Experimental and Numerical Investigations on the Parameters of a Synchronous Machine Prototype with High-Temperature Superconductor Armature Windings

Abstract

:1. Introduction

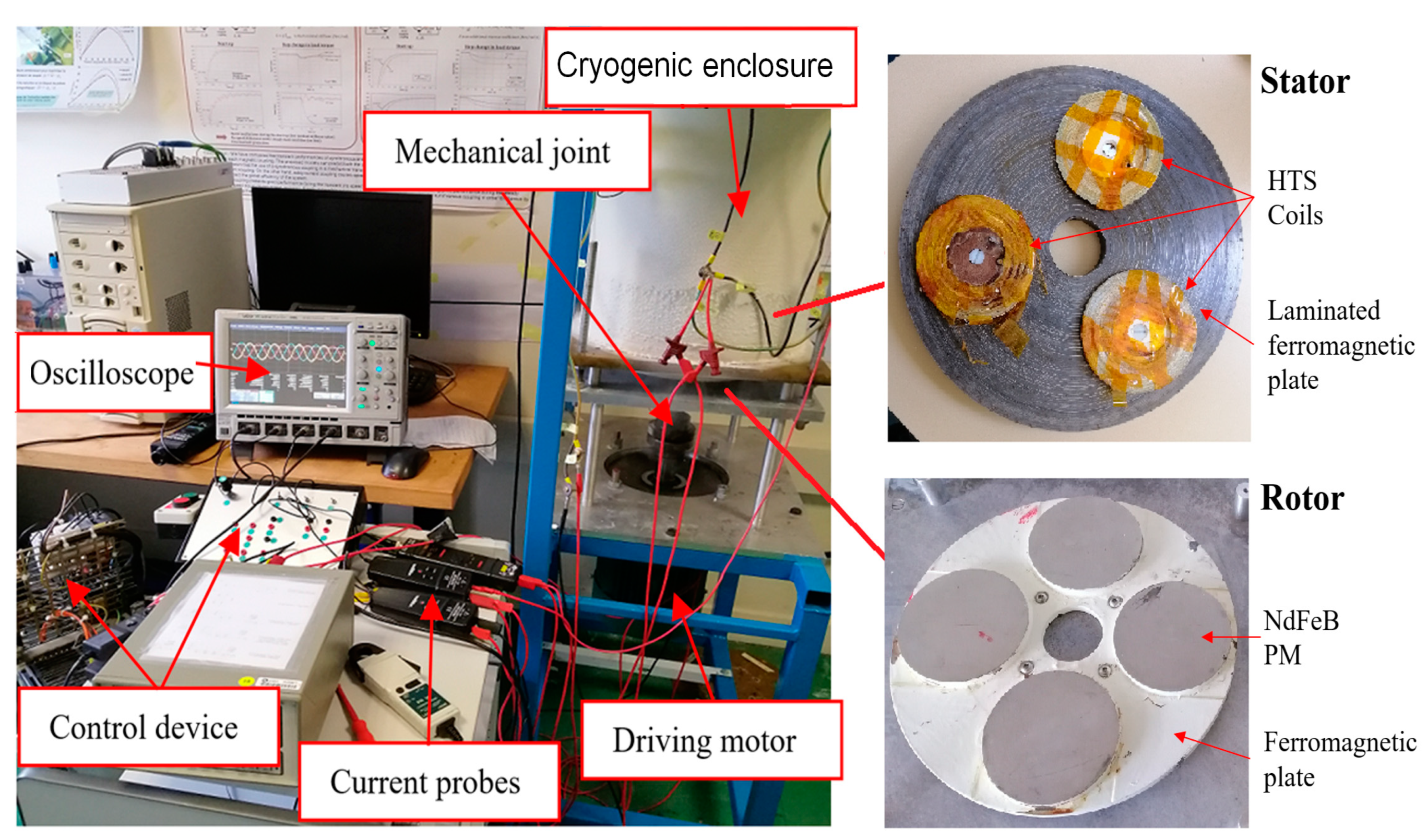

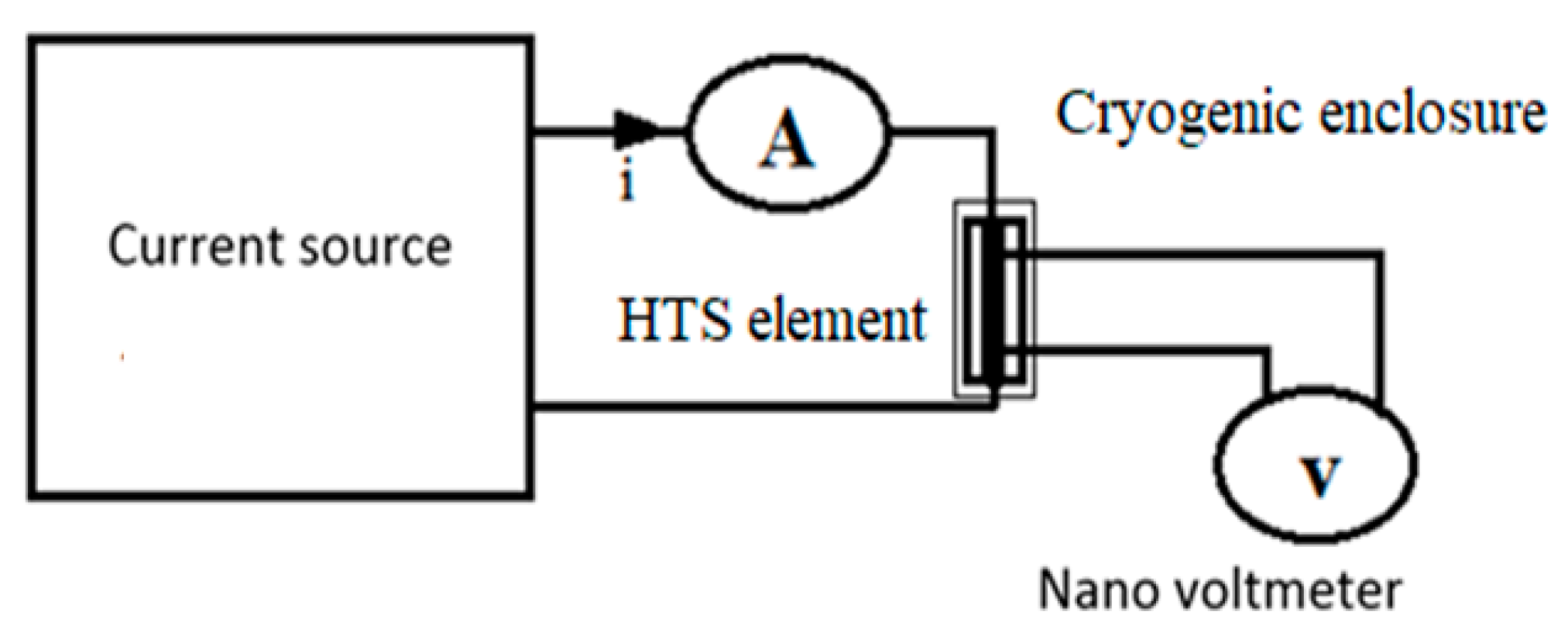

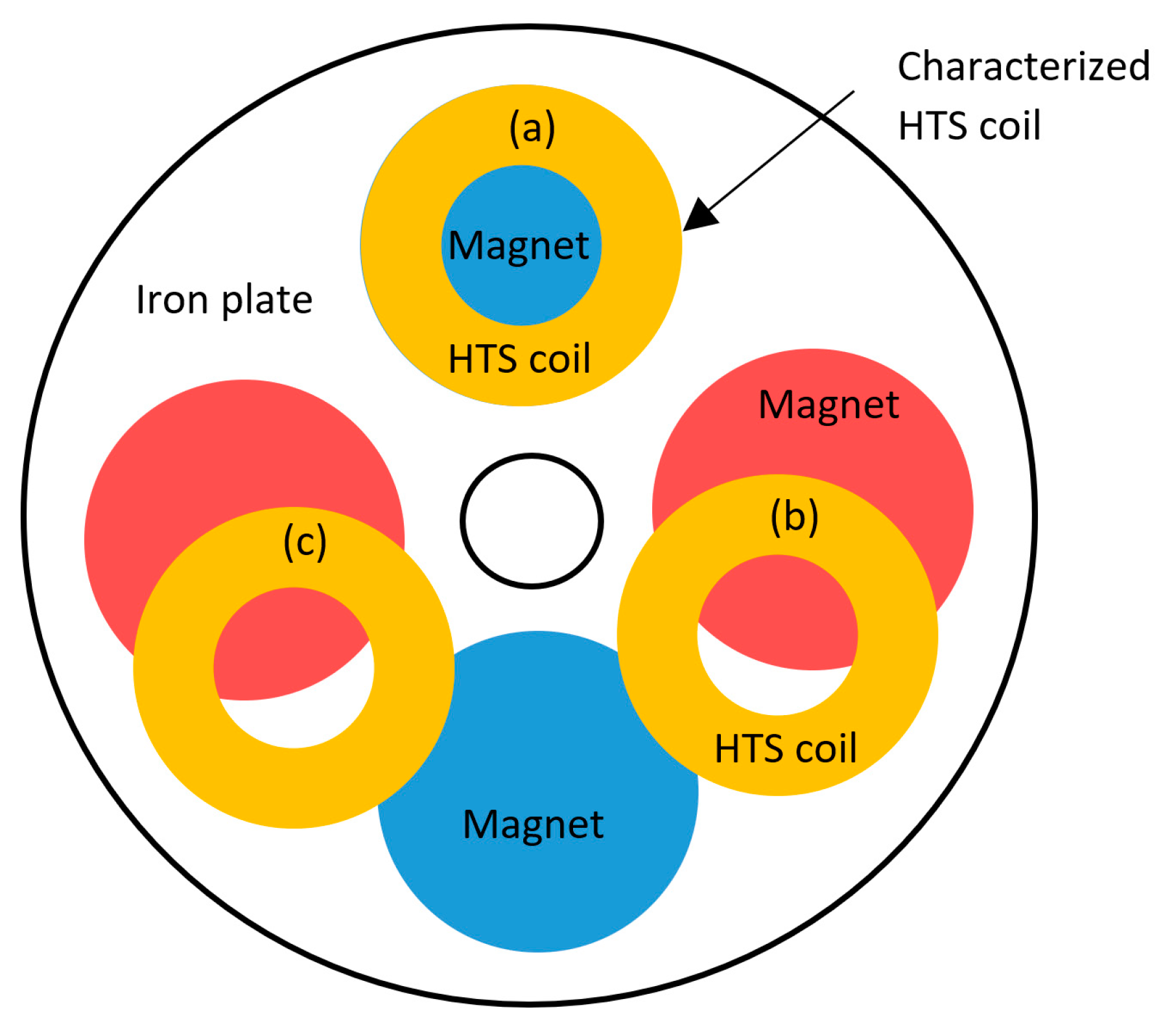

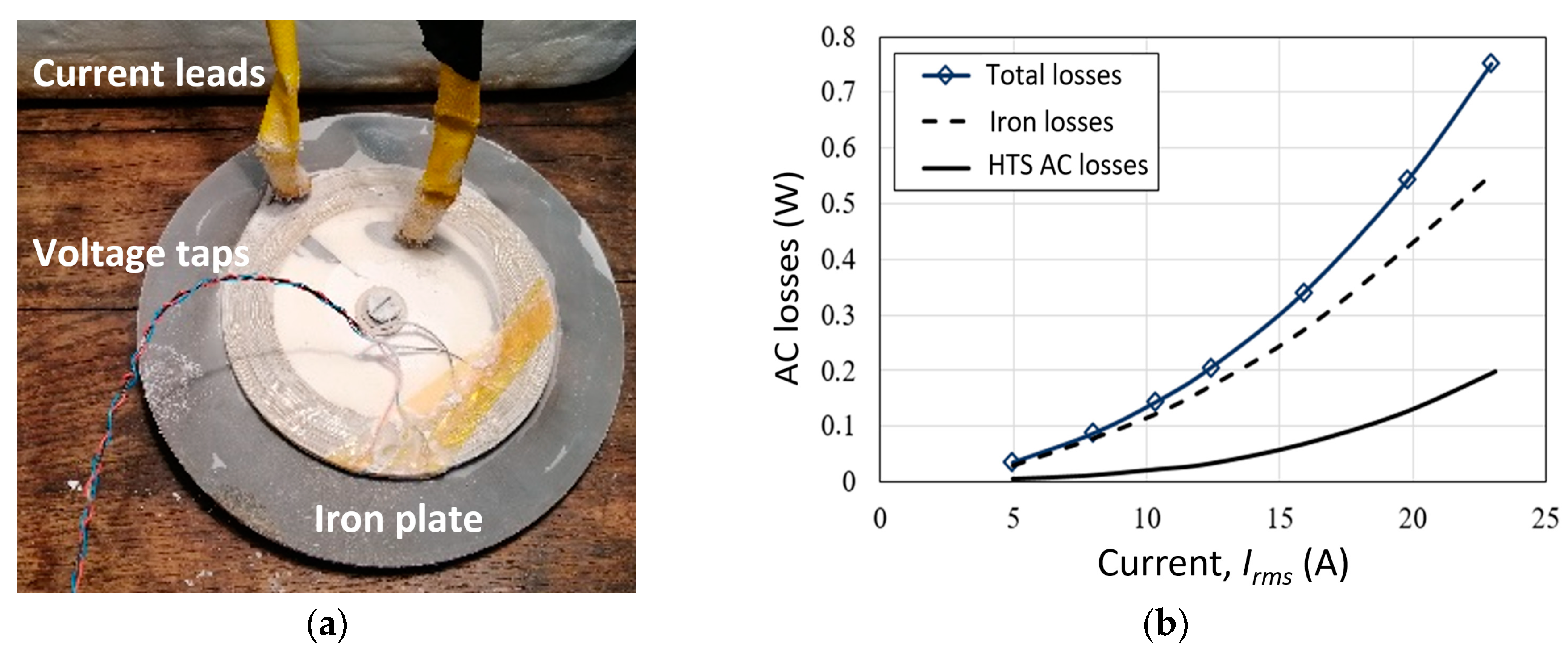

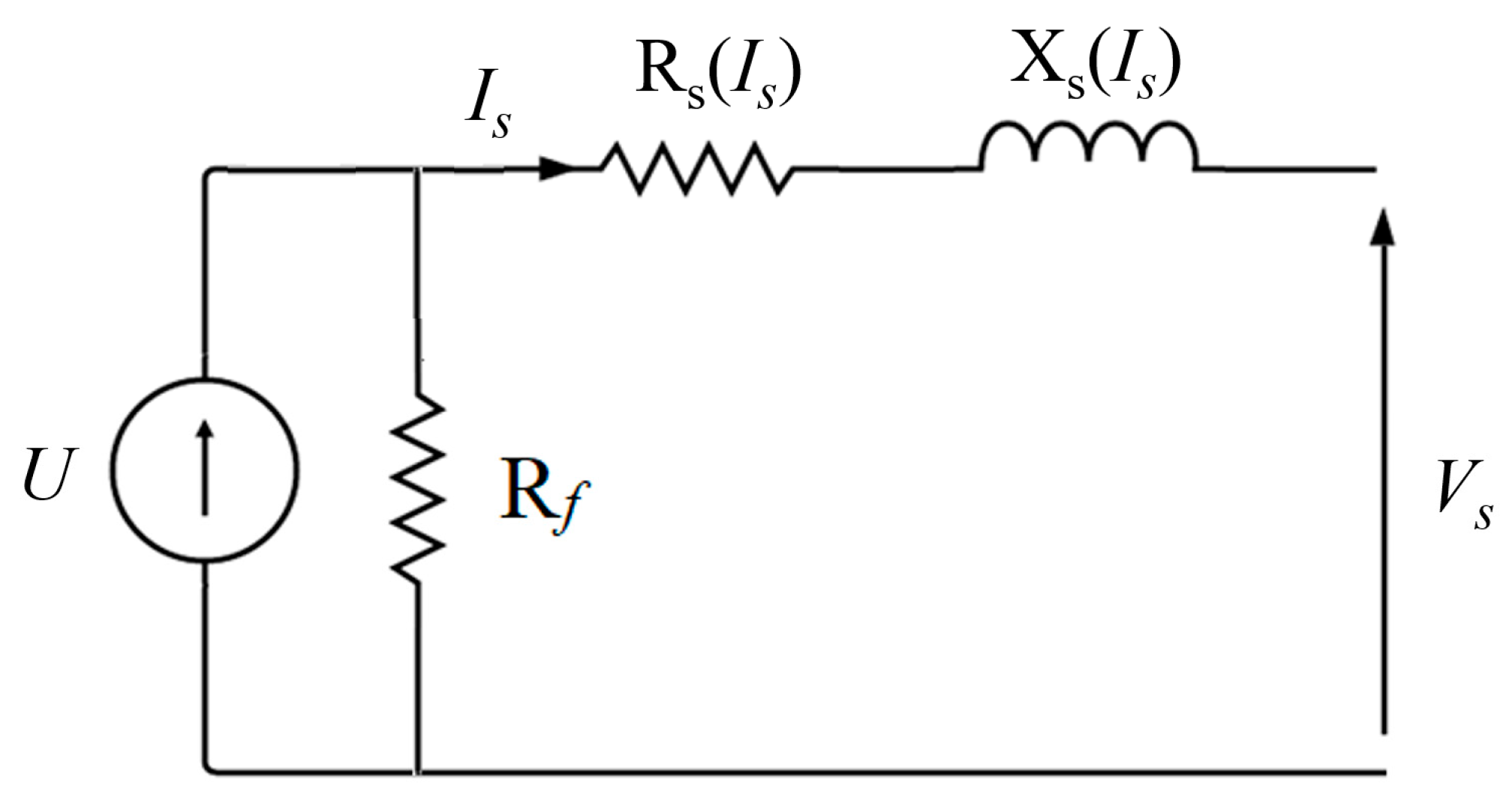

2. The HTS Synchronous Machine Prototype and Its Test Bench

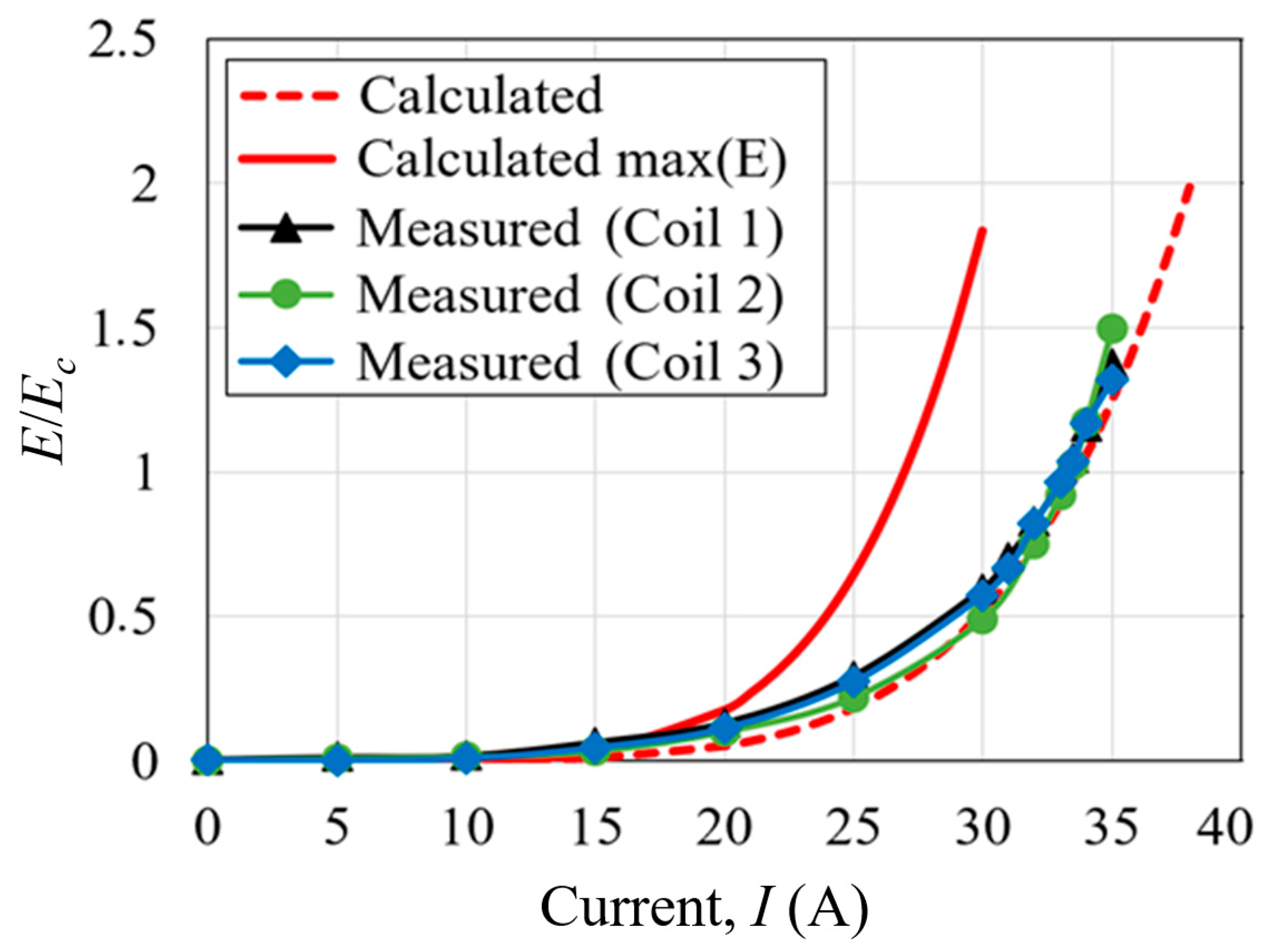

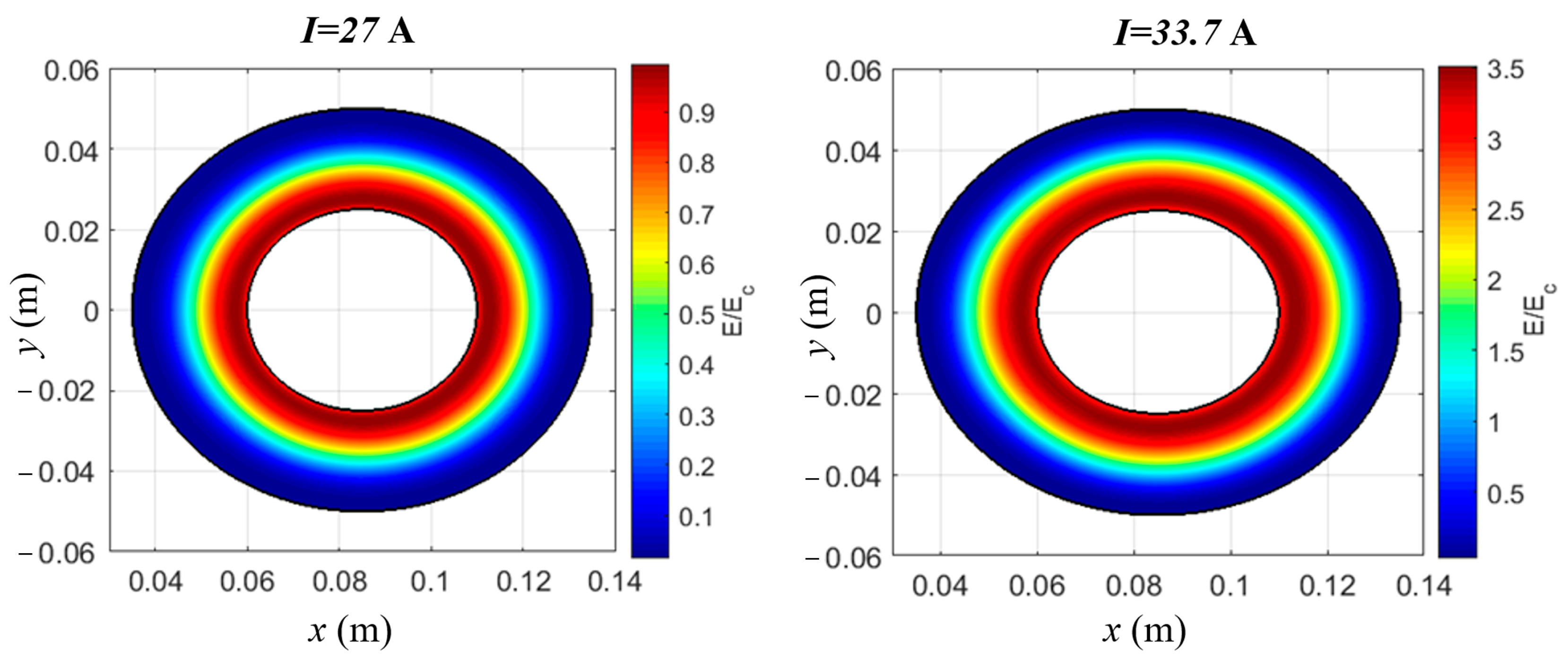

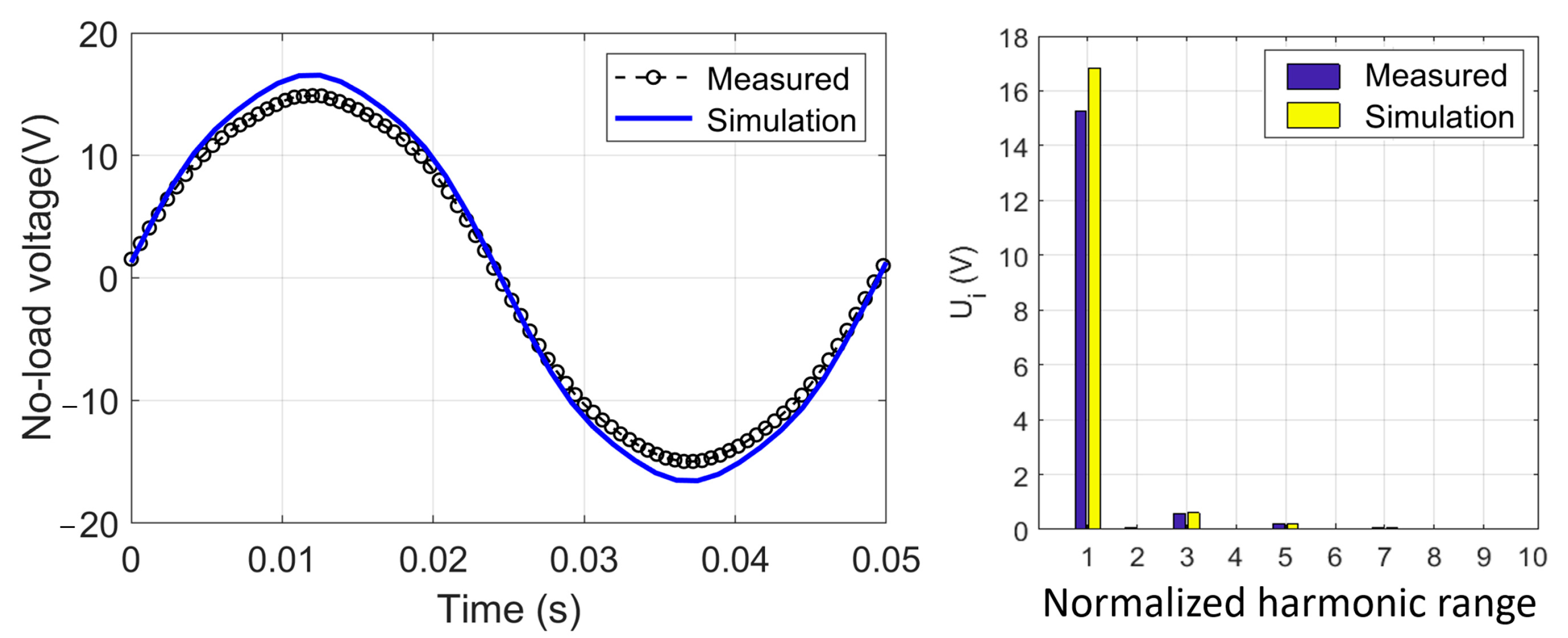

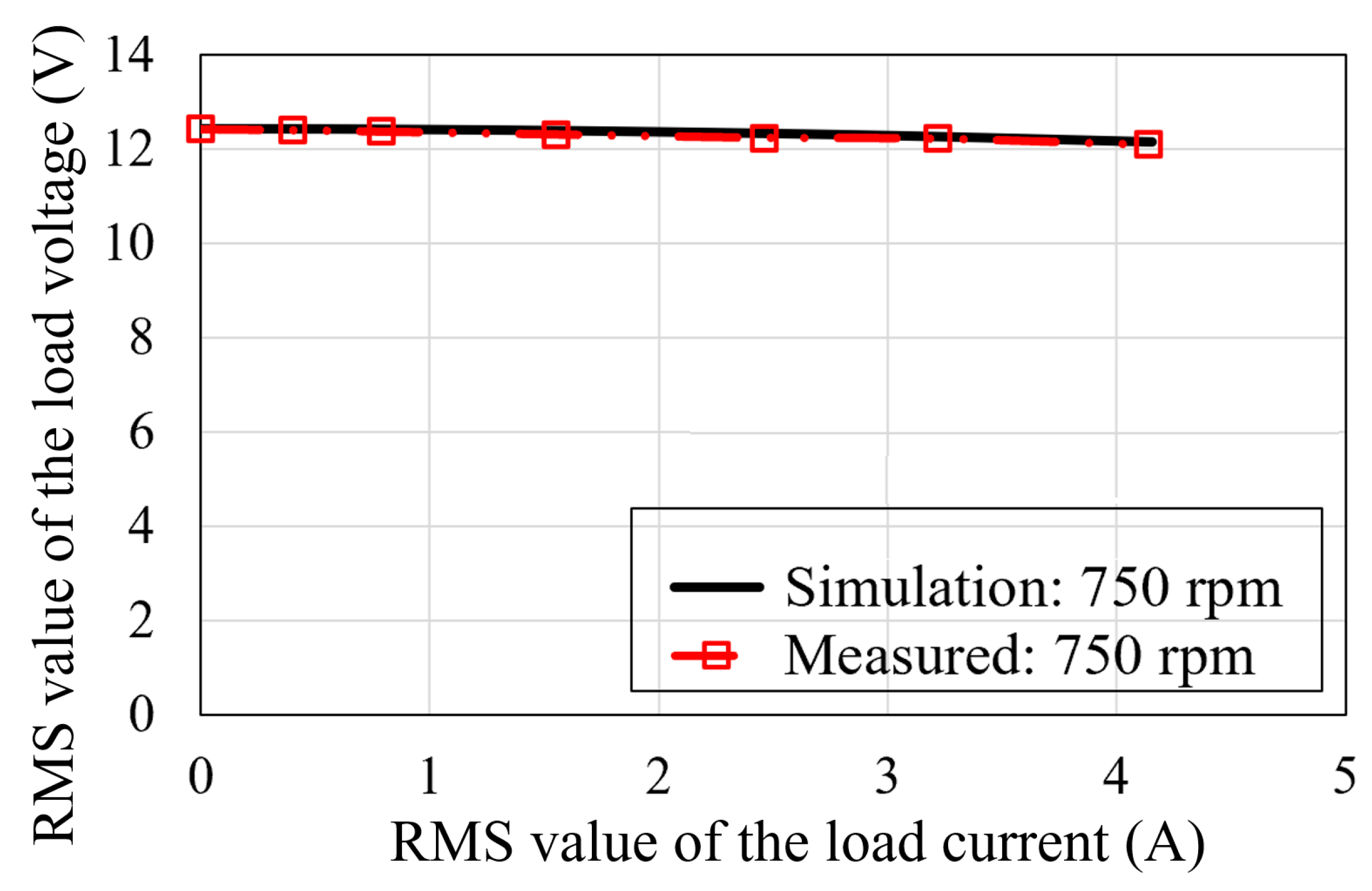

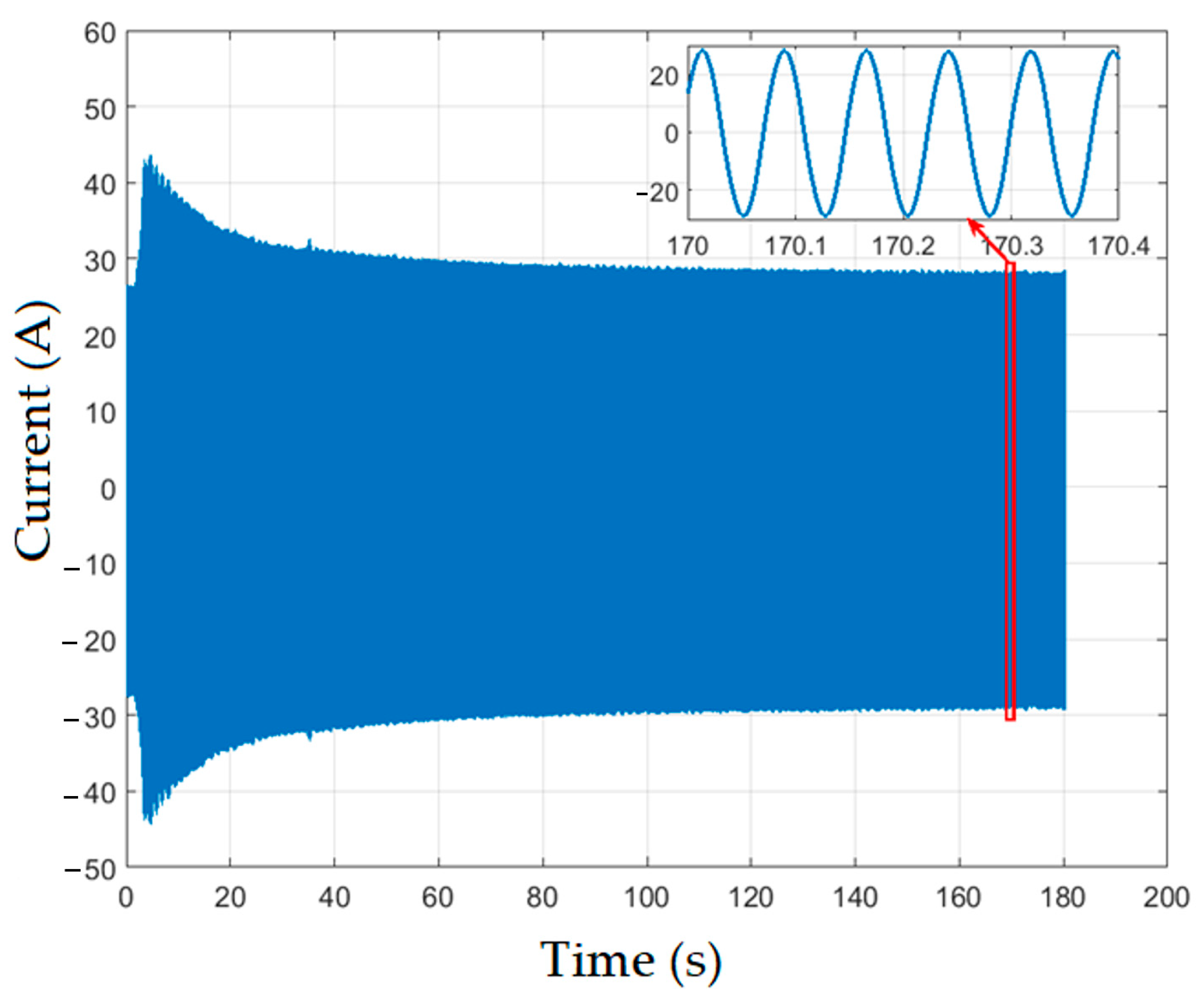

3. Numerical Modeling

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haran, K.S.; Kalsi, S.; Arndt, T.; Karmaker, H.; Badcock, R.; Buckley, B.; Haugan, T.; Izumi, M.; Loder, D.; Bray, J.W.; et al. High power density superconducting machines—Development status and technology roadmap. Supercond. Sci. Technol. 2017, 30, 123002. [Google Scholar] [CrossRef]

- Nick, W.; Frank, M.; Klaus, G.; Frauenhofer, J.; Neumuller, H.-W. Operational experience with the world’s first 3600 rpm 4 MVA generator at Siemens. IEEE Trans. Appl. Supercond. 2007, 17, 2030–2033. [Google Scholar] [CrossRef]

- Gamble, B.; Snitchler, G.; MacDonald, T. Full Power Test of a 36.5 MW HTS Propulsion Motor. IEEE Trans. Appl. Supercond. 2011, 21, 1083–1088. [Google Scholar] [CrossRef]

- Song, X.; Mijatovic, N.; Bührer, C.; Kellers, J.; Wiezoreck, J.; Krause, J.; Pütz, H.; Hansen, J.; Rebsdorf, A.V. Experimental Validation of a Full-Size Pole Pair Set-Up of an MW-Class Direct Drive Superconducting Wind Turbine Generator. IEEE Trans. Energy Convers. 2020, 35, 1120–1128. [Google Scholar] [CrossRef]

- Song, X.; Bührer, C.; Brutsaert, P.; Ammar, A.; Krause, J.; Bergen, A.; Winkler, T.; Dhalle, M.; Hansen, J.; Rebsdorf, A.V.; et al. Ground Testing of the World’s First MW-Class Direct-Drive Superconducting Wind Turbine Generator. IEEE Trans. Energy Convers. 2020, 35, 757–764. [Google Scholar] [CrossRef]

- Song, X.; Bührer, C.; Mølgaard, A.; Andersen, R.S.; Brutsaert, P.; Bauer, M.; Hansen, J.; Rebsdorf, A.V.; Kellers, J.; Winkler, T.; et al. Commissioning of the World’s First Full-Scale MW-Class Superconducting Generator on a Direct Drive Wind Turbine. IEEE Trans. Energy Convers. 2020, 35, 1697–1704. [Google Scholar] [CrossRef]

- Xian, W.; Yan, Y.; Yuan, W.; Pei, R.; et Coombs, T.A. Pulsed field magnetization of a high temperature superconducting motor. IEEE Trans. Appl. Supercond. 2011, 21, 1171–1174. [Google Scholar] [CrossRef]

- Berger, K.; Kapek, J.; Colle, A.; Grzesik, M.S.B.; Lubin, T.; Lévêque, J. 3-D Modeling of Coils for Pulsed Field Magnetization of HTS Bulk Pellets in an Electrical Machine. IEEE Trans. Appl. Supercond. 2018, 28, 6801205. [Google Scholar] [CrossRef]

- Alhasan, R.; Lubin, L.; Adilov, Z.M.; Lévêque, J. A New Kind of Superconducting Machine. IEEE Trans. Appl. Supercond. 2016, 26, 5203604. [Google Scholar] [CrossRef]

- Colle, A.; Lubin, L.; Ayat, S.; Gosselin, O.; Lévêque, J. Analytical Model for the Magnetic Field Distribution in a Flux Modulation Superconducting Machine. IEEE Trans. Magn. 2019, 55, 9000415. [Google Scholar] [CrossRef]

- Sekiguchi, D.; Nakamura, T.; Misawa, S.; Kitano, H.; Matsuo, T.; Amemiya, N.; Ito, Y.; Yoshikawa, M.; Terazawa, T.; Osamura, K.; et al. Trial Test of Fully HTS Induction/Synchronous Machine for Next Generation Electric Vehicle. IEEE Trans. Appl. Supercond. 2012, 22, 5200904. [Google Scholar] [CrossRef]

- Kovalev, K.; Ivanov, N.; Zhuravlev, S.; Nekrasova, J.; Rusanov, D.; Kuznetsov, G. Development and testing of 10 kW fully HTS generator. J. Phys. Conf. Ser. 2020, 1559, 012137. [Google Scholar] [CrossRef]

- Sugimoto, H.; Tsuda, T.; Morishita, T.; Hondou, Y.; Takeda, T.; Togawa, H.; Oota, T.; Ohmatsu, K.; Yoshida, S. Development of an Axial Flux Type PM Synchronous Motor With the Liquid Nitrogen Cooled HTS Armature Windings. IEEE Trans. Appl. Supercond. 2007, 17, 1637–1640. [Google Scholar] [CrossRef]

- Song, P.; Qu, T.; Yu, X.; Li, L.; Gu, C.; Li, X.; Wang, D.; Hu, B.; Chen, D.; Han, Z. Loss measurement and analysis for the prototype generator with HTS stator and permanent magnet rotor. Phys. C Supercond. 2013, 494, 225–229. [Google Scholar] [CrossRef]

- Qu, T.; Song, P.; Yu, X.; Gu, C.; Li, L.; Li, X.; Wang, D.; Hu, B.; Chen, D.; Zeng, P.; et al. Development and testing of a 2.5 kW synchronous generator with a high temperature superconducting stator and permanent magnet rotor. Supercond. Sci. Technol. 2014, 27, 044026. [Google Scholar] [CrossRef]

- Messina, G.; Tamburo De Bella, E.; Morici, L. HTS Axial Flux Permanent Magnets Electrical Machine Prototype: Design and Test Results. IEEE Trans. Appl. Supercond. 2019, 29, 5200605. [Google Scholar] [CrossRef]

- Grilli, F.; Kario, A. How filaments can reduce AC losses in HTS coated conductors: A review. Supercond. Sci. Technol. 2016, 29, 083002. [Google Scholar] [CrossRef]

- Statra, Y.; Menana, H.; Douine, B.; Lubin, T. Axial-Field Synchronous Machine With HTS Armature Windings: Realization and Preliminary Tests. IEEE Trans. Appl. Supercond. 2022, 32, 5200405. [Google Scholar] [CrossRef]

- Kikuchi, M.; Ayai, N.; Ishida, T.; Tatamidani, K.; Hayashi, K.; Kobayashi, S.; Ueno, E.; Yamazaki, K.; Yamade, S.; Takaaze, H.; et al. Development of New Types of DI-BSCCO Wire. SEI Tech. Rev. 2008, 66, 73–79. [Google Scholar]

- Statra, Y.; Fawaz, S.; Menana, H.; Douine, B. Experimental Electromagnetic Characterization of High Temperature Superconductors Coils Located in Proximity to Electromagnetically Active Materials. Fluid Dyn. Mater. Process 2022, 18, 1529–1537. [Google Scholar] [CrossRef]

- Statra, Y.; Menana, H.; Belguerras, L.; Douine, B. A volume integral approach for the modelling and design of HTS coils. Compel 2019, 38, 1133–1140. [Google Scholar] [CrossRef]

- Statra, Y.; Menana, H.; Douine, B. Integral Modeling of AC Losses in HTS Tapes with Magnetic Substrates. IEEE Trans. Appl. Supercond. 2022, 32, 5900407. [Google Scholar]

- Li, Y.; Jiang, Z.; Sidorov, G.; Koraua, R.; Sogabe, Y.; Amemiya, N. AC Loss Measurement in HTS Coil Windings Coupled with Iron Core. IEEE Trans. Appl. Supercond. 2019, 29, 4701805. [Google Scholar]

- Fukui, S.; Tsukamoto, S.; Nohara, K.; Ogawa, J.; Sato, T.; Nakamura, T. Study on AC Loss Reduction in HTS Coil for Armature Winding of AC Rotating Machines. IEEE Trans. Appl. Supercond. 2016, 26, 5203705. [Google Scholar] [CrossRef]

- Fukui, S.; Ogawa, J.; Takahashi, J.; Kobu, Y.; Sato, T.; Nakamura, T. Study on AC Loss Characteristics of 3-Phase HTS Coils with Iron Core and Its Reduction. IEEE Trans. Appl. Supercond. 2019, 29, 8201305. [Google Scholar] [CrossRef]

| Parameter | Value | |

|---|---|---|

| BSCCO tape | Ic @ 77 K (self-field) | 70 A |

| Width/Thickness | 2.8/0.33 mm | |

| HTS coils | Ic @ 77 K (self-field) | 43.3 A |

| Number of turns | 63 | |

| Inner/outer radii | 25/50 mm | |

| Thickness | 3.1 mm | |

| Nd-Fe-B magnets | Remanence | 1.25 T |

| Radius/Thickness | 50/10 mm | |

| Armature iron yoke | Thickness | 20 mm |

| Inner/outer radii | 25/152 mm | |

| Rotor iron yoke | Thickness | 10 mm |

| Inner/outer radii | 25/140 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menana, H.; Statra, Y. Experimental and Numerical Investigations on the Parameters of a Synchronous Machine Prototype with High-Temperature Superconductor Armature Windings. Condens. Matter 2023, 8, 94. https://doi.org/10.3390/condmat8040094

Menana H, Statra Y. Experimental and Numerical Investigations on the Parameters of a Synchronous Machine Prototype with High-Temperature Superconductor Armature Windings. Condensed Matter. 2023; 8(4):94. https://doi.org/10.3390/condmat8040094

Chicago/Turabian StyleMenana, Hocine, and Yazid Statra. 2023. "Experimental and Numerical Investigations on the Parameters of a Synchronous Machine Prototype with High-Temperature Superconductor Armature Windings" Condensed Matter 8, no. 4: 94. https://doi.org/10.3390/condmat8040094

APA StyleMenana, H., & Statra, Y. (2023). Experimental and Numerical Investigations on the Parameters of a Synchronous Machine Prototype with High-Temperature Superconductor Armature Windings. Condensed Matter, 8(4), 94. https://doi.org/10.3390/condmat8040094