Bionic Design and Adsorption Performance Analysis of Vacuum Suckers

Abstract

1. Introduction

2. Materials and Methods

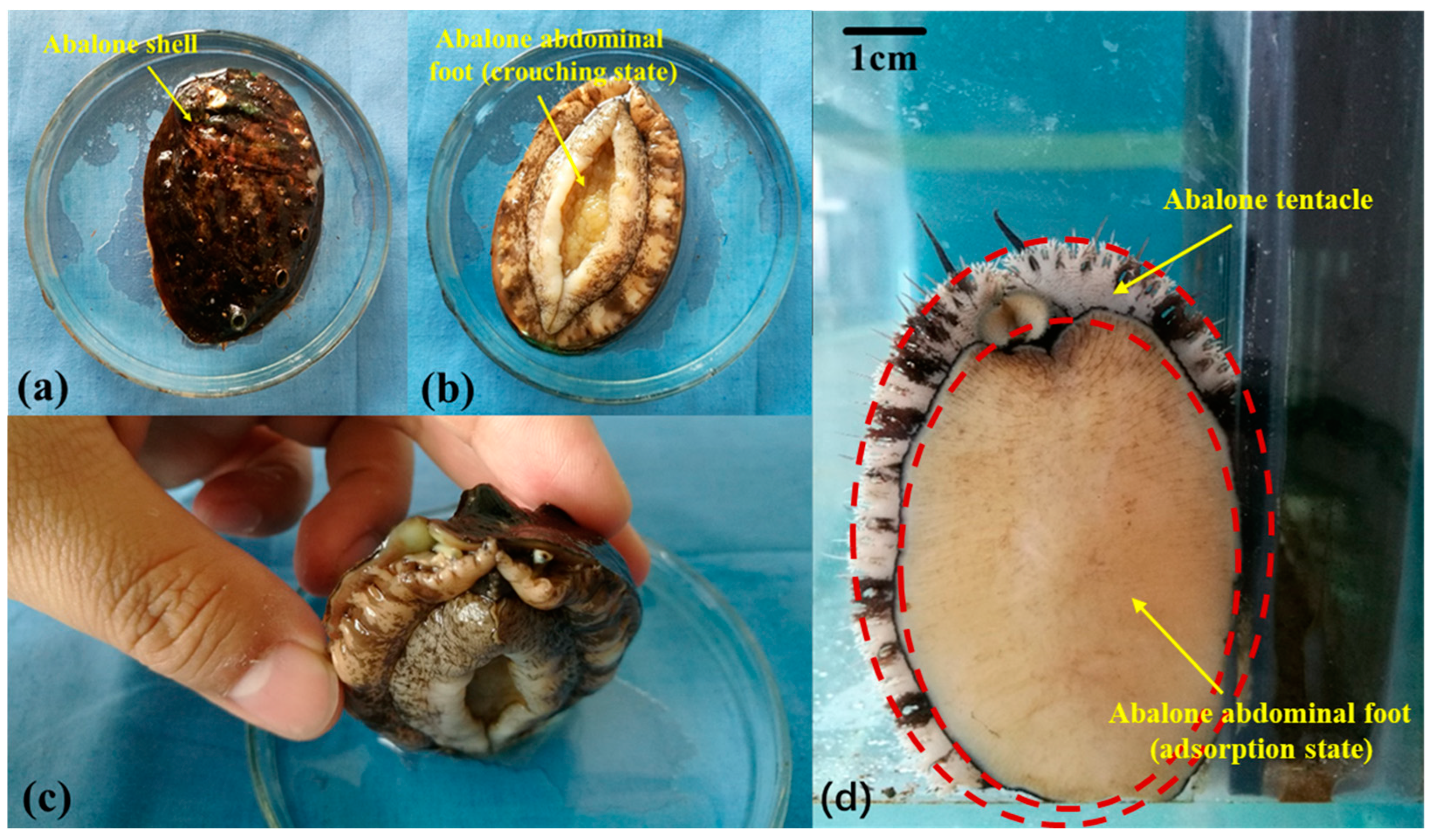

2.1. Observation of Abalone Abdominal Foot

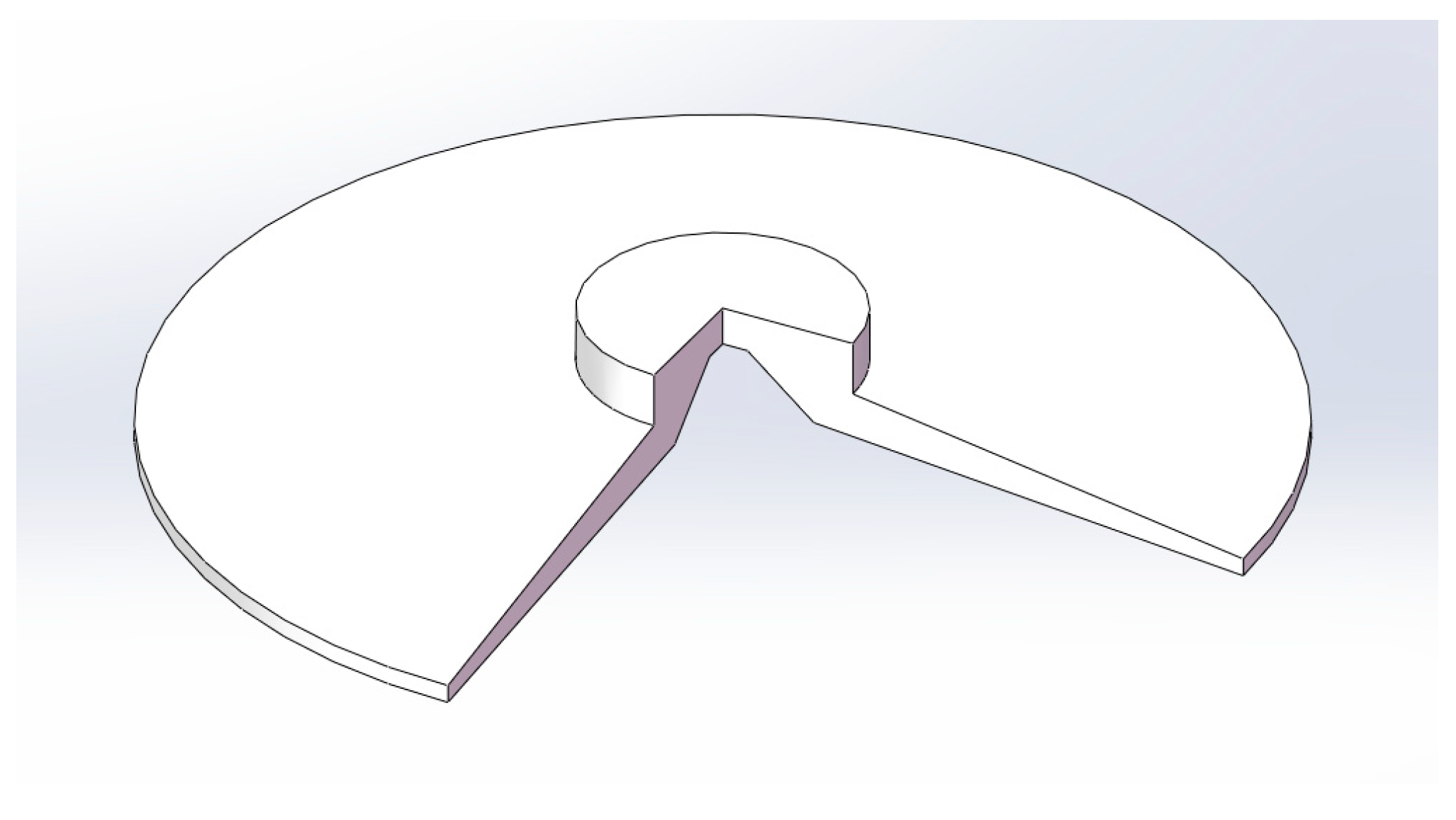

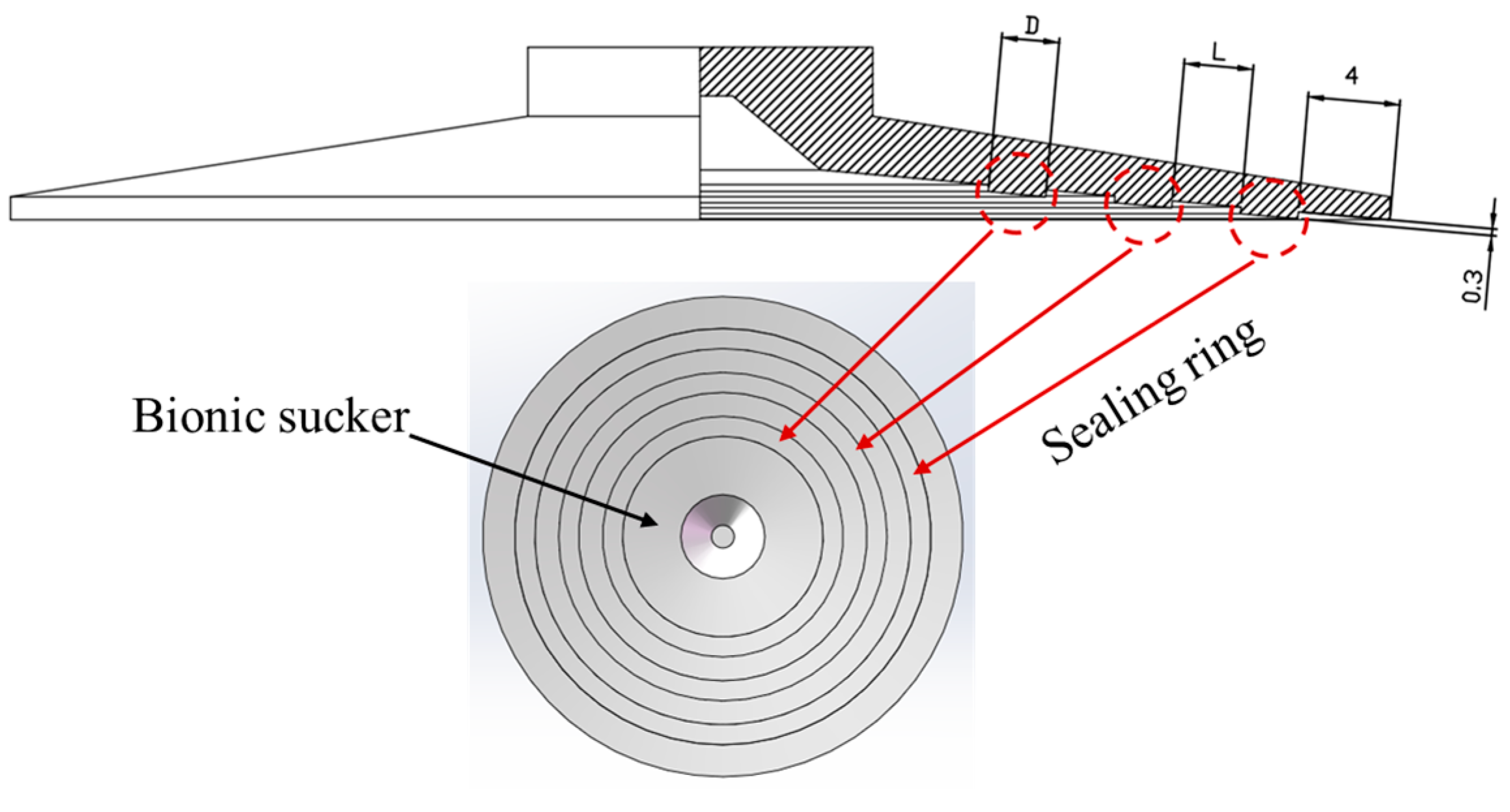

2.2. Bionic Sucker Design

2.3. Adsorption Experiment of Suckers

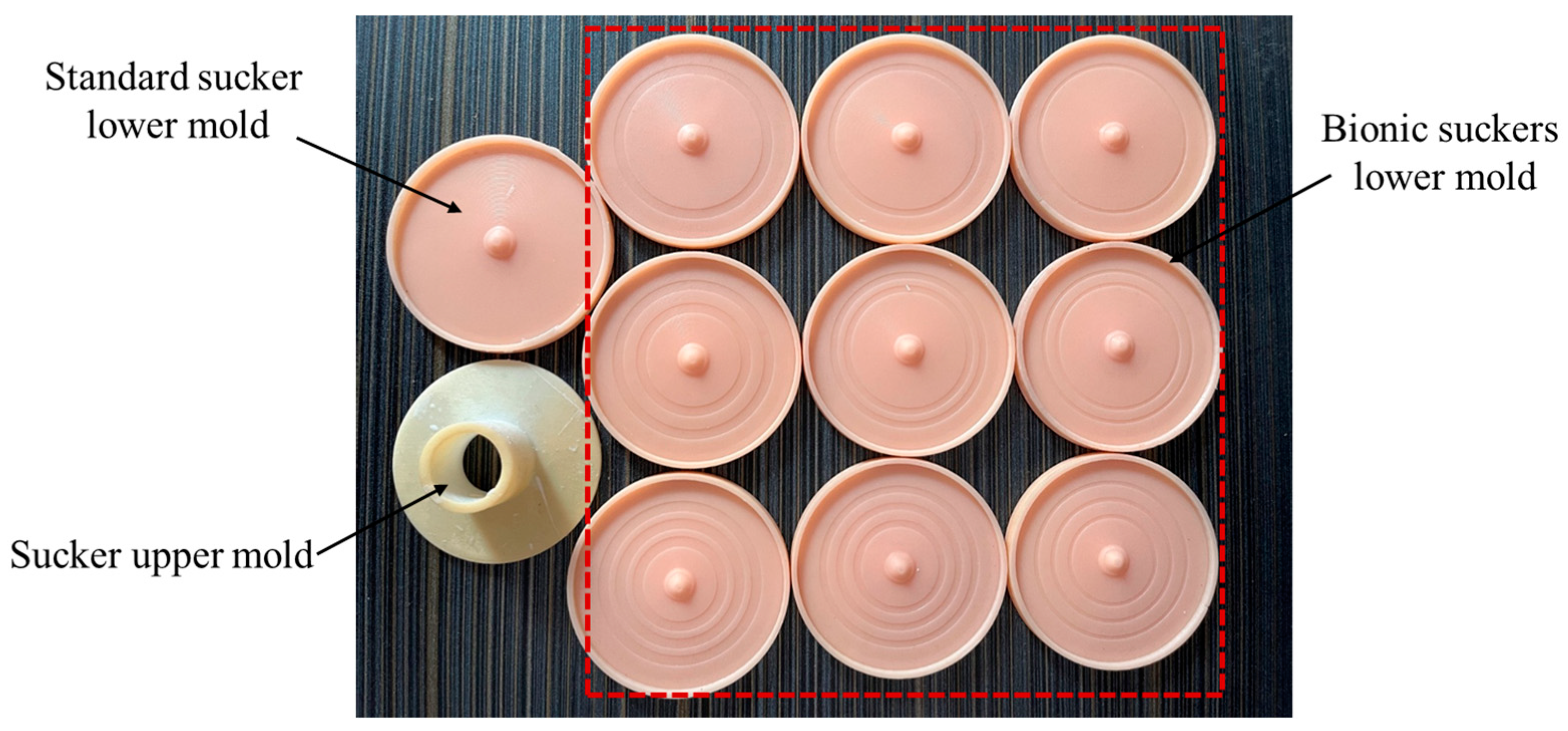

2.3.1. Preparation of Sucker Samples

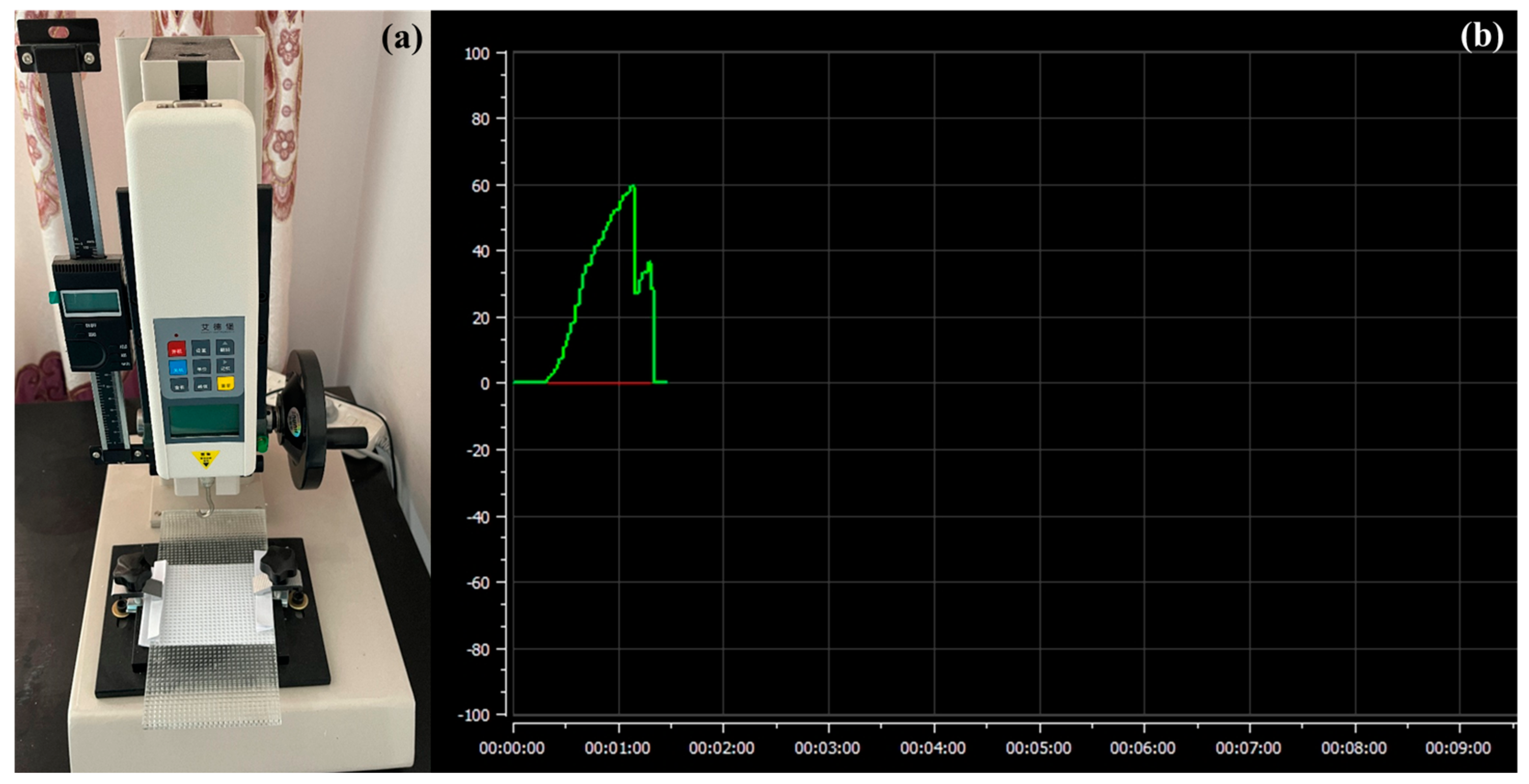

2.3.2. Sucker Tensile Test

3. Results

3.1. Orthogonal Experimental Design

3.2. Analysis of Orthogonal Test Results

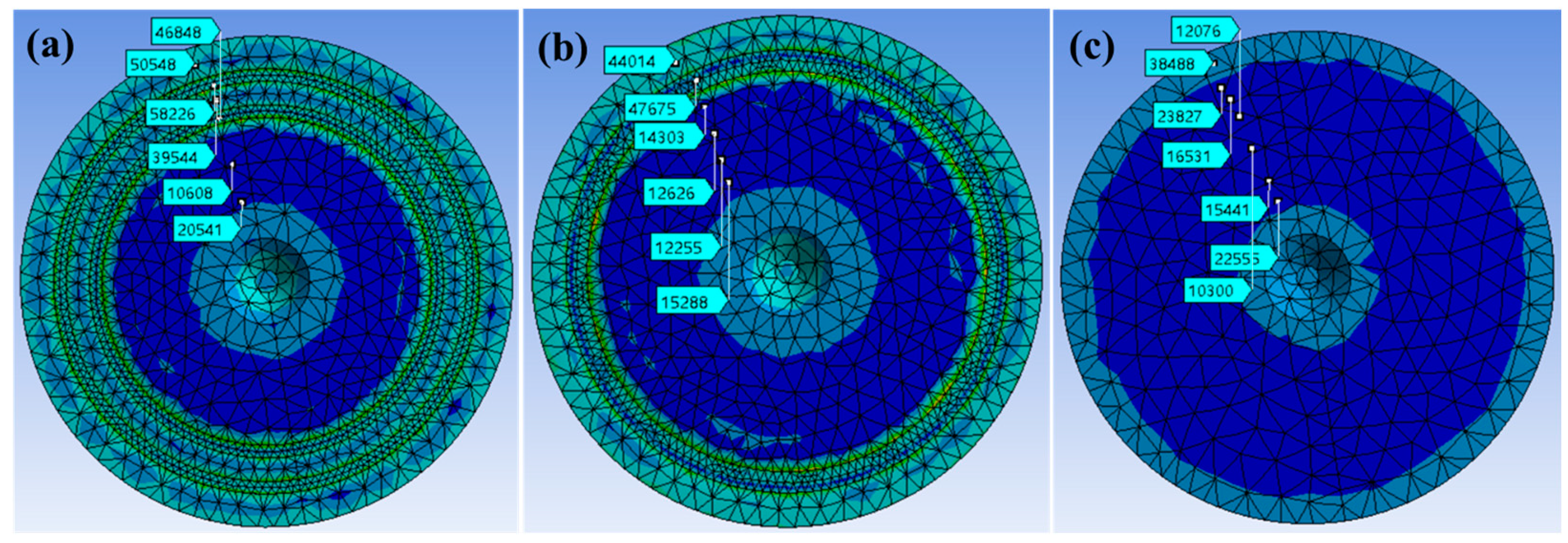

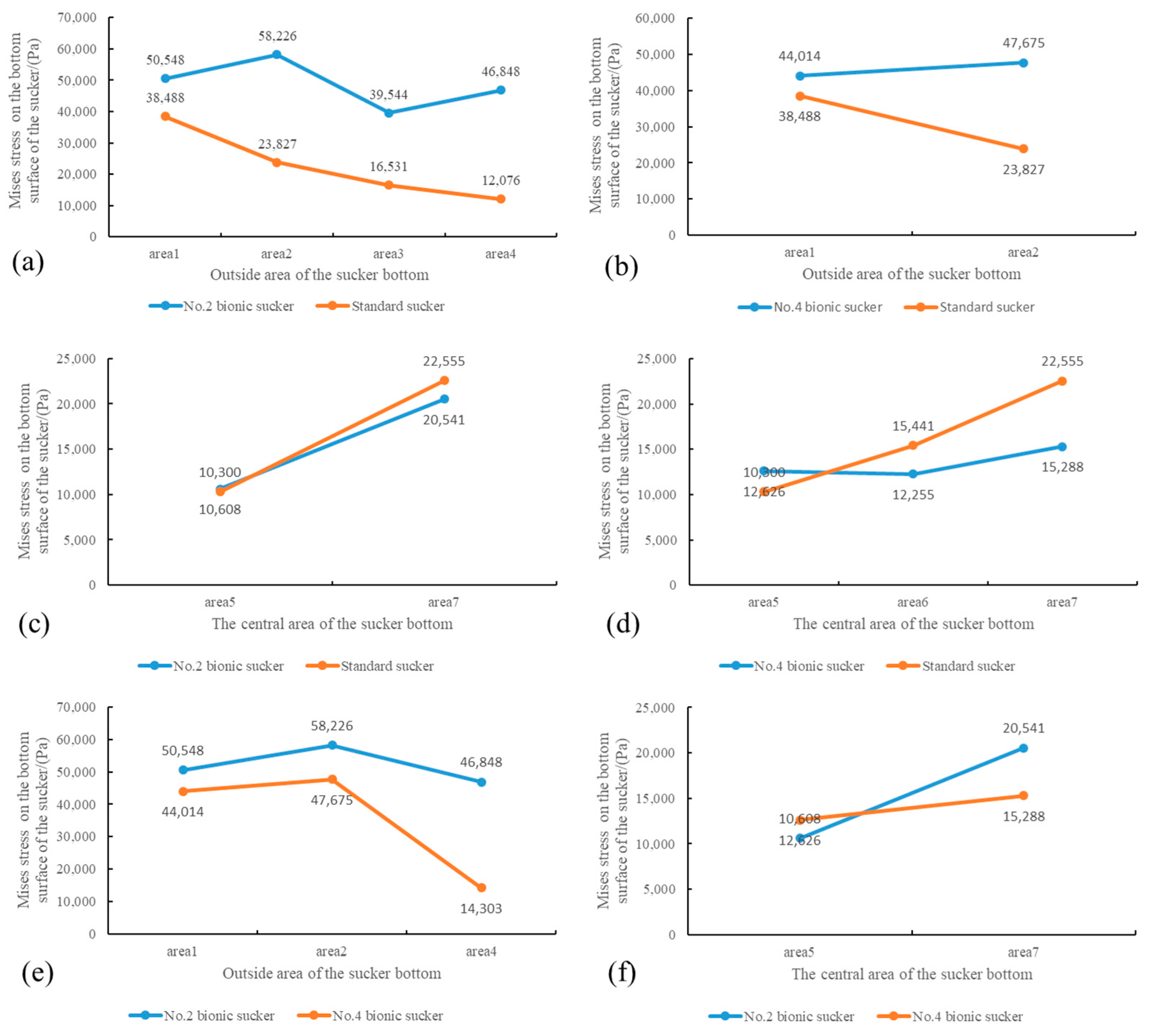

3.3. Simulation Analysis of Sucker Adsorption

3.4. Adsorption Mechanism Analysis of Sucker

4. Conclusions

- (1)

- The bionic design of the vacuum sucker can effectively improve the adsorption performance of the sucker. The primary and secondary factors affecting the adsorption performance of the sucker are the number, width and spacing of the sealing rings.

- (2)

- From the adsorption experiments of the sucker, it can be seen that at 60% vacuum, the bionic sucker with two sealing rings, a sealing ring width of 1.5 mm, and sealing ring spacing of 3 mm has the largest adsorption force. The maximum adsorption force is 15.8% higher than the standard sucker.

- (3)

- Compared with the standard sucker, the bionic sucker has a larger Mises stress on the sealing ring and the surrounding area, while the Mises stress in the central area of the sucker is smaller.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bai, L.-Q.; Song, Z.-K.; Wang, P. Simulation Analysis on Internal Flow Field of a Vacuum Suction Cup under Different Leakage Conditions. Mech. Eng. 2018, 7, 33–35+38. [Google Scholar]

- Qin, J.-H.; Deng, C.-Y.; Wang, D.-Q.; Li, W. Influence analysis of different layout methods on the vacuum adsorption device based on ANSYS method. J. Guilin Univ. Technol. 2017, 37, 713–717. [Google Scholar]

- Nie, J.-F.; Wang, T.; Xu, Y.N.; Chen, Z.; Ma, Q.-C. Vacuum Adsorption Test of Flexible Suction Cup. Chin. Hydraul. Pneum. 2020, 5, 131–137. [Google Scholar] [CrossRef]

- Zhen, J.; Yang, Z.; Wang, X.; Song, H. Design of an intelligent vacuum sucker device. J. Vac. Sci. Technol. 2017, 37, 1038–1043. [Google Scholar]

- Zhang, J.; Xue, W.; Liang, Y.; Yang, M. Vacuum adhesion technology and its application in construction machinery assembly. Constr. Mach. Maint. 2015, S1, 302–305. [Google Scholar]

- Chen, L.; Yun, Z.; Jiang, Y. Design and performance analysis of bionic sucker based on remora adhesion principle. J. Beijing Univ. Chem. Technol. Nat. Sci. Ed. 2018, 45, 100–105. [Google Scholar]

- Li, J.; Liang, D.; Lu, B.; Li, G. Research on non-contact handling sucker system. J. Instrum. 2018, 39, 108–116. [Google Scholar] [CrossRef]

- Schmalz—The New Corrugated Sucker SPB4f for the Packaging Industry. Available online: http://schmalz.gongboshi.com/news/index.php?itemid=52757 (accessed on 8 August 2024).

- AIRBEST. SOP Series Circular Sponge Sucker. Available online: https://www.airbest.cn/proinfo/index/289.html?dw_ctype=79 (accessed on 8 August 2024).

- Xianyu, P.E.N.G.; Chuandong, M.A.; Jiaxin, J.I.; Jing, L.I. Underwater Adhesion Mechanisms and Biomimetic Study of Marine Life. Tribology 2020, 40, 816–830. [Google Scholar] [CrossRef]

- Maie, T.; Blob, R.W. Adhesive force and endurance of the pelvic sucker across different modes of waterfall-climbing in gobiid fishes: Contrasting climbing mechanisms share aspects of ontogenetic change. Zoology 2021, 149, 125969. [Google Scholar] [CrossRef]

- Palecek, A.M.; Schoenfuss, H.L.; Blob, R.W. Sucker Shapes, Skeletons, and Bioinspiration: How Hard and Soft Tissue Morphology Generates Adhesive Performance in Waterfall Climbing Goby Fishes. Integr. Compar. Biol. 2022, 62, icac094. [Google Scholar] [CrossRef]

- Wang, S.; Luo, H.; Linghu, C.; Song, J. Elastic Energy Storage Enabled Magnetically Actuated, Octopus-Inspired Smart Adhe-sive. Adv. Funct. Mater. 2021, 31, 2009217.1–2009217.9. [Google Scholar] [CrossRef]

- Baik, S.; Hwang, G.W.; Jang, S.; Jeong, S.; Kim, K.H.; Yang, T.H.; Pang, C. Bioinspired Microsphere-Embedded Adhesive Architectures for an Electrothermally Actuating Transport Device of Dry/Wet Pliable Surfaces. ACS Appl. Mater. Interfaces 2021, 13, 6930–6940. [Google Scholar] [CrossRef]

- Huie, J.M.; Summers, A.P. The effects of soft and rough substrates on suction-based adhesion. J. Exp. Biol. 2022, 225, jeb243773. [Google Scholar] [CrossRef] [PubMed]

- Tsujioka, K.; Matsuo, Y.; Shimomura, M.; Hirai, Y. A New Concept for an Adhesive Material Inspired by Clingfish Sucker Nano-filaments. Langmuir ACS J. Surf. Colloids 2022, 38, 1215–1222. [Google Scholar] [CrossRef] [PubMed]

- Tramacere, F.; Beccai, L.; Mattioli, F.; Sinibaldi, E.; Mazzolai, B. Artificial Adhesion Mechanisms Inspired by Octopus Suckers. In Proceedings of the IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; RiverCentre: Saint Paul, MN, USA, 2012. [Google Scholar]

- Ditsche, P.; Wainwright, D.K.; Summers, A.P. Attachment to challenging substrates-fouling, roughness and limits of adhesion in the northern clingfish (Gobiesox maeandricus). J. Exp. Biol. 2014, 217, 2548–2554. [Google Scholar] [CrossRef] [PubMed]

- Ditsche, P.; Summers, A.P. Learning from Northern clingfish (Gobiesox maeandricus): Bioinspired suction cups attach to rough surfaces. Philos. Trans. R. Soc. B Biol. Sci. 2019, 374, 20190204. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.-N.; Yin, Z.-J.; Hu, H.-W.; Cheng, G.-G.; Zhang, Z.-Q. A bionic sucker design with high surface adaptability. J. Jilin Univ. (Eng. Technol. Ed.) 2024, 1–9. [Google Scholar] [CrossRef]

- Greco, G.; Bosia, F.; Tramacere, F.; Mazzolai, B.; Pugno, N.M. The role of hairs in the adhesion of octopus suckers: A hierarchical peeling approach. Bioinspir. Biomim. 2020, 15, 035006. [Google Scholar] [CrossRef]

- Cong, Q.; Xu, J.; Shi, X.-J.; Jin, J.-F.; Chen, T.-K. Bionic pit design and experiment of the sucker. J. Jilin Univ. (Eng. Technol. Ed.) 2024, 54, 1144–1152. [Google Scholar]

- Kim, J.M.; Coutinho, A.; Park, Y.J.; Rodrigue, H. Octopus-inspired suction cup array for versatile grasping operations. IEEE Robot. Autom. Lett. 2023, 8, 2962–2969. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, X.; Chen, Y.; Wainwright, D.K.; Kenaley, C.P.; Gong, Z.; Wen, L. A biorobotic adhesive disc for underwater hitchhiking inspired by the remora suckerfish. Sci. Robot. 2017, 2, eaan8072. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Zuo, P.; Xu, X.; Liu, J. Adhesion Behaviors of Abalone Under the Action of Water Flow. Front. Mech. Eng. 2021, 7, 659468. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Zuo, P.; Li, J.; Liu, J. A mechanics study on the self-righting of abalone from the substrate. Appl. Bionics Biomech. 2020, 2020, 8825451. [Google Scholar] [CrossRef]

- Li, J.; Ma, C.; Liu, J.; Dong, X.; Liu, J. The co-effect of microstructures and mucus on the adhesion of abalone from a mechanical perspective. Biosurface Biotribol. 2021, 7, 180–186. [Google Scholar] [CrossRef]

- Liu, X. Biological characteristics and artificial breeding technology of abalone. Anhui Agric. Sci. 2009, 37, 5872–5874. [Google Scholar]

- Lin, A.; Brunner, R.; Chen, P.; Talke, F.; Meyers, M. Underwater adhesion of abalone: The role of van der Waals and capillary forces. Acta Mater. 2009, 57, 4178–4185. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Liu, S.; Liu, J. Insights into adhesion of abalone: A mechanical approach. J. Mech. Behav. Biomed. Materials. 2018, 77, 331–336. [Google Scholar] [CrossRef] [PubMed]

- Xi, P.; Ye, S.; Cong, Q. Abalone adhesion: The role of various adhesion forces and their proportion to total adhesion force. PLoS ONE 2023, 18, e0286567. [Google Scholar] [CrossRef]

- Cheng, Y.; Du, M. Abalone aquaculture technology. Agric. Eng. Technol. 2016, 36, 72. [Google Scholar]

- Sun, L. Study on High Adhesion Performance of Abalone and Design of Bionic Sucker. Master’s Thesis, Jilin University, Changchun, China, 2017. [Google Scholar]

| Factor | Sealing Ring Width D/mm | Sealing Ring Number N | Sealing Ring Spacing L/mm | |

|---|---|---|---|---|

| Level | ||||

| 1 | 1.5 | 1 | 2 | |

| 2 | 2.5 | 2 | 3 | |

| 3 | 3.5 | 3 | 4 | |

| Factor | Sealing Ring Width D/mm | Sealing Ring Number N | Sealing Ring Spacing L/mm | Adsorption Force F/N | |

|---|---|---|---|---|---|

| Test Number | |||||

| 1 | 1.5 | 1 | 2 | 52 | |

| 2 | 1.5 | 2 | 3 | 63 | |

| 3 | 1.5 | 3 | 4 | 56.3 | |

| 4 | 2.5 | 1 | 4 | 47 | |

| 5 | 2.5 | 2 | 2 | 55.8 | |

| 6 | 2.5 | 3 | 3 | 52.1 | |

| 7 | 3.5 | 1 | 3 | 50 | |

| 8 | 3.5 | 2 | 4 | 52.6 | |

| 9 | 3.5 | 3 | 2 | 52 | |

| 10 | 0 | 0 | 0 | 54.4 | |

| ȳFj1 | 57.1 | 49.7 | 53.3 | ||

| ȳFj2 | 51.6 | 57.1 | 55 | ||

| ȳFj3 | 51.5 | 53.5 | 52 | ||

| RFj | 5.6 | 7.4 | 3 | ||

| Primary and secondary factors | N, D, L | ||||

| Optimal combination | N2D1L2 | ||||

| Factor | Sealing Ring Width D/mm | Sealing Ring Number N | Sealing Ring Spacing L/mm | Adsorption Force F/N | ||

|---|---|---|---|---|---|---|

| Test Number | ||||||

| 1 | 1.5 | 2 | 3 | 61.9 | Se = 0.187 fe = 2 | |

| 2 | 1.5 | 2 | 3 | 61.5 | ||

| 3 | 1.5 | 2 | 3 | 62.1 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, P.; Qiao, Y.; Nie, X.; Cong, Q. Bionic Design and Adsorption Performance Analysis of Vacuum Suckers. Biomimetics 2024, 9, 623. https://doi.org/10.3390/biomimetics9100623

Xi P, Qiao Y, Nie X, Cong Q. Bionic Design and Adsorption Performance Analysis of Vacuum Suckers. Biomimetics. 2024; 9(10):623. https://doi.org/10.3390/biomimetics9100623

Chicago/Turabian StyleXi, Peng, Yanqi Qiao, Xiaoyu Nie, and Qian Cong. 2024. "Bionic Design and Adsorption Performance Analysis of Vacuum Suckers" Biomimetics 9, no. 10: 623. https://doi.org/10.3390/biomimetics9100623

APA StyleXi, P., Qiao, Y., Nie, X., & Cong, Q. (2024). Bionic Design and Adsorption Performance Analysis of Vacuum Suckers. Biomimetics, 9(10), 623. https://doi.org/10.3390/biomimetics9100623