1. Introduction

Metaheuristic optimization algorithms have recently garnered significant attention and become a focal point for many computer science and engineering researchers. They are increasingly prevalent across various domains, including numerical optimization [

1,

2], cloud computing [

3], neural networks [

4], feature selection [

5,

6], classification [

7], clustering [

8], predicting chemical activities [

9], text document clustering [

10], and face detection & recognition [

11].

Examples of metaheuristic algorithms include Genetic Algorithms (GA) [

12], CMAES) [

13], Cuckoo Search Optimization (CS) [

14], the Harmony Search (HS) Algorithm [

15], Artificial Bee Colony (ABC) [

16], the Krill Herd Algorithm (KHA) [

17], the Ant Lion Optimizer (ALO) [

18], Moth-flame Optimization (MFO) [

19], the Crow search Algorithm (CSA) [

20], the Whale Optimizer Algorithm (WOA) [

21], the Lightning Search Algorithm (LSA) [

22], the Salp Swarm Algorithm (SSA) [

23], Harris Hawks Optimization (HHO) [

24], Virus Colony Search (VCS) [

25], and the Snake Optimizer (SO) [

26].

Metaheuristics (MHs) typically adopt strategies from swarm intelligence (SI), evolutionary algorithms (EA), physics-based principles, and human-based concepts. EAs are inspired by biological behaviors, while SI draws on food foraging, mutation, territorial fights, and mating behaviors. Physics laws and human behavior also influence optimizer development [

27]. Consequently, these refined algorithms are increasingly applied to effectively address challenges in engineering design optimization, yielding more promising solutions.

Despite the wide range of problem-solving capabilities offered by metaheuristics, the “No free Lunch” hypothesis suggests that no single MH can provide the best solution for every complex problem [

28]. Each optimization problem requires a specific strategy to be effectively addressed [

29].

While solving complex engineering problems, metaheuristics may have drawbacks such as slow convergence and being trapped in local search domains, resulting in higher computational costs [

30]. To address these limitations, researchers have devised hybridized, modified, and enhanced MHs that incorporate more beneficial attributes. A few examples include the Hybrid Grey Wolf and Crow Search [

31], Hybrid Heat Transfer and Passing Vehicle Search [

32], Hybrid Artificial Hummingbird-Simulated Annealing [

33], Modified Symbiotic Organisms Search [

34], Modified Marine Predator Algorithm [

35], Improved Ant Colony Optimization [

36], and Improved Salp Swarm Algorithm [

37]. To create effective MHs, a balance between global diversification and local intensification is crucial. Both exploration and exploitation phases are important in finding superior solutions and achieving results in the least amount of time. Despite numerous hybrid MHs being implemented in engineering design optimization over the last few decades, the quest for even more potent methods is ongoing. This field continues to evolve and presents new challenges for researchers to address.

The Artificial Electric Field Algorithm (AEFA) is a recent population-based algorithm proposed by Anita and Yadav [

38] that is inspired by the electrostatic force of Coulomb’s law. AEFA has been successfully employed in many applications such as photovoltaics [

39], fuel cell estimation [

40], the economic load dispatch problem [

41], non-linear system modeling [

42], the quadratic assignment problem [

43], soil shear [

44], and wind turbine allocation [

45].

In addition, many researchers have introduced different variants of AEFA algorithms. For example, Izci et al. [

46] hybridized AEFA with the Nelder–Mead simplex. Likewise, Petwal and Rani [

47] developed a multiobjective version of AEFA. They strengthened AEFA by adding polynomial mutation and bounded exponential crossover operators. A novel set of velocity and position bounds has been proposed by Anita et al. [

48] to address engineering problems. Anita and Yadav [

49] developed a discrete AEFA for high-order graph matching. Furthermore, a detailed study of stability and exploratory abilities was presented in [

50].

Kahraman et al. [

51] introduce a novel approach called the Natural Survivor Method (NSM), devised as a model for population management mirroring natural processes, taking into account environmental variables and analytical relationships. Within the NSM framework, scores reflecting individuals’ adaptability to their natural surroundings are computed to identify survivors. Additionally, the update mechanism in this proposed method is constructed based on NSM scores rather than traditional fitness values.

Although AEFA has demonstrated effectiveness in addressing intricate engineering problems, it exhibits a notable susceptibility to converging toward suboptimal solutions. The iterative process of population size selection poses challenges, as optimal sizes vary across different problems. Like any other algorithm, AEFA demonstrates a moderate convergence rate, potentially requiring more time than alternative algorithms to reach an optimal solution. Moreover, the efficacy of AEFA is notably contingent on parameter choices, including the number of particles, electric charge, and inertia. AEFA performance may be limited on large-scale problems due to high computational complexity. Moreover, AEFA may face premature convergence issues, particularly in multimodal optimization problems. Furthermore, if the algorithm focuses too much on exploration, it may sacrifice exploitation, and vice versa, thus striking a balance between global diversification and local intensification is crucial for optimizing performance. Hybridizing AEFA with other algorithms or the inclusion of performance improvement strategies can result in faster convergence, higher precision, and greater robustness [

52]. As AEFA is a relatively new optimizer, there is great potential for uncovering new improvements that can further enhance its efficiency and performance.

The objective of this research was to enhance the performance of the existing AEFA algorithm by addressing its limitations, with a focus on achieving faster convergence, increased accuracy, and improved robustness. To achieve these goals, a modified version of AEFA named modified AEFA (mAEFA) is introduced based on two techniques: Lévy flights and Simulated Annealing (SA). The first operator is used to increase randomness and the second is used to increase exploitation.

This study offers the following significant contributions:

The Lévy flight distribution mechanism is incorporated to increase the search space of AEFA and improve the exploration potential of the algorithm. This integration aims to prevent the algorithm from getting trapped in local optima, thereby contributing to an overall improvement in performance;

A simulated annealing mechanism is integrated with AEFA to improve search exploitation by allowing the algorithm to accept solutions that are worse than the current best solution with a certain probability, which helps to avoid getting stuck in local optima and explore other areas of the search space. This can lead to finding better solutions that may have been missed otherwise. Therefore, hybridizing simulated annealing into an algorithm can lead to improved performance and robustness;

A thorough evaluation of mAEFA performance, utilizing both quantitative and qualitative methods, is carried out on a variety of complex CEC 2017 constraint benchmarks with varying characteristics;

The behavior of mAEFA is evaluated and compared to 12 prevalent MH approaches on five engineering benchmark problems drawn from diverse fields.

The rest of this paper is structured as follows:

Section 2 discusses recent work on metaheuristics and

Section 3 introduces the original AEFA.

Section 4 presents the suggested modified version of AEFA.

Section 5 details the results of the conducted statistical tests and respective discussion, and

Section 6 concludes the paper, including outlining future directions.

2. Related Work

The Lévy flight (LF) mechanism is a popular choice for researchers aiming to bolster the optimization efficacy of algorithms, spanning diverse research domains such as control system design [

53], wind speed forecasting [

54], and high-dimensional optimization problems [

55]. Characterized by random steps, the application of LF enables optimization algorithms to navigate the vicinity of existing solutions, while intermittent significant leaps mitigate the risk of entrapment within local minima. For instance, Zhang et al. [

56] recently demonstrated that LF enhances particle diversity within PSO, thereby refining the accuracy of lithium-ion battery State-of-Health prediction. Similarly, Hussien et al. [

57] noted the efficacy of LF-based Transient Search Optimization in augmenting the transient response of terminal voltages within islanded microgrids. Furthermore, Barua et al. [

58] amalgamated the LF strategy with the Arithmetic Optimization Algorithm to address various engineering optimization challenges. Their findings underscore the hybrid algorithm’s superior optimization capabilities, requiring fewer evaluations and surpassing several established algorithms in performance benchmarks.

Simulated annealing (SA) is an MH extensively employed to enhance the search capability of optimization algorithms [

59]. Distinguished by its probabilistic jump feature, inspired by the physical process of annealing solids, SA effectively mitigates the risk of stagnation in local optima, facilitating the attainment of global optima. For example, Xu et al. [

60] endeavored to enhance the Whale Optimization Algorithm by integrating it with SA, yielding superior optimization performance and stability across multiple dimensional problems compared to alternative algorithms such as WOA, GWO, and PSO. Similarly, Fontes et al. [

61] employed a hybrid of SA and PSO for tackling the job shop scheduling problem, achieving high-quality solutions within reasonable computation times. In another study, Sajjad et al. [

62] noted that the incorporation of SA notably enhanced the convergence of the multiobjective Grasshopper Algorithm when applied to problem solving in IoT applications.

The performance of population-based metaheuristic algorithms is significantly influenced by the size, nature, and diversity of the initial population, as well as the number of iterations. Agushaka et al. [

63] observed that BA performed better with larger population sizes, while GWO, WOA, BOA, MS, and LSHADE-cnEpSin benefited from more iterations. Conversely, MFO, LSHADE, EHO, and HHO showed optimal performance with balanced population sizes and iterations. Kazimipour et al. [

64] categorize population initialization techniques based on randomness, compositionality, and generality aspects. While random number generators are commonly used for initialization, their limitations have prompted researchers to explore alternative distributions, such as Latin Hypercube Sampling (LHS), to enhance efficiency [

65]. Quasirandom sequences like Halton, Sobol, and Faure have demonstrated effectiveness in uniformly covering the search space, as seen in PSO and Global Best PSO. Chaotic sequences have also shown promise in initializing populations in CS and BFO, despite concerns about computational complexity. Hybridization with other metaheuristic algorithms, like the Greedy Randomized Adaptive Search Procedure (GRASP) and Metropolis–Hastings (MH), has the potential for improving initialization schemes, though scalability and time complexity are challenges. Leveraging ad hoc knowledge of the problem domain, as seen in the Bat Algorithm (BA), and innovative approaches such as patch environments and quasi-opposition-based learning in CS, aim to improve algorithm efficacy. Each method presents unique advantages and challenges, highlighting the importance of selecting suitable initialization strategies tailored to the problem domain and available computational resources [

63,

64,

65].

The MH process involves two main steps: selection of solution candidates from the population and determination of the search direction. Selection methods are vital in MHs and are categorized into three types: non-deterministic, deterministic, and probabilistic [

66]. Non-deterministic methods randomly select solution candidates to enhance search diversity. Deterministic methods consider fitness values, selecting the best candidates to guide the search towards successful positions. Probabilistic methods combine characteristics of both elitist and random methods, with examples including the roulette wheel and tournament methods. New selection methods, such as Fitness–Distance balance (FDB) [

66], Fitness–Distance-Constraint (FDC) [

67], Adaptive FDB [

68], and Dynamic FDB [

69], address specific challenges in MH search.

3. Artificial Electric Field Algorithm

The Artificial Electric Field Algorithm (AEFA) is a recent population-based metaheuristic algorithm that mimics Coulomb’s electrostatic force law [

38]. Coulomb’s electrostatic law states that the force between any two charged particles is inversely proportional to the distance squared between the particles and directly proportional to their charge product.

Particles can migrate/move in the search space. With the help of the electrostatic force, particles are able to interact with each other (either repulsion or attraction).

In AEFA, one only considers the attraction force, which means that particle with the highest charge will absorb other particles with lower charges. The objective function in AEFA is the candidate solution (particle) charges and the agent fitness value. To mathematically model the electric force, the following steps are used.

The position of i-th agent can be given as , where is the position of i-th agent at d-dimension.

The position of the best agent (solution) obtained by any particle,

i, at any time,

t, denoted as

, is given by the following Equation (

1)

where

is the position of the personal best particle.

is the position of the best charged particle determined based on fitness. The best objective value via all particles is given as

.

To calculate the total force that is acting on agent

i at time

t, the following equation is used

where

is a random number between 0 and 1,

N refers to the number of search agents, and

refers to resultant force that affect on the

i-th agent.

The acceleration of the

i-th agent at

d dimension can be calculated using Newton’s second law of motion as below

and

represent the charges and electric field of the

particle, and

refers to

particle mass. The velocity and position of particles can be updated using the two following equations:

where

is a random number belongs to the interval

. The particles’ charge can be obtained using fitness functions and assuming that each particle has the same charge.

5. Experimental Results and Discussion

To evaluate the proposed mAEFA method, this study employs the CEC’17 test suite, consisting of 30 functions commonly used to assess MHs [

71]. Five engineering problems are also used for evaluation. The objective is to assess the search capability and convergence behavior of the proposed method. Given the stochastic nature of MHs, the experiments are conducted 30 times to account for randomness and observe result variations across runs.

Several newly developed algorithms are employed for comparison with the suggested mAEFA. These algorithms consist of the Coronavirus Herd Immunity Optimizer (CHIO) [

72], Gravitational Search Algorithm (GSA) [

73], Smell Agent Optimization (SAO) [

74], Grasshopper Optimisation Algorithm (GOA) [

75], Particle Swarm Optimization (PSO) [

76], Liver Cancer Algorithm (LCA) [

77], and basic AEFA [

38]. For fairness in comparing algorithms, all were executed on the same hardware system to solve the CEC’17 test suite. The experiments were standardized with a maximum of 500 iterations. MATLAB 2021 served as the programming language for all algorithms, operating on a 64-bit Windows 8.1 system with an i7 Core and 8 GB RAM.

5.1. Experimental Series 1: CEC’17

5.1.1. Comparing mAEFA with State-of-Art Algorithms

CEC’17 includes functions representing diverse, complex, and dynamic optimization problems, commonly used for evaluating algorithm effectiveness. This study assesses the mAEFA algorithm using these functions, gaining insights into its effectiveness. Furthermore, it’s worth noting that each experiment is constrained by a maximum evaluation limit of 50,000 iterations. The setup entails employing 30 agents within a 30-dimensional space, as delineated in

Table 1. Throughout the entirety of the experimentation, MATLAB2021 is utilized as the programming language, operating on a 64-bit Windows 8.1 platform.

Table 2 presents the 30 functions, classified into four sets: F1 to F3 represents the unimodal set, F4 to F10 represents the multimodal set, F11 to F20 represents the hybrid set, and F21 to F30 represents the composition set. F2 is excluded from the evaluation process, leaving a total of 29 functions utilized to evaluate the mAEFA algorithm and other algorithms. The search range for all test functions, as indicated in

Table 2, spans from −100 to 100, with a dimensionality of 30. In order to test and validate the enhanced version of mAEFA, we conducted a comparison with the original AEFA as well as six other distinct algorithms: CHIO, GSA, SAO, GOA, PSO, and LCA. The parameter seetinbg of each algorithm is given in

Table 3.

The evaluation was based on the calculation of the average and standard deviation.

The comparison results are presented in

Table 4. It is evident from the table that the developed algorithm (mAEFA) ranks first in 20 out of the 29 functions. Additionally, mAEFA obtains the second-best results in four functions and the third-best result in three functions. In contrast, GSA ranks first in only five functions, while AEFA achieves the best results in only four functions. Among the majority of the CEC’17 29 test functions, the algorithms that exhibit the lowest performance are SAO, GOA, LCA, and CHIO.

To validate the effectiveness of mAEFA, the statistical results of the nonparametric Wilcoxon rank-sum (WRS) test are presented in

Table 5. This test helps determine the significance of the differences between mAEFA and other algorithms measured with a

p-value of ≤0.05. Based on the results, the mAEFA algorithm demonstrates superior performance compared to the LCA algorithm across all 29 test functions. It also outperforms SAO and GOA in 28 functions, CHIO in 27 functions, PSO in 25 functions, GSA in 24 functions, and AEFA in 17 functions, showcasing better results in each case.

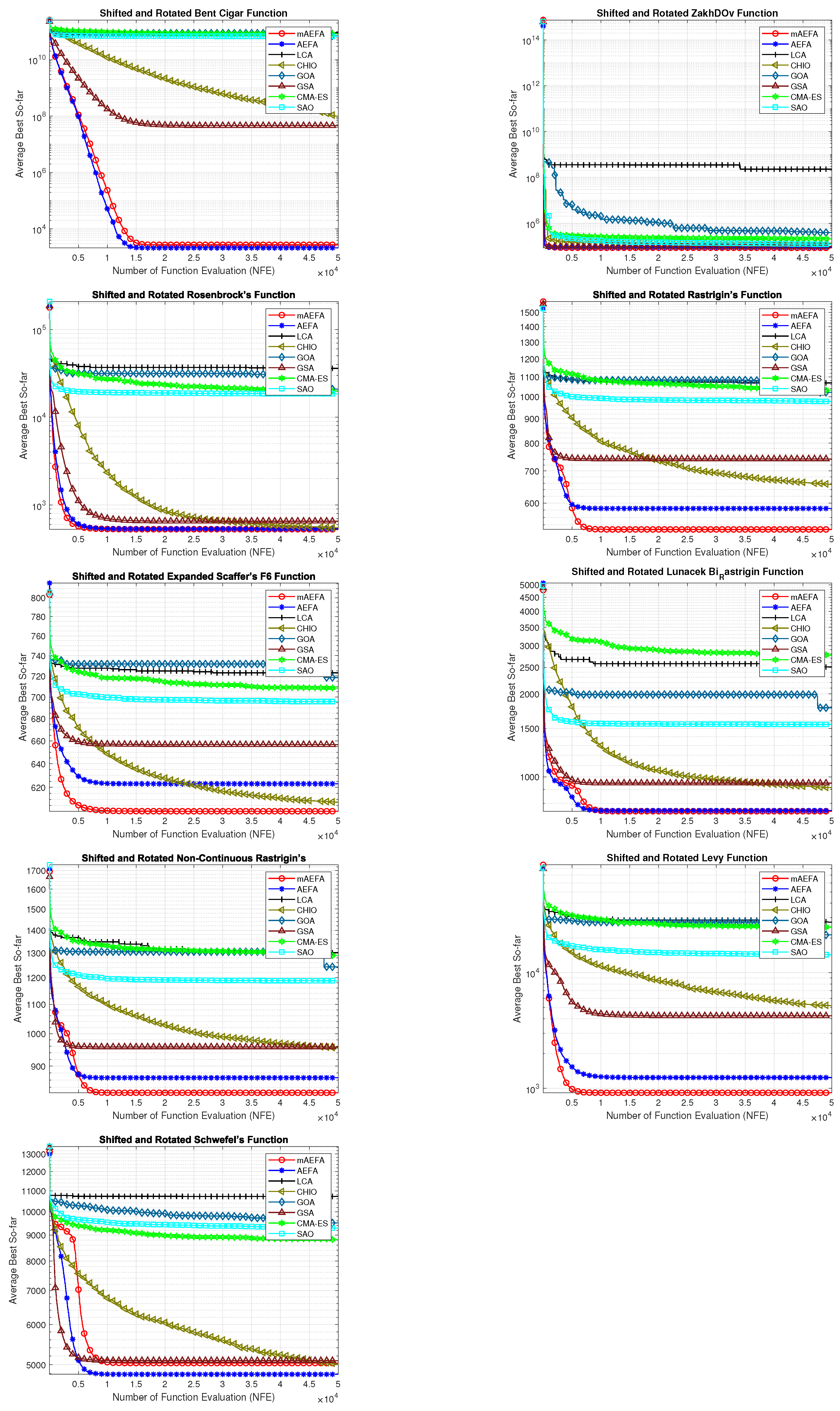

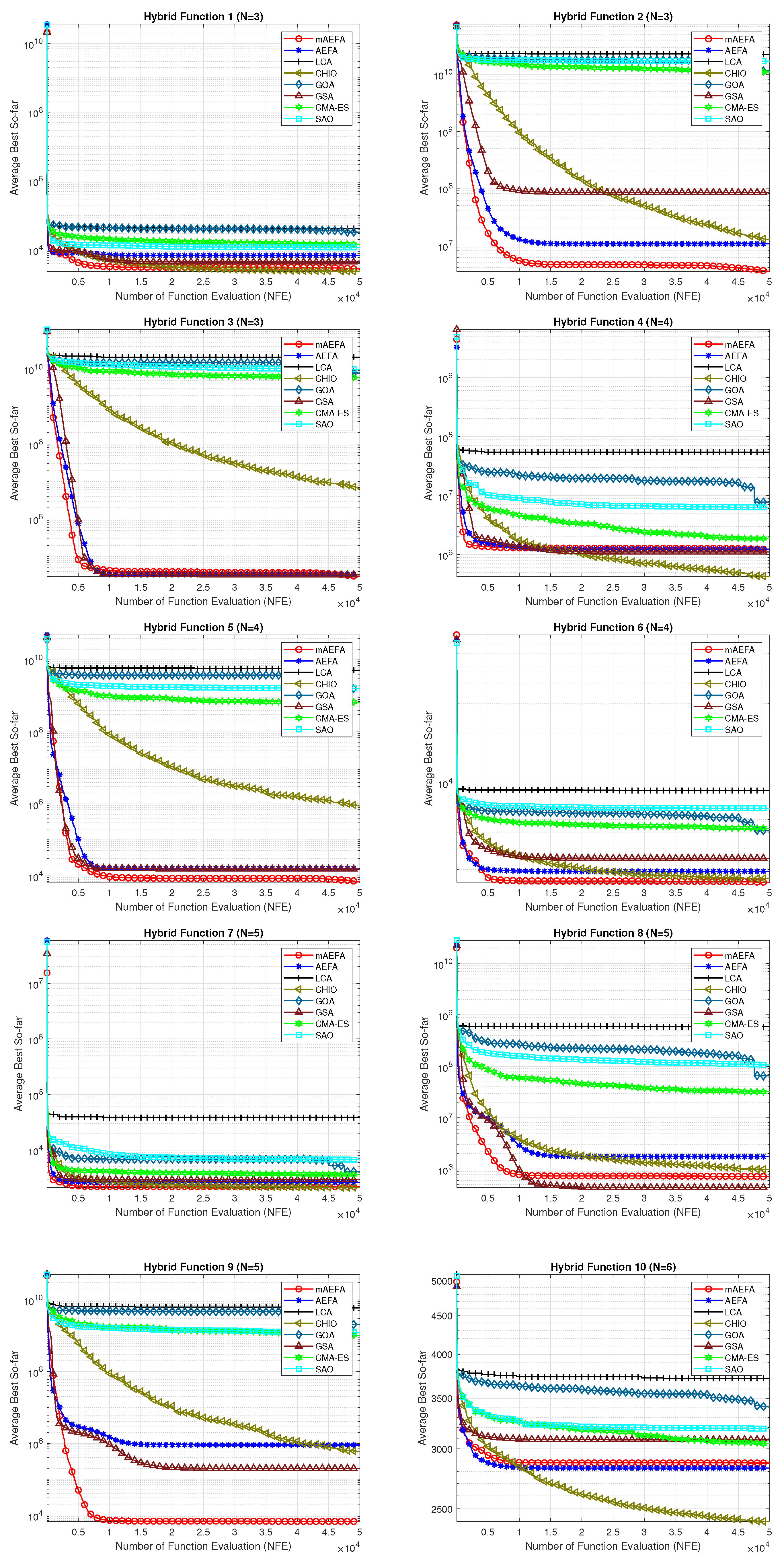

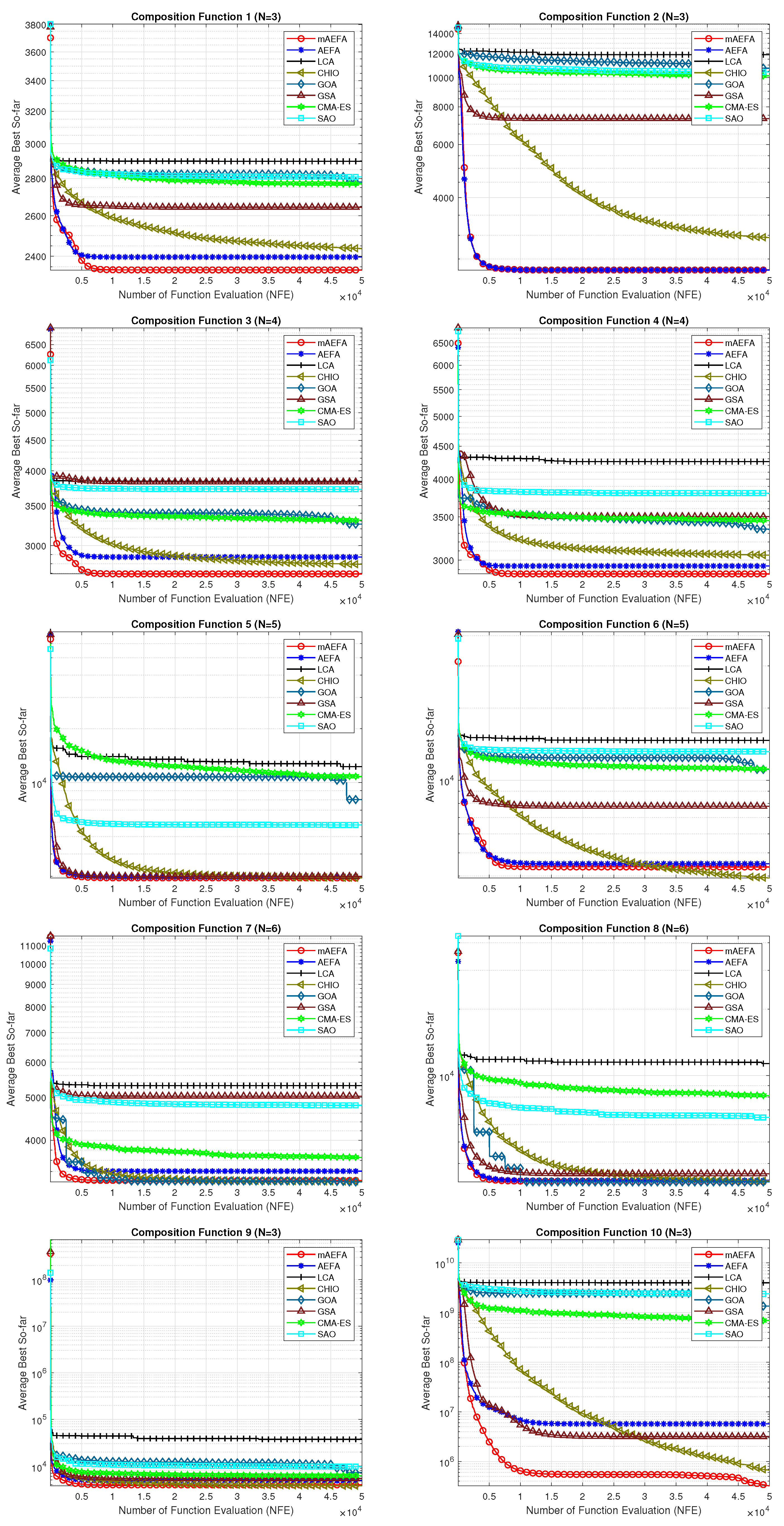

The convergence behavior of the proposed mAEFA algorithm, along with the other compared algorithms, applied to the CEC’17 functions is depicted in

Figure 2,

Figure 3 and

Figure 4. It can be observed that mAEFA demonstrates rapid convergence for F3–F6, F8, F11–F14, F16, F17, F19, F21, F23, F24, and F27–30 compared to the classical AEFA algorithm. Additionally, mAEFA on average depicted better convergence behavior relative to the other algorithms in most of the CEC test suite benchmarks. The mAEFA algorithm demonstrates a balanced exploration–exploitation trade-off, evident in its convergence plots, showcasing both faster convergence and the discovery of optimal solutions during the search process.

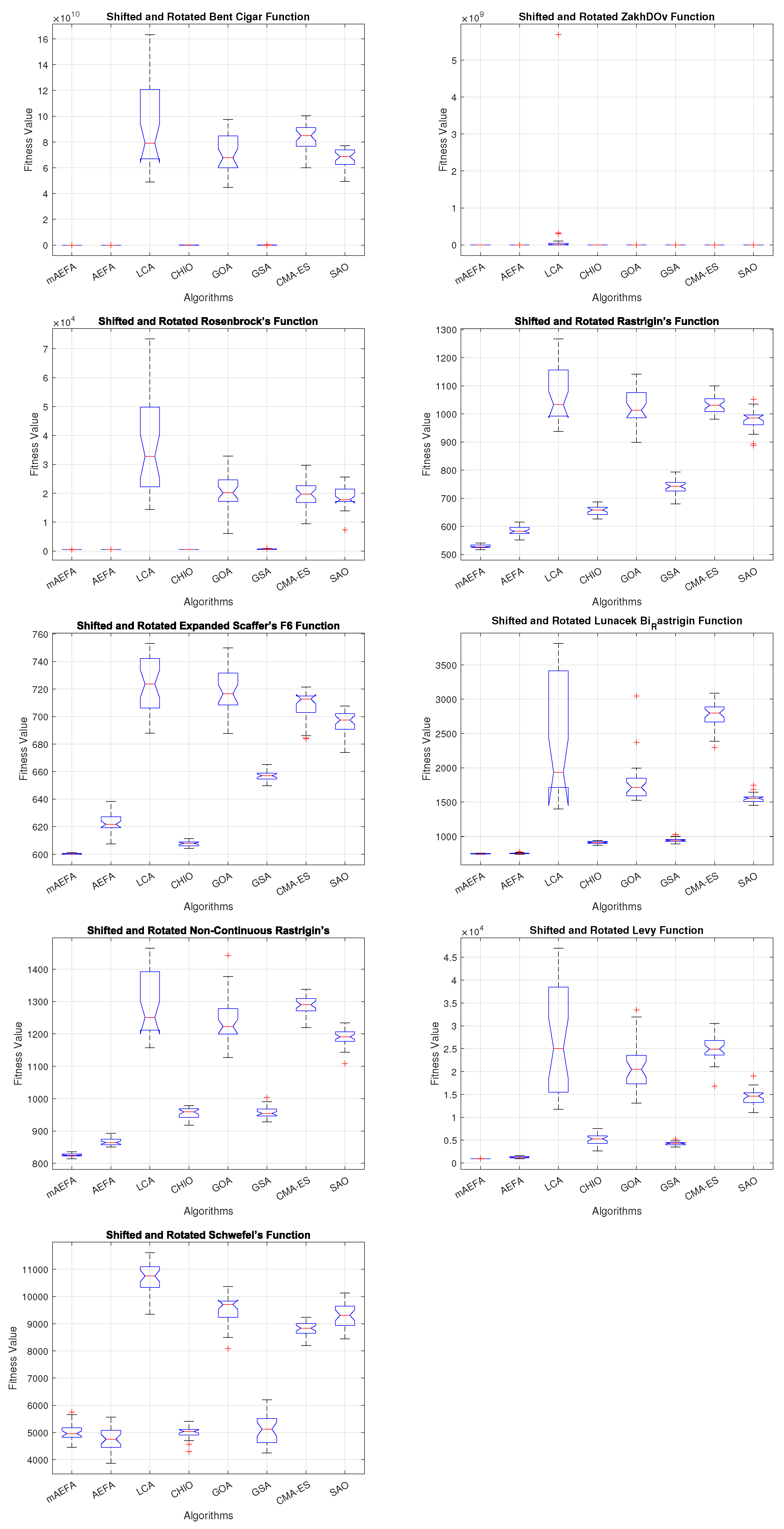

Additionally,

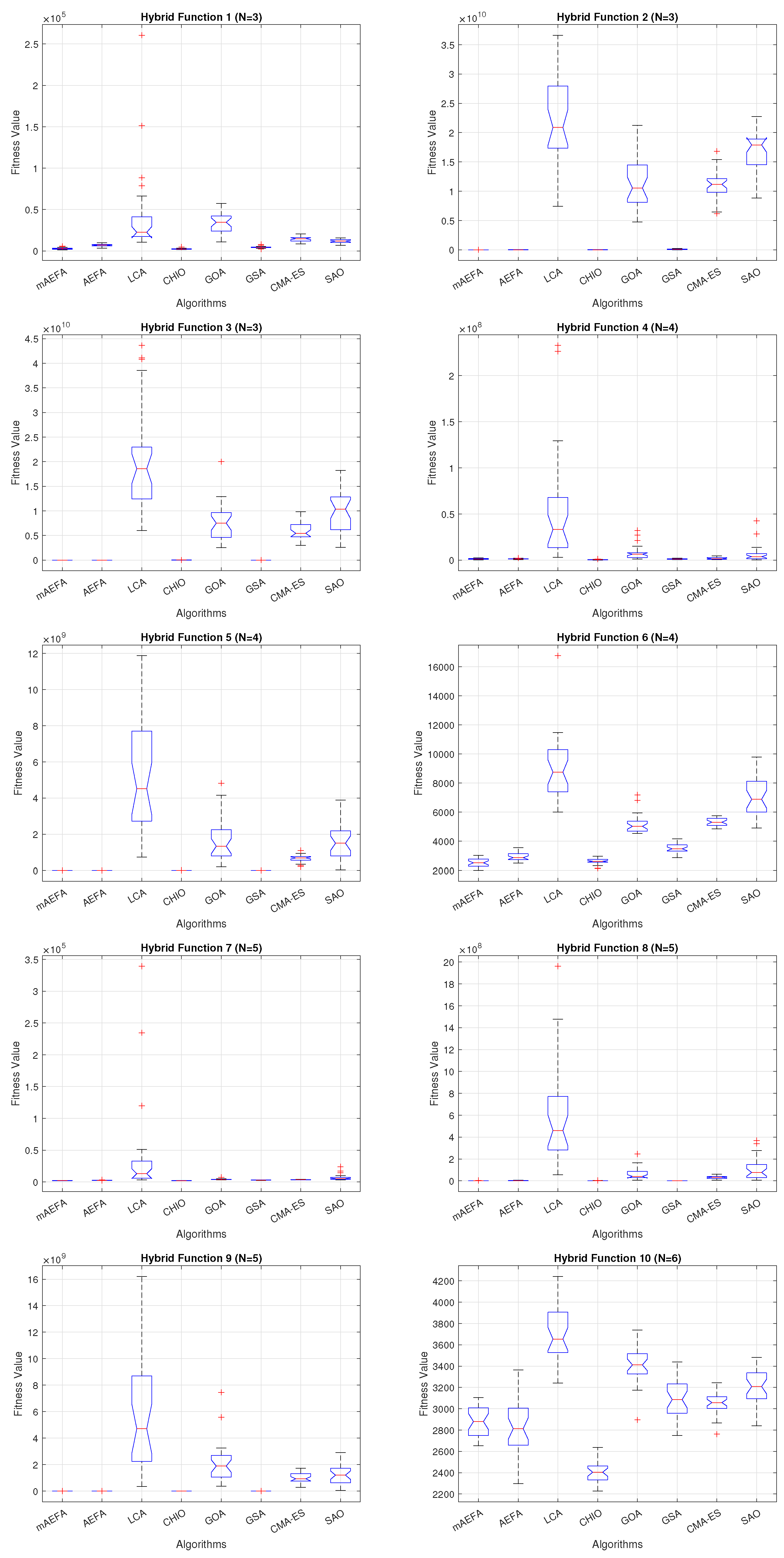

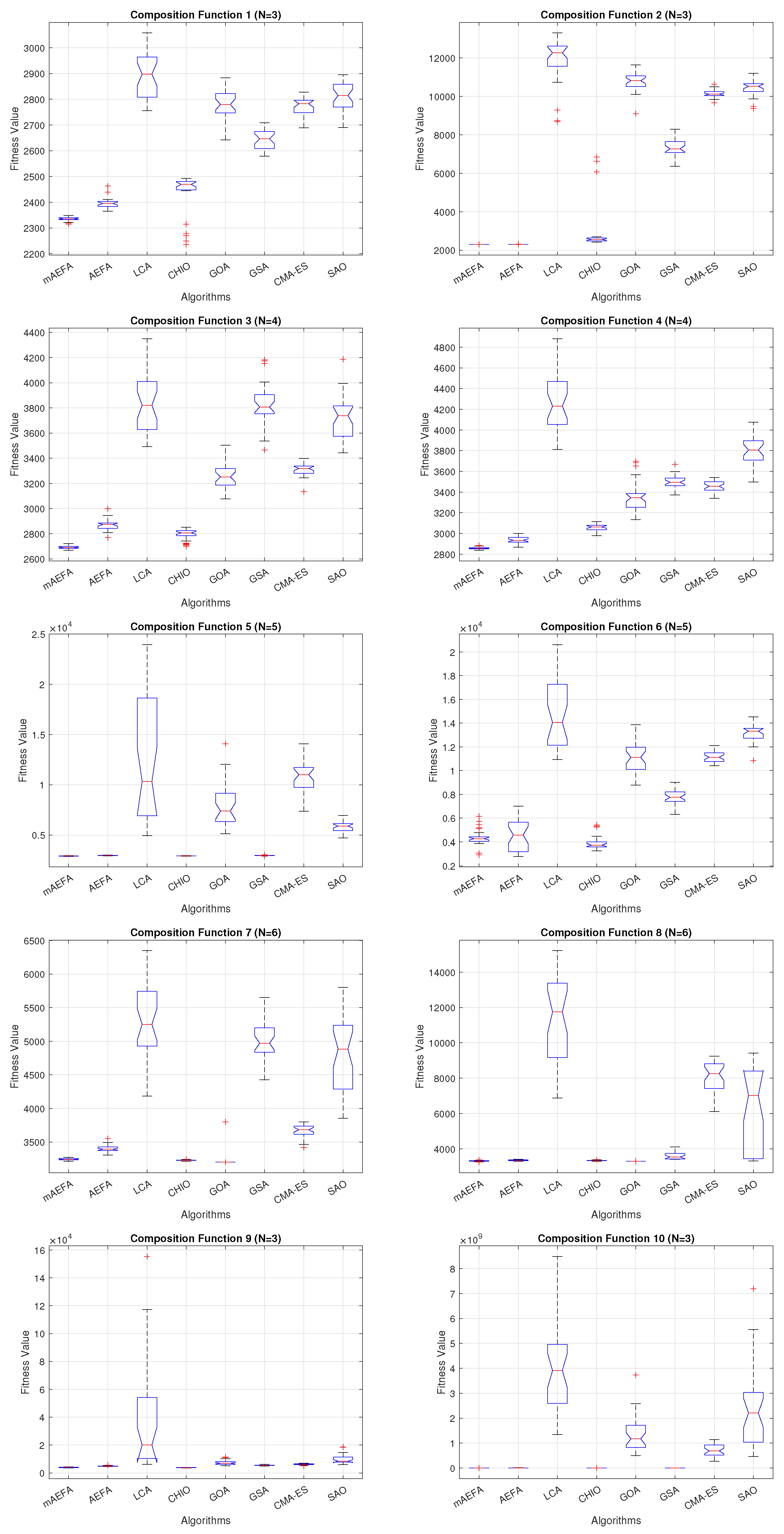

Figure 5,

Figure 6 and

Figure 7 shows box plots for the proposed algorithm and the other compared algorithms, highlighting the distribution of results and the degree of proximity and similarity across multiple runs. The box plot is utilized to represent the minimum, maximum, and mean values for each algorithm. Box plots serve as an effective visual representation for presenting the performance values obtained in the 1st, 2nd, and 3rd] quarters of the experiment. A horizontal line within the box denotes the median value, while the whiskers extending outside indicate the variability beyond the upper and lower quartiles. Ideally, smaller box sizes and lower variability are preferred.

Figure 5,

Figure 6 and

Figure 7 illustrate box plots for mAEFA for the majority of the functions, displaying narrow boxes with the lowest median and variability.

5.1.2. Comparing mAEFA with Fitness–Distance Balance Variants

In this subsection we compare mAEFA with two other FDB variants, namely FDB-SOS [

66] and dfDB-MRFO [

69].

Table 6 presents the statistical analysis results in terms of minimum, maximum, average, and standard deviation values, along with the ranks of the algorithms. Upon examination, mAEFA consistently outperforms the other variants across several functions, as evidenced by its lower minimum and average values, as well as its higher ranks in most cases. For example, in functions

F5–

F9,

,

F21–

F24, and

F26, mAEFA demonstrates superior performance with lower minimum and average values compared to dfDB-MRFO and FDB-SOS, resulting in higher ranks. Additionally, mAEFA shows competitive performance in other functions, such as

,

,

,

, and

, where it achieves comparable results to the other variants. Overall, the comparative analysis suggests that mAEFA exhibits favorable performance across a range of benchmark functions compared to dfDB-MRFO and FDB-SOS. These findings underscore the efficacy of mAEFA as a competitive algorithm for solving optimization problems, particularly in the context of the functions analyzed in this study.

5.2. Experimental Series 2: Engineering Problems

In this section, we explore five distinct engineering challenges to assess the effectiveness of the proposed solution in dealing with problems that involve constraints. The following constraint problems, which are commonly encountered and widely utilized, have been considered: speed reducer design (SRD), pressure vessel design (PVD), cantilever beam design (CBD) and the multi-product batch plant (MPBP) problem, and Industrial Refrigeration System Optimal Design.

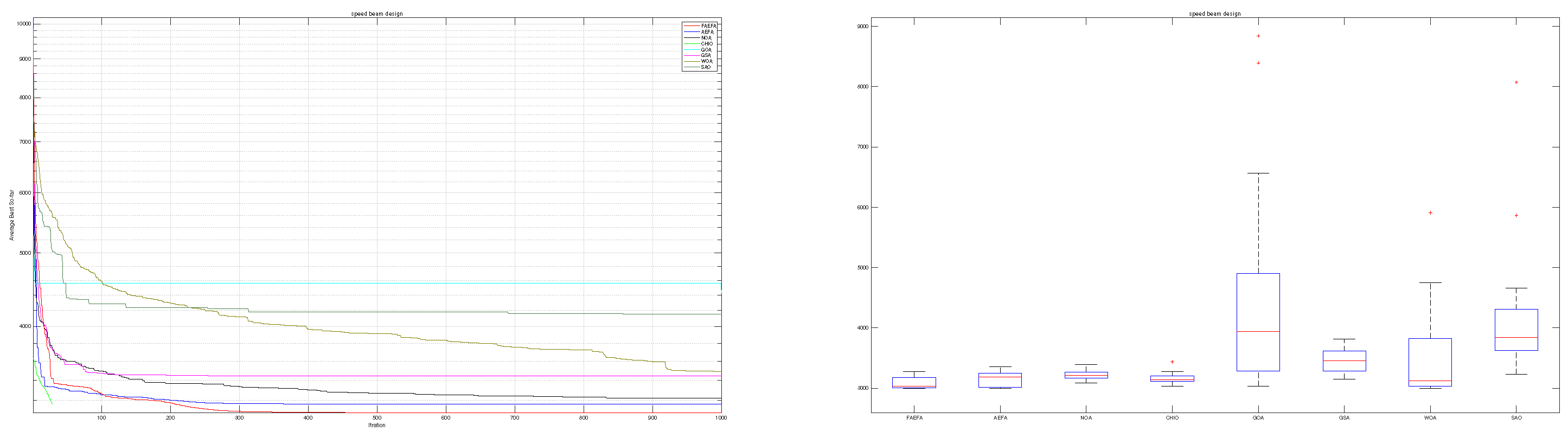

5.2.1. Speed Reducer Design Problem

This problem involves optimization with the objective of minimizing the weights associated with various design elements. The optimization process incorporates constraints related to gear teeth, stress, deflection ratios of bending, surface, and shafts [

78]. The SRD is based on seven design variables (

) that aim to minimize the weight. These variables represent face width, teeth module, pinion teeth number, the length of the first shaft between the bearings, the length of the second shaft between the bearings, and the diameters of the first and second shafts.

The mAEFA algorithm attains the top rank with a significantly low standard deviation, as indicated by the results in

Table 7. Furthermore,

Table 8 illustrates its competitive performance across all seven variables, underscoring the noteworthy differentiation of mAEFA in comparison to alternative algorithms.

Figure 8 illustrates a distinct divergence in convergence patterns among the algorithms, where mAEFA exhibits superior convergence by attaining exceptionally low values in the final iteration of the search process.

5.2.2. Pressure Vessel Design Problem

The PVD problem, introduced by Kannan and Kramer [

79], is the second engineering design problem in this study, assessing the effectiveness of the proposed mAEFA. This problem revolves around optimizing the cost associated with PVD, aiming to minimize it. The cost is determined by four design variables:

, which represent shell thickness, head thickness, inner radius, and cylinder length, respectively. Hashim et al. [

80] provide an extensive description of the mathematical model for this problem. The PVD problem’s mathematical model can be defined using the following set of equations.

According to the findings presented in

Table 9, the mAEFA algorithm obtains the first rank with a minimum mean value of 6412.152.

Figure 9 demonstrates comparable behavior across all algorithms, with mAEFA consistently achieving minimum values during the later iterations.

Table 10 presents the variable values obtained by each algorithm for this specific problem. Notably, mAEFA achieves competitive values for

and

, and it secures the second-lowest value for

.

Table 10 clearly indicates that mAEFA surpasses all algorithms, except for the LCA algorithm, indicating a substantial difference in its performance.

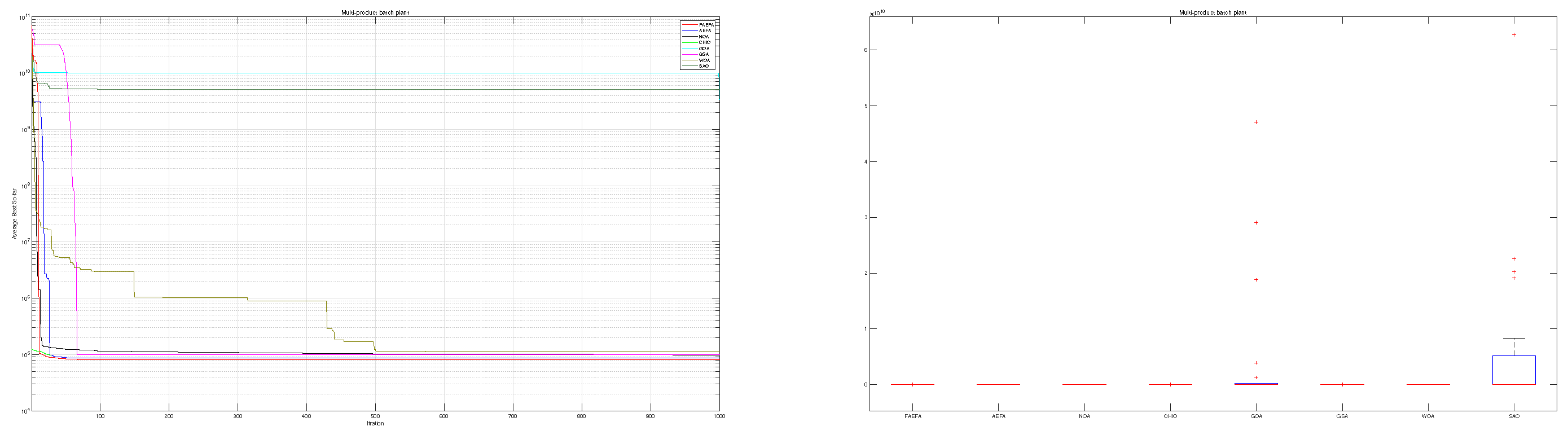

5.2.3. Multi-Product Batch Plant Problem

In the MPBP problem, the production process begins after the customer submits their order, with each order representing a specific product. Throughout production, the batch size for each order remains constant. Each order is assigned due dates and release dates. At each stage, there are dedicated processing units that exclusively operate within that stage. The objective of this problem is to minimize the makespan, considering additional constraints such as unallowed unit assignments, order due dates, release dates, and storage issues. The problem’s formulation is delineated by Equations (

12)–(

23), with Equation (

12) addressing the constraint related to order assignment, ensuring that each order (

i) can only be processed on a single unit (

j) at a specific step (

s).

Equations (

13)–(

15) reveal unit order sequencing, with Equations (

13) and (

15) indicating a singular first order for each unit

j, and Equation (

12) depicting sequence constraints for different orders

i and

i′ on the same unit

j.

Equations (

16) and (

17) represent unit assignment constraints. When integer variables

or

are activated, it implies that orders

and

i must be processed on the same unit

j.

Equations (

16)–(

19) represent order timing constraints. Equation (

18) pertains to timing constraints within one order’s various steps, while Equation (

19) addresses timing constraints for multiple orders on the same unit. Additionally, when considering unit release time

or order release time

, Equations (

20) and (

21) come into play. Equation (

22) is applicable for cases involving due date

.

The goal is to minimize the makespan, and the objective function is defined as follows:

Meeting all constraints is straightforward except for Equation (

22) when minimizing the makespan with metaheuristic algorithms. To accommodate Equation (

22), a penalty function is employed, and Equations (

24) and (

25) are utilized to calculate the objective function in this study:

Equation (

24) defines the penalty function, which is employed to penalize violations in Equation (

25). When the completion time of each order exceeds its respective due date, Equation (

24) comes into effect, leading to a reduction in the objective value in Equation (

25).

According to the data presented in

Table 11, the mAEFA algorithm secures the first position in terms of statistical ranking amongst all compared algorithms.

Table 12 showcases that mAEFA attains competitive results across various problem variables.

Figure 10 depicts that mAEFA, alongside some other algorithms, demonstrates similar convergence behavior reaching minimum values. However, both CHIO and SAO exhibit premature convergence behavior, indicating a tendency to get trapped in local minima.

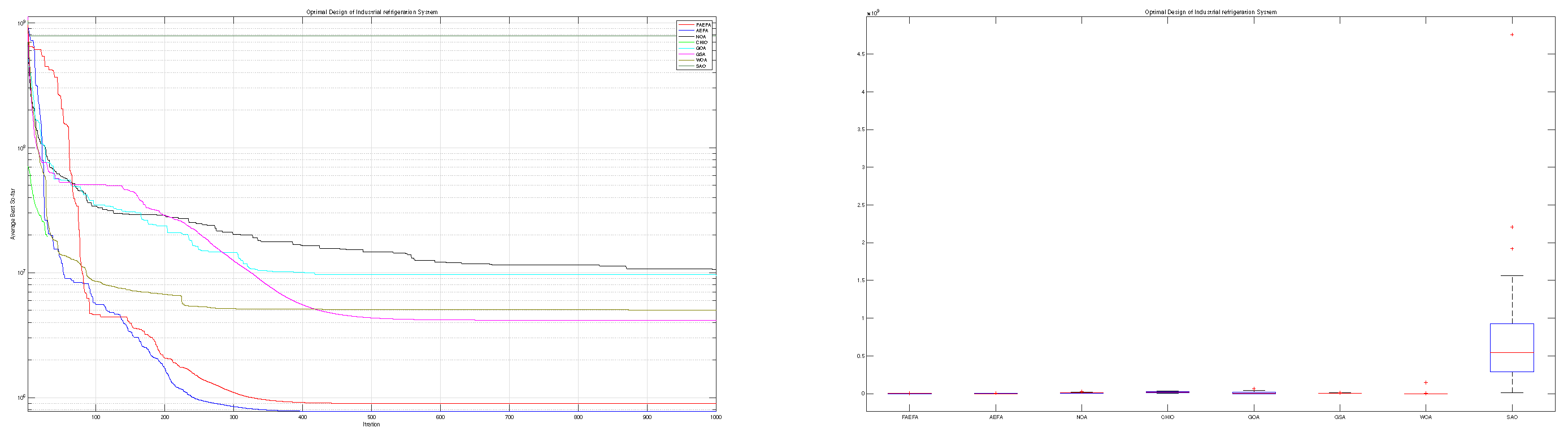

5.2.4. Industrial Refrigeration System Optimal Design

A refrigeration system utilizes coolant to decrease the temperature of a hot stream, going through three distinct phases. Each phase incorporates a heat exchanger on one side and a boiling cooler on the other. The pumping current is determined by the heat exchanger’s surface area. Moreover, the boiling temperature for the refrigerant is established at the start of each phase. Designing an efficient cooling system entails calculating the surface areas of the three surfaces of the liquid cooling heat exchanger.

The refrigeration system is designed to dissipate 4186.8 J/kg°C of heat while pumping a flow rate of 10,800 kg per hour from an initial temperature of 10 °C to −55 °C. Operating for a minimum of 300 days per year, the refrigeration system’s key parameters include a refrigerant latent heat (

) of 232.600 J/Kg and an overall heat transfer coefficient of 1130 J/s m

2 °C. The primary design objective is to minimize the cost of the three steps, as specified by Equation (

26).

The optimization aims to obtain competitive values for design variables, including fluid temperatures, heat exchange area, and liquid refrigerant addition rates in each step, with a focus on minimizing costs. The optimization process places significant emphasis on the temperature of the liquid refrigerant in each step, described as follows:

The temperature of the incoming fluid to the system is 10 °C, denoted as

, while the temperature of the outgoing fluid from the system is −55 °C, represented as

. It is essential for the output temperature at each step to be higher than the temperature of the refrigerant. As a result, the conditions for the design variables can be expressed as shown in Equations (

28)–(

33).

The log mean temperature difference at stage

i is:

The energy balance over refrigerant is:

is the penalty factor, where

is the ratio of heat flow, J/s. The energy balance over the fluid is:

where

is the specific heat of fluid, J/kg°C and V is the hot fluid pump ratio, kg/hr.

Based on the findings presented in

Table 13, the proposed mAEFA algorithm achieves a competitive rank when compared to other algorithms. Additionally, as indicated in

Table 14, mAEFA attains the smallest values for the majority of the problem variables and the best solution in comparison to other algorithms.

Table 14 demonstrates that mAEFA yields significant results in comparison to all other algorithms. Convergence behavior, as depicted in

Figure 11, varies among the algorithms in their approach towards the optimal solution. Notably, mAEFA demonstrates a favourable convergence pattern, reaching minimum values in later search iterations.

6. Conclusions and Future Work

The main contributions of this research work can be summarized as follows:

A modified mAEFA approach is developed by combining the original AEFA algorithm with Lévy flights, simulated annealing, and Adaptive s-best Mutation and Natural Survivor Method (NSM) mechanisms. The mAEFA utilizes Lévy flights distribution to enhance exploration and convergence, while the simulated annealing approach assists in avoiding local optima;

The performance of the mAEFA algorithm is scrutinized on various benchmark functions and engineering design problems. Comparative analysis with popular metaheuristics demonstrates the superiority and competitiveness of mAEFA;

In solving composite CEC’17 benchmark functions, mAEFA shows superior performance compared to other algorithms under comparison, except for specific functions. In unimodal, multimodal, and composite CEC’17 functions, mAEFA is either superior, equal, or ranked second among compared algorithms, with faster convergence observed;

Box plot analysis and Wilcoxon rank-sum test results further validate the superiority and robustness of mAEFA over comparative algorithms in CEC’17 test functions;

Performance testing of mAEFA on five engineering design problems demonstrates its superior capability to effectively solve practical optimization problems compared to other algorithms.

Nonetheless, similar to other metaheuristic algorithms, mAEFA faces limitations in solving all optimization problems across different domains, as highlighted by the No Free Lunch theorem. In future research, we aim to validate the effectiveness of the proposed mAEFA by testing it on more intricate continuous and discrete optimization problems. Moreover, there is potential to apply this algorithm to address various problems in diverse fields such as cloud task scheduling, image segmentation, engineering design, air quality prediction, finance, material science, and environmental sciences, among others.

In the future, a multiobjective version of the developed algorithm can be designed to tackle multiobjective problems. Furthermore, the authors intend to use the same combination to test other metaheuristic algorithms.