Extension of the Voronoi Diagram Algorithm to Orthotropic Space for Material Structural Design

Abstract

1. Introduction

2. Materials and Methods

2.1. Brief Description of the Proposed Design Method

2.2. Mathematical Formulation of the Smoothing Problem

| Algorithm 1. Smoothing structure algorithm |

| Inputs: mesh, β, η, e, K, Ndim, Mdim |

| Outputs: Binary map: clMap; clusters: Kmap |

| newmesh ← generate regular mesh (Ndim × Mdim) in the mesh domain |

| newmesh ← interpolated data of the parameter vector newmesh ← clusterization of newmesh by η on K clusters |

| color ← unique (Kmap) |

| clMap ← 0 |

| For each cluster in Kmap |

| clMap (cluster.center) = s |

| stPoint = cluster.center |

| clMap ← ColorStep(clMap, newmesh, cluster, stPoint, color; eps, s) |

| end for |

| clMap (clMap ≥ s) ← 1 |

| clMap (clMap < s) ← 0 |

| Algorithm 2. ColorStep algorithm |

| Inputs: mapColor, mapData, clusterN, point, color; eps, s |

| Outputs: mapColor |

| i ← point.i |

| j ← point.j |

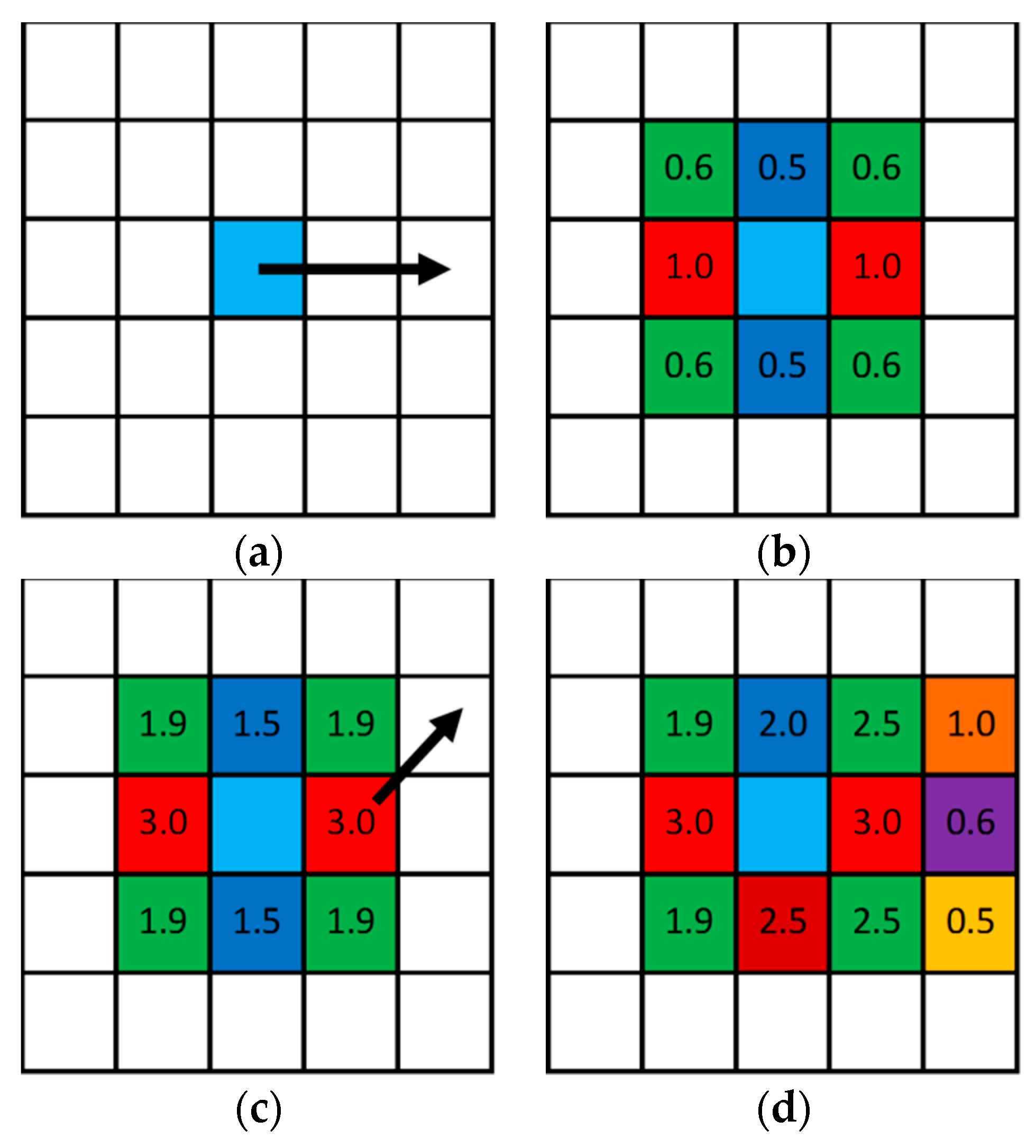

| e ← mapData.mainDirection(i, j) |

| e → direction: {[0, 1]; [1, 0]; [1, 1]; [−1, 1]} |

| tangent ← map(direction): {[1, 0]; [0, 1]; [−1, 1]; [1, 1]} |

| diag ← map(direction): {[1, 1] and [−1, 1]; [1, 0] and [0, 1]} |

| ptemp ← size (mapColor == s and mapData.cluster = color(clusterN)) |

| ptemp ← ptemp/size(mapColor and mapData.cluster = color(clusterN)) |

| β ← mapData.ellipticity(i, j) |

| p ← mapData. cluster(clusterN).meanPorosity |

| If |p(cluster) − ptemp|/ptemp > eps |

| break |

| end if |

| If mapColor [(i,j) ± direction] ≠ s and mapData.cluster = color(clusterN) then mapColor [(i,j) ± direction] += 1 |

| else |

| colorStep(mapColor, (i,j) ± direction, β, e, s) |

| end if |

| If mapColor [(i,j) ± tangent] ≠ s and mapData.cluster = color(clusterN) then mapColor [(i,j) ± tangent] += β |

| else break |

| colorStep(mapColor, (i,j) ± tangent, β, e, s) |

| end if |

| If mapColor [(i,j) ± diag] ≠ s and mapData.cluster = color(clusterN) then mapColor [(i,j) ± diag] += sqrt(2β2/(β2 + 1)) |

| else |

| colorStep(mapColor, (i,j) ± diag, β, e, s) |

| end if |

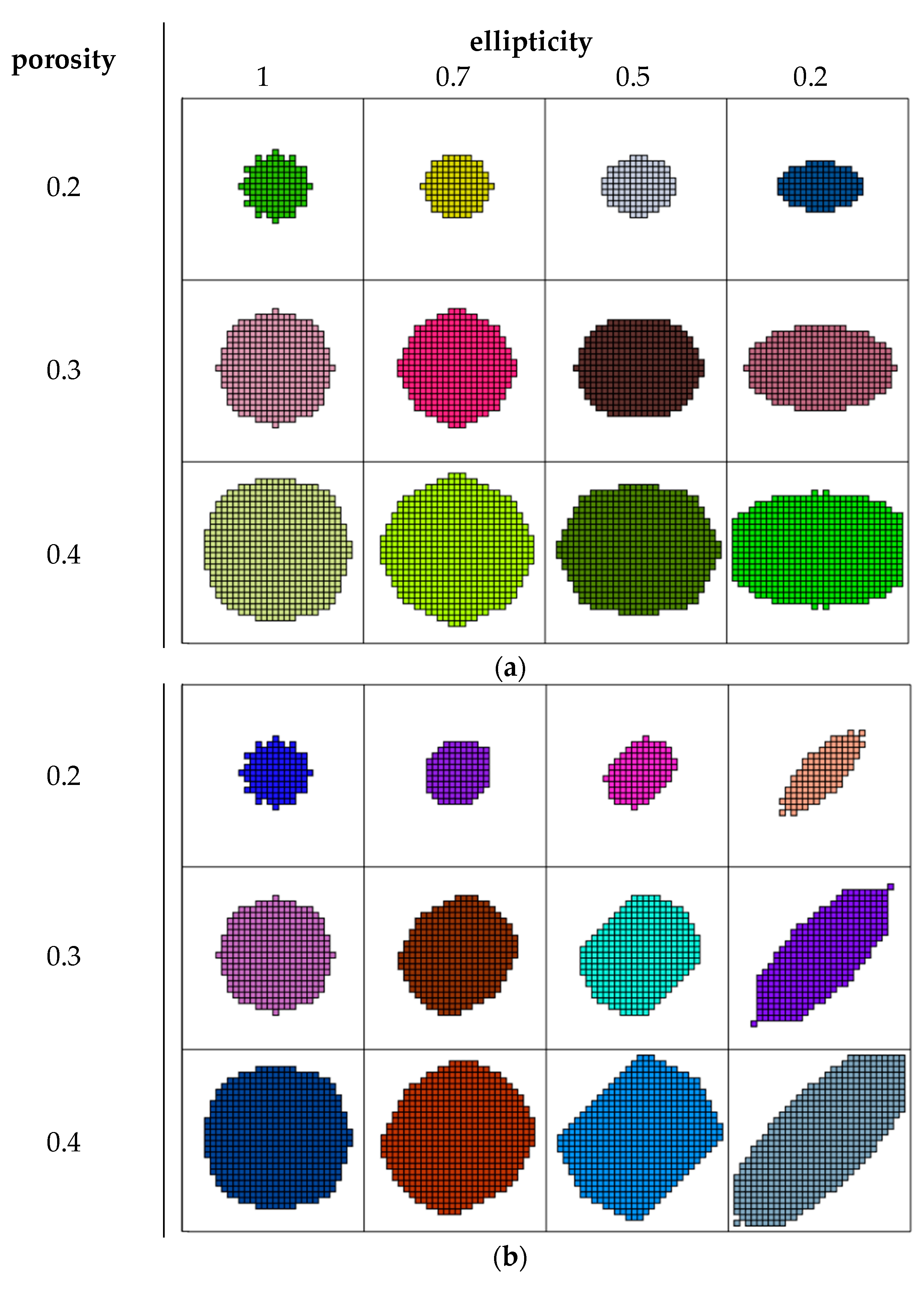

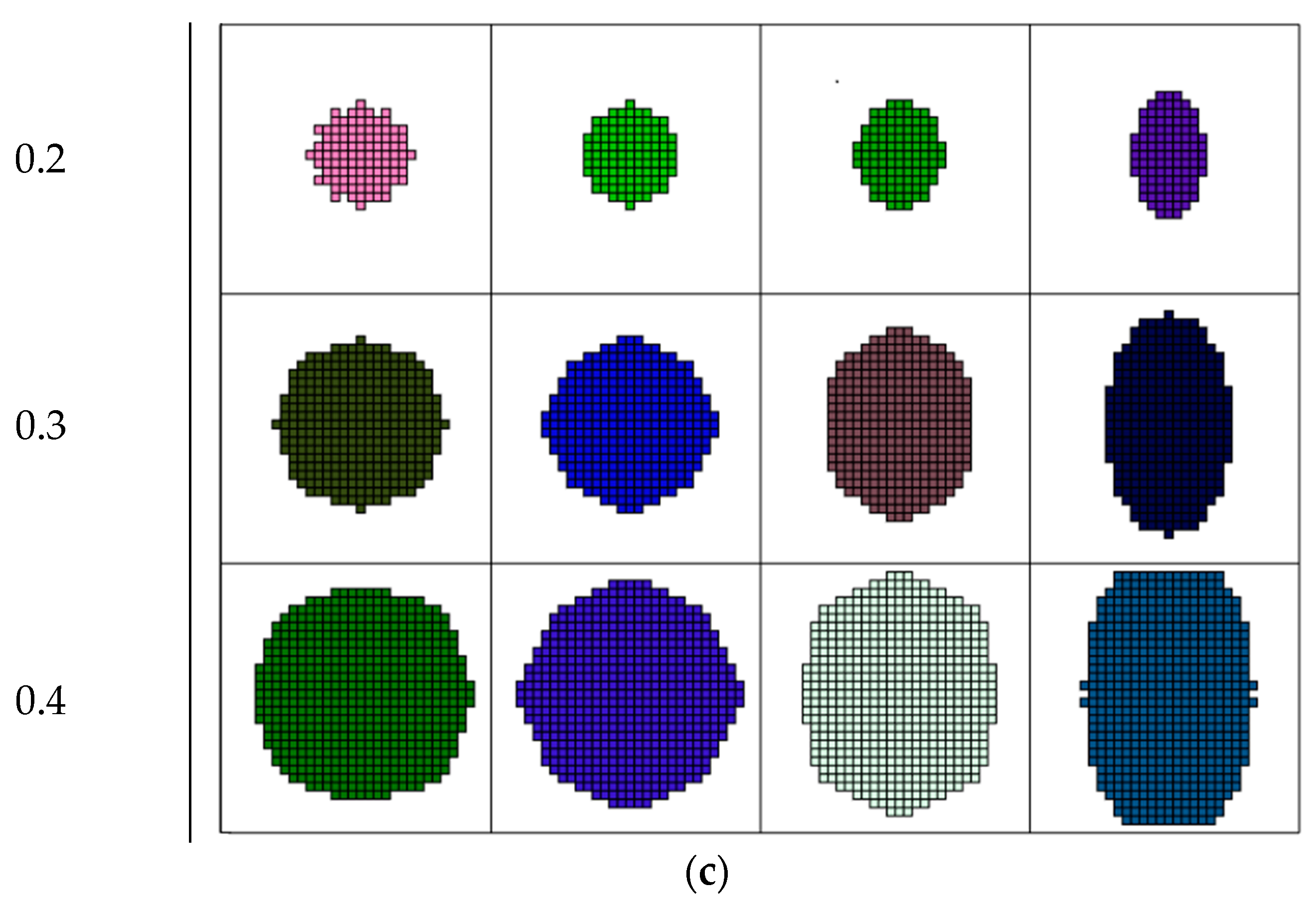

2.3. Test Task

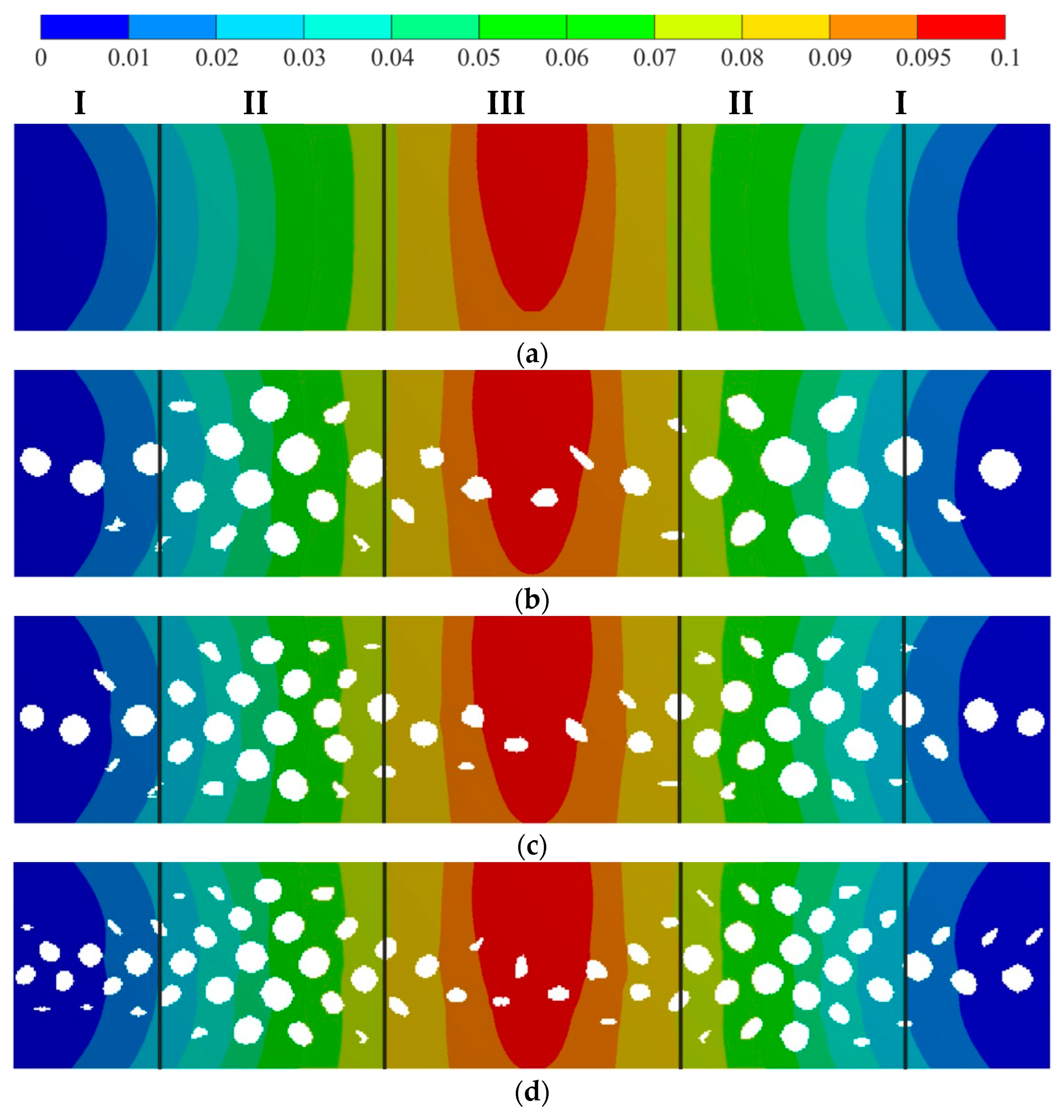

2.4. Model Task

3. Results and Discussion

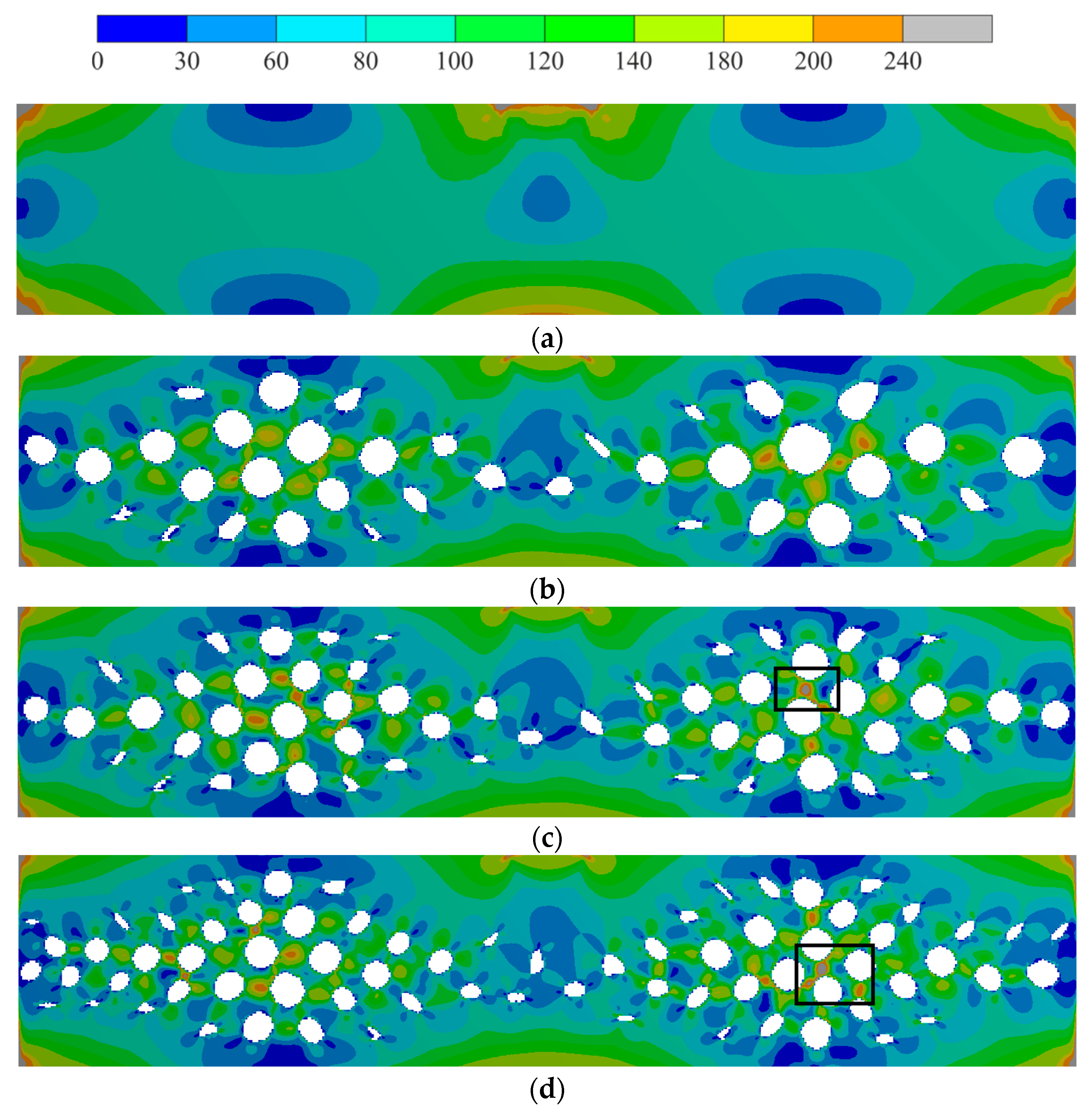

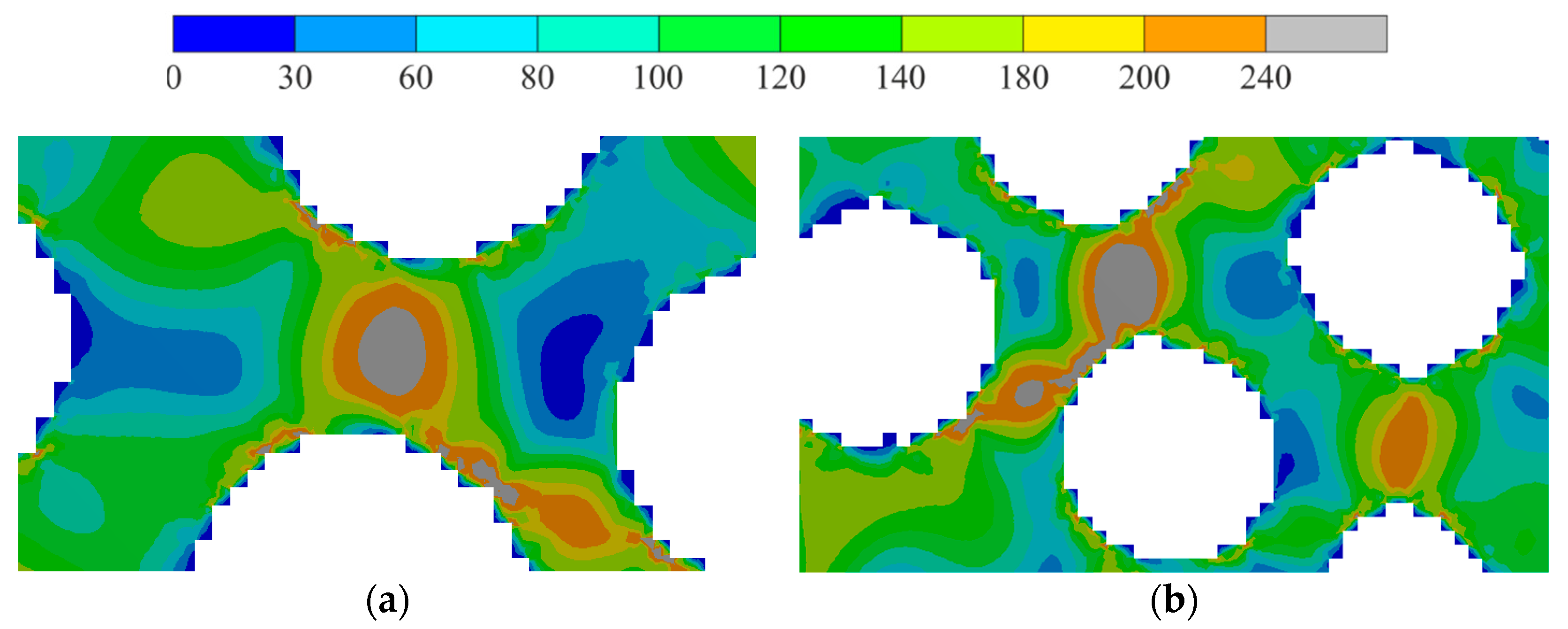

3.1. Test Task Results

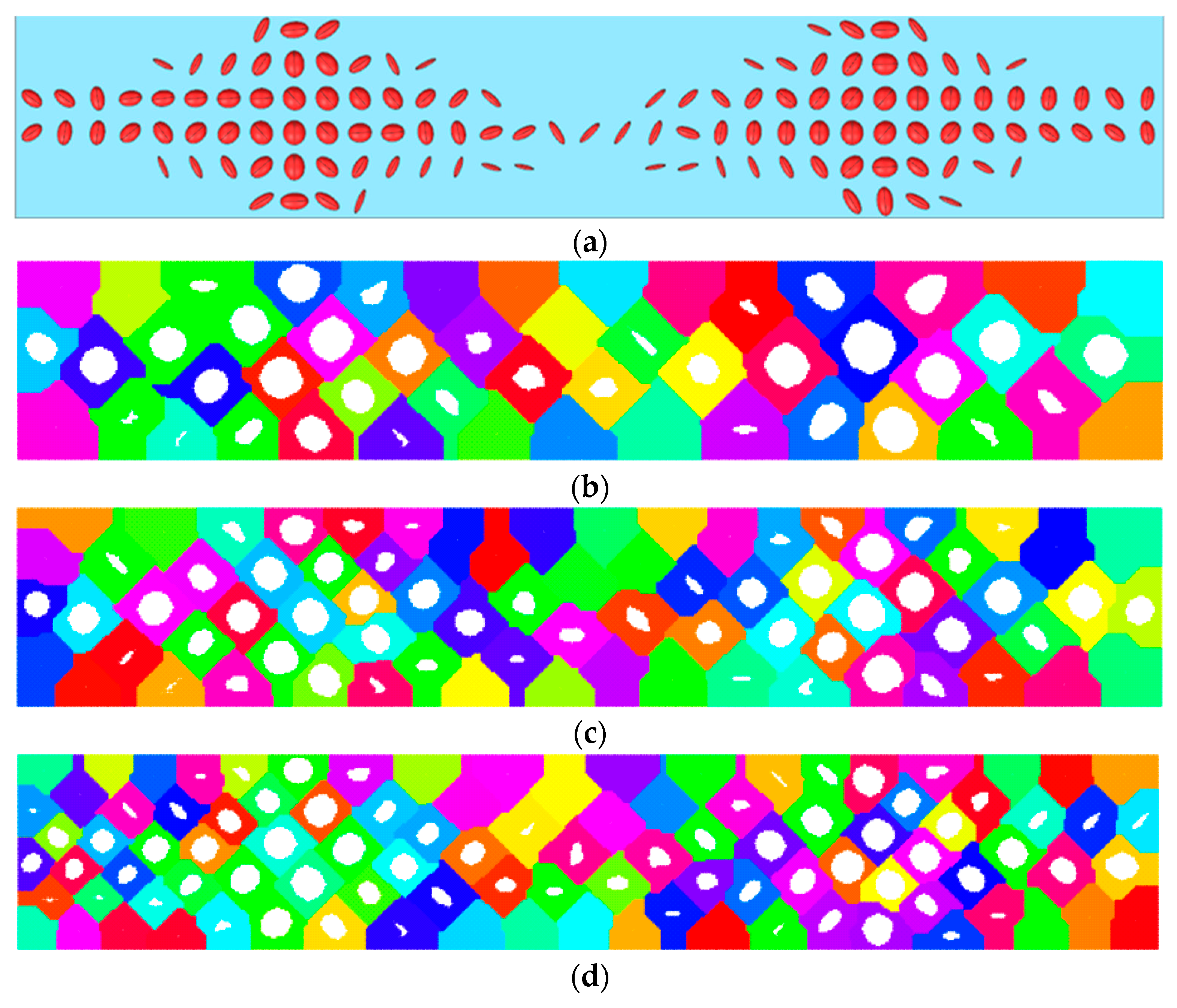

3.2. Lightening of the Original Construction

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rudert, M. Taking the next step in personalised orthopaedic implantation. J. Pers. Med. 2022, 12, 365. [Google Scholar] [CrossRef]

- Stojkovic, M.; Trajanovic, M.; Vitkovic, N. Personalized orthopedic surgery design challenge: Human bone redesign method. Procedia CIRP 2019, 84, 701–706. [Google Scholar] [CrossRef]

- Yuan, L.; Ding, S.; Wen, C. Additive manufacturing technology for porous metal implant applications and triple minimal surface structures: A review. Bioact. Mater. 2019, 4, 56–70. [Google Scholar] [CrossRef]

- Sufiiarov, V.S.; Orlov, A.V.; Popovich, A.A.; Chukovenkova, M.O.; Soklakov, A.V.; Mikhaluk, D.S. Numerical analysis of strength for an endoprosthesis made of a material with graded lattice structures. Russ. J. Biomech. 2021, 25, 55–66. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Current status and challenges of additive manufacturing in orthopaedics: An overview. J. Clin. Orthop. Trauma 2019, 10, 380–386. [Google Scholar] [CrossRef]

- Risse, L.; Woodcock, S.; Brüggemann, J.P.; Kullmer, G.; Richard, H.A. Stiffness optimization and reliable design of a hip implant by using the potential of additive manufacturing processes. Biomed. Eng. Online 2022, 21, 23. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Arabnejad, S.; Johnston, R.B.; Pura, J.A.; Singh, B.; Tanzer, M.; Pasini, D. High-strength porous biomaterials for bone replacement: A strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints. Acta Biomater. 2016, 30, 345–356. [Google Scholar] [CrossRef] [PubMed]

- Maslov, L.B.; Dmitryuk, A.Y.; Zhmaylo, M.A.; Kovalenko, A.N. Study of the strength of a hip endoprosthesis made of polymeric material. Russ. J. Biomech. 2022, 26, 19–33. [Google Scholar] [CrossRef]

- Maslov, L.; Borovkov, A.; Maslova, I.; Soloviev, D.; Zhmaylo, M.; Tarasenko, F. Finite Element Analysis of Customized Acetabular Implant and Bone after Pelvic Tumour Resection throughout the Gait Cycle. Materials 2021, 14, 7066. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Pan, Y.; Chen, J. Chemical constituents, pharmacologic properties, and clinical applications of bletilla striata. Front. Pharmacol. 2019, 10, 1168. [Google Scholar] [CrossRef] [PubMed]

- Sadyrin, E.V. Modeling the mechanism of reducing enamel mineral density in the vicinity of the fisure tip. Russ. J. Biomech. 2023, 27, 31–39. [Google Scholar] [CrossRef]

- Bolshakov, P.; Raginov, I.; Egorov, V.; Kashapova, R.; Kashapov, R.; Baltina, T.; Sachenkov, O. Design and Optimization Lattice Endoprosthesis for Long Bones: Manufacturing and Clinical Experiment. Materials 2020, 13, 1185. [Google Scholar] [CrossRef] [PubMed]

- Kichenko, A.A. Cancellous bone tissue remodeling: Mathematical modeling. Russ. J. Biomech. 2019, 23, 284–304. [Google Scholar] [CrossRef]

- Saleeva, L.; Kashapov, R.; Shakirzyanov, F.; Kuznetsov, E.; Kashapov, L.; Smirnova, V.; Kashapov, N.; Saleeva, G.; Sachenkov, O.; Saleev, R. The Effect of Surface Processing on the Shear Strength of Cobalt-Chromium Dental Alloy and Ceramics. Materials 2022, 15, 2987. [Google Scholar] [CrossRef]

- Babaei, M.; Kiarasi, F.; Asemi, K.; Hosseini, M. Functionally graded saturated porous structures: A review. J. Comput. Appl. Mech. 2022, 53, 297–308. [Google Scholar] [CrossRef]

- Deng, W.; Ni, H.; Liu, Y.; Chen, H.; Zhao, H. An adaptive differential evolution algo-rithm based on belief space and generalized opposition-based learning for resource al-location. Appl. Soft Comput. 2022, 127, 109419. [Google Scholar] [CrossRef]

- Podestá, J.M.; Méndez, C.G.; Toro, S.; Huespe, A.E.; Oliver, J. Material design of elastic structures using Voronoi cells. Numer. Methods Eng. 2018, 115, 269–292. [Google Scholar] [CrossRef]

- Kaveh, A.; Hamedani, K.B.; Hosseini, S.M.; Bakhshpoori, T. Optimal design of planar steel frame structures utilizing meta-heuristic optimization algorithms. Structures 2020, 25, 335–346. [Google Scholar] [CrossRef]

- Barg, S.; Flager, F.; Fischer, M. A design-focused, cost-ranked, structural-frame sizing optimization. J. Build. Eng. 2020, 30, 101269. [Google Scholar] [CrossRef]

- Bolshakov, P.; Kuchumov, A.G.; Kharin, N.; Akifyev, K.; Statsenko, E.; Silberschmidt, V.V. Method of computational design for additive manufacturing of hip endoprosthesis based on basic-cell concept. Int. J. Numer. Method Biomed. Eng. 2024, 40, e3802. [Google Scholar] [CrossRef]

- Angelucci, G.; Mollaioli, F. Voronoi-like Grid Systems for Tall Buildings. Front. Built Environ. 2018, 4, 78. [Google Scholar] [CrossRef]

- Liu, B.; Feng, J.; Chen, J.; He, Y.; Fu, J. A topology optimisation-based design method for 3D Voronoi porous structures and its application for medical pillows. Virtual Phys. Prototyp. 2023, 18, e2285392. [Google Scholar] [CrossRef]

- Liu, R.; Yao, G.; Gao, K.; Xu, Z.; Yang, Y.; Guo, X.; Yu, Z.; Zhang, Z.; Han, C. Study on mechanical properties of lattice structures strengthened by synergistic hierarchical ar-rangement. Compos. Struct. 2023, 304, 116304. [Google Scholar] [CrossRef]

- Gorny, B.; Niendorf, T.; Lackmann, J.; Thoene, M.; Troester, T.; Maier, H.J. In situ characterization of the deformation and failure behavior of non-stochastic porous struc-tures processed by selective laser melting. Mater. Sci. Eng. A 2011, 528, 7962–7967. [Google Scholar] [CrossRef]

- Lu, T.; Sun, Z.; Jia, C.; Ren, J.; Li, J.; Ma, Z.; Zhang, J.; Li, J.; Zhang, T.; Zang, Q.; et al. Roles of irregularity of pore morphology in oste-ogenesis of Voronoi scaffolds: From the perspectives of MSC adhesion and mecha-no-regulated osteoblast differentiation. J. Biomech. 2023, 151, 111542. [Google Scholar] [CrossRef]

- Yadav, N.; Kang, J.H.; Rybkowski, Z.K.; Yarnold, M.T.; He, W. Stress-weighted cen-troidal Voronoi tessellation for structural design. Finite Elem. Anal. Des. 2023, 216, 103905. [Google Scholar] [CrossRef]

- Liu, B.; Liu, M.; Cheng, H.; Cao, W.; Lu, P. A new stress-driven composite porous structure design method based on triply periodic minimal surfaces. Thin-Walled Struct. 2022, 181, 109974. [Google Scholar] [CrossRef]

- Liu, H.; Chen, L.; Jiang, Y.; Zhu, D.; Zhou, Y.; Wang, X. Multiscale optimization of additively manufactured graded non-stochastic and stochastic lattice structures. Compos. Struct. 2023, 305, 116546. [Google Scholar] [CrossRef]

- Frayssinet, E.; Colabella, L.; Cisilino, A.P. Design and assessment of the biomimetic capabilities of a Voronoi-based cancellous microstructure. J. Mech. Behav. Biomed. Mater. 2022, 130, 105186. [Google Scholar] [CrossRef]

- Lei, H.-Y.; Li, J.-R.; Xu, Z.-J.; Wang, A.-H. Parametric design of Voronoi-based lattice porous structures. Mater. Des. 2020, 191, 108607. [Google Scholar] [CrossRef]

- Bolshakov, P.; Kharin, N.; Kashapov, R.; Sachenkov, O. Structural Design Method for Constructions: Simulation, Manufacturing and Experiment. Materials 2021, 14, 6064. [Google Scholar] [CrossRef] [PubMed]

- Kharin, N.; Bolshakov, P.; Kuchumov, A.G. Numerical and Experimental Study of a Lattice Structure for Orthopedic Applications. Materials 2023, 16, 744. [Google Scholar] [CrossRef] [PubMed]

- Cadoret, N.; Chaves-Jacob, J.; Linares, J.-M. Structural additive manufacturing parts bio-inspired from trabecular bone form-function relationship. Mater. Des. 2023, 231, 112029. [Google Scholar] [CrossRef]

- Tung, C.C.; Lai, Y.Y.; Chen, Y.-Z.; Lin, C.-C.; Chen, P.-Y. Optimization of mechanical properties of bio-inspired Voronoi structures by genetic algorithm. J. Mater. Res. Technol. 2023, 26, 3813–3829. [Google Scholar] [CrossRef]

- Do, Q.T.; Nguyen, C.H.P.; Choi, Y. Homogenization-based optimum design of additively manufactured Voronoi cellular structures. Addit. Manuf. 2021, 45, 102057. [Google Scholar] [CrossRef]

| c00 | c10 | c01 | c11 | c21 | c31 | c12 | c22 | c13 | |

|---|---|---|---|---|---|---|---|---|---|

| E11, GPa | 109 | −3.9 | −5.3 | −192 | 287 | −115 | 319 | −209 | −136 |

| E22,33, GPa | 102 | 2.9 | 10.6 | −111 | 325 | −278 | −17.8 | −18.7 | 27 |

| G12,13, GPa | 10.7 | −0.1 | 0.25 | −2.7 | 13 | −10 | −3.9 | −0.1 | 4.1 |

| G23, GPa | 2.5 | −0.1 | −0.06 | −4.4 | 8 | −3.4 | 6.4 | −5 | −2.5 |

| υ12,13 | 0.011 | – | – | – | – | – | – | – | – |

| υ23 | 0.017 | – | – | – | – | – | – | – | – |

| Number of Clusters | Zones | ||

|---|---|---|---|

| I | II | III | |

| 50 | 5% | 15% | 2.8% |

| 75 | 4.5% | 14.8% | 2.5% |

| 100 | 4.3% | 14.8% | 2.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bolshakov, P.; Kharin, N.; Agathonov, A.; Kalinin, E.; Sachenkov, O. Extension of the Voronoi Diagram Algorithm to Orthotropic Space for Material Structural Design. Biomimetics 2024, 9, 185. https://doi.org/10.3390/biomimetics9030185

Bolshakov P, Kharin N, Agathonov A, Kalinin E, Sachenkov O. Extension of the Voronoi Diagram Algorithm to Orthotropic Space for Material Structural Design. Biomimetics. 2024; 9(3):185. https://doi.org/10.3390/biomimetics9030185

Chicago/Turabian StyleBolshakov, Pavel, Nikita Kharin, Alexander Agathonov, Evgeniy Kalinin, and Oskar Sachenkov. 2024. "Extension of the Voronoi Diagram Algorithm to Orthotropic Space for Material Structural Design" Biomimetics 9, no. 3: 185. https://doi.org/10.3390/biomimetics9030185

APA StyleBolshakov, P., Kharin, N., Agathonov, A., Kalinin, E., & Sachenkov, O. (2024). Extension of the Voronoi Diagram Algorithm to Orthotropic Space for Material Structural Design. Biomimetics, 9(3), 185. https://doi.org/10.3390/biomimetics9030185