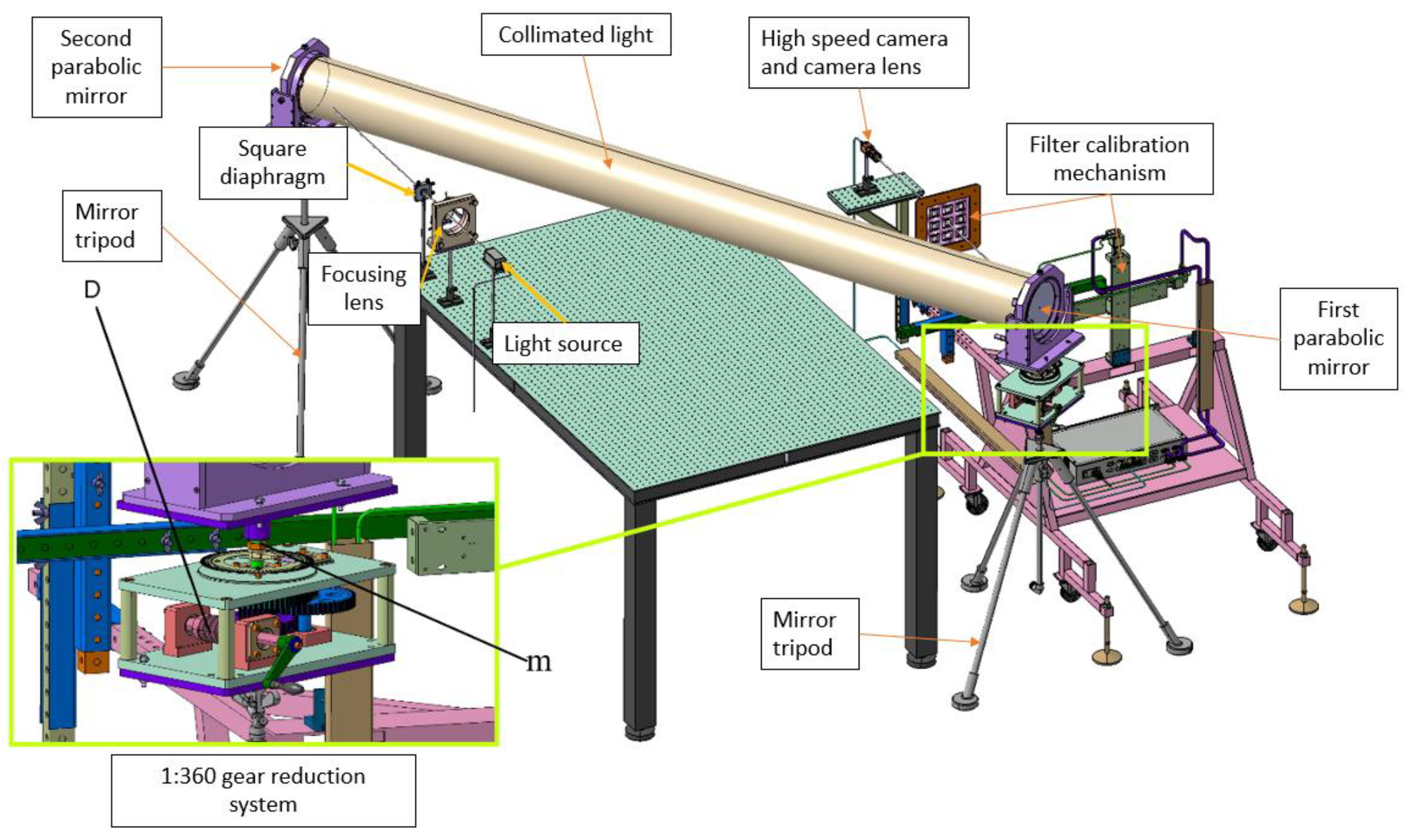

2.2. System Concept and Components

2.3. Additive Manufacturing Considerations Due to Design Constraints

3. Conclusions

4. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Settles, G.S. Schlieren and Shadowgraph Techniques: Visualizing Phenomena in Transparent Media; Springer: Berlin, Germany, 2001; pp. 1–406. [Google Scholar]

- Zheng, L.; Susa, A.J.; Hanson, R.K. Methodology of designing compact schlieren systems using off-axis parabolic mirrors. Appl. Opt. 2022, 61, 4857–4864. [Google Scholar] [CrossRef] [PubMed]

- Speak, G.S.; Walters, D.J. Optical Considerations and Limitations of the Schlieren Method; Reports and Memoranda No. 2859; Aeronautical Research Council, Ministry of Supply: London, UK, January 1950. Available online: https://reports.aerade.cranfield.ac.uk/bitstream/handle/1826.2/3415/arc-rm-2859.pdf (accessed on 22 August 2025).

- Settles, G.S. Schlieren and shadowgraph techniques: Visualizing phenomena in transparent media. Flow Meas. Instrum. 1985, 1, 103–116. [Google Scholar] [CrossRef]

- Stevenson, D. Quantitative Colour Schlieren Techniques. Master’s Thesis, University of the Witwatersrand, Faculty of Engineering and the Built Environment, Johannesburg, South Africa, 2011. [Google Scholar]

- Caltech Course Handout. Schlieren Visualization (Ae104b, Winter 2014); Section “2.2 Schlieren”. Available online: https://shepherd.caltech.edu/T5/Ae104/Ae104b_handout2015.pdf (accessed on 21 August 2025).

- Mishra, S.S. Measurement of Gaussian Beam Width Using Knife Edge; National Institute of Science Education and Research (NISER): Bhubaneswar, India, 2013. [CrossRef]

- Siegman, A.E. Lasers; University Science Books: Sausalito, CA, USA, 1986; pp. 647–653. [Google Scholar]

- Born, M.; Wolf, E. Principles of Optics, 7th ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Smith, W.J. Modern Lens Design, 2nd ed.; McGraw–Hill: New York, NY, USA, 2005. [Google Scholar]

- 60:1 Gear Ratio, 360 Teeth, Worm Gear. Available online: https://www.govolition.com/product/V82-S1C86Z-P064B360S (accessed on 20 August 2025).

- Worms & Worm Gears. 64 Diametral Pitch. OndrivesUS.com. Available online: https://dpk3n3gg92jwt.cloudfront.net/domains/ondrives/pdf/gears-worm-wheel-WG64.pdf (accessed on 20 August 2025).

- Formlabs Inc. Tough 2000 Resin. Available online: https://formlabs.com/eu/store/materials/tough-2000-resin/?srsltid=AfmBOorN-ABIu9Q7P6jYOpulbmLPfL-BfZTVsnyRv1kal9AEN9TH13U0 (accessed on 20 August 2025).

- Prisăcariu, E.G.; Vlăducă, I. Automated Calibration Mechanism for Color Filter Integration in Quantitative Schlieren Systems with Rectangular Light Sources. Inventions 2025, 10, 53. [Google Scholar] [CrossRef]

- Spur Gears. Available online: https://deewanbittal.files.wordpress.com/2017/12/md-4_gear.pdf (accessed on 20 August 2025).

- Osakue, E.E.; Anetor, L. A Contact Stress Capacity Model for Cylindrical Wormsets. FME Transactions 2022, 50, 1–10. [Google Scholar] [CrossRef]

- RoyMech. Worm Gears. Available online: https://roymech.org/Useful_Tables/Drive/Worm_Gears.html (accessed on 20 August 2025).

- Framo Morat USA. Worm Gear Sets. Available online: https://us.framo-morat.com/products/worm-gear-sets (accessed on 20 August 2025).

- Elesa-Ganter. DIN 469. Crank Handles. Available online: https://catalog.monroeengineering.com/Asset/din-469.pdf (accessed on 20 August 2025).

- Formlabs Europe. Formlabs—High-Resolution SLA and SLS 3D Printers for Professionals. Available online: https://formlabs.com/eu/ (accessed on 21 August 2025).

- Radić, A.; Potočnik, B.; Maroh, M.; Poberaj, I. On the application of components manufactured with stereolithographic 3D printing in high vacuum systems. Vacuum 2024, 220, 112083. [Google Scholar] [CrossRef]

- NASA Outgassing Database. Materials Data for Additive-Manufactured Photopolymers. NASA GSFC. Available online: https://outgassing.nasa.gov/ (accessed on 21 September 2025).

- Formlabs. Durable Resin. Available online: https://formlabs.com/store/materials/durable-resin/?srsltid=AfmBOopA0rBX45GRITZJL8149vGiYKeTh3FZb9jTp52BWXmwjxM01Gec (accessed on 21 August 2025).

- Formlabs Inc. Tough 1500 Resin Technical Data Sheet (Rev. 01, 27 January 2020). Available online: https://formlabs-media.formlabs.com/datasheets/Tough_1500_TDS_EN.pdf (accessed on 21 August 2025).

- Formlabs. Form 2 Desktop Stereolithography (SLA) 3D Printer. Available online: https://formlabs.com/3d-printers/form-2/ (accessed on 21 August 2025).

- Formlabs. Form 4BL Large-Format 3D Printer—Medical/Dental SLA Platform. Available online: https://formlabs.com/3d-printers/form-4bl/ (accessed on 21 August 2025).

- 3D Systems. DuraForm PA11 Natural (SLS). Tough Nylon with High Elongation and Impact Resistance. Available online: https://www.3dsystems.com/materials/duraform-pa11-natural-sls (accessed on 21 August 2025).

- Materialise. PA 12 (SLS). Available online: https://www.materialise.com/en/industrial/3d-printing-materials/pa12-sls (accessed on 21 August 2025).

- Formlabs. Fuse 1+ 30W Compact SLS 3D Printer (Fuse Series). Available online: https://formlabs.com/eu/3d-printers/fuse-1/ (accessed on 21 August 2025).

- CDME, Ohio State University. EOS P110 Selective Laser Sintering (SLS) System. Available online: https://cdme.osu.edu/eos-p110, (accessed on 21 August 2025).

- HP. HP Multi Jet Fusion 3D Printing Technology. Available online: https://www.hp.com/us-en/printers/3d-printers/products/multi-jet-technology.html (accessed on 21 August 2025).

- Morgan, R.V.; McReynolds, B.; Husmann, K.; McCoy, J.; Maki, R.N.; Holguin, R.M.; Bernardin, J.D.; Siranosian, A.A. Markforged Continuous Fiber Composite Material Testing; Report Number LA-UR-20-25195; Los Alamos National Laboratory: Los Alamos, NM, USA, September 2020. Available online: https://www.osti.gov/servlets/purl/1641543/ (accessed on 25 September 2025).

- Prusa Research. Composite Materials. Original Prusa 3D Printers. Available online: https://www.prusa3d.com/category/composites/ (accessed on 21 August 2025).

- UltiMaker. Composite Materials for 3D Printing. Available online: https://ultimaker.com/materials/composite-materials-for-3d-printing/ (accessed on 21 August 2025).

- Ensinger Plastics. PEEK Plastic—TECAPEEK. Available online: https://www.ensingerplastics.com/en/thermoplastic-materials/peek-plastic (accessed on 21 August 2025).

- Kondo, H. POM (Acetal/Delrin) 3D Printing—All You Need to Know. All3DP. Updated 13 January 2024. Available online: https://all3dp.com/2/pom-acetal-delrin-3d-printing/ (accessed on 21 August 2025).

- Prusa Knowledge Base. Object Orientation. Available online: https://help.prusa3d.com/article/object-orientation_1658 (accessed on 21 August 2025).

- Formlabs Support. Model Orientation Best Practices for SLA Printing. Available online: https://support.formlabs.com/s/article/Model-Orientation?language=en_US (accessed on 21 August 2025).

- Formlabs. Form 3+ Desktop Resin 3D Printer—Industrial-Quality SLA Platform. Available online: https://formlabs.com/3d-printers/form-3/ (accessed on 22 August 2025).

- Formlabs Community Forum. PreForm Touchpoint Size. General Discussion. Jackson, 27 July 2021. Available online: https://forum.formlabs.com/t/preform-touchpoint-size/31580 (accessed on 22 August 2025).

- Formlabs Support. Automatic Layout Settings for SLA Printing. Available online: https://support.formlabs.com/s/article/Automatic-layout-settings-for-SLA-printing?language=en_US (accessed on 22 August 2025).

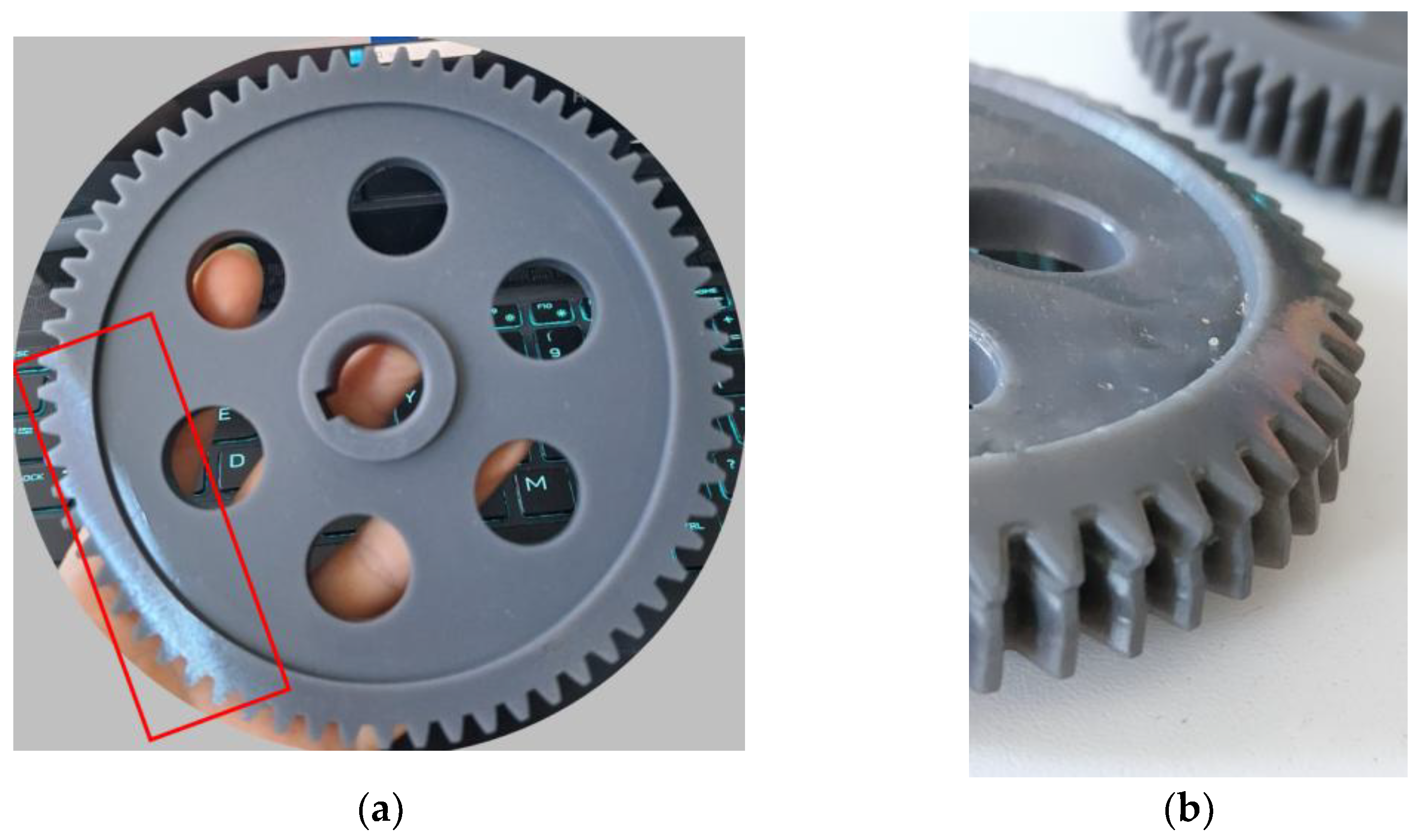

| Variable | Consideration | Final Design Choice |

|---|---|---|

| Gear module | Larger modules increase stiffness in resin | m = 2–3 |

| Tooth count distribution | Defines reduction ratio and load sharing | 1:30, 1:3, 1:4 stages |

| Worm geometry | Helix angle and start number affect smoothness/load | Single-start, m = 3 |

| Resin stiffness | Limits torque capacity vs. metals | Tough 2000 selected |

| Hub/web thickness | Must support orientation and reduce warping | Increased thickness in hubs/webs |

| Parameter | Gear Set 1–Steel Worm + Bronze Globoid Gear (Commercially Available) | Gear Set 2–Worm + Tough 2000 Resin Gear (3D Printed System) |

|---|---|---|

| Module [mm] | 0.4 | 3.00 |

| Base diameter (used) [mm] | 143.50 | 89.75 |

| Tooth width [mm] | 4.76 | 15.00 |

| Contact area [] | 0.9 | 21.21 |

| Allowable pressure [MPa] | 80 | 10 |

| Allowable tangential force [N] | 72 | 212 |

| Pitch radius [m] | 0.07175 | 0.044875 |

| Estimated allowable torque [] | 5.2 | 9.5 |

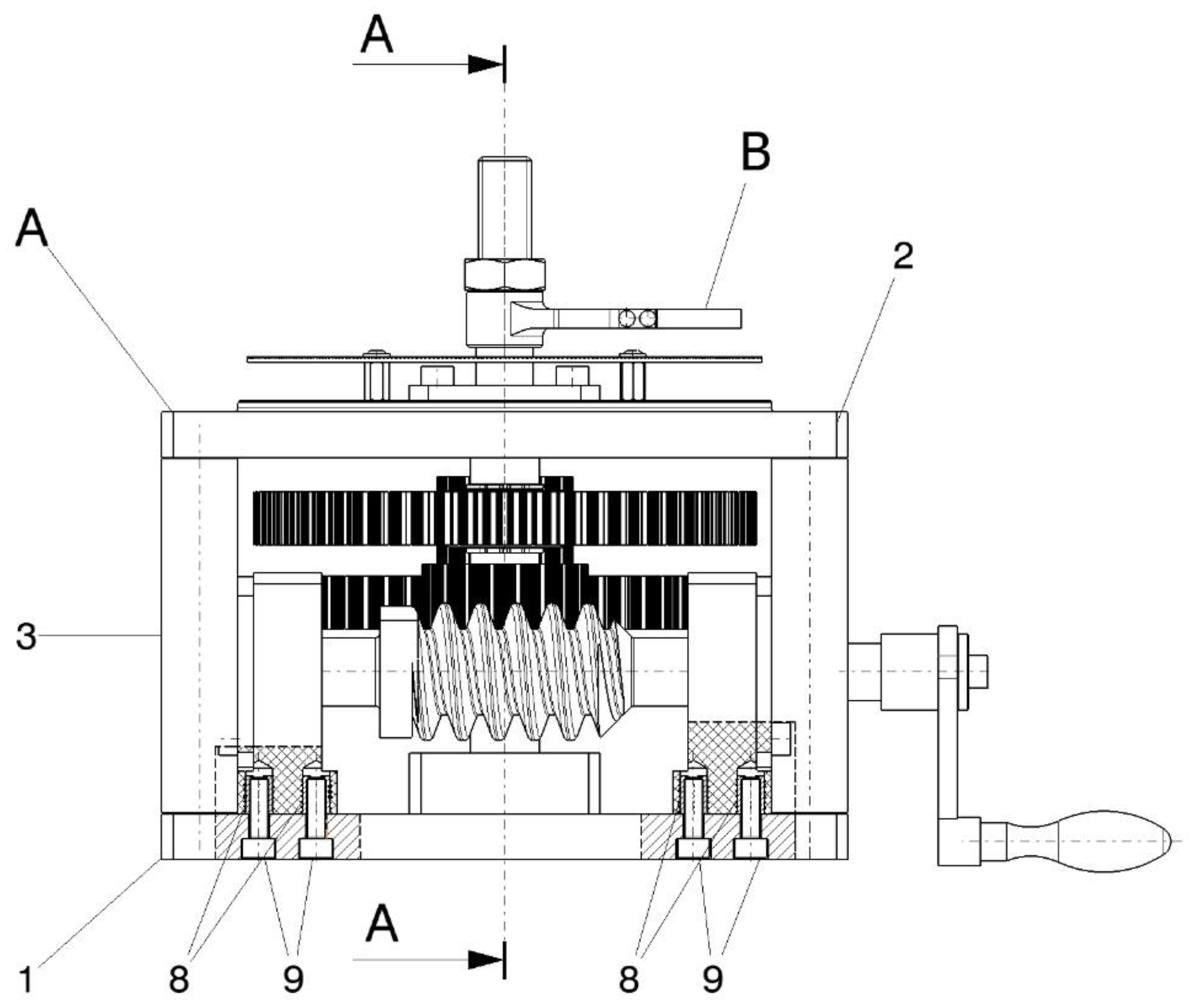

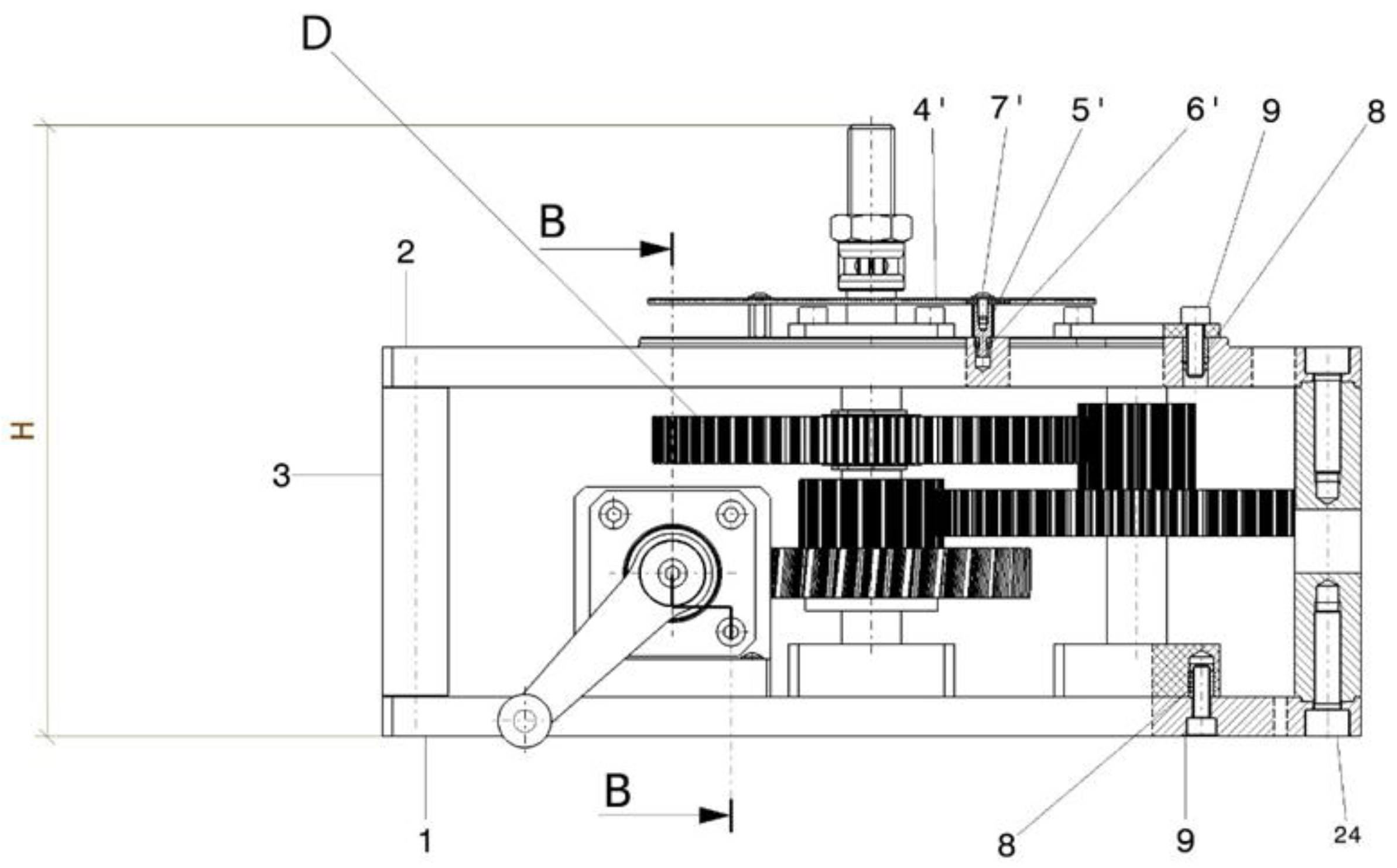

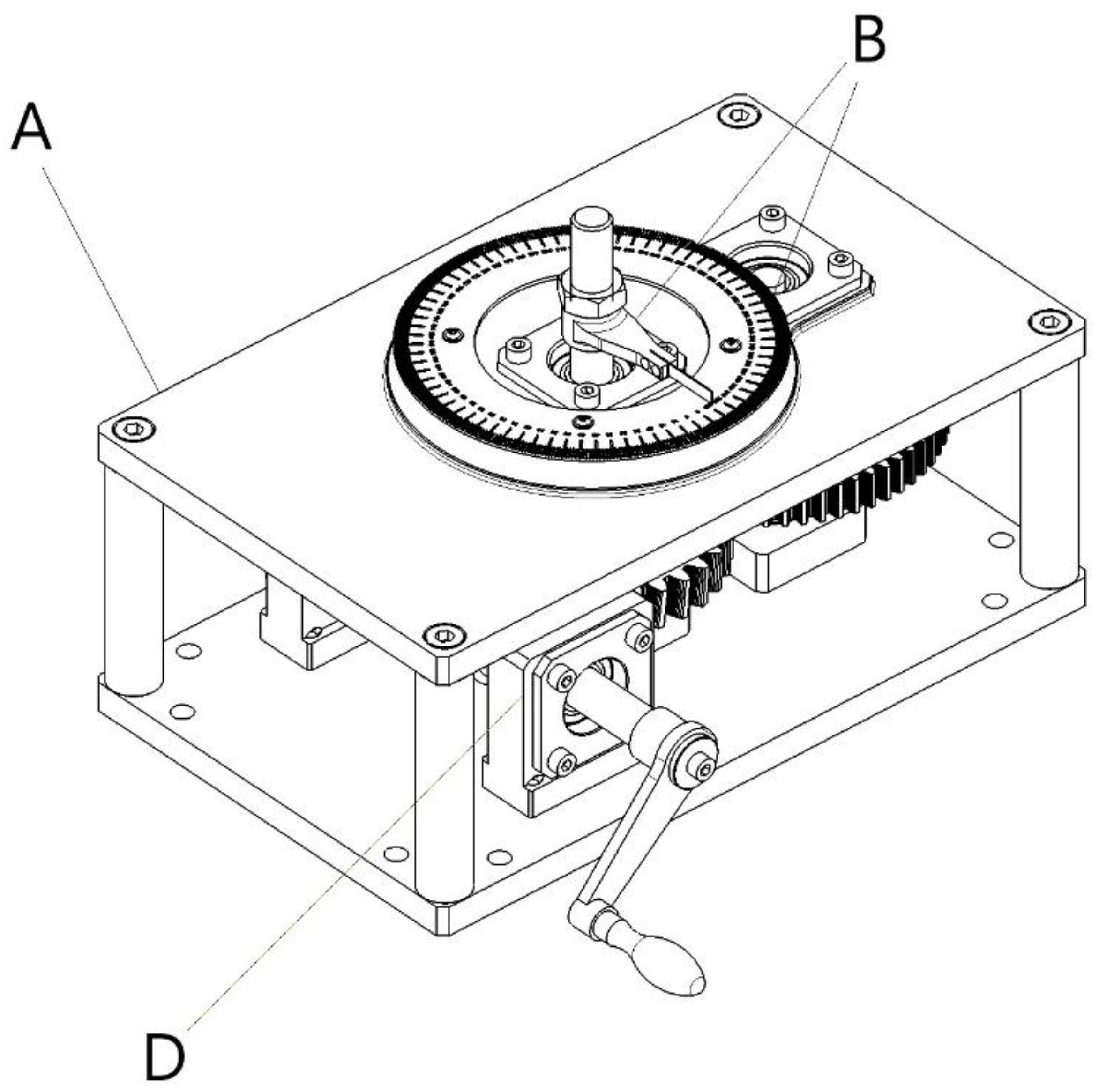

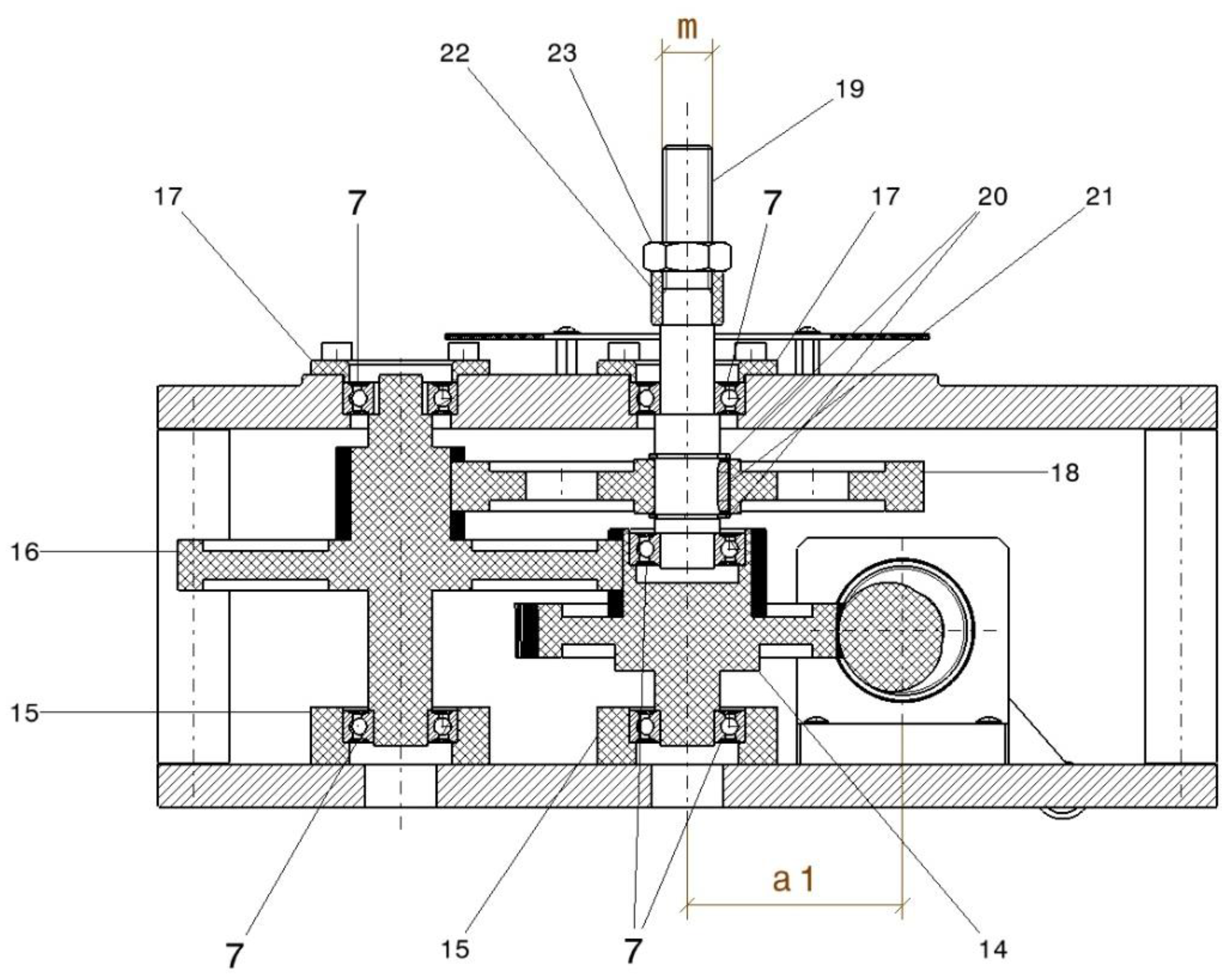

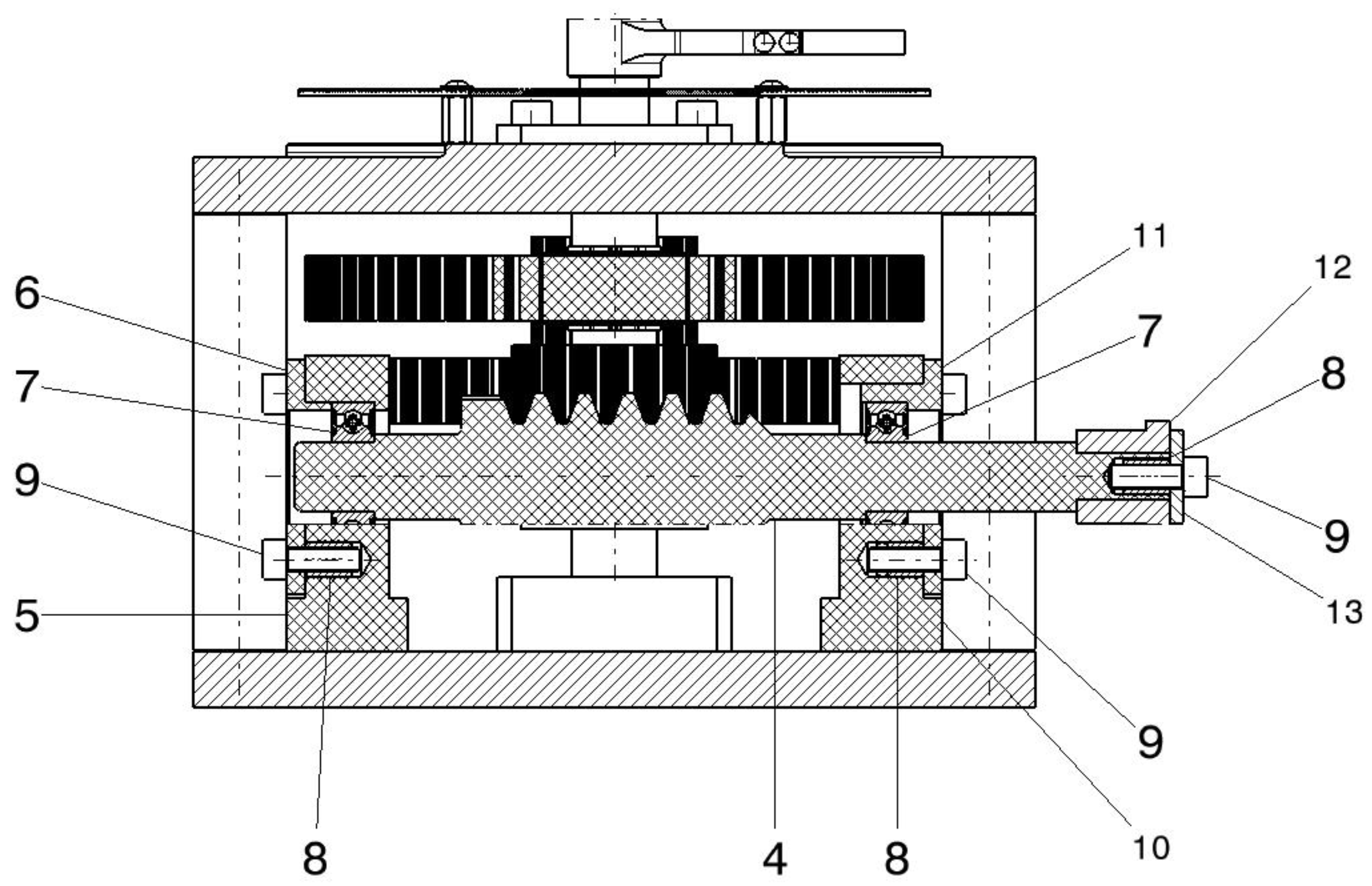

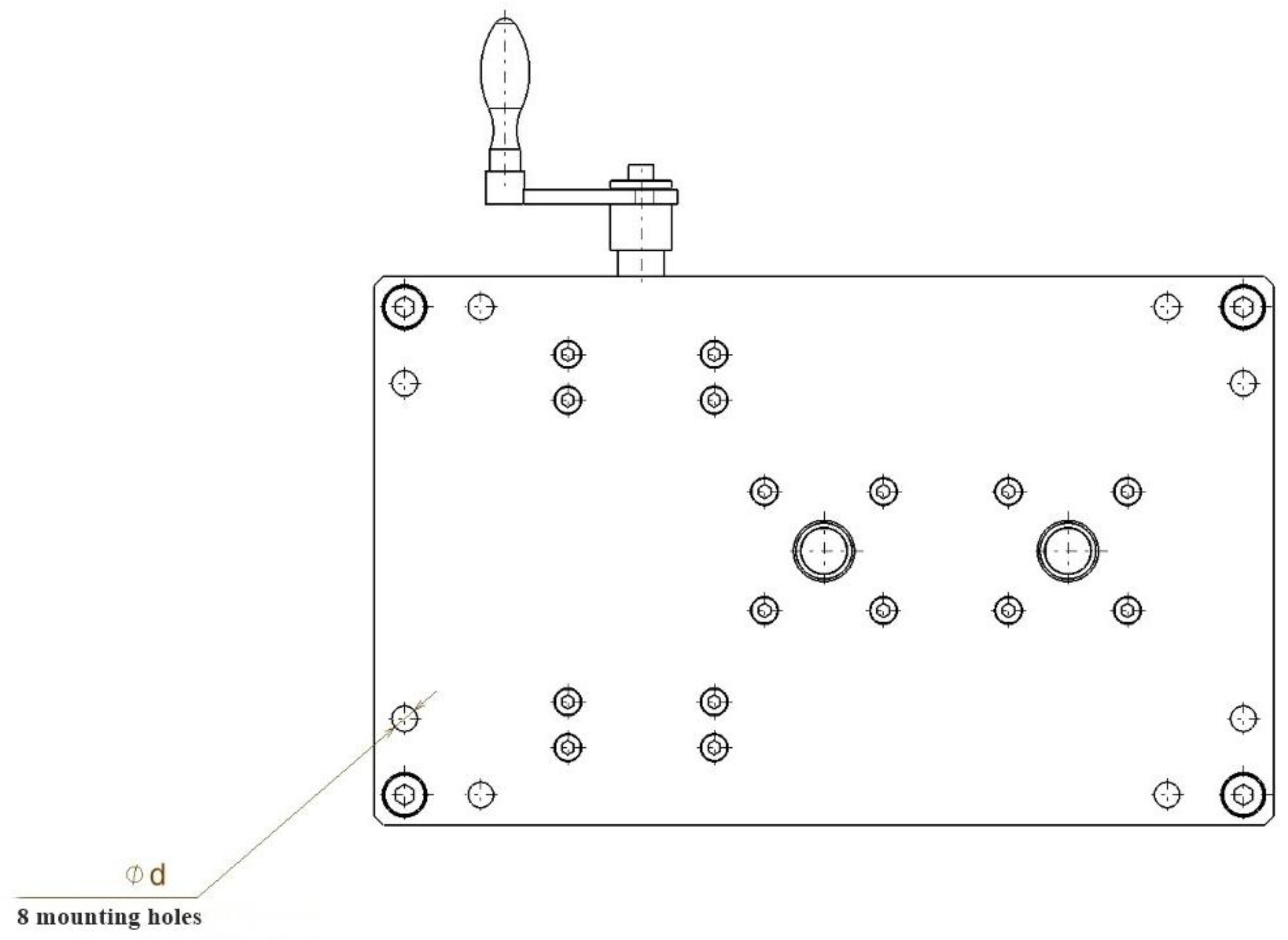

| Component Name/Type | Component nb. | Notes |

|---|---|---|

| Base plate (anodized duralumin) | 1 | Lower structural plate of housing A |

| Top plate (anodized duralumin) | 2 | Upper structural plate of housing A |

| Spacer cylinders (stainless steel) | 3 | Four spacers between plates, fixed with screws 24 |

| Cylindrical worm with involute teeth | 4 | Single start, module 3; main input driven by crank |

| Bearing housings (lower) | 5, 10, 15 | Support for ball bearings 7 |

| Bearing caps (lower) | 6,11 | Fix bearings in housings 5, 10 |

| Ball bearings (caged) | 7 | Support worm 4, compound gears 14, 16, and shaft 19 |

| Threaded metal inserts | 8 | Used to fix screws in plates/housings |

| Screws (general fasteners) | 9, 24 | Used to fix housings, caps, and plates |

| Standard crank with square socket | 12 | Input lever for worm 4 |

| Washer | 13 | Fixing washer for crank assembly |

| Compound gear (30 helical teeth + 20 spur teeth) | 14 | Driven by worm 4; shares shaft with spur gear z3 = 20 |

| Compound gear (60 spur teeth + 16 spur teeth) | 16 | Driven by gear z3 = 20; shares shaft with spur gear z5 = 16 |

| Bearing caps (upper) | 17 | Fix ball bearings in upper plate 2 |

| Spur gear | 18 | Mounted on metallic shaft 19, via key 21 and retaining rings 20 |

| Metallic shaft | 19 | Connects gears 14 and 18; output shaft with threaded coupling m |

| Retaining rings | 20 | Secure spur gear 18 on shaft 19 |

| Parallel key | 21 | Connects spur gear 18 to shaft 19 |

| Indicator needle assembly | I (1′, 2′, 3′) | Lamella support 1′, indicator plate 2′, rivets 3′ |

| Circular indicator dial (0–360°) | 4′ | Mounted on top plate 2 with nuts 5′ |

| Elevation nuts | 5′ | Used to fix circular dial 4′ |

| Threaded metal inserts (indicator system) | 6′ | For dial assembly |

| Screws (indicator system) | 7′ | For dial assembly |

| Nut for fixing indicator needle to shaft | 23 | Connects needle I to shaft 19 |

| Stage | Components | Module [mm] | Teeth | Notes | Reduction Ratio |

|---|---|---|---|---|---|

| T1-2 | Cylindrical worm, type ZE [5], single start | 3 | Engages with helical gear | ||

| Helical gear, | 3 | ||||

| T3-4 | Spur gear | 2 | Shares shaft with ; forms compound gear | ||

| Spur gear | 2 | Part of compound gear with | |||

| T5-6 | Spur gear | 2 | Shares shaft with ; forms compound gear | ||

| Spur gear | 2 | Output gear |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prisăcariu, E.G.; Vlăducă, I. Manual Resin Gear Drive for Fine Adjustment of Schlieren Optical Elements. Inventions 2025, 10, 89. https://doi.org/10.3390/inventions10050089

Prisăcariu EG, Vlăducă I. Manual Resin Gear Drive for Fine Adjustment of Schlieren Optical Elements. Inventions. 2025; 10(5):89. https://doi.org/10.3390/inventions10050089

Chicago/Turabian StylePrisăcariu, Emilia Georgiana, and Iulian Vlăducă. 2025. "Manual Resin Gear Drive for Fine Adjustment of Schlieren Optical Elements" Inventions 10, no. 5: 89. https://doi.org/10.3390/inventions10050089

APA StylePrisăcariu, E. G., & Vlăducă, I. (2025). Manual Resin Gear Drive for Fine Adjustment of Schlieren Optical Elements. Inventions, 10(5), 89. https://doi.org/10.3390/inventions10050089