Design and Performance Evaluation of a Feed Distribution Device in the Small-Scale Pneumatic Conveying Feeder for Recirculating Aquaculture Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Physical Properties of Feed Pellet

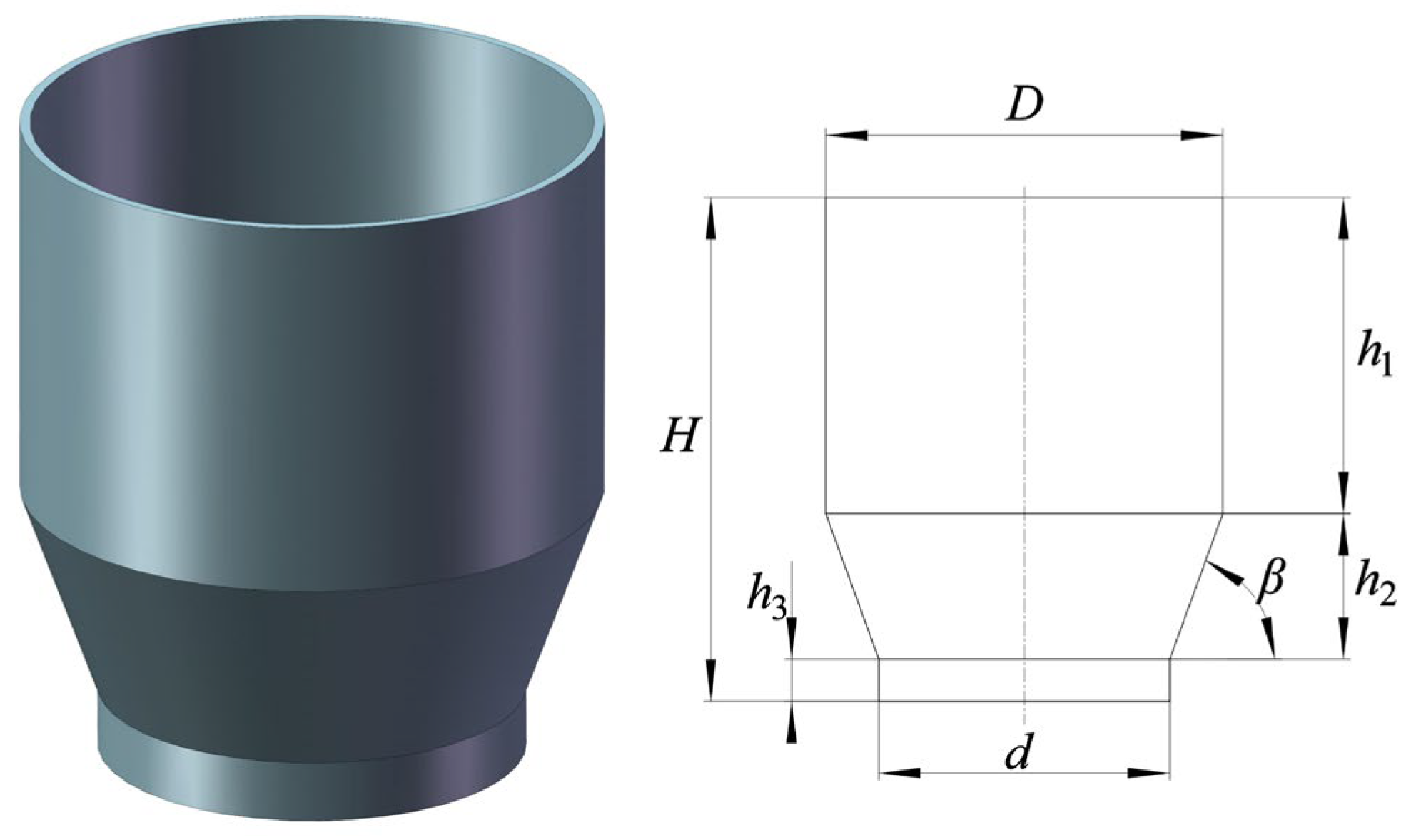

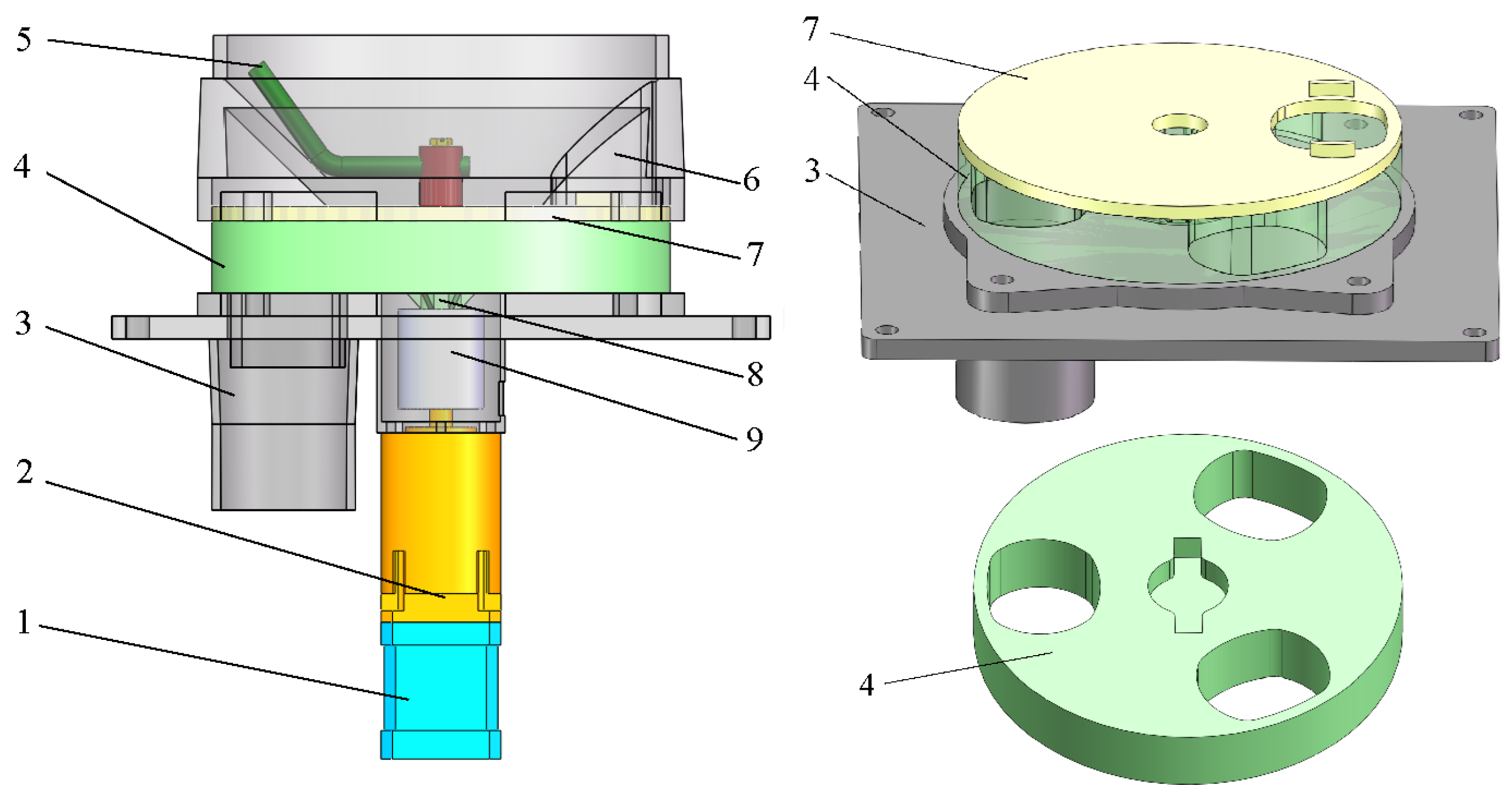

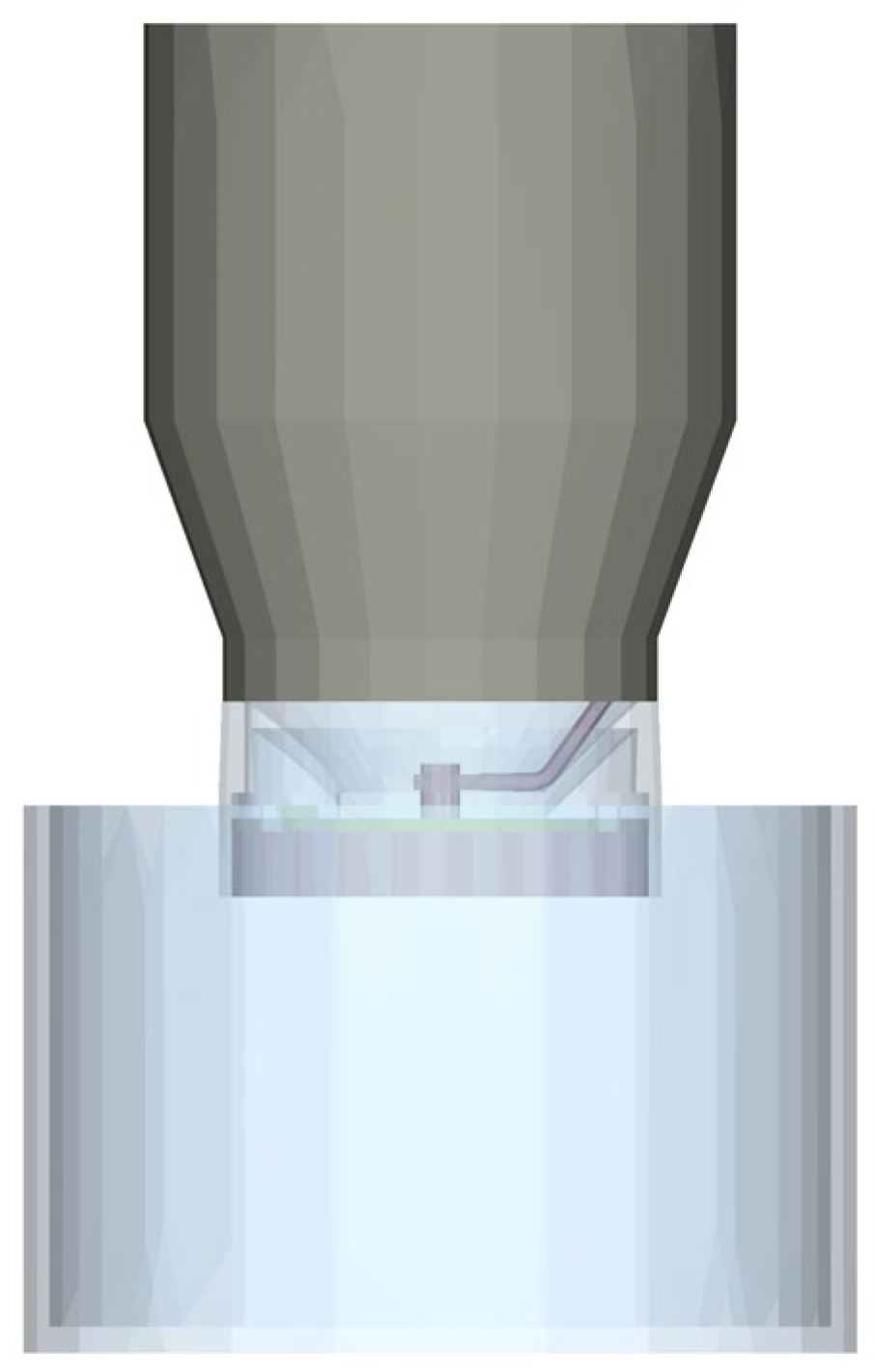

2.2. Hopper and Distribution Device Design

2.3. Simulation Modeling Process

2.4. Experimental Design

3. Results and Discussion

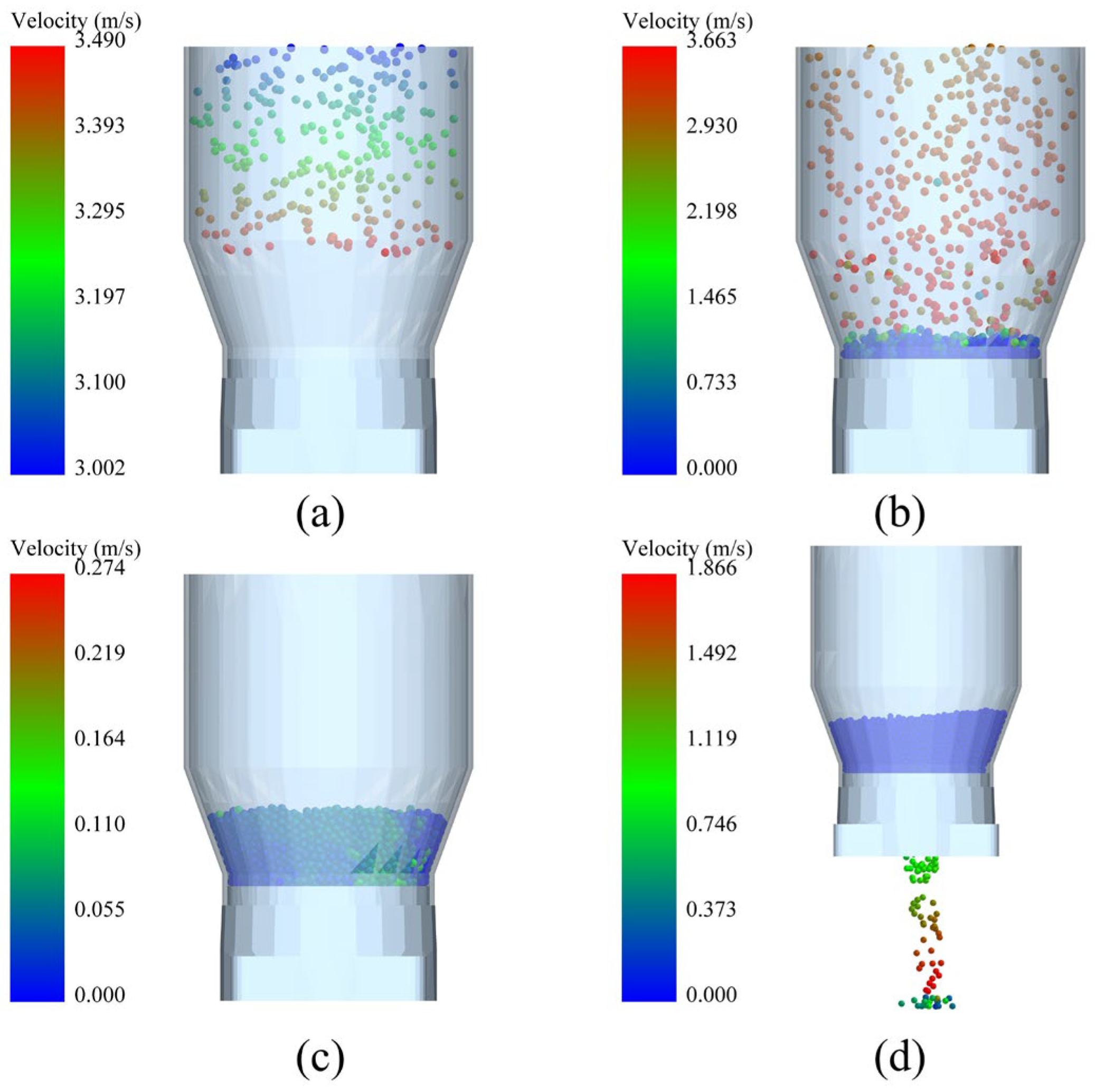

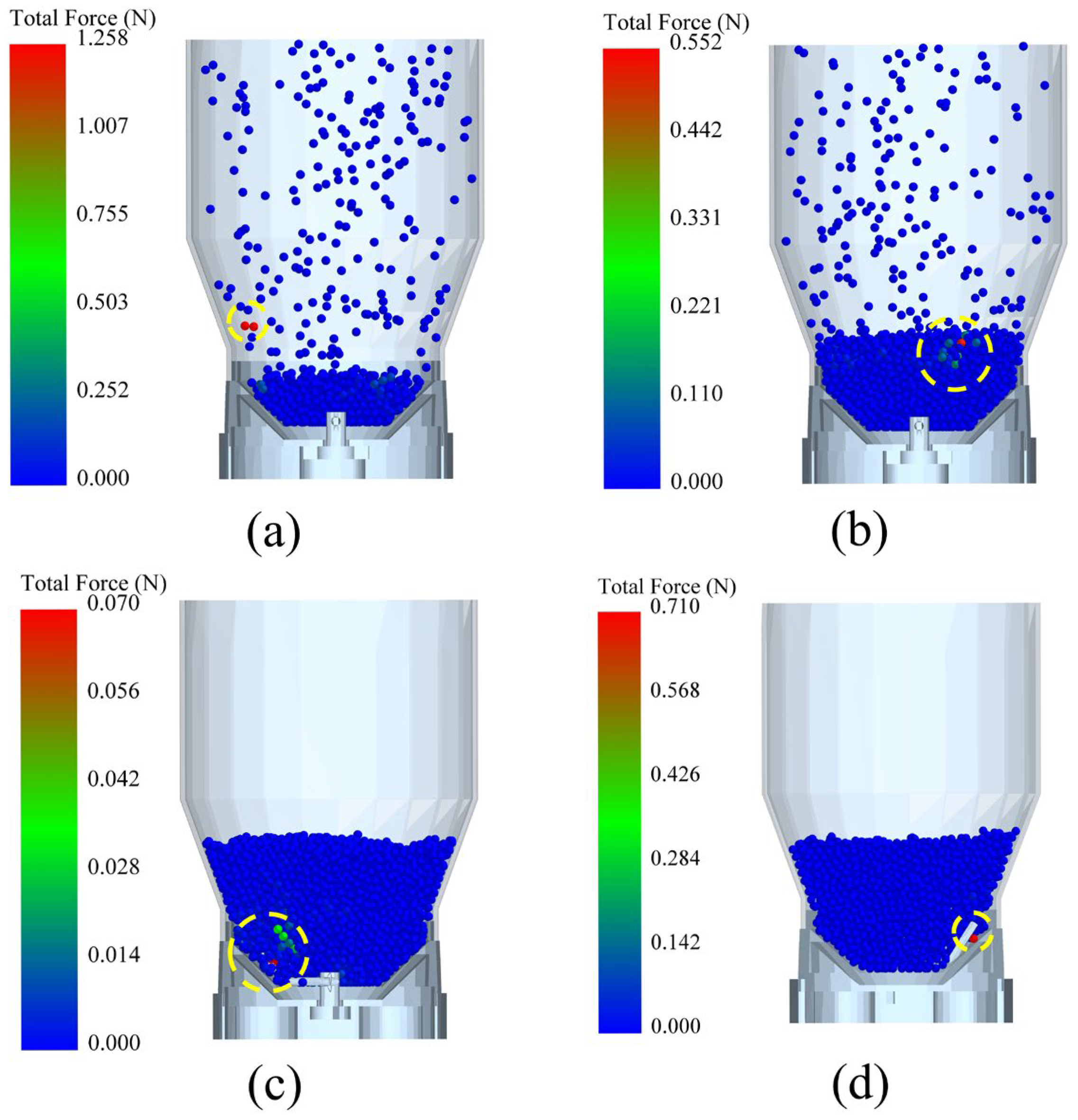

3.1. Motion and Force of Feed Pellets During the Distribution Process

3.2. Effects of Discharge Disk Rotational Speed on Single Feeding Quantity

3.3. Effects of Feed Pellet Proportion in the Hopper on Single Feeding Quantity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, H.; Hou, H.; Liu, Y. Research progress and development trend in recirculating aquaculture system. Fish. Sci. 2023, 42, 735–741. [Google Scholar]

- Chen, W.; Gao, S. Current status of industrialized aquaculture in China: A review. Environ. Sci. Pollut. Res. 2023, 30, 32278–32287. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Xu, D.M.; Lin, K.; Sun, C.; Yang, X. Intelligent feeding control methods in aquaculture with an emphasis on fish: A review. Rev. Aquac. 2018, 10, 975–993. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, X.; Liu, J.; An, D.; Wei, Y. Dynamic feeding method for aquaculture fish using multi-task neural network. Aquaculture 2022, 551, 737913. [Google Scholar] [CrossRef]

- Godoy-Olmos, S.; Jauralde, I.; Monge-Ortiz, R.; Milian-Sorribes, M.C.; Jover-Cerda, M.; Tomas-Vidal, A.; Martinez-Llorens, S. Influence of diet and feeding strategy on the performance of nitrifying trickling filter, oxygen consumption and ammonia excretion of gilthead sea bream (Sparus aurata) raised in recirculating aquaculture systems. Aquac. Int. 2022, 30, 581–606. [Google Scholar] [CrossRef]

- Liang, Q.; Liu, G.; Luan, Y.; Niu, J.; Li, Y.; Chen, H.; Liu, Y.; Zhu, S. Impact of feeding frequency on growth performance and antioxidant capacity of Litopenaeus vannamei in recirculating aquaculture systems. Animals 2025, 15, 192. [Google Scholar] [CrossRef]

- Chen, Z. Design and Experiment of an Intelligent Baiting Machine for Micropterus salmoides. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2024. [Google Scholar]

- Wang, G. Design and Test of Automatic Feeding Equipment for Circulating Aquaculture. Master’s Thesis, Shandong Agriculture University, Tai’an, China, 2022. [Google Scholar]

- Zhu, M.; Zhang, Z.; Huang, H.; Chen, H.; Cuan, X.; Dong, T. Research progress on intelligent feeding methods in fish farming. Trans. CSAE 2022, 38, 38–47. [Google Scholar]

- Huang, H.; Zhang, Y.; Wang, D.; Fu, Z.; Tian, H.; Shang, J.; Helal, M.; Lv, Z. Study the flow capacity of cylindrical pellets in hopper with unloading paddle using DEM. Agriculture 2024, 14, 523. [Google Scholar] [CrossRef]

- Sun, W.; Sun, Y.; Wang, Y.; He, H. Calibration and experimental verification of discrete element parameters for modelling feed pelleting. Biosyst. Eng. 2024, 237, 182–195. [Google Scholar] [CrossRef]

- Huang, J.; Wen, J.; Li, H.; Xia, Y.; Tan, S.; Xiao, H.; Duan, W.; Hu, J. Particle erosion in 90-Degree elbow pipe of pneumatic conveying System: Simulation and validation. Comput. Electron. Agric. 2024, 216, 108534. [Google Scholar] [CrossRef]

- Zhao, S.; Ding, W.; Zhao, S.; Gu, J.; Zhang, J. Performance analysis and optimization of pneumatic fishpond feeder based on EDEM-Fluent coupling. Trans. CSAM 2019, 50, 130–139. [Google Scholar]

- Song, J.; Wang, T.; Hu, G.; Zhang, Z.; Zhao, W.; Wang, Z.; Zhang, Y. Conveying characteristics of shrimp feed pellets in pneumatic conveying system and minimum power consumption dissipation factor. Aquacult. Eng. 2023, 102, 102347. [Google Scholar] [CrossRef]

- Kong, X.; Liu, J.; Yang, T.; Su, Y.; Geng, J.; Niu, Z. Numerical simulation of feed pellet breakage in pneumatic conveying. Biosyst. Eng. 2022, 218, 31–42. [Google Scholar] [CrossRef]

- Liu, S.; Li, G.; Liu, H.; Zheng, H.; Chen, J. Current development status of aquaculture equipment in China. J. Fish. China 2023, 47, 119615. [Google Scholar]

- Le Boucher, R.; Chung, W.; Lin, J.; Tan, L.; Poon, Z.; Lee, C. Optimizing automated feeder algorithms for feed intake prediction in barramundi (Lates calcarifer). Aquaculture 2023, 577, 739909. [Google Scholar] [CrossRef]

- Son, S.; Jeong, Y. An automated fish-feeding system based on CNN and GRU neural networks. Sustainability 2024, 16, 3675. [Google Scholar] [CrossRef]

- Chang, C.; Fang, M.; Jao, R.; Shyu, C.; Liao, I. Development of an intelligent feeding controller for indoor intensive culturing of eel. Aquacult. Eng. 2005, 32, 343–353. [Google Scholar] [CrossRef]

- Halstensen, M.; Ihunegbo, F.N.; Ratnayake, C.; Sveinsvold, K. Online acoustic chemometric monitoring of fish feed pellet velocity in a pneumatic conveying system. Power Technol. 2014, 263, 104–111. [Google Scholar] [CrossRef]

- Liao, Y.; You, Y.; Wang, D.; Zhang, X.; Zhang, H.; Ma, W. Parameter calibration and experiment of discrete element model for mixed seeds of oat and arrow pea. Trans. CSAM 2022, 53, 14–22. [Google Scholar]

- Peng, F.; Zhang, L.; Li, Z.; Chen, J. Calibration and verification of DEM parameters of wet-sticky feed raw materials. Sci. Rep. 2023, 13, 9246. [Google Scholar] [CrossRef]

- Wang, L.; Ji, M.; Zheng, Y.; Zheng, Y. Measurement and calibration of discrete element parameters for extruded floating feed pellets and ABS plastic. J. Phys. Conf. Ser. 2025, 2951, 012070. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Q.; Niu, F.; Yu, X.; Chang, Z.; Wu, F.; Zhang, M. Simulation and verification of discrete element parameter calibration of pulverized coal particles. Int. J. Coal Prep. Util. 2024, 1–20. [Google Scholar] [CrossRef]

- Yuan, F.; Yu, H.; Wang, L.; Shi, Y.; Wang, X.; Liu, H. Parameter calibration and systematic test of a discrete element model (DEM) for compound fertilizer particles in a mechanized variable-rate application. Agronomy 2023, 13, 706. [Google Scholar] [CrossRef]

- Liu, W.; Jin, H.; Li, H.; Li, X.; Zheng, K.; Wei, Z. Calibration of simulation parameters for potato minituber based on EDEM. Trans. CSAM 2018, 49, 125–135. [Google Scholar]

- Aas, T.S.; Oehme, M.; Sørensen, M.; He, G.; Lygren, I.; Åsgård, T. Analysis of pellet degradation of extruded high energy fish feeds with different physical qualities in a pneumatic feeding system. Aquacult. Eng. 2011, 44, 25–34. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, J.; Niu, Z.; Shi, L.; Liu, C. Experimental study on mechanical properties of pellet feed. J. Agric. Sci. Technol. 2019, 21, 82–90. [Google Scholar]

- Zhang, P.; Li, F.; Wang, F. Optimization and test of ginger-shaking and harvesting device based on EDEM software. Comput. Electron. Agric. 2023, 213, 108257. [Google Scholar] [CrossRef]

- Zhou, P.; Li, Y.; Liang, R.; Zhang, B.; Kan, Z. Calibration of contact parameters for particulate materials in residual film mixture after sieving based on EDEM. Agriculture 2023, 13, 959. [Google Scholar] [CrossRef]

- Zhang, L.; Li, B.; Sun, X.; Hong, Q.; Duan, Q. Intelligent fish feeding based on machine vision: A review. Biosyst. Eng. 2023, 23, 133–164. [Google Scholar] [CrossRef]

| Category | Parameters | Value |

|---|---|---|

| Feed pellets | Poisson’s ratio | 0.3 |

| Shear modulus/MPa | 33.08 | |

| Density (kg/m3) | 656.4 | |

| Equivalent diameter (mm) | 6.75 | |

| ABS plastic | Poisson’s ratio | 0.34 |

| Shear modulus/MPa | 3000 | |

| Density (kg/m3) | 1250 | |

| Contact parameters between the feed pellet and ABS plastic | Restitution coefficient | 0.533 |

| Static friction coefficient | 0.331 | |

| Rolling friction coefficient | 0.069 | |

| Contact parameters among feed pellets | Restitution coefficient | 0.550 |

| Static friction coefficient | 0.520 | |

| Rolling friction coefficient | 0.149 |

| Discharge Disk Rotational Speed (rpm) | |||||

|---|---|---|---|---|---|

| 28 | 24 | 20 | 16 | 12 | |

| Simulation | 259 ± 25 | 323 ± 26 | 425 ± 26 | 503 ± 65 | 709 ± 101 |

| Actual | 248 ± 24 | 292 ± 33 | 354 ± 28 | 418 ± 33 | 570 ± 72 |

| Error | 4.43% | 10.62% | 13.33% | 20.33% | 24.98% |

| Feed Pellet Proportion (%) | 15 | 35 | 55 | 75 | 95 | Coefficient of Variation |

|---|---|---|---|---|---|---|

| Single feeding quantity | 262 ± 17 | 297 ± 36 | 301 ± 43 | 296 ± 43 | 286 ± 35 | 12.46% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Ji, M.; Wu, K.; Weng, X.; Li, H. Design and Performance Evaluation of a Feed Distribution Device in the Small-Scale Pneumatic Conveying Feeder for Recirculating Aquaculture Systems. Fishes 2025, 10, 255. https://doi.org/10.3390/fishes10060255

Wang L, Ji M, Wu K, Weng X, Li H. Design and Performance Evaluation of a Feed Distribution Device in the Small-Scale Pneumatic Conveying Feeder for Recirculating Aquaculture Systems. Fishes. 2025; 10(6):255. https://doi.org/10.3390/fishes10060255

Chicago/Turabian StyleWang, Liang, Mingdong Ji, Kang Wu, Xudong Weng, and Haijun Li. 2025. "Design and Performance Evaluation of a Feed Distribution Device in the Small-Scale Pneumatic Conveying Feeder for Recirculating Aquaculture Systems" Fishes 10, no. 6: 255. https://doi.org/10.3390/fishes10060255

APA StyleWang, L., Ji, M., Wu, K., Weng, X., & Li, H. (2025). Design and Performance Evaluation of a Feed Distribution Device in the Small-Scale Pneumatic Conveying Feeder for Recirculating Aquaculture Systems. Fishes, 10(6), 255. https://doi.org/10.3390/fishes10060255