Experimental Study of Particle Interactions in Moderate to Dense Granular Shear Flows of Disks

Abstract

:1. Introduction

2. Materials and Methods

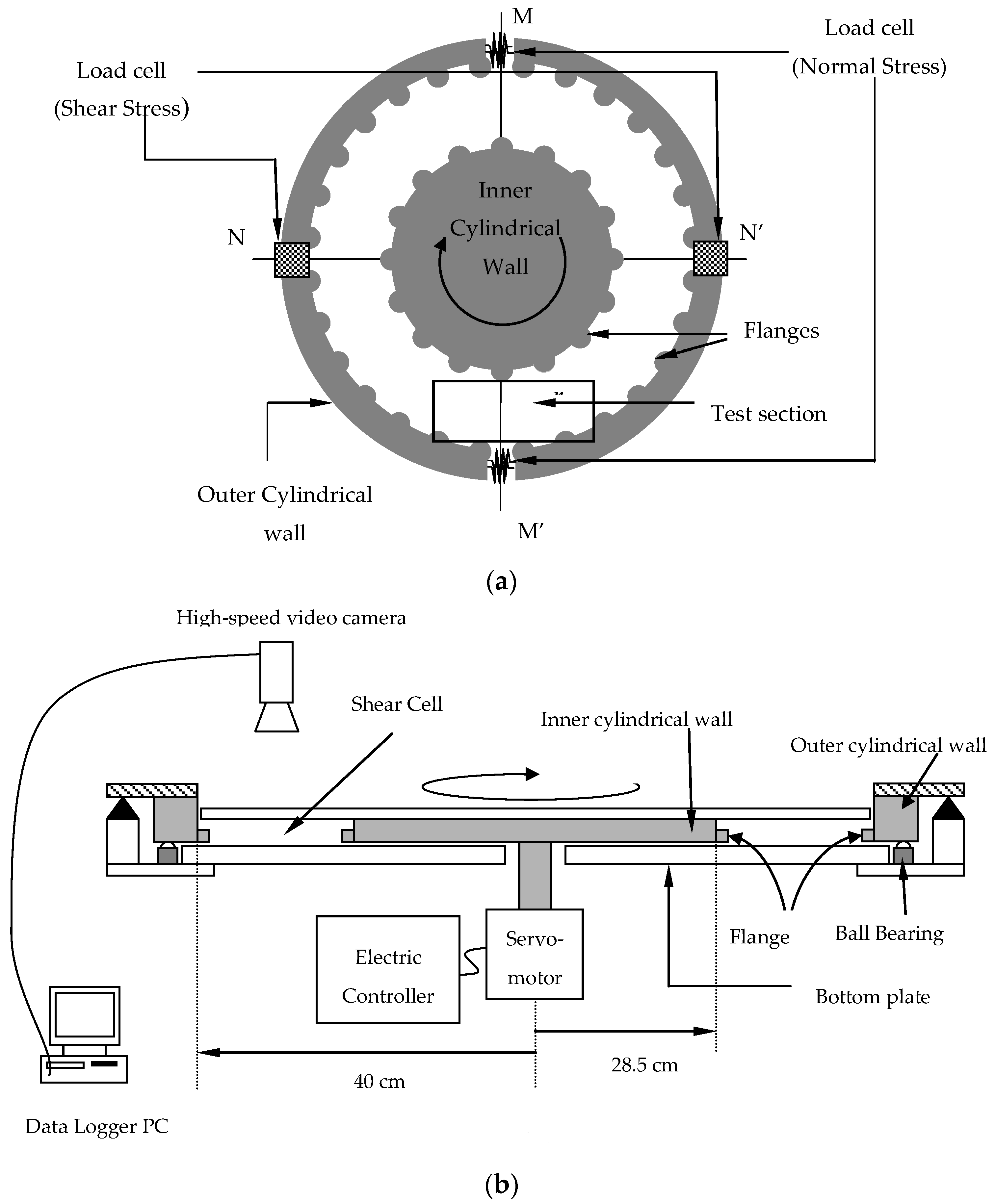

2.1. Shear Cell and Particles

2.2. Particle Tracking

2.3. Algorithms to Find Contact Properties

2.3.1. Collision-Detection Algorithm

2.3.2. Contact Duration

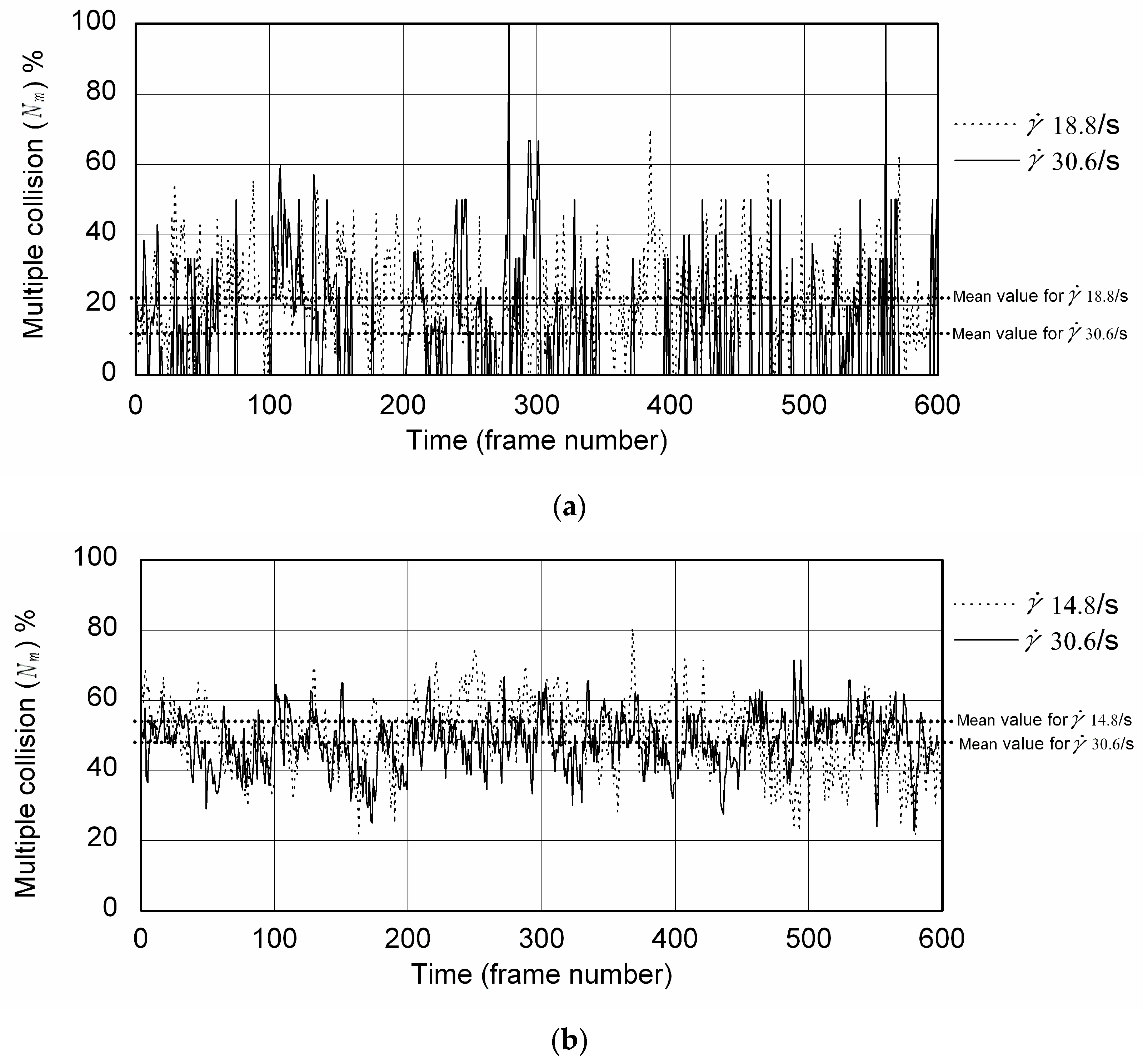

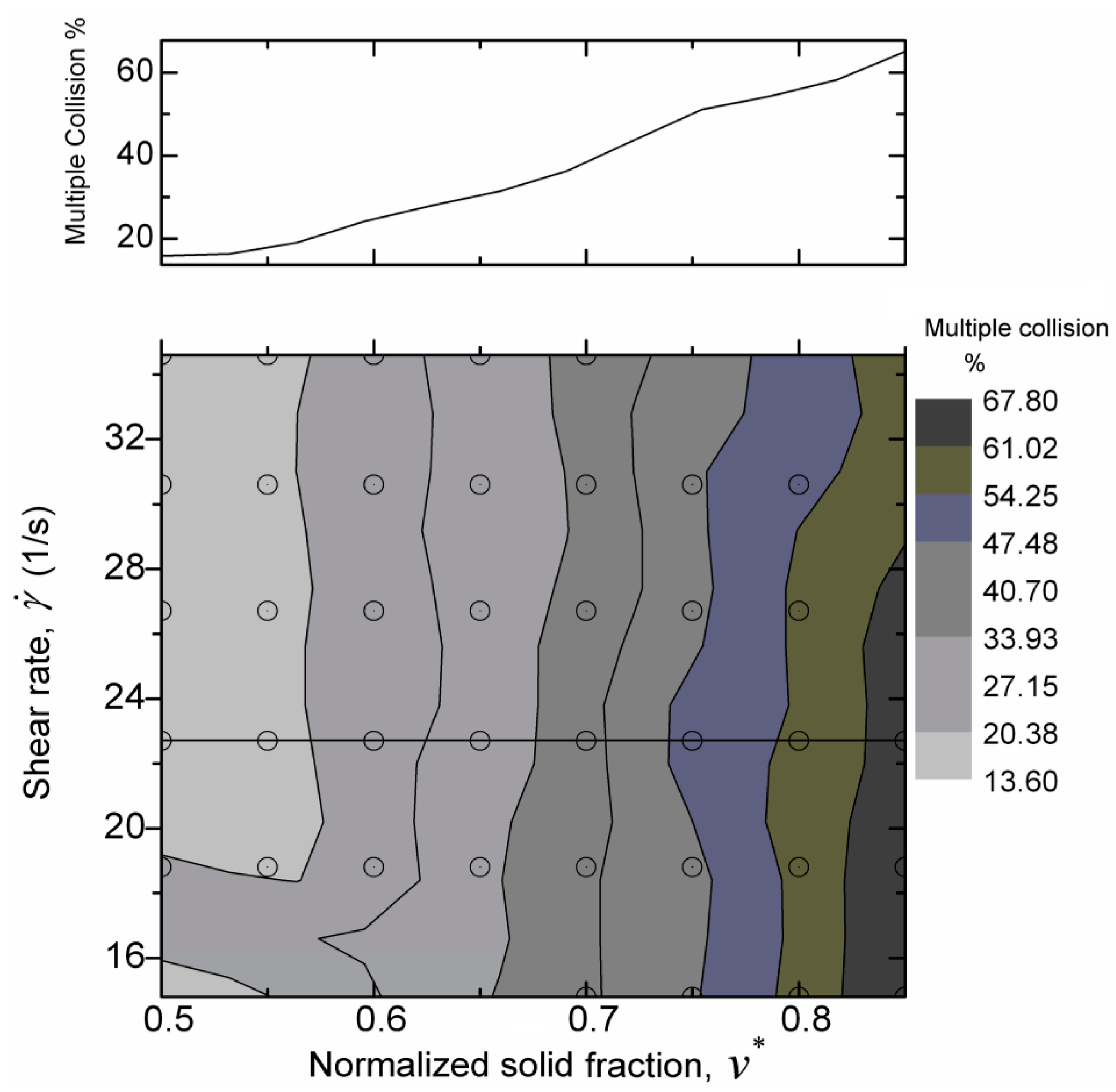

2.3.3. Multiple Collision Percentage

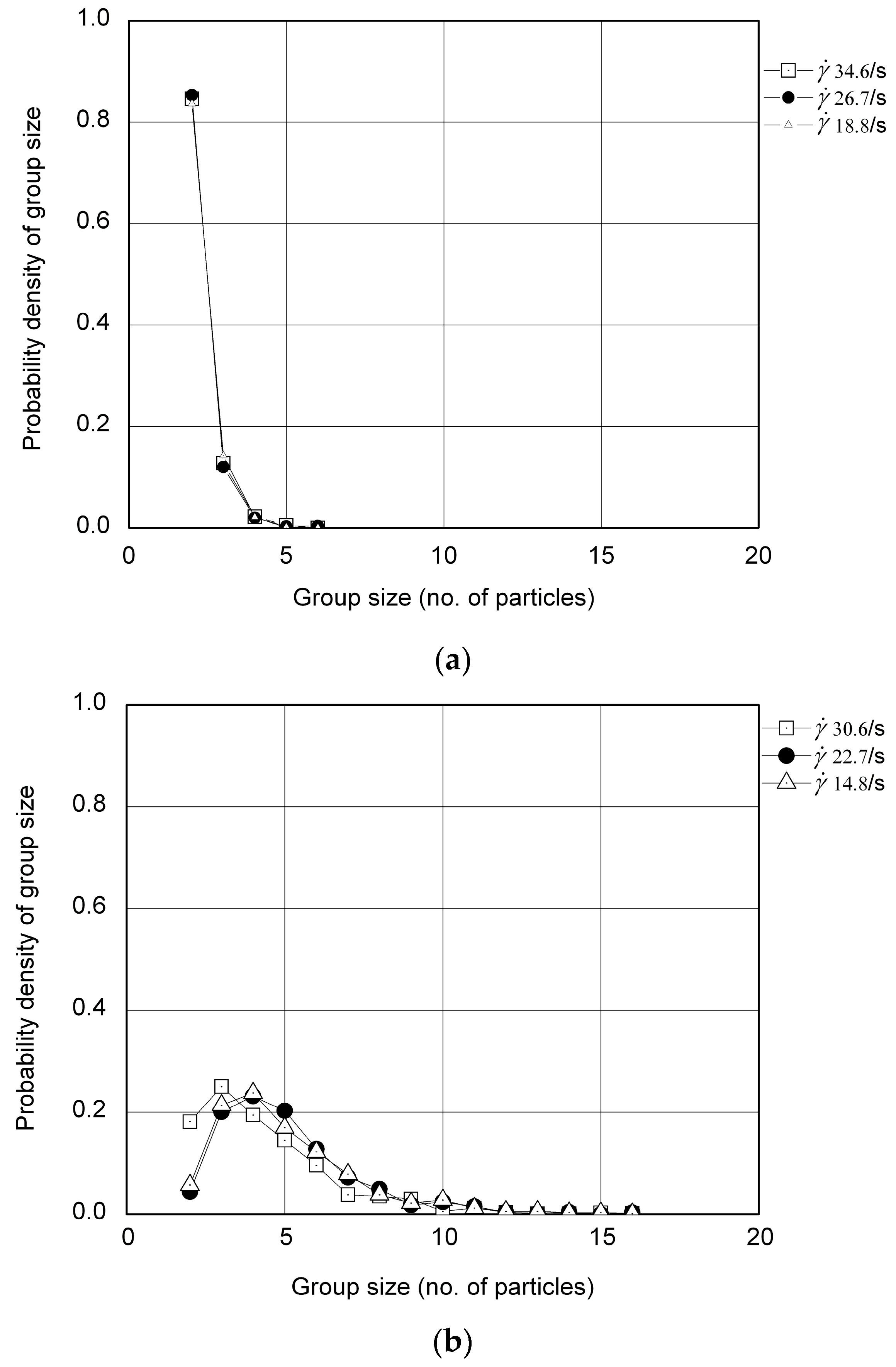

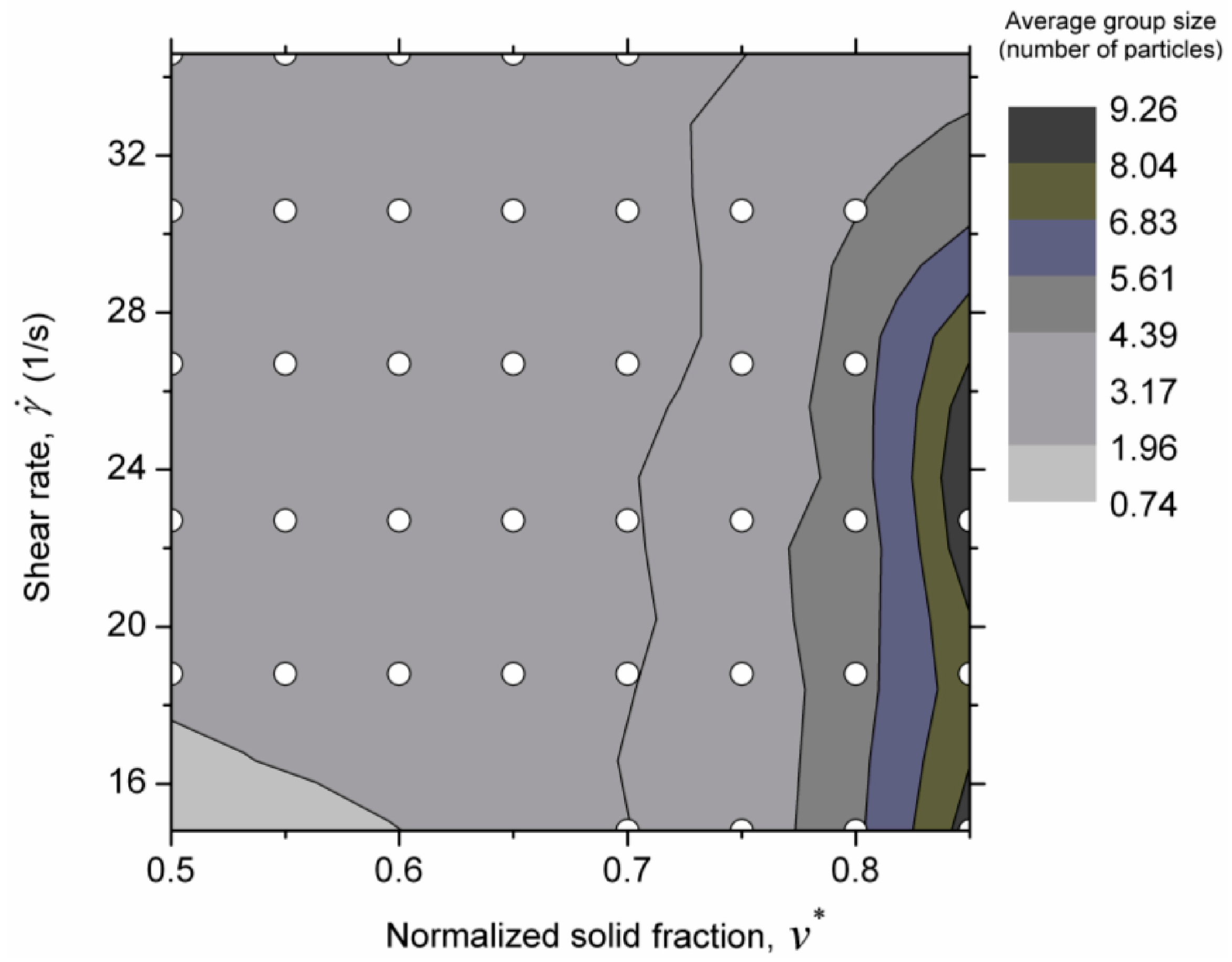

2.3.4. Group Size

3. Experimental Results

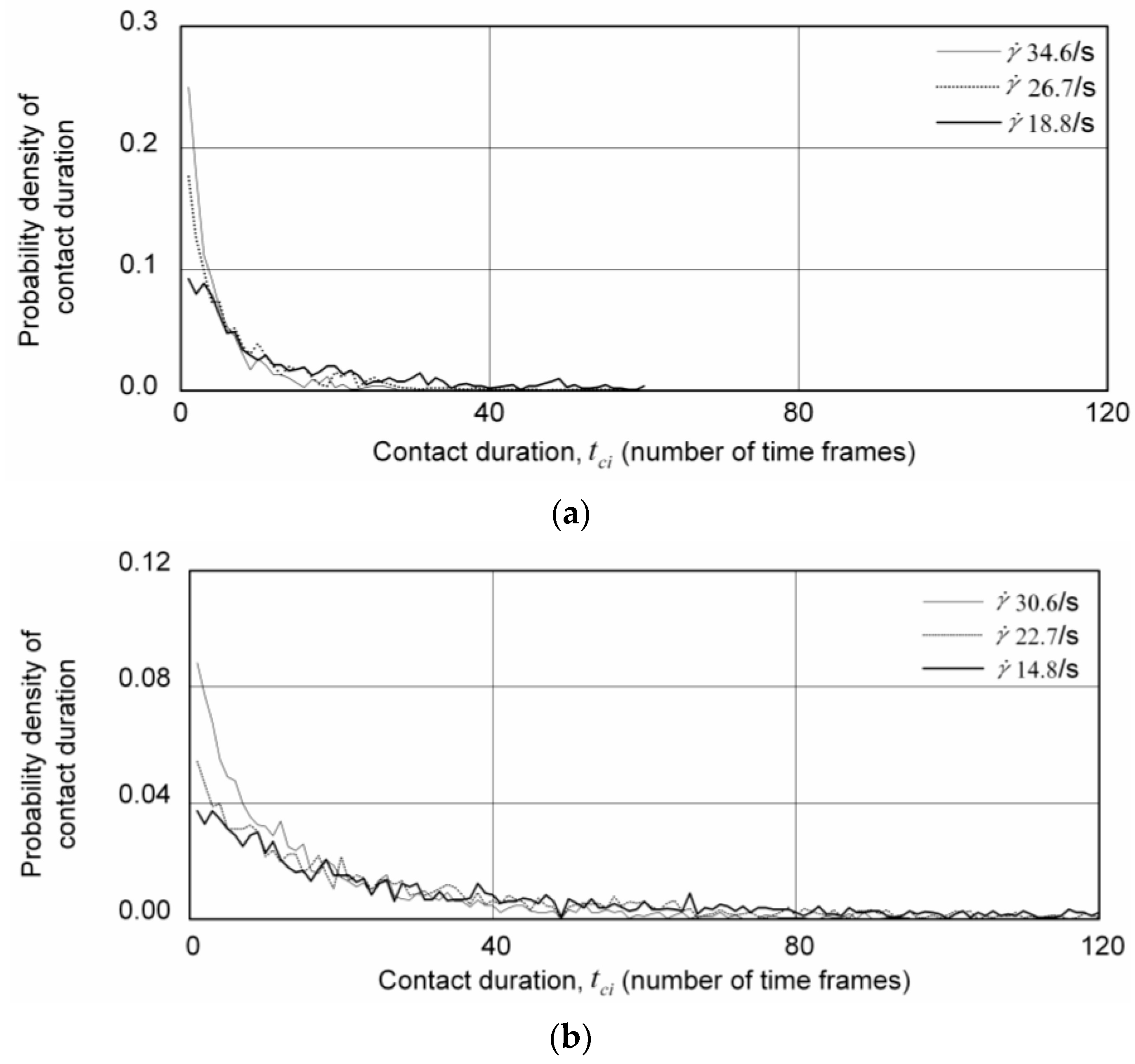

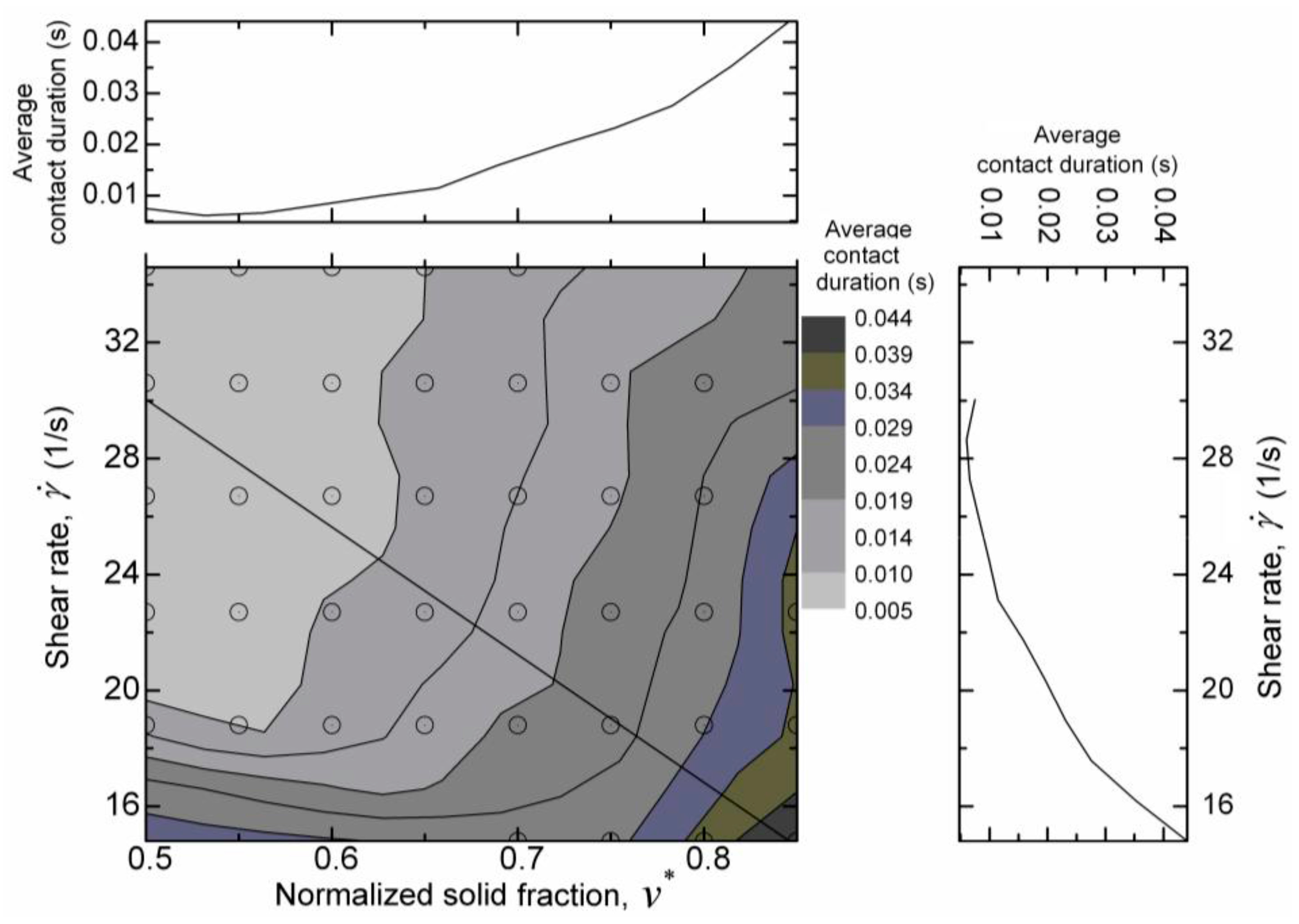

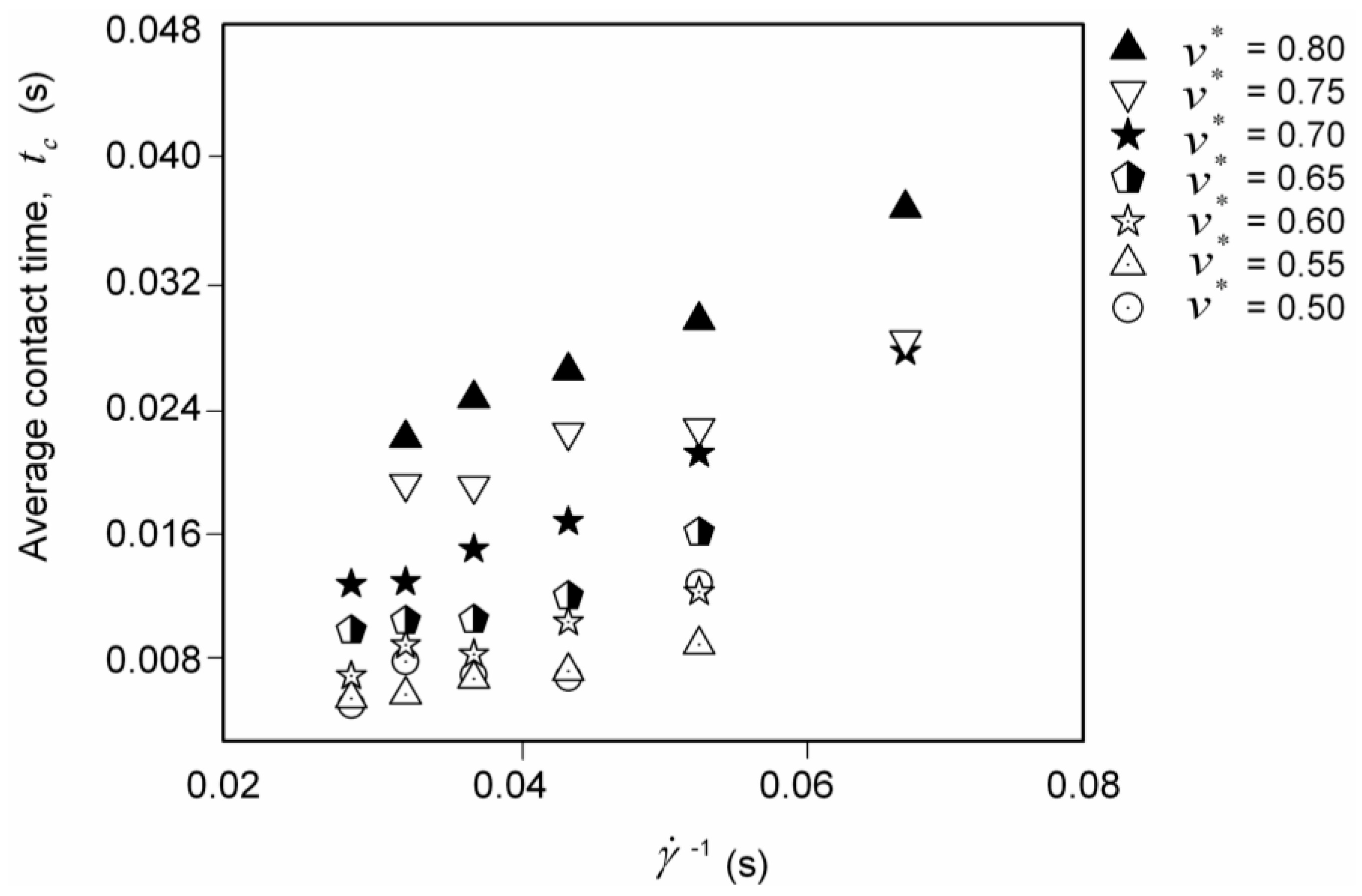

3.1. Particle-Particle Interaction Time

3.2. Length Scale of Multi-Particle Interaction

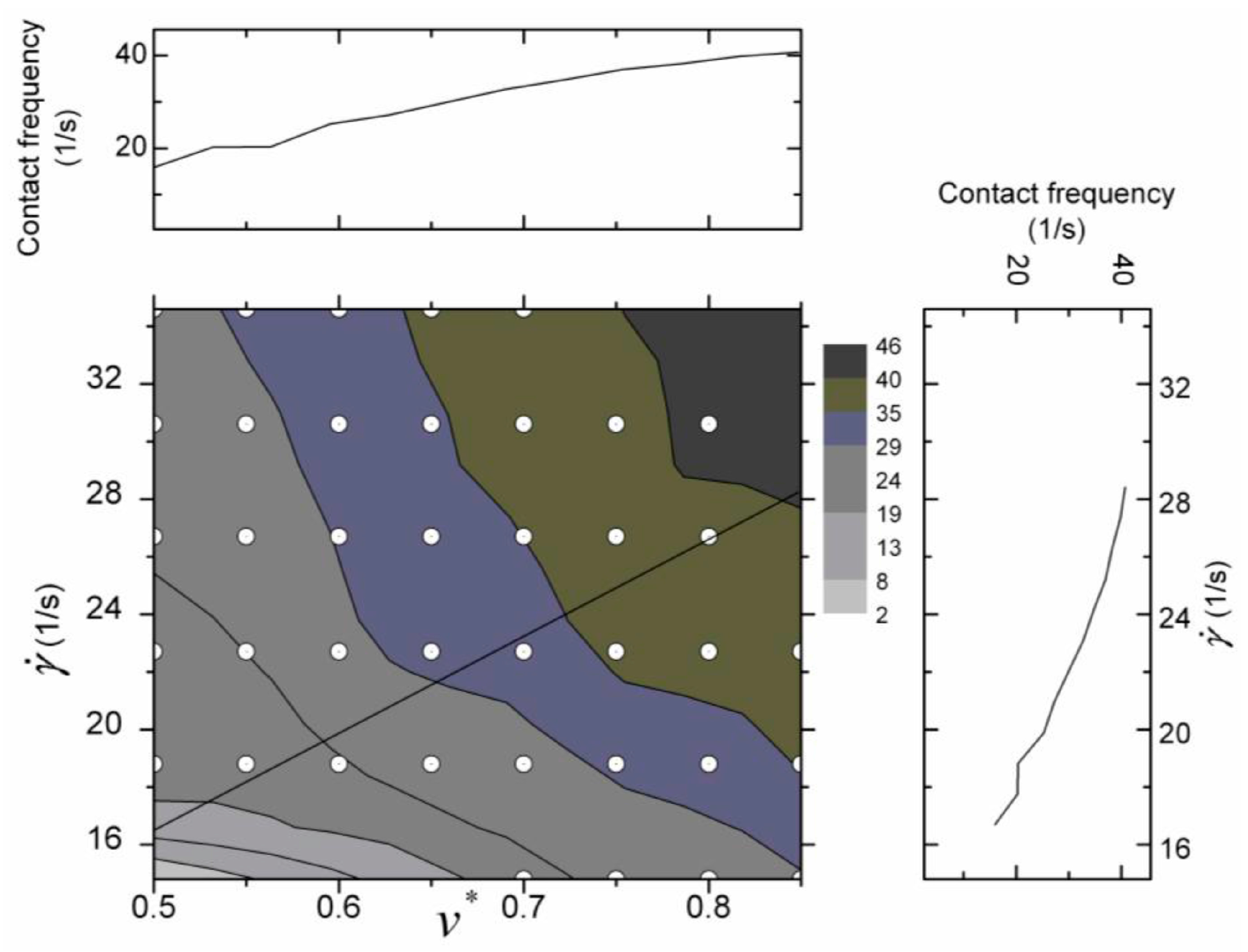

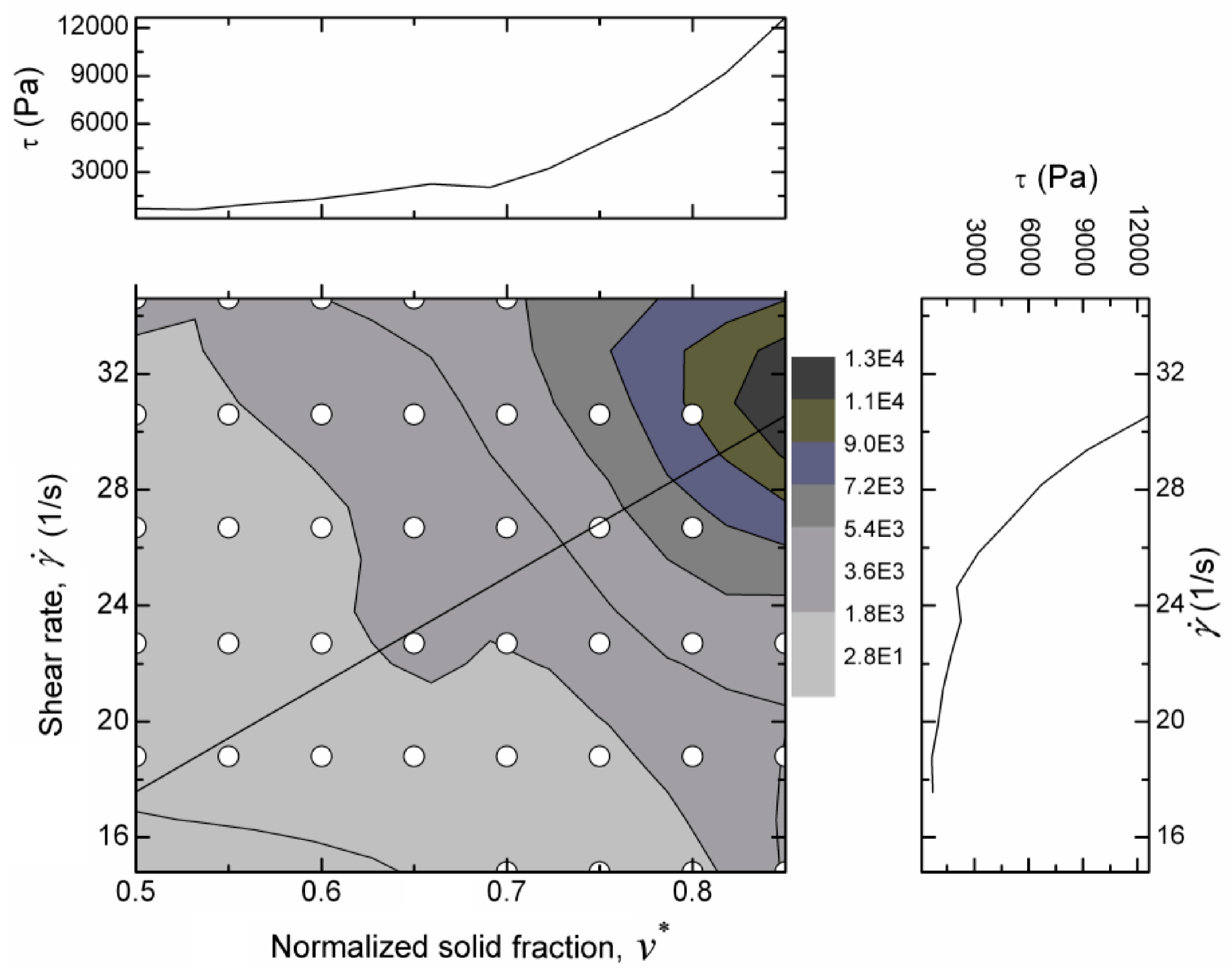

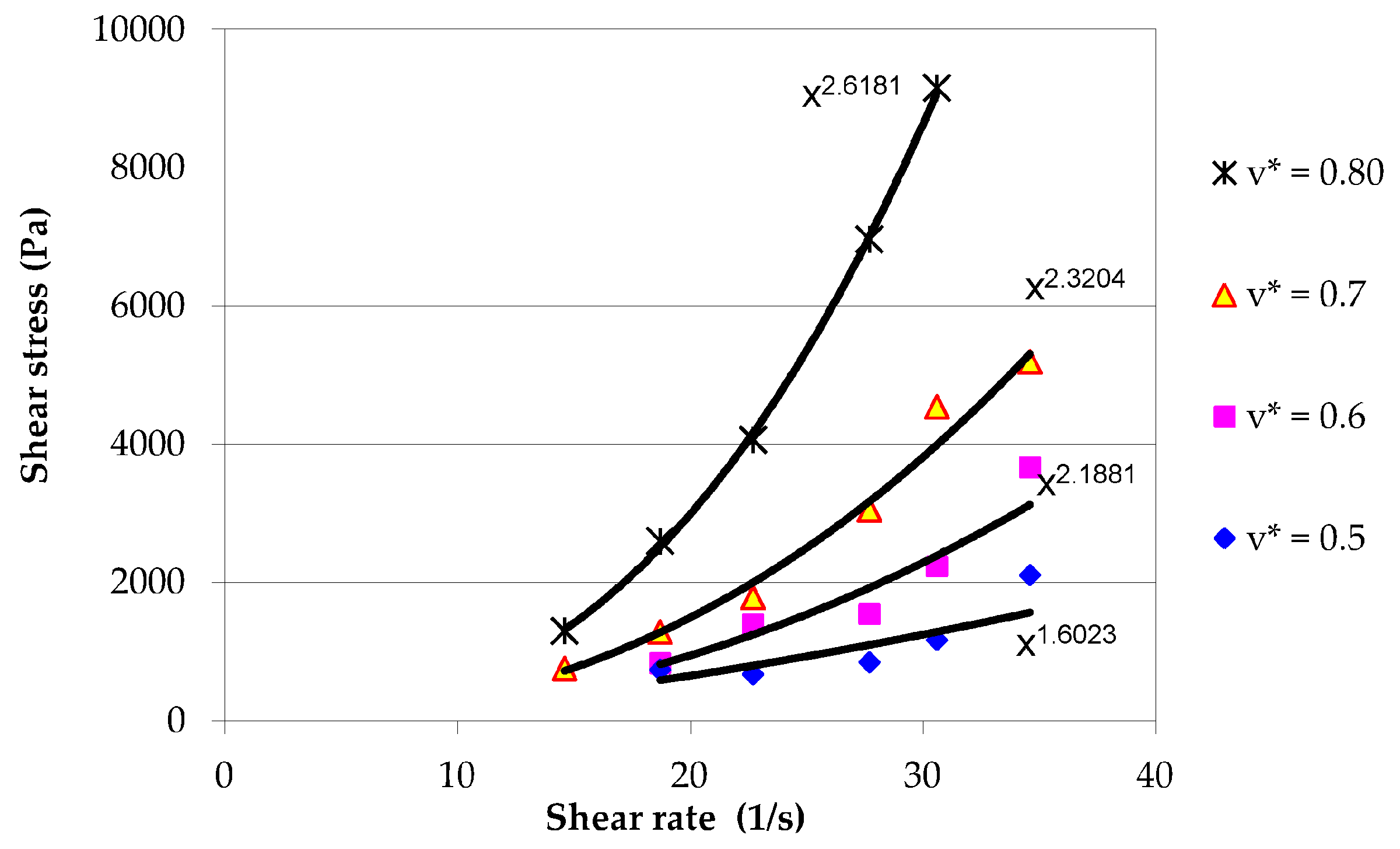

3.3. Contact Frequency and Generated Shear Stress

4. Discussions

5. Conclusions

Acknowledgments

Conflicts of Interest

Appendix A

References

- Campbell, C. Rapid Granular Flows. Annu. Rev. Fluid Mech. 1990, 22, 57–90. [Google Scholar] [CrossRef]

- Jaeger, H.M.; Nagel, S.R.; Behringer, R.P. The Physics of Granular Materials. Phys. Today 1996, 1, 32–38. [Google Scholar] [CrossRef]

- Drake, T.G. Granular flow: Physical experiments and their implications for microstructural theories. J. Fluid Mech. 1991, 225, 121–152. [Google Scholar] [CrossRef]

- Bagnold, R.A. Experiments on a gravity-free dispersion of large solid spheres in a Newtonian fluid under shear. Proc. R. Soc. Lond. A 1954, 225, 49–63. [Google Scholar] [CrossRef]

- Savage, S.B.; Jeffrey, D.J. The stress tensor in a granular flow at high shear rates. J. Fluid Mech. 1981, 110, 255–272. [Google Scholar] [CrossRef]

- Campbell, C. Granular shear flows at the elastic limit. J. Fluid Mech. 2002, 465, 261–291. [Google Scholar] [CrossRef]

- Shen, H.H.; Sankaran, B. Internal length and time scales in a simple shear granular flow. Phys. Rev. E 2004, 70, 051308. [Google Scholar] [CrossRef] [PubMed]

- Luding, S.; Goldshtein, A. Collisional cooling with multi-particle interactions. Granul. Matter 2003, 5, 159–163. [Google Scholar] [CrossRef]

- Hwang, H.; Hutter, K. A new kinetic model for rapid granular flow. Contin. Mech. Thermodyn. 1995, 7, 357–384. [Google Scholar] [CrossRef]

- Zhang, D.Z.; Rauenzahn, R.M. Stress relaxation in dense and slow granular flows. J. Rheol. 2000, 44, 1019–1041. [Google Scholar] [CrossRef]

- Zhang, D.Z. Evolution of enduring contacts and stress relaxation in a dense granular medium. Phys. Rev. E 2005, 71, 041303. [Google Scholar] [CrossRef] [PubMed]

- Ji, S.; Shen, H.H. Internal Parameters and Regime Map for Soft Polydispersed granular materials. J. Rheol. 2008, 52, 87–103. [Google Scholar] [CrossRef]

- Azanza, E.; Chevoir, F.; Moucheront, P. Experimental study of collisional granular flows down an inclined plane. J. Fluid Mech. 1999, 400, 199–227. [Google Scholar] [CrossRef]

- Blair, D.L.; Kudrolli, A. Collision statistics of driven granular materials. Phys. Rev. E 2003, 67, 041301. [Google Scholar] [CrossRef] [PubMed]

- Mueth, D.M. Measurements of particle dynamics in slow, dense granular Couette flow. Phys. Rev. E 2003, 67, 011304. [Google Scholar] [CrossRef] [PubMed]

- Elliot, K.E.; Ahmadi, G.; Kvasnak, W. Couette flows of a granular monolayer—An experimental study. J. Non-Newton. Fluid Mech. 1998, 74, 89–111. [Google Scholar] [CrossRef]

- Iwashita, K.; Ichiba, K.; Oda, M. Observations of rapidly sheared granular materials. J. JSCE 2004, 764, 147–156. (In Japanese) [Google Scholar] [CrossRef]

- Ichiba, K.; Iwashita, K.; Oda, M. Experimental study on stress ratio in rapid granular shear flow. In Proceedings of the 5th International Conference on Micromechanics, Powder and Grains, II, Stuttgart, Germany, 18–22 July 2005; pp. 751–755.

- Mahmood, Z.; Dhakal, S.; Iwashita, K. Measurement of Particle Dynamics in Rapid Granular Shear Flows. J. Eng. Mech. 2009, 135, 285–294. [Google Scholar] [CrossRef]

- Dhakal, S.; Iwashita, K.; Oda, M. Detecting collisions and finding contact durations in experimental granular flow. J. Appl. Mech. 2008, 11, 477–486. [Google Scholar] [CrossRef]

- Dhakal, S. Shear flow characteristics of densely packed granular material subjected to slow deformations. J. Nepal Geol. Soc. 2013, 46, 163–170. [Google Scholar]

- Kumaran, V. Dynamics of dense sheared granular flows. Part 1. Structure and diffusion. J. Fluid Mech. 2009, 632, 109–144. [Google Scholar] [CrossRef]

- Alam, M.; Luding, S. First normal stress difference and crystallization in a dense sheared granular fluid. Phys. Fluids 2003, 15, 2298–2312. [Google Scholar] [CrossRef]

- Pierson, T.C.; Costa, J.E. A Rheologic Classification of Subaerial Sediment–Water Flows. Geol. Soc. Am. Rev. Eng. Geol. 1987, 7, 1–12. [Google Scholar]

- You, C.; Zhao, H.; Cai, Y.; Qi, H.; Xu, X. Experimental investigation of inter-particle collision rate in particulate flow. Int. J. Multiph. Flow 2004, 30, 1121–1138. [Google Scholar] [CrossRef]

- Hockney, R.W.; Eastwood, J.W. Computer Simulation Using Particles; McGraw–Hill: New York, NY, USA, 1981. [Google Scholar]

- Allen, M.P.; Tildesley, D.J. Computer Simulation of Liquids; Clarendon Press: Oxford, UK, 1987. [Google Scholar]

- Vemuri, B.C.; Chen, L.; Vu-Quoc, L.; Zhang, X.; Walton, O. Efficient and Accurate Collision Detection for Granular Flow Simulation. Graph. Models Image Process. 1998, 60, 403–422. [Google Scholar] [CrossRef]

- McNamara, S.; Young, W.R. Dynamics of a freely evolving, two-dimensional granular medium. Phys. Rev. E 1996, 53, 5089–5100. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Motor speed | 3−180 rpm |

| Shear range, | 5–120 s−1 |

| Maximum torque of motor | 15 N·m |

| Radius of inner wall | 28.5 cm |

| Radius of outer wall | 40 cm |

| Shear cell height (H) | 11.5 cm |

| Diameter of flange | 2.47 cm |

| No. of flanges attached to inner wall | 37 |

| No. of flanges attached to outer wall | 52 |

| Parameters | Values |

|---|---|

| Diameter, D (mm) | 23 |

| Thickness (mm) | 6 |

| Mass (g) | 2.306 |

| Density (g/cm3) | 0.934 |

| Maximum packing factor, | 0.795 |

| Coefficient of restitution, e | 0.870 |

| Particle-particle coefficient of friction | 0.265 |

| Particle-floor coefficient of friction | 0.30 |

| Young’s Modulus (MPa) | 980 |

| Material stiffness (N/m) | 1.9944 × 106 |

| Poisson’s ratio | 0.2 |

| Tensile strength | 44.1 |

| Parameters | Values |

|---|---|

| Frame rate | 60–1000 Hz |

| Shutter speed | 30–10,000 Hz |

| Pixel resolution | 1280 × 512 |

| Number of frames possible | 2048 |

| Size of the test section | 20 × 11.5 cm2 |

| Number of pixels in one particle | 41.4 |

| Type of color | Monochrome |

| Solid Fraction | (% of Particle Diameter) | ||

|---|---|---|---|

| 0.48 | 8% | 20% | 10° |

| > 0.48 and < 0.56 | 5% | 15% | 7° |

| 0.56 | 2% | 8% | 4° |

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhakal, S. Experimental Study of Particle Interactions in Moderate to Dense Granular Shear Flows of Disks. Condens. Matter 2017, 2, 2. https://doi.org/10.3390/condmat2010002

Dhakal S. Experimental Study of Particle Interactions in Moderate to Dense Granular Shear Flows of Disks. Condensed Matter. 2017; 2(1):2. https://doi.org/10.3390/condmat2010002

Chicago/Turabian StyleDhakal, Subodh. 2017. "Experimental Study of Particle Interactions in Moderate to Dense Granular Shear Flows of Disks" Condensed Matter 2, no. 1: 2. https://doi.org/10.3390/condmat2010002

APA StyleDhakal, S. (2017). Experimental Study of Particle Interactions in Moderate to Dense Granular Shear Flows of Disks. Condensed Matter, 2(1), 2. https://doi.org/10.3390/condmat2010002