Biomimetic Cooling: Functionalizing Biodegradable Chitosan Films with Saharan Silver Ant Microstructures

Abstract

1. Introduction

1.1. Increased Indoor Environment Cooling Demand

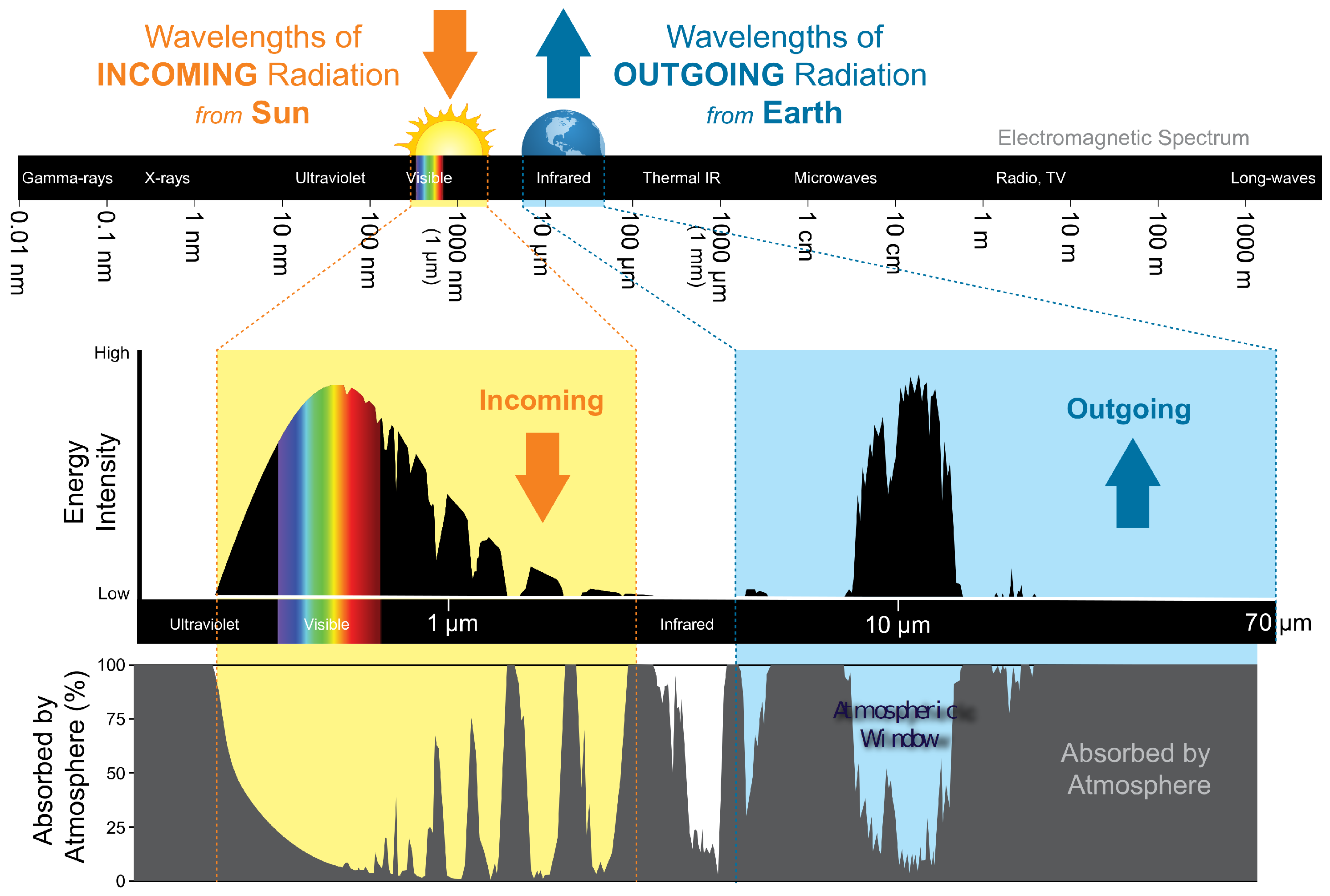

1.2. Passive Daytime Radiative Cooling

1.3. State-of-the-Art PDRC Solutions

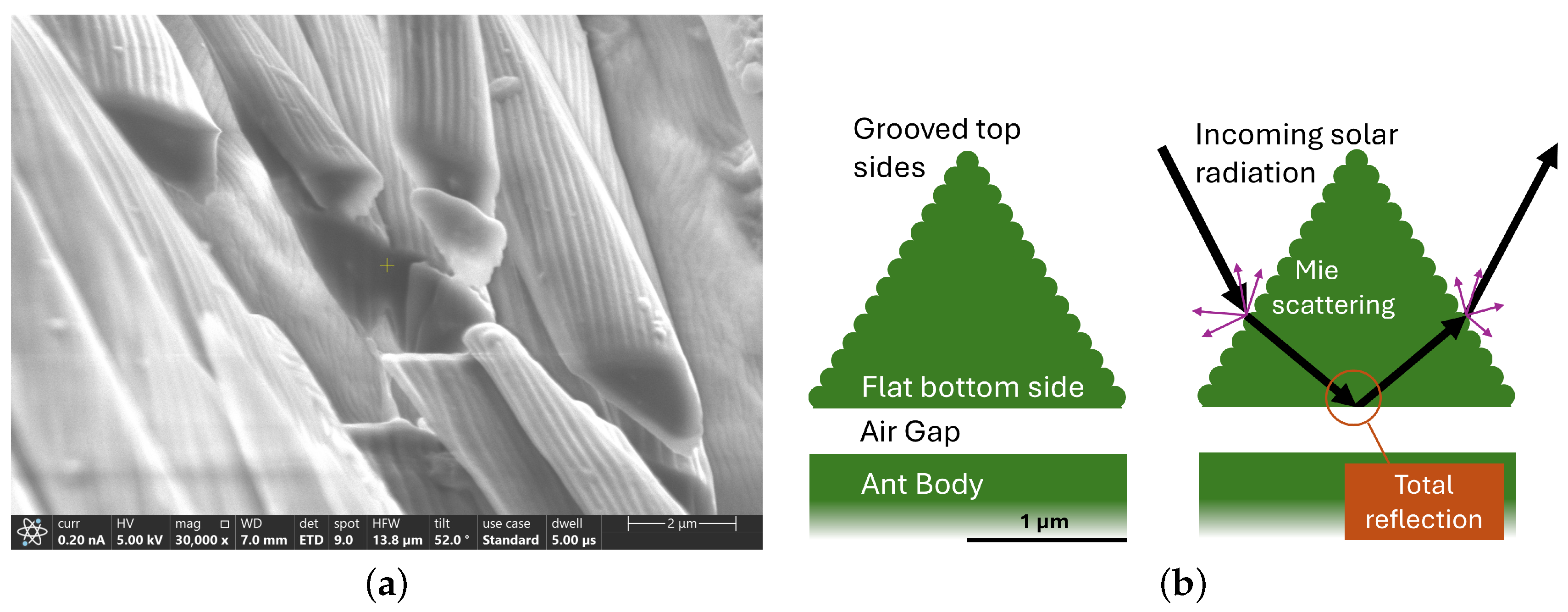

1.4. Saharan Silver Ants

1.5. Utilizing Chitin and Chitosan as PDRC Materials

1.6. Low-Cost and High-Impact PDRC Solutions

2. Materials and Methods

2.1. Chitin

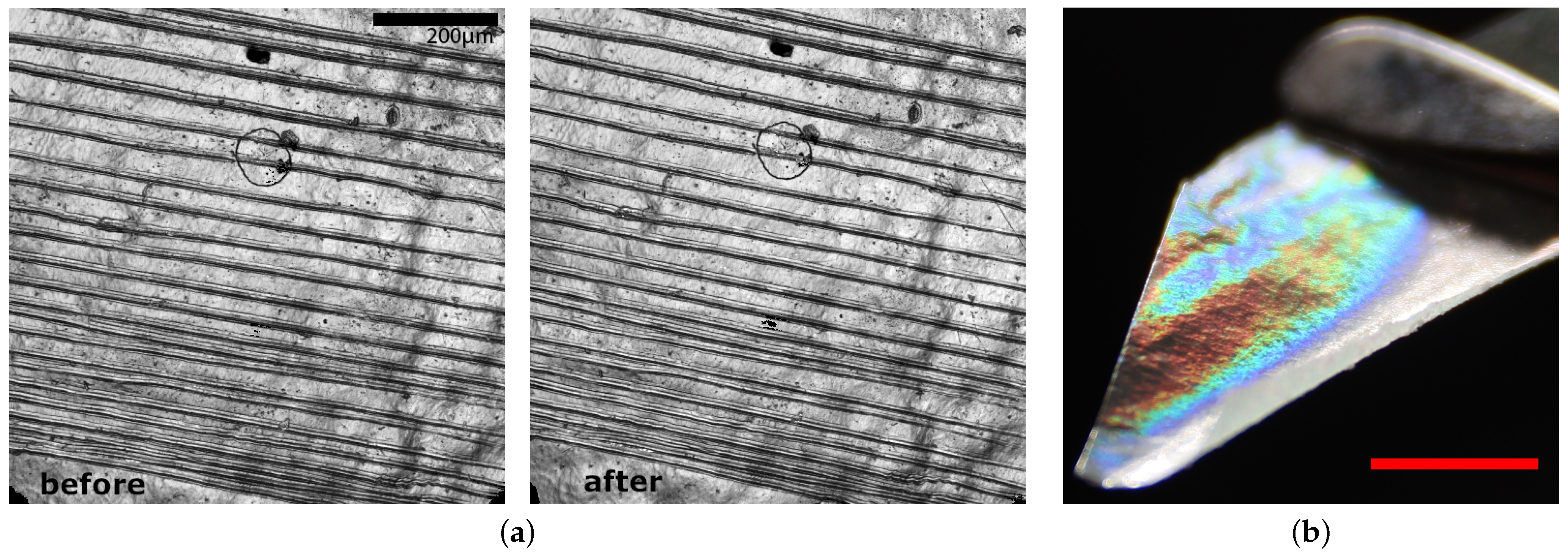

2.2. Weathering

2.3. Chitosan

2.4. Functional Structure Imprinting onto Chitosan

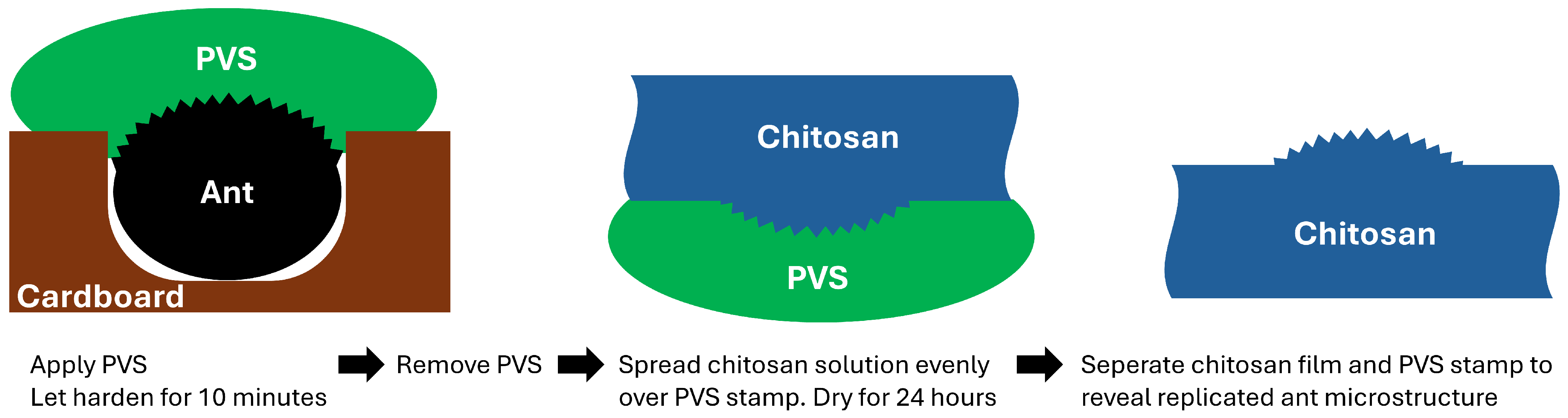

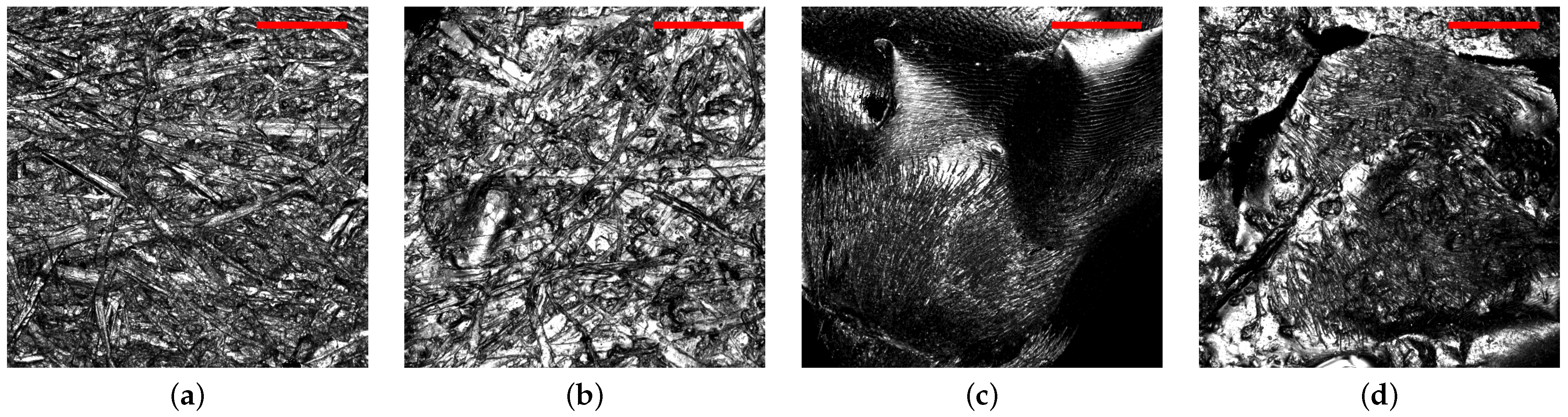

2.5. Imaging

2.5.1. Scanning Electron Microscopy

2.5.2. Confocal Microscopy

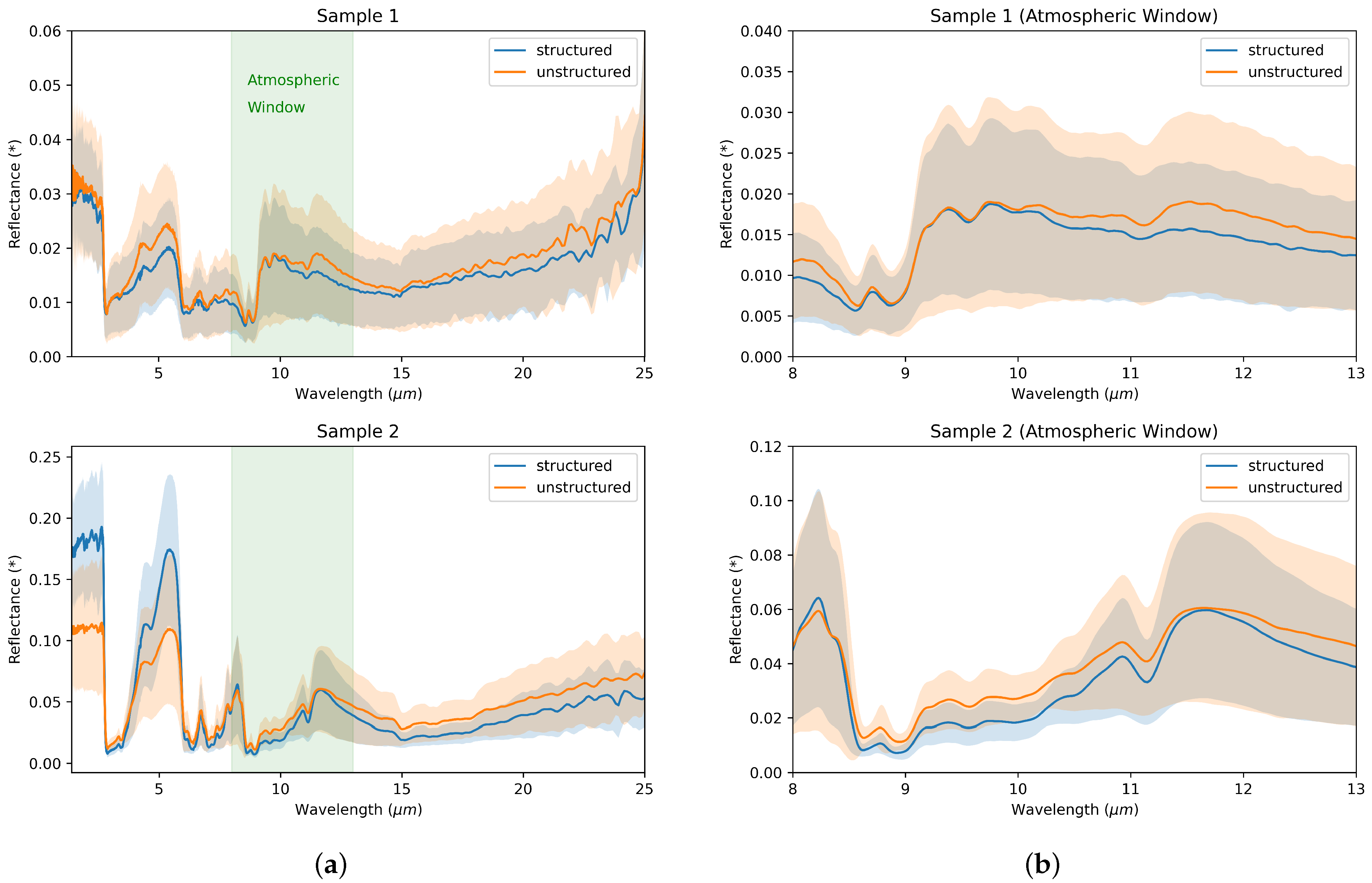

2.6. Spectroscopy

3. Results and Discussion

3.1. Weathering Tests

3.2. Chitosan Imprinted with Reflective Structures

3.3. Chitosan Imprinted with Cooling Structures

3.4. FTIR

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PDRC | Passive daytime radiative cooling |

| PRC | Passive radiative cooling |

| UV | Ultraviolet (light) |

| IR | Infrared (light) |

| PVS | Polyvinyl siloxane |

| SEM | Scanning electron microscopy |

| FTIR | Fourier-transform infrared (spectroscopy) |

| IEA | International energy agency |

| IEC | Indoor environment cooling |

| CD | Compact disc |

References

- What Are the Trends in Biologization and Advanced Manufacturing Technologies?—Fraunhofer ISI. 2024. Available online: https://www.isi.fraunhofer.de/en/themen/wertschoepfung/biologisierung-advanced-manufacturing-technologies.html (accessed on 27 July 2024).

- van Nieuwenhoven, R.W.; Drack, M.; Gebeshuber, I.C. Engineered Materials: Bioinspired “Good Enough” versus Maximized Performance. Adv. Funct. Mater. 2023, 34, 2307127. [Google Scholar] [CrossRef]

- Space Cooling—Analysis—IEA. 2024. Available online: https://www.iea.org/reports/space-cooling-2 (accessed on 27 July 2024).

- Sustainable, Affordable Cooling Can Save Tens of Thousands of Lives Each Year—Analysis—IEA. 2024. Available online: https://www.iea.org/reports/sustainable-affordable-cooling-can-save-tens-of-thousands-of-lives-each-year (accessed on 27 July 2024).

- The Future of Cooling—Opportunities for Energyefficient Air Conditioning—IEA. 2024. Available online: https://iea.blob.core.windows.net/assets/0bb45525-277f-4c9c-8d0c-9c0cb5e7d525/The_Future_of_Cooling.pdf (accessed on 27 July 2024).

- De Munck, C.; Pigeon, G.; Masson, V.; Marchadier, C.; Meunier, F.; Bousquet, P.; Tremeac, B.; Merchat, M.; Poeuf, P.; Lemonsu, A. How much air conditioning can increase air temperatures for a city like Paris (France)? Int. J. Climatol. 2013, 33, 210–227. [Google Scholar] [CrossRef]

- Salamanca, F.; Georgescu, M.; Mahalov, A.; Moustaoui, M.; Wang, M. Anthropogenic heating of the urban environment due to air conditioning. J. Geophys. Res. Atmos. 2014, 119, 5949–5965. [Google Scholar] [CrossRef]

- Yuan, C.; Zhu, R.; Tong, S.; Mei, S.; Zhu, W. Impact of anthropogenic heat from air-conditioning on air temperature of naturally ventilated apartments at high-density tropical cities. Energy Build. 2022, 268, 112171. [Google Scholar] [CrossRef]

- The AM 1.5 Spectrum. 2024. Available online: https://www.ossila.com/pages/standard-solar-spectrum (accessed on 18 September 2024).

- Zhao, D.; Aili, A.; Zhai, Y.; Xu, S.; Tan, G.; Yin, X.; Yang, R. Radiative sky cooling: Fundamental principles, materials, and applications. Appl. Phys. Rev. 2019, 6, 021306. [Google Scholar] [CrossRef]

- Chen, M.; Pang, D.; Chen, X.; Yan, H.; Yang, Y. Passive daytime radiative cooling: Fundamentals, material designs, and applications. EcoMat 2022, 4, e12153. [Google Scholar] [CrossRef]

- Wu, W.; Lin, S.; Wei, M.; Huang, J.; Xu, H.; Lu, Y.; Song, W. Flexible passive radiative cooling inspired by Saharan silver ants. Sol. Energy Mater. Sol. Cells 2020, 210, 110512. [Google Scholar] [CrossRef]

- Mandal, J.; Anand, J.; Mandal, S.; Brewer, J.; Ramachandran, A.; Raman, A.P. Radiative cooling and thermoregulation in the earth’s glow. Cell Rep. Phys. Sci. 2024, 5, 102065. [Google Scholar] [CrossRef]

- Shi, N.N.; Tsai, C.C.; Camino, F.; Bernard, G.D.; Yu, N.; Wehner, R. Keeping cool: Enhanced optical reflection and radiative heat dissipation in Saharan silver ants. Science 2015, 349, 298–301. [Google Scholar] [CrossRef]

- Bijarniya, J.P.; Sarkar, J.; Maiti, P. Review on passive daytime radiative cooling: Fundamentals, recent researches, challenges and opportunities. Renew. Sustain. Energy Rev. 2020, 133, 110263. [Google Scholar] [CrossRef]

- Liang, L.; Bai, S.; Lin, K.; Kwok, C.T.; Chen, S.; Zhu, Y.; Tso, C.Y. Advancing Sustainable Development: Broad Applications of Passive Radiative Cooling. Sustainability 2024, 16, 2346. [Google Scholar] [CrossRef]

- The Atmospheric Window—National Oceanic and Atmospheric Administration. 2023. Available online: https://www.noaa.gov/jetstream/satellites/absorb (accessed on 18 August 2024).

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef]

- Zhai, Y.; Ma, Y.; David, S.N.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalable-manufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef]

- Lin, C.; Li, Y.; Chi, C.; Kwon, Y.S.; Huang, J.; Wu, Z.; Zheng, J.; Liu, G.; Tso, C.Y.; Chao, C.Y.H.; et al. A Solution-Processed Inorganic Emitter with High Spectral Selectivity for Efficient Subambient Radiative Cooling in Hot Humid Climates. Adv. Mater. 2022, 34, 2109350. [Google Scholar] [CrossRef]

- Mandal, J.; Fu, Y.; Overvig, A.C.; Jia, M.; Sun, K.; Shi, N.N.; Zhou, H.; Xiao, X.; Yu, N.; Yang, Y. Hierarchically porous polymer coatings for highly efficient passive daytime radiative cooling. Science 2018, 362, 315–319. [Google Scholar] [CrossRef]

- Didari, A.; Mengüç, M.P. A biomimicry design for nanoscale radiative cooling applications inspired by Morpho didius butterfly. Sci. Rep. 2018, 8, 16891. [Google Scholar] [CrossRef]

- Krishna, A.; Nie, X.; Warren, A.D.; Llorente-Bousquets, J.E.; Briscoe, A.D.; Lee, J. Infrared optical and thermal properties of microstructures in butterfly wings. Proc. Natl. Acad. Sci. USA 2020, 117, 1566–1572. [Google Scholar] [CrossRef]

- Gebeshuber, I.C.; Zischka, F. Bulletin—Alumni Magazine of TU Wien, Nr. 54. 2024. Available online: https://issuu.com/tuwienalumniclub/docs/230301_bulletin54_web (accessed on 27 July 2024).

- Zhang, H.; Ly, K.C.S.; Liu, X.; Chen, Z.; Yan, M.; Wu, Z.; Wang, X.; Zheng, Y.; Zhou, H.; Fan, T. Biologically inspired flexible photonic films for efficient passive radiative cooling. Proc. Natl. Acad. Sci. USA 2020, 117, 14657–14666. [Google Scholar] [CrossRef]

- Xu, J.; Liu, D. A Study on the Radiation Cooling Characteristics of Cerambycini Latreille. Biomimetics 2024, 9, 34. [Google Scholar] [CrossRef]

- Jeong, S.; Tso, C.; Wong, Y.; Chao, C.; Huang, B. Daytime passive radiative cooling by ultra emissive bio-inspired polymeric surface. Sol. Energy Mater. Sol. Cells 2020, 206, 110296. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, Y.; King, J.L.; Kats, M.A.; Stebe, K.J.; Lee, D. Bioinspired Switchable Passive Daytime Radiative Cooling Coatings. ACS Appl. Mater. Interfaces 2023, 15, 48716–48724. [Google Scholar] [CrossRef]

- Gehring, W.; Wehner, R. Heat shock protein synthesis and thermotolerance in Cataglyphis, an ant from the Sahara desert. Proc. Natl. Acad. Sci. USA 1995, 92, 2994–2998. [Google Scholar] [CrossRef]

- Wehner, R. Desert ant navigation: How miniature brains solve complex tasks. J. Comp. Physiol. A 2003, 189, 579–588. [Google Scholar] [CrossRef]

- Pfeffer, S.E.; Wahl, V.L.; Wittlinger, M.; Wolf, H. High-speed locomotion in the Saharan silver ant, Cataglyphis bombycina. J. Exp. Biol. 2019, 222, jeb198705. [Google Scholar] [CrossRef]

- Freigassner, J.; van Nieuwenhoven, R.W.; Gebeshuber, I.C. From Nanostructure to Function: Functional Structures in Chitin and Keratin. Z. FüR Phys. Chem. 2024; submitted. [Google Scholar]

- Mao, X.; Guo, N.; Sun, J.; Xue, C. Comprehensive utilization of shrimp waste based on biotechnological methods: A review. J. Clean. Prod. 2017, 143, 814–823. [Google Scholar] [CrossRef]

- Lauster, T.; Mauel, A.; Herrmann, K.; Veitengruber, V.; Song, Q.; Senker, J.; Retsch, M. From Chitosan to Chitin: Bio-Inspired Thin Films for Passive Daytime Radiative Cooling. Adv. Sci. 2023, 10, 2206616. [Google Scholar] [CrossRef]

- Chitosan (448877 Sigma-Aldrich). 2024. Available online: https://www.sigmaaldrich.com/AT/en/product/aldrich/448877 (accessed on 27 July 2024).

- Chitosan 400 mg (Greenfood Natural Products). 2024. Available online: https://www.greenfood-shop.eu/alle-produkte-a-z/chitosan-400-mg_239_1550 (accessed on 27 July 2024).

- Zobl, S.; Salvenmoser, W.; Schwerte, T.; Gebeshuber, I.C.; Schreiner, M. Morpho peleides butterfly wing imprints as structural color stamp. BioInspir. Biomimetics 2016, 11, 016006. [Google Scholar] [CrossRef]

- Nicodemus, F.E. Directional Reflectance and Emissivity of an Opaque Surface. Appl. Opt. 1965, 4, 767–775. [Google Scholar] [CrossRef]

- Koehler, I. A Really Hot Topic—Passive Radiative Cooling and the Role of FTIR in Its Development. 2022. Available online: https://opticsblog.bruker.com/a-really-hot-topic-passive-radiative-cooling-and-the-role-of-ftir-in-its-development/ (accessed on 18 August 2024).

- Guide to FT-IR Microscopy. 2024. Available online: https://www.bruker.com/en/products-and-solutions/infrared-and-raman/ft-ir-microscopes/what-is-ft-ir-microscopy.html (accessed on 18 August 2024).

- Becking, L.B.; Chamberlin, J.C. A note on the refractive index of chitin. Proc. Soc. Exp. Biol. Med. 1925, 22, 256. [Google Scholar] [CrossRef]

- Introduction to Solar Radiation. 2024. Available online: https://www.atlas-mts.com/knowledge-center/weathering-standards-test-methods (accessed on 1 October 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zimmerl, M.; van Nieuwenhoven, R.W.; Whitmore, K.; Vetter, W.; Gebeshuber, I.C. Biomimetic Cooling: Functionalizing Biodegradable Chitosan Films with Saharan Silver Ant Microstructures. Biomimetics 2024, 9, 630. https://doi.org/10.3390/biomimetics9100630

Zimmerl M, van Nieuwenhoven RW, Whitmore K, Vetter W, Gebeshuber IC. Biomimetic Cooling: Functionalizing Biodegradable Chitosan Films with Saharan Silver Ant Microstructures. Biomimetics. 2024; 9(10):630. https://doi.org/10.3390/biomimetics9100630

Chicago/Turabian StyleZimmerl, Markus, Richard W. van Nieuwenhoven, Karin Whitmore, Wilfried Vetter, and Ille C. Gebeshuber. 2024. "Biomimetic Cooling: Functionalizing Biodegradable Chitosan Films with Saharan Silver Ant Microstructures" Biomimetics 9, no. 10: 630. https://doi.org/10.3390/biomimetics9100630

APA StyleZimmerl, M., van Nieuwenhoven, R. W., Whitmore, K., Vetter, W., & Gebeshuber, I. C. (2024). Biomimetic Cooling: Functionalizing Biodegradable Chitosan Films with Saharan Silver Ant Microstructures. Biomimetics, 9(10), 630. https://doi.org/10.3390/biomimetics9100630