1. Introduction

The importance of colorimetric measurements is well known and has been assessed by UNI, the Italian standardization body, and by CEN (Comité Européen de Normalisation) [

1]. Color measurements can be carried out in situ by colorimetric and spectrophotometric techniques; these are the most used in Cultural Heritage because they are not invasive or destructive with respect to the analyzed sample. Spectrophotometric analysis is based on the study of the spectral reflectance factor (SRF%) trend in the visible range of the electromagnetic spectrum (400–700 nm). The behavior of the SRF% provides information about the optical characteristics of a material, and it is used to specify its colors [

2]. When a reflectance spectrum from an object’s surface is recorded under standard operative conditions, the spectral curve can in fact be used for the quantitative specification of color. By the integration of SRF% curves, software processes calculate the color coordinates in a selected space codified by CIE (Commission Internationale de l’Eclairage) by considering the selected illuminant and the color matching functions [

2].

Furthermore, the SRF% trend represents an assisting tool for pigment identification by comparison between the acquired curves and those stored in a specific database under the same experimental conditions [

3,

4,

5,

6].

In the Cultural Heritage field, the study of color coordinate trends instead is useful for many applications. It could be important for evaluating the difference between colors of neighboring areas in artworks, before and after restoration; for monitoring the degradation phenomena in natural and artificial stones [

7,

8,

9]; or for monitoring color alteration in paintings produced by degraded varnish or due to the action of improper light sources and to high variation in relative humidity and temperature [

10,

11,

12,

13].

Especially in conservation and restoration programs, color measurements, performed at different times for evaluating possible color changes, require specifying all measurement parameters such as the illuminant, measurement area, selection of specular components included and/or excluded, and viewing conditions, including the scale adjustment procedure.

According to International Bureau of Weight and Measures, the term “calibration” refers to the establishment of a relation between the value measured by the instrument and the certificate reference target in order to find and eliminate systematic errors of an instrument’s scale [

14]. In general use, the calibration also includes the process of adjusting the output or indication on a measurement instrument to correspond with the value of the applied standard, within a specific accuracy [

2]. This latter operation, which we named scale adjustment, is fundamental for spectrophotometric and color specification, especially in the case of chromatic difference evaluation. Measurements of spectral reflectance, indeed, are usually not made as absolute measurements of the incident and reflected radiant flux but rather as measurements relative to a standard of known reflectance value. The CIE recommends the perfect reflecting diffuser as a reference for making measurements of the reflectance factor [

15]. A perfect reflecting diffuser is defined as the ideal uniform diffuser with a reflectance equal to unity [

16,

17]. There is no material that has the properties of a perfect reflecting diffuser; however, through specific techniques and tools, it is possible to calibrate using a white standard representing the ideal uniform diffuser [

18].

Normally, each device, such as colorimeters and spectrophotometers, is provided by the supplier with its coupled white standard, and a standard procedure for scale adjustment is suggested. This obligatory procedure starts by taking two measurements. The first one is used to establish the zero of the scale, and it is performed by using a specific attachment for the instrument that absorbs all light. The second is made with the white standard, for setting the maximum of the scale. When you buy the instrument, the device for performing the zero scale is optional, and this could make you think that it is not necessary. Concerning this, research work aimed to evaluate specifically what happens if during a measurement campaign the minimum scale adjustment (black) passage is skipped. During measurements, it is in fact possible to perform the adjustment of the lightness axis only by the maximum value corresponding to the white reference and using as minimum value (corresponding to “black”) the electronic noise of the instrument.

In the Cultural Heritage field, especially for measurements conducted in situ, in a museum or during archaeological excavations, and scheduled at different times, there may not be the appropriate conditions for performing the minimum and maximum scale adjustment according to the standard procedure. This research work aimed to evaluate the influence of different scale adjustment conditions on color difference assessment. Color measurements were carried out on two types of samples: certified standards and painting samples. The certified standards aid in developing consistent color reproduction for manufacturers of products such as textiles, papers, and paints, and they provide highly stable, reproducible spectral reflectance. The painting samples, produced in the laboratory according to old recipes, do not have standardized optical characteristics.

3. Results and Discussion

In

Table 4, the color coordinates L*, a*, and b* measured on the standards listed in

Table 1 are reported. The uncertainties associated were about 3%.

To better highlight the color differences due to the adjustment conditions, ΔE*

ab was calculated by considering the measurement carried out with the PC procedure as the target and the other adjustment conditions as samples. The results are reported in

Table 5.

Table 5 shows that ΔE*

ab presented higher values in terms of color perception in the case of SS-PC, particularly for the red and orange with respect to yellow and green. Violet was the hue least subject to variation in this case. According to the thresholds in [

24], skillful observers can notice the color differences for WS-PC. Most of the ΔE*

ab values for WO, WD, and SK fall within those not perceptible by the human eye [

24]. In order to determine the influence of each color coordinate in ΔE*

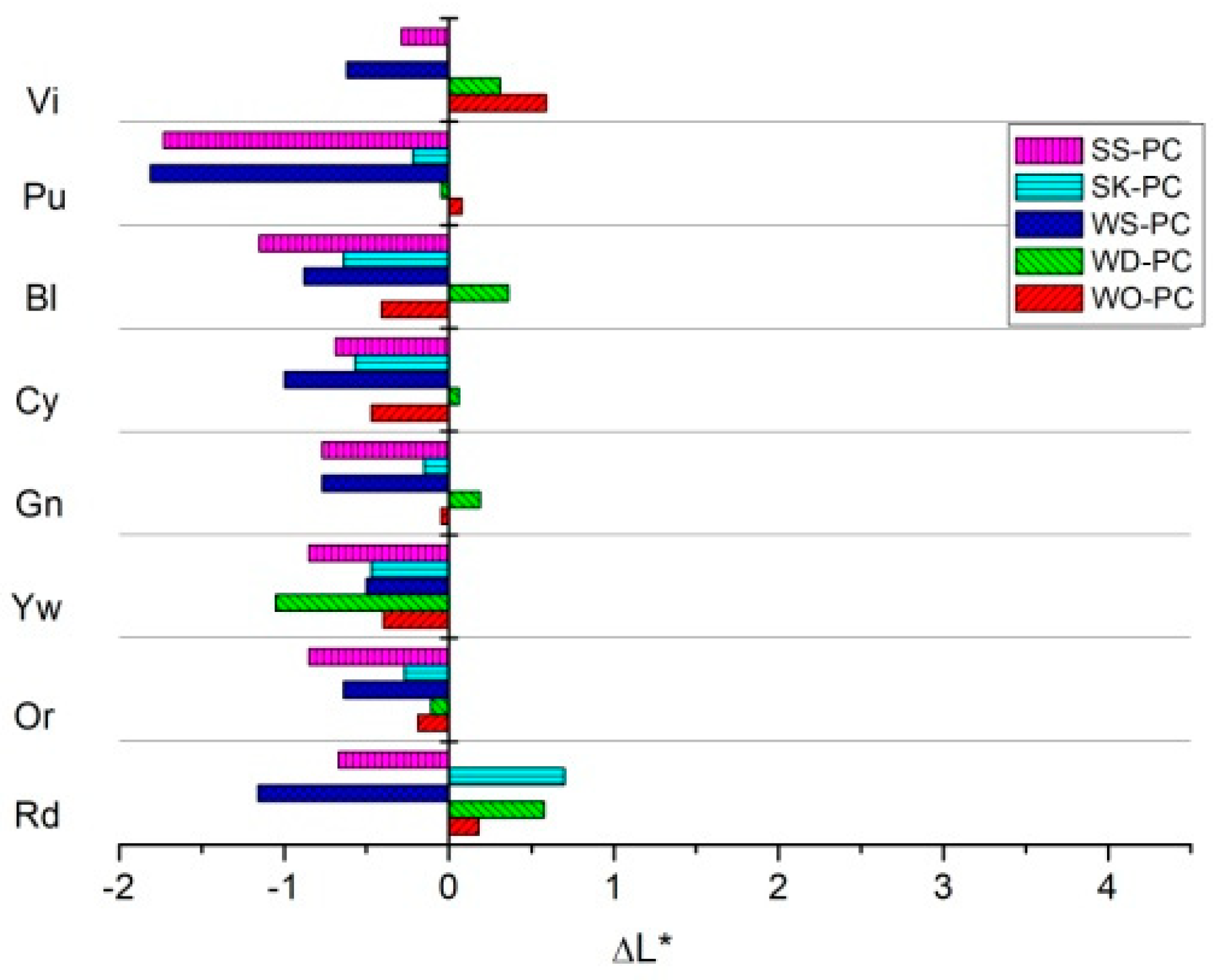

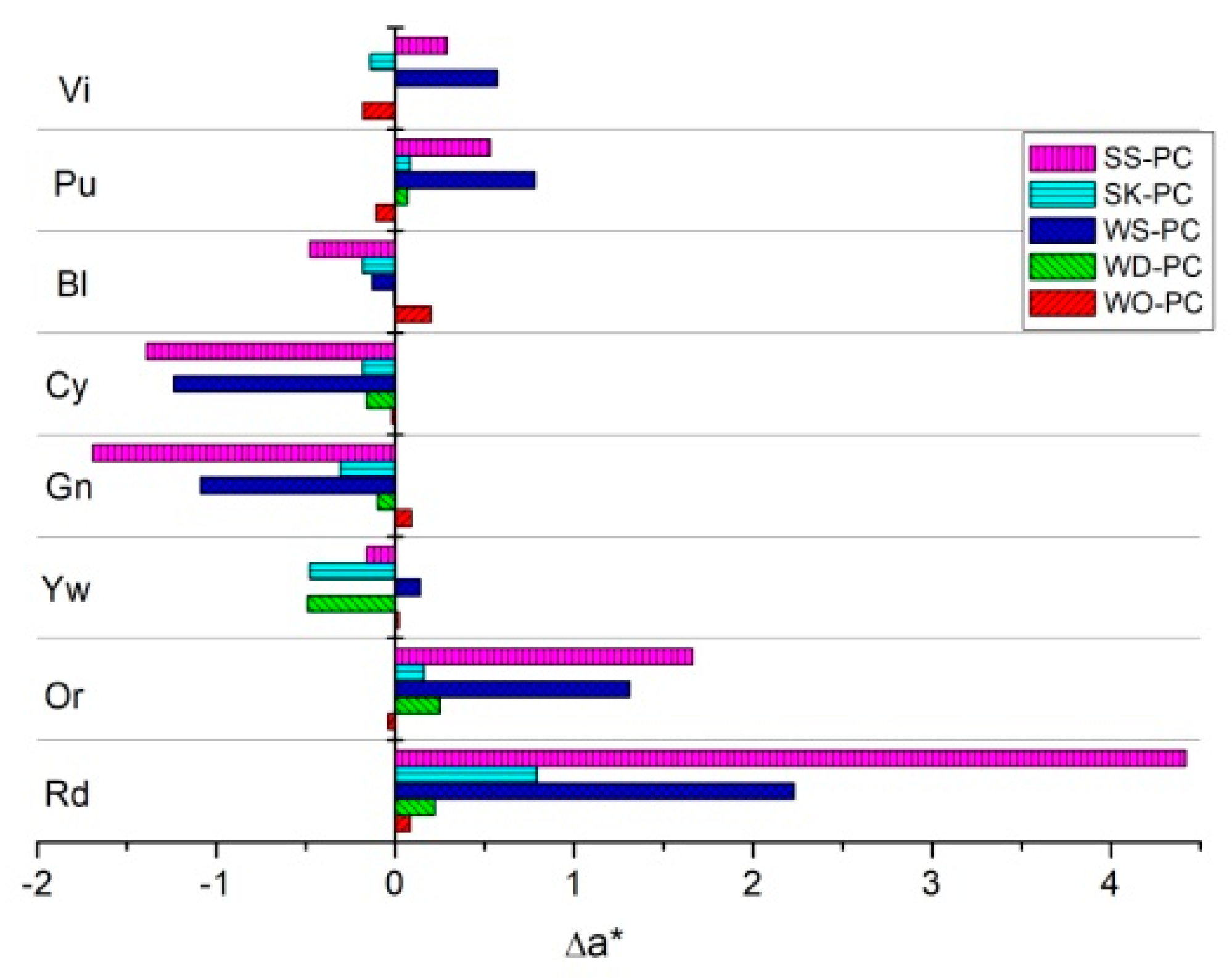

ab quantities, ΔL*, Δa*, and Δb* are plotted in

Figure 2,

Figure 3 and

Figure 4. In general, we cannot see systematic variations in the color coordinate values in the functions of the procedures adopted, and among these procedures, the worst are SS and WS. We can observe this in

Figure 2,

Figure 3 and

Figure 4. In particular, in

Figure 2, we observe negative ΔL* values for all standards until a value of 2 for the purple standard. Regarding Δa*,

Figure 3 shows meaningful red shift for the Vi, Pu, Or, and Rd standards, with values up to 4, and green shift for Bl, Cy, Gn, and Yw for the SS and WS procedures. The higher values of Δb* (up to 3.5) also observed in this case are related to the SS and WS procedures, and in particular, we see yellow shift for the Gn, Yw, Or, and Rd standards and blue shift for the Pu, Bl, Cy, and Vi ones (

Figure 4). Not only the lightness but also the color coordinates (a*, b*) are influenced by the use of different adjustment procedures, in some cases in a significant way.

Concerning the painting samples,

Table 6 and

Table 7 respectively report the color coordinates and the ΔE*

ab values calculated with the different scale adjustment procedures with respect to the PC one. Considering the thresholds discussed in

Section 2.3, like for the standard samples, the SS and WS procedures present higher values of ΔE*

ab. In general, with respect to the values reported in

Table 5 for standards, painting samples present higher values of ΔE*

ab that reach, in some cases (PC-WS and PC-SS), values greater than 5 [

24]. To better evaluate the contribution of each CIELAB coordinate to the color difference, ΔL*, Δa*, and Δb* are plotted in

Figure 5,

Figure 6 and

Figure 7.

Figure 5 shows positive ΔL* values for all procedures and for all hues. This behavior is totally different from that for the standards. Δa* presents significant red shift only for SS and WS for blue paintings and green shift for yellow and red ones (

Figure 6). SS and WS procedures, in comparison to PC, present significant blue shift for yellow and red samples (

Figure 7). The tendency found for the painting samples is different from that for the standards, for which the shifts are correlated with the hue. Furthermore, in relation to the standards, the absolute variations are greater for the painting samples. This evidence could be explained by considering the non-Lambertian surface of the laboratory samples and the possible influence of the egg tempera. In order to support this hypothesis, it would be necessary to increase the number of samples in order to have a statistically consistent number.

4. Conclusions

The aim of this research work was to contribute to the evaluation of the role played by scale adjustment on color measurement, with particular attention to color difference quantification. To evaluate the influence of scale adjustment, certified standards and painting samples were measured using a spectrophotometer. The results showed that during a colorimetric measurement campaign, together with other measurement conditions and parameters, the adjustment procedure must be indicated. In result communication, the omission of this important step in the colorimetric measurements could in fact lead to the reporting of color variations which are not “real” due to the use of different references for the reflectance maximum (white) and minimum (black) values.

The results from both certified standards and painting samples show nonsystematic uncertainty. This is important in the case of comparison of data acquired with different scale adjustment procedures at different times, which could invalid chromatic change evaluations. In all fields, especially in Cultural Heritage, this is a relevant issue, because it could have consequences in terms of conservation and restoration programs.

In relation to the standard procedure, performed using both white plate calibration and a black box device, WO is the procedure that ensured the highest reliability. All other possible procedures must be excluded.