Effects of Polymerization Initiators on Plastic Scintillator Light Output

Abstract

1. Introduction

2. Materials and Methods

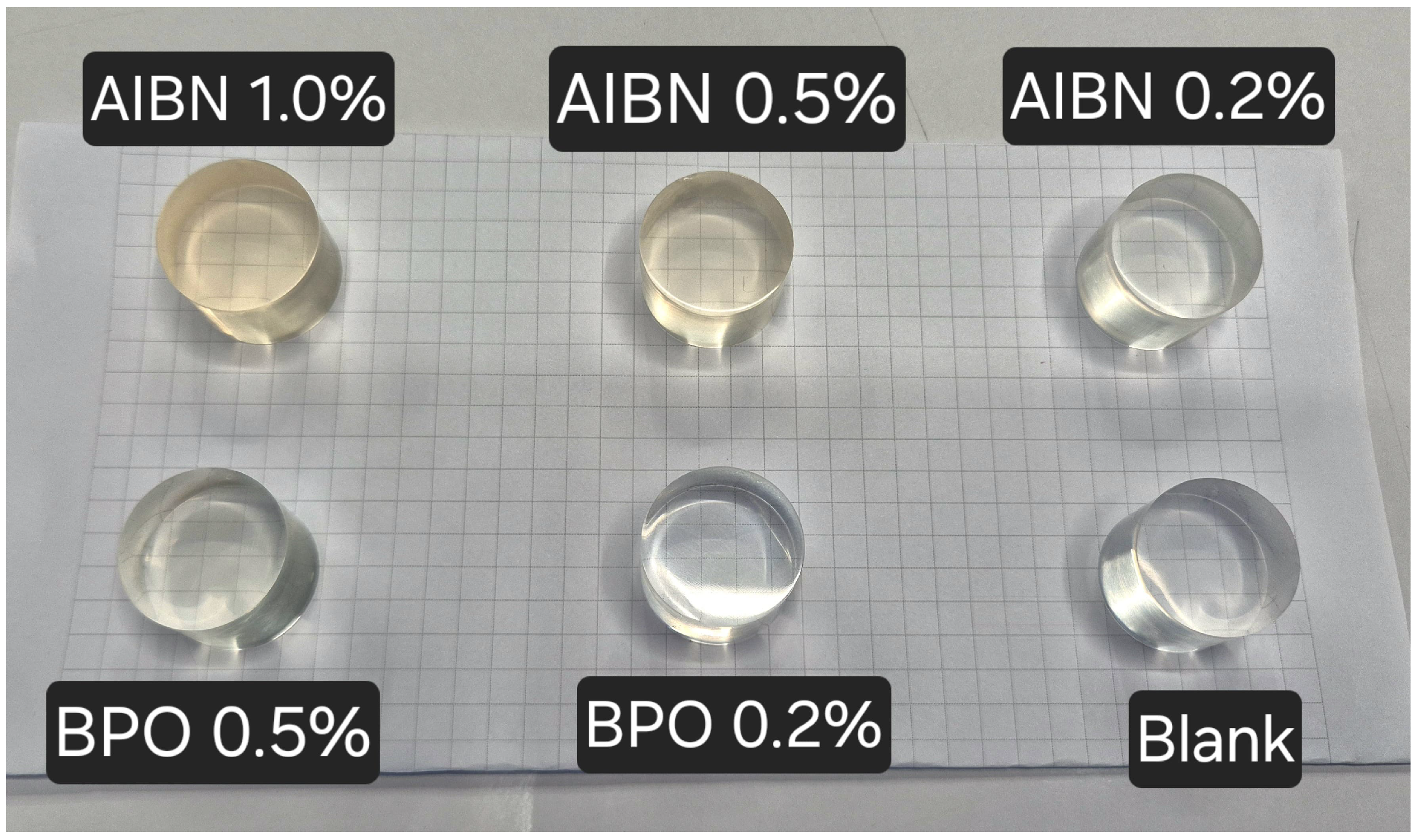

2.1. Synthesis of the Plastic Scintillator Samples

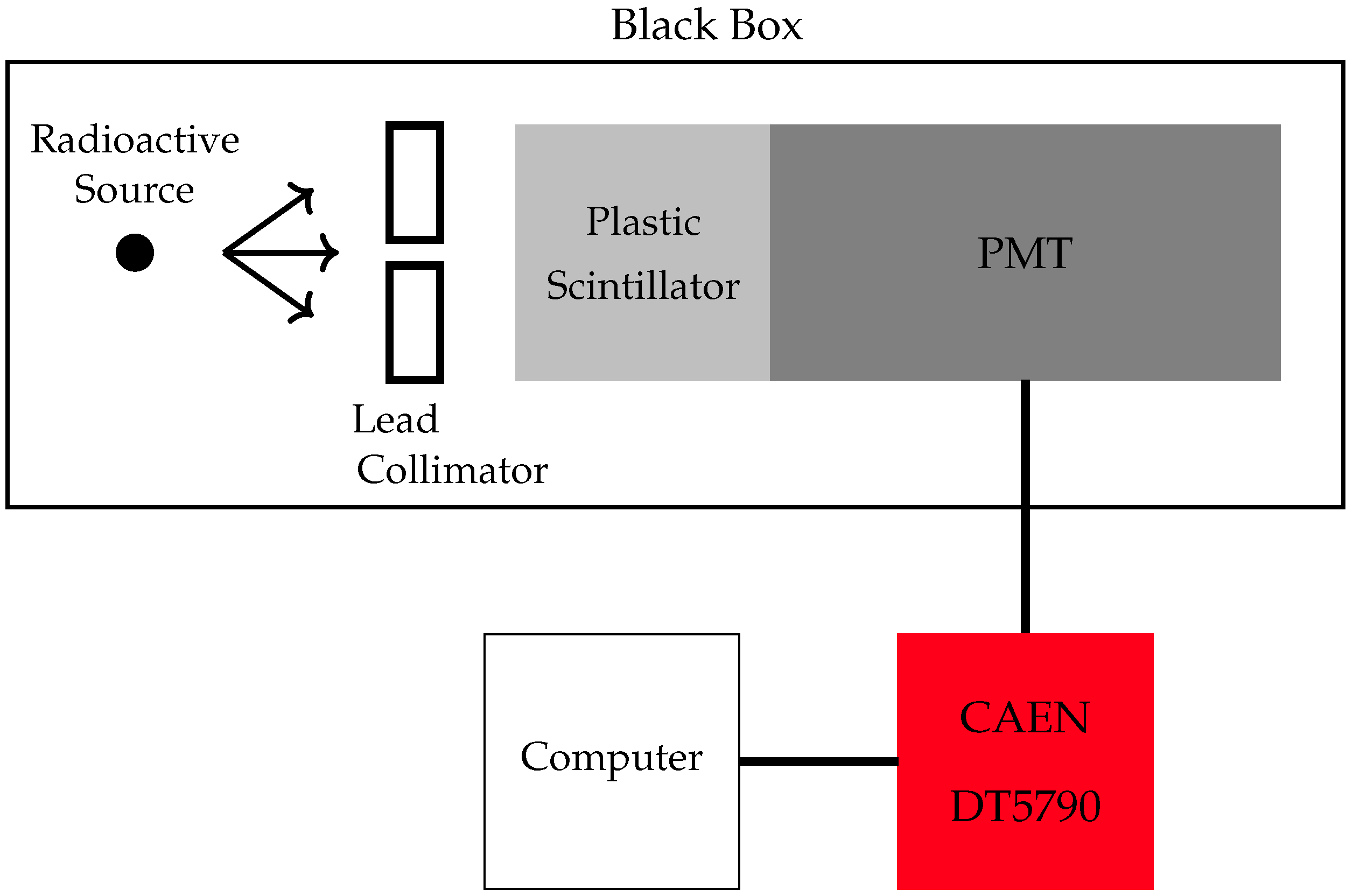

2.2. Light Yield Measurement of the Plastic Scintillator Samples

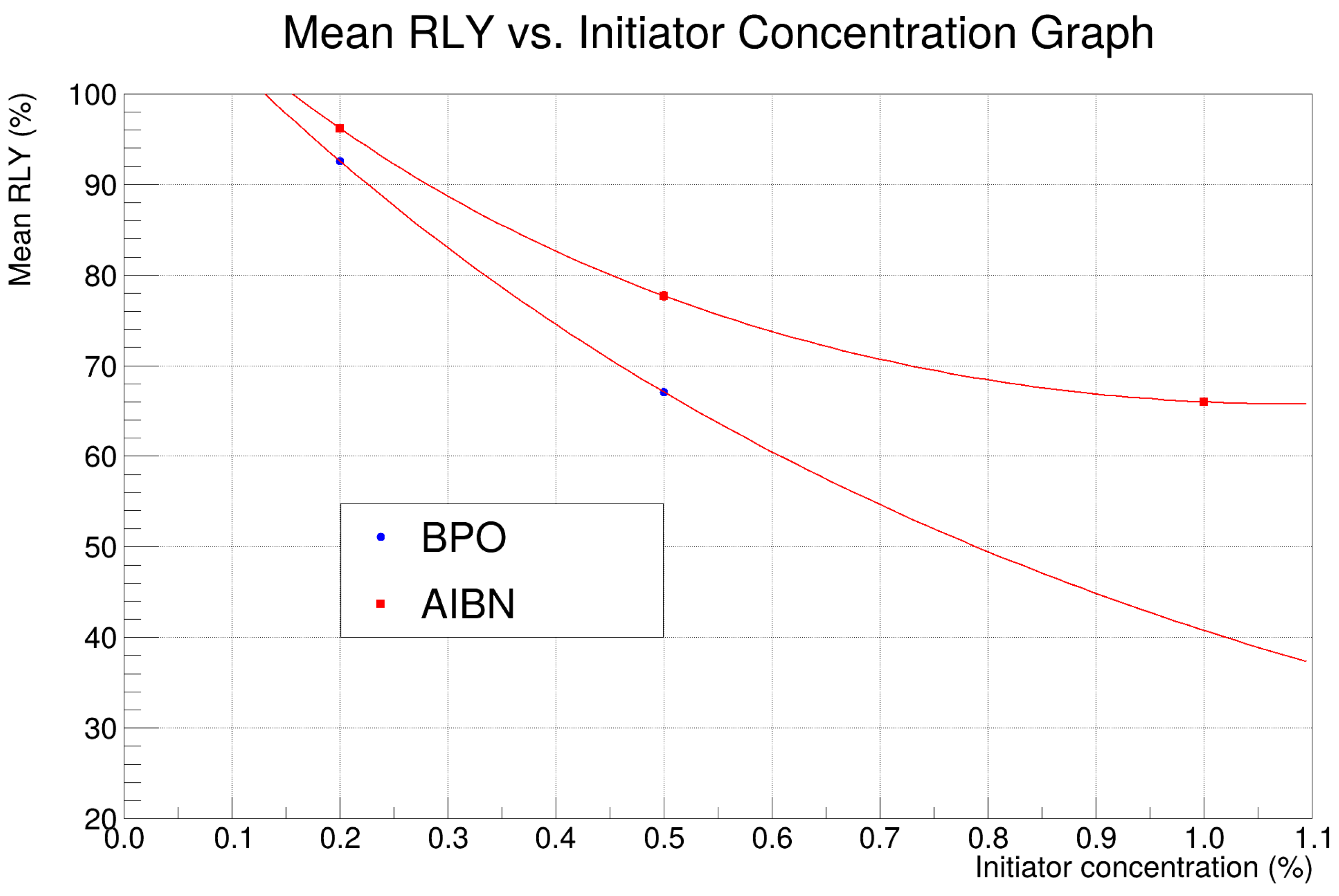

3. Results

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AIBN | 2,2-Azobis(2-methylpropionitrile) |

| BPO | Benzoyl peroxide |

| PS | Polystyrene |

| PVT | Polyvinyltoluene |

| PMT | Photomultiplier Tube |

| RMS | Root Mean Square |

| RLY | Relative Light Yield |

| LY | Light Yield |

| PPO | 2,5-Diphenyloxazole |

| POPOP | 1,4-bis(5-phenyl-2-oxazolyl)benzene |

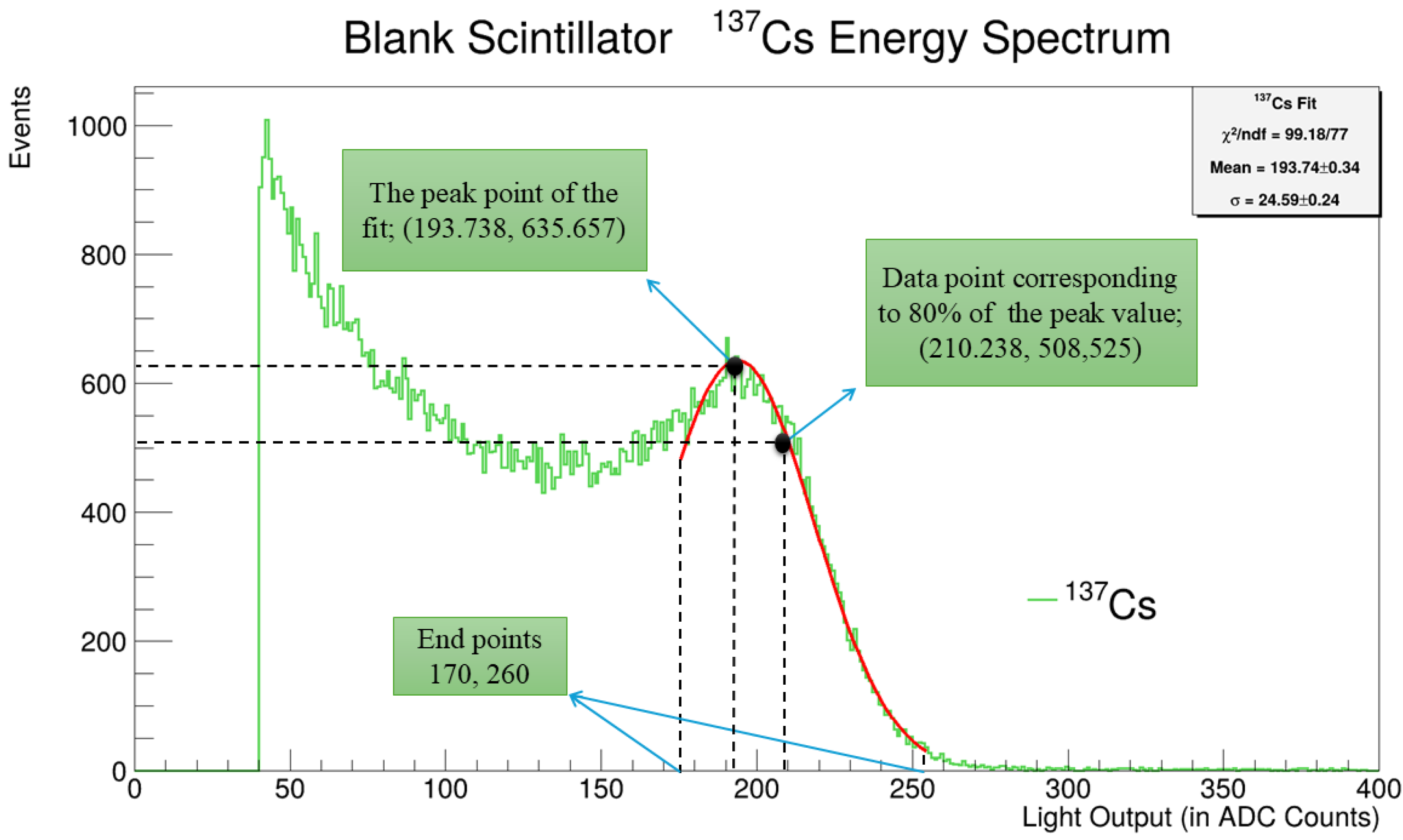

Appendix A. Compton Edge Gaussian Fit

- The peak value of the Compton edge part of the spectrum remains inside the chosen fit ranges.

- The fit ranges are chosen such that the value is minimized and a shift results only in a maximum of mean RLY change.

- Once the peak point of the fit is determined, the data point corresponding to of the peak value is located. Therefore our results are based on raw data, not the fit values.

Appendix B. Error Propagation

References

- Beaulieu, L.; Beddar, S. Review of plastic and liquid scintillation dosimetry for photon, electron, and proton therapy. Phys. Med. Biol. 2016, 61, R305. [Google Scholar] [CrossRef] [PubMed]

- Beddar, A. Plastic scintillation dosimetry and its application to radiotherapy. Radiat. Meas. 2006, 41, S124–S133. [Google Scholar] [CrossRef]

- Ozturk, S. Nuclear reactor monitoring with gadolinium-loaded plastic scintillator modules. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2020, 955, 163314. [Google Scholar] [CrossRef]

- Aad, G.; Abajyan, T.; Abbott, B.; Abdallah, J.; Khalek, S.A.; Abdelalim, A.A.; Aben, R.; Abi, B.; Abolins, M.; AbouZeid, O.; et al. Observation of a new particle in the search for the Standard Model Higgs boson with the ATLAS detector at the LHC. Phys. Lett. B 2012, 716, 1–29. [Google Scholar] [CrossRef]

- Arnison, G.; Astbury, A.; Aubert, B.; Bacci, C.; Bauer, G.; Bézaguet, A.; Böck, R.; Bowcock, T.; Calvetti, M.; Carroll, T.; et al. Experimental observation of isolated large transverse energy electrons with associated missing energy at s=540 GeV. Phys. Lett. B 1983, 122, 103–116. [Google Scholar] [CrossRef]

- Armengaud, E.; Augier, C.; Benoît, A.; Benoît, A.; Bergé, L.; Bergmann, T.; Blümer, J.; Broniatowski, A.; Brudanin, V.; Censier, B.; et al. Background studies for the EDELWEISS dark matter experiment. Astropart. Phys. 2013, 47, 1–9. [Google Scholar] [CrossRef]

- Mei, D.M.; Hime, A. Muon-induced background study for underground laboratories. Phys. Rev. D 2006, 73, 053004. [Google Scholar] [CrossRef]

- Williamson, J.F.; Dempsey, J.F.; Kirov, A.S.; Monroe, J.I.; Binns, W.R.; Hedtjärn, H. Plastic scintillator response to low-energy photons. Phys. Med. Biol. 1999, 44, 857. [Google Scholar] [CrossRef]

- Lee, H.; So, J.; Kang, C.; Kim, G.; Kim, S.; Lee, J.; Lee, M.; Yoon, W.; Kim, Y. Development of a scintillation light detector for a cryogenic rare-event-search experiment. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2015, 784, 508–512. [Google Scholar] [CrossRef]

- Qadr, H.M. Comparison of energy resolution and efficiency of NaI (TI) and HPGe detector using gamma-ray spectroscopy. J. Phys. Chem. Funct. Mater. 2020, 3, 24–27. [Google Scholar]

- Lo Presti, D.; Russo, G.V.; Leonora, E.; Aiello, S.; Randazzo, N.; Sipala, V.; Longhitano, F. Characterization Technique of Sub-Millimeter Scintillating Fibers. In Proceedings of the 2011 IEEE Nuclear Science Symposium and Medical Imaging Conference (NSS/MIC), Valencia, Spain, 23–29 October 2011; pp. 2104–2108. [Google Scholar] [CrossRef]

- CMS Collaboration. The CMS Hadron Calorimeter Project: Technical Design Report; CERN: Geneva, Switzerland, 1997. [Google Scholar]

- Si APDs|Hamamatsu Photonics—hamamatsu.com. Available online: https://www.hamamatsu.com/us/en/product/optical-sensors/apd/si-apd.html (accessed on 30 May 2025).

- Head-on Type|Hamamatsu Photonics—hamamatsu.com. Available online: https://www.hamamatsu.com/eu/en/product/optical-sensors/pmt/pmt_tube-alone/head-on-type.html (accessed on 30 May 2025).

- Mirzoyan, R.; Laatiaoui, M.; Teshima, M. Very high quantum efficiency PMTs with bialkali photo-cathode. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2006, 567, 230–232. [Google Scholar] [CrossRef]

- Gektin, A.; Korzhik, M. Inorganic Scintillators for Detector Systems; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Zaitseva, N.; Glenn, A.; Carman, L.; Paul Martinez, H.; Hatarik, R.; Klapper, H.; Payne, S. Scintillation properties of solution-grown trans-stilbene single crystals. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2015, 789, 8–15. [Google Scholar] [CrossRef]

- Jana, A.; Cho, S.; Patil, S.A.; Meena, A.; Jo, Y.; Sree, V.G.; Park, Y.; Kim, H.; Im, H.; Taylor, R.A. Perovskite: Scintillators, direct detectors, and X-ray imagers. Mater. Today 2022, 55, 110–136. [Google Scholar] [CrossRef]

- Akgün, B.; Öztürk, S.; Nurdan, K.; Özcan, V.E.; Ünel, N.G.; Kolbaşı, A.; Elibollar, E.; Ünal, A.; Kandemir, M.; Şahin, Y.; et al. Characterization of plastic scintillator samples produced by a university-SME Collaboration. Phys. Scr. 2024, 99, 055302. [Google Scholar] [CrossRef]

- Brown, J.; Laplace, T.; Goldblum, B.; Manfredi, J.; Johnson, T.; Moretti, F.; Venkatraman, A. Absolute light yield of the EJ-204 plastic scintillator. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2023, 1054, 168397. [Google Scholar] [CrossRef]

- Holl, I.; Lorenz, E.; Mageras, G. A measurement of the light yield of common inorganic scintillators. IEEE Trans. Nucl. Sci. 1988, 35, 105–109. [Google Scholar] [CrossRef]

- Hajagos, T.J.; Liu, C.; Cherepy, N.J.; Pei, Q. High-Z sensitized plastic scintillators: A review. Adv. Mater. 2018, 30, 1706956. [Google Scholar] [CrossRef]

- Odian, G. Principles of Polymerization; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Plastic Scintillators, 2021st ed.; Hamel, M., Ed.; Topics in Applied Physics; Springer Nature: Cham, Switzerland, 2021. [Google Scholar]

- Clark, G.W.; Scherb, F.; Smith, W.B. Preparation of Large Plastic Scintillators. Rev. Sci. Instrum. 1957, 28, 433–437. [Google Scholar] [CrossRef]

- Tam, A.K.; Boyraz, O.; Unangst, J.; Nazareta, P.; Schreuder, M.; Nilsson, M. Quantum-dot doped polymeric scintillation material for radiation detection. Radiat. Meas. 2018, 111, 27–34. [Google Scholar] [CrossRef]

- Sahi, S.; Chen, W.; Jiang, K. Luminescence enhancement of PPO/PVT scintillators by CeF3 nanoparticles. J. Lumin. 2015, 159, 105–109. [Google Scholar] [CrossRef]

- Gosau, J.M.; Harrah, L.A.; Hoyt, A.E. Polysilylene copolymers for ultrafast scintillator applications. 2. Thin film formulations. Radiat. Phys. Chem. 2001, 62, 127–132. [Google Scholar] [CrossRef]

- Debnath, C.; Kar, S.; Agrawal, A.K.; Shukla, M.; Verma, S. Development of Trans-Stilbene/PMMA Polymer Composites and Their Optical Characterization for Scintillation-Based Imaging and Detector Applications. IEEE Trans. Nucl. Sci. 2024, 71, 2432–2441. [Google Scholar] [CrossRef]

- Serraïma-López, D.; Guillén, M.; Bagán, H.; Tarancón, A. Scintillation and structural properties of copolymers and mixtures of styrene, 9-vinylcarbazole and 4-vinylbenzyl chloride based plastic scintillators. Appl. Radiat. Isot. 2024, 211, 111409. [Google Scholar] [CrossRef] [PubMed]

- Almog, Y.; Levy, M. Effect of inititiator on the molecular weight distribution in dispersion polymerization of styrene. J. Polym. Sci. Polym. Chem. Ed. 1980, 18, 1–11. [Google Scholar] [CrossRef]

- Meltzer, T.H.; Tobolsky, A.V. Kinetics of Polymerization of Styrene Initiated by the System Benzoyl-Peroxide-Dimethylaniline. J. Am. Chem. Soc. 1954, 76, 5178–5180. [Google Scholar] [CrossRef]

- Mahl, A.; Lim, A.; Latta, J.; Yemam, H.A.; Greife, U.; Sellinger, A. Methacrylate based cross-linkers for improved thermomechanical properties and retention of radiation detection response in plastic scintillators. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2018, 884, 113–118. [Google Scholar] [CrossRef]

- Bedrik, A.I.; Velmozhnaya, E.S.; Zhmurin, P.N.; Lebedev, V.N.; Titskaya, V.D. Properties of polystyrene-based scintillator with gadolinium phenylbutanate. Inorg. Mater. Appl. Res. 2014, 5, 399–402. [Google Scholar] [CrossRef]

- Li, W.; Tao, M.; Li, Y.; Shi, J.; Wu, H.; Wang, J.; Wang, Z.; Ren, G.; Wu, Y. NaI:Tl,6Li-PVT composite scintillator toward neutron and gamma discrimination. Radiat. Meas. 2022, 159, 106882. [Google Scholar] [CrossRef]

- User, S. EJ-550, EJ-552-Silicone Grease-Eljen Technology—eljentechnology.com. 2025. Available online: https://eljentechnology.com/products/accessories/ej-550-ej-552 (accessed on 28 February 2025).

- DT5790—caen.it. 2025. Available online: https://www.caen.it/products/dt5790/ (accessed on 14 March 2025).

- National Nuclear Data Center. NuDat 3 Database. 2025. Available online: https://www.nndc.bnl.gov/nudat3/ (accessed on 4 May 2025).

- Safari, M.J.; Davani, F.A.; Afarideh, H. Differentiation method for localization of Compton edge in organic scintillation detectors. arXiv 2016, arXiv:1610.09185. [Google Scholar] [CrossRef]

- Frangville, C.; Grabowski, A.; Dumazert, J.; Montbarbon, E.; Lynde, C.; Coulon, R.; Venerosy, A.; Bertrand, G.H.; Hamel, M. Nanoparticles-loaded plastic scintillators for fast/thermal neutrons/gamma discrimination: Simulation and results. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2019, 942, 162370. [Google Scholar] [CrossRef]

| Radioactive Source | Gamma Ray Energy (keV) | The Compton Edge Energy (keV) |

|---|---|---|

| 22 | 511 and 1275 | 341 and 1062 |

| 137 | 662 | 478 |

| 54 | 835 | 640 |

| 60 | 1174 and 1333 | 1041 |

| Scintillator | 22Na @ 341 keV [%] | 137Cs @ 478 keV [%] | 54Mn @ 640 keV [%] | 60Co @ 1041 keV [%] | 22Na @ 1062 keV [%] |

|---|---|---|---|---|---|

| Blank | 100.0 ± 0.0 | 100.0 ± 0.0 | 100.0 ± 0.0 | 100.0 ± 0.0 | 100.0 ± 0.0 |

| AIBN 0.2% | 96.1 ± 0.5 | 96.2 ± 0.6 | 96.8 ± 0.4 | 96.2 ± 0.2 | 95.8 ± 0.1 |

| AIBN 0.5% | 77.5 ± 0.4 | 76.9 ± 0.5 | 78.0 ± 0.3 | 77.5 ± 0.3 | 78.5 ± 0.2 |

| AIBN 1.0% | 65.9 ± 0.5 | 65.2 ± 0.3 | 66.2 ± 0.3 | 66.2 ± 0.3 | 66.3 ± 0.3 |

| BPO 0.2% | 92.4 ± 0.6 | 92.2 ± 0.3 | 92.7 ± 0.3 | 92.7 ± 0.1 | 92.9 ± 0.2 |

| BPO 0.5% | 66.5 ± 0.3 | 66.6 ± 0.5 | 67.6 ± 0.3 | 67.3 ± 0.2 | 67.5 ± 0.4 |

| Scintillator | Mean RLY [%] | RLY Error [%] |

|---|---|---|

| Blank | 100.00 | 0.0 |

| AIBN 0.2% | 96.2 | 0.4 |

| AIBN 0.5% | 77.7 | 0.5 |

| AIBN 1.0% | 66.0 | 0.4 |

| BPO 0.2% | 92.6 | 0.3 |

| BPO 0.5% | 67.1 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kandemir, M.; Akgün, B. Effects of Polymerization Initiators on Plastic Scintillator Light Output. Instruments 2025, 9, 19. https://doi.org/10.3390/instruments9030019

Kandemir M, Akgün B. Effects of Polymerization Initiators on Plastic Scintillator Light Output. Instruments. 2025; 9(3):19. https://doi.org/10.3390/instruments9030019

Chicago/Turabian StyleKandemir, Mustafa, and Bora Akgün. 2025. "Effects of Polymerization Initiators on Plastic Scintillator Light Output" Instruments 9, no. 3: 19. https://doi.org/10.3390/instruments9030019

APA StyleKandemir, M., & Akgün, B. (2025). Effects of Polymerization Initiators on Plastic Scintillator Light Output. Instruments, 9(3), 19. https://doi.org/10.3390/instruments9030019